Marcegaglia Buildtech Realpont system 75, Tel Dal T5/Uniform system, Realpont system 105 Instruction Manual

Instruction manual

Prefabricated frames

SUPPLY

MATERIAL ZC

REMARKS The weight refers to nominal

Various modes of

supply are available:

• sale

• sale with buyback agreement

• rent

• rent with redemption

All these modes of supply can be

combined with the following services:

• assembly

• disassembly

• service at the building site

hot dip galvanized steel

ZZ

Sendzimir galvanized steel

ZE

electro-galvanized steel

VR

painted steel

TR

tropicalized steel

LG

wood

AL

aluminium

gage values

* Production

on request

Index

REALPONT SYSTEM DESCRIPTION

Prefabricated frames: Realpont system 75

Prefabricated frames: Realpont system 105

Realpont system components

TEL DAL T5/UNIFORM SYSTEM DESCRIPTION

Prefabricated frames: Tel Dal T5/Uniform system

Tel Dal system T5 components

Uniform system components

TUBE-COUPLER SYSTEM DESCRIPTION

Tube-coupler system components 26

04

05

06

14

15

20

INSTRUCTIONS FOR USE

Pre-erection

Erection

Use

Dismantling

Transport

ANCHORAGES

General characteristics

Tie anchorage

Ring anchorage

Screw-down anchorage

Bracing anchorage

Truss beam in tube-coupler anchorage

Anchorage with reinforced rod for reinforced concrete

Anchorage with steel structural plates

ERECTION SEQUENCE

Connection elements

Realpont system erection sequence

30

31

33

34

34

36

37

39

41

41

43

45

46

48

49

CERTIFICATIONS

Certifications

64

Instruction manual • Prefabricated frames

1

Instruction manual • Prefabricated frames

2

Description

Realpont system

Prefabricated frames: Realpont system 75

Prefabricated frames: Realpont system 105

Realpont system components

04

05

06

Instruction manual • Prefabricated frames

3

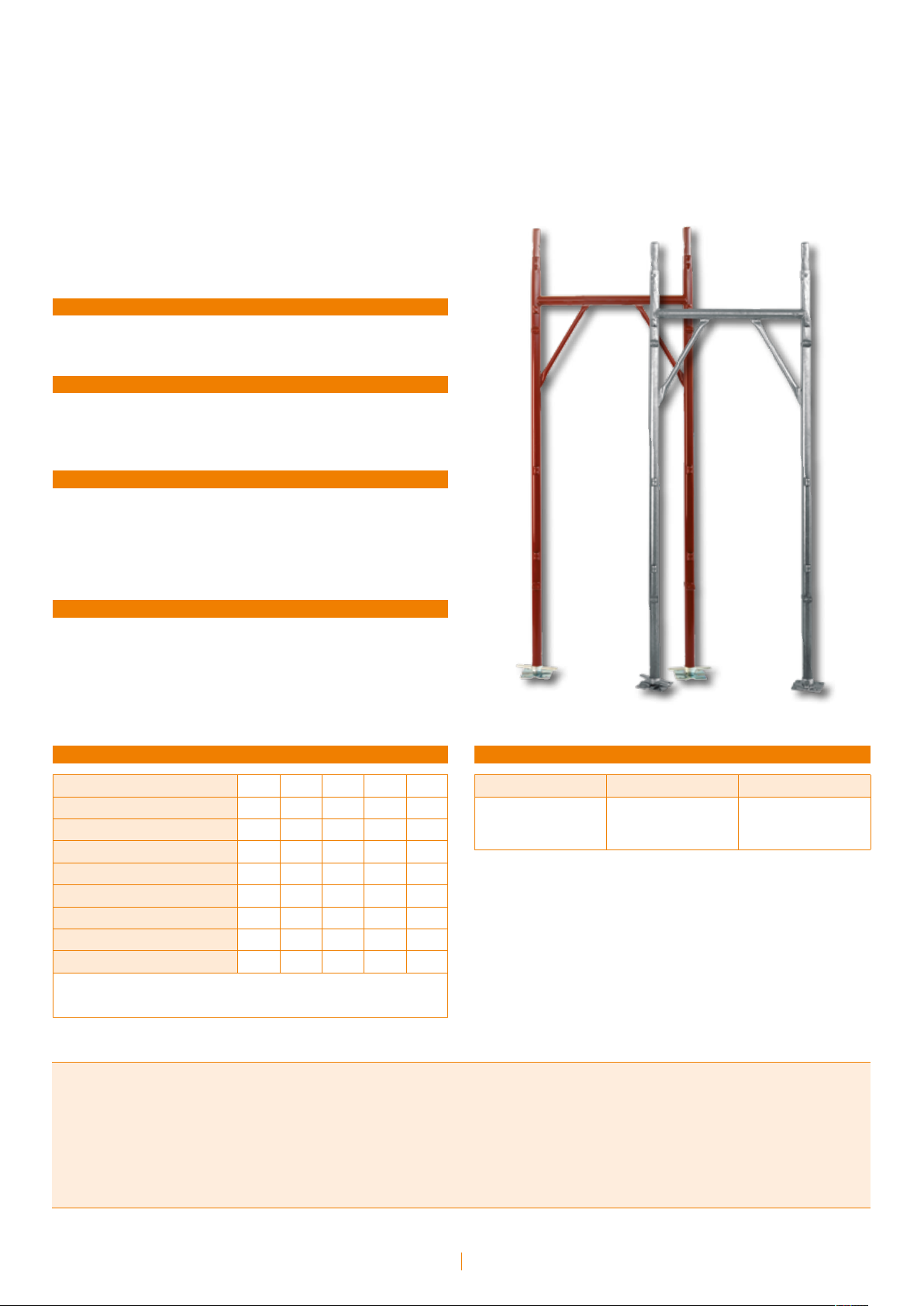

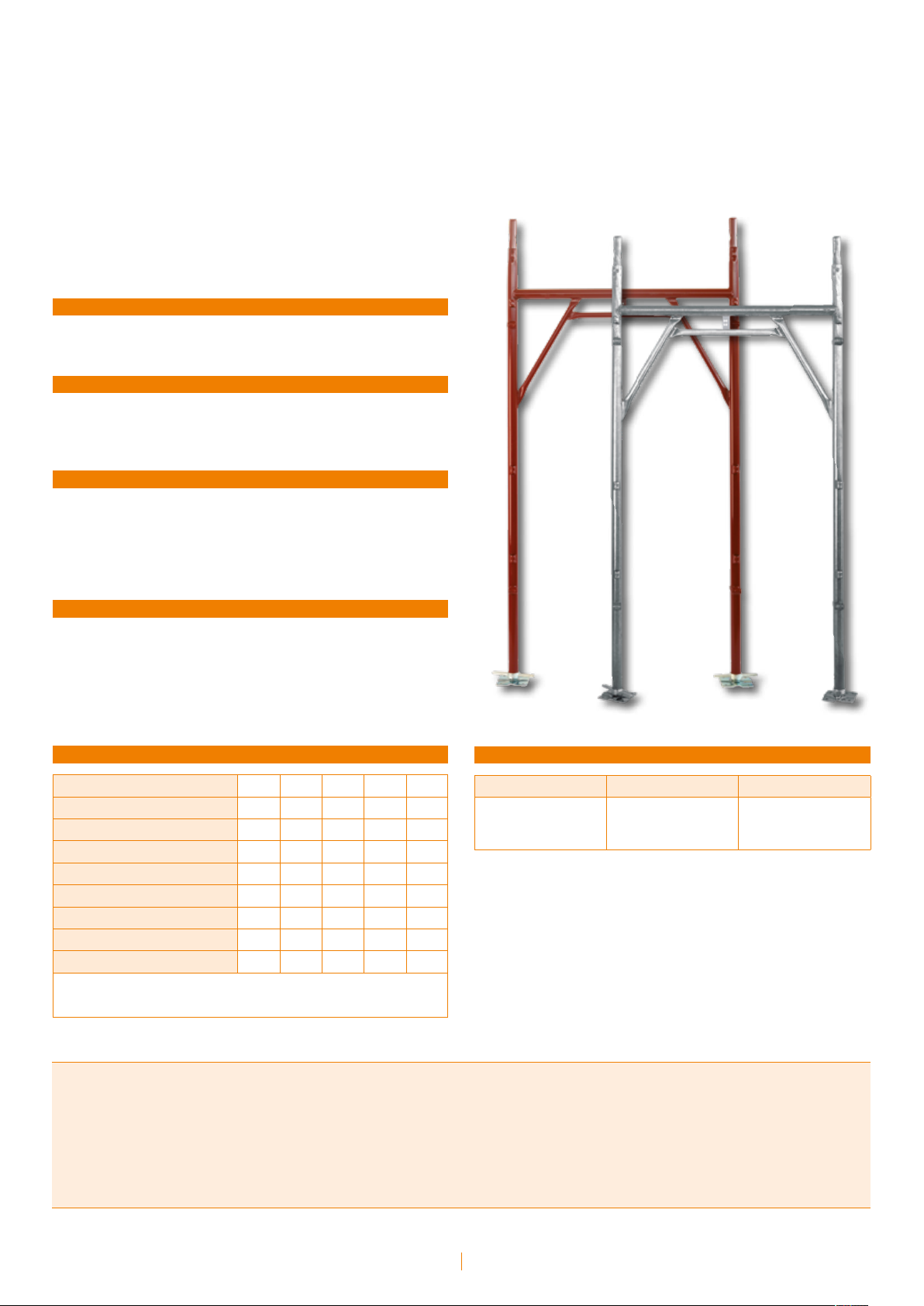

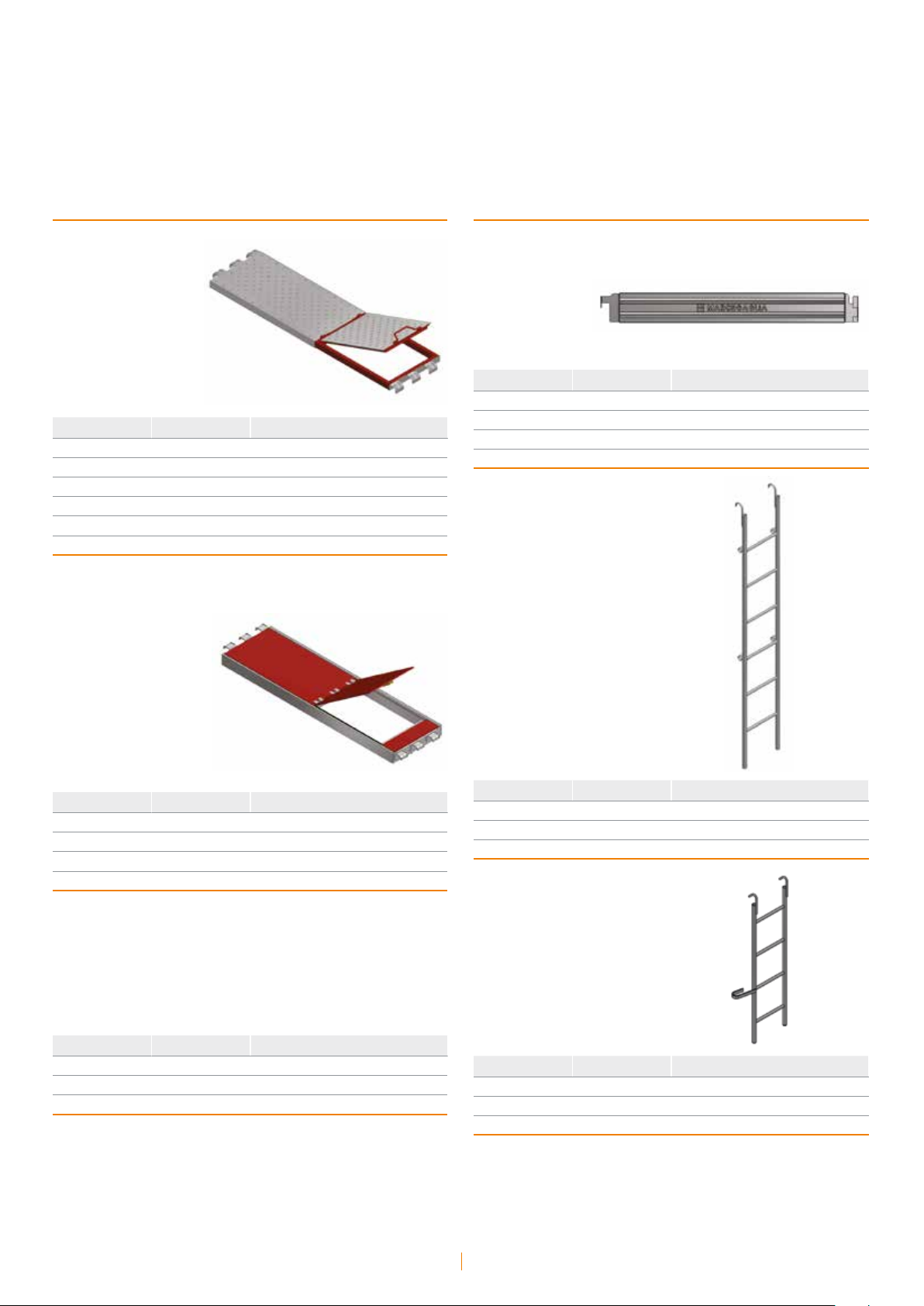

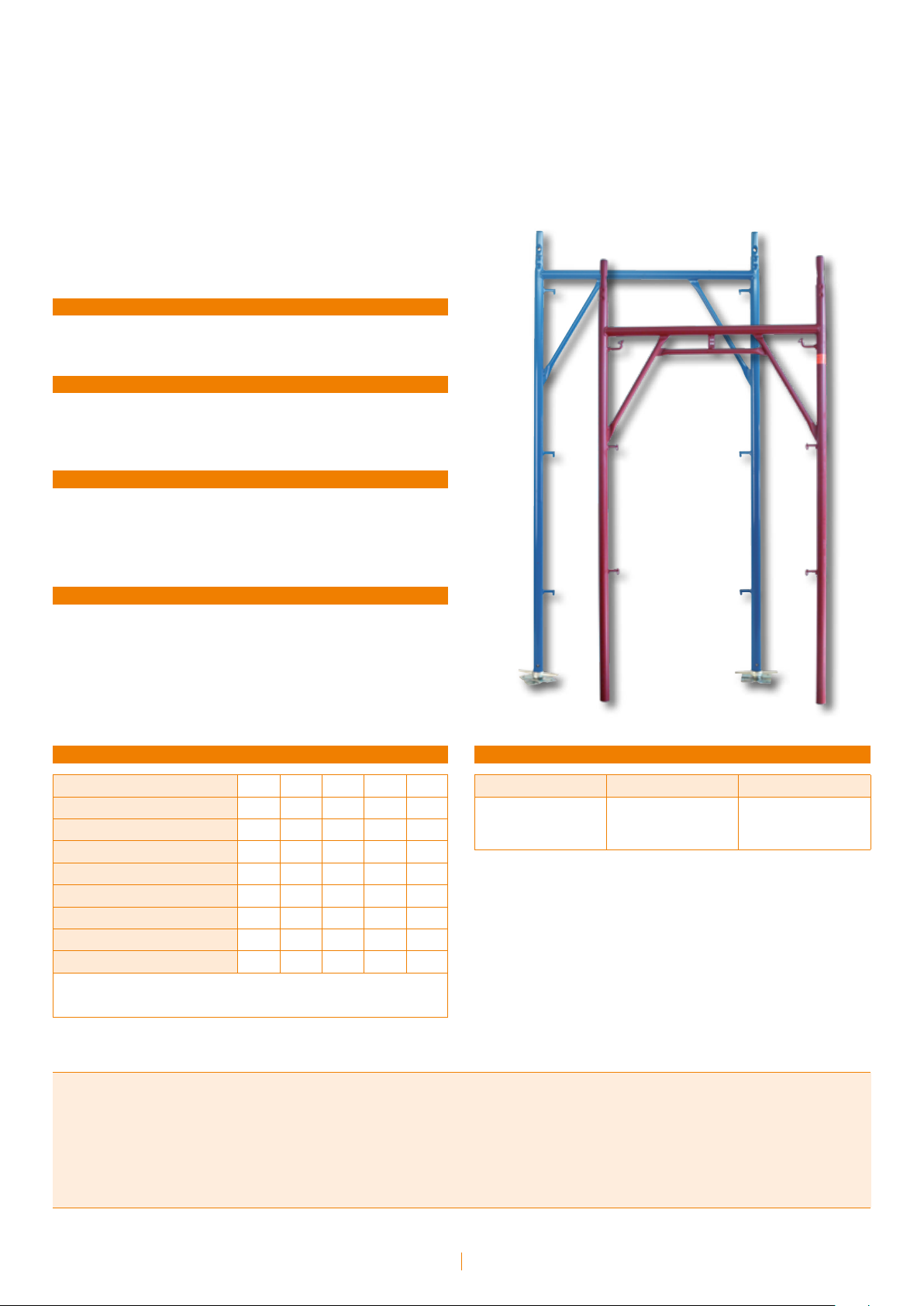

Prefabricated frames:

Realpont system 75

System with 75 cm frames with bushings

750 mm deep/wide frame • Painted or hot dipped galvanizing protection

Erection of 2500 mm and 3000 mm mixed bay structures • Bushing fittings

SUPPLY

Sales, rent.

UPRIGHTS MATERIAL

- Steel grade S235JR

- Steel tubes: 48.3 mm outside diameter, 2.9 mm S235JRH nominal gage

PROTECTION

- Hot dip galvanized: guaranteed min. coating thickness 55 micron (mean

value);

- Painting performed by immersion with resistance tested to ASTM D

2247-87 moist-room test;

- Col or: red

CHARACTERISTICS

- Bushing fittings;

- Modular bushing fittings to obtain 1.8 m, 2.5 m and 3,0 m mixed bays;

- Safe erection;

- Licensed for uniform building loads of 300 daN/m2 (cl IV, EN12811)

TUBE CHARACTERISTICS ACCORDING TO EN10219

Outside diameter (mm)

Thickness (mm)

