Marathon Special Products all products Catalog

2018 PRODUCT CATALOG

SINCE

Since 1931, Marathon® Special Products have

served the electrical/electronic component

industry and have consistently met and/or

exceeded customer quality requirements and

expectations. Our facility in Bowling Green, Ohio,

USA, contains all engineering and warehousing

operations, as well as most manufacturing and

testing operations. Our ability to mold, stamp

and assemble all of our parts makes us unique in

the industry. Marathon products include power

blocks, terminal blocks, fuse holders and custom

products.

For more than 85 years, we have developed a

reputation as an industry leader in innovation and

quality. Our team has a long history of providing

first class service and responsiveness.

MANUFACTURED

IN THE USA

WE CREATE A BETTER

TOMORROW BY EFFICIENTLY

CONVERTING POWER INTO MOTION

The whole world is on the move today. Everything from people

and products to ideas and information. That means business

has to be on the move, as well. We keep products – and

businesses – moving forward, our products and solutions help

make the world go.

QUALITY

As an ISO 9001 registered company, our team is committed

to achieving customer satisfaction by providing high quality

products which meet or exceed customer needs and

expectations.

CUSTOMER TESTIMONIALS

> “One of the most reliable suppliers on my line card!”

INNOVATION

We will grow with new technologies that deliver real value

for our customers.

CUSTOMER TESTIMONIALS

> “They are a company striving for innovation rather than

imitation.”

CUSTOMER CARE

Our world class customer service team is committed to

maintaining our status as an industry leader. With an average

tenure of 20+ years, our reps know how to “Make it Easy for

the Customer”.

CUSTOMER TESTIMONIALS

> “When you work with someone for over 30 years, you can

form a special bond working together.”

> “Great customer service and customer focus.”

> “Level of service is tops! Keep doing what you do.”

Developing CUSTOM PRODUCTS is what differentiates us from the rest of the industry.

Our core value is to provide quality solutions to meet our customers’ needs.

We have the engineering and manufacturing capabilities to provide:

• Custom hardware configurations to terminal blocks

• Custom power block designs

• Custom fuse holder designs

• Custom terminal block designs for any application

• Custom ratings that aren’t available

Our product development team can quickly respond to your requests with the use of 3D modeling,

analysis, rapid prototyping and a UL approved test lab to accelerate the performance verification process for any

testing requirements.

finite element

TABLE OF CONTENTS

General Info............................................................................................1

POWER BLOCKS

• Index & Descriptions.........................................................................5

• Bulk Fastening..................................................................................6

• Enclosed...........................................................................................7

• Splicer/Distribution............................................................................9

• High Voltage....................................................................................15

• Stud Configurations.........................................................................17

• Misc Configurations........................................................................20

• Covers.............................................................................................21

TERMINAL BLOCKS

• Index & Descriptions.......................................................................22

• Specialty Terminal Blocks

› Studded Feed Thru..................................................................23

› Single Stud Connection...........................................................25

› Motor Blocks...........................................................................26

› Grounding Lugs & Connectors................................................27

• Heavy Duty Terminal Blocks

› Deadfront Type........................................................................28

› Barrier Type.............................................................................30

• Barrier Terminal Blocks

› Double Row & Accessories.....................................................31

› Single Row & Accessories......................................................33

› Military Class..........................................................................35

› Navy Class..............................................................................36

• Sectional Terminal Blocks

› DIN (Euro-Style).......................................................................37

› NEMA® (Barrier).......................................................................39

POWER BLOCKS TERMINAL BLOCKS FUSE HOLDERS

FUSE HOLDERS

• Index & Descriptions.......................................................................42

• Fuse Holders...................................................................................45

• Accessories.....................................................................................55

Terms & Conditions..............................................................................57

Warnings...............................................................................................59

Index.....................................................................................................60

NEMA is a trademark of National Electrical Manufacturers Association. All Rights Reserved.

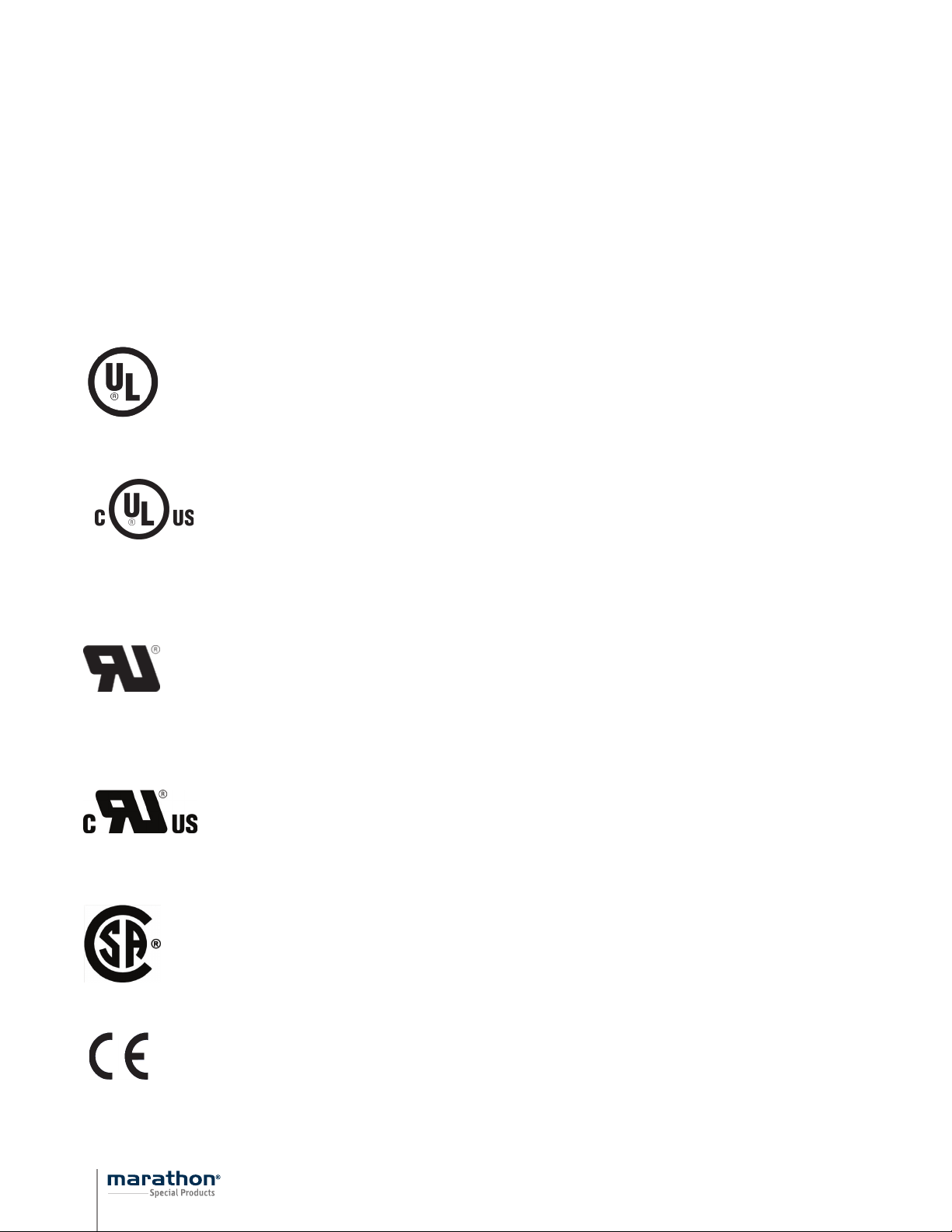

GENERAL INFORMATION

AGENCY APPROVALS:

The majority of products manufactured under the Marathon® Special Products brand are Underwriters

Laboratories and Canadian Standards Association approved.

The approval status of products can be found throughout the catalog. Below are the different approval types

and brief descriptions.

On February 1, 1994, the development and manufacturing of products under the Marathon Special Products

brand name were registered to ISO standards. We are currently registered to ISO 9001:2008 quality standards.

Listed products by Underwriters Laboratories have been evaluated to U.S. safety

requirements. These products are qualified for use in equipment without end-use agency

approval when applied within the product’s rated performance.

Listed products by Underwriters Laboratories have been evaluated to both U.S. and Canadian

safety requirements. These products are qualified for use in equipment without end-use

agency approval when applied within the product’s rated performance.

Recognized products by Underwriters Laboratories have been evaluated to U.S. safety

requirements. These products are components of a larger product or system and have

guidelines addressing the suitability when used in an end product.

Recognized products by Underwriters Laboratories have been evaluated to U.S. and Canadian

safety requirements. These products are components of a larger product or system and have

guidelines addressing the suitability when used in an end product.

Certified by Canadian Standards Association, suitable for use in other equipment where

Canadian Standards Association determines the suitability of the combination.

Compliance with European Union Low Voltage Directive.

