Marchand Electronics XM9L-KK, XM9L-3KK, XM16L-3KK, XM16L-KK, XM9L-3WAY Assembly Manual

Marchand Electronics Inc.

XM9L-KK, XM9L-3KK, XM16L-KK, XM16L-3KK, XM9L-3WAY

High Performance Electronic Crossover.

Assembly of DeLuxe Cabinet

The high performance crossover kits have a cabinet, front

panel controls, rear panel connectors and power cord.

The kits also include a PS10-K power supply. The 2 way

units also have two crossover boards. The 3 way units

have 4 crossover boards.

The assembly of the four different models is very similar.

The differences between the four models will be

indicated in the text where appropriate.

Install the fuse holder in the panel. The white washer is

installed on the outward side. Gently tighten the nut. Too

much force will crack the housing.

Install the line cord using the strain relief. Place the strain

relief 9" from the end of the line cord and squeeze tightly

with pliers. Insert the cord and strain relief into the hole in

the rear panel until it snaps in.

The assembly of the rear panel is now complete. Put it

aside until later.

Assembly of Rear Panel

The rear panel holds the RCA connectors and the power

cord and the fuse holder.

Install the 6 ( 8 for 3-way) RCA connectors in the holes

input, high pass, low pass. The 3-way unit also has two

connectors in the holes marked mid. The left channel has

the connectors with the BLACK insulators. The right

channel gets the RED insulators. Each connector has two

insulators, one with a shoulder and the other is flat. Make

sure the shoulder is inserted in the hole of the panel.

Install the flat insulator on the other side of the panel.

Install the solder lug and the nut. Tighten the nut well.

Attach wires to the RCA connectors. Prepare 4 (6 for 3way) pairs of wire by taking a 10" length of red and brown

wire and twisting together. Slip a 3/4" length of heat shrink

tubing over the end of each wire at one side of the pair.

Strip 1/4" of insulation off each wire. Solder the brown wire

onto the solder lug of the connector. Solder the red wire

into the center pin of the connector. Slip the heat shrink

tubing over the solder joints. Shrink the tubing with a heat

gun. If no heat gun is available use the heat of a soldering

iron.

Repeat this for all RCA connectors.

The two way units come with detachable line cord and a

power voltage selector switch. The 3-way units have an

attached line cord.

Please use the appropriate instructions below.

Attached line cord

Removable line cord

Install the voltage selector switch using the 6/32 hardware.

Install the power entry module using the 6/32 hardware.

Install the fuse holder. The assembly of the rear panel is

now complete. Put it aside until later.

Assembly of Shell

First assemble the PS10-K power supply and the XM9 or

XM16 crossover boards according to the instructions

provided. Note: (1) Do NOT install the board mounted

RCA connectors that are normally provided with the

crossover kits. They are not used in the high performance

crossover. (2) Replace the LF353 op amps with the better

op amps. On the XM9 boards the OPA2134 is inserted in

positions IC1, IC2, IC3 and IC4. On the XM16 the

OPA2134 is inserted in positions IC1, IC2, IC3, IC4, IC5

and IC6. Please make sure that the IC's are installed

correctly.

Place the shell on a flat surface with the bottom down.

Notice the pattern of four holes near one side of the

bottom of the shell. Place the shell so that this pattern is

on the left hand side. The front of the cabinet is now

towards you.

Install the PS10 power supply with 4 standoffs in the 4

holes on the left of the cabinet, as described above. The

two position terminal block of the PS10 faces towards the

rear of the cabinet.

The crossover boards will now be installed temporarily.

Notice the 4 rectangular patterns of 10 holes in bottom of

the shell Each pattern hold a crossover board. The

© 2000 Marchand Electronics Inc. PO Box 473, Webster, NY, 14580 www.marchandelec.com (716) 872 0980 FAX: (716) 872 1960

1

crossover boards are placed with P6 and P7 facing the

rear of the cabinet. Use 4 standoffs to install each board.

Use the second hole from the rear of the shell for the

standoffs. The XM9 then also uses the fourth hole and the

XM16 uses the fifth hole from the rear. For the 2-way units

mount the two crossovers in the two center positions in

the shell.

Figure 1 Power entry with voltage selector switch.

5 black buttonhead screws or flathead screws.

Figure 3: Sum-mode switch cable

Putting it all together

Prepare 2 (4 for 3-way unit) cables as shown in Figure 4.

The two way unit uses one cable 8" long and another 11"

long. The 3-way unit has two additional cables 6" long and

15" long.

