PRODUCT INFORMATION PACKET

Model No: 184TTGN6544

Catalog No: U990-P

5 HP Explosion Proof Motor, 3 phase, 1800 RPM, 230/460 V, 184T Frame, EPFC

Explosion Proof NEMA Motors

Regal and Marathon are trademarks of Regal Beloit Corporation or one of its affiliated companies.

©2020 Regal Beloit Corporation, All Rights Reserved. MC017097E

1 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 71 of 7

Product Information Packet: Model No: 184TTGN6544, Catalog No:U990-P 5 HP Explosion Proof Motor, 3 phase, 1800 RPM, 230/460 V, 184T Frame,

EPFC

Nameplate Specifications

Output HP 5 Hp Output KW 3.7 kW

Frequency 60 Hz Voltage 230/460 V

Current 12.4/6.2 A Speed 1755 rpm

Service Factor 1.15 Phase 3

Efficiency 90.2 % Power Factor 83.5

Duty Continuous Insulation Class F

Design Code B KVA Code J

Frame 184T Enclosure Explosion Proof Fan cooled

Thermal Protection Thermostats (N/C) Ambient Temperature 40 °C

Drive End Bearing Size 6206 Opp Drive End Bearing Size 6206

UL UL Listed; also, UL Certified for Canada CSA N

CE N IP Code 54

Hazardous Location

EXP PROOF CL I GR C&D CL II GR

F&G T3B

Technical Specifications

Electrical Type Squirrel Cage Inverter Rated Starting Method Line Or Inverter

Poles 4 Rotation Reversible

Resistance Main 2.62 Ohms Mounting Rigid Base

Motor Orientation Horizontal Drive End Bearing Ball

Opp Drive End Bearing Ball Frame Material Cast Iron

Shaft Type T Overall Length 17.87 in

Frame Length 10.00 in Shaft Diameter 1.125 in

Shaft Extension 2.85 in Assembly/Box Mounting F1 ONLY

Connection Drawing A-EE7308T Outline Drawing 035660-1000

This is an uncontrolled document once printed or downloaded and is subject to change without notice. Date Created:27/05/2020

