8720A-4

Technical

Manual

THERMAL CAMERA

P4428

© Marconi Applied Technologies Limited

This report, which is released on the

understanding that the Company’s

proprietary rights therein are recognised

and that it is solely for the information of

the recipient, must not be copied either as

a whole or in part, or disclosed to any

third party or used as the basis for the

manufacture or sale of apparatus, without

prior written permission from the Company.

CONTENTS

FRONT FOLD

Section 1 General Descriptions Page

Picture of Complete P4428 1

Brief Specification 2 - 4

Operating and Technical Descriptions 5 - 13

Internal Assembly Details 14 - 18

Batteries 19 - 23

Camera Disassembly and Tube replacement 24 - 25

Modification Record 26 - 27

Section 2 Fault Finding and Setup

Primary Fault Check Procedures 28 - 32

Camera Electrical Set -Up 33 - 35

REAR FOLD

Section 3 Diagrams

Block Diagram 1

Circuit Diagrams and Layouts :

1) Scan and Monitor Board (Old & New) 2 - 6

2) Video Processing Board (Old & New) 7 - 10

3) Voltage Regulator Board (Old & New) 11 - 14

Parts Lists

Scan and Monitor Board (Old & New) 15 - 21

Video Processing Board (Old & New) 22 - 28

Voltage Stabiliser Board (Old & New) 29 - 31

Voltage Stabiliser Unit (Old & New) 32

Chassis 33

Yoke Assembly 34

Front Plate Assembly 35

Case 36

Battery Cartridges 37

Battery Substitution Unit 38

Accessories 39

Section 4

Detailed Fault Checklists 40 - 60

Waveforms 61 - 71

- 1 -

P4428 Pyroelectric Vidicon Camera

Complete with Voltage Stabiliser Unit

Specification

- 2 -

SPECIFICATION

1. Camera

The camera has been designed to operate in the hostile conditions

encountered in a fire-fighting environment.

Weight 3.0Kg (camera including muff and harness)

Material Case - Polycarbonate

Harness - Nylon

Muff PVC/Nylon flame retardant - felt liner

Visor Neoprene

Immersion The camera will withstand driving spray and total

immersion in water.

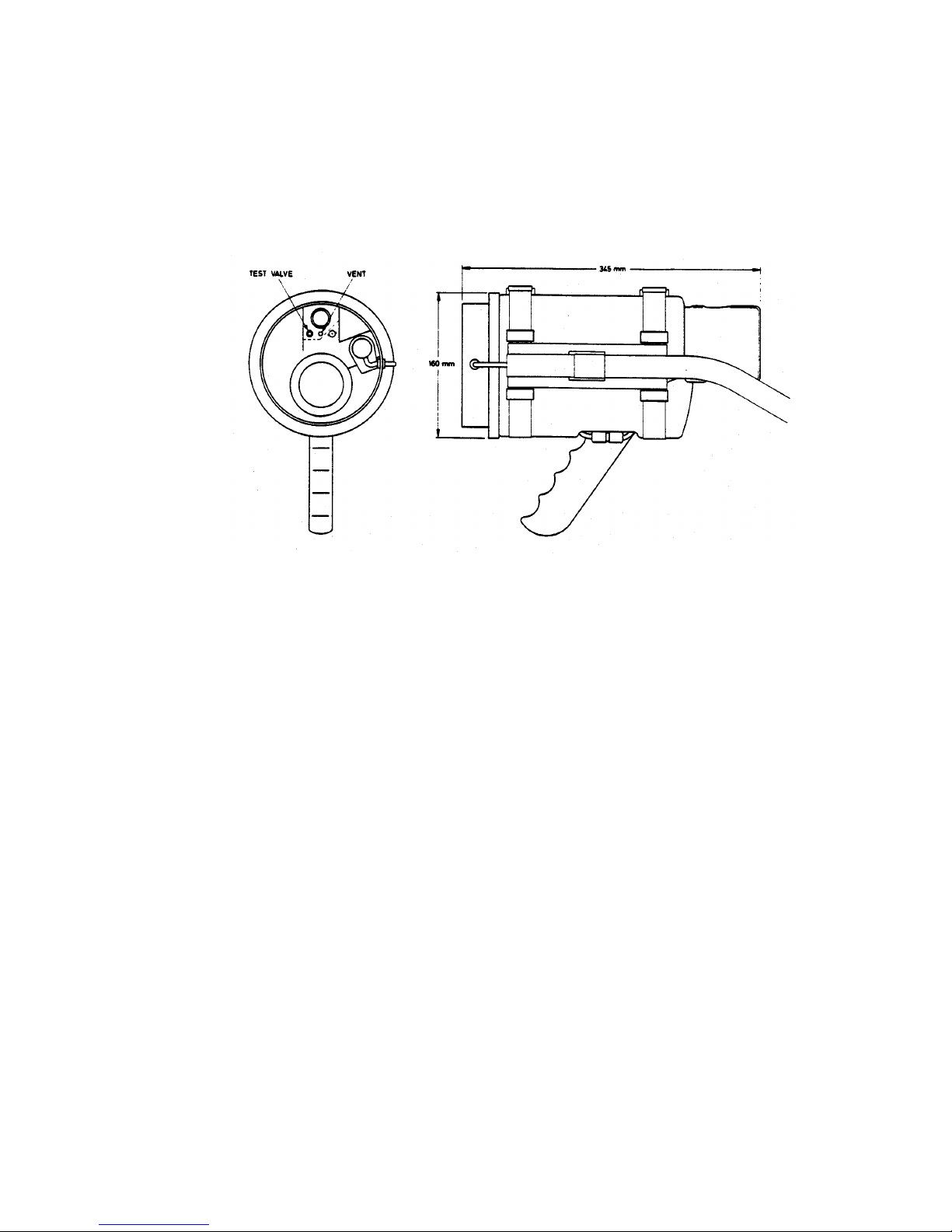

Case Sealing A test valve is provided so that sealing tests may

be executed using a vacuum pump.

