CAFER RACER 69mm

Cortesia de www.marcadoresdemoto.com

Cortesia de www.marcadoresdemoto.com

Thank you for purchasing speedometer, before operating the unit, please read the instruction thoroughly and retain it for the future reference.

INsTRUCTION

Notice

1. applications only.

DC 12V

2.For installation, please follow the steps described in manual. Any damage caused by wrong installation shall be imputed to the users.

3.To avoid the short circuit, please don't pull the wire when installing. Don't break or modify the wire terminal.

4.Do not disassemble or change any parts excluding the manual description.

5.The interior examination or maintenance should be executed by our professionals.

MARK MEANING:

NOTE

You could get the installation details from the information behind the mark.

Some processes must be followed to avoid the affection caused by wrong installation.

WARNING!

CAUTION!

Accessory

1-1

LCD meter X 1

1 2 3

Some processes must be followed to avoid damages to yourself or the public.

Some processes must be followed to avoid the damage to the vehicle.

Passive speed sensor X 1

RPM X 1 wire set

4

LIGHT ON FLASH

PRESS THE

BUTTON ONE

TIME

M8/ S type speed

sensor X 1bracket

PRESS THE

BUTTON 3

SECONDS

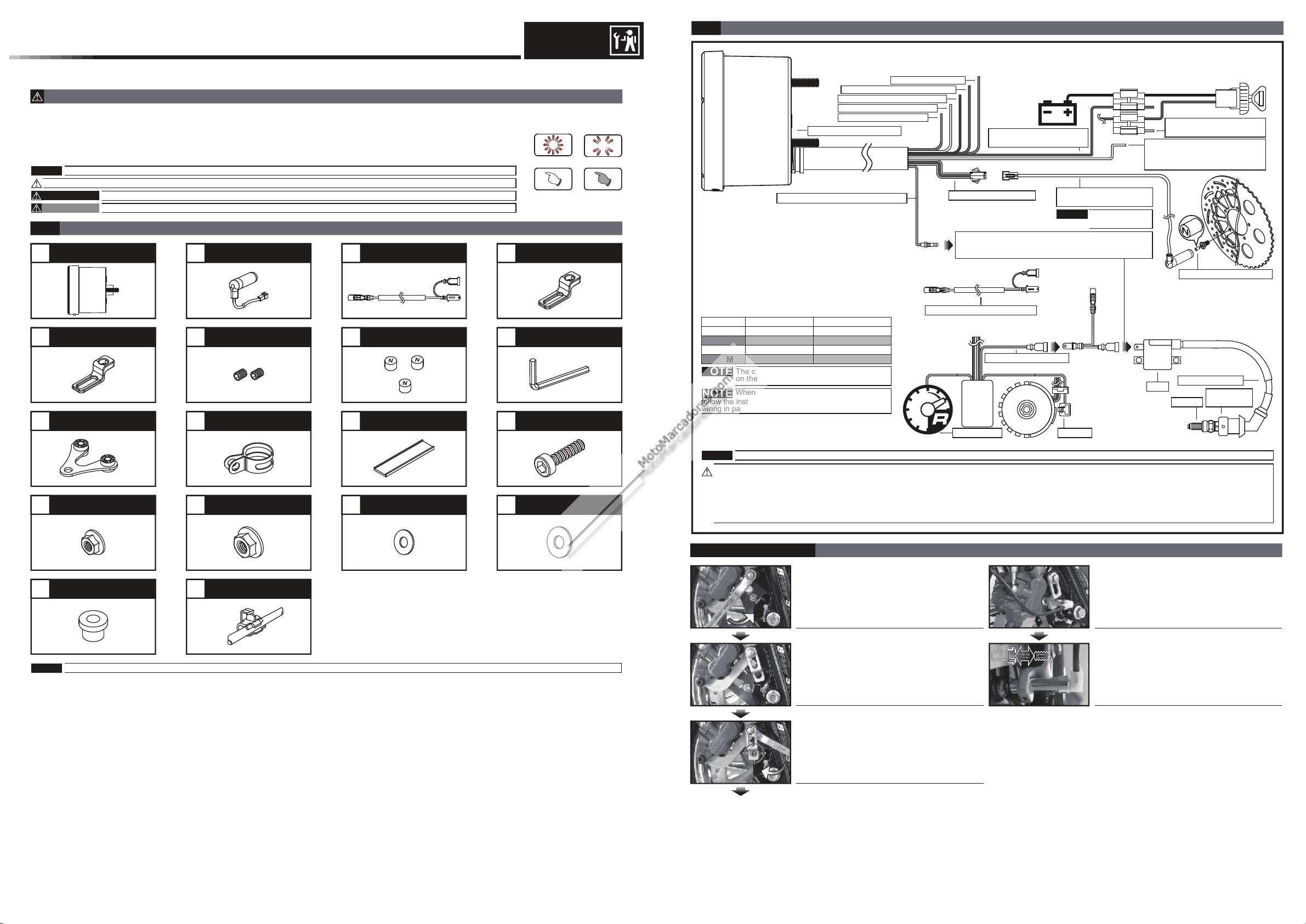

Wiring installation instructions

2-1

LCD meter (A ccessory 1

Dark brown RPM Signal wire─

Purple Neutral

Orange Left- turn signal(+ 12V)─

Blue Right turn signal(+12V )─

Yellow High beam─ (+12V)

Gray Warning la mp(- )─

─ (-)

)

Red / Postive pole (Connect

to the battery DC 12V)

Speed sensor wiring

Please choose either Type A or Type B RPM wire

according to the need and then follow the

instruction below to install at the proper position.

Digital speed signal

sensor (Accessory 2)

Speed Sensor is

NOTE

a "Hall Sensor ".

Brown / "+"Wire connect key

on main power switchDC 12V

Black / Ground wire connect

to the vehicle body or the

engine (It must be a good

ground)

Magnet (Accessory 8)

M10/ S type speed

5 6

sensor X 1bracket

