Marathon Electric NEMA 182T – 286T Installation, Operation, and Maintenance Instructions

Installation, Operation, and Maintenance

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE

OWNER: READ AND SAVE THESE INSTRUCTIONS

Instructions

NEMA 182T – 286T, IEC 112 -180

Permanent Magnet Motors Operated On

Variable Frequency Drives (VFD)

SAFETY INSTRUCTIONS

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

WARNING: Warning indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Caution indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE: Notice indicates a situation not related to personal injury which, if not

avoided, may result in motor or equipment damage.

Before installing, using, or servicing this product, carefully read and fully understand

the instructions including all warnings, cautions, & safety notice statements. To reduce

risk of personal injury, death and/or property damage, follow all instructions for proper

motor installation, operation and maintenance.

Although you should read and follow these instructions, they are not intended as a

complete listing of all details for installation, operation, and maintenance. If you have

any questions concerning any of the procedures, or if you have a safety concern not

covered by the instructions, STOP, and call the appropriate motor company listed on the

motor nameplate. The phone number can be found on the web site listed above.

Table of Contents

1.0 SAFETY INFORMATION

1.1 Electrical Safety

1.2 Mechanical Safety

1.3 Environmental Safety

2.0 RECEIVING & INSPECTION

2.1 Initial Inspection

2.1.1 Packing List & Inspect

2.1.2 Turn Motor Shaft

2.1.3 Check Nameplate

2.2 Handling

2.2.1 Lifting Angle Limitations

2.3 Storage

2.3.1 Bearing Lubrication

2.3.2 Shaft Rotation

2.3.3 Damp or Humid Storage Locations

3.0 INSTALLATION AND OPERATION

3.1 Location

3.1.1 Selecting a Location

3.1.2 Ambient Temperature Limits

3.1.3 Construction Selection per Location

3.1.3.1 Totally Enclosed

3.1.3.2 Hazardous Locations Motors

3.2 Mounting Motor

3.2.1 Rigid Base (Footed)

3.2.2 Rigid Base Hole Selection -6 or 8 Hole Bases

3.2.3 Vertical Mounting

3.3 Application Assembly to Motor

3.3.1 General: Proper Alignment

3.3.2 Direct Coupling

3.3.3 Direct Connected

3.3.4 Belted

3.3.4.1 Sheave Diameter Requirements

3.3.4.2 Number of Belts

3.3.4.3 Sheave Location

3.3.4.4 Belt Tension

3.3.5 Permanent Magnet Motor VFD Operation

3.3.5.1 Overspeed Capability

3.3.5.2 Cable Lengths

3.3.5.3 VFD Grounding

3.3.5.4 Stray Voltage On Accessory Leads

3.3.6 Accessories

3.3.6.1 General

3.3.6.2 Brake Motors

3.3.6.3 Space Heaters

3.3.6.4 Thermal Protection

3.3.6.5 RTD Alarm & Trip Settings

3.3.7 Guards

3.4 Electrical Connections

3.4.1 Power Supply / Branch Circuit

3.4.1.1 Fuses, Breakers, Overload Relays

3.4.1.2 AC Power Supply Limits

3.4.2 Terminal Box

3.4.2.1 Conduit opening

3.4.3 Lead Connections

3.4.4 Ground Connections

3.4.4.1 Electrical Interference

3.4.5 Start Up

3.4.5.1 Start Up – No Load Procedure

3.4.5.2 Start Up – Load Connected Procedure

4.0 MAINTENANCE

4.1 General Inspection

4.1.1 Ventilation

4.1.2 Insulation

4.1.3 Electrical Connections

4.1.4 Seal Condition

4.1.5 Safety Labels

4.2 Lubrication and Bearings

4.2.1 Grease Type

4.2.2 Bearing Operating Temperature

4.2.3 Lubrication Interval

4.2.4 Lubrication Procedure

4.2.5 Lubrication Example

4.3 Trouble Shooting

4.3.1 General Trouble-Shooting Warnings

_________________________________________________________________________________________________________________________

1.0 SAFETY INFORMATION

1.1 ELECTRICAL SAFETY

WARNING: ELECTRICAL SHOCK HAZARD

Electrical connections shall be made by a qualified electrician in

accordance with all applicable codes, ordinances and sound practices.