A vent is also included which releases at an

internal excess pressure of 7 p.s.i.

Electrical

Power 3.7W Nominal

Voltage range 8.7V D.C. input

Battery life 10 size AA alkaline disposable cells - typically 2

hours.

10 size AA Nickel Cadmium rechargeable cells -

typically 1 hour.

(Note: rechargeable cells may need to be fully

cycled a few times to achieve maximum charge

capacity.)

Video The external video signal is nominally 1 Volt 625

lines 50Hz (CCIR compatible) or 525 lines 60 Hz

75Ω termination set at manufacture.

Specification

- 3 -

Temperature Resolution

200 lines per picture height for a temperature difference of 2EC (Chopped) -

1EC (Panned).

Lens

The lens has a hard anti -reflection coating and may be cleaned as necessary

with an appropriate soft cloth.

Focal length 18mm, f/0.8

Angle of View 57E

Spectral Response 8 to 14µm

P8092 pyroelectric vidicon PEVICON manufactured by Marconi Applied

Technologies Limited.

Electromagnetic Compatibility CE

The camera and VSU of cameras serial number above 6000 comply with the

requirements of EU directive 89/336 EEC.

Specification

- 4 -

2. Voltage Stabiliser

Mechanical

Weight 0.5Kg (less batteries)

Material Polycarbonate

Electrical

Input 9.5 to 15 volts

Output 8.7V @ 400mA D.C.

P4428K Voltage Stabiliser

Operating and Technical Descriptions

- 5 -

P4428 GENERAL DESCRIPTION

The P4428 hand -held thermal imaging camera uses the P8092 pyroelectric

vidicon, and provides a thermal television picture in the 8 to 14 micron

radiation band. It is enclosed in a sealed injection moulded polycarbonate

case and is intended for use in fire-fighting applications. The camera is a self

contained unit with a wide-angle germanium lens, giving a viewing angle of 57

degrees, with an integral viewfinder/monitor. The camera is fully automatic

with operation selection of 'Panned' or 'Chopped' mode of operation. Power is

provided by a reloadable battery cartridge which fits into the voltage stabiliser

unit attached to the camera harness. A video output socket is provided for

remote surveillance.

Where difference exist between the versions of camera those for the surface

mount board set (SMT) are given in square brackets [................].

1. ELECTRICAL SPECIFICATION

1.1. Power Requirements

The equipment requires a 9.3 to 15 volt supply at approximately 0.4

amps. A battery cartridge is provided which uses 10 standard 'AA' size

1.5 volt disposable alkaline cells.∗ The output from this pack is 15 volts

nominal and is regulated to 8.7V and current limited to 700mA by the

voltage stabiliser unit. At least 1.5 hours operation is possible on each

set of batteries. For use with external power supplies an adaptor is

available.

Alternatively 10 rechargeable AA cells (type NCC-50) may be used

with a reduced operating time of approximately 1 hour, depending on

cell capacity.

∗

See also Appendix 1.

1.2. Video Output

Composite video is supplied to an internal viewfinder/monitor. A BNC

video output socket is provided for an external monito r. This requires a

75Ω termination. Circular blanking is added to obscure edge effects of

the over-scanned target.

1.3. Performance

In the panned mode the temperature resolution at the centre of the field

of view is less than 0.5EC differential scene temperature at a spatial

resolution of 100 TV lines and better than 0.2EC at 20 TV lines,

assuming unity emissivity. (See also P8092 data sheet).

Operating and Technical Descriptions

- 6 -

2. MECHANICAL SPECIFICATION

2.1. Dimensions

Camera: 27cm x 17cm dia. (excluding pistol grip and visor)

Voltage Stabiliser Unit: 18cm x 6.5cm x ll.5cm

2.2. Weight

Camera: (including harness, muff, visor and pistol grip) 3.0kg

Voltage Stabiliser Unit: (less batteries) 0.5kg

2.3. The camera case comprises a two part polycarbonate moulding

retained by a breech type locking ring.

The voltage stabiliser unit is a polycarbonate moulding.

3. OPERATING MODES

The signal is proportional to the rate of change of the temperature of

the pyroelectric target and decays within 10 seconds of exposure. To

obtain a continuous signal from a stationary object a shutter is used to

obscure the target at field rate. Alternatively the image - or camera may be moved or panned.

3.1. Shutter

A rotating shutter is incorporated into the front of the camera. It is

synchronous in rate and phase with the camera scanning beam. The

images obtained are alternately inverted in polarity. They are

synchronously re-inverted and balanced in the video channel to give

continuous positive images. Shading correction circuits aid balance

between the signals and minimise flicker.

4. LINE FLYBACK GAS PEDESTAL

The ion pedestal within the tube is enhanced by increasing the beam

current during line flyback, i.e. by pulsing Gl positively. By this means a

larger signal is obtained from the tube. An automatic circuit detects and

regulates the ion pedestal.

5. OPERATING PROCEDURE

Plug the battery cartridge into the voltage stabiliser ensure the

connection between the stabiliser and camera is made, then switch on.

A satisfactory operating voltage is confirmed by observing that the

LEDs in the viewing window illuminate. A circular image will now be

obtained after a target discharge period and the camera chopped or

panned operating mode may be selected as required.

