Marathon Electric all products Application Information

AGENCY LISTINGS

UL and CSA

Where applicable, Marathon Electric’s motors are UL Listed for

explosion proof enclosures, UL Recognized construction for

non-explosion proof enclosures, and UL Recognized as a

motor/protector combination. Our motors are also CSA Certified

for both explosion proof and non-explosion proof enclosures.

AC Motors

Non-Explosion Proof UL File No. CSA File No.

NEMA 48-449 Frame E49747 LR2025

NEMA 500 and 5000 Frame — LR2025*

IEC 63-90 Frame E49747 LR2025

IEC 100-280 Frame E49747 LR2025

#

* Does not include coverage for use with VFD

#

Domestic product only

Explosion Proof UL File No. CSA File No.

NEMA 56-326 Frame E12044 LR47504

NEMA 364-449 Frame E12044 LR21839

Fire Pump Motors UL File No. CSA File No.

NEMA 143-510 EX5190 LR2025

PMDC Motors

Non-Explosion Proof UL File No. CSA File No.

NEMA -56-145 E57948 LR33543

CE (Conformity Europeanne)

CE marking on the nameplates of Marathon Electric motors is

available upon request. Note that only the "Low Voltage"

directive applies to electric motors. Contact a factory

representative for details. Non-explosion proof microMAX

™

,

BlackMax

®

and BlueMax®(TENV and TEFC) standard (catalog)

models have the CE Mark on the nameplate.

ATEX Directive (Atmospheres Explosibles)

Mandatory by law, the European Union (EU) Directive 94/9/EC

requires that electric motors in contact with a potential ignition

source carry the CE mark, notified body identifier, Ex symbol,

equipment group and category, plus the date code.

NEMA (National Electrical Manufacturers Ass’n)

All Marathon Electric motors are manufactured in accordance

with all applicable NEMA standards in MG1-2003. When

applied in accordance with the "Guidelines for Application of

Three Phase Motors on Variable Frequency Drives", Marathon

Electric motors are in full compliance with NEMA MG12003, Part 31, Section 4.4.2, as pertaining to voltage spikes.

460 volt motors must withstand voltage spikes of up to 1426

volts; 575 volt motors must withstand spikes up to 1788 volts.

See "Insulation Systems" for additional detail on this subject.

Commitment to RoHS and WEEE European

Directives

European Directive 2002/95/EC “Restriction of Use of Certain

Hazardous Substances” (RoHS) and Directive 2002/96/EC

“Directives on Waste Electrical and Electronic Equipment”

(WEEE) were enacted to control the amount of certain

hazardous substances contained in products shipped into the

E.U. Restricted substances include lead, mercury, cadmium,

hexavalent chromium, polybrominated biphenyls and

polybrominated dipheynl ethers.

The scope of products covered, affecting motors, is:

• Large household appliances

• Small household appliances

• IT and telecommunications equipment

• Consumer equipment

• Electrical and electronic tools (except large scale stationary

and industrial tools)

• Toys, leisure and sports equipment

• Automatic dispensers

In addition to the exemption above, the Directives do not

currently apply to medical devices, monitoring and control

instruments, spare parts for the repair or reuse of electrical and

electronic equipment placed on the market before July 1, 2006,

and most military and state security equipment.

Regal Beloit Corporation worked closely with suppliers to

assure that product falling within the scope of these directives

meets the specified levels of these substances. The directives

took affect July 1st, 2006 however many products were

converted in May and June. The products converted are motors

in NEMA frame size 145 and below, both AC and DC motors

with the following exceptions:

• Sleeve bearing motors (an exemption has been applied

for). A compliant ball bearing equivalent motor can be

ordered.

• Brake motors in 56-145 frame will have to be ordered

specifically as RoHS compliant.

• Some motors with specialty electro-mechanical components.

BEARINGS

FRAME SIZE STANDARD TYPE COMMENTS

48 Shield Ball Sleeve bearing as noted

56 - 145T Sealed Ball

182 - 444T Double Shield Ball

284 - 449TS Single Shield Ball

445T - 6805 Double Shield Ball Direct - coupled loads

445T - 6805 Roller (DE)/Ball Belted loads

* Belting data must be provided on all belted applications

Standard horizontal motors can be mounted in a vertical shaft

down orientation (except brakemotors). Contact a factory

representative for shaft up mounting arrangements.