Insert all the orange wires from each of the power cables

into the terminal block on the PS10 marked +.

Cut a piece of red wire 3" long and strip 1/4" of insulation

from each end.

Gather the red wires from the power cables and one end

of the 3" red wire and insert them into the terminal block

on the PS10 marked GND.

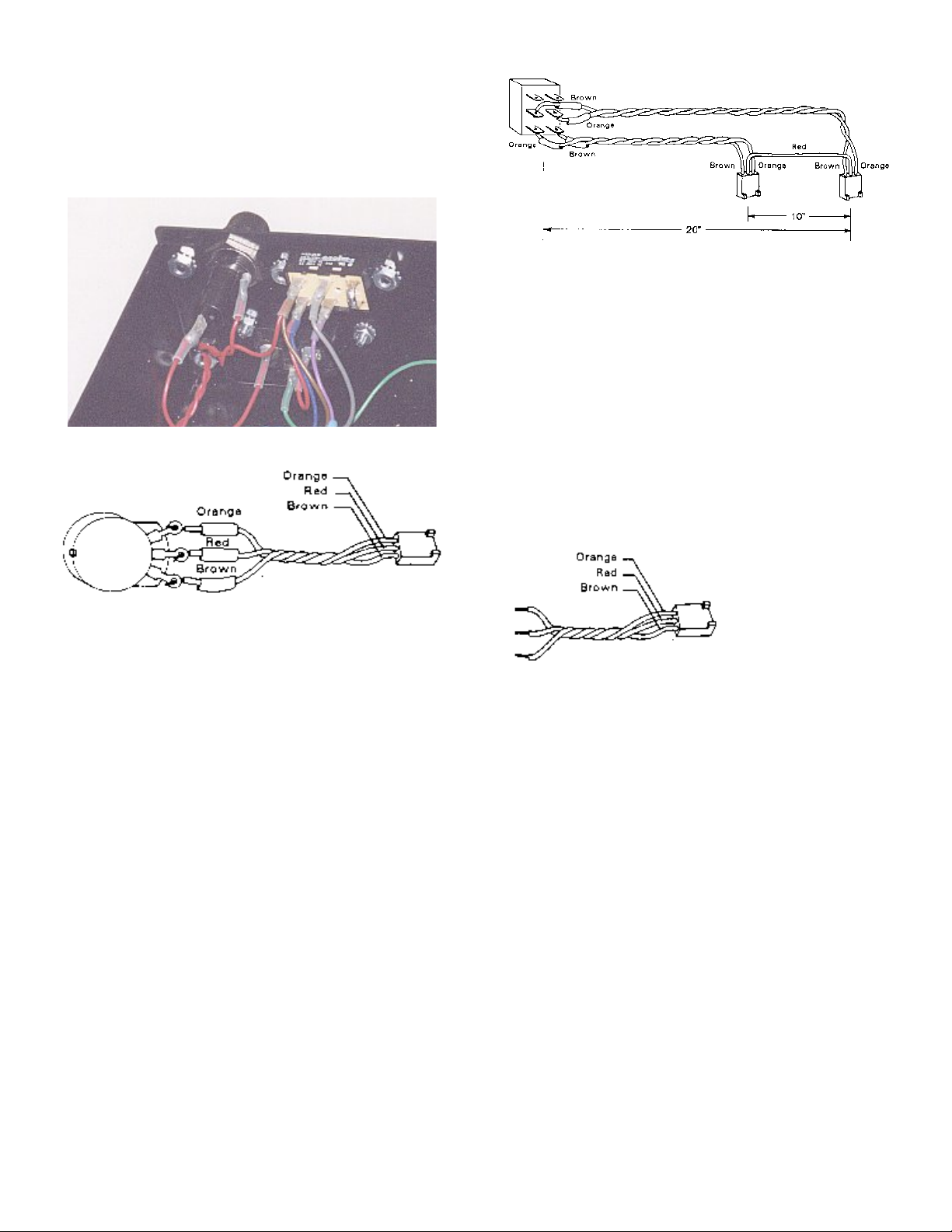

Figure 2: Potentiometer Cable

Assembly of Front Panel

Install the 6 (4) 10K potentiometers in the positions

labeled level and damping. Tighten the nuts well. One

DPDT switch mounts in the position marked power and

the other DPDT switch mounts in the position marked

sum. There is a hole left for the indicator LED. Do not

install this LED yet at this time.