2

Section (cm

Moment of inertia (cm

Section modulus (cm

Radius of gyration (cm)

Nominal weight (kg/m)

Ultimate stress (N/mm

Elongation at rupture (%)

Thickness tolerance: ≤ 5%

Tolerance on the mass ± 5% on parts of at least 10 Ton

Other tolerances: as per ISO 65 recommendations

)

4

)

3

)

2

)

48,30 40,00 38,00 38,00 26,90

2,9 2 4 2,5 2

4,14 2,38 4,27 2,78 1,56

10,7 4,32 6,26 4,41 1,22

4,43 2,16 3,29 2,32 0,907

1,61 1,34 1,21 1,25 0,88

3,27 1,87 3,38 2,18 1,24

≥ 360 ≥ 360 ≥ 360 ≥ 360 ≥ 360

≥ 24 ≥ 24 ≥ 24 ≥ 24 ≥ 24

STANDARD DIMENSIONS

Width Span Module

750 mm 1800 mm

2500 mm

3000 mm

2000 mm

Fix height

Manufacturing Standards

- Aut. Min. n.15/0009997/14.03.01.03 del 01/06/2005

- Est. 15/VI/3800/14.03.01.02 del 03/08/2006

- Decreto legislativo 9 Aprile 2008 n. 81

- D.M. 02/09/68

- D.M. 23/03/90 n. 115

- Circolari 44/90 e 156 AA.GG./STC.

- Disciplinare UNICMI sul marchio SQ

Instruction manual • Prefabricated frames

4

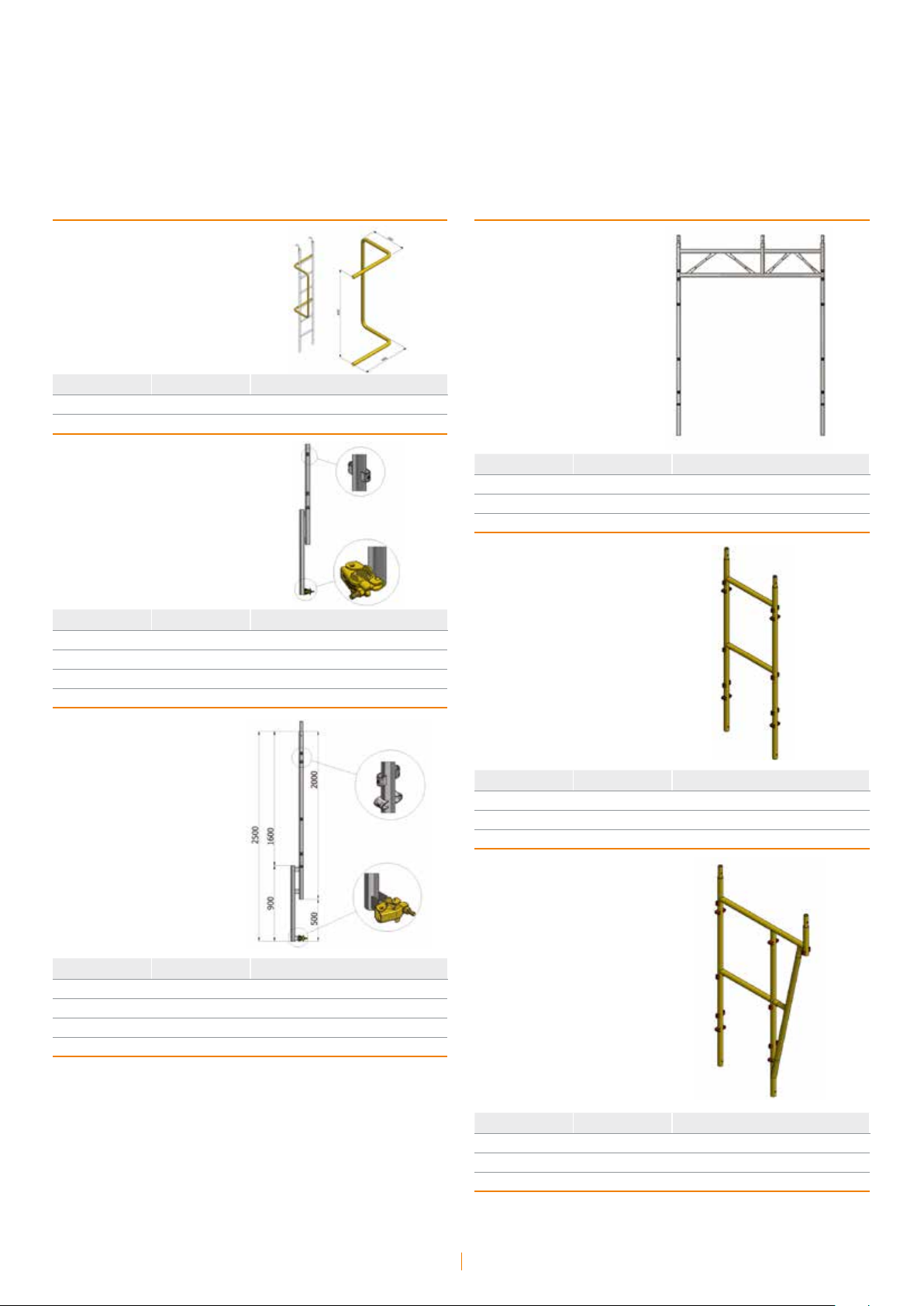

Prefabricated frames:

Realpont system 105

System with 105 cm frames with bushings

Installation of 1050 mm deep working bays • Protection or hot dipped

galvanizing protection • Erection of 2500 mm and 3000 mm mixed bay

structures • Bushing fittings.

SUPPLY

Sales, rent.

UPRIGHTS MATERIAL

- Steel grade S235JR

- Steel tubes: 48.3 mm outside diameter, 2.9 mm S235JRH nominal gage

PROTECTION

- Hot dip galvanized: guaranteed min. coating thickness 55 micron (mean

value);

- Painting performed by immersion with resistance tested to ASTM D

2247-87 moist-room test;

- Col or: red

CHARACTERISTICS

- Bushing fittings;

- Modular bushing fittings to obtain 1.8 m, 2.5 m and 3,0 m mixed bays;

- Safe erection;

- Licensed for uniform building loads of 300 daN/m2 (cl IV, EN12811)

TUBE CHARACTERISTICS ACCORDING TO EN10219

Outside diameter (mm)

Thickness (mm)

2

Section (cm

Moment of inertia (cm

Section modulus (cm

Radius of gyration (cm)

Nominal weight (kg/m)

Ultimate stress (N/mm

Elongation at rupture (%)

Thickness tolerance: ≤ 5%

Tolerance on the mass ± 5% on parts of at least 10 Ton

Other tolerances: as per ISO 65 recommendations

)

4

)

3

)

2

)

48,30 40,00 38,00 38,00 26,90

2,9 2 4 2,5 2

4,14 2,38 4,27 2,78 1,56

10,7 4,32 6,26 4,41 1,22

4,43 2,16 3,29 2,32 0,907

1,61 1,34 1,21 1,25 0,88

3,27 1,87 3,38 2,18 1,24

≥ 360 ≥ 360 ≥ 360 ≥ 360 ≥ 360

≥ 24 ≥ 24 ≥ 24 ≥ 24 ≥ 24

STANDARD DIMENSIONS

Width Span Module

1050 mm 1800 mm

2500 mm

3000 mm

2000 mm

Fix height

Manufacturing Standards

- Aut. Min. Realpont 15/0006649/14.03.01.01 del 12/04/2005

- Est. 15/VI/3799/14.03.01.01 del 03/08/2006

- EU 92 15/0009998/14.03.01.03 del 01/06/2005

- Decreto legislativo 9 Aprile 2008 n. 81

- D.M. 02/09/68

- D.M. 23/03/90 n. 115

- Circolari 44/90 e 156 AA.GG./STC.

