Mar Cor Purification 23G 2 Element, 23G 6 Element, 23G 3 Element, 23G 4 Element, 23G 5 Element Operation And Maintenance Manual

...

Mar Cor Purification

23G-SERIES REVERSE OSMOSIS SYSTEM

Operation and Maintenance Manual

OS1157051 Rev. G 13July07

NOTICE

For personal and system safety, and for

optimum product performance, make sure

you thoroughly read and understand the

contents of this manual before installing,

using, or maintaining this product.

OS1157051 REV. G A 13-July-07

This page intentionally left blank.

OS1157051 REV. G B 13-July-07

A

TABLE OF CONTENTS

1.0 GENERAL INFORMATION

1.1 General Description

1.2 The Manual

1.3 Safety Summary

1.3.1 Read This Manual

1.3.2 Use Proper Power Connections

1.3.3 Device Labeling

1.4 Flow Description

1.5 Machine Nomenclature

1.6 Machine Permeate Quality

1.7 Machine Features

1.8 Specifications for 23G Machine

1.8.1 RO Feedwater Specifications

1.8.2 Permeate (Product Water) Flow Rate

1.8.3 Concentrate Flow Rate

1.8.4 Primary Operating Pressure

1.8.5 Pump

1.8.6 Reverse Osmosis Machine Rejection

1.9 Service Assistance

1.10 Medical Membrane Element Specification for Water Purification

2.0 INSTALLATION

2.1 Machine Location

2.2 Pluming

2.2.1 Inlet Plumbing

2.2.2 Valve for Clean-In-Place (CIP)

2.2.3 Concentrate Outlet Connection

2.2.4 Permeate Outlet Connection

2.3 Electrical

2.4 Machine Lockout

3.0 PREPARATION AND START-UP

3.1 Pretreatment for Water Purification

3.2 Initial Start-up

3.3 Daily Start-up and Operation Checklist

OS1157051 REV. G 13-July-07

4.0 ECM-100 OPERATION

4.1 ECM-100 General Description of Operation

4.2 ECM-100 Displays and Controls

4.2.1 System Status Lights – Left Column

4.2.2 System Status Lights – Right Column

4.2.3 Keypad – Control Section

4.2.4 Keypad – Menu Select Section

4.2.5 Liquid Crystal Display (LCD)

4.2.6 ECM-100 Passcode

4.2.7 Factory Settings Storage

4.2.8 Display Menus

4.3 ECM-100 Operation

4.3.1 Selecting Parameters and Changing Settings

4.3.2 Responding to an Alarm

4.3.3 ECM-100 Clean-In-Place (CIP Operation)

4.4 ECM-100 Display Screens

4.4.1 ECM Display Screen Hierarchy

4.4.2 Detail of Date and Time Operation (Menu 01)

4.4.3 Detail of Alarm Limits Operation (Menu 02)

4.4.4 Detail of Timer Presets Operation (Menu 03)

4.4.5 Detail of Accumulated Hours Operation (Menu 04)

4.4.6 Detail of Log Tables Operation (Menu05)

4.4.7 Detail of Calibration Operation (Menu 06)

4.4.8 Detail of Print Current Values Operation (Menu 08)

4.4.9 Detail of Metric/US Select Operation (Menu 09)

4.4.10 Detail of Perm High Conductivity Alarm Operation (Menu 10)

4.4.11 Detail of Factory Settings Operation (Menu 11)

4.4.12 Detail of Auto-On Tank Full Operation (Menu 12)

4.4.13 Detail of Comm Port Speed Operation (Menu 13)

5.0 MACHINE OPERATION AND MAINTENANCE

5.1 Daily Requirements

5.2 Weekly Requirements

5.3 Quarterly Requirements

5.4 Semi-annual Requirements

5.5 Annual Requirements

5.6 Flushing

OS1157051 REV. G 13-July-07

B

5.7 Step-Wise Cleaning

5.7.1 Installation of the 23G CIP

5.7.2 General Clean-In-Place Procedure

5.8 Sanitizing Using a CIP System

5.9 Membrane Element Cleaners and Sanitizers for 23G Machines

5.10 Pre-filter Replacement Procedure

5.11 Recording Performance Data

5.12 Preparing Machine for Movement

5.13 Membrane Element Replacement

5.13.1 Membrane Element Removal

5.13.2 Membrane Element Installation

5.14 Flow Control Adjustments

5.14.1 Leaks

5.15 Permeate Divert

5.16 Product Water Pressure Relief

6.0 OPTIONAL FEATURES AND ACCESSORIES

6.1 Level Controls

6.2 PH Controller/Sensor (ECM-100-pH)

6.3 Remote Alarm Interface - Six Channel

6.4 Printer/Computer Interface

6.4.1 Printer Interface

6.4.2 Computer Interface

6.4.3 Computer Connection

6.4.4 Printer Connection

6.4.5 Print Test

6.4.6 Print Functions

7.0 TROUBLESHOOTING

7.1 Emergency Alarm Bypass

7.1.1 Permeate Conductivity High or Rejection Low Alarms

7.1.2 Rejection Low Alarm Due to Failed Feed Conductivity Probe

7.1.3 Temperature High Alarm

7.1.4 pH Alarms

7.1.5 Pressure

7.1.6 Permeate Flow (Stuck at Zero)

7.2 General ECM-100 Reference/Troubleshooting Guidelines

7.2.1 Resetting the ECM-100

7.2.2 Check the Main Board Terminal Strip for Good Connections

7.2.3 Check the Relay Board Terminal Strip for Good Connections

7.2.4 Low Rejection Warning (Due to High Purity Feedwater)

7.2.5 Verifying the Temperature Circuitry of the Main Board

7.2.6 Difficulty Calibrating Permeate Conductivity

7.2.7 Information to Obtain Before Contacting Your Equipment Supplier

OS1157051 REV. G 13-July-07

C

8.0 23G SOFTWARE

8.1 Calibration Procedures – Version 2 Software

8.2 pH Calibration Procedure – Software Version V2

8.3 V2 Logic Board

8.4 Temperature Calibration Procedure – V2

8.4.1 Cleaning the Feed Conductivity Sensor

8.4.2 Calibrating the Temperature

8.5 Conductivity Calibration Procedure – V2

8.5.1 Measuring the Conductivity of Feed and Permeate Samples

8.5.2 Verifying the Percent Rejection Reading on the ECM-100

8.5.3 Displaying the Feed Conductivity on the ECM-100

8.5.4 Calibrating the Feed Conductivity

8.5.5 Restoring the Rejection Low Alarm Setting

8.5.6 Calibrating the Permeate Conductivity

8.6 Pressure Transducer Calibration Procedure – V2

8.7 Flow Calibration Procedure – V2

8.7.1 Calculating Permeate Flow Rate

8.7.2 Calculating Concentrate Flow Rate

8.7.3 Calibrating the Concentrate and Permeate Flow Rate Offsets

8.7.4 Verifying the Concentrate and Permeate Flow Rate Slopes

8.7.5 Calibrating the Concentrate and Permeate Flow Rate Slopes

9.0 RETURNED GOODS AUTHORIZATION PROCEDURE

10.0 SERVICE ASSISTANCE

11.0 SPARE PARTS LISTS

Valves

Prefilters

6-Channel Remote

Flow Block and Connectors

Pump and Motor Assemblies (Three-phase, 60 Hz)

Pump and Motor Assemblies (Three-phase, 50 Hz)

Pump and Motor Assemblies (Three-phase, 50 Hz)

Pump and Motor Assemblies (Single-phase)