Failure to follow these instructions could result in serious personal

injury, death and/or property damage. Only qualified personnel who

are familiar with the applicable National Code (USA = NEC) and local

codes should install or repair electrical motors and their accessories.

WARNING: ELECTRICAL HAZARD: Failure to connect

motor and variable frequency drive in accordance with the drive

manufacturer’s documentation may result in serious injury, death,

and/or property damage.

WARNING: ELECTRICAL LIVE CIRCUIT HAZARD

Do not touch electrically live parts. Disconnect, lockout and tag input

power supply before installing or servicing motor (includes accessory

devices). Use a voltmeter to verify that power is off before contacting

conductors.

WARNING: ELECTRICAL SHOCK HAZARD

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not open terminal box or touch

unprotected terminals while the motor shaft is rotating. Failure to do so

may cause serious injury or death to personnel.

WARNING: ELECTRICAL HAZARD

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not operate the motor or allow

equipment to back drive the motor above the maximum RPM listed on

the motor nameplate. Failure to do so may cause serious injury or

death to personnel or damage the motor or system equipment.

WARNING: ELECTRICAL GROUNDING HAZARD

Failure to properly ground motors, per the National Electrical Code

(NEC) Article 430 and local codes may cause serious injury or death to

personnel. For general information on grounding refer to NEC Article

250. (Also see “Ground Connections section 3.4.4“).

WARNING: MAGNETIC FIELD HAZARD

Permanent magnet motor rotors, when removed from the stator,

expose surrounding personnel and equipment to powerful magnetic

fields which may cause serious health hazards to persons with

pacemakers, hearing aids, or other implanted electronic medical

devices and may impact other electronic devices such as mobile

phones, credit cards, etc.

NOTICE: MOTOR NOT SUITED FOR OPERATION ON LINE POWER

Permanent magnet (PM) motors can only be operated by a PM motor

compatible VFD (Variable Frequency Drive). Connecting directly to

line power may result in motor damage.

1.2 MECHANICAL SAFETY

WARNING: LOOSE PARTS HAZARD

Before starting the motor, remove all unused shaft keys and loose

rotating parts to prevent them from flying off. Failure to follow these

instructions could result in serious personal injury, death and/or

property damage.

WARNING: ROTATING PARTS HAZARD

Keep extremities, hair, jewelry and clothing away from moving parts.

Failure to follow these instructions could result in serious personal

injury, death and/or property damage. See section 3.3.7.

WARNING: DO NOT DISASSEMBLE:

Due to powerful magnetic fields, disassembly and assembly of

permanent magnet motors should only be performed by the

manufacturer or specialized personnel authorized by the manufacturer.

Only qualified personnel who are familiar with the applicable national

codes, local codes and sound practices should install or repair electric

motors and their accessories. See the Magnetic Field Hazard in

section 1.1

1.3 ENVIRONMENTAL SAFETY

WARNING: HAZARDOUS LOCATIONS

The NEC and the local authority having jurisdiction must be consulted

concerning the installation and suitability of motors for use in

Hazardous Locations, in accordance with NEC Article 500. The local

authority having jurisdiction must make the final determination of what

type of motor is required. The application and operation is beyond the

control of the motor manufacturer. Failure to do so may cause serious

injury or death to personnel.

2.0 RECEIVING AND INSPECTION

2.1 INITIAL INSPECTIONS

WARNING: ELECTRICAL SHOCK HAZARD

Shaft rotation produces voltage at motor leads and connected

equipment even when motor is disconnected from power source. Do

not open terminal box or touch unprotected terminals while the motor

shaft is rotating. Failure to do so may cause serious injury or death to

personnel.

2.1.1 CHECK PACKING LIST AND INSPECT the

packaging to make certain no damage has occurred in shipment.

If there is visible damage to the packaging, unpack and inspect

the motor immediately. Claims for any damage done in shipment

must be made by the purchaser against the transportation

company.

2.1.2 TURN MOTOR SHAFT (see Electrical Shock Hazard

above) by hand to be certain that it rotates freely. Note: Motor will

not turn freely if leads are shorted together. User may feel small

pulsations when turning shaft due to the magnets in rotor. Shaft

seals and bearing seals may add drag.

CAUTION: Observe caution when working near threads or

keyways. Finger or ring contact may cause injury.

2.1.3 CHECK NAMEPLATE for conformance with purchase

order requirements and compliance with power supply and control

equipment requirements.