Install wires to potentiometers. Prepare 3 8" lengths of

red, orange and brown wire. Strip 1/4" of insulation from

each end. Solder one end of each wire to a potentiometer,

as shown in Figure 2. Note the color orientation. Use 3/4"

of heat shrink tubing over each potentiometer terminal.

Shrink with heat gun. Solder a metal terminal to the free

end of each wire. Insert the terminals into the 3 -pin

female Molex connector. Be sure to insert the proper

colors into the proper connector positions.(Note: all of the

3-pin female connectors in this kit use the same color

orientation).

Twist the wires to form a 3-wire cable.

Repeat above step for all potentiometers.

Install wires to the sum mode switch as shown in . Be

careful to use the right color wires as shown. Use heat

shrink tubing as indicated. Some kits come with a DPST

rocker switch instead of the toggle switch. The rocker

switch does not have the two unused terminals that are

shown in .

The front panel will be attached to the main chassis using

Figure 4: Power cable

Cut a piece of brown wire 3" long and strip 1/4" of

insulation from each end.

Gather the brown wires from the power cables and one

end of the 3" brown wire and insert them into the terminal

block on the PS10 marked --.

Double check: RED is GND, ORANGE is + and BROWN

is -.

Identify which end of the LED is the cathode (negative)

lead. The LED has a flat on its side next to this lead. Trim

both leads to about 1/4".

Cut both leads of the 10K resistor to 1/4" long.

Solder one of leads of the resistor to the cathode of the

LED.

Using 1" of heat shrink tubing, connect the free end of the

3" brown wire (from the negative terminal of the power

supply) to the free lead of the resistor. slide the tubing

over the resistor, against the LED, to cover the

connections on both ends of the resistor.

Using 1/2" of heat shrink tubing, solder the red wire from

the ground terminal of the power supply to the remaining

lead of the LED (anode).

The PS10 power supply of the crossover should be

grounded to the cabinet through a power resistor.

Solder one lead of the power resistor to the solder lug.

Solder a 3” length of wire to the other end of the 2.4K

© 2000 Marchand Electronics Inc. PO Box 473, Webster, NY, 14580 www.marchandelec.com (716) 872 0980 FAX: (716) 872 1960

2

power resistor.

Solder lug

Resistor

Wire to PS10 output

ground

220VAC

110VAC

PS10

PS10

Front Panel

DPDT switch

Rear Panel

Fuse Holder

Rear Panel

Power entry

Rear Panel

Voltage selector

GREEN/

YELLOW

N

L

PS10 transformer

terminal block

WHITE

BLACK

WHITE

BLACK

BLACK

BLACK

BROWN

RED

RED

Wire to

case

Front Panel

DPST rocker switch

Rear Panel

Fuse Holder

Rear Panel

Power entry

Rear Panel

Voltage selector

GREEN/

YELLOW

N

L

PS10 transformer

terminal block

WHITE

BLACK

WHITE

BLACK

BLACK

BLACK

BROW N

RED

RED

Wire to

case

WHITE

Install the shrink tubing over the resistor and part of the

solder lug.

Attach the solder lug to the cabinet using a 6-32 screw

and nut. Use one of the available holes near the PS10.

Insert the free end of the wire in the center terminal of

the three position terminal block of the PS10 output. This

is the neutral DC output.

Figure 5

Install the LED into the front panel. First insert the black

grommet through the hole in the front panel from the

outside. Then insert the LED into the grommet from the

inside. The grommet snaps around the base of the LED

and holds it in place.

Check that all the pieces of heat shrink tubing are properly

positioned over the connections they are supposed to

protect and shrink with a heat gun.

Now the AC power wiring will be hooked up to the power

supply.

Figure 6

Attached line cord

Separate the power cord wires back to about 1/4" from

the strain relief and cut one of the wires about 2" from the

strain relief. Slip 1/2" of heat shrink tubing over the short

wire and solder it to the center connector of the fuse

holder. Cut 1/2" of heat shrink tubing and slip it over the

remaining power cord wire. Solder the wire to the center

connector of the power switch.

Cut an 8" piece of red high voltage (thick insulation)

hookup wire, strip 1/4" at each end and solder to the

bottom terminal of the power switch. Use 1/2" of heat

shrink tubing over this connection as well.

Secure the free end of the wire in the leftmost terminal of

the 4-position terminal block (AC input) on the PS10

power supply board.

Cut a 2" piece of brown high voltage hookup wire and

secure the free end of the wire in the rightmost terminal of

the 4-position terminal block (AC input) on the PS10

power supply board.

