Marco Friia User Manual

Instruction Manual

Machine P/N: 1000864# & 1000865#

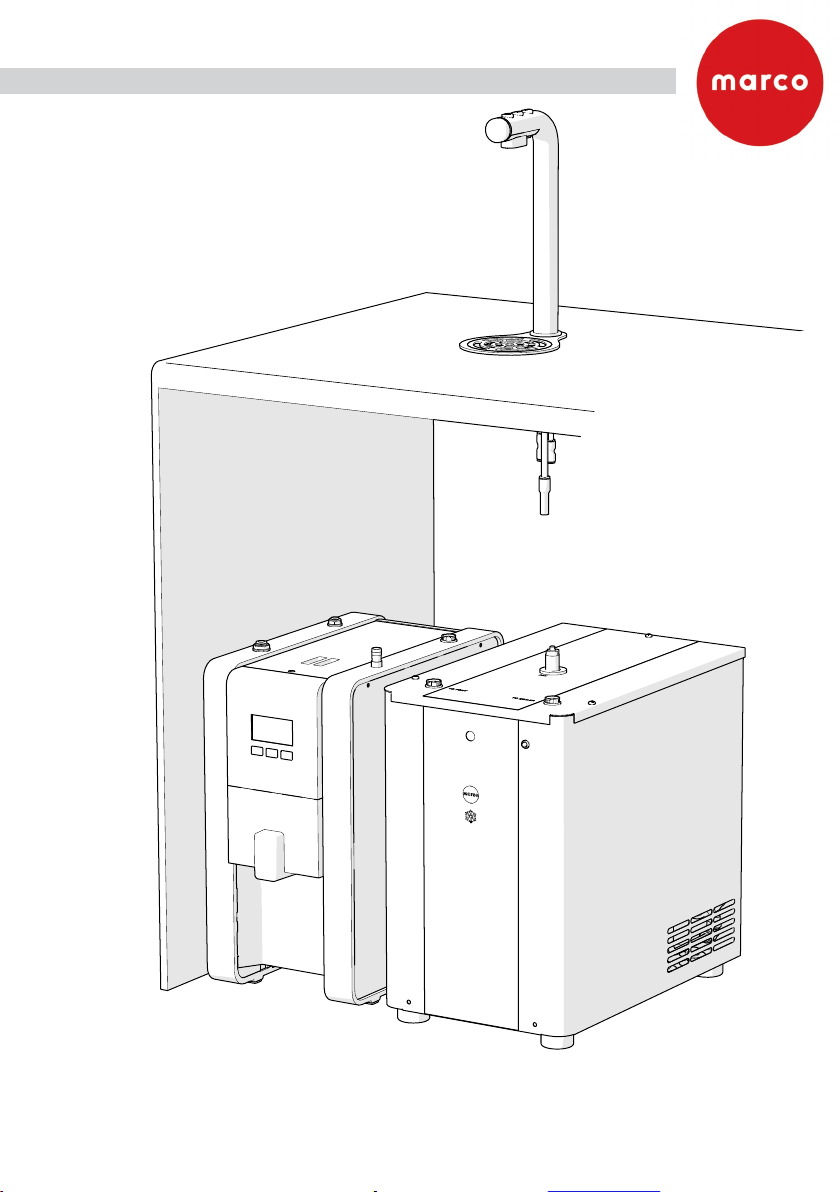

FRIIA

1

Contents

Introduction.................................................................................................................................3

1. Specication............................................................................................................................4

Installation requirements.............................................................................................4

2. Safety......................................................................................................................................4

4. Basic Installation.....................................................................................................................7

Chiller Installation........................................................................................................7

CO2 Installation...........................................................................................................8

3. Operation................................................................................................................................9

5. Sanitzation and Cleaning.......................................................................................................11

6. Troubleshooting.....................................................................................................................12

7. FRIIA Installation Guide.........................................................................................................13

Box Contents

FRIIA Cold/Carbonated Part no.

Chiller

Chiller to Boiler Cable

1m length 3/8” Tube

(water)

1m length 6mm Tube

(CO2)

User Manual

It is highly recommended to t a water regulator to the supply feed. In the event of

mechanical failure a regulator set correctly will ensure the water supply is cut. Marco

suggests 10 litres continuous ow.

Machine BTU per hour (btu/h)

Chiller 682.43

Chiller/Carb 1023.64

Boiler 9554

1000861

1501180

1800627

1800628

n/a

FRIIA Cold Part no.