Marathon Electric motors employ the use of Mobil POLYREX

®

EM grease, a specially formulated bearing grease designed for

electric motors. POLYREX®EM provides superior lubricity,

durability and resists corrosion, rust and washout. POLYREX

®

EM is a registered trademark of Mobil Corporation.

Maximum safe mechanical speed capability is a function of

bearing size, type and grease selection, as well as rotor balance

specifications. Consult the “Maximum Safe Mechanical Speed

Limits” chart in the “Overspeed Capability” section.

Note that these values do not imply maximum constant

horsepower RPM.

APPLICATION INFORMATION

SB300 – Prices and Specifications are subject to change without notice.

10

Application Information

EFFICIENCY

The efficiency of a motor is the ratio of its useful power output

to its total power input and is usually expressed in a

percentage. Marathon Electric offers standard, high efficient

EPAct, and premium efficient (XRI

®

) ratings. Standard

efficiency motors may only be used on applications that are

exempt from EPAct. The high efficient motor line is in

compliance with the Energy Policy Act of 1992 (EPAct) and/or

Canadian efficiencies as set by NRCan. The XRI

®

line is a

premium efficiency line, which exceeds mandated efficiencies

of EPAct and /or NRCan. Unless otherwise noted, XRI

®

premium efficient motors in this catalog meet NEMA Premium

®

the newly promoted efficiency levels by NEMA and the

Consortium for Energy Efficiency (CEE).

ELECTRICAL TYPE/STARTING METHOD

Motors in this catalog are capacitor start, split phase,

permanent split capacitor, or three phase. Capacitor Start

motors have high starting torque, high breakdown torque, and

relatively low starting current. Split phase motors have medium

starting torque and medium starting current. Permanent split

capacitor motors have low starting torque and low starting

current. Three phase motors have high starting, extra

breakdown torque, and typically very low starting current.

Single phase motors cannot be applied on variable frequency

drives with three phase output.

ENCLOSURE AND METHOD OF COOLING

Marathon Electric motors are available in various enclosures;

Dripproof (DP), Dripproof Force Ventilated (DPFV), Totally

Enclosed Fan Cooled (TEFC), Totally Enclosed Non-Ventilated

(TENV), Totally Enclosed (TEAO) and Totally Enclosed Blower

Cooled (TEBC). Application conditions will determine the type

of motor enclosure required.

Dripproof motors have open enclosures and are suitable for

indoor use and in relatively clean atmospheres. Dripproof

motors have ventilating openings constructed so that drops of

liquid or solid particles falling on the machine at an angle of not

greater than 15 degrees from the vertical cannot enter the

machine.

Totally enclosed motors are suitable for use in humid

environments or dusty, contaminated atmospheres. Totally

enclosed non-ventilated motors are NOT cooled by external

means. Totally enclosed fan cooled motors are cooled by

external means that are part of the motor but not in the

internal workings of the motor. Totally enclosed air over

motors are sufficiently cooled by external means, provided

by the customer.

HAZARDOUS DUTY™

Hazardous Duty™ motors are totally enclosed (fan cooled or

non-ventilated) motors designed for applications in

hazardous atmospheres containing explosive gases and/or

combustible dusts.

North American installations

North American standards for electric motors generally fall into

one of two divisions. Division 1 Explosion Proof motors are UL

Listed in accordance with NFPAClass I (Flammable Gases) or

Class II (Combustible Dusts) and Groups (gases or dusts),

depending upon the atmosphere. Division 2 motors are CSA

Certified and are marked similarly to Division 1 equipment.

Inverter Duty motors through 449T are CSA Certified for use in

Division 2 locations.