Meter bracket X 1

9 10

M5 X P0.8 nut X 3 M6 washer X 1

13

Aluminum bush X 1

17

Hexagon socket

screw X 2

Handle bar clamp X 1

M6 X P1.0 nut X 1 M5 washer X 3

14

Connect terminal X 8

18

D6 X 5L mm magnet X 6

7

Rubber X 1

11

15 16

2.5 mm spanner X 1

8

M6 X 10L screw X 1

12

Main switc h wiring reference:

"+" Color "-" Color

YAMAHA

HONDA

SUZUKI

SYM

NOTE

NOTE

follow the instruction. If you connect the red & brown

wiring in parallel will cause the meter work improperly.

NOTE

Brown

Brown

Black

Black Green

The color li sted above may di

on the model .

When connecting the power wiring, please

When connecting the power wiring, please follow the instruction. If you connect the red & brown wiring in parallel will cause the meter work improperly.

Black

Black

Green

ffer de pending

RPM wire set

Tachometer

(Accessory 3)

Ignition coil positive

Flywh eel

EMS

CDI

Ignit ion

pulse

pick up

Coil

Spark plug wire

Spark plug

cap

Spark

The RPM w ire i nst allatio n

Please check the polarity of your ignition coil, before you connect the RPM sensor type B there. An incorrect installation can lead to a defect of the meter or destroy

the electrical system of your vehicle.

Transistor Ignition: If your vehicle has a transistor ignition system, connect the tach to the negative pole of the ignition coil.

ignition: If your vehicle has a CDI ignition system, connect the speed sensor to the positive pole of the ignition coil.

CDI

MOTO / SCOOTER

S type speed sensor bracket instruction

Loose the screw on the caliper

Install the speed sensor.

NOTE

Please contact if the items you open are not the same, with the above-listed one.the local distributor

Install the S type bracket on the caliper.

Please adjust the bracket to the proper angle

and then screw it up. Please make sure the

disc screw could pass the hole on

for you to install the sensor into the same hole

for catching the speed signal.

the bracket

Adjusting the distance between the sensor

and screw to get the best speed signal.