Chiller

Chiller to Boiler

Cable

1m length 3/8”

Tube (water)

User Manual

2

1000860

1501180

1800627

n/a

Introduction

The information provided in this manual is intended to assist in the installation and maintenance of the Marco FRIIA System. Please

read the instructions carefully to prevent accidents and ensure an efcient installation. This manual is not a substitute for any safety

instructions or technical data afxed to the machine or its packaging. All information in this manual is current at the time of publication

and is subject to change without notice. Only technicians or service providers authorised by Marco should carry out installation and

maintenance of these machines. Marco accepts no responsibility for any damage or injury caused by incorrect or unreasonable

installation and operation. Do not allow anyone to operate the equipment unless suitably trained. Keep the equipment in good

working order and do not allow any modications unless authorised by the manufacturer.

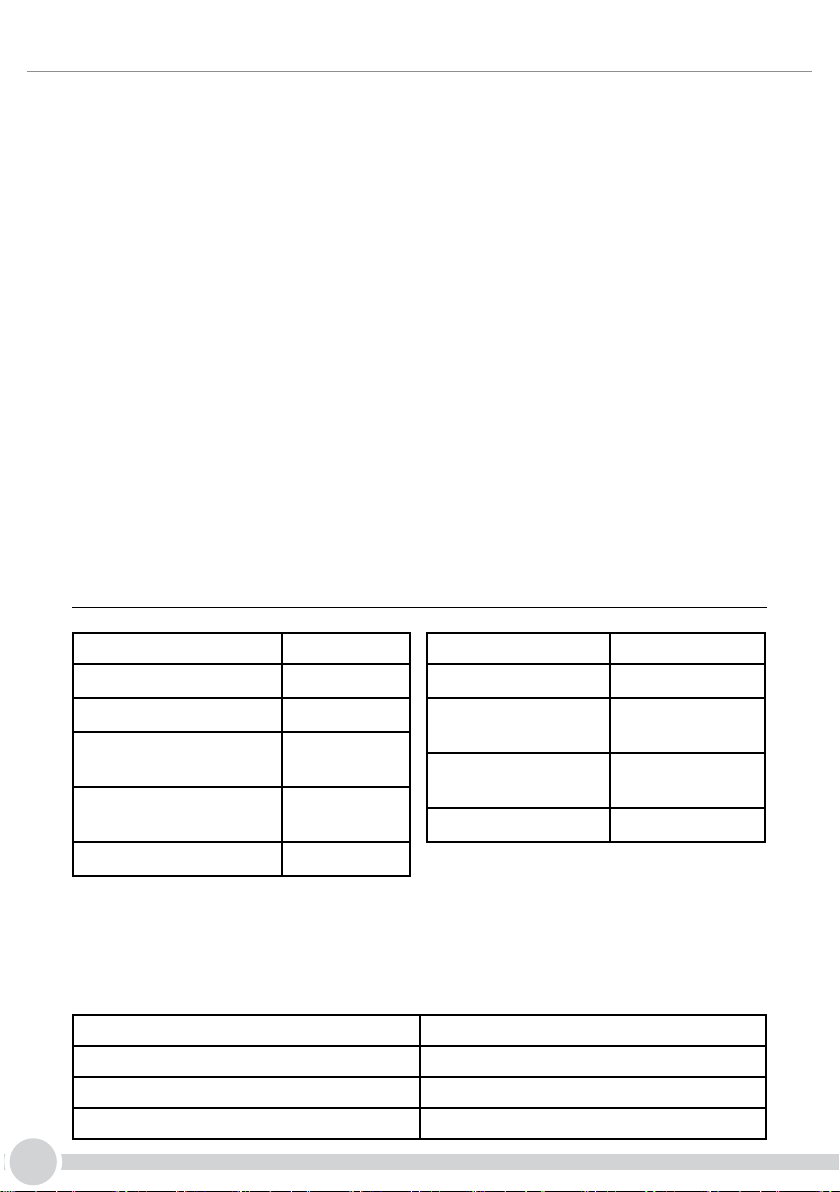

RATING PLATE

A

B

C

D

E

FRIIA Chiller

230 V.a.c.

2 amps

120W

50Hz

100-900 kPa

1000860

A. Model Number and name.

B. Product serial code (mmyyxxxxxx)

C. Rated Voltage.

D. Rated Power.

E. Contact details.

F. WEEE Logo

F

This logo indicates that the product must not be disposed

of as household waste. To help prevent possible harm to

human health and/or the environment, the product must

be disposed of in an approved and environmentally safe

recycling process. For further information on how to dis-

G

pose of this product correctly, contact product supplier,

or the local authority responsible for waste disposal in

your area.