2.2 HANDLING

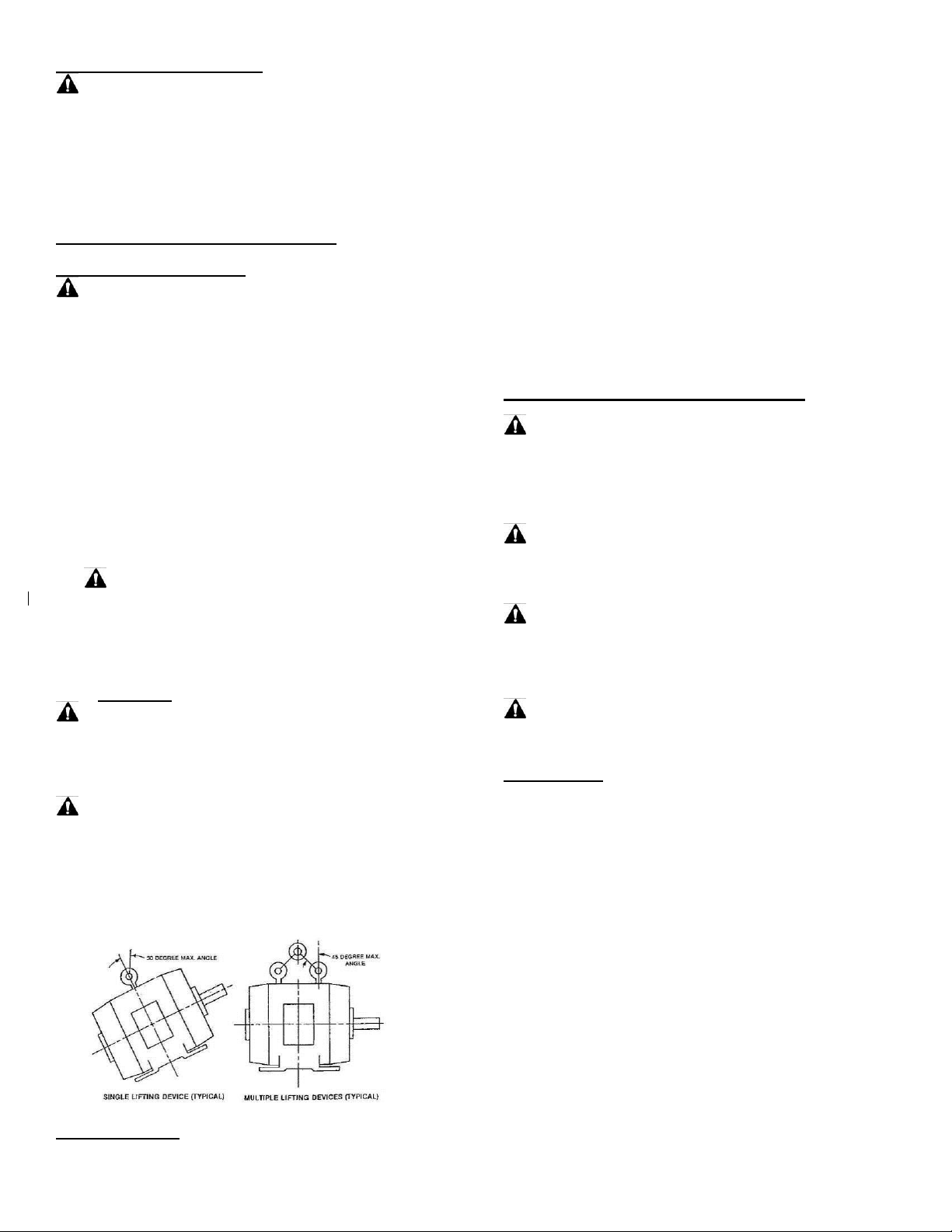

WARNING: FALLING OBJECT HAZARD

Eyebolts or lifting lugs, where provided, are intended for lifting only the

motor and accessories mounted by the motor manufacturer (unless

specifically stated otherwise on the motor). Utilizing the motor lifting

provision to lift other components such as pumps and gear boxes

could result in serious personal injury, death and/or property damage.

WARNING: FALLING OBJECT HAZARD

Before using the lifting provision, check the eyebolts and/or other lifting

means to assure they are not bent or damaged and are completely

threaded, seated & secured to the motor. Equipment to lift motor must

have adequate lifting capacity. While lifting the motor, DO NOT stand

under or in the vicinity of the motor. Failure to follow these instructions

could result in serious personal injury, death and/or property damage.