Please make sure the distance is under

to get the best signal.

2 mm

wh 035 ba0 02

P.S.

Cortesia de www.marcadoresdemoto.com

Cortesia de www.marcadoresdemoto.com

The active speed sensor could be installed by the metal parts to detect the speed.

EX. 1 The disc screw.

EX. 2 The disc to detect the disc gap. (Please make sure the distances between the gaps are the same in advance to avoid wrong

speed signal.)

EX. 3 The sprocket to detect the disc gap. (Please make sure the distances between the gaps are the same in advance to avoid wrong

speed signal.)

We will suggest you to catch the speed

maximum sensor points the speed sensor could detect is 20 points per turn.

After installation, please use your hand to turn the tire to see is everything ok. The LED on the active speed sensor will light up once

the signal is detected.

EX. 1

The hexagon socket disc screw

speed

senso r

speed

senso r

the detec t range

speed

senso r

the detec t range

speed

senso r

speed

senso r

The best detect area: The edge of the hexagon socket screw.

The hexagon screw

The best detect area: The middle of the screws.

EX. 2

speed sen sor spee d sensor

the detec t range

The disc

The best detect area: Please detect the speed signal from the gaps of the disc.

EX. 3

speed sen sor spee d sensor

The sprocket

The best detect area: Please detect the speed signal from the gaps of the sprocket.

from the disc screws. The more the sensor points are, the better the speed accuracy is. The

Please don't catch the signal from the middle hole of the hexagon socket screw to avoid wrong signal.

Some hexagon screw center is with a small hole in the center in this case, we will suggest you to catch

the signal from the edge of the screw like the hexagon socket screw.

Please note that there are discs with the gaps in different difference, and this method will not work on it!

Please note that there are sprockets with the gaps in different difference, and this method will not work

on it!