Operating and Technical Descriptions

- 7 -

6. COMPLETE SET UP FOR NEW TUBE

6.l. Replacing Tube

See Appendix 2.

6.2. Gl and Pedestal Control Adjustments

These controls are adjusted using the values of I G4 (BEAM) and I G4

(BEAM + PEDESTAL) pre-determined for each tube during factory test

to obtain a specific value of pedestal current. Using the jack lead and a

micro-ammeter, plug the jack into the Ig4 socket (Scan board). Turn

the pedestal amplitude control (Scan board RV110), fully clockwise

[anticlockwise SMT boards] for minimum Ig4; adjust the G1 control

(Scan board RV111), for recommended I G4 (BEAM) value and then

increase the reading to the recommended I G4 (BEAM + PEDESTAL)

value using the pedestal amplitude control.

Typical Values: I G4 (BEAM) = 4µA

I Gg4 (BEAM + PEDESTAL) = 11µA

Alternatively if relevant figures are not available for the tube, firstly

adjust IG4 current for 4µA as instructed in the previous paragraph.

Monitor the head amplifier output voltage on an oscilloscope and adjust

the pedestal control for a forward line scan pedestal of 175mV.

NB The I G4 (BEAM + PEDESTAL) value can be noted for future

reference.

6 3. Picture Acquisition

An image will normally be obtained with the camera controls

undisturbed from the previous tube. Set the camera to 'pan' mode.

Turn the circular blanking control slightly anticlockwise to display the

entire target image. Adjust the line and field shading pre-sets for

minimum shading either by inspecting the picture or preferably by

displaying the relevant field/line video waveforms on an oscilloscope.

Adjust for minimum shading using the parabola and tilt correction

waveforms. Switch to 'chop' and cover the lens. The black level control

may now be adjusted for a signal level of 1.5V on the oscilloscope.

This provides optimum range for the output level clamp. Shading may

sometimes be further improved by re-orientating the tube for minimum

symmetrical shading. If this is necessary the picture acquisition section

will have to be repeated.

Operating and Technical Descriptions

- 8 -

7. OPERATING FACILITIES AND ADJUSTMENTS

7.1. Electrode Supplies

Pre-set controls are located on the scan board.

i) G2 Fixed voltage 175 volts

ii) G3 Pre-set for 80 volts (RV109)

iii) G4 Fixed voltage 135 volts

iv) G1 Variable from 0 to -60 volts (RV111)

v) Target (CPS) Pre-set to 0 volts

7.2. 8.7 Volt Supply

This basic supply is pre-set in the voltage stabiliser unit (VR400 [VR1]).

7.3. Magnetic Focus

The control is located on the scan board (RV116).

NB The magnetic focus control should be used to adjust the tube

electrical focus in preference to varying G3.

7.4. Line Linearity

A saturable reactor is used to control the line linearity and width. It is

located on the scan board (L100). [SMT version requires turns to be

adjusted]

7.5. Scan Adjustments

The following controls are provided:

horizontal shift RV101; vertical amplitude RV112; vertical shift RV113.

7.6. Video Adjustments

Set the alignment controls (RV102, RV103 scan board) for even target

illumination and adjust the shading and black level controls (video

board) as covered in the picture acquisition section 6.3.

7.7. Circular Blanking

To increase the signal out of the tube it is usual to overscan the target.

This also prevents charging of the unscanned portion of the TGS

crystal. The edges of the resultant circular picture have bright

highlights. A circular blanking generator is provided whose output is

used to gate the video waveform. By adjusting the 'size' control the

unwanted video can be masked, (RV206, video board). The shape of

the circle is adjusted by a pre-set control on video board (RV207). The

shift controls may be used to centre the target image.

NB Correct circular blanking is essential for automatic video balance

and iris function.

Operating and Technical Descriptions

- 9 -

7.8. Flicker Suppressor

The flicker suppressor is a digital field store, used to eliminate flicker

between alternate fields in 'chop' mode. Adjustments are provided for

clock frequency (RV209), RAM input-output data phase (RV210) [not

required on SMT version], alternate-line interlace (RV212) and store

vertical position (RV211). No adjustment of these should be necessary

during setting-up. The balance control RV208 may be used to minimise

flicker in the 'chop' mode.

7.9. Output Video Level Clamp

Because the video signal is proportional to rate of change of

temperature and decays within a few seconds, unwanted changes in

black level can occur if the camera is moved after the signal from

objects in the field of view has decayed. In order to maintain a suitable

black level, an automatic circuit detects the coldest signal in the scene

and maintains its level 300mV above blanking level, in order that

details in cold objects can be seen.

8. CIRCUIT DESCRIPTION

8.1. The Synchronising Generator (Video Board)

The sync generator uses a RCA integrated circuit type CD22402,

which is locked to its own 500kHz crystal oscillator. Conversion from

625 lines 50Hz to 525 lines 60Hz is possible by opening the solder link

between pin 18 and 19 of the integrated circuit.

8.2. Video Head Amplifier

The head amplifier is located on the video board and is a high gain, low

noise amplifier with a nominal bandwidth of 5MHz (6dB). The cascade

input stage utilises a J309 FET which has a low input capacitance and

a high Yfs. The LM733 [NE592] amplifier compensates for the falling

input frequency response by incorporating a capacitor which bypasses

its feedback loop. The output is then passed to the main video

amplifier.

8.3. Video (ion Pedestal Stabilisation)

The video signal is clamped by Q210 [TR3] and then taken via P200/18

to the scan board where the unwanted positive pedestal portion of the

waveform is removed. The remaining negative pedestal is compared

with the reference voltage on RV110 (the pedestal drive control) and

the resultant output defines the voltage to which the G1 grid is switched

during the line flyback period. Hence the ion pedestal is maintained

against changes in the tube characteristics.