1

GENERAL INFORMATION

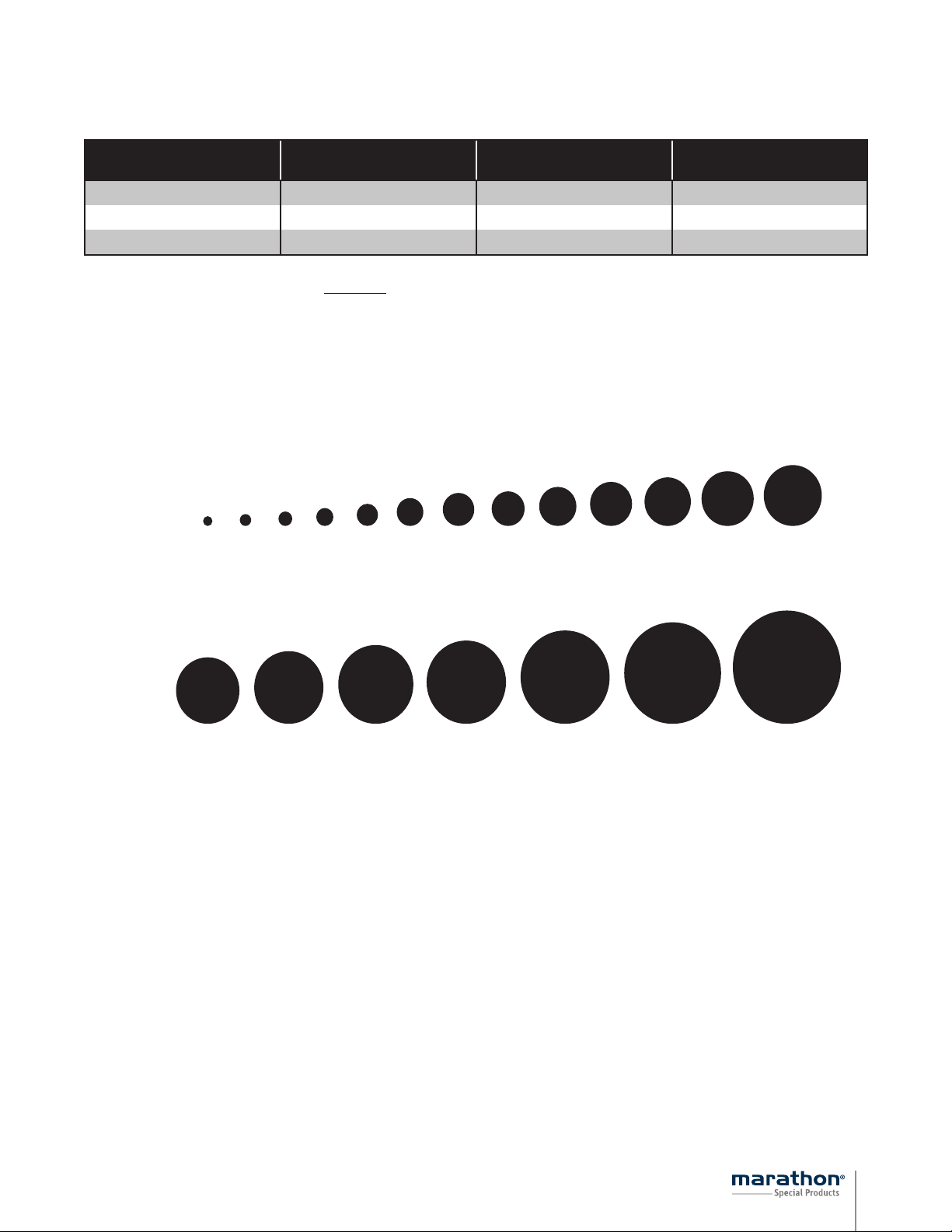

TOLERANCES FOR CATALOG DIMENSIONS:

LENGTH DIMENSIONS TOLERANCE ALL OTHER DIMENSIONS TOLERANCE

1.0” - 5.0” ± .030 X.X” ± .030

5.1” - 10.0” ± .050 X.XX” ± .020

10.1” - 15.0” ± .060 X.XXX” ± .010

Note: Catalog dimensions are for guidance only and are not to be construed as inspection standards.

This catalog is intended to present product data that will help the end user with design application. We reserve

the right to change or update without notice.

STRANDED WIRE SIZES AND AMPACITY FOR 750 C WIRE (COPPER)

Per UL Table 310.15 (B) (16)

SIZE

DIAMETER

AMPS

SIZE

DIAMETER

AMPS

SCCR INFORMATION:

The requirements of the National Electric Code (NEC) and UL 508A now require many electrical panels to carry

a Short Circuit Current Rating (SCCR). Analyzing the SCCR of individual components and overcurrent protection

devices is a method of determining the SCCR of an electrical assembly.

Many of our recognized and listed power blocks have now been tested and approved for higher SCCR. The

higher ratings are based on proper wire sizes and the appropriate circuit protection device (fuses or circuit

breakers). UL 508A does allow default SCCR for power distribution blocks of 10,000A with no additional testing.

#14

.073

20

250kcmil

.580

255

#12

.092

25

#10

.115

35

300kcmil

.635

285

#8

.146

50

#6

.184

65

350kcmil

.690

310

#4

.235

85

#3

.281

100

400kcmil

.730

335

#2

.295

115

#1

.335

130

500kcmil

.820

380

1/0

.380

150

2/0

.420

175

600kcmil

.893

420

3/0

.475

200

4/0

.530

230

750kcmil

.998

475

2

GENERAL INFORMATION

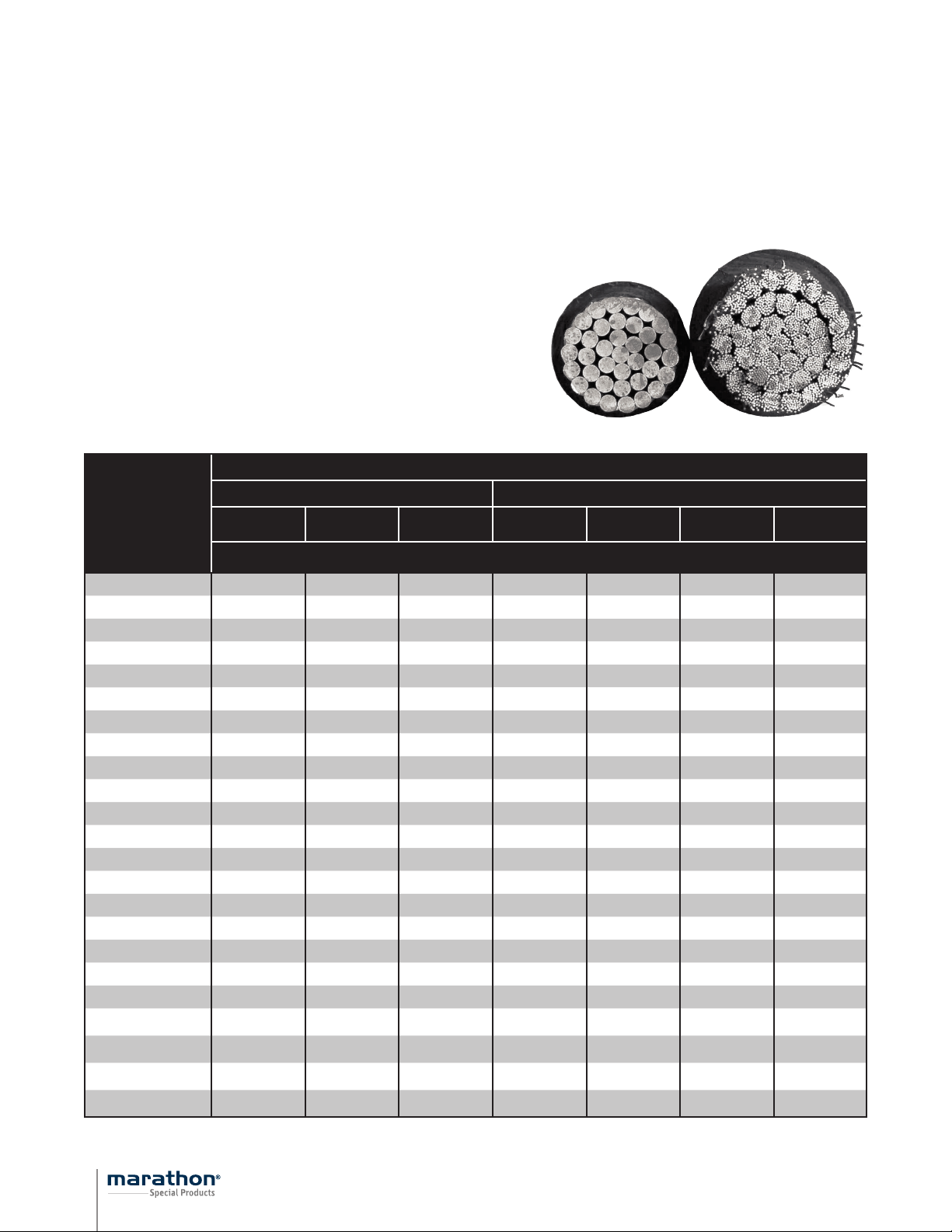

FLEXIBLE STRANDED WIRE INFORMATION:

Traditionally, power blocks and fuse holders have been evaluated for use with rigid (Class B & C) wire only.

The majority of our products have been evaluated for use with flexible stranded wire classes such as Class

G, H, I (DLO) and K per UL 486A-B. This enables customers to be UL and NEC compliant while using flexible

classes of wire without the use of crimp type terminals. We also supply a range of studded products to

allow for the use of crimp terminals, which are recommended for larger wire sizes (greater than #1 AWG).

Flexible stranded wire classes differ in that they also bring

additional considerations to address such as an increase in wire

diameter and the number of strands per a given wire size. The

photo to the right shows two 250 kcmil wires of different classes.

The one on the left is the traditional Class B with 37 strands. The

one on the right is a finely stranded Class K. Although they are

the same wire classification of 250, you can see the Class K is

larger in diameter. This illustrates the need to specify a terminal

to accept a larger standard wire size. The table below shows the

increase in strand count per each wire size.

AWG/KCMIL

WIRE GAUGE

AWG

#20 - 7 19 - - - 10

#18 - 7 19 - - - 16

#16 - 7 19 - - - 26

#14 - 7 19 - - 19 41

#12 - 7 19 - - 19 65

#10 - 7 19 - - 27 104

#8 7 7 19 49 133 41 168

#6 7 7 19 49 133 63 266

#4 7 7 19 49 133 105 420

#2 7 7 19 49 133 161 665

#1 19 19 37 133 259 210 836

1/0 19 19 37 133 259 266 1064

2/0 19 19 37 133 259 342 1323

3/0 19 19 37 133 259 418 1666

4/0 19 19 37 133 259 532 2107

250 kcmil 37 37 61 259 427 637 2499

300 kcmil 37 37 61 259 427 735 2989

350 kcmil 37 37 61 259 427 882 3458

400 kcmil 37 37 61 259 427 980 3990

500 kcmil 37 37 61 259 427 1225 5054

CSA

COMPACT

RIGID STRANDED FLEXIBLE STRANDED

CLASS B CLASS C CLASS G CLASS H CLASS I (DLO) CLASS K

NUMBER OF STRANDS*

600 kcmil 37 37 61 427 427 1470 6065

750 kcmil 37 61 61 427 427 1850 7581

1,000 kcmil 37 61 61 427 427 2527 10101

*Specific quantity of strands may differ by manufacturer.