G. Regulatory standard logo

This equipment has been designed and tested to comply

with all applicable regulatory standards set by

international, independent and government authorities.

• This document shall be applied to equipment intended for the EC market only.

3

1. Chiller Specification

Safe operating temperature: N from +16 ° C to +32 ° C (standard class)

Cooling system: Aluminium black heat exchanger.

Colling capacity: 35-40 litres/hour.

Electrical requirements: Two 13 amp sockets operating on 230V single phase.

Voltage and frequency ratings: 230V / 50Hz.

Max power consumption (chiller): 200W.

Compressor nominal power: 1/8 HP.

Refrigerant type and quantity: R290 / 45 gr.

Carbonator volume (just for SW versions): 1ltr.

Net Weight: 35kg.

1.1 Installation Requirements (See also Basic Installation p7, Installation Guide p13)

Mains water pressure required

downstream of any lter systems:

If mains pressure is below 1 bar or the

ow rate is less than 2L/min:

Water connection: 3/8” Quick connection tting.

Electrical requirements: Two 13 amp sockets operating on 230V single phase.

Machine location: The machine must be located in a well ventilated space, at least 10cm (3.9inch)

22 - 140psi (150 - 1000kPa) (1.5 - 10 bar)

t a device capable of increasing the mains pressure (autoclave or similar). ensure

your water net is able to supply at least 2L/min water owrate.

around back and top for ventilation.

2. Safety

2.1 IMPROPER USE

This equipment is deisgned solely for the use and conditions as outlined in this manual. The use of this equipment for any other

purpose is not permitted in any circumstance.

This unit can be used by adults without any experience and knowledge under supervision or after instruction on the safe use of the

equipment and have understood the risks. Children should not operate the equipment. Installation cleaning and user maintenance

must not be carried out by children.

This equipment is not intended to be used by people (including children) with reduced physical or sensory capacities or with a lack of

experience and knowledge, unless under supervisionor instructed by someone responsible for their safety.

For safety reasons, and in accordance with the current legislation, any repair operations on the equipment must be carried out by

the Service Centre.

• Do not alter or tamper with the internal dispenser components; if they are not operating properly contact the Service Centre.

• Do not place anything on top of the Boiler or Chiller

• Do not run any other liquid besides water through the system.

• If you believe the system to be damaged, contact Marco Beverage systems.

2.3 SYMBOLS USED IN THE MANUAL

This manual uses the following safety symbols to draw the operator’s attention to all operations which must be strictly observed in

order to prevent injury to persons or damage to the equipment.

DANGER

Shows the existence, on or around the equipment, of a real risk of death or severe injury for the

operator and other persons; it is therefore essential to take the greatest care and proceed with the

greatest caution.

4

WARNING

Shows the existence, on or around the equipment, of a potential risk of death or severe injury for the

operator or other persons; it is therefore essential to take great care and proceed with the greatest

caution.

CAUTION

Shows the existence, on or around the equipment, of a potential risk of minor injury for the operator

or other persons; it is therefore essential to take great care and proceed with the greatest caution.

2.4 LIST OF HAZARDS

The following list of hazards draws attention to safety aspects which must be considered at all times by anyone using the equipment.

DANGER

CO2 (CARBON DIOXIDE)

CO2 cylinders must always be stored in a well-ventilated place where the air can ow in and out. Great

care must be taken to prevent CO2 leaks throughout the system, including the gas cylinders.

If a CO2 leak is suspected, especially in a small area, ventilate the contaminated area at once, persons

exposed to high concentrations of CO2 will experience trembling, swiftly followed by unconsciousness

and suffocation.

DANGER

ELECTRICAL MAINS

Always disconnect the equipment from the electricity supply before carrying out any work, to prevent

DANGER

GAS CYLINDER LOCATION

To prevent the risk of injury or damage, the CO2 cylinder must always be kept in a vertical position

against a wall, held in place by a chain xed to a bracket. Do not expose the bottle to heat sources or

very low temperatures.

Only super-dry food grade CO2 should be used.