Operating and Technical Descriptions

- 10 -

8.4. Video Processing

Two stages of amplification are used with a combined gain of

approximately 25. The first stage utilises an LM733 [NE592] video

amplifier which has a gain of 5 and also acts as a phase splitter giving

outputs of both positive and negative phase. The video phases are

further amplified (x 5) and then recombined in a balanced video

selection, each phase being switched synchronously with a signal

derived from the shutter blade. Circular blanking is then added to the

video waveform before being passed to the flicker suppressor. Balance

between the two phases is achieved by comparing the signals in the

video averaging comparator, V204 [IC3], whose output acts on the

negative phase. A clamp pulse is produced from the line blanking

waveform using V106, delayed and timed by V202 [IC4], and used to

sample the video black level. The resulting signal is compared with the

required black level, set by RV204 (and RV200 in 'pan' [automatically

in SMT version]), in the comparator V204 and the feedback loop

completed by causing the comparator output to control the dc level in

the main amplifier V201. Shading correction signals are taken from the

circle generator and added to the black level circuit.

The video signal level varies between the pan and chopped modes of

operation. To correct this the shutter switch also modifies the channel

gain and black level by switching transistor Q204 [TR6] and resistors

R227, R228 and RV200 [R34, R35].

8.5. Circular Blanking Generator (Video Board)

The circle is produced using the principle of intersecting parabolas.

Line and field blanking waveforms are separately double integrated,

the first stage producing ramp waveforms and the second parabolas.

A crossing detector (V209) [IC12] then produces the circle which

operates on both positive (Q205)[TR8] and negative (Q206) [TR9]

video signals.

The shape of the circle is controlled by the field parabola amplitude,

RV207, and the size by applying a dc shift to the line parabola, RV206.

The ramp and parabolic waveforms are used for shading correction

and are added to the video signal via the black level circuit.

8.6. Flicker Suppressor (Video Board)

Flicker is removed by delaying one field of video information and

adding it to the next; thus the flicker, which inverts every field, is

cancelled and the signal, which is of the same polarity on all fields, is

doubled. In order to achieve the delay, the signal is digitised, written

into RAM, and read out on the following field. The data is then

converted to analogue form and added to the then present signal which

comes directly from the video input.

Meanwhile the present signal is digitised and written into the memory

location which has just been read to provide the delayed data. The

address then moves to the next location. A short delay (V211) is

needed in the direct path to balance propagation delays encountered in

reading the store.

Operating and Technical Descriptions

- 11 -

The store is arranged as 128 x 256 bytes of 6 bits each. This

corresponds to an array of 128 picture elements in each of 256 of the

288 lines in each field. This array is placed centrally on the screen by

delaying in both line and field directions. The field delay monostable

(1/2 V215)[IC14] is triggered by the trailing edge of field blanking,

generating a 'high' at its Q output which resets the line counter V218

[IC17]. The reset pulse disappears when Q returns to its low state after

a timing period of about 16 lines, and when the next line blanking edge

sets the line delay monostable (1/2 V215) [IC14], V218 [IC17] is

clocked and advances one count. The cycle repeats for 256 lines,

when the 9th bit of the line counter goes high, clearing the line delay

monostable and preventing further clock pulses. The line counter

remains in this State until the next field blanking edge, which resets the

line counter and enables the time delay monostable.

The pixel counter V216, V217 [IC15,16] is similar in operation. The

trailing edge of line blanking starts the line delay monostable whose Q

output clears the pixel counters. This clears the carry outputs and

enables the clock. Counting starts on the first clock pulse after the line

delay timer takes the clear inputs high, and progresses until the 127th

count, when the carry outputs of the pixel counter are both high. This

stops the clock via D218 and (1/4 V214) [D14 & IC13]and the counters

wait in this state until cleared by the next line blanking edge.

The 13 least significant addresses are used to address the RAMS

V221 -V224 [IC18]. The two most significant addresses are decoded in

(1/2 V219) to select one of the four RAMs at a time [simply addressed

SMT]. The other (1/2 V219) [IC 19 logic] is used as a divider to

generate alternate write and output enables from successive clock

cycles, after shaping by (1/4 V214) [IC13]. The write enable is also

used to enable the outputs of the A to D converter, (whose data

conversion is clocked from the master clock) so that data is available

for the RAM write cycle. On the previous clock cycle, the RAM outputs

are enabled to transfer data to the output latch V225 [IC20]where it is

held and converted to analogue form. This is then added to the direct

signal, which is delayed by 250ns to balance the RAM reading time

and propagation delays, in the summing amplifier V212 [TR20, TR21].

Storage effects on the circular blanking edge are removed by Q214

[TR16]and syncs are added by Q215 and Q216 [TR18, TR19]. Video

is distributed to the internal monitor and external video socket.

8.7. Output Video Level Clamp (Video Board)

This circuit detects the most negative level appearing in picture period

(Q217, gated by D212) [TR17, D8], compares this level in V213 [IC10]

with a fixed reference set by R307 and R308 [R68,70], and applies an

error signal to V212 [TR20, TR21] via R293 [R65], maintaining the

most negative video excursion at a level suitable for observation.

Operating and Technical Descriptions

- 12 -

8.8. Motor Control (Scan Board)

The shutter motor blade completes one revolution for one frame of

video. The dc motor is locked in phase with the scanning beam by

comparing field drive (divided by two) with a pulse from a light sensor

and creating a feedback loop using a phase locked loop circuit.