3

GENERAL INFORMATION

FEEDER & BRANCH CIRCUIT VOLTAGE REQUIREMENTS PER UL STANDARDS

SPACING REQUIREMENTS PER APPLICATION TYPE

LINE TO LINE

THRU

AIR

OR

OVER

SURFACE

UL STANDARD

(UP TO 251-600V)

(1)

PARTS OF OPPOSITE

508A Feeder Circuits 1” 2” 1” Listed Power Distribution Blocks EPB, 134, 135

508A Branch Circuits 3/8” 1/2” 1/2” Class B or C Recognized Terminal Blocks 141, 132, 133, 145

1995 HVAC Circuits

(1)

All cited standards and ratings should be verified to the current revision and full requirements.

(2)

Listed power distribution blocks can be used in all applications as they exceed spacing requirements

• Recognized power terminal blocks may be suitable in a feeder circuit should they meet the spacing requirements at the application

voltage level (see charts below)

(3)

Primary series promoted - 142, 143 & 144 are still available

(4)

UL 1995 control circuits used to start, stop, regulate or control the speed of a motor is to comply with the standard for industrial control

equipment, UL 508 (per 3.10.3.1).

(4)

3/8” 1/2” 1/2” Class B or C Recognized Terminal Blocks 141, 132, 133, 145

LIVE

PART TO

GROUND

PRODUCT TO SATISFY

MINIMUM

(2)

REQUIREMENTS

COMPLIANT

PRODUCT SERIES

(3)

UL 1953 SPACING REQUIREMENTS (MAX, IN INCHES) - LISTED “POWER DISTRIBUTION BLOCKS”

VOLTAGE THROUGH AIR OVER SURFACE

0-125 0.500 0.750

126-250 0.750 1.250

251-1000 1.000 2.000

UL 1059 SPACING REQUIREMENTS (MAX, IN INCHES) - RECOGNIZED “TERMINAL BLOCKS”

CLASS* VOLTAGE THROUGH AIR OVER SURFACE

51-150 0.500 0.750

A

B

C

Class A: Service, including deadfront switchboards, panel boards and service equipment

Class B: Commercial appliances including business equipment and electronic data processing equipment

Class C: Industrial, general

151-300 0.750 1.250

301-600 1.000 2.000

51-150 0.063 0.063

151-300 0.094 0.094

301-600 0.375 0.500

51-150 0.125 0.250

151-300 0.250 0.375

301-600 0.375 0.500

4

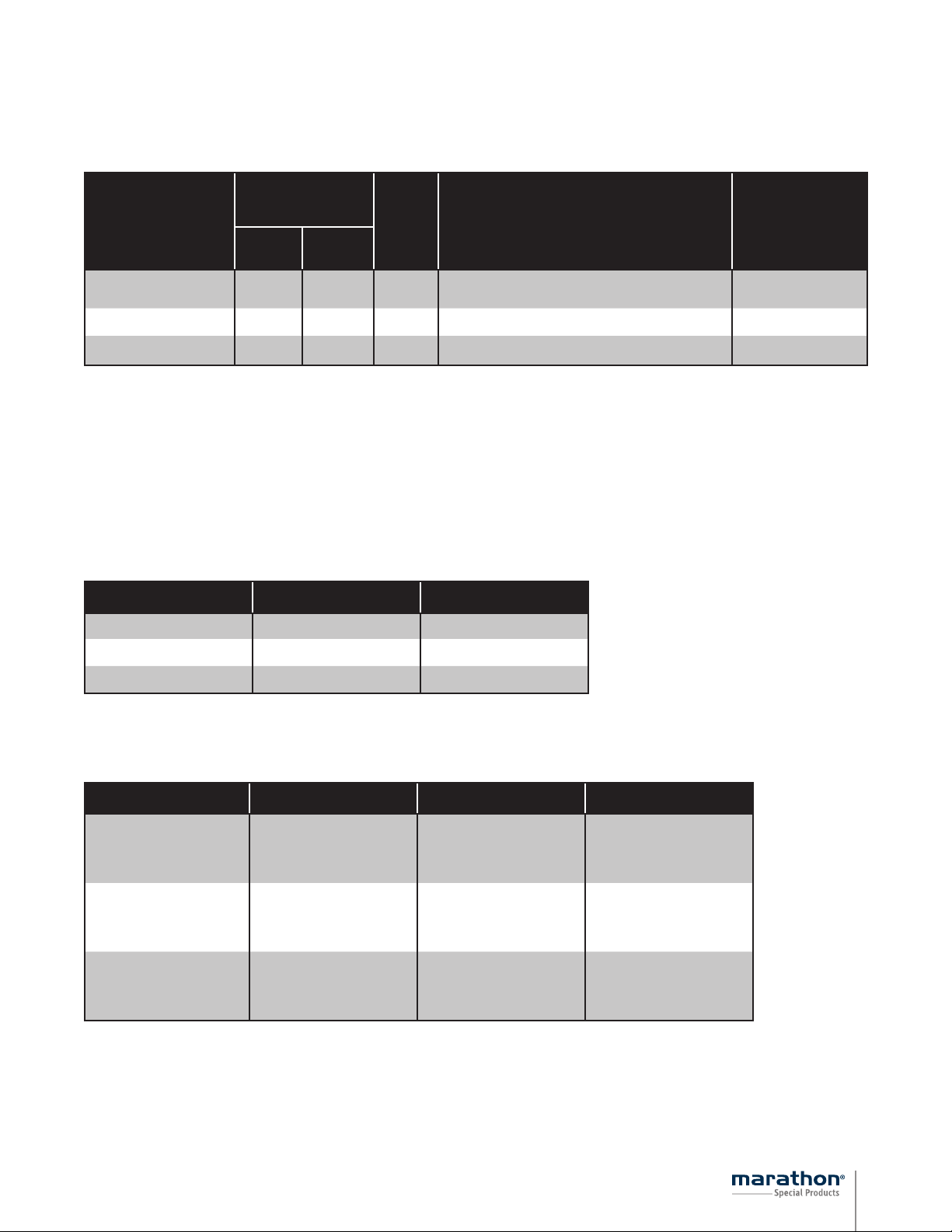

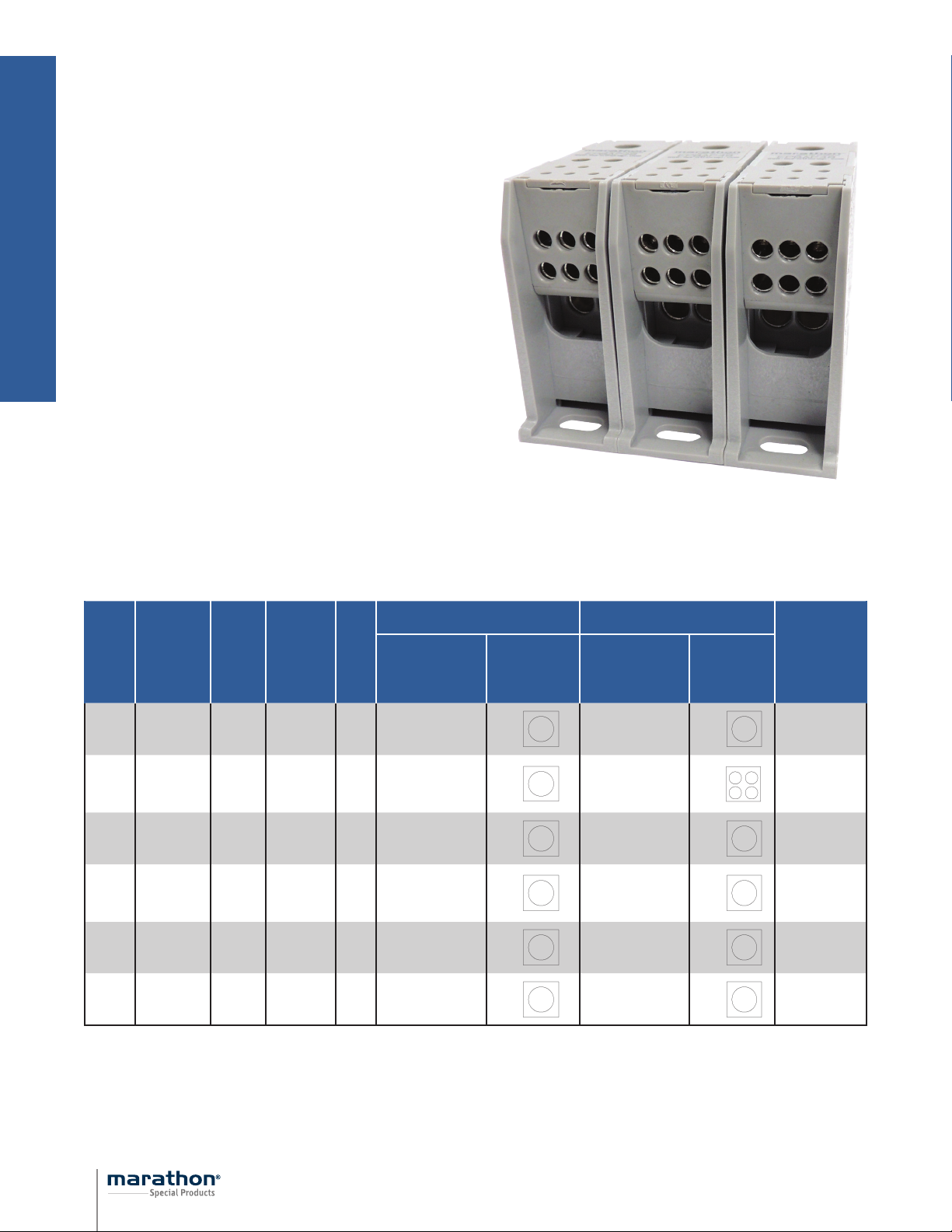

POWER BLOCK TYPES

POWER BLOCKS

POWER BLOCK TYPE

BULK

FASTENING

(BFPB)

ENCLOSED

(EPB)

SPLICER

&

DISTRIBUTION

HIGH VOLTAGE

(HVPB)

PAGE

#

6

7

9

15

DESCRIPTION IMAGE

The BFPB Series is a single pole design that consists of a series of

stud fasteners to allow you to terminate various combinations of

crimp lugs or exible bus bar with one conguration. The series is

ideal for use with exible stranded wire terminations or large and

abnormal wiring combinations.