2.2.1 LIFTING ANGLE LIMITATIONS

2.3 STORAGE: Motors, not put into service immediately, must

be stored indoors in a clean, dry location. Avoid locations with large

temperature swings that will result in condensation. Motors must be

covered to eliminate airborne dust and dirt. If the storage location

exhibits high vibration, place isolation pads under motor to minimize

damage to motor bearings.

2.3.1 BEARING LUBRICATION: Bearings are grease

packed at the factory; relubrication upon receipt of motor or while

in storage is not necessary. If stored more than one year, add

grease per lubrication instructions (Table 4-4) before start-up.

2.3.2 SHAFT ROTATION: (see Electrical Shock Hazard

Warning in section 2.1) It is recommended that the motor shaft be

rotated 5 to 10 rotations every three months to distribute the

grease in the bearings. This will reduce the chance for corrosion

to form on the bearing rolling elements and raceways. Note: User

may feel small pulsations when turning shaft due to the magnets

in rotor. Shaft seals and bearing seals may add drag.

2.3.3 DAMP OR HUMID STORAGE LOCATIONS: Treat

unpainted flanges, shafts, and fittings with a rust inhibitor. Apply

appropriate power to the motor’s space heaters (if so equipped).

3.0 INSTALLATION AND OPERATION

WARNING: ELECTRICAL SHOCK HAZARD

Only qualified personnel who are familiar with and understand the

appropriate national codes, local codes and sound practices should

install or repair electrical motors and their accessories. Installation

should conform to the appropriate national code as well as local codes

and sound practices. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

WARNING: ELECTRICAL LIVE CIRCUIT HAZARD

Do not touch electrically live parts. Disconnect, Lockout and Tag input

power supply before installing or servicing motor (includes accessory

devices). Use a voltmeter to verify that power is off before contacting

conductors.

WARNING: ELECTRICAL SHOCK HAZARD

Shaft rotation produces voltage at PM motor leads and connected

equipment even when motor is disconnected from power source. Do

not open terminal box or touch unprotected terminals while the motor

shaft is rotating. Failure to do so may cause serious injury or death to

personnel.

WARNING: ELECTRICAL SAFETY

Refer to Section 1.0 for additional warnings before proceeding with

installation and operation.

3.1 LOCATION

3.1.1 SELECTING A LOCATION: Consideration should be

given to environment and ventilation. Motors should be installed

in an area that is protected from direct sunlight, corrosives,

harmful gases or liquids, dust, metallic particles, and vibration. A

motor with the proper enclosure for the expected operating

condition should be selected. Provide accessible clearance for

cleaning, repair, service, and inspections (See section 3.1.3 for

construction clearances). The location should be considered for

possible future motor removal or motor handling. The free flow of

air around the motor should not be obstructed.

3.1.2 AMBIENT TEMPERATURE LIMITS: The ambient

temperatures of the air inlet to the motor should not exceed 40°C

(104°F) or be less than -30°C (-22°F) unless the motor nameplate

specifically states an ambient temperature outside of these limits.

The ambient inside an enclosure built around the motor shall not

exceed the nameplate ambient. For ambient temperatures outside

of these limits consult the motor manufacturer.

NOTICE: INSULATION DEGRADATION WARNING

Insulation at high temperatures ages at an accelerated rate. Each

10°C increase in temperature reduces the insulation life by one

half.

3.1.3 CONSTRUCTION SELECTION PER LOCATION

3.1.3.1 TOTALLY ENCLOSED MOTORS are suitable for

indoor or outdoor standard service applications. Severe duty

construction is recommended for severe service applications.

TEAO or AOM (Totally Enclosed Air Over) motors must be

mounted in the air stream. When the motor nameplate states

a minimum airflow the motor must be mounted in an air

stream meeting this minimum value.

TEFC (Totally Enclosed Fan Cooled) motors must meet a

minimum distance equal to ½ the shaft height between the

fan guard grill openings and the nearest obstruction.

3.1.3.2 HAZARDOUS LOCATIONS MOTORS: Not all

motors covered by this manual are intended for hazardous

duty locations. Motors intended for hazardous duty locations

are labeled with the division and class.