When the operating mode is switched from chopped to panned the

phase locked loop is immobilised and the circuit seeks the point at

which the shutter blade obscures part of the sensor such that the

sensor output when smoothed is held at half its peak value, producing

zero voltage across the motor, thus holding the shutter in the fully open

position.

8.9. Scans, HT and Auxiliary Supplies

Field Scan

A field ramp is generated by an operational integrator controlled by

field drive. This is converted to a current ramp by sensing the voltage

across a resistor (R151) in series with the field coil. Field shift is

obtained by providing a dc offset across the field coil, a virtual earth

being established at pin 9 of connector P103.

Line Scan

A 10µs pulse is produced from the line blanking waveform. This is us ed

to switch a standard television choke-coupled line output stage. Since

the charge produced by the pedestal pulse has to be dispersed

uniformly with respect to the scanning beam, the line flyback has to be

linearised. The half sine wave voltage is truncated by coupling, using a

secondary winding, to the supply via a diode. The current waveform is

hence a linear sawtooth during flyback.

The shift control varies the dc bias through the scan coil.

A saturable reactor is connected in series with the line coil to improve

linearity.

HT Supplies

All HT voltages are derived from an overwind on the line scan

transformer.

8.10. Power Control

The main 8.7V camera supply is stabilised remotely in the voltage

stabiliser unit by amplifier V400 [V1] operating on the series transistor

Q402 [V1, Q3]. A foldback current limit circuit senses excess currents

in R406 [R22] to protect against surge and fault conditions. The battery

voltage level indicator senses the voltage across the series regulator

and varying numbers of illuminated LEDs show the battery condition.

Excess voltage is prevented from reaching the camera under fault

conditions by the protection circuit Q407 [Q2]. Battery life is extended

by a circuit V401 [V2] which detects a minimum voltage, greater than

the saturation voltage, across Q403 [Q3] and maintains this voltage by

reducing the reference voltage appearing on V400 pin 2 [V1]. Thus the

supply rail is maintained in regulation as it collapses.

Operating and Technical Descriptions

- 13 -

8.11. Magnetic Focus

A current regulator, V105, Q113, is used to supply the focus current,

the value of which is set by control RV116.

8.12. Target Discharge

Under adverse overload conditions it is possible that the tube target

may become positively charged and the tube cease to function. To

alleviate this condition a discharge sequence operates every time the

equipment is switched on. G4, and hence G3 (via D120), is held at 9V

for 5 seconds and then charges to its normal operating value with a

time constant of 270ms.

8.13. G4 Monitoring

A jack socket (P108) is wired in series with the G4 supply so that the

electrode current may be monitored when setting up the tube.

8.14. Internal Monitor

A miniature CRT is used to provide a self-contained monitor viewed

through a magnifying lens. The monitor has its own field scan circuit

while the line scan and EHT transformer circuits share drive waveforms

with the tube. A moulded Cockcroft-Walton multiplier produces 4KV

from the EHT transformer output waveform.

A secondary winding of the EHT transformer also provides low voltage

supplies for monitor field scan, line shift, alignments and battery

indicator.

The video output of the equipment is displayed on the monitor by

modulation of the control grid G1. RV113 is the gain (contrast) control

and RV107 the dc level (brightness) control. The focus is set by

RV105.

8.15. Automatic Iris Control

The circuit is designed to close the lens iris when continual overloads

appear on the video signal.

Video peaks are sensed and compared with an average video level

taken from the alternate field balancing circuit. When the differential

signal exceeds a threshold, pre -set by RV118, the aperture is reduced

by the motor driven iris until the overload is removed.

For large overloads a rapid shutdown mechanism operates on a

second threshold via Q117 and Q118 and the iris shuts down to a fully

closed position. Limit switches operate at the extremes of the iris

movement position.

8.16. Desiccator

A desiccator with an integral indicator is fitted to the back plate lying

over the video board. This is normally blue and turns pink when

moisture is present.

Internal Assembly Details

- 14 -

Viewing Lens

Scan Board

Elapsed Time

Indicator

Iris Motor

P4428 Internal View (A)

Internal Assembly Details

- 15 -

Head Amp Video Board

Shutter Blade

Shutter

Sensor

P4428 Internal View (B)

Internal Assembly Details

- 16 -

Viewing Lens

Monitor

Shutter

Sensor Iris Motor

Shutter

Blade

P4428 Internal View (C)

Internal Assembly Details

- 17 -

Pevicon Tube Base

Tube

TubeClamp

Yoke Adjustment

Yoke Fixing

Screws

Yoke

Neoprene

Gasket

Video to

Scan Board

Connector

P4428 Internal View (D)

Internal Assembly Details

- 18 -

Shutter Blade

Retaining

Screws (4)

Iris Motor

Shutter

Motor

Shutter

Sensor

Germanium Lens Iris Limit Switches Iris Drive Belt

P4428 Internal View (E)

Batteries

- 19 -

10. BATTERIES

There are two battery cartridges for the P4428, the P4428B (white or

red label) which is intended for disposable primary cells and the

P4428R (black label) which is supplied with rechargeable cells.

10.1 Using Primary batteries

Only Alkaline Manganese chemistry AA cells will give the specification

operational time. The other common types, Zinc Chloride and Zinc

Carbon will last less than 10 minutes and may cause the camera to fail

to start on a 'new' set of batteries.

Changing the Batteries

1) Unscrew battery compartment cap on the end of the voltage

stabiliser unit.

2) Tilt the voltage stabiliser unit to allow the battery cartridge to

slide out.

3) Remove the screw from the top of the battery cartridge to

release the cover from th e battery carrier.