Sensor

Electrical

Membrane Elements

4-inch Housing Spare Parts

Test Kits

Clamps

Miscellaneous

OS1157051 REV. G 13-July-07

D

Figure Title

1.1 Membrane Element with Interconnectors

1.2 System Schematic

1.3 Typical Flow Diagram for 23G Systems

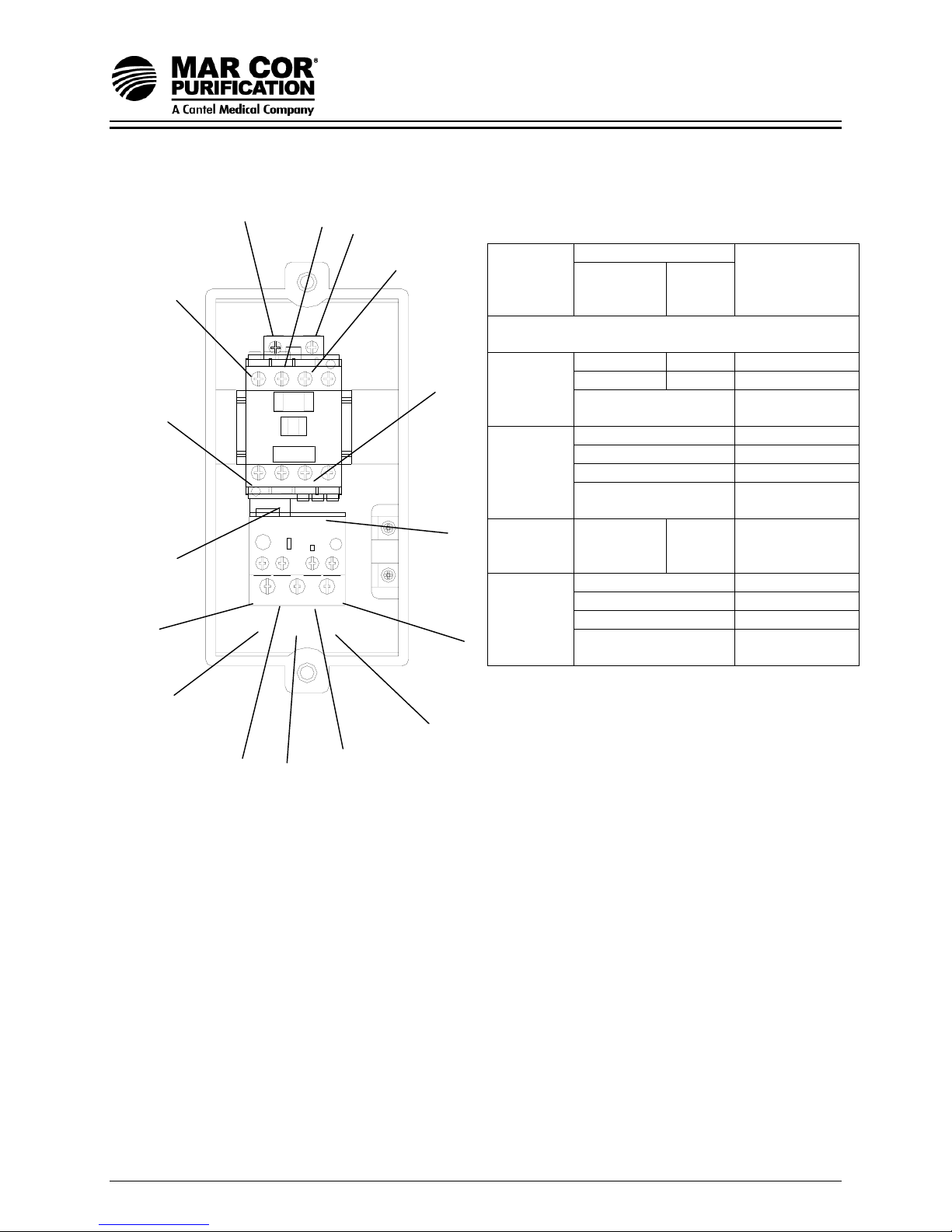

2.4 Three-Phase Motor Wiring

4.5 ECM-100 Front Panel

4.6 23G Series ECM-100 Main Board Electrical Diagram

4.7 23G Series ECM-100 Relay Board Electrical Diagram

5.8 Brine Seal at the Exit End

5.9 Membrane Element Installation

5.10 Cross-Sectional View Membrane Element and Housing

5.11 Flow Control Manifold

7.11 ECM-100

Table Title

1.1 23G Model Number Matrix

1.2 Shipping Weights and Dimensions

2.3 Single-Phase Electrical Connections

2.4 Three-Phase Electrical Connections

4.5 ECM-100 Alarm Settings

4.6 ECM-100 Timer Settings

5.7 Dry Chemical Cleaners

5.8 Liquid Chemical Cleaners

6.10 Example of ECM-100 History Log

List of Figures

List of Tables

OS1157051 REV. G 13-July-07

E

23G-Series RO System

1.0 GENERAL INFORMATION

1.1 General Description

CAUTION:

When used as a medical device, Federal law restricts this device to sale

by or on the order of a physician, per 21 CFR 801.109 (b).

Your Mar Cor Purification 23G reverse osmosis machine is a durable

piece of equipment which, with proper care, will last for many years.

These instructions give operating and maintenance details vital to the

sustained performance of the machine.

Reverse Osmosis (RO) is the separation of one component of a solution

from another component by means of pressure exerted on a

semipermeable membrane. In other words, reversing the natural passage

of a liquid from a concentrate solution to a more dilute solution by using

external pressure. Removal of ionic, organic, and suspended/dissolved

impurities occurs during the RO process. Unlike a filter, which separates

by “normal” filtration, the membrane element separates using a process

called cross-flow filtration. Feedwater solution is separated into two

streams, permeate and concentrate, and collected from both sides of the

membrane. A semipermeable RO membrane, under sufficient pressure,

allows passage of purified water while rejecting and concentrating

dissolved and suspended solids.

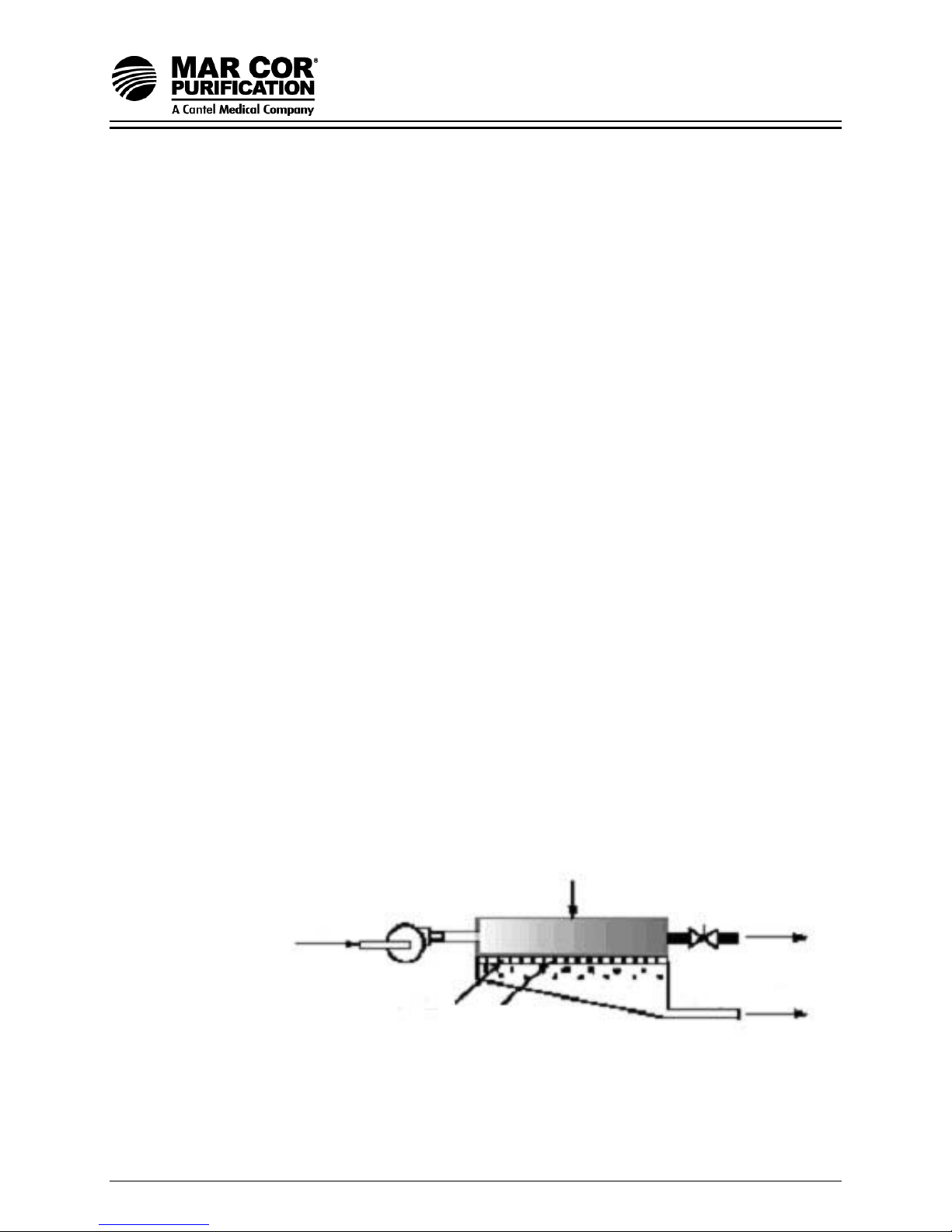

Mar Cor Purification manufactures a spiral-wound membrane package,

with turbulent flow design. This membrane element module collects the

purified water within a central tube (permeate tube), as represented in

Figure 1.1.