WARNING: HAZARDOUS LOCATIONS

Hazardous Locations motors are intended for installations in

accordance with NEC Article 500. For all installations involving

Hazardous Locations motors, consult the applicable national

codes, local codes, and the authority having jurisdiction. Failure

to do so may cause serious injury or death to personnel.

Division 2 Installations – Class I only: Use only motors

that are CSA Certified and bear the CSA Certification Mark.

These motors include a phrase on the main motor

nameplate that indicates the motor is CSA Certified for Class

I, Division 2 / Zone 2 locations.

WARNING: EXPLOSION HAZARD

A motor should never be placed in an area with a hazardous

process or where flammable gases or combustible materials

may be present unless it is specifically designed and

nameplated for this type of service. Hazardous Locations

motors are intended for installations in accordance with NEC

Article 500. For all installations involving Hazardous Locations

motors, consult the NEC, local codes, and the authority having

jurisdiction. Failure to follow these instructions could result in

serious personal injury, death and/or property damage. (For

other limitations see section 1.3).

3.2 MOUNTING MOTOR

3.2.1 RIGID BASE (FOOTED): The motor must be

securely installed to a rigid foundation or a mounting surface to

minimize vibration and maintain alignment between the motor

shaft and the load’s shaft. The mounting surfaces of the four

mounting pads must be flat within 0.01 inches for 210 frame &

smaller; 0.015 inches for 250 frame & larger. [IEC 0.25 mm for

130 frame & smaller, 0.38 mm for 160 frame & larger]. This may

be accomplished by shims under the motor feet. For special

isolation mounting, contact manufacturer for assistance

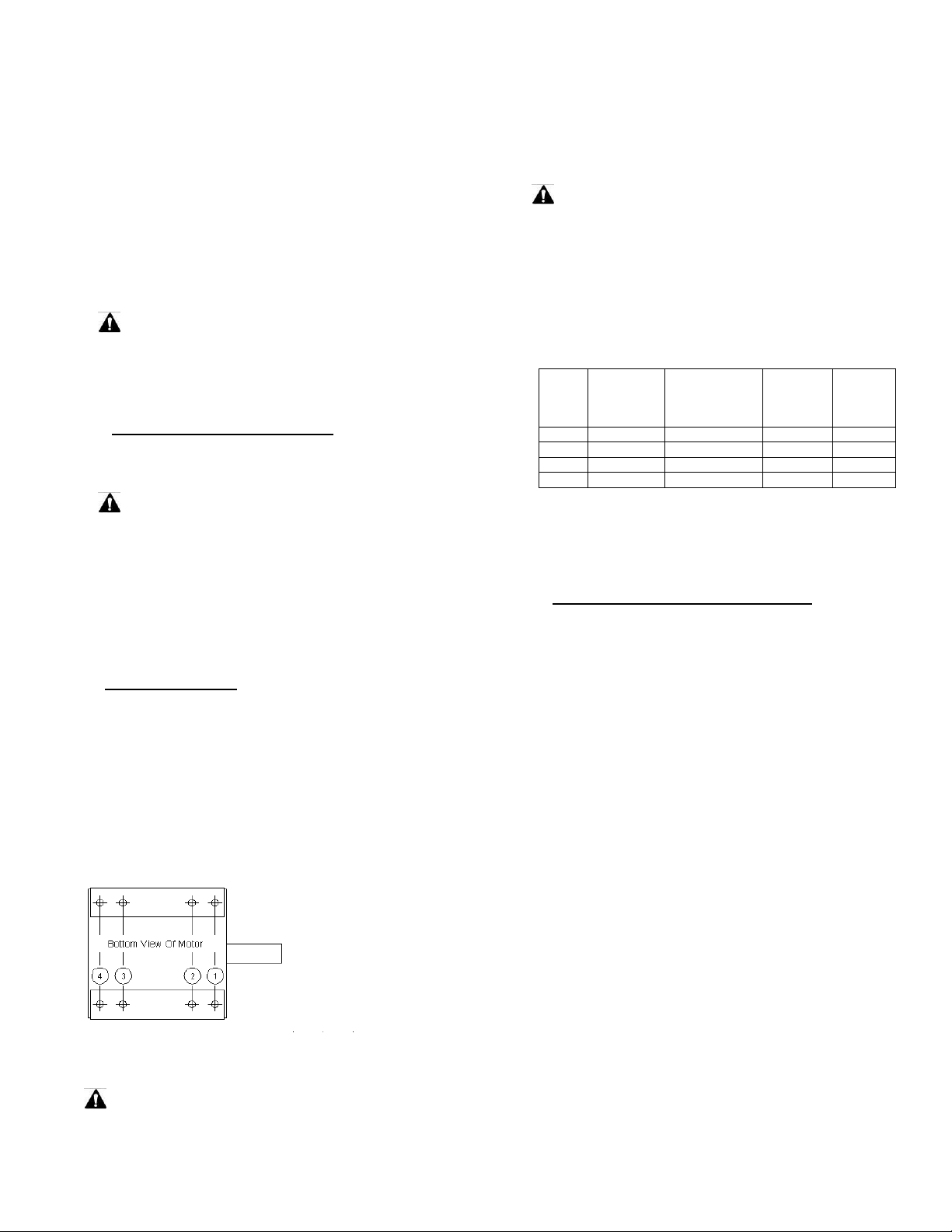

3.2.2 RIGID BASE HOLE SELECTION -6 OR 8 HOLES

3.2.3 VERTICAL MOUNTING

WARNING: FALLING OBJECT HAZARD

The lifting provision on standard horizontal footed motors is not

designed for lifting the motor in a vertical shaft up or shaft down

position. (see Diagram 2.2.1). Doing so may cause the motor to

fall. Lifting method / provisions for mounting a rigid base (footed)

motor vertically is the responsibility of the installer.

VERTICAL SHAFT DOWN: Most standard horizontal motors

through 449 Fr. (excluding brake motors) can be mounted in a

vertical shaft down orientation. For vertical brake motors see

section 3.3.6.2.

VERTICAL SHAFT UP:

WARNING: HAZARDOUS LOCATIONS VERTICAL