- Disciplinare UNICMI sul marchio SQ

- n. 15/VI/3974/14.03.01.02 del 3 agosto 2006

- n. 15/VI/7369/14.03.01.02 del 5 maggio 2008

Instruction manual • Prefabricated frames

5

Realpont system - Components

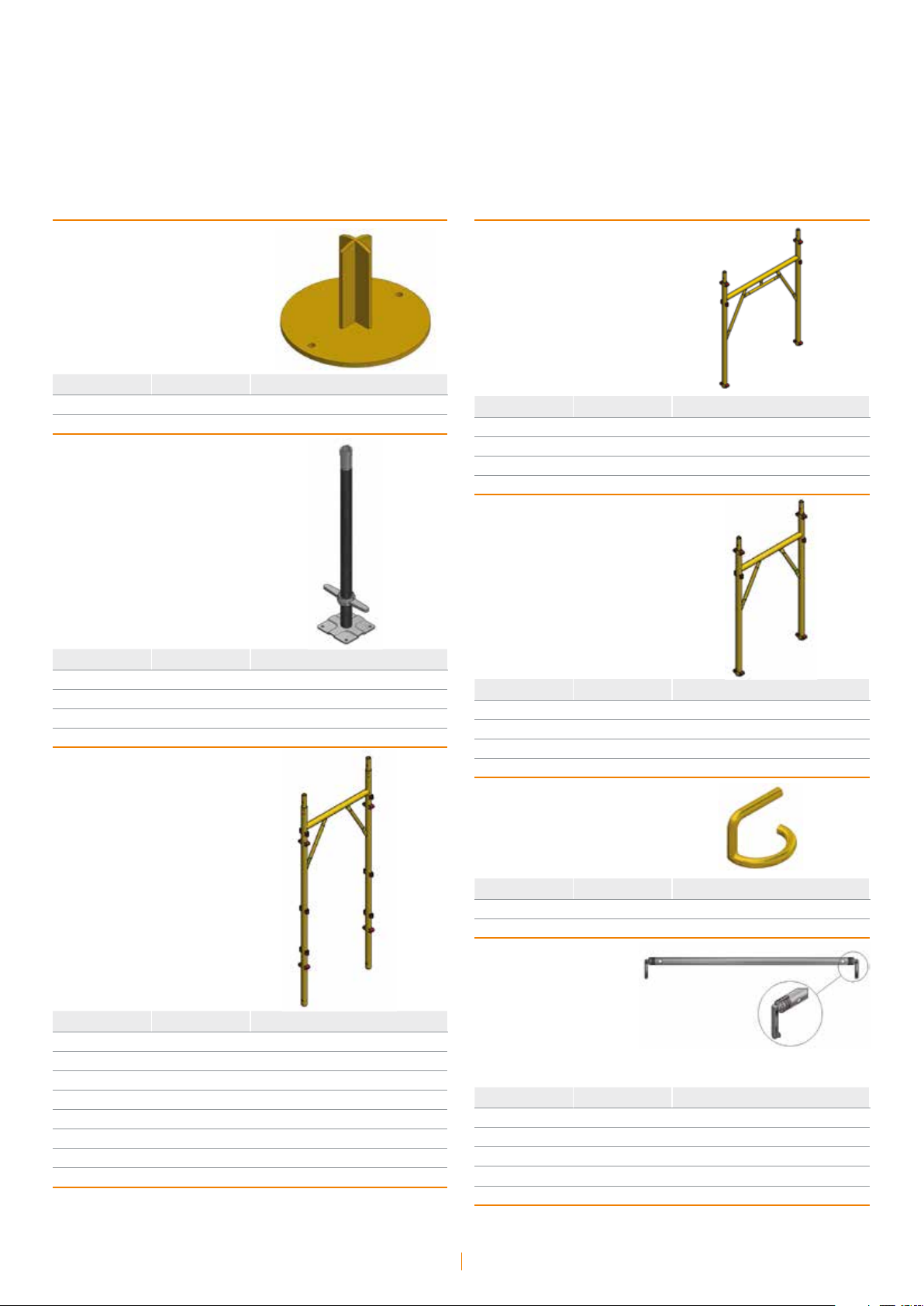

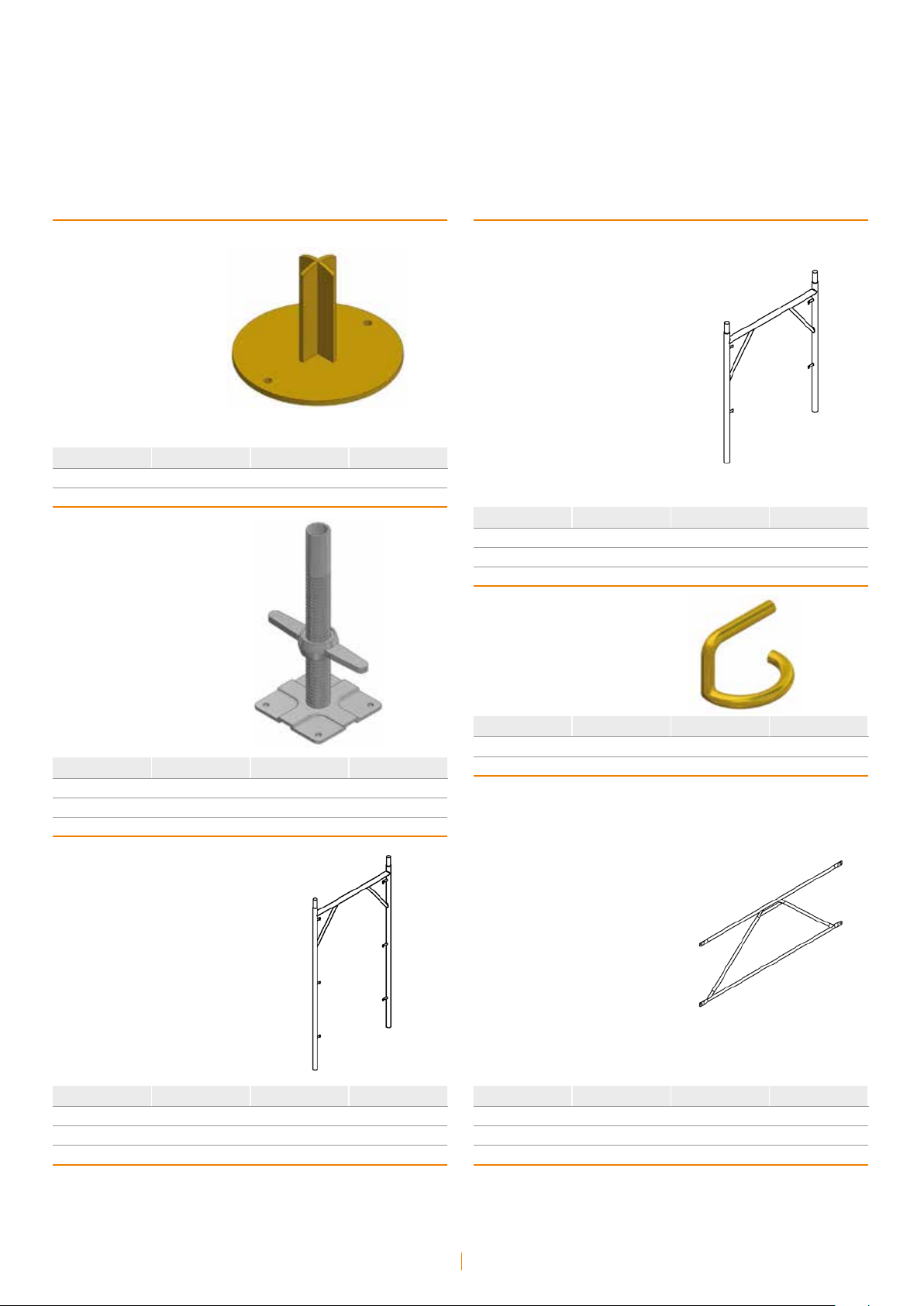

Base plate

mm

48 TR IT/EN 3030100006 0,92

material

cod daN

Adjustable base jack

mm

355 ZE IT/EN 3040800902 2,49

700 ZE IT/EN 3060300141 3,30

1000 ZE IT/EN 3040501012 4,69

material

cod daN

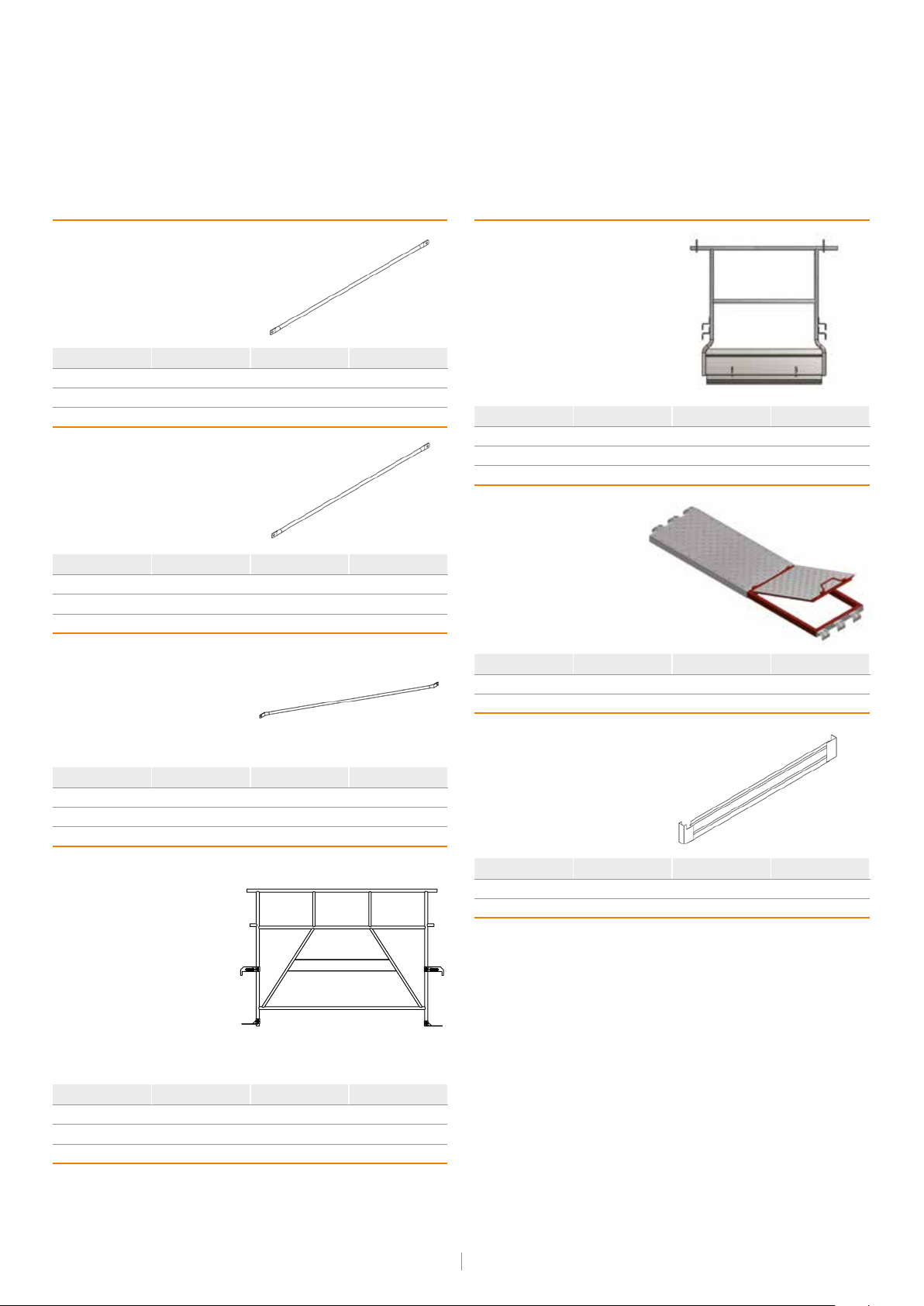

Realpont frame

Realpont half-frame

mm

1050x1300 VR IT 3040105980 15,04

1050x1300 ZC IT 3040105981 15,08

1050x1300 ZC EN 3040105991 15,99

material

cod daN

Realpont compensation-frame

mm

750x1300 VR IT 3040106130 13,17

750x1300 ZC IT 3040106131 13,90

750x1300 ZC EN 3040105961 14,50

material

cod daN

mm

750x2000 VR IT 3040106100 18,14

750x2000 ZC IT 3040106101 19,24

750x2000 ZC EN 3040106071 19,31

1050x2000 VR IT 3040106000 20,10

1050x2000 VR EN 3040107000 20,32

1050x2000 ZC IT 3040106001 21,13

1050x2000 ZC EN 3040107001 21,13

material

cod daN

Spigot pin

mm

100 TR IT/EN 3040701006 0,12

material

cod daN

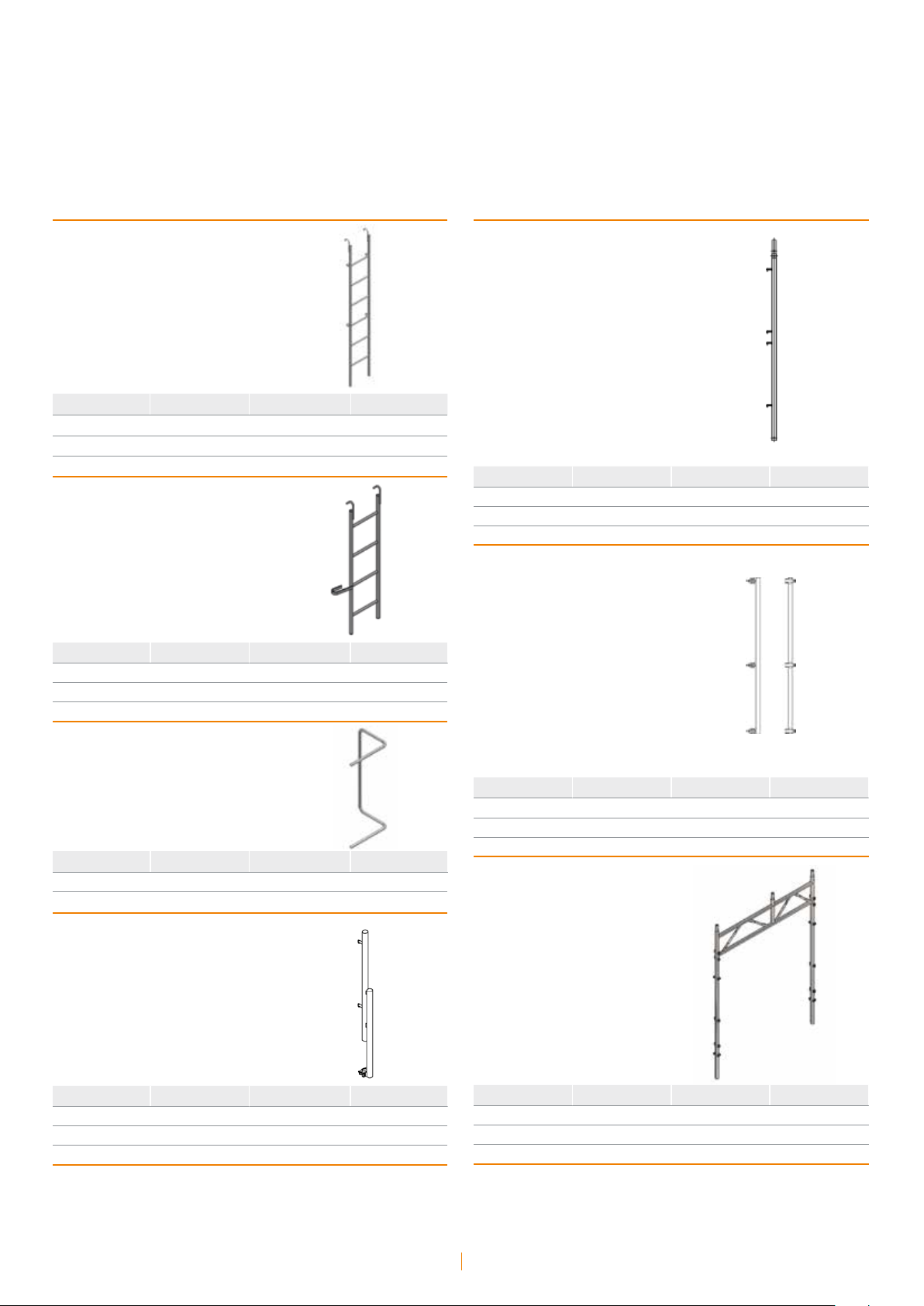

Guardrail with forged

connection devices

mm

1800 VR IT 3040201010 2,76

1800 ZZ IT/EN 3040201015 2,88

2500 ZZ IT/EN 3040201175 5,80

3000 ZZ EN 3040201705 6,69

material

cod daN

Instruction manual • Prefabricated frames

6

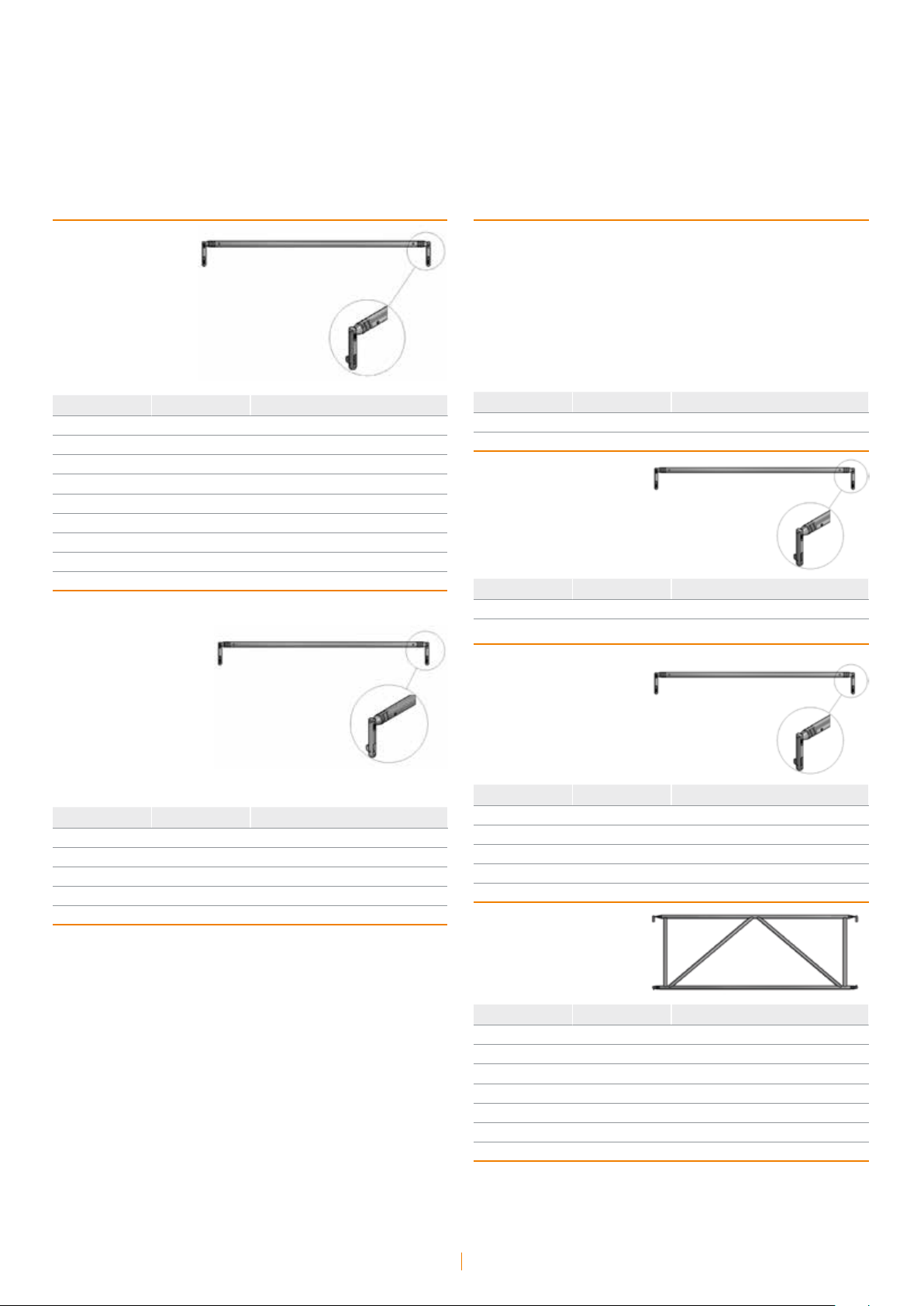

Horizontal-diagonal

brace

Horizontal-diagonal brace

for pedestrian walk-thru frame

with forged connection device

mm

748x1800 VR IT 3040206160 2,86

748x1800 ZZ IT 3040206165 3,33

748x2500 ZZ IT 3040206175 5,94

748x3000 ZZ EN 3040201725 6,87

1048x1800 VR IT/EN 3040206010 3,12

1048x1800 ZZ IT/EN 3040206015 3,26

1048x2500 ZZ IT/EN 3040201195 6,23

1048x3000 ZZ EN 3040201715 7,05

material

cod daN

Horizontal-diagonal brace

for tapered ends

with forged

connection devices

mm

348x1800 ZZ IT 3040202065 2,93

348x2500 ZZ IT 3040201165 5,85

648x1800 ZZ 3040201266 3,03

648x2500 ZZ IT 3040201155 5,88

material

cod daN

mm

1798x3000 ZZ EN 3040201745 7,68

material

cod daN

Vertical-diagonal brace

mm

1800 VR IT 3040201000 3,25

material

cod daN

Vertical-diagonal

brace with forged

connection devices

mm

1800 ZZ IT 3040201005 3,40

2500 ZZ IT 3040201185 6,40

2500 ZZ EN 3040201195 6,23

3000 ZZ EN 3040201715 7,05

material

cod daN

Double fencing

structure

mm

1800 VR IT 3040201900 9,10

1800 ZC IT 3040201901 10,09

1800 ZC EN 3040201791 8,85

2500 ZZ IT 3040201911 15,08

2500 ZC EN 3040201801 15,42

3000 ZC EN 3040201851 18,80

Instruction manual • Prefabricated frames

7

material

cod daN

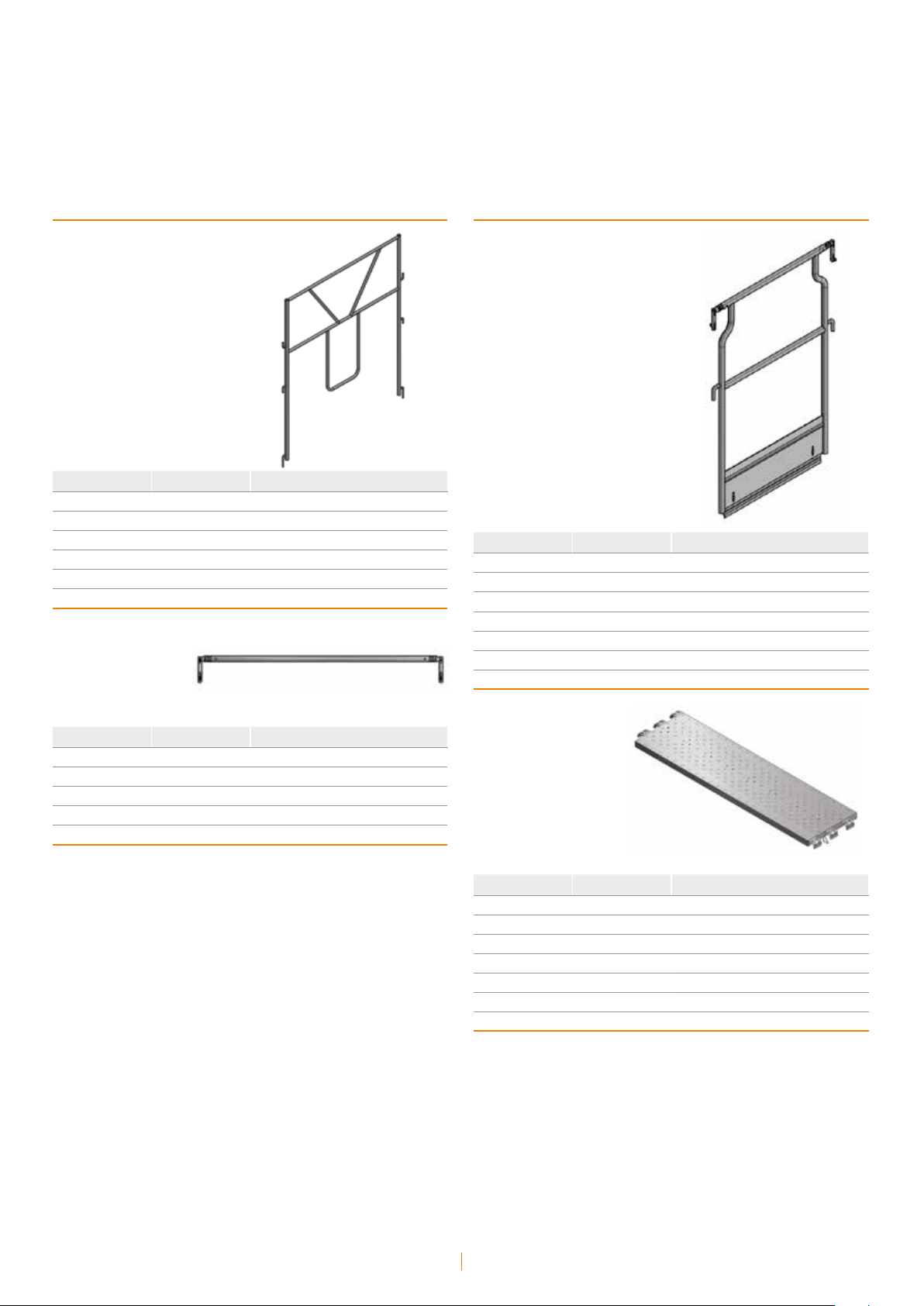

Steel denitive

guardrail frame

Side fencing structure

with toeboard

mm

750 ZC EN 3040201691 14,08

1050 ZC EN 3040201681 15,10

1800 ZC EN 3040201661 16,98

2500 ZC EN 3040201671 18,74

3000 ZC EN 3040201751 21,96

material

cod daN

Transom

mm

750 VR IT 3040206180 1,16

750 ZZ IT 3040206185 1,66

1050 VR IT 3040206060 1,94

1050 ZZ IT 3040206065 2,02

material

cod daN

mm

750 VR IT 3040206040 8,25

750 ZC EN 3040206141 8,67

750 ZC IT 3040206041 9,37

1050 VR IT 3040206100 10,75

1050 ZC EN 3040206131 10,82

1050 ZC IT 3040206101 11,23

material

cod daN

Securdeck scaffold

steel plank

mm