The EPB Series are enclosed versions of our traditional power

block congurations. This series consists of a modular single pole

design that provides touch proof protection for splicer and distribution connector styles.

Splicer and distribution power blocks are our traditional NEMA

style offering. Splicer power blocks provide the same number

of wire inputs as outputs, and distribution power blocks provide

multiple load outputs per each incoming wire.

The HVPB series are high voltage (1500 AC/DC) versions of our

traditional power block congurations. This series consists of a

modular single pole design for splicer, distribution and studded

connector styles.

®

Studded power blocks are part of our traditional NEMA style

STUD

CONFIGURATIONS

MISCELLANEOUS

CONFIGURATIONS

offering. These power blocks provide studs, or a combination of

17

bare wire terminals with the stud to terminate crimp lugs or bus

bar to distribute power.

Miscellaneous power blocks are part of our traditional NEMA

style offering. These power blocks provide tapped holes or quick-

20

connects in addition to bare wire terminals to splice or distribute

power.

STANDARDS:

Regal’s Marathon® Special Products power blocks are either UL recognized or listed. Most have either CSA

certification or cUR recognition for Canadian customers, as well as compliance to CE (Component IEC 60947-7-1).

RECOGNIZED power terminal blocks comply to UL 1059 and CSA C22.2 No. 158. All of our power blocks

meet the 600V spacing requirements for application classes B & C and some Class A (135s): See General

Information (pg 4) for class descriptions.

LISTED power distribution blocks comply to UL 1953. These are all rated 600V and are intended to be used

on the load side of service equipment in accordance with the National Electrical Code, NFPA 70. Listed

power blocks provide feeder circuit terminal spacing requirements of UL508A.

NEMA is a trademark of National Electrical Manufacturers Association. All Rights Reserved.

5

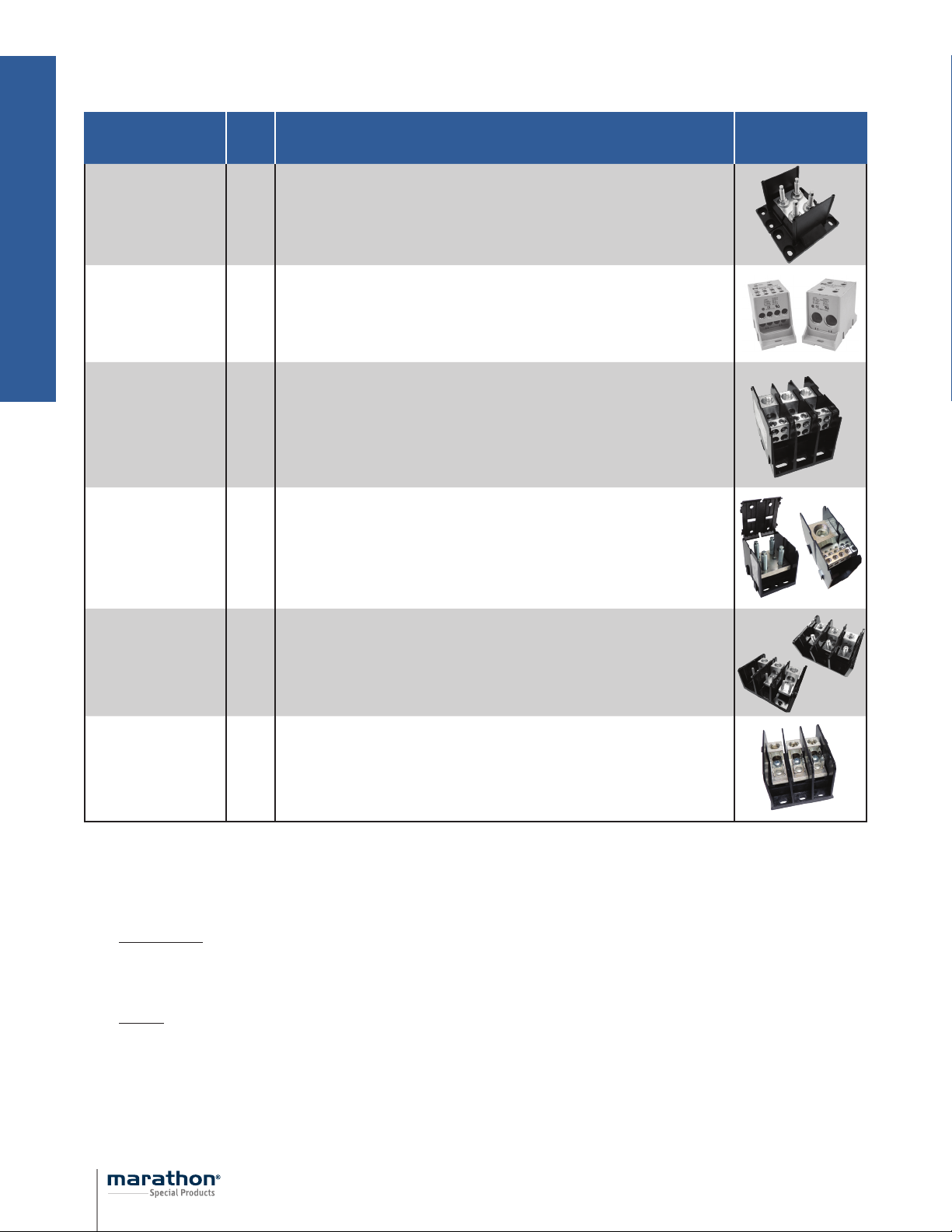

BULK FASTENING

ELECTRICAL:

1605 amps

1000 volts AC/DC (cULus)

High SCCRs:

• 100kA with fusing

• 35kA standard (no OCPD)

Flexible stranded wire compliant

Multiple wire ratings

STANDARDS:

UL 1059 recognized file no. XCFR2.E62806

cUR recognized file no. XCFR8.E62806 (UL 1059)

RoHS compliant

WEBSITE RESOURCES:

POWER BLOCKS

Detailed product data sheets

• Material information

• Termination & mounting specifications

• Detailed SCCR information

Dimensional drawings & 3D CAD files

Accessories available

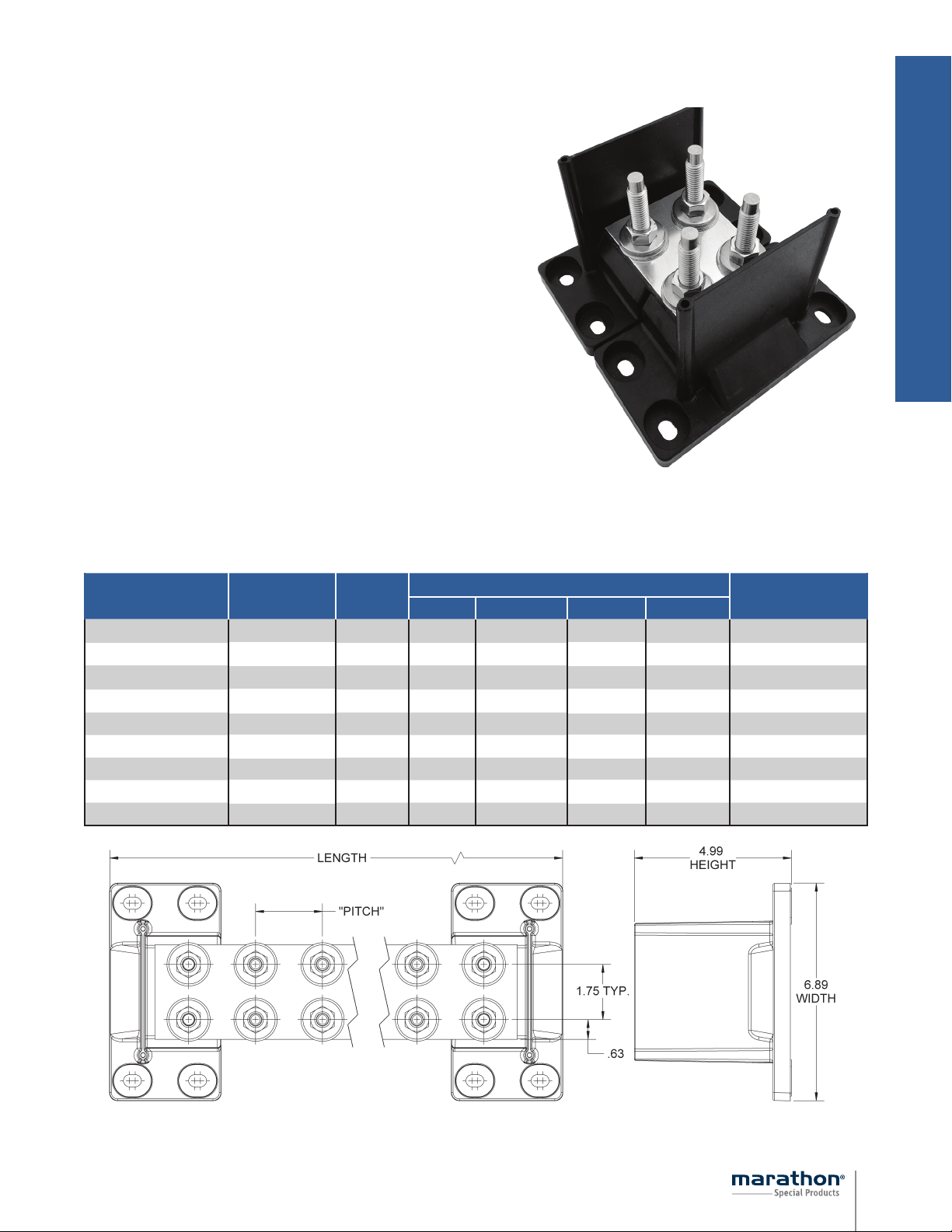

CATALOG #

BFPB 50 2 2 2 1/2 2.125 7. 1 4 6.89 4.99 CC BFPB 2 2

BFPB 50 2 3 3 1/2 2.125 9.27 6.89 4.99 CC BFPB 2 3

BFPB 50 2 4 4 1/2 2.125 11.39 6.89 4.99 CC BFPB 2 4

BFPB 50 2 5 5 1/2 2.125 13.52 6.89 4.99 CC BFPB 2 5

BFPB 50 2 6 6 1/2 2.125 15.64 6.89 4.99 CC BFPB 2 6

BFPB 37 1 3 3 3/8 1.625 8.27 6.89 4.99 CC BFPB 1 3

BFPB 37 1 4 4 3/8 1.625 9.89 6.89 4.99 CC BFPB 1 4

BFPB 37 1 5 5 3/8 1.625 11.52 6.89 4.99 CC BFPB 1 5

BFPB 37 1 6 6 3/8 1.625 13.14 6.89 4.99 CC BFPB 1 6

STUD

POSITIONS

STUD

SIZE

PITCH LENGTH WIDTH HEIGHT

DIMENSIONS (INCHES)