4) Remove the old batteries and replace with a fresh set. Change

all the batteries together and do not mix cell types in one

cartridge. It is essential that the batteries are put into the carrier

the correct way round, refer to the diagram for correct positions.

5) Replace the outer cover and tighten the retaining screw.

6) Insert the battery cartridge into the voltage stabiliser unit and

replace the cap.

LR6 is the IEC designation for AA size batteries using Alkaline

Manganese che mistry. Manufacturers designation for this battery type

vary, e.g. Duracell MN1500, Ever Ready Energizer, Varta 4006. It

should be noted that the statement "Equivalent to ........" on a battery

may only mean that it is the same size, not that it gives equivalent

performance.

Power checkers incorporated in some LR6 batteries are not accurate

gauges of expected battery life as they measure the off load cell

voltage. With poor cells they may show 75% or more whilst the

batteries are incapable of supplying the camera’s power requirements.

The open circuit voltage of the cartridge is between 14 and 16V

depending on charge state. It is fused at 1A.

Batteries

- 20 -

10.2 Using Rechargeable Batteries

The rechargeable battery cartridge P4428R contains 10 NiCd ‘AA’

cells of 600mAh capacity. The cartridge should be recharged using the

cartridge container type P4428CA and charger unit type P4428UA.

The charger is a 50mA constant current charge requiring 14 to 16

hours for a full charge of an empty set of cells. The open circuit

voltage of the cartridge is approximately 12V regardless of charge

state. It is fused at 1A.

The use of rechargeable cells will give inaccurate battery life indication,

as half scale to the camera end point will be only a few minutes. As

such it is not recommended for operational use.

10.3 Illustrations

Cover

Release

Screw

Polarity

Indicator

1A Fuse

Spring (-ve) Connection

Batteries

- 21 -

Batteries

- 22 -

10.4 Additional Instructions for Replacing the Battery Fuse

1) Follow instructions on changing the batteries up to and including

step 3.

2) Remove the two batteries covering the fuse slot identified by the

‘fuse’ label.

3) Using the battery cartridge wrench provided (attac hed to the cap

lanyard) unscrew the central contact on the bottom of the battery

pack.

4) Remove the contact and fuse support rod, be sure to retain the

black separating ring.

5) Remove the fuse through the slot in the centre of the battery.

6) Replace the fuse with a ceramic 20mm 1A fuse.

7) Replace the contact, separating ring and fuse support rod and

tighten.

8) Replace the two batteries removed at step 2.

9) Follow steps 5 and 6 as for changing batteries.

Batteries

- 23 -

Camera Disassembly

- 24 -

11. CAMERA DISASSEMBLY

Camera Case Removal

1) Remove the harness and the main part of the insulation muff.

2) Disconnect the voltage stabiliser unit by unplugging the in-line

connector situated by the pistol grip.

3) Hold the camera with the lens uppermost, depress the front

plate and rotate the breech ring clockwise to unlock the case.

4) Remove the camera from its rear case.

5) To replace, reverse the above procedure. Whenever possible a

new sealing ring should be fitted.

To Remove Front Plate, Lens Assembly and Tube

1) Remove case as above.

2) Remove internal R.F.Screen by desoldering front earth tag and

removing two screws on rear of chassis.

3) With camera standing on its front, remove the four front retaining

screws taking care not to damage the shutter blade.

4) Unplug P101 and carefully lift the camera chassis away from the

front.

5) Remove the chassis front plate and lens assembly complete by

removing the four retaining screws (see diagram page 18).

6) Loosen the tube clamp, remove the tube retaining ring on the

front of the yoke and carefully withdraw the tube from the yoke

whilst holding the tube base. Note the tube orientation for

replacement (see diagram page 17).

7) Replace using the reverse of the above procedure taking care to

install the sealing gasket between the lens and the case front.

The dessicant container should be replaced with a new or

reconditioned part.

Camera Disassembly

- 25 -

R.F. Screen Earth Tag

(Shown unsoldered) Breech Ring

Locating

Notch

Case Front

Locating Screws

Internal R.F.Screen

P4428 Case Removal Diagram

(Shown without muff and harness)

Modification Record

- 26 -

12 Modification Record

Mod 1 Video Processing to ESA 56493AA

Mod 2 Video Processing to ESA 56493BA (November 1984)

Mod 3 Video Processing to ESA 56493BA

Fitted with P4428/3 scan and P4428/3 video boards.

Electrically identical to Mod 2. (August 1985)

Mod 4 Modification to sample video for iris on

alternate fields only. (February 1987)

Scan Board to ESA 56492AA

C171 changed from 0.1F to 0.22F

R180 changed from 12k to 6k8

Video Processing to ESA 56493BA

Diode D218 (IN916) added as below.

Mod 5 Video Processing to ESA 56493CA

Scan Board to ESA 54692A (October 1987)

Mod 6 Video Processing to ESA 56493CA

Scan Board to ESA 54692AA

Fitted with P4428/5 Scan

Fitted with P4428/7 Video

P4428K Cable restraint modified to

ESA 350123AA issue 7 (August 1990)

Mod 7 Corrections to P4428/7 Video solder mask. (October 1990)

Modification Record

- 27 -

Mod 8 Monitor tube change from 40CB4M to 40JB4.

Resistor changes to suit new monitor: R111 – Wire Link

R112 – 15MΩ

R113 – 10MΩ

R144 – 5M6Ω

In some later cases the heater requires a resistor in parallel

(P104 pin 3 to pin 6) to obtain the correct split between

Pevicon and CRT. This should be added / adjusted for 5.8 to

6.0 V across the Pevicon heater. (December 1990)

Mod 9 Modifications for CE marking (EMC compliance). Cameras

are numbered from 6000 onwards.