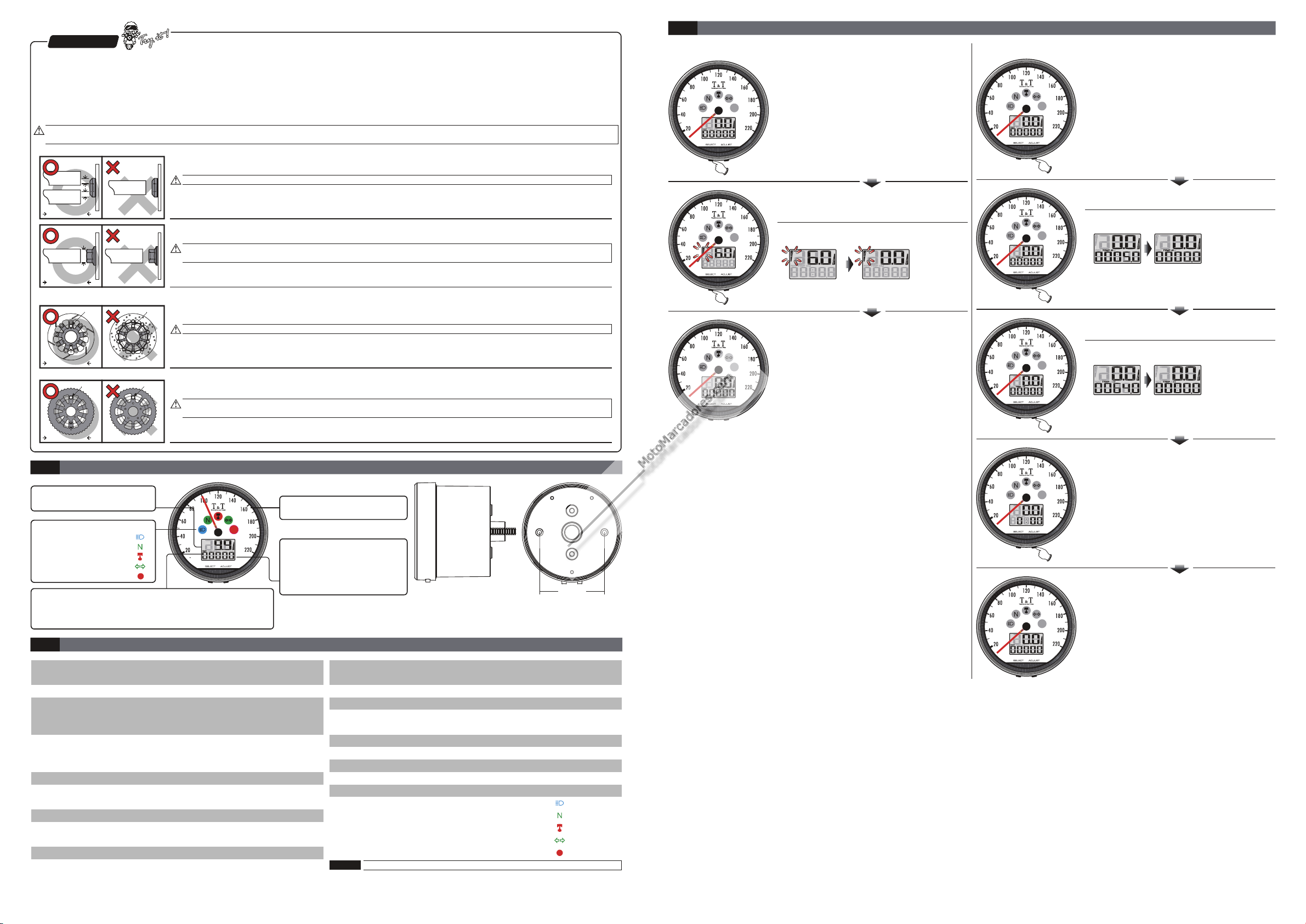

Function switch instruction

3-3

●Select button function instruction

●

In RPM screen, Press the Select button once

to switch function from ODO to

record

● Max. RPM record

In screen, Press the Select

button once to switch from the

record

●

Hold pressing the Adjust button for 3 seconds

to reset the

●The RPM screen.

.

Max. RPM

Max. RPM

function to the main screen.

Max. RPM record.

●Ad

just button function instruction

● A

djust In ODO screen, press the button once to

switch the function from ODO meter to trip A.

● Adjust In trip A screen, press the button once to

switch from trip A to trip B

ld pressing the Adjust button for 3 seconds

●Ho

to reset the trip A.

● Adjust In trip B screen, press the button once

to switch from trip B to clock screen.

●Hold pressing the Adjust button for 3 seconds

to reset the trip A.

the detec t range

Basic function instruction

3-1

Tachometer

Display range:20,000 RPM●

Telltales

●High beam (Blue)

●Neutral (Green)

●RPM Shift light RED( )

●Repeater Green( )

●Reserve RED( )

Clock

24 H●

3-2

●Speedometer

Trip meter

Display range: 0~9999.

●

automatically after 0~9999.9 km (mile).

Display unit: 0.1 km (mile).

●

Function, setting instruction

Display range: 0~220

Display unit: km/h & MPH or alternative

○Display internal

○Odometer

<0.5 second

Display range: 0~99999 km (mile), reset

automatically after 99999 km (mile)

isplay unit: 1 km (mile)

D

○Trip meter A . B

Display range: 0~9999.9 km (mile), reset

automatically after 0~9999.9 km (mile).

Display unit: 0.1 km (mile).

○Top speed rec

ord

○Tire circumference

Display range: 0~220

Setting range 300~2,500 mm:

Sensor point: 1~20 Setting unit 1 ‧ :

●Tachometer

○The shift light

Display range:20,000 RPM

Setting range:5000~20000 RPM

Setting unit:100 RPM

○Warning

○RPM input pulse

F-OFF (LIGHT ON) FLASH‧F-ON ( )

Display range:0.5 1~6,

9 km (mile), reset

km/h

km/h

Speedometer

Display range: 0~220 km/h ●

Odometer

Display range: 0~99,999

●

km (mile), reset automatically

after 99,999 km (mile)

Display unit: 1 km (mile)

●

○The RPM input pulse

○Max. RPM record

●Clock

●Backlight brightness

●Effective voltage

●Effective temperature range

●Meter standard

●Meter size

Meter weight●

Telltales●

Design and specification are subject to change without notice!