COVER PART #

BFPB 50 2 2

6

ENCLOSED - SPLICER/DISTRIBUTION

POWER BLOCKS

ELECTRICAL:

115 to 760 amps

600 volts AC/DC (UL)

High SCCRs (35 to 100kA) with fusing or circuit breakers

Flexible stranded wire compliant

Multiple wire ratings

STANDARDS:

UL 1953 listed - or - UL 1059 recognized

• Listed file no. QPQS.E309401

• Recognized file no. XCFR2.E62806

CSA certified file no. LR19766 (CSA C22-2 No. 158)

CE (Component IEC 60947-7-1)

RoHS compliant (All)

WEBSITE RESOURCES:

Detailed product data sheets

• Material information

• Termination & mounting specifications

• Multiple wire rating specifications

• Detailed SCCR information

Dimensional drawings & 3D CAD files

Accessories available

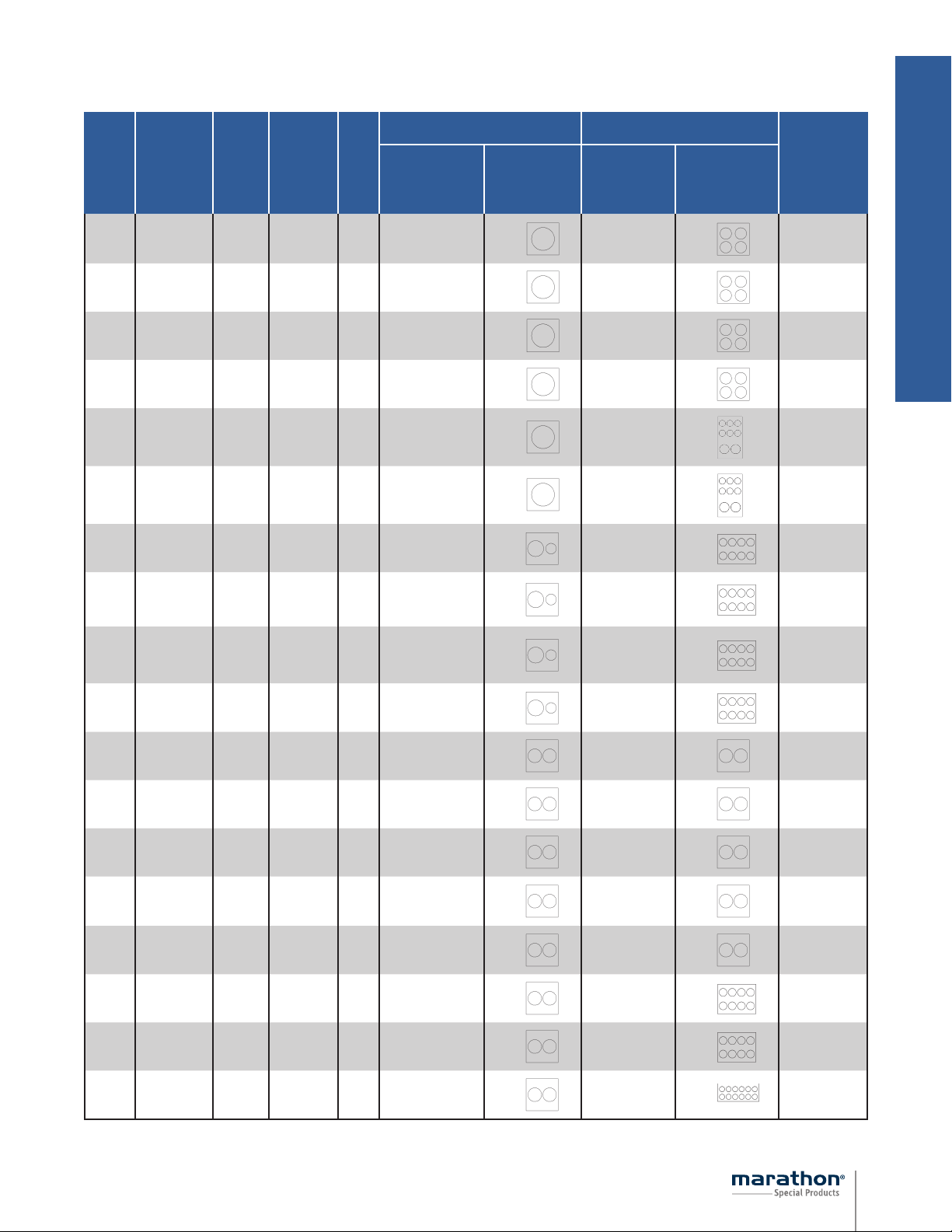

EPBAP48

LINE SIDE LOAD SIDE

AMPS CATALOG #

MOUNTING

11 5 EPBAD21

11 5 EPBAD24

200 EPBAD42 DIN 100,000 AL 3/0 - #14 1 3/0 - #14 1 Yes

200 EPBAP42 Panel 100,000 AL 3/0 - #14 1 3/0 - #14 1 Ye s

200 EPBCD42 DIN 100,000 CU 3/0 - #14 1 3/0 - #14 1 Yes

200 EPBCP42 Panel 100,000 CU 3/0 - #14 1 3/0 - #14 1 Yes

DIN/

Panel

DIN/

Panel

MAX

STYLE

SCCR

100,000 AL #2 - #14 1

65,000 AL #2 - #14 1

WIRE RANGE

AWG/kcmil

MATERIAL

CONNECTOR

CONNECTOR

OPENINGS/

POLE

WIRE RANGE

AWG/kcmil

#2 - #14 1 Yes

#10 - #18 4 Ye s

CONNECTOR

OPENINGS/

POLE

COMPLIANT

FEEDER

CIRCUIT

PER UL508

7

ENCLOSED - SPLICER/DISTRIBUTION

LINE SIDE LOAD SIDE

AMPS CATALOG #

MOUNTING

STYLE

MAX

SCCR

WIRE RANGE

AWG/kcmil

MATERIAL

CONNECTOR

CONNECTOR

OPENINGS/

POLE

WIRE RANGE

AWG/kcmil

CONNECTOR

OPENINGS/

POLE

FEEDER

CIRCUIT

COMPLIANT

PER UL508

POWER BLOCKS

200 EPBAD45 DIN 100,000 AL 3/0 - #14 1

200 EPBAP45 Panel 100,000 AL 3/0 - #14 1 #2 - #14 4 Yes

200 EPBCD45 DIN 100,000 CU 3/0 - #14 1 #2 - #14 4 Yes

200 EPBCP45 Panel 100,000 CU 3/0 - #14 1 #2 - #14 4 Yes

200 EPBAP48 Panel 100,000 AL 3/0 - #14 1

200 EPBAD48 DIN 100,000 AL 3/0 - #14 1

335 EPBAD74 DIN 10,000 AL

335 EPBAP74 Panel 100,000 AL

335 EPBCD74 DIN 10,000 CU

400 - #6/

2/0 - #14

400 - #6/

3/0 - #14

400 - #6/

3/0 - #14

1/1

1/1

1/1

#2 - #14 4 Yes

#6 - #14

#2 - #14

#6 - #14

#2 - #14

#2 - #14 8 --

#2 - #14 8 --

#2 - #14 8 --

8

8

Yes

Yes

335 EPBCP74 Panel 100,000 CU

510 EPBAD71 DIN 10,000 AL 250 - #6 2 250 - #6 2 --

510 EPBAP71 Panel 100,000 AL 250 - #6 2 250 - #6 2 --

510 EPBCD71 DIN 10,000 CU 250 - #6 2 250 - #6 2 --

510 EPBCP71 Panel 100,000 CU 250 - #6 2 250 - #6 2 --

760 EPBAP81 Panel 100,000 AL 500 - #4 2 500 - #4 2 Yes

760 EPBAP84 Panel 100,000 AL 500 - #4 2 2/0 - #14 8 Ye s

760 EPBCP84 Panel 100,000 CU 500 - #4 2 2/0 - #14 8 Yes

760 EPBAP86 Panel 100,000 AL 500 - #4 2 #4 - #14 12 Yes

400 - #6/

3/0 - #14

1/1

#2 - #14 8 --

8

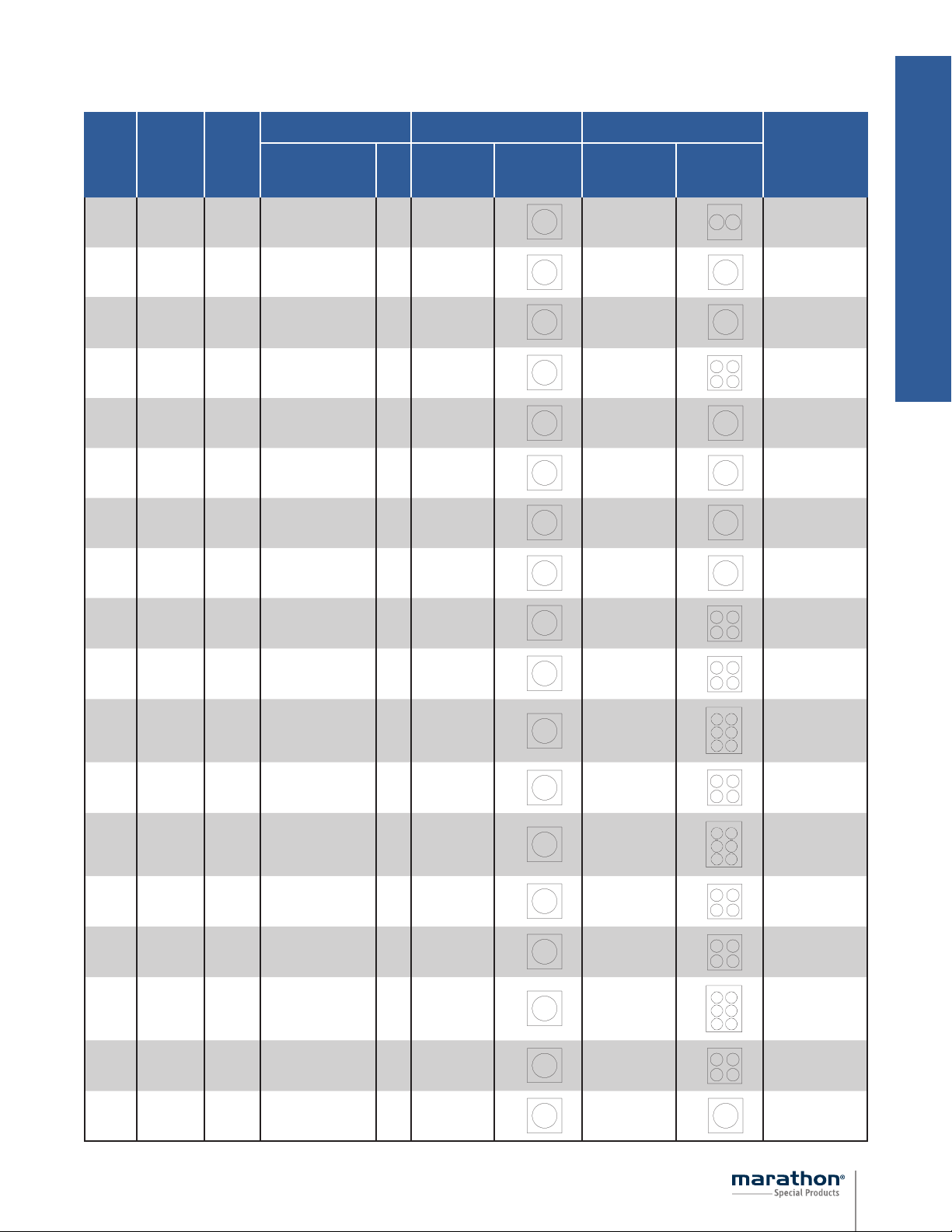

SPLICER/DISTRIBUTION

POWER BLOCKS

ELECTRICAL:

60 to 2280 amps

600 volts AC/DC (UL)

High SCCRs (35 to 100kA) with fusing or circuit breakers

Flexible stranded wire compliant

Multiple wire ratings

STANDARDS:

UL 1953 listed - or - UL 1059 recognized

• Listed file no. QPQS.E309401

• Recognized file no. XCFR2.E62806

CSA certified file no. LR19766 (CSA C22-2 No. 158)

CE (Component IEC 60947-7-1)

RoHS compliant (All)

WEBSITE RESOURCES:

Detailed product data sheets

• Material information

• Termination & mounting specifications

• Multiple wire rating specifications

• Detailed SCCR information

Dimensional drawings & 3D CAD files

Accessories available

1413400

ORDERING CODE:

SERIES

XXX

SERIES

132 0/1/2/3 2.54 3.00 2.42 SNAP-ON

133 1/2/3 5.36 4.00 3.33 SNAP-ON

134

135

140

141

142

143

144

145

*Covers can be found on Page 21

POLES

X

POLES

(x)