1800x330x50 ZZ IT/EN 3070102041 10,80

2500x330x50 ZZ IT/EN 3070102051 14,38

3000x330x50 ZZ IT/EN 3070102161 16,75

3000x330x75 ZZ IT/EN 3070102071 19,90

1800x490x50 ZZ IT/EN 3070102011 15,16

2500x490x50 ZZ IT/EN 3070102021 21,30

material

cod daN

Instruction manual • Prefabricated frames

8

Steel plank

with trapdoor

Toeboard

mm

1800x490x50 PZ 3070100011 28,68

1800x490x50 ZZ 3070100031 28,68

2500x490x50 ZZ 3070800031 38,41

1800x660x60 ZZ 3150200191 35,04

2500x660x60 ZZ 3150200201 45,38

material

cod daN

Aluminium-plywood plank

with frontal opening trapdoor

mm

1800x660 AL 3070101149 20,63

2500x660 AL 3070101139 26,35

3000x660 AL 3070101521 31,53

material

cod daN

mm

1800 ZC 3070200001 5,02

2500 ZC 3070200051 7,35

3000 ZC 3070200071 7,321

material

cod daN

Ladder

mm

2000 VR 3070300130 6,05

2000 ZC 3070300131 7,35

material

cod daN

Compensation frame ladder

Aluminium-plywood plank

with frontal opening trapdoor and ladder

mm

2500x660 AL IT/EN 3070101129 32,38

3000x660 AL EN 3070101069 38,06

material

cod daN

mm

1330 VR 3070300160 6,05

1330 ZC 3070300161 7,35

Instruction manual • Prefabricated frames

9

material

cod daN

Ladder handrail

Walk-thru frame

mm

- ZC 3070300141 2,78

material

cod daN

Simple reinforced terminal

mm

- VR IT 3040404080 7,15

- ZC IT 3040404081 7,84

- ZC EN 3040303021 7,84

material

cod daN

Top guardrail upright

mm

1796x2516 ZC IT 3040104081 33,68

1796x2400 ZC EN 3040104051 34,14

material

cod daN

Lower support

mm

- VR IT 3040101030 18,21

- ZC IT 3040101031 19,66

material

cod daN

mm

2000 VR IT 3040404090 11,82

2000 ZC IT 3040404091 12,36

2000 ZC EN 3040404111 12,36

material

cod daN

Upper support

mm

650x1050 VR IT 3040106020 25,93

650x1050 ZC IT 3040106021 27,10

Instruction manual • Prefabricated frames

10

material

cod daN

Bracket

for Realpont system 75

Bridging ledger

mm

750 ZC IT 3040306031 6,54

750 VR IT 3040306030 6,82

750 ZC EN 3040307501 7,01

material

cod daN

Bracket

for Realpont system 1050

mm

1050 VR IT 3040306000 8,50

1050 ZC IT 3040306001 7,98

1050 ZC EN 3040307201 8,58

material

cod daN

Bracket brace

mm

750 ZC IT/EN 3040306041 8,30

1050 VR IT/EN 3040305010 8,44

1050 ZC IT/EN 3040305011 8,73

material

cod daN

Street protection fan

mm

3600 VR IT 3040604020 41,84

3600 ZC IT/EN 3040604021 43,50

5000 ZC IT/EN 3040601031 52,82

5400 VR IT 3040604040 60,66

5400 ZC IT/EN 3040604041 63,06

material

cod daN

Bridging ledger junction

mm

748 ZC EN 3040603021 10,78

748 ZC IT 3040606011 5,63

1048 VR IT/EN 3040605010 8,47

1048 ZC IT 3040605011 8,95

material

cod daN

Bracket

for loading

platform

mm

- VR IT 3040301050 9,19

- ZC IT 3040301051 9,65

- ZC EN 3040800401 18,60

material

cod daN

mm

1048 VR IT 3040306900 13,01

1048 ZC IT/EN 3040306901 13,46

Instruction manual • Prefabricated frames

11

material

cod daN

Instruction manual • Prefabricated frames

12

Description

Tel Dal T5/Uniform system

Prefabricated frames: Tel Dal T5/Uniform system

Tel Dal system T5 - Components

Uniform System - Components

14

15

20

Instruction manual • Prefabricated frames

13

Prefabricated frames:

Tel Dal T5/Uniform system

System with 105 cm frames with pawl

1050 mm deep/wide frame • Painted protection by immersion • Erection

of 1800 mm mixed bay structures • Pawl fittings

SUPPLY

Sales, rent.