Brine Seal

Permeate Tube

Feed Solution

Permeate

Feed Channel Spacer

Membrane

Concentrate

Permeate Carrier

Membrane

Feed Channel Spacer

Outer Wrap

Figure 1.1 Membrane Element with Interconnectors

OS1157051 Rev G 1 13-July-07

23G-Series RO System

1.2 The Manual

This manual has been prepared to provide the operator with information

on the installation, operation, maintenance, and troubleshooting of 23G

Water Purification Systems.

The manual is supplemented with drawings and schematics for

clarification whenever possible.

1.3 Safety Summary

The safety summary does not contain all of the safety statements in the

manual. Other safety statements are included within the manual text and

are enhanced and defined as follows:

NOTE:

Indicates statements that provide further information and clarification.

CAUTION:

Indicates statements that are used to identify conditions or practices that could

result in equipment or other property damage.

WARNING:

Indicates statements that are used to identify conditions or practices that could

result in injury or loss of life. FAILURE TO FOLLOW WARNINGS COULD

RESULT IN SERIOUS INJURY OR DEATH TO HEMODIALYSIS PATIENTS OR

OPERATOR.

1.3.1 Read This Manual

Prior to operating or servicing this device, this manual must be read

and understood. Keep it and other associated information for future

reference and for new operators or qualified personnel near the

machine.

1.3.2 Use Proper Power Connections

Use proper wiring and connection methods as stated in this

manual.

1.3.3 Device Labeling

Do not, under any circumstances, remove any Caution, Warning, or

other descriptive labels from the devices until the conditions

warranting the label are eliminated.

Operating definitions are provided to help you further understand

your machine:

OS1157051 Rev G 2 13-July-07

23G-Series RO System

Permeate Rate [Product Water Rate (Qp)]

Permeate rate is the flow rate of purified water which has passed

through the membrane and out of the membrane element;

expressed in gal/min (gpm) or gal/hr (gph) [in metric, liter/min (Lpm)

or cubic meters/hour (m3/h)]. Specified permeate rates are

normally at 77°F (25°C).

Concentrate Rate [Waste Water Rate (Qc)]

Concentrate rate is the flow rate of water containing rejected solids

to drain in gpm or gph (Lpm or m3/h).

Feed Rate (Qr)

Feed rate is the flow rate of incoming water in gpm or gph (Lpm or

m3/h). Feedwater rate equals permeate rate plus concentrate rate.

Recovery

Recovery is the percentage (%) of feedwater converted to

permeate. For example, 75% recovery means that out of a given

feed rate, 75% is produced as pure water (permeate).

Concentration

Concentration equals the Total Dissolved Solids (TDS) of any

stream (feedwater, concentrate or permeate) of a solution

expressed as milligrams per liter (mg/L) or conductivity

(microSiemens/cm).

Cf = Feed Concentration

= Permeate Concentration

C

p

Cc = Concentrate Concentration

C

avg

= Average Concentration in Machine

Salt (Ionic) Rejection

Salt (Ionic) Rejection is the percent of dissolved salt rejected by the

membrane, calculated from an average concentration over the

membrane.

Salt (Ionic) Passage

Salt (Ionic) Passage is the percent of dissolved salts passed

through the membrane.

OS1157051 Rev G 3 13-July-07

23G-Series RO System

Primary Pressure (Pp)

Primary Pressure (Pp) is the pressure between the pump discharge

and the feed port of the first membrane element housing.

Final Pressure (Pf)

Final Pressure (P

) is the pressure between the concentrate outlet

f

of the last housing and the concentrate valve.

Pre-filter Pressure (P

Pre-filter Pressure (P

)

pre

) is the water pressure entering the pre-filter.

pre

Post-filter Pressure (P

Post-filter Pressure (P

)

post

) is the water pressure leaving the pre-

post

filter.

Membrane Elements

Membrane elements are the key to reverse osmosis. Interleaved

layers of semipermeable membrane, spacer and permeate carrier

spiraled around a central permeate tube make up the element. The

spacer allows for movement of the concentrate past the membrane,

and the permeate carrier carries the pure water out of the

membrane element. The elements that Mar Cor Purification uses

are spiral-wound membrane elements with a turbulent flow design.

The membrane element collects the permeate water within the

central tube, called the permeate tube.

Recovery 75%

100 mg/L

Feed

OS1157051 Rev G 4 13-July-07

C

avg

Pump

24 gpm

(C

(Q

)

f

)

f

Membrane

Porous

Backing Material

Figure 1.2 System Schematic

375 mg/L

6 gpm

8.3 mg/L

18 gpm

)

(C

c

Concentrate

)

(Q

c

(C

)

p

Permeate

)

(Q

p

23G-Series RO System

An example of how to calculate salt rejection and recovery:

Average Concentration (C

2 2

Rejection = (C

(C

Passage = (C

(C

Recovery = (Q

(Q

) - (Cp) x 100 250 - 6.2 x 100 = 97.5%

avg

) 250

avg

) x 100 6.2 x 100 = 2.5%

p

) 250

avg

) x 100 6 gpm x 100 = 75%

p

) 8 gpm

f

) = (Cf) + (Cc) 100 mg/L + 400 mg/L = 250 mg/L TDS

avg

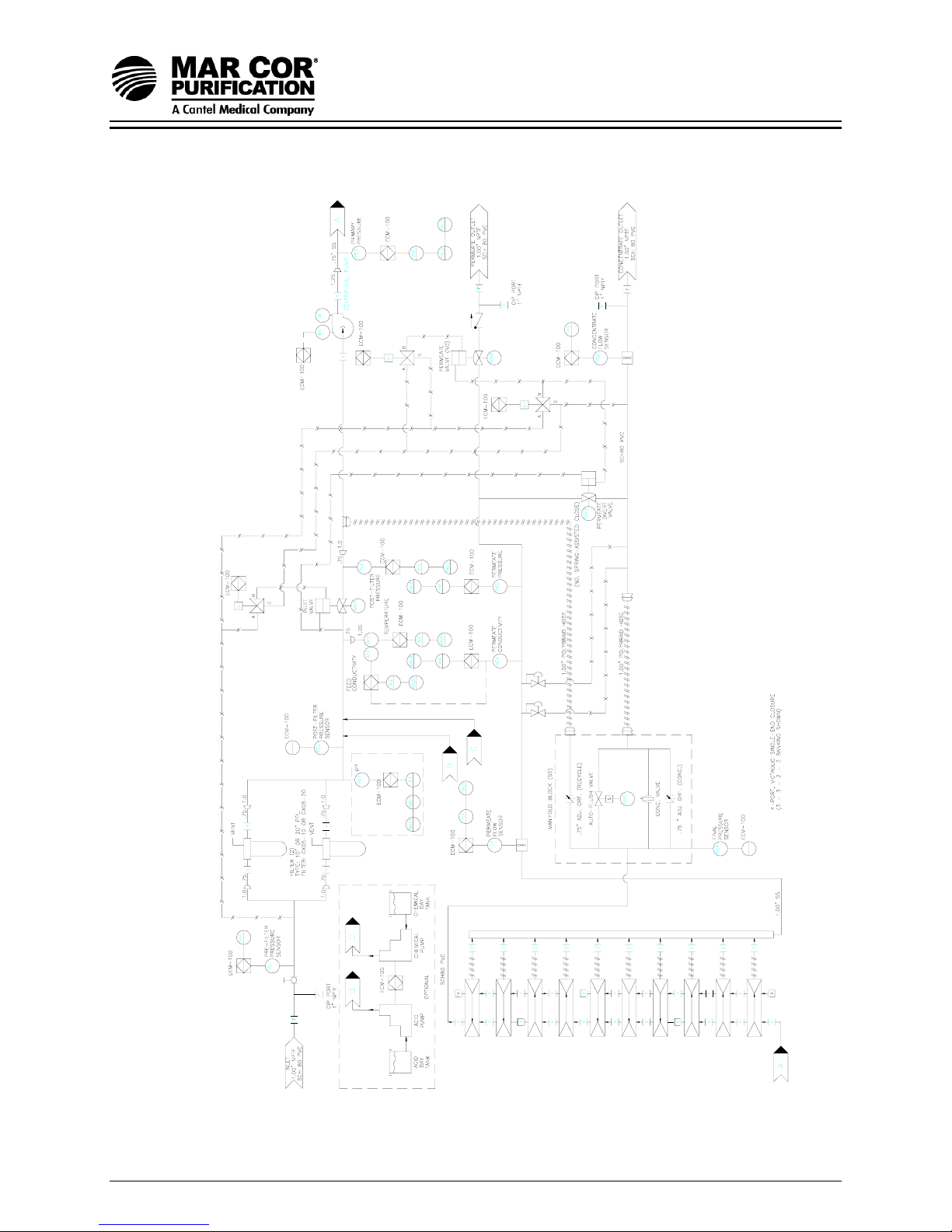

1.4 Flow Description

The pretreated feedwater passes through a disposable 5 micron cartridge

filter (pre-filter) which removes suspended solids. Filtered water then flows

to the inlet control valve. This solenoid-actuated valve is controlled by

Enhanced Controller/Monitor (ECM-100) and opens when the machine is

turned on, allowing water to flow to the pump inlet. When the machine is

turned off, the valve closes, preventing laminar flow through the

membrane element, which would lead to shortened membrane life.

The pump feeds water to the membrane element housings in a series

and/or parallel configuration, depending upon the design flow rates. The

direction of water flow is indicated by an arrow on each membrane

element housing.

Permeate from each membrane element housing is collected at the

permeate manifold where a common check valve prevents backflow into

the membrane elements. A pressure sensor is provided to allow the ECM100 to monitor excessive backpressure and initiate an immediate alarm

and machine shutdown should the setpoint be exceeded. Permeate is

directed through a turbine flow sensor and contacts a conductivity sensor

before reaching the outlet point of the machine.

OS1157051 Rev G 5 13-July-07

23G-Series RO System

The concentrate leaves the last membrane element housing and flows into

the manifold block. This concentrated water is then divided into recycle

and concentrate streams. The recycle portion mixes with the feedwater by

returning to the inlet piping, allowing higher machine recovery while still

maintaining adequate crossflow through the membrane elements. The

concentrate valve on a 23G machine is used to increase the concentrate

flow rate for flushing. The normal concentrate flow rate is controlled by the

concentrate orifice. The concentrate valve or orifice has three functions: it

controls the amount of concentrate flowing to the drain; it controls the

pressure within the machine; and it helps control system recovery. A

solenoid-controlled Autoflush valve is also provided in the concentrate line

to provide periodic intervals of increased drain flow rate controlled by the

ECM-100. The concentrate portion leaving the manifold block is directed

through a turbine flow sensor before reaching the outlet point of the

machine.

OS1157051 Rev G 6 13-July-07

23G-Series RO System

Figure 1.3 Typical Flow Diagram for 23G Systems

OS1157051 Rev G 7 13-July-07

23G-Series RO System

1.5 Machine Nomenclature

Mar Cor Purification water purification machines are numbered in such a

way as to indicate the permeate flow and quality you can expect from the

machine. The nomenclature (model number) of your machine is shown on

the serial number label on the side panel of the machine.

Table 1.1

23G Model Number Matrix

RO, 23G XXXX,

XXX, X, XX, XXXX

Rated Permeate Flow

GPD

3000

4500

6000

7500

9000

10500

12000

13500

15000

16500

Volts

208

230

460

380

Hertz

6=60

5=50

Recovery

50%

75%

Options

Single

Phase

W/Casters

1.6 Machine Permeate Quality

23G machines use high rejection, polymeric membrane, providing the

ultimate in high purity water.

OS1157051 Rev G 8 13-July-07

23G-Series RO System

1.7 Machine Features

Mar Cor Purification 23G Series machines contain an array of useful

standard features to provide additional system safety and reliability, to

simplify system monitoring and data collection, and to ensure the longest

membrane life.

Standard features include:

• 50% and 75% recovery models available.

• Multi-stage centrifugal stainless steel pump, submersible design.

• Enhanced controller/monitor (ECM-100); includes parameter

display, alarms, and machine status indicators.

• Automatic inlet shut-off valve.

• Common check valve in the permeate line to prevent backflow.

• Pre-filter housings and 5 micron cartridge filters.

• Pre- and post-filter pressure indication.

• Primary and final pressure indication.

• Permeate backpressure indication.

• Product water divert.

• Product water pressure relief.

• Concentrate and percent rejection indication for permeate quality

and membrane performance monitoring.

• Temperature indication for feedwater temperature monitoring.

• Membrane element housings made of all 304 stainless steel.

• Autoflush - programmable periodic high velocity membrane flushing

to maintain long membrane life. Set at factory and adjustable in the

field.

• Inlet low pressure alarm automatically shuts off the machine to

prevent pump damage, should inlet pressure fall to an inadequate

level.

• Components in contact with the RO water (permeate) are made of

either inert plastic (nylon, poly-ethylene, Noryl*, polypropylene,

PVC, EPDM, Nitrile) or stainless steel materials.

• Memory for more than 400 sets of historical operating data

(generated by approximately 2.5 full months of continuous

operation).

• Comprehensive alarm package, with adjustable limits and common

time-out, to ensure safety and proper operation. Alarm is both

visual and audible. Alarms include:

OS1157051 Rev G 9 13-July-07

23G-Series RO System

• high/low primary pressure (immediate shutdown on primary high

pressure)

• low inlet post-filter pressure

• high permeate pressure (immediate shutdown)

• high/low pH

• high temperature

• high permeate conductivity

• low permeate conductivity

• low permeate flow

• low percent rejection

• high pre-filter pressure drop

• high membrane pressure drop

NOTE:

All alarms except high primary pressure, high permeate pressure, and

high temperature are ignored in Clean in Place (CIP) mode.

*Noryl is a trademark of General Electric Company.

OS1157051 Rev G 10 13-July-07

23G-Series RO System

Specifications for 23G Machines

1.7.1 RO Feedwater Specifications

The rated flow for all machines in this section is based upon the

following feedwater specifications. Limits should not be exceeded

without consulting the factory.

Inlet Pressure Rated; 30 psi (2.1 bar)

Maximum; 60 psi (4.1 bar)

Minimum; 20 psi (1.4 bar)

Temperature1 35-77°F (2-25°C) not to exceed 85°F (29°C)

Langelier Saturation Negative 0.1

Index of Concentrate

2

Continuous Free Chlorine (mg/L)3 Less than 0.1 ppm

Silt Density Index4 Less than 3

Iron 0 ppm

Other Impurities

5

Pre-filter 5 micron cartridge(s)

Inlet Connection Thread 1-inch Female National Pipe (FNPT)

1. Continuous operation over 85°F (30°C) may cause

permanent decline in the membrane element performance.

Actual permeate flow rates typically increase/decrease by

1.4% for each 1°F change in temperature. For other

temperatures, use “Temperature Factor Chart” (Technote

113) to determine permeate rate. Contact authorized

equipment supplier if feedwater is outside these parameters.

OS1157051 Rev G 11 13-July-07

23G-Series RO System

2. The Langelier Saturation Index (LSI) of the concentrate must

be negative to minimize the possibility of calcium scale

formation on the membrane surface. Refer to ASTM

Standard D3739.

3. Chlorine should be removed prior to the PA membrane in

order to prolong the functional life of the membrane element.

Microbiological growth will not affect the membrane itself, but

may cause fouling and significant permeate flow rate

decline. See Membrane Specification Sheet for additional

information.