NOTE

45 mm

Setting range:Hi-ACT (Positive wave pulse)

Lo-ACT (Negative wave pulse)

Display range: 0~20,000 RPM

24 H

Setting range:1-5 (Darkest)~5-5 (Brightest)

Setting unit:Each level represent

s 20%

DC 12v

-10~+60 °C

JIS D 0203 S2

85.5 X 54.5 mm

Around 330 g

High beam (Blue)

Neutral (Green)

RPM Shift light (RED)

Repeater (Green)

Reserve (RED)

● Adjust In clock screen, press the button once

to switch from clock to ODO screen.

●The ODO screen.

wh 035 ba0 02

Function setting instruction

Cortesia de www.marcadoresdemoto.com

Cortesia de www.marcadoresdemoto.com

4

●In main screen, hold pressing the Select +

Adjust button for 3 seconds to enter the

setting screen.

Speed unit setting

4-1

●Press the button one time to enter the

speed unit setting

●●EX.To cha nge t he se tt ing f rom k m/h t o

MP H.

Pres s the Adjus t but ton t o cha nge t he

setting .

註

NOTE

Now the d i s fla shi ngef au lt

NOTE

NOTE

●●Pres s the Sele ct bu tto n onc e to go b ack t o

the Sp eed unit sett ing s cre en.

EX. Th e Spe ed un it se tting is cha nge d

from k m /h t o MPH.

●Pres s the Adjus t but ton o nce t o go ba ck to

th e tire circu mfe ren ce an d sen sor p oint

se tting s cre en.

4-2

●Press the Select button one time to enter the

tire circumference setting

Select

Defa ult :km /h

Setting range: km/h or .MPH

The odometer & trip meter will change

together with the speed unit.

The tire circumference and sensor point setting.

●

●Press the Select button to move to the digit

註

NOTE

NOTE

●

●

the set ting, p lease make sure the setting n umber i s

corre ct befo re you make the se ttin g.

You could define the valve

as the starting point and the

terminal point to measure

the wheel circumference

with a measuring tape.

●Pr ess t he Adj ust b utt on to choose the

●

●

●

●Press the Select button to move to the

註

NOTE

●Pr ess t he Adj ust b utt on to choose the

EX. The tire circumference is 1,300 mm.

you want to set.

Defa ult :1, 000 m m

Now the d i s fla shi ngef au lt

The tire cir cumference se tting range:

300~1,00 0 mm, and the digit y ou set is

from left to right in order.

CAUTION!

Pleas e measu re the ti re circ umference ( the tir e you wil l

insta ll the se nsor on) and make sure th e number of

magne t senso r point ( You could in stall t he magn et into

the dis c screw o r the spr ocket screw.)

The spe ed disp layed on the met er will be affec ted by

cm

130

sett ing n umb er.

Press the Select button once to go back to

the sensor point setting screen.

EX. The tire circumference setting is

changed from 1,000 mm to 1,300 mm.

EX. The sensor point you want to set is 6.

digit you want to set.

Defa ult :01 P

Now the d i s fla shi ngef au lt

The sensor point setting range:

1~20 points. You could change the

setting from left to right.

sett ing n umb er.

●Pr ess t he Se lec t butto n onc e to go back t o

th e tire circu mfe ren ce an d sen sor p oint

se tting s cre en.

●Pres s the Adjus t but ton o nce t o go ba ck to

th e RPM p ulse and i nput signa l set tin g

se tting s cre en.

RPM pulse and settinginput signal

4-3

●Pres s the but ton o ne ti me to e nte r

th e RPM p ulse setti ng.