2 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 72 of 7

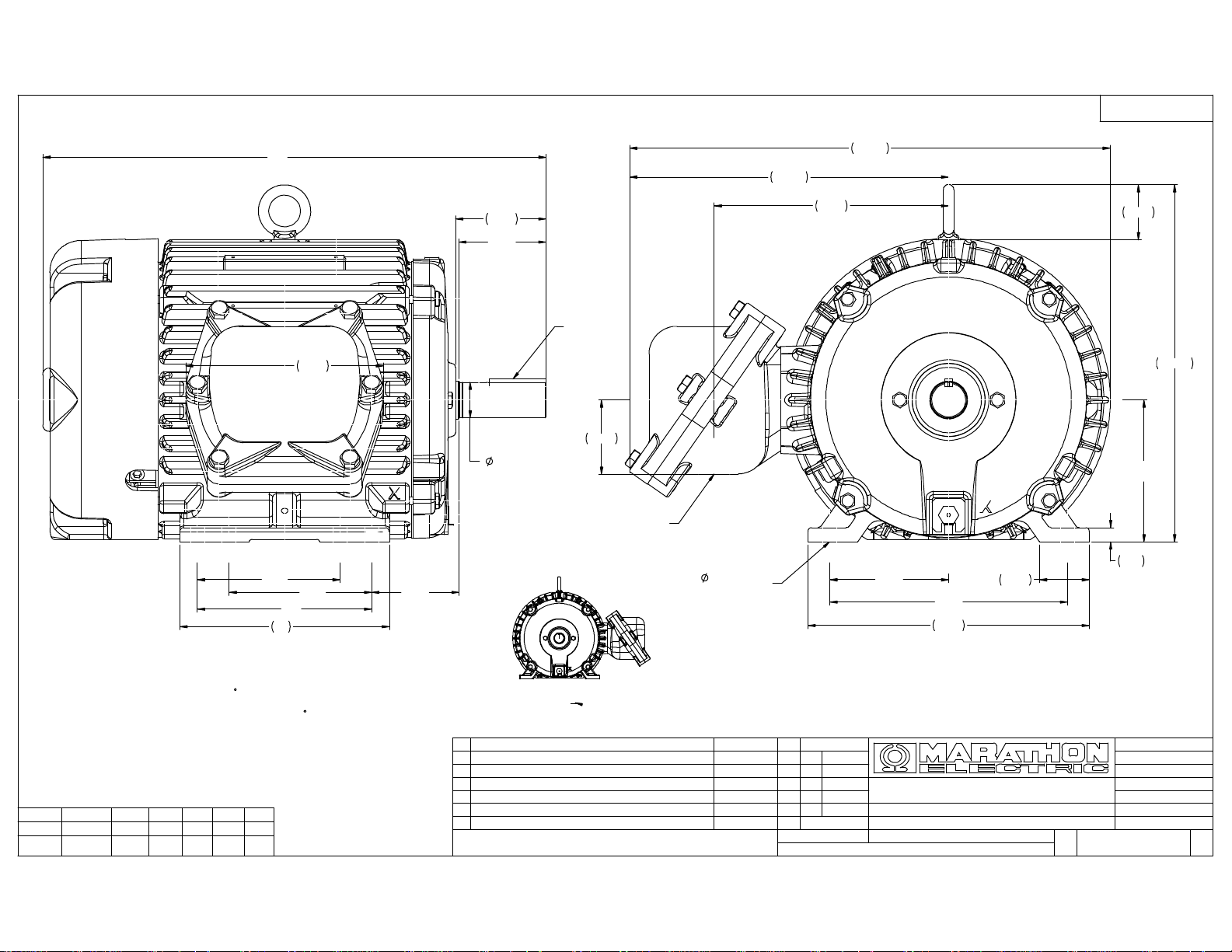

035660

2FF

(c)

15.16

10.06

2.85

7.40

1.73

2.75

.25x.25x1.75

KEY

6.24

11.27

2.34

1.1250

1.1245

3/4" NPT

LEAD HOLE

4.50

4.44

.45

.41-.46 THRU

2FF

2.75

8 HOLES

2F

B

3.75

1.57

7.50

8.88

NOTES:

1. NAMEPLATE TO BE READ FROM CONDUIT BOX SIDE

OF MOTOR.

2. CONDUIT BOX CAN ROTATED IN 90 STEPS.

3. CONDUIT BOX CAN MOUNTED ON OPPOSITE SIDE BY

REMOVING BRACKETS AND TURNING FRAME 180 .

THIS MODIFICATION CAN BE PERFORMED ONLY BY

THE ORIGINAL EQUIPMENT MANUFACTURER, OR BY

A FACILITY THAT IS COVERED UNDER UNDERWRITERS

LABORATORIES INC. CATEGORY PTKQ. TITLED "MOTORS

AND GENERATORS REBUILT FOR USE IN HAZARDOUS

LOCATIONS."

1000 184 17.87 8.61 7.50 5.50 3.75

800 182/184 15.87 6.61 5.50 4.50 2.75

DASH FRAME C B 2F 2FF BS

11/4/2011 5:39:41 AM - Converted by Connexus

F2 LOCATION

3

ADDED F2 VIEW.

2 CHANGED 1000 FRAME FROM 182/184 TO 184 ISAAC 11-2933

1

CHG'D 1000 FRAME DIM FROM 2.75 TO 3.75

NO

THIS DRAWING IN DESIGN AND DETAIL IS OUR PROPERTY AND MUST NOT BE USED EXCEPT

IN CONNECTION WITH OUR WORK. ALL RIGHTS OF DESIGN AND INVENTION ARE RESERVED.

THIS IS AN ELECTRONICALLY GENERATED DOCUMENT - DO NOT SCALE THIS PRINT

REVISION

ST 11/04/2011

KBB

6/28/2011AJEH

PN

2/10/2011

BY & DATE

AK

CHK

RFP

DIST

TOLERANCES

UNLESS SPECIFIED

DEC

INCHES

.X

±.1

.XX

±.03

.XXX

±.005

.XXXX

±.0005

ANG

±7'30"

WA - NLV

3 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 73 of 7

TITLE

OUTLINE - EPFC

180 FR.

MAT'L

FINISH

CAD FILE

035660

DRAWN

CTO 07-05-2007

CHK

ML 3/26/2008

APPR

SW 3/26/2008

SCALE

7:16

REF

FMF

PREV

DRAWING NOSIZE REV

B

035660

3

Uncontrolled Copy

HIGH VOLTAGE

(U1) T1

(V1) T2

(W1) T3

(U2) T4

(U3) T7

(V2) T5

(V3) T8

(W2) T6

(W3) T9

LOW VOLTAGE

(U1) T1

(U3) T7

(V1) T2

(V3) T8

LOW VOLTAGE

T4 T5 T6

P1

HIGH VOLTAGE

T4 T7 T5 T8 T6 T9

L1

L2

L3

L1 T7 T1 L2 T8 T2 L3 T9 T3

L1 T1 L2 T2 L3 T3

P2

NOTE FOR FACTORY USE ONLY:

TO SURGE TEST FOR COMMON CONNECT:

HIGH VOLT: CONNECT P1 TO T1

THEN P2 TO L1

LOW VOLT: CONNECT P1 TO T1 & T7,

THEN P2 TO L1

L1

L2

P1

P2

PROT.