4. Maintenance of feedwater Silt Density Index (SDI) as noted

would minimize membrane fouling and extend cleaning

intervals. Treatment of feed waters with higher SDI values is

possible with more frequent cleaning and/or filter changes.

Refer to ASTM Standard D4189.

5. Components such as silica, barium, manganese, strontium,

etc., must be below saturation in the concentrate. Contact

your equipment supplier for clarification if unsure.

6. It is recommended that an adjustable pressure regulator be

installed just prior to the RO in order to allow adjustment of

inlet pressure to RO. Regulator must be able to provide

adequate flow to RO.

1.7.2 Permeate (Product Water) Flow Rate

As stated on the serial number label (assumes no permeate

backpressure, 1000 mg/L TDS maximum feed concentration, and

rated temperature).

To estimate the permeate output with backpressure, use the

formula below:

(Permeate Flow on Label) x (Operating Pressure) - (Permeate Backpressure)

(Operating Pressure)

Maximum Permeate Backpressure: 60 psi (4.1 bar)

Permeate Outlet: 1-inch female NPT

1.8.3 Concentrate Flow Rate

Factory set as stated on serial number label.

Concentrate Outlet 1-inch female NPT

OS1157051 Rev G 12 13-July-07

23G-Series RO System

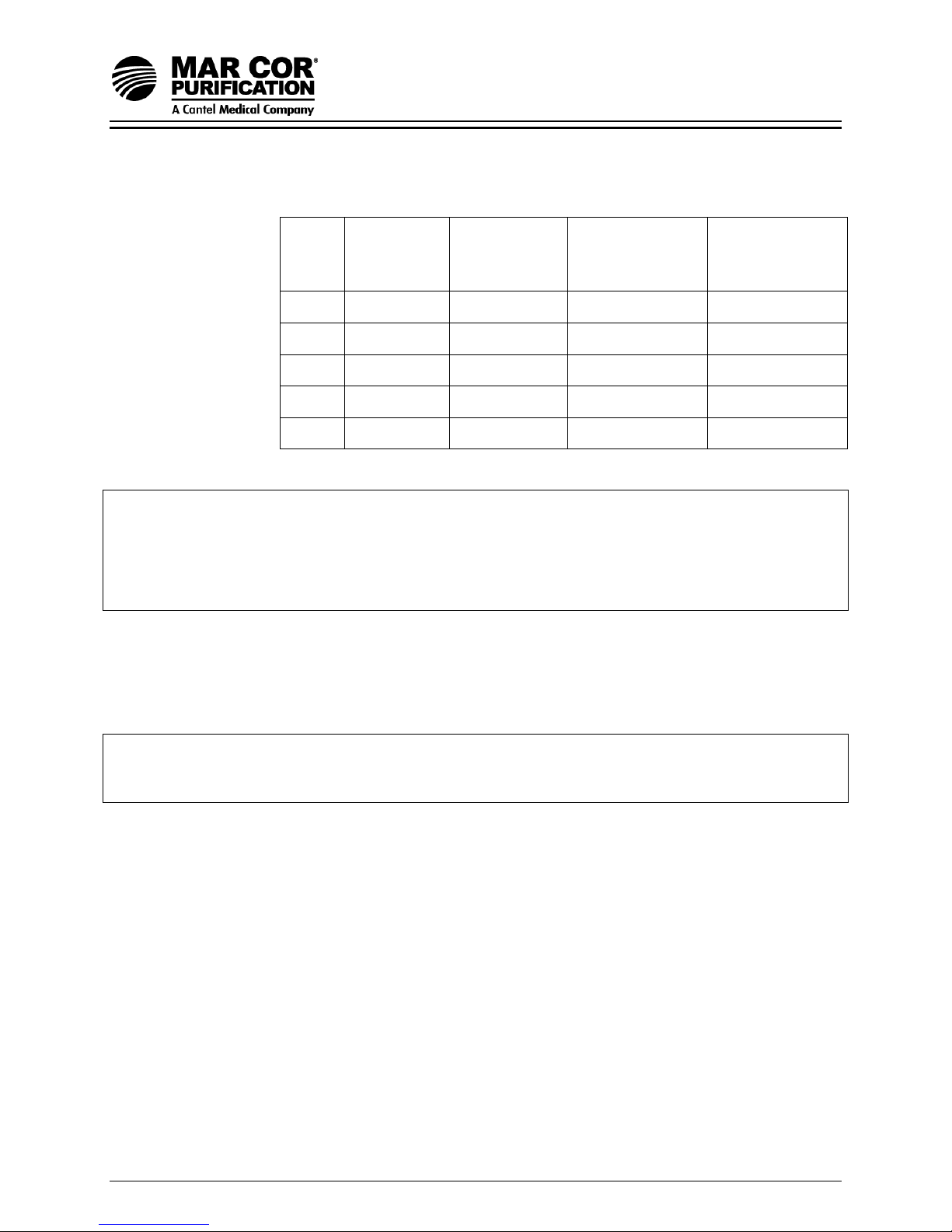

1.8.4 Primary Operating Pressure

Motor

(Hp)

Frequency

(Hz)

Pump

Model

Minimum

Boost Primary

Pressure (PSI)

Maximum

Boost Primary

Pressure (PSI)

3 60 QS1818VB 120 270

5 60 QS2818VB 100 250

7.5 60 QS2825VB 170 350

3 50 QS1828VB 120 280

5 50 QS2825VB 100 250

NOTE:

Boost pressure = (primary pressure — post-filter pressure).

NOTE:

Primary and final pressure parameters may vary depending upon machine design and

installation conditions.

1.8.5 Pump

Multi-stage centrifugal, approximate primary operating pressure of

200 psi (13.8 bar) excluding line pressure.

NOTE:

Actual operating pressure may vary depending upon machine design and installation

conditions.

1.8.6 Reverse Osmosis Machine Rejection

Typical Ionic Rejection (TDS) 95 - 99%

Average Molecular Weight Cutoff* 150 MW

*The molecular weight cutoff is based on the pore size of the

membranes and the nature of the organic molecule (size/shape).