●

Enter the number of ignition signals per

crankshaft revolution ( P value).

This may vary according to the vehicle

manufacturer/model and type of engine:

●

If a 4-stroke engine fires at every second

crankshaft revolution, enter P=0.5 (on 1-,

2- and 3-cylinder 4-stroke engines with one

ignition coil for each cylinder)

●

If a 4-stroke engine fires once per crankshaft

revol

4-stroke engines with one ignition coil for two

cylinders)

●

2-stroke engines fire once per crankshaft

revolution; enter P=1

●

In the case of vehicles which have a

distributor (mostly cars), you can enter P

values up to 4, according to the number of

cylinders.

●

If you do not know how often your engine

fires per crankshaft revolution, s

assuming the standard setting (P=1) the

instrument cannot be damaged if you do

this. If an incorrect engine

rpm is displayed, you should vary the P value

by entering it manually until the figure

displayed is realistic.

●

Example illustration: The setting is changed

from P=1 to P=2.

●

Press the selection button and change to the

function for setting the shift war

Sele ct

“ ”

ution, enter P=1 (on 2-, 4- and 6-cylinder

tart by

–

ning

●

EX. We w oul d lik e to ch ang e the s ettin g

to L oAc t. (The nega tiv e imp uls e)

●

Pres s the Adjus t but ton t o cho ose t he in put

si gn al yo u wan t to se t.

註

NOTE

註

NOTE

註

NOTE

●●Press the Select button once to go back to

●Pres s the Adjus t but ton o nce t o go ba ck to

●Pres s the Sele ct bu tto n one t ime t o ent er

●●EX: You want the shift light to light on at

註

NOTE

註

NOTE

●Pres s the Adjus t but ton t o cho ose t he

Defa ult :Hi Act

Now the d i s fla shi ngef au lt

The impulse setting range is

between Hi (the positive impulse)&

Lo (the negative impulse)

If the tachometer can't detect the

signal (No RPM is displayed on the

screen), you could choose another

setting, and check it again.

the RPM pulse and input signal setting

screen.

EX. The input signal setting is changed

from HiAct to LoAct.

th e shift ligh t and s hif t lig ht wa rning sett ing

se tting s cre en.

Shiftlight setting

4-4

th e Shift ligh t set tin g.

8000 RPM Please change the shift light

setting value to 8500 directly.

Press the Select button to move to the digit

you want to set.

Defa ult :8, 000 RPM

Now the d i s fla shi ngef au lt

Setting

range 5,000~20,000 RPM

Setting

sett ing n umb er.

:

unit 100 RPM

:

●Pres s the Sele ct bu tto n to ch oos e the

Cortesia de www.marcadoresdemoto.com

Cortesia de www.marcadoresdemoto.com

Shif t lig ht

EX: Now t he sh if t lig ht se tti ng is c han ged

●

from 8, 000RPM to 8,500 R PM.

●

EX. You wan t to se t the shif t lig ht F- ON

(F lash) .

●Pres s the Adjus t but ton t o cho ose t he

se tting n umb er.

NOTE

Now the d i s fla shi ngef au lt

NOTE

sett ing .

Defa ult : Lig ht onF -OFF ( )

Setting range: F-OFF(Light on)

F-ON(Flash).

、

●

EX. Now the setting is changed from 0:00

to 10:00.

●

Press the Select button to enter the minute

setting.

●●EX. To change the setting to 14:10.

Press the Select button to move to the digit

you want to set.

Defa ult :0 minutes.

NOTE

Now the d i s fla shi ngef au lt

Setting range: 00~59 minutes.

NOTE

●

EX. You want to set the backlight at

(60%).

●

Press the Adjust button to choose the setting

number.

Defa ult :5- 5

NOTE

Now the d i s fla shi ngef au lt

Setting range:1-5(Darkest)~5-5

NOTE

(Brightest),5 different levels available.

Setting unit:20% per level.

The backlight brightness will change

immediately after you set the value.

●●Press the Select button one time to enter

the backlight setting.