MOUNT: Hazardous locations motors must NOT be mounted

vertically shaft up without approval by the motor manufacturer.

Without proper retaining provisions the rotor may move axially

and contact components, creating a spark hazard.

Belted or Radial Load when mounted vertically: The

following frame sizes / constructions with applied (axial) down

loads within the limit stated are acceptable when mounted vertical

shaft up.

Table 3-1 Belted or Radial Load Applications (All speeds)

Frame

Size

Enclosure

Construction

Shaft Up

OK

Max

Applied

Down

Load2

180

TEFC

All

Yes

35 lbs

210

TEFC

All

Yes

40 lbs

250

TEFC

All

Yes

40 lbs

280

TEFC

Cast Iron

Yes

30 lbs

Notes:

The max applied down load is any applied load external to the

motor, including such things as sheave weight, fan loads, axial

belt force, pump load, etc. If the application is direct drive with

no applied radial load or is beyond the limits listed, consult the

motor manufacturer.

3.3 APPLICATION ASSEMBLY TO MOTOR

NOTICE: EQUIPMENT DAMAGE

Do not connect or couple motor to load until correct rotational direction

is established.

3.3.1 GENERAL: PROPER ALIGNMENT of the motor

and driven equipment minimizes vibration levels, maximizes

bearing life, and extends the overall life of the machinery. Consult

the drive or equipment manufacturer for more information.

NOTICE: BEARING FAILURE

During assembly do NOT force components onto the shaft.

Striking or hammering the component may result in bearing

damage.

3.3.2 DIRECT COUPLING: Use flexible couplings if

possible.

For applications that apply radial, axial or moment loading on the

motor shaft see section 3.3.3.

NOTICE: BEARING FAILURE

Unless approved by the motor manufacturer, do NOT direct

couple a vertical shaft up motor or roller bearing motor. Direct

coupling a vertical shaft up motor or a motor with a roller bearing

may result in bearing damage.

3.3.3 DIRECT CONNECTED: Radial loading for direct

connected equipment (gears, fans etc.) must be approved by the

motor manufacturer unless within the maximum overhung load

limits (Table 3-2). Combined loading (axial, radial and/or

moments) must be approved by motor manufacturer. For belted

loads see section 3.3.4.

Location 1 and 3 holes for short frame:

(NEMA) 182, 213, 254, 284

(IEC) 112S, 132S, 160M, 180M

Location 2 holes are for F1,

F2 Conversion (if provide)

Location 1 and 4 holes for long frames:

(NEMA) 184, 215, 256, 286

(IEC) 112M, 132M, 160L, 180L

Loading...

Loading...