THREE PHASE

DUAL VOLTAGE MOTOR

PROT.

T1

T4

T7

T9

T6

T3

T8

T5

THERMO-PROTECTORS

CONNECTED IN SERIES

RED

OR

PURPLE

BLACK

BLACK

YELLOW

BROWN

ORANGE

BLACK

BLACK

T2

PURPLE

RED

BLUE

OR

RED

P1 (TB1)

T1 (U1)

T4 (U2)

T9 (W3)

T7 (U3)

T8 (V3)

T6 (W2)

T5 (V2)

T2 (V1)

T3 (W1)

P2 (TB2)

(W1) T3

(W3) T9

L3

(U2) T4

(V2) T5

(W2) T6

DRAWING REVISION

ECO

ECO DESCRIPTION

T

ECO-0159915

ADDED TERMINAL CONNECTION DIAGRAM

COPYRIGHT REGAL BELOIT AMERICA, INC. ALL RIGHTS RESERVED.

PROPRIETARY AND CONFIDENTIAL INFORMATION - THIS DOCUMENT IS THE PROPERTY OF

REGAL BELOIT AMERICA, INC. ("OWNER") AND CONTAINS OWNER'S PROPRIETARY

INFORMATION. ANY PERSON, CORPORATION OR OTHER FIRM RECEIVING IT IS DEEMED,

BY RECEIVING IT, TO AGREE THAT IT, AND/OR ANY PART OF IT, SHALL NOT BE DISCLOSED

TO ANY PERSON, CORPORATION OR OTHER ENTITY, DUPLICATED, AND/OR USED, EXCEPT

AS EXPRESSLY APPROVED IN WRITING IN ADVANCE BY OWNER. THIS DOCUMENT SHALL

BE RETURNED TO OWNER UPON REQUEST. IT MAY BE SUBJECT TO CERTAIN

RESTRICTIONS UNDER APPLICABLE EXPORT CONTROL LAWS AND REGULATIONS.

REVISION BY

ZR

APPROVED BY

DR

NOTE: LEAD'S COLOR CAN BE YELLOW OR WHITE FOR MT2 PLANT

DATE

01-14-2019

DATE

01-15-2019

DRAWN BY

DATE

APPROVED BY

DATE

REFERENCE

THIRD ANGLE

PROJECTION

SMC

05-13-1992

05-13-1992

EE7308/EE7300

PROT.

VIEW OF TERMINAL END

TM

Regal Beloit America, Inc.

TB

DESCRIPTION

CONN DIAGRAM-INTERNAL

MATERIAL

SIZE

DRAWING NUMBER

3 PHASE - DUAL VOLTAGE MOTOR

A

4 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 74 of 7

EE7308T

PROCESS/FINISH

SHEET

1 OF 1

CERTIFICATION DATA SHEET

Model#: 184TTGN6544 AA WINDING#: K1844215 NONE 1

CONN. DIAGRAM: A-EE7308T ASSEMBLY: F1 ONLY

OUTLINE: 035660-1000

TYPICAL MOTOR PERFORMANCE DATA

HP KW SYNC. RPM F.L. RPM FRAME ENCLOSURE KVA CODE DESIGN

5&3 3.7&2.24 1800 1755&1465 184T EPFC J B

PH Hz VOLTS FL AMPS START TYPE DUTY INSL S.F AMB°C ELEVATION

3 60/50 230/460#190/

380

12.4/6.2&9.6/4.8LINE OR

INVERTER

CONTINUOUSF3 1.15/1.15 40 3300

FULL LOAD EFF:

90.2&90.2

3/4 LOAD EFF: 90.2 1/2 LOAD EFF: 90.2 GTD. EFF ELEC. TYPE NO LOAD AMPS

FULL LOAD PF:

83.5&79

3/4 LOAD PF: 78.5 1/2 LOAD PF: 70 89.5 SQ CAGE INV RATED 5.6 / 2.8

F.L. TORQUE LOCKED ROTOR AMPS L.R. TORQUE B.D. TORQUE F.L. RISE°C

15 LB-FT 92 / 46 34.5 LB-FT 230 45 LB-FT 300 50

SOUND PRESSURE

@ 3 FT.