Before connecting the pressure reducer to the gas cylinder, always vent any dirt from the valve, and

close the cylinder valve after few seconds

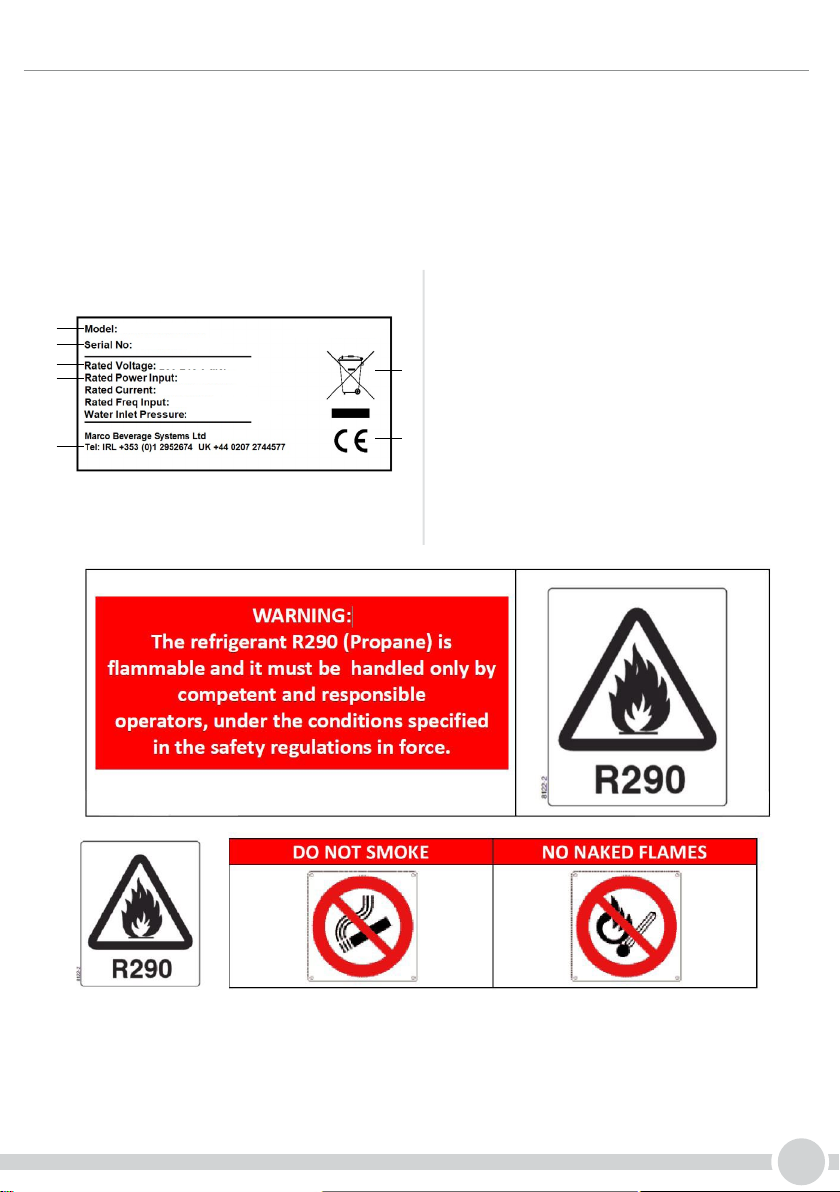

DANGER

Keep the ventilation openings on the equipment and on the cabinet in which the system is installed

free from obstruction.

DANGER

AUTHORIZED TECHNICAL STAFF

The refrigerant R290 (Propane) is ammable and it must be handled only by competent and responsible

operators, under the conditions specied in the safety regulations in force.

CAUTION

ELECTRICAL REQUIREMENTS

The electrical circuit must be correctly earthed and connected by means of a suitable differential safety

breaker.

CAUTION

REPLACEMENT OF THE POWER CABLE

If the power cable is damaged, it must be replaced by the manufacturer or their assistance service or a

similarly qualied person in order to prevent any possible risk.

CAUTION

LOW TEMPERATURE

If the equipment is exposed to temperatures lower than O°C, the water inside could turn to ice and

damage the equipment.

CAUTION

SANITISATION

Before sanitising the equipment, carefully read the instructions given by the sanitisation product

manufacturer and put on all the necessary personal protective equipment (gloves, masks, etc.).

Ensure that the premises are well ventilated.

The sanitisation operations should only be carried out by specialised technical assistance personnel.

5

DANGER

ELECTRICAL MAINS

Always disconnect the equipment from the electricity supply before doing any work on it, to prevent

damage and health hazards.

CAUTION

ELECTRICAL REQUIREMENTS

The electrical circuit must be correctly earthed and connected by means of a suitable differential

safety breaker.

CAUTION

ELECTRIC POWER SUPPLY

Do not connect or disconnect the machine from the socket with wet hands.

Insert the plug into the wall socket rmly.

Do not pull on the supply cable in order to remove the plug from the socket.

CAUTION

REPLACEMENT OF THE POWER CABLE

If the power cable is damaged, it must be replaced by the manufacturer or their assistance

service or a similarly qualied person in order to prevent any possible risk.

