Marathon Special Products 135X705 Data Sheet

Product Data Sheet

135X705

Power Distribution Block

UL Listed

Category QPQS

950 Amps, 600 Volts (AC/DC)

Provides Feeder Circuit Terminal Spacing up to 600 Volts per UL 508A, Section 10.

Wire Range:

Line Side: (2) 750kcmil – 1/0 AWG

Load Side: (3) 250 kcmil – 6 AWG and (12) 2 – 14 AWG

See tables below for SCCR wire ranges, flexible stranded and multiple wire approvals.

Electrical Ratings:

• 950A copper wire, 770A aluminum wire (Based on NEC Table 310-16, 75°C columns)

• UL Voltage Rating: 600 Volts AC/DC (UL 1953)

• Factory and Field Wiring

Agency Certifications:

• UL Listed, Investigated to UL 1953, File QPQS.E309401

• RoHS Compliant

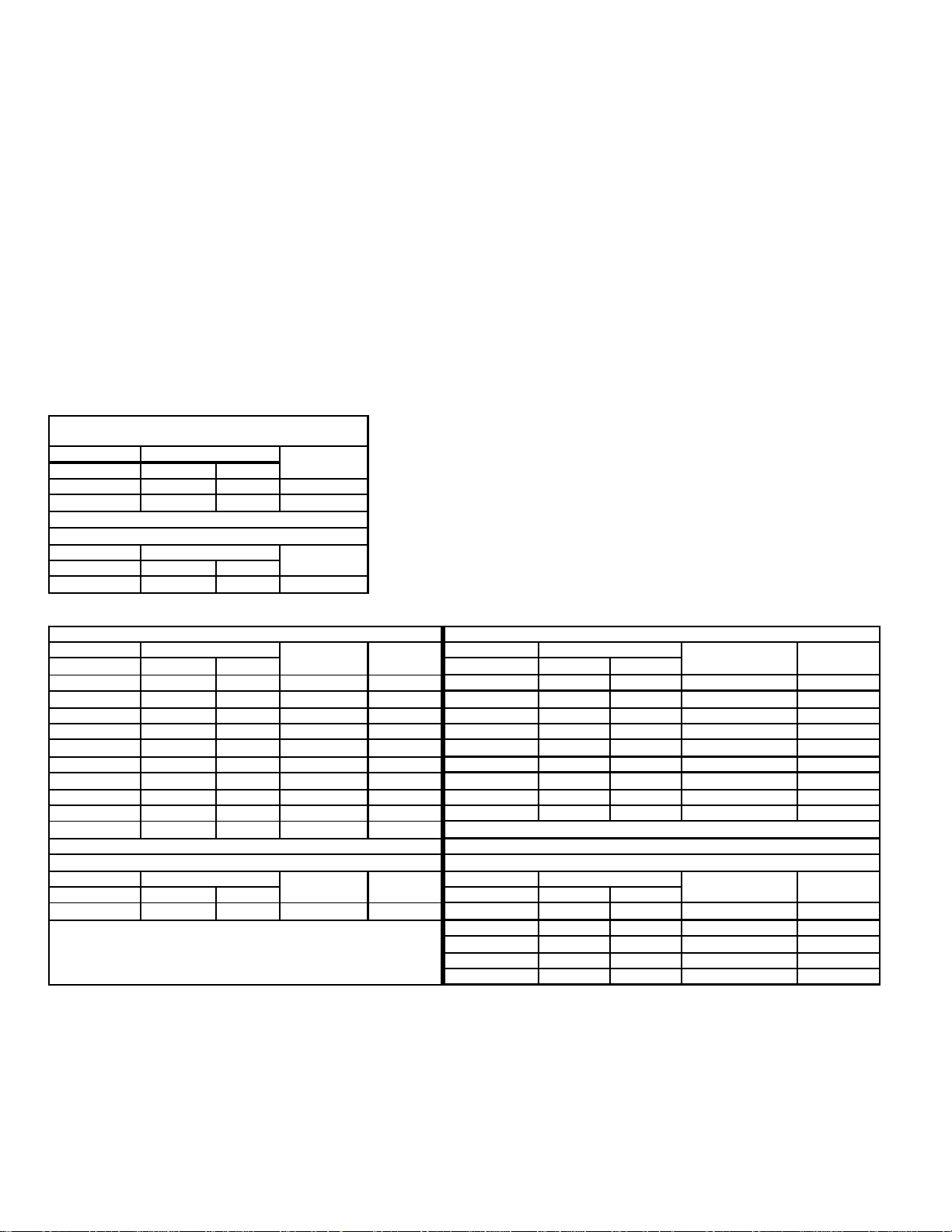

Short Circuit Current Ratings:

SCCR Rating applies for Copper Stranded wire only

UL Class B, C (known as Rigid Stranded, Building Wire, Code Wire)

UL Class G, H, I (Flexible Stranded, includes DLO)

Suitable Conductors (kcmil/AWG)

Copper, St ra nd ed

Line Load

Size Class Size Class J T RK1 RK5 G

25 0 - 2 B, C

3 /0 - 2 G, H, I 10 0,000 60 0

750 - 1/0 B,C 250 -6 B,C

535-1/0 G, H, I 3/0 - 6 G, H, I

# 2 Op en ing

2 - 6 B, C

4 - 6 G, H, I

For DC power or any wire combinations or Overcurrent Protection not shown- SCCR is

10,000A

Overcur rent Protectio n

Class/Max Amp Rating

600 700

300 200 1006060

300

300 300 200

600

200

100 60

SCCR , RM S Volt s

SYM Amps Max

Minimum Enclosure Size: 20” x 24” x 8” (3840 cu. In)

G

750

1/0

67.8

600

B, C

q

C

2

2

S

yp

p

p

g

A

G

G

Mechanical Ratings:

• Maximum insulator base temperature: 125°C (257°F) UL RTI

• Flammability rating of insulator base: UL 94 V-0

Materials:

• Connector: High conductivity aluminum, tin plated

• Insulator base: Glass filled polycarbonate (thermoplastic)

• Terminal screws: Aluminum, tin plated and Steel, nickel plated

• Connector mounting screw: Steel, zinc plated

Wire Ranges, Wire Types, Torque Ratings: 135X705

UL Class B, C (known as Rigid Stranded, Building Wire, Code Wire)

UL Class G, H, I (Flexible Stranded, includes DLO)

Line Side 2) 750 kcmil - 1/0 AWG

Copper Condu ctor

Wire Size Torque

kcmil - AW

-

53 5 - 1/ 0 6 7.8 6 0 0 G ,H , I

N.m in. lbs UL Class

Aluminu m Con ductor

Wire Size Torque

kcmil - AWG N.m in. lbs Type

750 - 1/0 67.8 600 Stranded

Load Side 3) 250 kcmil - 6 AW

Copp er Conduc tor Copper Conductor

Wire Size Tor

kcmil - AWG N.m in. lbs UL Class Opening kcmil - AWG N.m in. lbs UL Class Opening

250 31.0 275 B,

4/0 31.0 275 B,C 1 3 5.7 50 B,C 1

3/0 31.0 275 B, C, G, H, I 1 4 5.7 50 B, C, G, H, I 1

2/0 31.0 275 B, C, G, H, I 1 6 5.7 50 B, C, G, H, I 1

1/0 31.0 275 B, C, G, H, I 1 8 5.7 50 B, C, G, H, I 1

1 31.0 275 B, C, G, H, I 1 10 4.5 40 B, C, G, H, I* 1

31.0 275 B, C, G, H, I 1 1

3 31.0 275 B, C, G, H, I 1 14 4.5 40 B, C, G, H, I* 1

4 31.0 275 B, C, G, H, I 1 *Also Solid Cu 1

631.0275B, C, G, H, I1

Wire

ize Torque No. Per Wire Size Torque No. Per

kcmil - AWG N.m in. lbs T

250 - 6 31.0 275 Stranded 1 2 5.7 50 Stranded 1

ue No. Per Wire Size Torque No. Per

125.750B, C1

Aluminum Conductor

eO

eningkcmil - AWG N.m in. lbs TypeO

3 5.7 50 Stranded 1

4 5.7 50 Stranded 1

6 5.7 50 Stranded 1

Load Side 12) 2 -14 AW

4.5 40 B, C, G, H, I* 1

luminum Conduct or (#8 AWG Minimum)

enin

Installation:

• Wire strip length, line side tap – 1 ¾”

• Wire strip length, load side tap, top row large – 7/8”, small ½”

bottom row large– 1 7/8” small – 7/8”

• Panel mountable: recommended fastener (4) per pole, ¼ “ or 6mm

Torque to 30 in. lbs. (3.4 N.m)

Loading...

Loading...