New VSU PCB and mechanical design (applied to all

cameras)

VSU to camera cable changed.

Front Plate and Lens wiring changed.

Chassis changed (applied to all cameras)

Change to RF screen

Note that the spare parts for these cameras are different and

not compatible with previous MOD levels. Always quote the

serial number when ordering spares.

(January 1997 for EC customers)

Mod 10 New Scan PCB (DAS 547526 AA)

New Video PCB (DAS 547584 AA)

Boards redesigned due to component obsolescence issues

and now using surface mount parts. These are fully

compatible with the older board types and will be supplied as

spare parts.

Minor setup differences:

Battery indication no longer adjusted (setup 28)

Pan signal level automatically adjusted (setup 15)

No data phase adjustment (setup 20)

Some pot directions changed, see text.

Select on test resistor for CRT heaters now on PCB (R200)

(March 2000)

Mod 11 New boards as Mod 10 to EMC build standard. (June 2000)

Fault Check Procedures

- 28 -

SECTION 2 FAULT FINDING AND SETUP

1 PRIMARY FAULT CHECK PROCEDURE

The following checklists should aid fault finding on the P4428 camera

to enable simple faults to be remedied and if necessary complete

boards changed. After a board or tube change the camera must be

electrically set up following the procedures detailed on pages 34 and

35.

For working on the camera the following basic skills are assumed : -

1) The ability to use and interpret the results from an

oscilloscope.

2) Some familiarity with a correctly working P4428 camera.

3) Knowledge of basic camera operation and terminology.

The following facilities are assumed :-

1) A Video Monitor capable of reproducing 625 line 50Hz

pictures (525 line 60Hz for USA) with 75Ω video input.

2) A Dual Trace oscilloscope with X10 probes and a

multimeter (AVO or similar).

3) A 1A 12V dc current limited supply with a means of

measuring supply current.

The following checklists are designed so as to locate the possible area

in which the fault lies based upon the easily observed or measured

fault conditions. For more detailed examination of faults these

checklists refer to “flow diagrams” and waveforms located in the rear

fold section of this manual. Page numbers to which these refer will be

given in the lists.

When working through the checklists the following points should be

noted :-

1) Keep a note of each waveform checked and the reason, if any,

why if failed to correspond to the given waveform.

2) The checklists are designed to locate single faults, multiple

problems may require working through the checklists several

times.

3) A suitable thermal scene for testing purposes is an anglepoise

bench lamp, with a low voltage bulb (25-40W), pointed away

from the camera, so that the heated metal shade and arm of the

lamp provide a heat image against the general (cool)

background. Small point sources of heat should not be used

(soldering irons, naked flames etc) since if a fault in the iris

circuit exists permanent damage to the tube may result.

Fault Check Procedures

- 29 -

4) If the faults exhibited by the camera do not fit into those listed in

the checklists or if advice is required before major board change

work is undertaken, please contact the factory or agent, stating

the serial number and fault symptoms. Marconi Applied

Technologies will be pleased to advise and assist. Note the

factory should be consulted with respect to cameras still under

warranty before any work is undertaken.

Initial Conditions

1) Fit new batteries, switch on camera.

2) Select ‘chop’ mode of operation and point camera at a suitable

thermal scene.

Checklist 1

1) Is there a picture? Yes. Go to Checklist 2.

2) Is there any battery voltage indication? Yes. Go to Checklist 5.

Switch off camera. Remove battery cartridge and check fuse.

3) Is fuse blown? Yes. Go to checklist 4.

Check condition and orientation of batteries.

Replace complete battery cartridge with known working unit.

4) Is there any change to camera condition? Yes. Restart

checklist if any faults remain.

Switch off camera.

Replace complete voltage stabiliser unit if possible, if not

available go the checklist 6.

Checklist 2

1) Is there any battery voltage indication? Yes. Go to checklist 3.

Remove camera from case and connect to external power

supply. (See case removal and external supply connection

page 32).

2) Start battery indicator checklist. See page 48 rear fold.

Fault Check Procedures

- 30 -

Checklist 3

Remove camera from case, connect to external PSU (refer to page 32).

At this point there should be a picture with circular blanking on the internal

monitor. If not start checklist 5.

Use the following instruction sets to determine the type of picture :-

1) The picture is :a) Almost white but still responds to some images.

i) Switch to Pan mode.

Is there any change? Yes. Start alternate field

balance checklist page 54 rear fold.

Start iris control checklist page 48 rear fold.

Replace lens assembly if mechanical failure of

lens.

b) Out of focus.

Plug in external monitor (refer to page 32).

i) Is the picture in focus on the external monitor?

Yes. Start monitor checklist page 49 rear fold.

Start focus regulator list page 46 rear fold.

c) Bars or lines moving or stationary across picture.

Start motor checklist page 47 rear fold.

Start video checklist page 51 rear fold.

d) Intermittent.

Check image on external monitor, is it stable?

Yes. Start monitor checklist page 49 rear fold.

Start video checklist page 51 rear fold.

e) Unstable.

Start head amplifier checklist page 56 rear fold.

f) Flickering.

Start flicker suppressor checklist page 53 rear fold.

Start motor checklist page 47 rear fold.

Fault Check Procedures

- 31 -

Checklist 4

Unplug voltage stabiliser from camera, connect external supply (refer page

32). Check current consumption. If greater than 0.1A start voltage stabiliser

checklist page 59 rear fold. Plug voltage stabiliser into camera.

Check current consumption of camera. If greater than 0.5A refer to Factory.

Checklist 5

Plug in external monitor.