OS1157051 Rev G 13 13-July-07

23G-Series RO System

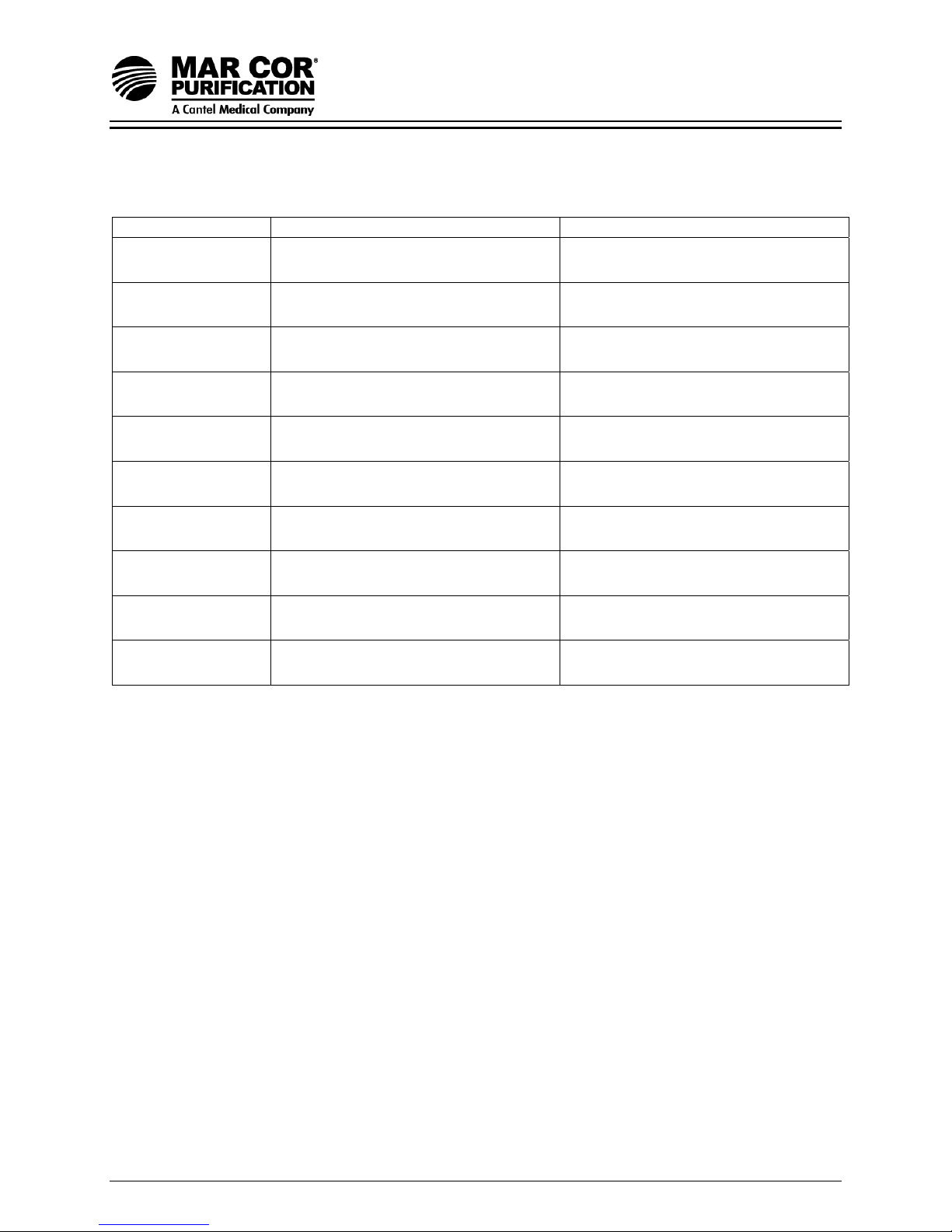

Table 1.2 Approximate Shipping Weights and Dimensions

Model Number Shipping Dimensions Shipping Weight

23G 2 Element 65” D x 34” W x 78” H

(165 cm D x 86 cm W x 200 cm H)

23G 3 Element 65” D x 34” W x 78” H

(165 cm D x 86 cm W x 200 cm H)

23G 4 Element 65” D x 34” W x 78” H

(165 cm D x 86 cm W x 200 cm H)

23G 5 Element 65” D x 34” W x 78” H

(165 cm D x 86 cm W x 200 cm H)

23G 6 Element 81” D x 34” W x 78” H

(205 cm D x 86 cm W x 200 cm H)

23G 7 Element 81” D x 34” W x 78” H

(205 cm D x 86 cm W x 200 cm H)

23G 8 Element 81” D x 34” W x 78” H

(205 cm D x 86 cm W x 200 cm H)

23G 9 Element 81” D x 34” W x 78” H

(205 cm D x 64 cm W x 200 cm H)

23G 10 Element 81” D x 34” W x 78” H

(205 cm D x 64 cm W x 200 cm H)

23G 11 Element 90” D x 34” W x 88” H

(228 cm D x 64 cm W x 224 cm H)

655 lbs

(298 kg)

685 lbs

(311 kg)

725 lbs

(330 kg)

815 lbs

(370 kg)

845 lbs

(384 kg)

925 lbs

(420 kg)

1025 lbs

(466 kg)

1060 lbs

(480 kg)

1100 lbs

(500 kg)

1200 lbs

(545 kg)

1.9 Service Assistance

If service assistance is required, take the following steps:

1. Consult the Troubleshooting Section of this manual (Section 7.0). If

the problem cannot be identified and corrected by any of the

procedures found in the troubleshooting section, then

2. Call your equipment supplier.

Prior to making the call, have the following information available:

Machine installation date

Model number (found on right-hand side of front panel)

Serial number (found on right-hand side of front panel)

Daily log sheets

Current operating parameters (i.e., flow, operating pressures, pH,

etc.)

Description of the problem

Current software version (from memory chip on inside of door)

OS1157051 Rev G 14 13-July-07

23G-Series RO System

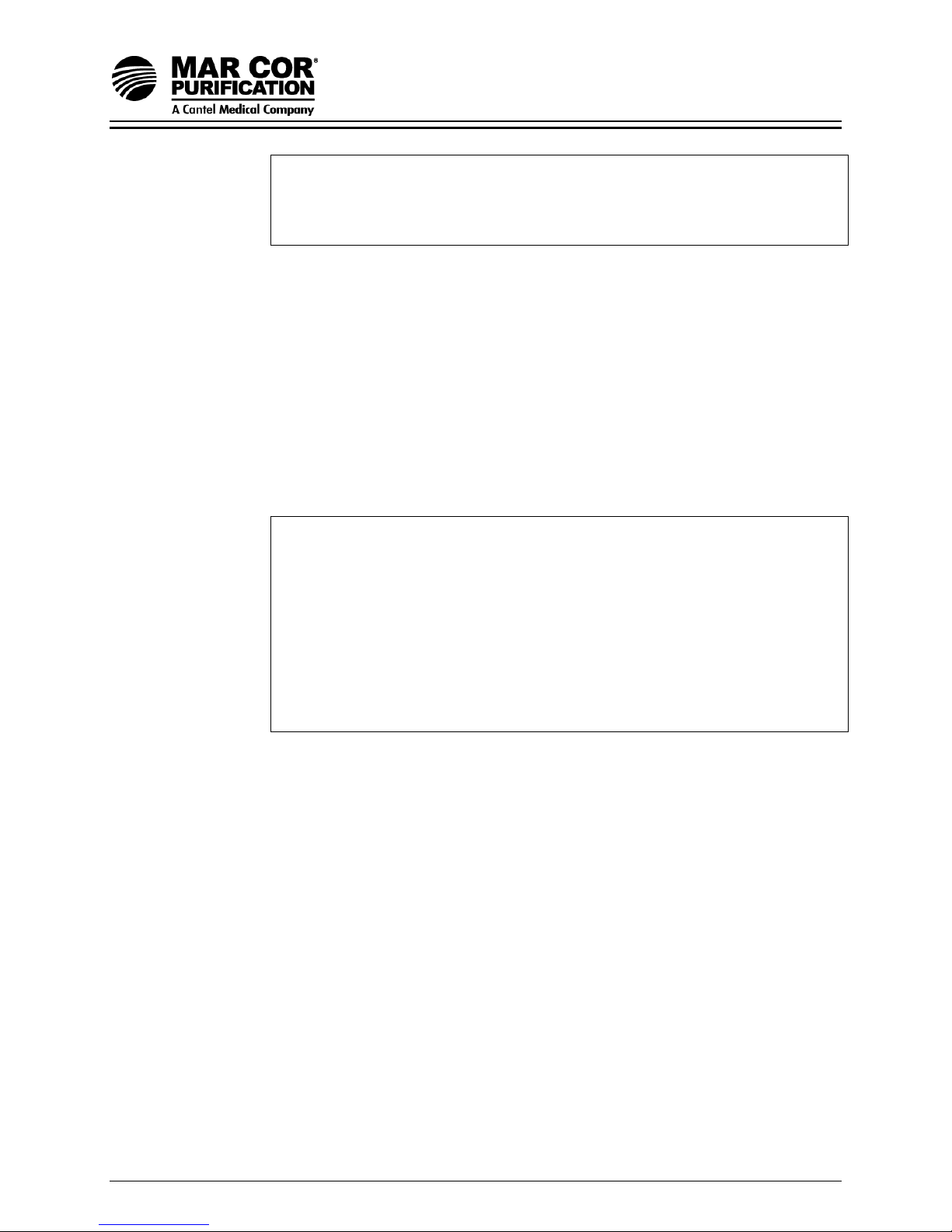

1.10 Medical Membrane Element Specification

NaCl rejection: 99.0% Average (98.0% minimum)

Based on a 2,000 mg/L NaCl solution at 225 psig (1,551 kPa) operating

pressure, 77 °F (25 °C), pH 7.5, 15% recovery, after 24 hours. Individual

element flow may vary 15%.

Design Parameters

Maximum pressure: 300 psig (2070 kPa)

Typical cleaning: <200 psig (1450 kPa)

Maximum temperature

Operating: 90 °F (32 °C)

Cleaning: 85 °F (29 °C) *

Operating pH: 5.0- 10.0

Cleaning pH: 2.0 - 11.5

Feed NTU: < 1

Feed SDI: < 3

Chlorine tolerance: 1,000 ppm-hours Dechlorination recommended

Maximum Delta P: 10 psig (69 kPa) per element

* CAUTION: Operating the system at above 85°F during cleaning can cause significant

pump damage.