European installations

Motors for hazardous locations in Europe must meet a

different set of standards and require different markings than

those of North America. CENELEC sets the standards for

equipment in hazardous locations for Europe. Motors for

explosive atmospheres in Europe are often referred to as

flameproof

or non-sparking motors. These motors must comply

with the ATEX Directive. The ATEX Directive covers all

electrical equipment used in explosive atmospheres. To ensure

compliance with the Directive, equipment must meet the

essential ATEX requirements and carry the CE mark on the

nameplate. Other information required on the nameplate is the

Ex symbol, group & category, date code, EEx, protection

method, gas group, and temperature code. (Example: EEx d

IIB T4 CE0359 Ex II 2 G/D 2004)

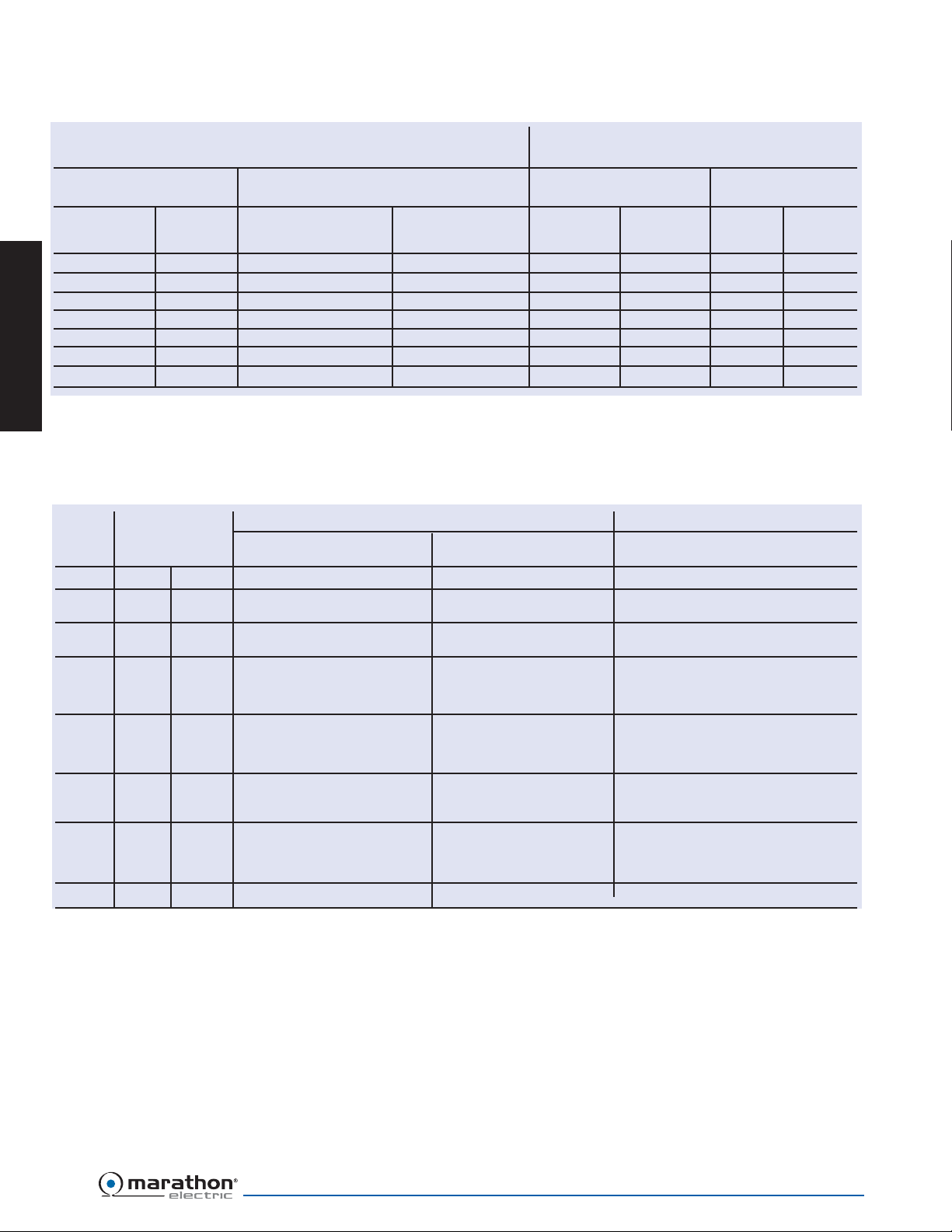

The tables on page 12 describe Marathon Electric’s

capabilities by Area Classification and by

Temperature Code.