UPRIGHTS MATERIAL

- Steel grade S235JR

- Steel tubes: 48.3 mm outside diameter, 2.9 mm nominal gage

PROTECTION

- Painting performed by immersion with resistance tested to ASTM D

2247-87 moist-room test;

- Color: blue for Tel Dal T5, red for Uniform

CHARACTERISTICS

- Pawl fittings;

- Span: 1,8 m;

- Safe erection;

- Licensed for uniform building loads of 300 daN/m

2

(cl. IV, EN 10811)

TUBE CHARACTERISTICS ACCORDING TO EN10219

Outside diameter (mm)

Thickness (mm)

2

Section (cm

Moment of inertia (cm

Section modulus (cm

Radius of gyration (cm)

Nominal weight (kg/m)

Ultimate stress (N/mm

Elongation at rupture (%)

Thickness tolerance: ≤ 5%

Tolerance on the mass ± 5% on parts of at least 10 Ton

Other tolerances: as per ISO 65 recommendations

)

4

)

3

)

2

)

48,30 40,00 38,00 38,00 26,90

2,9 2 4 2,5 2

4,14 2,38 4,27 2,78 1,56

10,7 4,32 6,26 4,41 1,22

4,43 2,16 3,29 2,32 0,907

1,61 1,34 1,21 1,25 0,88

3,27 1,87 3,38 2,18 1,24

≥ 360 ≥ 360 ≥ 360 ≥ 360 ≥ 360

≥ 24 ≥ 24 ≥ 24 ≥ 24 ≥ 24

DIMENSIONS

Width Span Module

1050 mm 1800 mm 2000 mm

Fix height

Manufacturing Standards

- Aut. Min. n.19647/PR-7/B-9 del 10/03/1978

- Aut. Min. n.23455/OM-4 del 04/02/1998

- Decreto legislativo 9 Aprile 2008 n. 81

- D.M. 02/09/68

- D.M. 23/03/90 n. 115

- Circolari 44/90 e 156 AA.GG./STC.

Instruction manual • Prefabricated frames

14

Tel Dal system T5 - Components

Base plate

mm material cod. daN

48 TR 3030100006 0,92

Adjustable base jack

Half-frame Tel Dal T5

mm material cod. daN

1330x1050 VR 3040104010 14,26

1330x1050 ZC 3040104011 14,30

Spigot pin

mm material cod. daN

330 ZE 3040501062 2,42

1000 ZE 3040501012 4,69

Frame Tel Dal T5

mm material cod. daN

2000x1050 VR 3040104000 18,83

2000x1050 ZC 3040104001 19,00

mm material cod. daN

10 TR 3040701006 0,12

Double guardrail P22

mm material cod. daN

- VR 3040204030 7,42

- ZC 3040204031 8,00

Instruction manual • Prefabricated frames

15

Ledger P11

mm material cod. daN

- VR 3040204020 2,42

- ZC 3040204021 2,76

Vertical-diagonal brace

mm material cod. daN

- VR 3040204000 2,99

- ZC 3040204001 3,06

Side fencing structure

with toeboard T5

mm material cod. daN

- VR 3040206120 12,05

- ZC 3040206121 12,39

Steel plank

with trapdoor

Horizontal-diagonal brace

mm material cod. daN

- VR 3040204050 2,68

- ZC 3040204051 2,60

Aluminium temporary

guardrail frame

mm material cod. daN

1048 AL 3040201919 12,33

1800 AL 3040201879 12,85

mm material cod. daN

1800x500x50 ZZ 3070100011 28,68

Toeboard

mm material cod. daN

1800x500 ZZ 3070100001 18,29

Instruction manual • Prefabricated frames

16

Ladder

Upright TD4

mm

2000 VR 3070300130 6,05

2000 ZC 3070300131 7,35

material

cod. daN

Compensation frame ladder

mm material cod. daN

1330 VR 3070300160 3,96

1330 ZC 3070300161 4,15

Ladder handrail

mm material cod. daN

- VR 3040404020 7,07

- ZC 3040404021 7,42

Reinforcement upright RP12

mm material cod. daN

2000 VR 3040406030 8,26

2000 ZC 3040406031 8,58

mm material cod. daN

- ZC 3070300141 2,78

Top guardrail

upright Tel Dal

mm material cod. daN

- VR 3040404000 7,84

- ZC 3040404001 7,29

Walk-thru frame

mm material cod. daN

- VR 3040104060 32,16

- ZC 3040104061 33,68

Instruction manual • Prefabricated frames

17

Guardrail ledger

for walkthrough passage

with forged

connection device

Vertical-diagonal brace

for walkthrough passage

with forged

connection device

mm material cod. daN

- ZZ 3040204105 4,26

Horizontal-diagonal brace

for walkthrough passage

with forged

connection device

mm material cod. daN

- ZZ 3040204125 5,84

Horizontal-diagonal brace

for walkthrough passage

with cold-pressed

connection device

mm material cod. daN

- ZZ 3040204115 5,03

Lower support Tel Dal

mm material cod. daN

- VR 3040104040 17,70

- ZC 3040104041 18,90

mm material cod. daN

- VR 3040204120 5,44

Instruction manual • Prefabricated frames

18

Upper support Tel Dal

mm material cod. daN

- VR 3040104030 25,32

- ZC 3040104031 26,25

Inside bracket

mm material cod. daN

330 VR 3040304050 4,29

330 ZC 3040304051 4,43

Street protection fan

mm material cod. daN

- VR 3040301050 9,19

- ZC 3040301051 9,65

Bridging ledger

Bracket for non axial piers

mm material cod. daN

1050 VR 3040304060 7,76

1050 ZC 3040304061 7,98

Bracket brace

mm material cod. daN

1050 VR 3040304070 8,63

1050 ZC 3040304071 8,93

mm material cod. daN

3600 VR 3040604000 24,39

3600 ZC 3040604001 25,08

Joists junction

mm material cod. daN

- VR 3040604010 5,60

- ZC 3040604011 5,78

Instruction manual • Prefabricated frames

19

Uniform System - Components

Base plate

mm material cod. daN

48 TR 3030100006 0,92

Adjustable base jack

Half-frame Uniform

mm material cod. daN

1330x1050 VR 3040102010 14,79

Spigot pin

mm material cod. daN

10 TR 3040701006 0,12

Side fencing truss Uniform

mm material cod. daN

330 ZE 3040501062 2,42

1000 ZE 3040501012 4,69

Frame Uniform

mm material cod. daN

2000x1050 VR 3040102000 19,73

mm material cod. daN

- VR 3040402020 8,15

Ledger Uniform

mm material cod. daN

- VR 3040202010 2,27

Instruction manual • Prefabricated frames

20

Vertical and

horizontal-diagonal brace

Uniform

Steel plank

with trapdoor

mm material cod. daN

- VR 3040202000 2,68

Transom Uniform

mm material cod. daN

- VR 3040202030 1,82

Side fencing structure

with toeboard Uniform

mm material cod. daN

- VR 3040202040 8,58

mm

1800x490x50 ZZ 3070100011 28,68

material

cod. daN

Toeboard

mm

1800x200 ZZ 3070200001 5,02

material

cod. daN

Ladder

mm material cod. daN

2000 VR 3070300130 6,05

2000 ZC 3070300131 7,35

Aluminium temporary

guardrail frame

mm

1800 AL 3040201919 12,33

material

cod. daN

Instruction manual • Prefabricated frames

21

Compensation frame ladder

mm material cod. daN

1330 VR 3070300160 3,96

1330 ZC 3070300161 4,15

Top end

double element Uniform

mm material cod. daN

- VR 3040402010 9,00

Ladder handrail

mm material cod. daN

2000 ZC 3070300141 2,78

Top guardrail

upright Uniform

Lower support Uniform

mm material cod. daN

- VR 3040102030 17,10

Upper support Uniform

mm

- VR 3040402000 7,15

material

cod IT daN IT

mm material cod. daN

- VR 3040102020 24,95

Instruction manual • Prefabricated frames

22

Bracket for non axial

piers Realpont/Uniform

mm material cod. daN

1050 VR 3040306000 8,50

1050 ZC 3040306001 8,82

Bridging ledger

mm material cod. daN

3600 VR 3040604000 24,39

3600 ZC 3040604001 25,08

5400 VR 3040601020 50,70

5400 ZC 3040601021 52,32

Bracket brace

mm material cod. daN

1050 VR 3040306010 8,44

1050 ZC 3040306011 8,73

Street protection fan

Bridging ledger junction

mm material cod. daN

1050 VR 3040605010 8,47

1050 ZC 3040605011 8,95

mm material cod. daN

- VR 3040301050 9,19

- ZC 3040301051 9,65

Instruction manual • Prefabricated frames

23

Instruction manual • Prefabricated frames

24

Description

Tube-coupler system

Tube-coupler system - Components 26

Manufacturing standards

- Aut. Min. 15/VI/2702/14.03.01.01 del 12/02/2009

- Est. 15/VI/11535/14.03.01.02 del 24/06/2009

- UNI EN 74, EN 39

- Decreto legislativo 9 Aprile 2008 n. 81

- Disciplinare UNICMI sul marchio SQ

Instruction manual • Prefabricated frames

25

Tube-coupler system - Components

Base plate

mm material cod. daN

48 TR 3030100006 0,92

Adjustable base jack

4-bolts right

angle coupler

mm material cod. daN

- TR 3020300006 1,42

- TR 3020300032 1,35

Simple 4-bolts coupler

mm material cod. daN

355 ZE 3040800902 2,49

1000 ZE 3040501012 4,69

2-bolts right

angle coupler

mm material cod. daN

- TR 3020600006 0,88

mm material cod. daN

- TR 3020200006 1,93

Swivel coupler

mm material cod. daN

- TR 3020400006 1,45

Instruction manual • Prefabricated frames

26

Pivot coupler

Pin

mm material cod. daN

- TR 3020000006 1,73

Simple coupler

mm material cod. daN

- TR 3020500006 0,69

Head coupler

mm material cod. daN

- ZC 3030000001 0,63

Anchoring screw

mm material cod. daN

- - 3030200000 1,68

Steel caster

mm material cod. daN

- TR 3020100006 0,94

Scaffold tube S235JR

mm material cod. daN

- ZZ 3010800035 3,45/ml

mm material cod. daN

- VR 3030300000 10,00

Instruction manual • Prefabricated frames

27

Instruction manual • Prefabricated frames

28

Instructions for use

Pre-erection

Erection

Use

Dismantling

Transport

30

31

33

34

34

Instruction manual • Prefabricated frames

29

Pre-erection

CHECKING THE TECHNICAL DOCUMENTATION

e documentation described in the following sections must be available on the work site at all times.

Some of the documentation will be provided by the scaffolding manufacturer and some by the authorized technician from the Company

making use of the scaffolding.

Project

Full details of the scaffolding must be given and detailed erection

designs must be attached containing construction details-where

applicable-detailing:

• anchorages

• structural nodes

• load distribution at the base

• specific information regarding the correct erection of the scaffolding

in question

e project must respect the regulations of the countries where the

scaffolding is to be erected. For non-standard configurations or configurations higher than 20 m, it is suggested that a project signed and

stamped by the authorized technician be drawn up.

Technical Report

e report must contain all static verifications that fall outside those

described in the Ministerial Authorizations or standard designs.

It must be signed and stamped by an authorized technician.

Instruction manual and Anchorage manual

ese are documents provided by the manufacturer to ensure correct

use of its products.

CHECKING THE MATERIAL TO BE USED

Clothing

Working attire - overalls, gloves, shoes and all clothing must bear the

CE mark and comply with EN 510 Cat.II. Standards.

Other provisions

A room or location should be set aside on the work site for first aid in

the event of accidents. A first-aid kit must also always be on hand for

immediate, preliminary assistance with injuries.

Material suitability

It is good practice on the work site to arrange for all parts of the scaffolding to be periodically examined to ensure that all is in working

order.