1) Is there a picture on the external monitor?

Yes. Start monitor video checklist page 50 rear fold.

2) Is there a raster on the internal monitor?

Yes. Start Checklist 7.

Remove case and connect external supply (refer page and page

Start and work through all scan checklists page 41 to page 46

rear fold, than all video checklists page 51 to page 58 rear fold

then tube base checklist page 60 rear fold.

Checklist 6

With external supply connected start voltage stabiliser checklist page 59 rear

fold.

Checklist 7

Remove case and connect external supply.

Is there a blanking circle on internal monitor?

Yes. Start video checklist page 51 rear fold.

Start circular blanking checklist page 55 rear fold.

Start black level checklist page 58 rear fold.

Fault Check Procedures

- 32 -

Removing Camera Case (See also Diagram Page 25)

1) Remove the harness and the main part of the insulation muff.

2) Disconnect the voltage stabiliser unit by unplugging the in-line

connector situated by the pistol grip.

3) Hold the camera with the lens uppermost, depress the front

plate and rotate the breech ring clockwise to unlock the case.

4) Remove the camera from its rear case.

5) To replace, reverse the above procedure, whenever possible a

new sealing ring should be fitted.

Connecting External Power Supply

1) Switch off the camera.

2) Remove battery cartridge from the voltage stabiliser unit.

3) Plug in battery substitution unit P4428D.

4) Connect the red lead to +12V and the black lead to 0V of a

current limited 1A d.c. supply.

Connecting External Monitor

1) Using a suitable lead with BNC connectors plug the monitor into

the video socket located on the front plate of the camera.

2) Ensure the monitor is terminated in 75 ohms.

Electrical Setup

- 33 -

14. P4428 CAMERA ELECTRICAL SETUP PROCEDURE

Items in square brackets are the differences for the new SMT boards

1. Before switching on turn G1 pot RV111 anti-clockwise

[clockwise] and pedestal pot RV110 clockwise [anticlockwise].

Select pan mode. Turn flicker suppressor off by setting RV212

fully anticlockwise.

2. Switch camera on and note current consumption, if greater than

500mA after the target discharge period suspect a fault.

3. Set line flyback to 10µs, measure on Q100 tag [TP103] adjust

RV100.

4. Set trailing edge of blanking to lead flyback by 3½µs, measure

on Q211 gate [TP111] adjust RV117.

5. Check G2 ≈ 170V (Measure on D103)

Check G4 ≈ 130V (Measure on socket P108)

Check G3 ≈ 80V (TP105) Adjust using RV109

Check heater voltage on P 104 pins 3 to 6 [ or across 8.7V and

R200] and change R200 if required to achieve 5.9 -6.0V across

the Pevicon heater.

6. Open circular blanking (RV206).

7. Set beam current to 4µA using RV111 (G1). Measure using a

3.5mm jack socket on the scan board and 50µA meter.

8. Set pedestal by setti ng head amp output to 175mV measured at

R219/R220 [TP6] on the video board adjust RV110 on Scan

board.

9. Centralise circular image with alignments and horizontal shift

controls RV102, RV103 and RV101. Set vertical amplitude of

image with RV112 and horizontal amplitude with L100

[Horizontal adjustment requires change to number of turns on

coil] to obtain a circular target of 38 to 42µs width.

10. Focus G2 aperture spot in centre of picture using RV116.

11. Recheck the setting of G3 and items 7 to 10 above as these are

interactive.

Electrical Setup

- 34 -

12. Reduce circular blanking sizeRV206 and adjust circle shape

RV207 (monitor raster set to 3:4 ratio). The circle should be

34.7µs wide and 15.8ms or 13.4ms high (625/525 TV systems

respectively)

13. Check video at L201 [TP5] and adjust the shading controls to

achieve as flat a signal as possible, in both line and field rates

(RV202, RV205 field and RV203,RV201 line).

14. Switch to chop mode and set video signal to 1.3V measuring at

L201 [TP5] on the video board adjusting RV204.

15. Switch to Pan mode and set video signal to 1.3V measuring at

L201 [TP5] on the video board adjusting RV200. [No longer

required].

16. Turn on flicker suppressor with RV212.

17. Set period of clock pulse to 43µs measured on pin 11 of V214

[pin 3 of IC13] adjusting RV209.

18. Adjust RV212 to minimise vertical patterning.

19. Open circle (RV206) until top and bottom of stored area is

visible. Centralise stored area (RV211). In the case of a 525

line camera only the top stored area will be visible, so RV211

maybe set fully clockwise. Reset circle.

20. Switch camera to chop mode and adjust RV210 to the centre of

the range where there is no picture noise. [Switch camera to

chop, no adjustment required]

21. Adjust RV208 to give minimum flicker.

22. Switch to pan mode. Check "park" position of shutter blade.

Switch to chop, check output of sensor is approximately 3V

measured at R173 [or TP113].

23. Check sensor output is locked to field rate and swings below 2V

and above 6V measured at R173 [or TP113]. Select R170 for

an error pulse of 0 to 2ms on V108.5 [TP112].

24. Switch to pan. Check operation of iris and adjust sensitivity

using RV118.

25. Adjust internal monitor scans and shifts (RV119, L101 RV108

and RV104), for a circular and central image.

Electrical Setup

- 35 -

26. Adjust brightness and contrast of internal monitor (RV107 and

RV106).

27. Check and adjust optical focus by moving yoke assembly.

Check yoke rotation.

28. Check LED battery indicators. Adjust RV115 for offset and R114

for range [no adjustment]. Rail drop out point should be below

9.2V.

29. Check overall quality of picture and mechanical assembly.

Loading...

Loading...