3

1/2/3

2/3

1/2/3/4

1/2/3

1/2/3

1/2/3

1/2/3

COVER

INDENTIFIER

XXX XX

Random

3-digit

OPTION

Blank = No Cover

CH = Snap-On (Hinge) Cover Attached

Identifier

DIMENSIONS (INCHES) 3-POLE

WIDTH LENGTH HEIGHT

5.64 5.00 3.92 SNAP-ON

10.08 5.73 4.77 SNAP-ON

5.38 2.90 2.06 SCREW-ON

2.12 2.29 1.62 SNAP-ON

2.75 2.88 1.78 SCREW-ON

5.00 4.00 2.61 SCREW-ON

6.03 4.75 2.91 SCREW-ON

8.54 5.5 3.13 SCREW-ON

1333595CH

COVER TYPE

AVAILABLE *

9

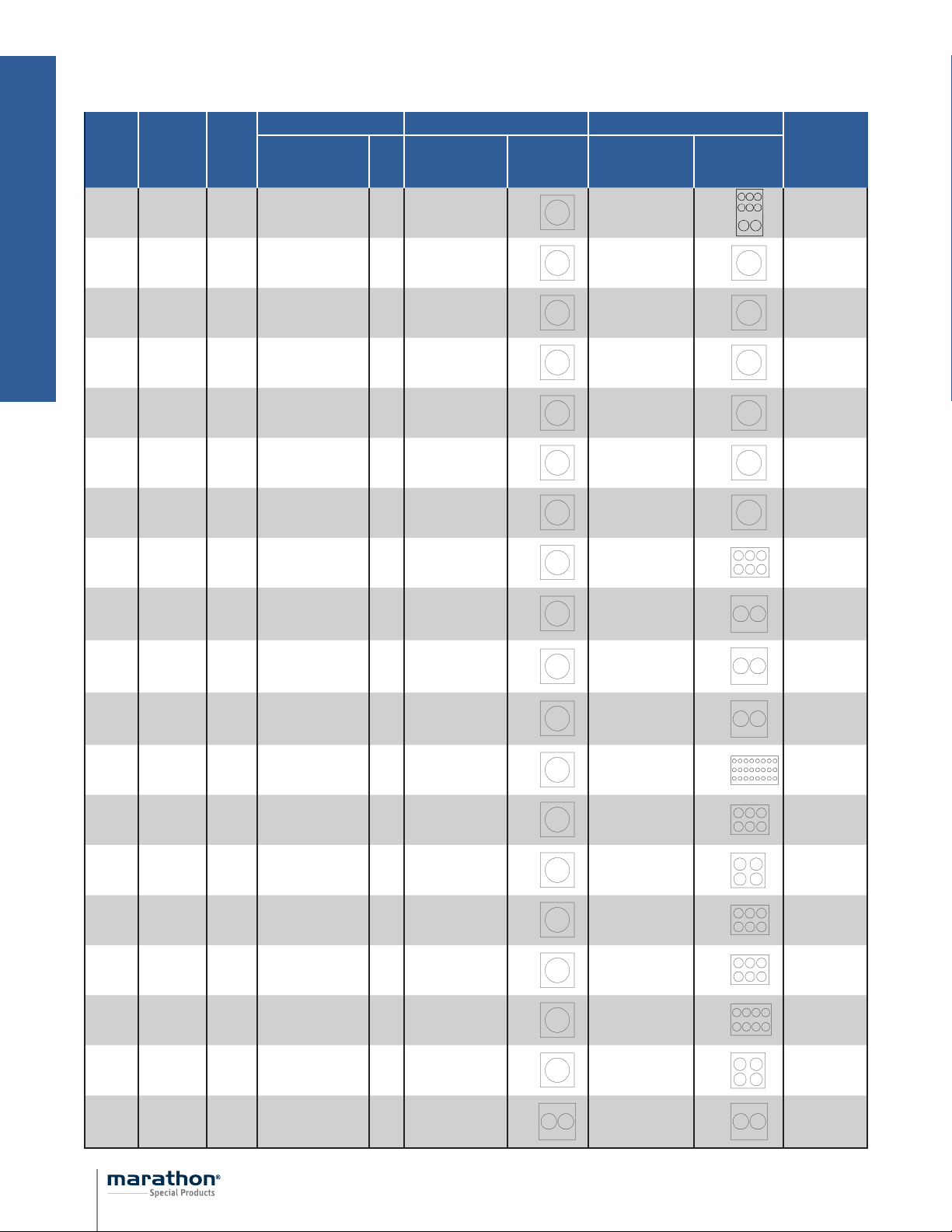

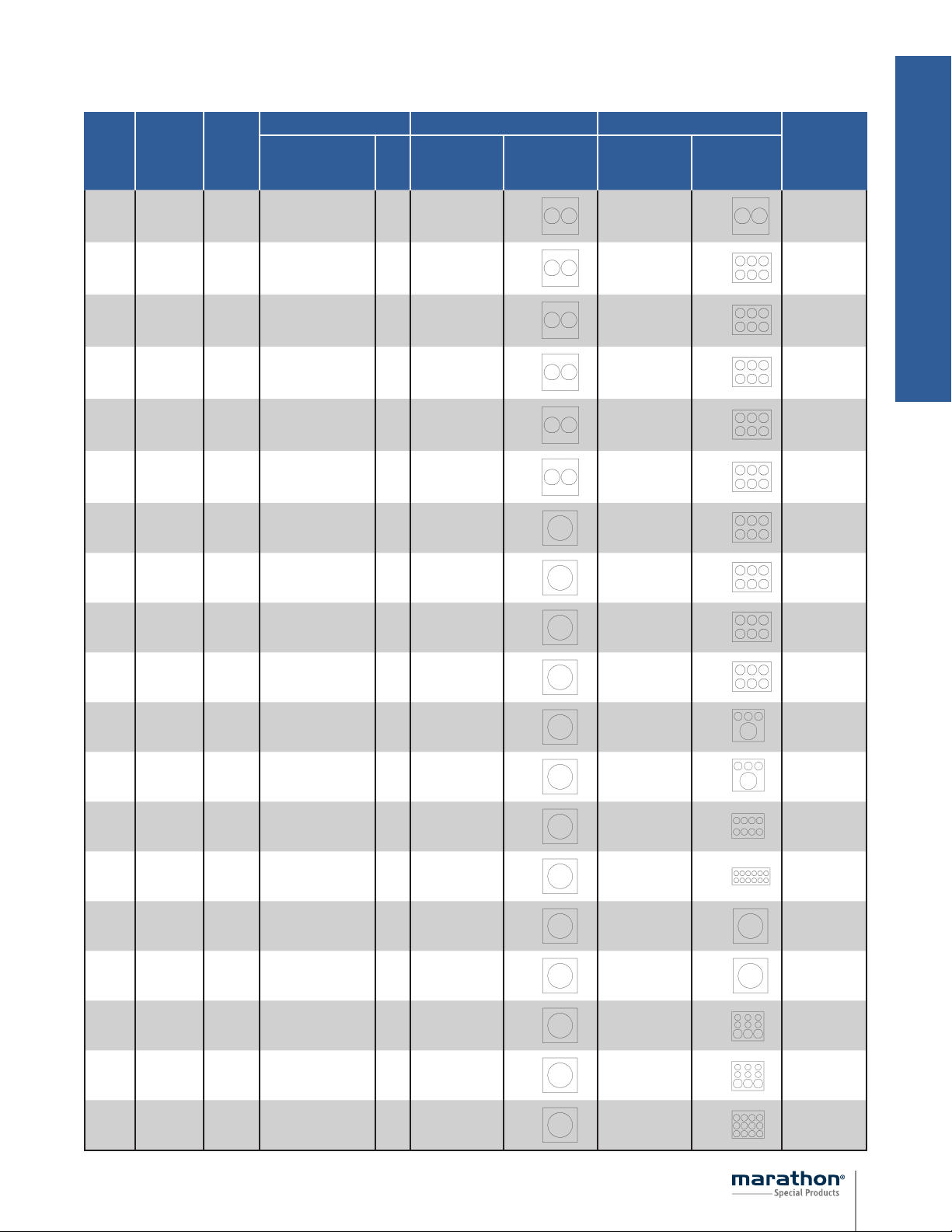

SPLICER/DISTRIBUTION

MATERIAL LINE SIDE LOAD SIDE

AMPS CATALOG#POLES

60 141x403 1/2/3/4 Thermo-Plastic AL #2 - #14 1

11 5 141x300 1/2/3/4 Thermo-Plastic AL #2 - #14 1 #2 - #14 1 --

11 5 142x552 1/2/3 Phenolic AL #2 - #14 1 #2 - #14 1 --

11 5 141x400 1/2/3/4 Thermo-Plastic AL #2 - #14 1 #10 - #18 4 --

150 142x121 1/2/3 Phenolic CU 1/0 - #14 1 1/0 - #14 1 --

175 132x572 0/1/2/3 Thermo-Plastic AL 2/0 - #14 1 2/0 - #14 1 --

175 142x572 1/2/3 Phenolic AL 2/0 - #14 1 2/0 - #14 1 --

175 132x972 1/2/3 Thermo-Plastic CU 2/0 - #14 1 2/0 - #14 1 --

(x)

INSULATOR

CONN.

AWG/kcmil

WIRE

RANGE

CONNECTOR

OPENINGS/

POLE

WIRE RANGE

AWG/kcmil

#10 - #18 2 --

CONNECTOR

OPENINGS/

POLE

CIRCUIT

COMPLIANT

PER UL508

FEEDER

POWER BLOCKS

175 132x570 0/1/2/3 Thermo-Plastic AL 2/0 - #14 1 #4 - #14 4 --

175 142x570 1/2/3 Phenolic AL 2/0 - #14 1 #4 - #14 4 --

175 132x580 0/1/2/3 Thermo-Plastic AL 2/0 - #14 1 #4 - #14 6 --

175 140x402 2/3 Phenolic AL 2/0 - #14 1 #4 - #14 4 --

175 140x401 2/3 Phenolic AL 2/0 - #14 1 #4 - #14 6 --

175 132x970 0/1/2/3 Thermo-Plastic CU 2/0 - #14 1 #4 - #14 4 --

175 142x970 1/2/3 Phenolic CU 2/0 - #14 1 #4 - #14 4 --

175 1343580 3 Thermo-Plastic AL 2/0 - #14 1 #4 - #14 6 Yes

200 1343570 3 Thermo-Plastic AL 3/0 - #14 1 #2 - #14 4 Yes

200 1343572 3 Thermo-Plastic AL 3/0 - #14 1 3/0 - #14 1 Yes

10

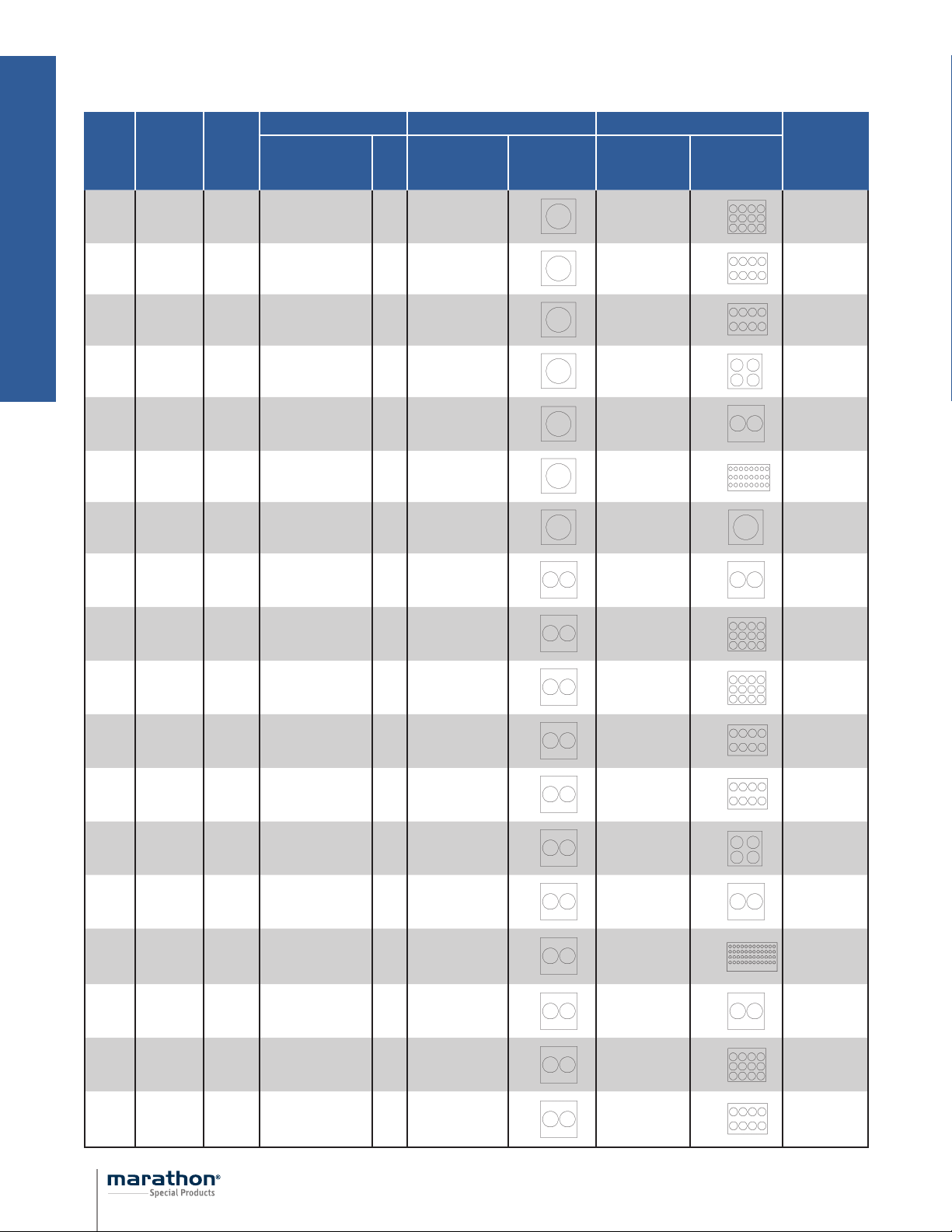