For rented equipment, it is especially important that the end user

company and the manufacturer of the rented equipment draw up a

monitoring plan, paying particular attention to the following:

• Checking the verticality of the uprights. Inclines greater than the

manufacturer’s declared dimensional tolerance are not acceptable.

• Checking the welding on prefabricated frames. Should a visual check

raise concerns about the condition of a frame, use Magni ux or other

similar penetrant liquid methods and/or discard the frame.

• Checking that the pawls and bushings for diagonal and transom

couplings are working properly. Avoid using deformed and/or rebuilt

elements.

• Checking the painted or galvanized surface protection. To ensure prolonged durability over time and depending on the location where being

used, check all elements carefully to ensure there is no oxidation.

• Checking that the coupling grips (6 daNm) are tight, also checking the

condition of the threads of the bolts being used.

All nuts must always screw and unscrew perfectly.

e quality and quantity of all materials that are to be used must be

carefully checked prior to use on site as described below.

Correspondence between materials used and those

that have been authorized

e materials listed on the specifications and those that are on the

work site must be checked to ensure they match. Using parts from

scaffoldings made by other manufacturers is not allowed.

Mixed use of couplings/tubes that integrate with the scaffolding

system is permitted. Each part of the scaffolding can be mounted

separately from an adjoining part within a single system and joined to

non-structural tubes/couplings.

Personal safety

All personal safety devices required by law must be available on the

work site and utilized by the workers. ese devices are:

Safety belts

ese must meet European regulation requirements, bear the CE marking and must have passed the prescribed technical testing.

• Check that the metal ledger boards clamp together properly by making use of the device located on the planks for the purpose.

• Checking the straightness of the couplings used. Plastic deformations

of any of the element that comprises the system are not acceptable.

A compulsory check of the scaffolding soundness must be carried out

a er each major climatic event. is can also include materials that have

not yet been erected.

Storage on the work site

An area on the work site should be set aside for storing the scaffolding

material to facilitate movement and organize the loading and unloading of material in the best manner possible, thereby reducing operational costs and the risks of accidents that are a common occurrence in

disorganized environments.

For tall buildings, partial storage of quota material is advisable by

making use of loading areas duly set up that can then be used even

a er the scaffolding has been erected, thereby facilitating work on

site. Materials should be stored in appropriate containers and storage

chests. It is essential that a covered area also be made available (shed

or alter- native) to bench-mount joints, or where checks can be carried

out on materials.

Instruction manual • Prefabricated frames

30

Erection

During the erection stage, the mounting designs and the prescriptions

issued by the Site Engineer must be scrupulously followed. As regards

the stages of scaffolding erection, adhere to local regulations.

e main areas on which to focus attention during the erection stages

follow.

STARTING POINT OF THE SCAFFOLDING

e elements described below must be carefully verified and checked.

Scaffolding bases

An outline of the scaffolding corresponding to the erection plan must

be marked off.

e maximum distance from the building (20 m) must be respected

and checked.

Should this not be possible, with the approval of the project designer or

Works Director, add approach planks to the façade or guardrails even

on the inner side.

Face

Before laying the bases, a suitable face must be prepared of coarse gravel

and/or lean concrete if there are to be heavy loads at the foot, or, more

generally, wooden approach planks must be laid out continuously, lengthways along the façade.

Controls at the foot of the scaffolding

It is good practice to at least carry out the following checks at the foot

of the scaffolding:

• Avoid placing more than 2 planks under the base.

• Always rivet the base plates to the planks.

• Check the screwing out of the base plates. Screwing out to a maximum

of 20 cm is recommended. Greater screwing out is permitted as long as

speci c technical veri cations have been carried out or additional cross

bracings are added at the base of the sca olding.

• Check that the faces are level and that they are centered in relation to

the bases.

• Check the correct distribution of loads at the foot of the sca olding,

verifying the consistency, e ciency and proper placement of the distribution elements placed under the base plates (wooden planks, metal plates,

concrete screw nuts, etc.).

• Check the correspondence between the start of the sca olding uprights

in use against those in the erection design and especially the designs

found in the system Ministerial Authorization Booklet. Should they not

correspond, the technical documentation must be modi ed by modifying

the project or, if necessary, modifying the erection depending on choices

made for the project.

SCAFFOLDING STRUCTURE

It is important that periodic checks be scheduled for the following:

Verticality of the uprights

e verticality of the uprights must be checked periodically. Inclines

Instruction manual • Prefabricated frames

31

other than those foreseen in the dimensional allowance designs of the

system’s elements are not permitted.

In the event that uprights are not parallel to a plumb line, they must be

dismantled and erected again, if possible, or alternatively appropriate

static verifications must be carried out that will guarantee that the

specific scaffolding is suitable to fulfill the requirement for which it

was initially intended.

Should dismantling and re-erection of the scaffolding not be possible,

joints can be used to add a parallel reinforcing upright to the existing

scaffolding.

Anchorages

Anchorages must be positioned every 22 square meters of scaffolding

façade or, in special cases, in the number and in the positions shown in

the erection plan. e type of anchorages, their functioning, the static

verifications and the checks to be carried out are information that

must be provided together with the technical documentation.

Access ladders

e rungs of the scaffolding ladders must conform to the requirements

of the EN12811 standards, moreover the following must be checked:

• e type of ladder must conform to regulation requirements and with

what is described in the manufacturer’s manual.

• A protective guardrail must always be installed.

• e ladders must be self-blocking and tted with anti-slip feet.

Wood planks

Wood planks must always conform with what is shown in the design

plan and, in particular, the following points must be carefully checked:

• e planks must be free of traversing knots and in any event, the reduction of the reagent section areas must not be more than 10%.

• Declared minimum thicknesses must always be respected.

• Planks with overlaps (corners or changes of direction)must be appropriately riveted, above all in sca oldings where wooden joists are

carrying the sca old (for example on loading mounts).

Connections

As a minimum, the following must be checked:

• Plugs: Plugs must be present and properly inserted in all the joints in

the frame and loose uprights, and in all the items listed in the manufacturers’ manual.

• Gudgeon pins: Plugs must be present and properly inserted in longitudinal tube joints when using the tube-coupler system.

• truss beams

• hoisting connections

• anchorages

e checks must be carried out periodically, even while the scaffolding is in use, at intervals to be determined according to the use being

made, but not longer than 2 months.

In any case, a check must be carried out following a major climatic

event.

Metal ledger boards

e correct erection of the metal ledger boards must be checked, as

must their detachment prevention locks, using a suitable device (a

triangular rod or wedge).

Loading mounts

In cases where loading mounts with wooden scaffolding are used, the

following must be checked:

• Adherence of the trusses to the project speci cations regarding dimen-

sions, number and position.

• In any case, position the trusses close to the structural nodes.

• Check the correct thickness and positioning of the wooden planks.

• Check that the planks are riveted to the trusses.

• Check that the work loads are compatible with those speci ed in the

project.

Service lifts to the scaffolding

When li s are installed, the proper positioning of the anchorage must

be checked and above all that such anchorages are completely separate

from those of the scaffolding.

If this is not possible, the special anchorages to be used must be

covered by a report on the calculations, and by a specific erection plan

showing the loads to be borne.

Protective sheets

In cases where protective sheets are used the following must first be

ascertained:

• Determine the sheet permeability to wind; the information should be

provided by the manufacturer; if it is not, ascertain wind permeability

experimentally, empirically or theoretically.

• Verify that the permeability coincides with that indicated in the calculation report. Should it not, adjust veri cations to the new loads and, if

necessary, integrate the sca olding and anchorage structures.

• Wedge couplings: in multi-level systems in which wedge coupling connections are used, the correct insertion of the wedge into the node plate

must be veri ed before proceeding with the erection of the next piece

Grip of the joints

It is imperative that the correct grip of the joints (6 daNm) be checked

with a torque wrench of all the structures or parts of particularly

important structures:

• projecting parts

• In such event, pay particular attention to check that the erection and

functioning of the anchorages correspond with the designs and veri cations detailed in the designs.

Instruction manual • Prefabricated frames

32

Use

Winches and Pulleys

When winches or pulleys – even temporary – are used, the parts of the

scaffolding affected by such equipment must be checked.

ee checks must be shown on the calculation report if the equipment

is also to be used during work execution.

e carrying capacity of the winch or pulley must always be visible and

adjustable. In the absence of specific information in this regard, the

following formula may be used to determine the dynamic increment of

the vertical load in suspension for carrying out correct static checks:

ϕ = coefficiente di incremento dinamico

V = velocità del carico in movimento espresso in m/sec

ϕ = 1 + 0,6 x V

PERSONNEL SAFETY DURING INTERMEDIATE ERECTION

STAGES

In addition to the prescriptions stipulated by local regulations, the main

areas on which to focus attention are described below.

Scaffolding workers

scaffolding safety plan must have the names and specific responsibilities of the persons involved in organizing the work and erecting the

scaffolding.

Holding and auxiliary cables

Check the correct positioning and use of the holding and auxiliary

cables as prescribed by the regulations in force and check in detail the

stipulations regarding their length and strength.

Use of personal safety devices

e correct use and efficiency of safety clothing having the characteristics

already described in the ‘Personnel safety’ section must be checked periodically. e period is determined in relation to the duration of the work and

of the personnel present on the work site.

Hoisting of materials

is is a dangerous phase of the works during which the following

precautions must be taken:

Overlapping of personnel

Organize the erection teams in such a way that they are never positioned one above the other on the same part of the scaffolding.

While works are underway the scaffolding may undergo structural

modifications due to the particular requirements of the work site not

take into account during the planning stage.

It is important that the scaffolding be checked continually and that, as

a minimum, the following are verified.

Overloads

In the event the end user requests unusual overloads, notices indicating

the load capacity must be positioned on the scaffolding and checks that

the assembled structure corresponds to the project design and the calculation report must be carried out.

Passive security elements

Periodically checks must be carried out to ensure that passive security

devices have not been removed from the scaffolding; these include:

• overhead and frontal guardrails

• frontal and overhead toeboards

Planks with trapdoors must be shut if not in use.

e anchorages must never be removed unless such is called for under

the work program and in the erection plan of the scaffolding.

Machinery present on the scaffolding

Unless otherwise prescribed, boring machinery, vibrators, compressors

and whatever else could affect the stability of the scaffolding must not be

used.

In the event the job calls for such type of machinery, check that the

dynamic increase of the load has been taken into account in the calculation report.

Earthing

e presence and the type of earthing present on the scaffolding must

be calculated in accordance with the regulations in effect.

In the same way the documentation relating to the machinery on the

scaffolding must always be checked and brought up to date.

• Check the load capacity, the type and the correct functioning of the

winch and the pulley. Also check the ‘Winches and Pulleys’ section regarding technical veri cations.

• Organize the work in such a way that there are never loads suspended

above the heads of workers mounting the equipment.

• Check that the bay on which the raised material is to be stacked is suitable for carrying the weight. Check the technical speci cations and the

calculation report to ascertain the projected technical capacities.

Instruction manual • Prefabricated frames

33

Dismantling Transport

During dismantling, as during the erection stage, all precautions required by the regulations in force relating to safety equipment must be

taken.

At the very least, the following areas must be checked.

Removal of passive safety devices

• When dismantling the sca olding oor by oor, check that in the transitory stage, and a er the removal of the protective guardrails, no workers

are present on that oor or at least that they are adequately protected

with safety belts, holding and auxiliary cables on rigid parts of the struc

ture such as done during the erection stage.

• During partial dismantling of the following piers, check that guardrails

and the head toeboards are always reassembled.

• e movement of material disassembled from the sca olding must always be organized in a closed and safe manner. Storage of materials on

the sca olding must be avoided at all times.

Anchorages

• Floor anchorages must only be disassembled a er having dismantled

the overhead structure.

• Always check that at all times - including the dismantling stage of the

sca olding - that no portions are higher than 4 m above the level of the

last anchorage.

Transport must be organized in detail analogous to the preceding phases

and, as a minimum, paying particular attention the areas described

belo w.

Supply

Transport must be staggered so that only the materials that are strictly

necessary during the erection stage are on hand, thereby avoiding excessive stock piles within the worksite.

Check the size, the holding capacity of the delivery area as well as the

rate at which the scaffolding is being erected (see ‘Storage on the work

-

site’).

Materials

Check the correspondence between the projected supply quantity, the

materials present on the worksite and those listed on the travel documents.

Returned materials

Returned material must be organized in containers by planks, frames

and accessories so that the best use is made of available space and the

number of journeys is kept to minimal.

• Where there are projecting parts, the anchorages and the parts of the

structure subject to pull must be dismantled working on the bay below.

Storage

Set aside and display items which have been damaged or deformed.

On the ground, in an area of the work site that has been set aside (see

‘Storage on the work site’), set aside all dismantled materials, organized

by categories, tying them in bundles or putting them in their packaging

to facilitate loading and transport.

Instruction manual • Prefabricated frames

34

Anchorages

General characteristics

Tie anchorage

Ring anchorage

Screw-down anchorage

Bracing anchorage

Truss beam in tube-coupler anchorages

Anchorage with reinforced rod for reinforced concrete

Anchorage with steel structural plate

36

37

39

41

41

43

45

46

Instruction manual • Prefabricated frames

35

General characteristics

JOINT CREEP STRENGTH

During static checks, creep strength must be considered and determined

through crimp tests in officially and legally recognized laboratories:

• Right-angle couplers with 4 bolts

average resistance: Rm = 1915 daN

resistance at 5% fractile: R

= 1756 daN

5

permissible resistance: R = 1756/1,5 = 1170 daN

• 4-bolt right-angle coupler with holding joint

average resistance: Rm = 2855 daN

resistance at 5% fractile: R

= 2717 daN

5

permissible resistance: R = 2717/1,5 = 1811 daN

CHARACTERISTICS OF THE MATERIALS USED

Materials having the geometrical and mechanical characteristics listed

below are to be used:

SPLIT RINGS

e extraction strength of the split rings must be provided by the manufacturer and in any case it is a good rule to apply a safety factor of ϒ=1,5.