IEC DEGREES OF PROTECTION vs. MARATHON

ELECTRIC’S STANDARD CONSTRUCTION

The enclosure terminology for an IEC motor is a

combination of the IP (Ingress Protection) and IC (Inherent

Cooling) codes. Each number in the IP code stands for a

different degree of protection.

IP12 - Dripproof

IP22 - Dripproof with screens, or die cast aluminum

bracket

IP43 - Totally Enclosed

IP54 - Totally Enclosed Severe Duty

IP55 - Totally Enclosed Severe Duty with V-Ring Shaft

seals, and/or “Smart Ring” rotating shaft seal and

Neoprene gaskets

IP56 - Totally Enclosed Severe Duty with rotating Shaft

seals (eg. Inpro/Seal VBX bearing isolator) and

Neoprene gaskets

APPLICATION INFORMATION

SB300 – Prices and Specifications are subject to change without notice.

11

Application Information

APPLICATION INFORMATION

SB300 – Prices and Specifications are subject to change without notice.

12

Application Information

Division 1 Explosion Proof/Zone 1 Flameproof Division 2/Zone 2 Non-Sparking

TEMPERATURE Class I Area Classification Class II Area Classification* Class I Area Classification

CODES (Flammable Gases, Vapors or Mists) (Combustible Dusts) (Flammable Gases, Vapors or Mists)

Temp. UL/CSA ATEX Division 1/Zone 1 Division 1/Zone 21 Division 2/Zone 2

280OC T2A T2(280)

Explosion Proof - Class I, Group D

(Group C as noted)

260OC T2B T2(260)

XRI®Severe Duty & IEEE-841 @ 1.15 S.F.,

Class I, Groups A,B,C,D (Sine wave power)

Available through Marathon's Mod Central

215OC T2D T2(215)

on Totally Enclosed EPAct, XRI®, XRI®Severe Duty

or IEEE-841 @ 1.0 S.F. on PWM VFD,

Class I, Groups A, B, C, D

Available through Marathon's Mod Central

200OCT3 T3

on Totally Enclosed EPAct, XRI®, XRI®Severe Duty

or IEEE-841 @ 1.0 S.F., Sine wave power

Class I, Groups A, B, C, D

Explosion Proof - Class I, Group D Explosion Proof - Class II,

165OC T3B T3(165)

(Group C as noted), Sine wave Groups F & G, Sine wave

or PWM power or PWM power

160OC T3C T3(160)

Available through Marathon’s Mod Available through Marathon’s Mod

Central on Explosion Proof - Class I, Central on Explosion Proof - Class II,

Group C & D @ 1.0 S.F. - Group F & G @ 1.0 S.F. -

Contact Factory Contact Factory

135OCT4 T4 ATEX compliant motors ATEX compliant motors

Marathon Electric Hazardous Duty Motor Temperature Code Chart

* Class II, Division 2 motors are not available from Marathon Electric, Zone 22 groups are not defined by ATEX.

Class I Area Classification Class II Area Classification

(Flammable Gases, Vapors or Mists) (Combustible Dusts)

Europe - ATEX Europe - ATEX

North America (Category G - Gases) North America (Category D - Dusts)

Division 1 Division 2 Division 1

Explosion TEFC &

Zone1 Zone 2

Explosion Division2

Zone 21 Zone 22

Proof TENV

Flameproof Non-Sparking

Proof

Flameproof Non-Sparking

Group A

①

Group A Group IIC, Category G

①

Group IIC, Category G - - - -

Group B

①

Group B Group IIC, Category G

①

Group IIC, Category G - - - Group C Group C Group IIB, Category G Group IIB, Category G - - - Group D Group D Group IIA, Category G Group IIA, Category G - - - -

- - - - Group E

①

---

- - - - Group F Group F

①

Category D -

- - - - Group G Group G

①

Category D -

Marathon Electric Hazardous Duty Motor Area Classification Chart

- Group is not applicable to that Division or Zone, or is not defined.

① Group is not available from Marathon Electric.

Loading...

Loading...