Use jumpers on the 4-position terminal block of the PS10

power supply to select line voltage, as shown in Figure 6.

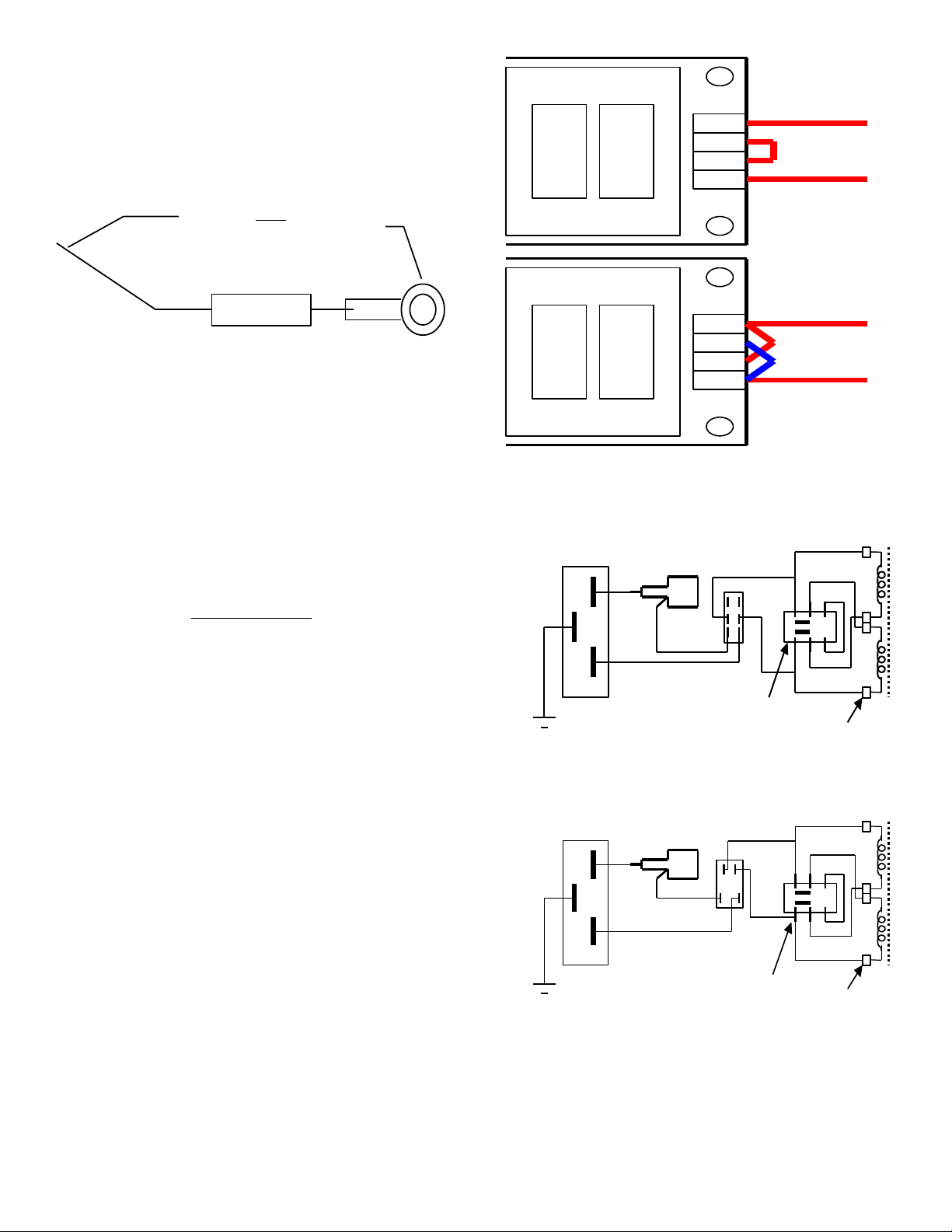

Figure 7. Power entry with voltage selector switch on rear

panel and toggle switch on front panel.

Figure 8. Power entry with voltage selector switch on rear

panel and rocker switch on front panel.

© 2000 Marchand Electronics Inc. PO Box 473, Webster, NY, 14580 www.marchandelec.com (716) 872 0980 FAX: (716) 872 1960

3

Connect the 2 (4) power cables from the power supply to

Removable line cord

Refer to Figure 1 and Figure 7 or Figure 8 when

installing the power supply wiring for the removable line

cord. If your kit has a DPDT toggle switch then use

Figure 7. If your kit has a DPST rocker switch the use

Figure 8.