Ring properties to be requested from the manufacturer:

A

= area of the leg of the ring on the wedge insert

t

W

= resistance module corresponding to area A

t

σ = 1600 daN/cm² unless otherwise specified by the manufacturer

H= permissible resistance to the extraction of the ring using a safety

factor of x 1.5 on the completed withdrawal value supplied by the manufacturer.

Tube Ø 48.3 x 3.2 in S235JRH steel

A = 4,59 cm²

J = 11,69 cm²

W = 4,85 cm³

i = 1,59 cm

σ 1 = 1600 daN/cm²

σ 2 = 1800 daN/cm²

LOADS

Load bearings are determined orthogonally and longitudinally on the

scaffolding façade and those acting on the single anchorages in accordance with the regulations in force and the project calculation designs.

Determine:

F

= orthogonal load acting on the scaffolding façade and on the single

1

anchorage

F

= longitudinal load acting on the façade of the scaffolding and on the

2

whole scaffolding

Instruction manual • Prefabricated frames

36

Tie anchorage

ERECTION PLAN

Effected according to the following layouts:

A

C

metal

decking

metal decking

scaffolding frame

scaffolding frame

B

metal

decking

scaffolding frame

Instruction manual • Prefabricated frames

37

Tie anchorage

CHECKING THE ANCHORAGE SUBJECT TO AN F1 LOAD

Checks to be carried out are the following:

• joint creep check:

F

< R

1

• tensile strength check of the anchorage tube:

F

1

σ = _____ < σ1

A

• compression strength check of the anchorage tube

L = the free length of the anchorage tube

L

λ = _____

i

e value of ω in relation to λ is determined according to regulations in

force.

• instability check

WARNINGS

When using tie anchorages, it is recommended to carry out the following:

• check the correct hold of the anchorage joints to ensure creep resistance;

• connect the anchorage tubes in line with the structural nodes of the

scaffolding;

• insert wooden planks as load distributors between the tie anchorage

tube side/edge and the structure of the building being worked on to

avoid contact stress peaks (Hertzian pressure), which could otherwise be

damaging to the structure.

F

1

σ = ω _____ < σ1

A

Should the instability check not pass the test, the anchorage tube must

be sectioned making use of tube-couplers or the anchorage tube must be

doubled.

CHECKING THE ANCHORAGE SUBJECT TO AN F2 LOAD

e whole scaffolding’s F2 load can be absorbed by a number of C type

anchorages strategically distributed on the scaffolding façade, but preferably, barring any obstacles, along the scaffolding outer piers.

Placing n the number of C type anchorages on the scaffolding, the acting

load on each will be: F*= F

/n.

2

Load acting on a single anchorage tube with an inclination of α:

F*/2

Fd = _____

cos α

L= the free length of the anchorage tube

L

λ = _____ from which is determined ω

i

F

d

σ = ω _____ < σ1

A

Instruction manual • Prefabricated frames

38

Ring anchorage

ERECTION PLAN

Effected according to the following layouts

A

C

metal decking

metal decking

ring

scaffolding frame

scaffolding frame

B

D

metal decking

metal decking

scaffolding frame

ring

scaffolding frame

ring

Instruction manual • Prefabricated frames

39

Ring anchorage

CHECKING THE ANCHORAGE SUBJECT TO AN F1 LOAD

e checks to be carried out are the following:

• joint creep check:

F

< R

1

• tensile strength check of the anchorage tube:

F

1

σ = _____ < σ*

A

• tensile buckling of the anchor check:

consider a pull eccentricity on the anchor e=4 cm for A type anchorages.

Stress acting on the anchor:

Tensile stress: F

Bending moment: M1=F

1

x e

1

Verify:

F

1

M

1

σ = _____ + _____ < σ*

A

Wt

t

CHECKING THE ANCHORAGE SUBJECT TO AN F2 LOAD

F2 loads as calculated in the ‘Loads’ section is divided on n number of C

or D type anchorages.

Load acting on an individual anchorage:

F*= F

/n.

2

Load acting on single anchorage tube having an inclination of α:

F*/2

Fd = _____

cos α

• checking the anchorage tube:

L= the free length of the anchorage tube

L

λ = _____ from which is determined ω

i

F

d

σ = ω _____ < σ1

A

• tensile buckling check of the anchor:

• tensile stress check of the anchor

For symmetric type B anchorages, stress will be that of simple traction

only:

F

1

σ = _____ < σ*

A

t

• extraction check of the anchor

RE= resistance to extraction as provided by the manufacturer of the

anchors.

R

E

H = _____ permissible resistance to extraction

1,5

Verify:

F

< H

1

Tensile stress: F

Bending moment: M = F

d

x e

d

Verify:

F

d

M

1

σ = _____ + _____ < σ*

A

F

t

d

WARNINGS

For ring anchors the following verifications are recommended:

• check the type and consistency of the wall and, according to the acting

load, choose the most suitable type of anchor as supplied by the manufacturer.

• reduce the ‘e’ eccentricity of the joint between the anchorage tube and

the anchor to the minimum possible.

• check the correct hold of the joints.

• check the correct placing and working of the mounted anchors. In

special cases, it is advised that extraction tests are carried out so that

reliable values can be obtained of the actual resistance to extraction.

Instruction manual • Prefabricated frames

40

Anchorage with force screw Ancoraggio a sbadacchio

ERECTION PLAN

Effected according to the following layout

metal

decking

scaffolding frame

ERECTION PLAN

A monolateral constraint, resistant only to erected compression as laid

out in the following diagrams.

metal

decking

scaffolding frame

In special cases, when other types of anchorages are not permitted, force

screws can be used, provided their working is checked and monitored

while in use.

e risk in using these types of anchorages lies in the difficulty of determining the resistance that such anchorages can guarantee.

e resistance of the anchorage is in proportion to the force that the

screw is able to ensure and to the friction coefficient lying between the

wall and the force plate.

To correctly define the load of force, load cells placed the bases may

be used. However, such a solution is costly and only justifiable for very

particular types of work.

An alternative solution consists of determining whilst work is in progress the actual resistance RR on a trial anchorage and using a calculation of permissible resistance: R

=RR/2.

c

WARNINGS

It is recommended to connect the anchorage tube as near as possible to

the force screw or at the extremity of the tube in order to avoid bending

the tube itself.

LOADS

e bracing anchorage may only take orthogonal compression loads

on the façade. e F

load acting on each orthogonal anchorage on the

1

scaffolding façade is determined in accordance with the calculations

detailed in the project and the regulations in force. e F

load can be

1

made up of two addends:

F

= F1a + F

1

1b

F1a= compression component on the anchorage caused by orthogonal

wind pressure on the scaffolding façade

F

= compression component on the anchorage arising from the structu-

1b

ral geometry. For example, the horizontal component of the load carried

by the brace of the jutty, shown in ‘Erection plan - Bracing anchorage”.

CHECKING THE ANCHORAGE SUBJECT TO AN F1 LOAD

e checks to be carried out are the following:

• joint creep check:

F

< R

1

• compressive strength check of the anchorage tube:

L = free length of the anchorage tube

L

Instruction manual • Prefabricated frames

41

Bracing anchorage

λ = _____ from which ω is derived from the tables of existing

standards and regulations.

i

Checking instability

F

1

σ = ω x _____ < σ1

A

• compressive strength check of the regulating screw

Limit the screwing out of the screw within a maximum of 15 ÷ 20 cm in

order to omit factors of instability and only carry out resistance checks.

F

1

σ = ω x _____ < σ1

A

• check the wooden planks distributors

Place a wooden plank underneath the base of the regulating screw to act

as a load distributor

S = 5 cm plank thickness

AL = 400 cm² 20 x 20 cm plank

σL = 60 daN/cm² permissible stress on the wooden plank

Resistance check:

F

σ = _____ < σ

1

L

Al

WARNINGS

For bracing anchorages, it is recommended to carry out the following:

• check the correct positioning, the quality and the efficiency of the

wooden planks under the base acting as the load distributors

• limit the screwing out of the regulating screw to never exceed 20 cm

• check the proper dismantling of the joints so as to guarantee creep

resistance.

Instruction manual • Prefabricated frames

42

Truss beam in tube-coupler

anchorage

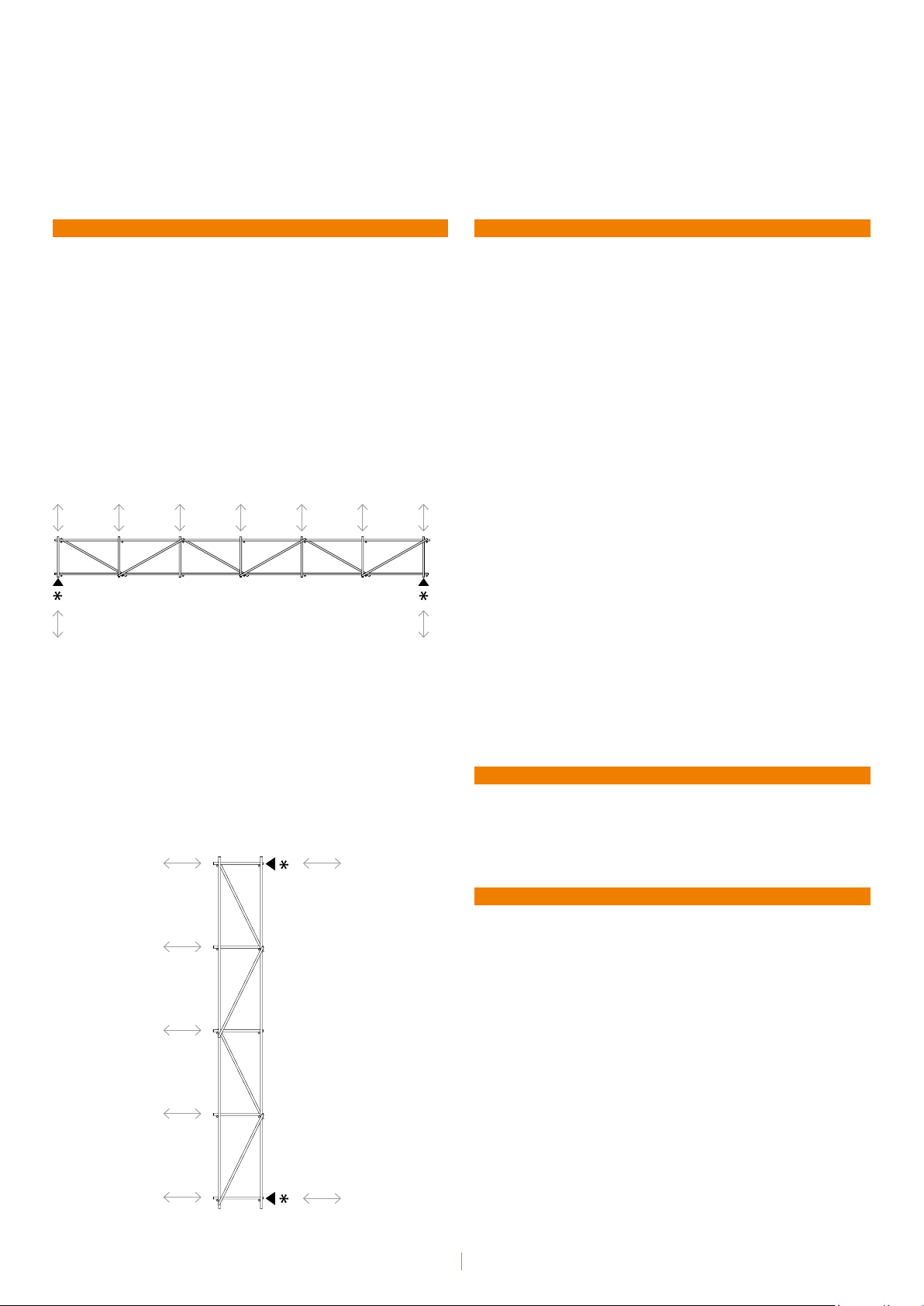

ERECTION PLAN OF HORIZONTAL BEAMS

For buildings under construction with framed structures in reinforced

concrete or steel, or for building maintenance with large areas of glass,

it is not possible to distribute the anchorages uniformly on the façade

of the scaffolding. In such cases, truss beams in tube-couplers can be

used laid out horizontally or vertically on the inside of the scaffolding

framework in such a way as to disperse the wind pressure on to the

anchorages at the end of the truss beams only.

ERECTION PLAN OF VERTICAL BEAMS

Truss beams can be erected on every bay or on alternate bays to act as

loads.

Truss beams can be mounted on alternating piers or on all the piers to

act as loads, and especially depending on whether or not metal ledger

boards are present on each bay acting as braces and, therefore, as horizontal load distributors.

Typical anchorage Typical anchorage

Instruction manual • Prefabricated frames

43

Truss beam in tube-coupler

anchorage

LOADS

e wind pressure (Pw) is calculated according to the regulations and

standards in force and the project diagrams applicable to the scaffolding

surface exposed to the wind. e nodal load acting on the truss beam

anchorages must be calculated.

• horizontal truss beam

For example for diagram No. 1 in the ‘Truss beam in tube-coupler an

chorage’ section, there must be 2 modules on every node.

e result is the following:

Q

x 2S

o=Pw

w

A static layout of horizontal truss beam anchorages:

Q

R

0

0

Q

0

Q

0

Q

0

Q

0

Q

0

Q

R

• vertical truss beam

For example, in design no. 2 in the “Truss beam in tube-coupler ancho

rage’ section, there must be 2 modules on every node. e result is the

following:

CHECKING THE TRUSS BEAMS

Having defined the acting loads and the static diagrams as explained in

the previous section, proceed with defining the truss beams using the

Ritter method or models utilizing finished elements or whatever other

methods are available for the purpose of obtaining the maximum stress

loads:

Tmax = maximum shear action

Mmax = maximum bending moment

• horizontal anchorage beam

Use tubes of ∅ 48.3 x 3.2 steel 235JRH for constructing the beams

described in the previous sections.