SPLICER/DISTRIBUTION

POWER BLOCKS

MATERIAL LINE SIDE LOAD SIDE

AMPS CATALOG#POLES

(x)

200 1343548 3 Thermo-Plastic AL 3/0 - #14 1

255 143x123 1/2/3 Phenolic AL 250 kcmil - #6 1

255 140x801 2/3 Phenolic CU 250 - #6 1 250 - #6 1 --

310 140x303 2/3 Phenolic AL 350 - #6 1 350 - #6 1 --

310 143x126 1/2/3 Phenolic AL 350 - #6 1 350 - #6 1 --

310 133x126 1/2/3 Thermo-Plastic AL 350 - #6 1 350 - #6 1 --

310 1343582 3 Thermo-Plastic AL 350 - #6 1 350 - #6 1 Yes

310 140x404 2/3 Phenolic AL 350 - #6 1 #4 - #14 6 --

INSULATOR

WIRE RANGE

AWG/kcmil

CONN.

CONNECTOR OPENINGS/POLE

WIRE RANGE

AWG/kcmil

#6 - #14

#2 - #14

250 kcmil - #6 1 --

CONNECTOR

OPENINGS/

POLE

8 Yes

FEEDER

CIRCUIT

COMPLIANT

PER UL 508

310 133x554 1/2/3 Thermo-Plastic AL 350 - #6 1 2/0 - #14 2 --

310 140x410 2/3 Phenolic AL 350 - #6 1 2/0 - #14 2 --

310 143x554 1/2/3 Phenolic AL 350 - #6 1 2/0 - #14 2 --

310 133x324 1/2/3 Thermo-Plastic AL 350 - #6 1 #8 - #14 24 --

335 144x401 1/2/3 Phenolic AL 400 - #6 1 #2 - #14 6 --

335 143x552 1/2/3 Phenolic AL 400 - #6 1 #2 - #14 4 --

335 143x553 1/2/3 Phenolic AL 400 - #6 1 #2 - #14 6 --

335 1343553 3 Thermo-Plastic AL 400 - #6 1 #2 - #14 6 Yes

335 144x560 1/2/3 Phenolic AL 400 - #6 1 #2 - #14 8 --

335 133x552 1/2/3 Thermo-Plastic AL 400 - #6 1 #2 - #14 4 --

350 133x305 1/2/3 Thermo-Plastic AL 2/0 - #14 2 2/0 - #14 2 --

11

SPLICER/DISTRIBUTION

MATERIAL LINE SIDE LOAD SIDE

AMPS CATALOG#POLES

(x)

350 143x306 1/2/3 Phenolic AL 2/0 - #14 2

350 143x555 1/2/3 Phenolic AL 2/0 - #14 2 #4 - #14 6 --

350 133x555 1/2/3 Thermo-Plastic AL 2/0 - #14 2 #4 - #14 6 --

350 1343555 3 Thermo-Plastic AL 2/0 - #14 2 #4 - #14 6 Yes

350 143x955 1/2/3 Phenolic CU 2/0 - #14 2 #4 - #14 6 --

350 133x955 1/2/3 Thermo-Plastic CU 2/0 - #14 2 #4 - #14 6 --

380 143x953 1/2/3 Phenolic CU 500 - #4 1 #2 - #14 6 --

INSULATOR

WIRE RANGE

AWG/kcmil

CONN.