EX: ackli

from to .

5-5 (100%) 3-5 (60%)

ght setting The b setting is changed

3-5

●Press the Select button once to enter the

external odometer setting screen.

●

EX. Set the odomete r to 50 00 km .

●Pr ess t he Se lec t butto n to move to the di git

yo u wan t to set.

Defa ult : mile00 ,00 0km( )

NOTE

Now the d i s fla shi ng

NOTE

ef au lt

Display range:0~99,999 km (mile)

●●Press the Select button once to go back to

the RPM input signal and shiftlight setting

screen.

EX. The shiftlight setting is changed

from F-OFF(Light on) to F-ON(Flash).

ress the Adj ust b utt on to c hoo se th e

●P

cl ock s ettin g scr een .

Clock setting

4-5

●Press the Select button one time to enter

the clock setting.

●Pr ess t he Adj ust b utt on to choose the

setting n umb er.

●

Press the Select button once to go back to

the clock setting screen.

● EX. Now the setting is changed from 10:

to 10:10.

●Pr ess t he Adj ust b utt on to choose the

ba cklig ht se tti ng sc ree n.

00

●P

ress the Adj ust b utt on to

od ometer dis pla y scr een .

Me ter Odo meter display

4-7

●Press the button to enter the odometer

display screen.

●

EX. The internal odometer display is 12500

km.

●Press the Select button once to enter the

external odometer setting screen.

This disp aly o nly f or vi ewi ng cu rrent

mile age o n the mete r.

Select

choo se th e

●Pr ess t he Adj ust b utt on to ch

setting n umb er.

●

Pres s the Sele ct bu tto n onc e to go

ba ck to t he Meter Odomet er sc ree n.

●

EX. Th e odo met er se tting has be en

ch anged from 0 km t o .

Pres s the Adjus t but ton X 3 to go

●

ba ck to t he main screen.

●The main screen.

oose the

5, 00 0 km

secon ds

●●EX. To change the setting to 10:00.

number.

NOTE

NOTE

註

Press the Adjust button to choose the setting

Defa ult :0 H.

Now the d i s fla shi ngef au lt

Setting range: 0~23 H.

Backlight setting

4-6

●Press the Select button one time to enter the

backlight setting.

●Pr ess t he Adj ust b utt on to choose the

external odometer setting screen.

External Odo meter s etting

4-8

Trouble shooting

Cortesia de www.marcadoresdemoto.com

Cortesia de www.marcadoresdemoto.com

5

The following situation do not indicate malfunction of the meter. Please check the following before taking it in for repair.

Trouble TroubleCheck item Check item

The meter doesn't work

when the power is on.

Speed does not appear

or appear incorrectly.

Tachometer does not

appear or appear

incorrectly.

※If still can't solve the problems according to the steps above, please contact with distributors or us.

●

The power doesn't supply to the meter.

→

Please make sure the wiring is connected.

The wiring and fuse are not broken.

→

The battery is broken or the battery is too

old to supply enough power

make the meter work.

●

Please make sure the speed sensor is

connected correctly.

●

Please check the tire-size setting.

→

please refer to the m

Please check the RPM sensor wiring is

●

connected correctly.

●

Please check the spark plug is R type or

not. If not, please replace the spark plug

with the R type spark plug.

●

Please check your setting.

→

Please refer to the manual a3.

DC 12V to

anual a2.

The clock is incorrect.

Backlight doesn't work or

doesn't have enough

brightness

Telltale doesn't work

●Do

you connect the wiring correctly.

→

Please chec

connects to the battery, and main

switch positive wiring (Brown) connects

to the main switch.

Please check your setting.

●

Please refer to the manual a5.

→

The harness connection might be wrong

●

Please check the backlight wire is properly

→

connected according to t

Please check your setting.

●

Please refer to the manual a6.

→

●

The harness conne

Please check the harness wire is properly

→

connected according to the instruction.

k the positive wire (Red)

he instruction.

ction might be wrong

Loading...

Loading...