WARNING

MALFUNCTION

If smoke, unusual smells or strange noises are emitted from the machine, disconnect it

immediately from the socket and contact the local retailer or technical service assistance.

Use of the machine in these conditions could cause res or electric shocks.

ATTENTION

If the equipment is installed in a kitchen, European Standard EN 60335-2/75 species that it

must be connected to an equipotential circuit via a wire with section between 2,5 and 10 mm2.

This connection must be carried-out by a skilled technician, in compliance with the regulation

in force in the country of use.

WARNING

WATER SUPPLY

Connect the water dispenser exclusively to a line of drinkable water supply.

WARNING

WATER SUPPLY

In order to avoid accidental ooding due to losses that may occur on the water supply line,

external or internal device it is necessary to install the appropriate anti-ooding valve “WATER

BLOCK” (not included in the unit) .

DANGER

CO2 (CARBON DIOXIDE)

CO2 cylinders must always be stored in a well-ventilated place where the air can ow in and out. Great

care must be taken to prevent CO2 leaks throughout the system, including the gas cylinders.

If a CO2 leak is suspected, especially in a small area, ventilate the contaminated area at once, persons

exposed to high concentrations of CO2 will experience trembling, swiftly followed by unconsciousness

and suffocation.

DANGER

Do not use or store cylinders of CO2 at temperatures above 35°C.

Do not use or store cylinders of CO2 inside the appliance.

DANGER

PRESSURE REDUCER

Never connect CO2 cylinder directly to the equipment. Always use a suitable pressure reducer.

DANGER

GAS CYLINDER LOCATION

To prevent the risk of injury or damage, the CO2 cylinder must always be kept in a vertical position

against a wall, held in place by a chain xed to a bracket. Do not expose the bottle to heat sources or

very low temperatures.

Only super-dry food grade CO2 should be used.

Before connecting the pressure reducer to the gas cylinder, always vent any dirt from the valve, and

close the cylinder valve after few seconds.

6

DANGER

ELECTRICAL MAINS

Always isolate chiller from power supply before doing any work on it, to prevent damage and health

hazards.

CAUTION

Before carrying out the following operations, carefully read the instructions given by the sanitization product manufacturer and make sure all personal protective equipment (gloves, masks, etc.) is worn correctly.

The sanitization of the product lines must only be carried out by specialized technical service personnel.

During the sanitization operations, attach a warning sign to the tower concerned, to inform any other

personnel that this operation is in progress, and that it is forbidden to dispense beverages.

DANGER

ELECTRICAL MAINS

Always isolate chiller from power supply before doing any work on it, to prevent damage and health

hazards.

ATTENTION

Do not spray water on the device; this could cause electric shocks or res.

3. Basic Installation (See also Installation Guide p13)

3.1 UNPACKING INSTRUCTIONS

•The chiller must be handled only in a vertical position. Transporting the appliance in a horizontal position can cause severe damage

to the refrigerator.

•Remove the exterior and interior packing. Packing materials (especially any plastic bags) should be stored out of the reach

of children, as a potential source of danger. When disposing packaging parts, please follow current regulations on the matter,

separating carton from plastic parts.

•Always check that the equipment that is delivered corresponds to the model indicated in the accompanying document.

•The equipment is shipped in a cardboard box. Once the packaging has been removed, check the equipment has not been damaged

in transit; if damage is found, notify the carrier.

3.2 ELECTRICAL INSTALLATION PROCEDURE

When installing the machine, always observe the local regulations and standards. The appliance is supplied with a moulded power

cord. A suitable mains power supply socket should be available within easy access of the appliance so that it can be disconnected

easily after install.

3.3 PLUMBING INSTALLATION PROCEDURE

• Ensure that the equipment is installed according to local plumbing & water regulations.

• Fit a stop valve on a cold water line and attach a 3/8” BSP male tting, (E.g. 3/4” x 1/2” 311 or washing machine type stop valve).

• Connect water supply lines following the installation drawings. As per installation guide (starting page 14)

• In case lter systems are used verify that they satisfy the requirements of the legislation in force.

• If the lter is new, turn on water and ush at least 10 liters (2.5 gallon) through the lter before to connect it to the cooler; if the

lter is a used one, connect water inlet to the chiller.

• To ensure that the maximum value of pressure of 3 Bar is not exceeded the chiller integrates a pressure reducer.

• Turn on the water to ush any impurities, dust etc from the inlet hose and water pipe. Allow several litres through. Especially for

new installations.

7

Loading...

Loading...