SOUND POWER ROTOR WK^2 MAX. WK^2 SAFE STALL TIME STARTS

/HOUR

APPROX. MOTOR

WGT

62 dBA 72 dBA 0.5 LB-FT^2 50 LB-FT^2 25 SEC. 2 130 LBS.

*** SUPPLEMENTAL INFORMATION ***

DE BRACKET

TYPE

ODE BRACKET

TYPE

MOUNT

TYPE

ORIENTATION SEVERE

DUTY

HAZARDOUS

LOCATION

DRIP

COVER

SCREENS PAINT

STANDARD STANDARD RIGID HORIZONTAL TRUE EXP PROOF CL

I GR C&D CL II

GR F&G T3B

FALSE NONE BLUE (EPOXY)

BEARINGS GREASE SHAFT TYPE SPECIAL DE SPECIAL ODE SHAFT

MATERIAL

FRAME

MATERIAL

DE OPE

BALL BALL POLYREX EM T NONE NONE 1144

STRESSPROOF

(C-223)

CAST IRON

6206 6206

THERMO-PROTECTORS THERMISTORS CONTROL SPACE /n HEATERS

THERMOSTATS PROTECTORS WDG RTDs BRG RTDs

TSTATS (N/C) NOT NONE NONE NONE FALSE NONE VOLTS

If Inverter equals NONE, contact factory for further

information

*

N

O

T

E

S

*

INVERTER TORQUE: CONSTANT 10:1

INV. HP SPEED RANGE: NONE

ENCODER: NONE

NONE NONE

NONE NONE PPR

BRAKE: NONE NONE

NONE P/N NONE

NONE NONE

NONE FT-LB NONE V NONE Hz

DATE: 06/28/2017 07:37:34 AM

FORM 3531 REV.3 02/07/99

Uncontrolled Copy

5 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 75 of 7

** Subject to change without notice.

Uncontrolled Copy

6 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 76 of 7

Speed (RPM)

230/460#190/380

Current (Amps)

P

E

10.0

15.0

0.0

5.0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

20.0

TORQU

25.0

30.0

35.0

40.0

45.0

50.0

30.0

40.0

50.0

0% 20% 40% 60% 80% 100% 120% 140%

F

60.0

70.0

EFF

80.0

100.0

90.0

Torque (ft-lb)

Efficiency (%) P.F. (%) Current (Amps)

46.0 41.0 25.0 6.2 2.80 5.0

34.5 31.0 45.0 15.0 0.00 1800

0 900 1600 1755 1800

P.F. (%)

Submitted by:

Customer:

Attention:

Date:

1800 1790 1780 1765 1755 1,745 1740 0

0.00 3.7 7.4 11.5 15.0 17.5 19.0 34.5

6.5 47.0 70.0 78.5 83.5 84.5 86.0 48.0

LR Pull-Up BD Rated Idle

FAREEDA DUDEKULA

2.80 3.0 3.8 5.0 6.2 7.2 7.8 46.0

6/19/2017 184TTGN6544

Load 0% 25% 50% 75% 100% 115% 125% LR

Current (Amps)

Torque (ft-lb)

RPM

Efficiency (%)

Motor Speed Data

LOAD

85.5 90.2 90.2 90.2 89.5 88.5

Data Sheet

Torque Amps

Speed -Torque Curve

Motor Load Data

RPM

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

A

M

P

S

Rotor/Shaft wk²

Duty

Ambient

Elevation

Ref Wdg

Sound Pressure @ 1M

VFD Rating

Outline Dwg 035660-1000

Conn. Diag A-EE7308T

0

0

Additional Specifications:

1.5080 1.1280 3.6910 5.6930 104.3280

R1 R2 X1 X2 Xm

EQUIV CKT (OHMS / PHASE)

Design

LR Code letter

Service Factor

Temp Rise @ FL

Construction

Voltage

Frequency

HP

Sync. RPM

Frame

Enclosure

Information Block

K1844215 NONE

CONSTANT 10:1

62 dBA

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

A

M

P

S

CONT

1,000

0.50

feet

Lb-Ft²

1.15

50

40

°

°

C

C

60

B

J

Hz

TEFC

TFN

184

V

Submittal

Data @

460

v

Uncontrolled Copy

7 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 77 of 7

Loading...

Loading...