Two rocker switches are included in the kit that has

rocker switches. The illuminated switch with the colored

lens is used for the power and the one without the lens is

used for the sum switch. Note that the rocker switch has

two pairs of contacts; one pair is closer together than the

other. Use the pair that is cose together for the wires that

go to the transformer.

Use high voltage (thick insulation) #22 hookup wire to

make the connections between the power entry

connector, the power switch on the front panel and the

power selector switch on the rear panel and the fuse

holder. Install heat shrink tubing over all junctions. Use

wire colors as shown in .

Make sure to securely install the grounding wire between

the ground terminal on the power entry connector and

the chassis. Solder a 3” piece of green/yellow hookup

wire to one of the solder lugs provided. Solder the free

end of the wire to the ground terminal and secure the

solder lug to the chassis with one of the 6/32 screws

holding the rear panel.

Set the voltage selector switch to the proper voltage

before proceeding.

Attached AND Removable line cord

Install a 1A fuse in the fuse holder.

We will now test the power supply. Plug the cord in and

turn on the power switch. The two LED indicators on the

power supply and the front panel LED indicator should all

light.

UNPLUG the power cord before proceeding.

Now the RCA connectors are to be connected to the

circuit boards. Note that the circuit boards have groups of

3 holes marked P6,P7,P8 on the XM9 and P5,P6,P7 on

the XM16. The twisted pairs from the RCA connectors

connect to these locations according to the tables below.

There are four tables (1..4), one for each configuration of

the crossover network. Be sure to solder the red wire to

the small hole in the center of the group, and the brown

ground wire to one of the 3 larger holes in the group. The

boards will have to be removed in order to do the

soldering. On the 3-way units there also is a set of two

jumper wires between the boards. Make the jumper

connection by running a red wire between the center holes

of the locations indicated and a brown wire between the

grounds at the locations indicated. For example, for the

XM16L-3KK there is a jumper wire between P5 of the left

board and P7 of the left center board, etc.

There are several trimmer potentiometers on the

crossover boards. They should all be set to the center

position.

© 2000 Marchand Electronics Inc. PO Box 473, Webster, NY, 14580 www.marchandelec.com (716) 872 0980 FAX: (716) 872 1960

the crossover boards. On the XM9 the cables are plugged

into connectors marked P2. On the XM16 the power

cables are plugged into the connectors marked P1.

The sum-mode cable is hooked to two 3-pin molex

connectors according to the table 5.

The level and damping controls are hooked up

according to table 6.

There are several jumpers on each board. These

jumpers serve to enable the off board level and damping

controls. Near each connector that was used in table 6

there is a 3 position male connector, labeled 1J2 or 3J4 or

5J6. A jumper block should be placed on each of these

connectors. If a cable was connected to the P connector,

then the jumper should be placed over the RIGHT two

pins. If no cable was connected the jumper should be

placed over the LEFT two pins.

Make sure all the jumpers have been installed.

Install the control knobs onto the level and damping

controls. The knobs should be installed so that the arrow

indicator on the knob is at the 12 o'clock position when the

control is centered. The position of the knob when it is

turned fully clockwise is thus left-right mirrored from when

it is turned fully counterclockwise. When installed in this

symmetric fashion, the calibration on the front panel will be

correct.

3-Channel Unit

The 3-channel unit use 3 crossover boards and one LD28

summer board. There is no sum switch. The LD28 board

is installed to the left of the 3 crossover boards, as seen

from the front of the unit. The power supply cable to the

LD28 is the same as for a crossover board. The output

marked OUT4+ of the LD28 Should be connected to the

connector marked “sum” on the rear panel. The 3 inputs

marked IN1, IN2 and IN3 should be connected to the low

pass outputs of the crossover boards. Use black/red

twisted wire pairs for these connections; the red wire being

the signal and the black wire the ground. Note that the

low-pass outputs of the crossover boards now have two

connections each: to the output connectors and to the

summer board.

Frequency Modules

Install the frequency modules for the proper frequencies.

For the two way units all frequency modules have the

same value. On the 3 way units, install the frequency

modules with the LOWER frequency into the Left and

Right-center boards, and the frequency modules with the

HIGHER frequency into the Left-Center and Right boards.

The Top Cover of the unit can be installed now or at a

later time. Fasten the top with 4 6/32 x 1/4" screws. In

case it is difficult to insert the screws, loosen the screws

that hold on the front and rear panels and try again. Now

fasten all screws well.

The assembly is now completed.

4

Loading...

Loading...