Both the transoms and the diagonals of the beans are added to the scaf

folding structure and immediately laid underneath the metallic decking

which forms the work bays.

Such beam elements will therefore only be subject to loads arising from

0

the results of the preceding sections.

erefore resistance and instability checks are carried out on the tran

soms and diagonals most subject to stress.

• vertical anchorage beams

e diagonals are made of tubes ∅ 48.3 x 3.2 in S235JRH steel coupled

0

to the transoms with swivel joints, while the beam transoms take advan

tage of the scaffolding uprights.

e resistance and instability checks of the scaffolding uprights must

therefore take into account both the vertical loads of traditional scaffol

ding on the uprights and the loads consequent to the bending moment

acting on the vertical truss beam.

-

-

-

-

Q

x 2S

v=Pw

w

Static diagram of the anchoring vertical truss beam

Q

Q

Q

Q

Q

v

v

v

v

v

R

R

ANCHORAGES OF THE EXTREMTIES

Every truss beam must be anchored to the part it is serving.

Refer to the anchorage types already described and see previous section

for the checks that have to be carried out.

v

WARNINGS

It is recommended to check the following:

• check the tightening torque of the joints

• check for the presence of metal ledger boards on bays which act as

horizontal load dividers

• depending on the type of anchorages placed on the end of the truss

beams, see the applicable warnings that apply to each under ‘Warnings’.

v

Instruction manual • Prefabricated frames

44

Anchorage with reinforced rod

for reinforced concrete

ERECTION PLAN

reinforcing rod sunk in

the casting

reinforced concrete wall

metal

decking

scaffolding

frame

CHECKING THE ANCHORAGE SUBJECT TO AN F1 LOAD

e checks to be carried out are the following:

• joint creep check:

F

< R

1

• tensile strength check of the anchorage tube

F

1

σ = _____ < σ1

A

• reinforcing rod check

e type of concrete and its characteristic Rbk resistance should be

considered;

in the absence of such information, assume Rbk= 250 daN/cm²

Based on the Rbk, the regulations in force provide the value of the resi

stance to adhesion of the reinforcing rod (τco).

e resistance to adherence of the rod in the concrete (RA):

∅ = reinforcing rod diameter

L’ = length of each of the 2 sections of reinforcing rods present within

the concrete casting

τco = concrete adherence resistance

-

CHARACTERISTICS OF THE MATERIALS USED

Materials having the geometrical and mechanical characteristics listed

below are to be used:

Tub e ∅ 48.3 x 3.2 in S235JRH steel

A = 4,59 cm²

J = 11,69 cm²

W = 4,85 cm³

i = 1,59 cm

σ 1 = 1600 daN/cm²

σ 2 = 1800 daN/cm²

Ton d e ∅ 8 FEB44K steel reinforcing rod for reinforced concrete

σ A = 2.600 daN/cm²

σ A = 0,5 daN/cm²

LOADS

e type of anchorage is only capable of supporting orthogonal loads

to the facade. For loads parallel to the façade, other types of anchorages

must be used as described above.

F1 load are determined in accordance with the regulations in force and

the calculation designs of the project.

RA = (∅ x π x L’ x 2) x τ

• adherence of the rod in the concrete check

F

< R

A

1

• strength check of the reinforcing rod

F

σ = _____ < σ

1

A

2 x AA

WARNINGS

e following is recommended:

• check the correct positioning of the rod in the concrete and the techni

cal/geometric properties (Φ ; AA)

• check the correct hold of the joints.

-

Instruction manual • Prefabricated frames

45

Anchorage

with structural steel plates

ERECTION PLAN

In the event of there being a particular geometry to the scaffolding

(suspended bearing) and/or particularly high loads, a steel plate joined

to the wall with mechanical anchors can be used.

metal

decking

scaffolding

plate detail

In general and in particular for the layout shown in ‘Anchorage with

structural steel plate’, the vertical load applied by the scaffolding uprights

must be added to the wind element.

CHECKING THE ANCHORAGE PLATE

With reference to the erection diagram and the ‘Anchorage with structural steel plate’ loads, carry out resistance checks on the plates acting as

loads:

• upper plate:

T = N

i

N = Ni x e

resistance check

M

σ = _____ < σ1

Wp

T

τ = _____ < π1

Ap

σ id = √ σ² + 3 π² < σ1

• lower plate

T = N

e

N = H M = Ne x e

CHARACTERISTICS OF THE MATERIALS USED

Materials having the geometrical and mechanical characteristics listed

below are to be used:

Tub e ∅ 48.3 x 3.2 in S235JRH steel

A = 4,59 cm²

J = 11,69 cm²

W = 4,85 cm³

i = 1,59 cm

σ 1 = 1600 daN/cm²

σ 2 = 1800 daN/cm²

Anchorage with structural steel plate; S235JR steel

Should ribbing be found, the geometric/mechanical properties to be

taken into consideration are:

AP = reagent area of the ribbing section

WP = resistant module of the ribbing section

σ 1 = 1600 daN/cm²

σ 2 = 1800 daN/cm²

LOADS

e acting load on the anchor plate is transmitted by the ledger or by the

upright that is directly attached to it.

verification of the anchors

N

M

σ = _____ + _____ < σ1

A

W

p

p

T

τ = _____ < π1

Ap

σ id = √ σ² + 3 π² < σ1

• verification of the anchors

e loads acting on the single anchors are:

T

Tb = _____ shear on the single anchor

2

M

Nb = _____ shear on the single anchor

d

e Tb and Nb values must be compared with the bearing capacities of

each anchor as supplied by the maker, reduced by the safety coefficient

2.2.

Instruction manual • Prefabricated frames

46

Erection sequence

Instruction manual • Prefabricated frames

47

Connection

elements

m

e

t

s

y

s

t

n

o

P

l

a

e

R

-

s

g

n

i

t

t

g

n

i

h

s

u

B

5

T

m

e

t

s

y

s

l

a

D

l

e

T

-

s

g

n

i

t

t

l

w

a

P

m

e

t

s

y

s

m

r

o

f

i

n

U

-

s

g

n

i

t

t

l

w

a

P

a

D

l

e

T

-

s

g

n

i

t

t

l

w

a

P

m

e

t

s

y

s

H

l

Instruction manual • Prefabricated frames

48

Erection sequence

1 • positioning the base

2 • positioning the frames

4 • inserting the ledger

5 • erection second frame with guardrail

3 • leveling the base

6 • erecting the second ledger

Instruction manual • Prefabricated frames

49

Erection sequence

7 • erecting the vertical-diagonal brace

8 • checking the level

10 • checking the level

11 • erecting the next modules

9 • checking the distance from the facade

12 • erecting the next modules

Instruction manual • Prefabricated frames

50

Erection sequence

13 • erecting the next modules

14 • inserting the anchorage

16 • erecting metal ledger boards

17 • erecting metal ledger boards

15 • inserting the anchorage

18 • erecting plank with trapdoor

Instruction manual • Prefabricated frames

51

Erection sequence

19 • erecting plank with trapdoor

20 • ladder of the plank with trapdoor

22 • first level

23 • passage to the upper level

21 • inserting the ladder of the plank with trapdoor

24 • attaching the holding cable before mounting the bay

Instruction manual • Prefabricated frames

52

Erection sequence

25 • closing the trapdoor

26 • start of frame erection of level 1

28 • erecting level 1 frame

29 • erecting frame pins

27 • erecting level 1 frame

30 • erecting the level 1 ledger

Instruction manual • Prefabricated frames

53

Erection sequence

31 • erecting 1st level guardrail 32 • erecting the level 1 vertical-diagonal brace

t

n

o

P

l

a

e

R

-

e

r

u

t

c

u

r

t

s

l

i

a

r

d

r

a

u

g

l

a

c

i

p

y

t

m

r

o

f

i

n

U

-

e

r

u

t

c

u

r

t

s

l

i

a

r

d

r

a

u

g

l

a

c

i

p

y

t

u

r

t

s

l

i

a

r

d

r

a

u

g

l

a

c

i

p

y

t

u

r

t

s

l

i

a

r

d

r

a

u

g

l

a

c

i

p

y

t

e

T

-

e

r

u

t

c

e

T

-

e

r

u

t

c

5

T

l

a

D

l

H

l

a

D

l

Instruction manual • Prefabricated frames

54

Erection sequence

33 • erecting the next level 1 modules

34 • erecting the level 1 rear ledger

36 • level 1 toeboard detail

37 • level 1 toeboard detail

35 • erecting the level 1 toeboard

38 • erecting the level 1 toeboard

Instruction manual • Prefabricated frames

55

Erection sequence

39 • erecting 1st level side fencing

40 • erecting 1st level side fencing

42 • erecting the level 2 planks

43 • erecting the level 2 planks

41 • erecting an anchorage on level where needed

44 • erecting the level 2 planks with trapdoor

Instruction manual • Prefabricated frames

56

Erection sequence

45 • erecting the level 2 planks with trapdoor

46 • erecting planks on all level 2 modules

48 • erecting top upright joint on level 2

49 • passage to the level 2

47 • erecting top upright on level 2

50 • erecting transoms and guardrails on level 2

Instruction manual • Prefabricated frames

57

Erection sequence

51 • erecting 2nd level side fencing

52 • erecting street protection guard

54 • street protection guard detail

55 • erecting street protection guard planks

53 • street protection guard detail

56 • erecting street protection guard planks

Instruction manual • Prefabricated frames

58

Erection sequence

57 • street protection guard planks detail

58 • erecting bracket brace

60 • erection of the plank with bracket brace

61 • erecting the planks on the brackets

59 • erecting plank bracket brace

62 • erecting the planks on the brackets

Instruction manual • Prefabricated frames

59

Erection sequence

63 • erecting the connections of the pedestrian walk-through frame

64 • erecting the planks on the pedestrian walk-through frame

66 • erecting carriage beam connecting beams

67 • erecting decking on the carriage beam

65 • erecting carriage beams

68 • erecting frames and transoms above the carriage beams

Instruction manual • Prefabricated frames

60

Erection sequence

69 • erecting the vertical-diagonal brace above the carriage beams

70 • end of erection above the carriage beams

Instruction manual • Prefabricated frames

61

Instruction manual • Prefabricated frames

62

Certifications

Instruction manual • Prefabricated frames

63

Tube-coupler system

CNAS - MCC

Test report

no. 2009-52558

ICECON

Certificat

de conformitate

nr. 0835/2017

IGQ

Certificati di prodotto

P021A

Ponteggio metallico fisso

a tubi e giunti

Steel tube scaffold

couplers

China

Technischen

Universität München

Prüfbescheinigung

gemäß DIN EN 74

Rohr-KupplungsSystem 9466

Schele de fațadă,

din oțel T/C

Romania

Italy

Prefabricated frames:

Realpont 75 system

Germany

CNAS - MCC

Test reports no. TC-JG1Q-2009-09 ; 15; 16; 17; 18.

Frame Realpont 75

Horizontal diagonals

Bracket, Bridging ledger

China

Instruction manual • Prefabricated frames

64

ICECON

Certificat de conformitate

nr. 0834/2017

IGQ

Certificato

di prodotto P021I

Schele de fațadă,

din oțel RP 75

Romania

Prefabricated frames:

Realpont 105/EU92 system

Realpont 75 a telai

prefabbricati

Italy

CNAS - MCC

Test reports no. TC-JG1Q-2009-08; 15; 16; 17; 18.

Frame Realpont 105

Horizontal diagonals

Bracket, Bridging ledger

ICECON

Certificat de conformitate

nr. 0834/2017

Schele de fațadă,

din oțel RP 105

China

IGQ

Certificati di prodotto

P021H, P021L

Realpont 105/EU92

a telai prefabbricati

Germany

Romania

Instruction manual • Prefabricated frames

65

Prefabricated frames:

Tel Dal T5/Uniform system

ICECON

Certificat de conformitate

nr. 459/2007

IGQ

Certificati di prodotto P021D

ICECON

Certificat de conformitate

nr. 0836.1/2017

Schele de fațadă,

din oțel Uniform

Schele de fațadă,

din oțel T5

Romania

IGQ

Certificati

di prodotto P021F

Uniform a telai

prefabbricati

Tel Dal 3, Tel Dal 5 bis,

Tel Dal 5 ter

Italy

Romania

Prefabricated frames:

Tel Dal H system

Italy

IGQ

Certificati di prodotto

P021E

Tel Dal H a telai

prefabbricati

Italy

Instruction manual • Prefabricated frames

66

Prefabricated frames

IGQ

Certificati di prodotto

P021B

IGQ

Certificati di prodotto

P021C

HTP a telai

prefabbricati

Italy

IGQ

Certificati di prodotto

P021M

RP 390 a telai

prefabbricati

PRATICUS a telai

prefabbricati

Italy

IGQ

Certificati di prodotto

P021N

RP 490 a telai

prefabbricati

Italy

IGQ

Certificati di prodotto

P021O

T5-SX a telai

prefabbricati

Italy

Italy

Instruction manual • Prefabricated frames

67

Deck planks

CNAS - MCC

Test report

no. TC-JG1-Q-2009-10

CNAS - MCC

Test report

no. TC-JG1-Q-2009-11

Metal plank mm 330x1800

China

CNAS - MCC

Test report

no. TC-JG1-Q-2009-12

Metal plank mm 490x1800

Metal plank mm 330x2500

China

CNAS - MCC

Test report

no. TC-JG1-Q-2009-13

Metal plank mm 490x2500

China

China

Instruction manual • Prefabricated frames

68

• September 2019 - EN

Construction equipment division

Divisione cantieristica edile

via Giovanni della Casa, 12

20151 Milano - Italy

Tel. +39 . 02 30 704 1

Fax +39 . 02 33 402 706

cantieristica@marcegaglia.com

www.marcegagliabuildtech.com

Loading...

Loading...