CONNECTOR

OPENINGS/

POLE

WIRE RANGE

AWG/kcmil

2/0 - #14 2 --

CONNECTOR

OPENINGS/

POLE

FEEDER

CIRCUIT

COMPLIANT

PER UL 508

POWER BLOCKS

380 133x953 1/2/3 Thermo-Plastic CU 500 - #4 1 #2 - #14 6 --

380 144x551 1/2/3 Phenolic AL 500 - #4 1 #2 - #14 6 --

380 145x579 1/2/3 Phenolic AL 500 - #4 1 #2/0 - #14 6 --

380 133x587 1/2/3 Thermo-Plastic AL 500 - #4 1

380 143x587 1/2/3 Phenolic AL 500 - #4 1

380 145x594 1/2/3 Phenolic AL 500 - #4 1 #2 - #14 8 --

380 145x552 1/2/3 Phenolic AL 500 - #4 1 #2 - #14 12 --

420 144x557 1/2/3 Phenolic AL 600 - #4 1 600 - #4 1 --

420 133x360 1/2/3 Thermo-Plastic AL 600 - #2 1 600 - #2 1 --

420 133x588 1/2/3 Thermo-Plastic AL 600 - #2 1

#2 - #14

350 - #6

#2 - #14

350 - #6

#2 - #14

1/0 - #14

3/1

3/1

6/3

--

--

--

420 1343588 3 Thermo-Plastic AL 600 - #2 1

420 133x595 1/2/3 Thermo-Plastic AL 600 - #2 1 #4 - #14 12 --

#2 - #14

1/0 - #14

6/3

Yes

12

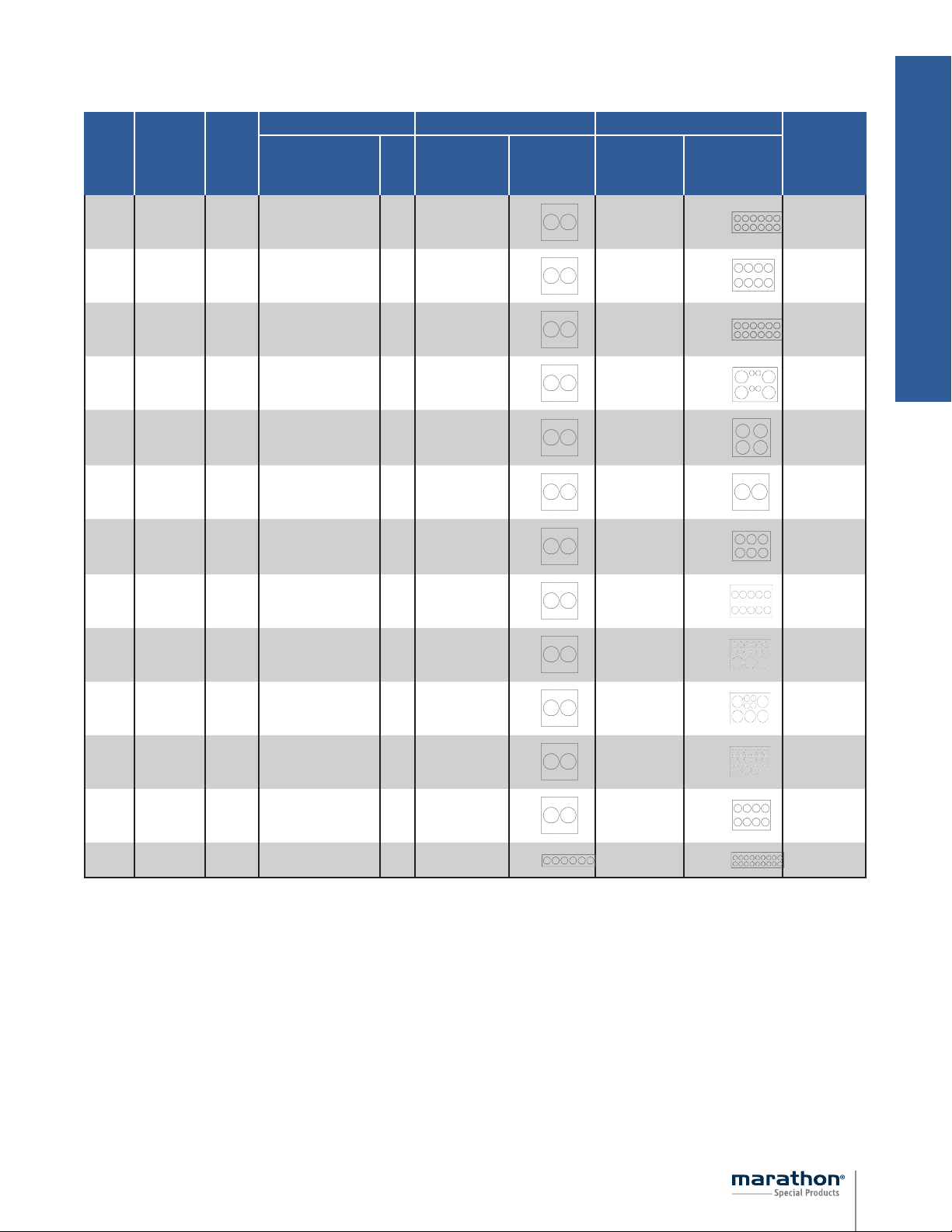

SPLICER/DISTRIBUTION

POWER BLOCKS

MATERIAL LINE SIDE LOAD SIDE

AMPS CATALOG#POLES

(x)

420 1343595 3 Thermo-Plastic AL 600 - #2 1

420 133x585 1/2/3 Thermo-Plastic AL 600 - #2 1 #2 - #14 8 --

420 1343585 3 Thermo-Plastic AL 600 - #2 1 #2 - #14 8 Ye s

420 133x575 1/2/3 Thermo-Plastic AL 600 - #2 1 2/0 - #14 4 --

420 133x565 1/2/3 Thermo-Plastic AL 600 - #2 1 250 - #6 2 --

420 135x601 1/2/3 Thermo-Plastic AL 600 - #2 1 #6 - #14 24 --

475 135x701 1/2/3 Thermo-Plastic AL 750 - 1/0 1 750 - 1/0 1 Ye s

INSULATOR

WIRE RANGE

AWG/kcmil

CONN.

CONNECTOR

OPENINGS/

POLE

WIRE RANGE

AWG/kcmil

#4 - #14 12 Yes

CONNECTOR

OPENINGS/

POLE

FEEDER

CIRCUIT

COMPLIANT

PER UL 508

1

510 133x320 1/2/3 Thermo-Plastic AL 250 - #6 2 250 - #6 2 --

510 133x596 1/2/3 Thermo-Plastic AL 250 - #6 2 #4 - #14 12 --

510 1343596 3 Thermo-Plastic AL 250 - #6 2 #4 - #14 12 Yes

510 133x597 1/2/3 Thermo-Plastic AL 250 - #6 2 #2 - #14 8 --

510 1343597 3 Thermo-Plastic AL 250 - #6 2 #2 - #14 8 Ye s

510 133x598 1/2/3 Thermo-Plastic AL 250 - #6 2 2/0 - #14 4 --

620 145x129 1/2/3 Phenolic AL 350 - #4 2 350 - #4 2 --

620 1331348 1 Thermo-Plastic AL 350 - #4 2 #8 - #14 48 --

760 145x301 1/2/3 Phenolic AL 500 - #4 2 500 - #4 2 --

760 145x592 1/2/3 Phenolic AL 500 - #4 2 #4 - #14 12 --

760 145x586 1/2/3 Phenolic AL 500 - #6 2 2/0 - #14 8 --

13

SPLICER/DISTRIBUTION

MATERIAL LINE SIDE LOAD SIDE

AMPS CATALOG#POLES

(x)

INSULATOR

WIRE RANGE

AWG/kcmil

CONN.

760 145x992 1/2/3 Phenolic CU 500 - #4 2

CONNECTOR

OPENINGS/

POLE

WIRE RANGE

AWG/kcmil

#2 - #14 12

CONNECTOR

OPENINGS/

POLE

FEEDER

CIRCUIT

COMPLIANT

PER UL 508

760 145x986 1/2/3 Phenolic CU 500 - #4 2 2/0 - #14 8 --

760 145x408 1/2/3 Phenolic AL 500 - #6 2 #2 - #14 12 --

840 145x411 1/2/3 Phenolic AL 600 - #2 2

3/0 - #6

#4 - #14

4/4

950 135x605 1/2/3 Thermo-Plastic AL 600 - #2 2 350 - #6 4 --

950 135x702 1/2/3 Thermo-Plastic AL 750 - 1/0 2 750 - 1/0 2 Yes

950 135x703 1/2/3 Thermo-Plastic AL 750 - 1/0 2 250 - #6 6 Yes

POWER BLOCKS

--

1

1

950 135x704 1/2/3 Thermo-Plastic AL 750 - 1/0 2 2/0 - #14 10 Yes

950 135x705 1/2/3 Thermo-Plastic AL 750 - 1/0 2

950 135x706 1/2/3 Thermo-Plastic AL 750 - 1/0 2

950 135x707 1/2/3 Thermo-Plastic AL 750 - 1/0 2

#2 - #14

250 - #6

#2 - #14

250 - #6

#2 - #14

3/0 - #6

12/3

4/5

12/4

950 135x708 1/2/3 Thermo-Plastic AL 750 - 1/0 2 3/0 - #6 8

2280 1453401

(1)

UL Listed when purchased without a cover (CH). When purchased with a cover, the product is UL Recognized to US and

2

1 Phenolic AL 500 - #4 6 2/0 - #14 18 --

Canadian standards (cURus).

(2)

Special 1-pole power block with the dimensions of a 3-pole 145 series power block.

Yes

Yes

Yes

Yes

1

1

1

1

1

14

Loading...

Loading...