Element Performance Feed Concentration

Ion mg/L % Rejection

Sodium 68.0 99.4

Calcium 80.0 99.8

Magnesium 21.0 99.8

Potassium 4.1 99.4

Sulfate 163.0 99.8

Bicarbonate 132.0 99.3

Chloride 51.0 99.4

Silica 9.3 92.0

TDS 528.0 99.4

Based on a mixed salt feed solution at 225 psig (1,551 kPa) operating pressure,

77 °F (25 °C), pH 7.5, 15% recovery, after 24 hours.

OS1157051 Rev G 15 13-July-07

23G-Series RO System

2.0 INSTALLATION

2.1 Machine Location

At least 45 inches (114 cm) of space should be allowed above the

membrane element housings for easy removal and loading of membrane

elements. Provide adequate workspace on sides and front for easy

access.

NOTE:

If necessary, housings may be detached from the frame for membrane

element removal due to space restrictions around the machine.

2.2 Plumbing

2.2.1 Inlet Plumbing

The feedwater source should be plumbed to the 1-inch FNPT inlet

point on the 23G machine. If the inlet pressure is in excess of 60

psi (4.1 bar) or fluctuates by more than 5 psi (0.3 bar), a pressure

regulator should be installed ahead of the connection. A low

pressure sensor is installed on every 23G machine to protect

against low inlet pressure. The 23G should not be installed where

the feedwater dynamic inlet pressure is less than 20 psi (1.4 bar). If

inlet pressure is less than 20 psi (1.4 bar), a booster pump must be

installed ahead of the connection.

2.2.2 Valves for Clean-In-Place (CIP)

All 23G units have separate CIP connections. Valves should be

installed on both the main and inlet cleaning connections of the inlet

stream. The permeate outlet and concentrate outlet plumbing

streams include factory installed manual shutoff valves.

CAUTION:

Do not operate the machine with all concentrate and permeate

connections closed. Severe damage to the unit may result.

2.2.3 Concentrate Outlet Connection

Connect a 1.0-inch hose or pipe to the concentrate outlet and run to

an open drain. To avoid drainage to the machine during nonoperation, the concentrate outlet plumbing should be placed at a

height which is at least equal to the height of the machine. A siphon

break may also be installed in the concentrate line for added

protection. The concentrate outlet hose or pipe can be any length,

and the diameter should match the outlet of the machine.

OS1157051 Rev G 16 13-July-07

23G-Series RO System

NOTE:

Soft, flexible hose can be used, but must be installed in a manner

which prevents “kinks” or other restrictions that will increase back

pressure and reduce permeate flow rate to the drain.

2.2.4 Permeate Outlet Connection

Connect a 1.0-inch I.D. hose or pipe to the permeate outlet and run

to the storage tank (if applicable) or distribution loop (after

distribution loop, points of use).

The pure water (permeate) should be transported to the point-ofuse via noncorroding inert-type tubing pipe or hose. Examples are:

food grade flexible nylon tubing, stainless steel tubing or PVC

piping.

NOTE:

Soft, flexible hose can be used, but must be installed in a manner

which prevents “kinks” or other restrictions that will increase back

pressure and reduce permeate flow rate to the drain.

NOTE:

Do not use copper or galvanized tubing or piping to carry the

permeate. Only food grade materials and/or appropriate NSF

materials should be used.

2.3 Electrical

The ECM-100 controls and monitors the operation of the 23G, requiring a

dedicated 115/230 VAC 60/50Hz, 15/10 A, 220 VAC, single-phase power

source. All control output devices (motor starter, solenoid valves, chemical

pumps) draw power from this source (through ECM-100 relay outputs) in

addition to the ECM-100 itself. Refer to Figures 2.3 and 2.4 for connection

details and ECM-100 inputs and outputs.

The ECM-100 monitors system-operating parameters for alarm conditions

to safeguard the machine’s operation. User variation of the alarm limits

and timer presets (set at the factory) are possible by accessing the

appropriate function from the system operations menu and following the

respective directions for making the changes.

The 23G pump is wired at the factory to an IEC overload protection

magnetic motor starter that is controlled by the ECM-100.

The procedure for connecting the electrical wiring for installation of the

23G follows:

OS1157051 Rev G 17 13-July-07

23G-Series RO System

1. Connect the ECM-100 power cord to a properly grounded 15 A,

115 VAC/60Hz or 10 A 220 VAC/50Hz, single-phase outlet. An

appropriate termination should be installed on the electrical cord for

220 VAC service. Surge protection for single-phase service is

recommended.

The ECM-100 relay output contacts are rated to handle a control

ON relay-type circuit. V2 relay boards, supplied in all 23G machines

after November 1998, are designed to handle a maximum load of

3.0 AMPS. The current requirements of all output devices (such as

a remote alarm horn and light) must be within these limits.

The power cord of the ECM-100 should be connected to a power

receptacle tied to a “protective earth” ground to ensure a safe,

common ground for the entire 23G unit, including the three-phase

motor. DO NOT remove the grounding wire from the pump casing,

the unit frame or a power supply grounding terminal.

WARNING:

ALL SUPPLY CIRCUITS MUST BE DISCONNECTED BEFORE OBTAINING

ACCESS TO TERMINALS.

2. Separate power supplies are required for CIP and main pump.

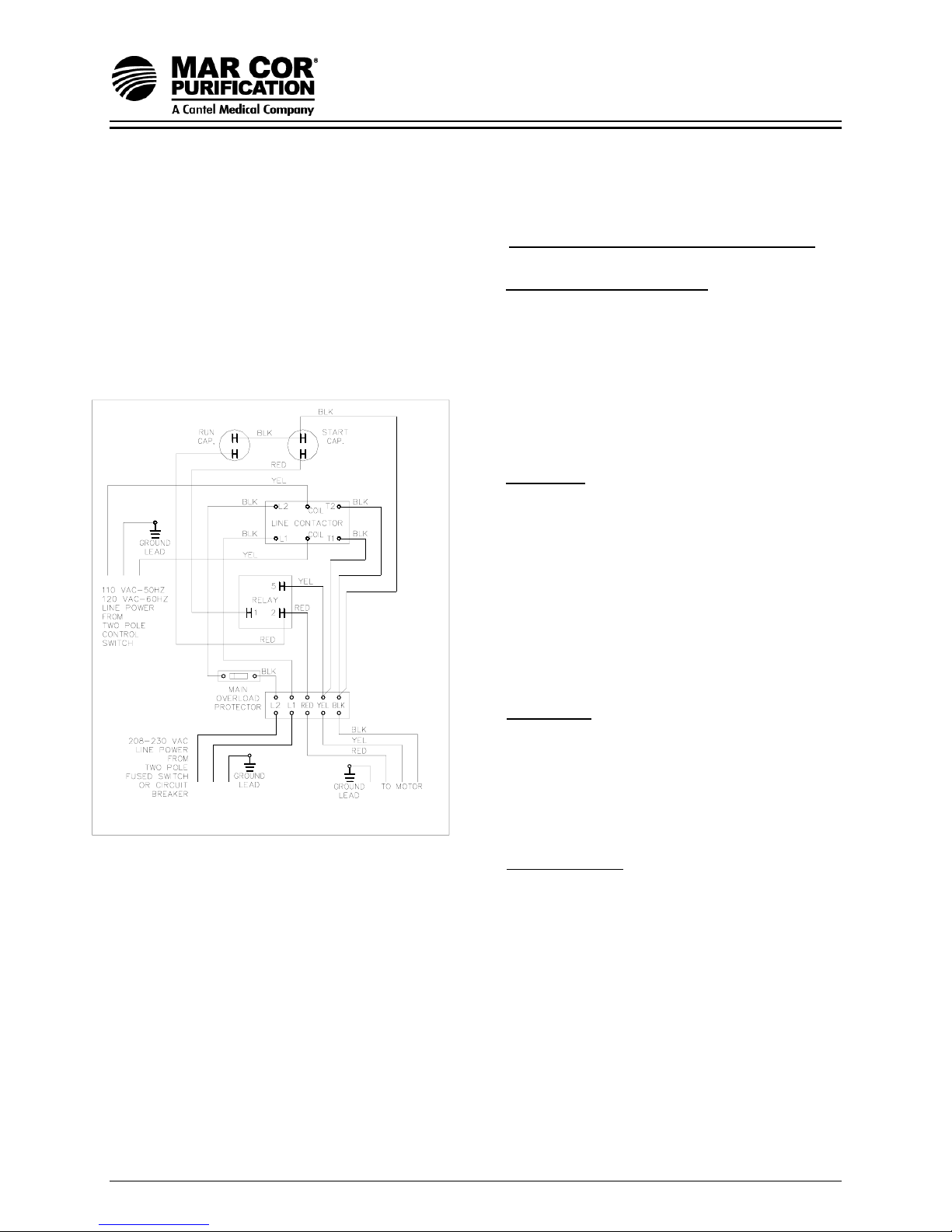

3. Connect the magnetic motor starter to the proper voltage, phase

and cycles to match motor voltage and phase. Install the wires as

indicated in Table 2.3 (single-phase) or Figure 2.4 and Table 2.4

(three-phase). The overload trip point on the pump motor starter

may need to be adjusted slightly to match the actual voltage being

provided. Check the tag on the motor starter indicating the factory

wiring. A separate, fused disconnect for the motor wiring with the

proper overload and short-circuit protection for the Hp and amp

draw of the motor is required. Bussmann Low-Peak Yellow LPSRKSP fuses or equal are recommended for the disconnect.

NOTE:

Field wiring must comply with all applicable national and local electrical

codes.

OS1157051 Rev G 18 13-July-07

23G-Series RO System

2.4 Machine Lockout

In general, the machine should be operated in AUTO mode in which

conditions are confirmed electronically. The ECM-100 terminal strip has

terminals available for linking other treatment equipment, such as a

softener, to the operation of the 23G machine or monitoring the status of

other equipment. The status of this equipment is indicated by LightEmitting Diode (LED) lights on the ECM-100. When operating in HAND

mode, it is the operator’s responsibility to ensure adequate feedwater

supply and storage tank capacity.

Lockouts are ignored in HAND mode, such as full tank level, etc. CIP

mode ignores temperature and pH alarms.

The Pretreatment Lockout input can be used in AUTO mode to shut down

the machine (all outputs turned off) when there is an interruption of

feedwater supply, such as when a pretreatment filter is backwashing. The

terminals for the Pretreatment Lockout on the ECM-100’s main strip look

for an “open” contact to shut down the machine and illuminate the blue

Pretreatment Lockout LED light.

OS1157051 Rev G 19 13-July-07

23G-Series RO System

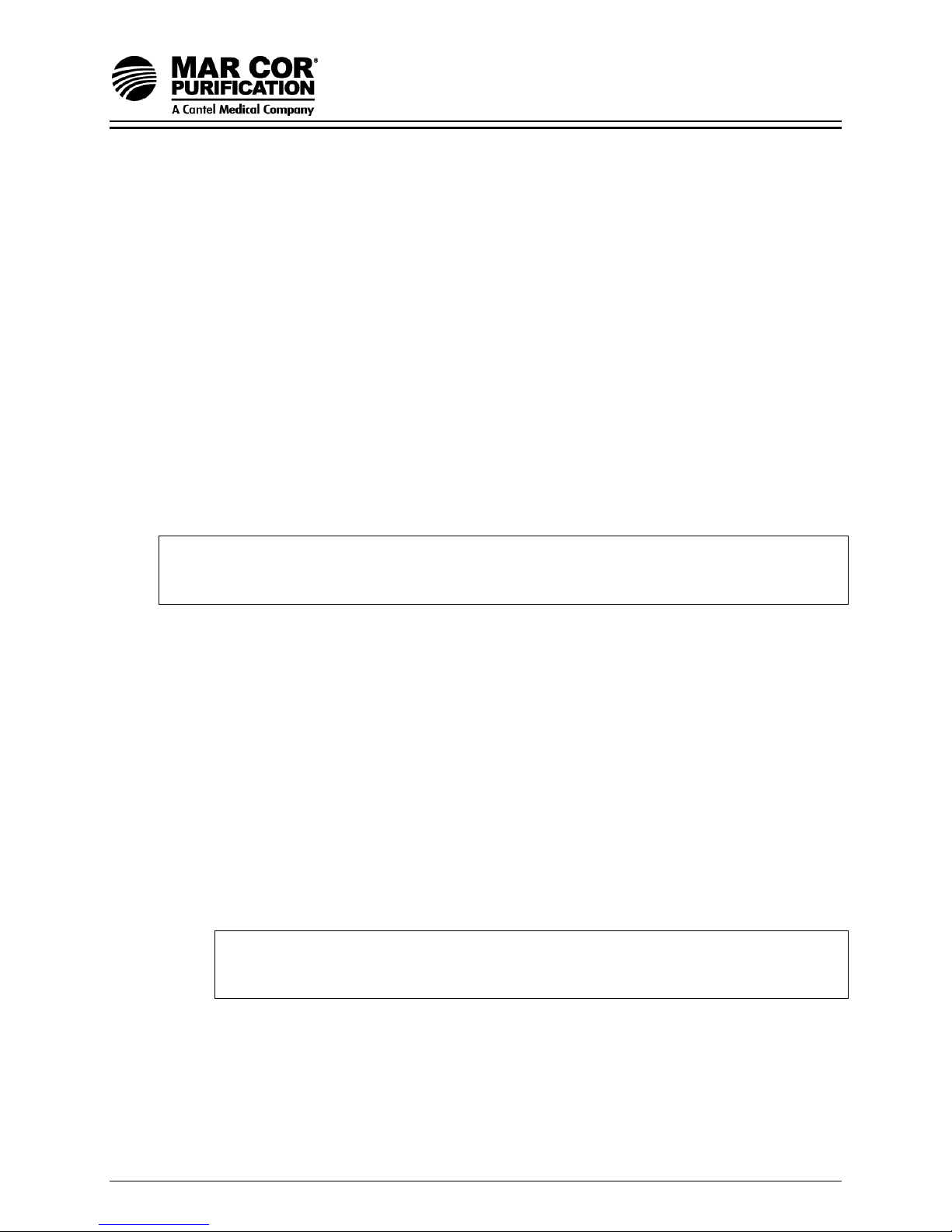

BE SURE POWER IS TURNED OFF

Checking Procedure:

A. Main Overload Protector: (Check for

continuity between the terminals.)

1. Ohmmeter Setting: R x 1.

2. Terminal Connections: Ohmmeter

B. Capacitor: (Disconnect one lead from

leads to overload terminals. Set

switch of overload to on. Meter will

read zero ohms. Set switch to off,

meter will read infinity.

each capacitor prior to checking.)

1. Ohmmeter Setting: R x 1000.

2. Terminal Connections: Individual

capacitor terminals.

3. Ohmmeter Reading: Pointer should

swing toward zero then drift back

toward infinity. No deflection means

C. Relay Coil:

D. Relay Contact

capacitor is open. Steady low

reading means it is shorted.

(Disconnect lead from terminal 5.)

1. Ohmmeter Setting: R x 1000

2. Terminal Connections: #5 and #2 on

relay.

3. Ohmmeter Reading: 5.0 / 6.7.

:

(Disconnect lead from terminal 1.)

1. Ohmmeter Setting: R x 1.

2. Terminal Connections: #1 and #2 on

relay.

3. Ohmmeter reading should be zero.

Table 2.3 Single-Phase Electrical Connections

OS1157051 Rev G 20 13-July-07

23G-Series RO System

A

A

1

L2

2

Table 2.4 Three-Phase

Electrical Connections

L1

L3

Wire

Source

Note: The connections listed below apply to 23G

models with THREE PHASE motor power

T1

T3

Elect

Enclosure

Motor

Wire Color

60 Hz 50 Hz

Black Brown 96

White Blue A2

Green/yellow

Red T1

Yellow T2

Black T3

Green/yellow

14

T2

Motor

Starter

Short Red

Jumper

98

External

Power

Supply

Green/yellow

95

Short

Brown

Jumper

#1 L1

#2 L2

#3 L3

Motor

Starter/Thermal

Overload

Connection

Common

Ground

Common

Ground

A1 to 96

Common

Ground

T1

T3

96

T2

97

Figure 2.4 Three-Phase Motor Wiring

OS1157051 Rev G 21 13-July-07

Loading...

Loading...