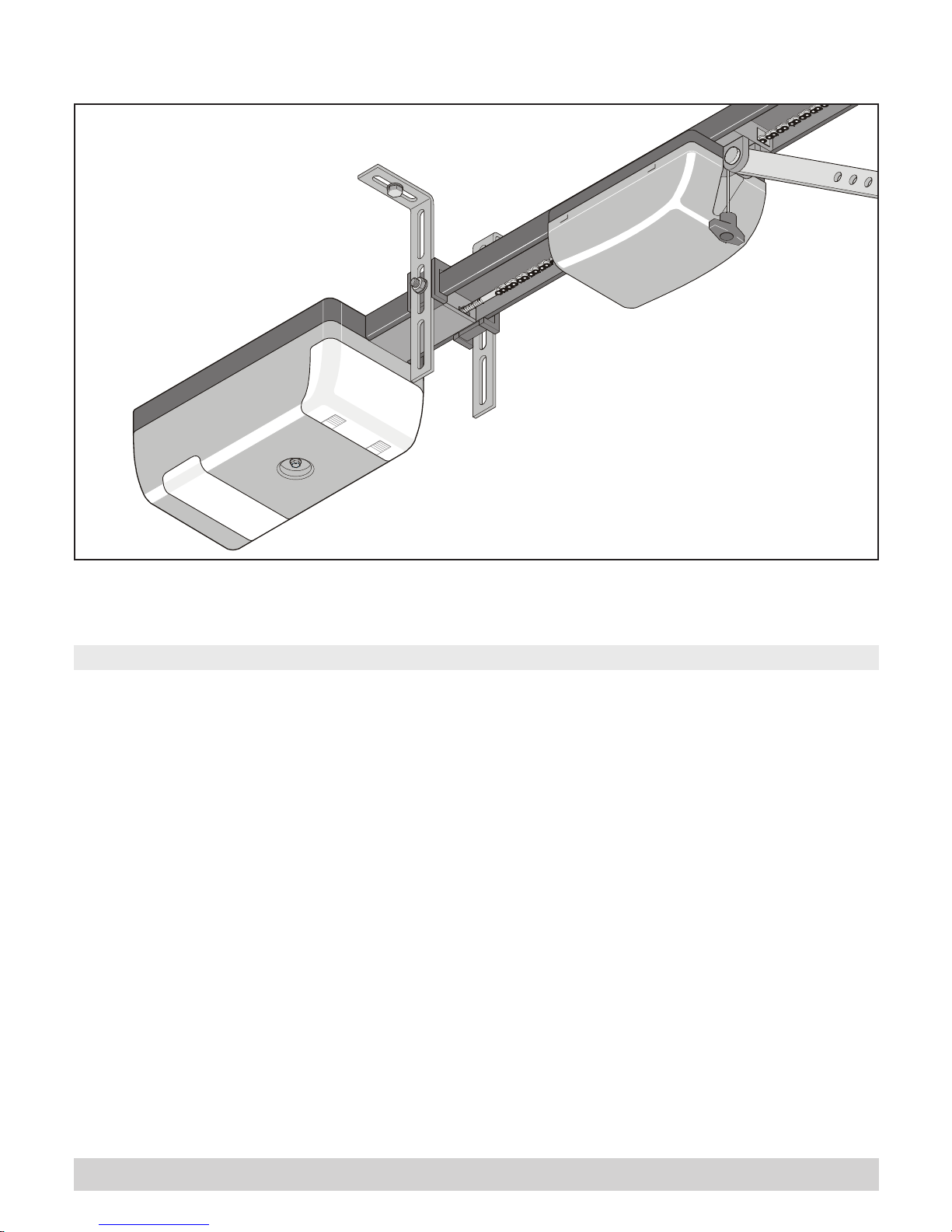

Marathon 550 SL, 800 SL, 1100 SL Instructions Manual

10514V000-462001-0-OCE-Rev.A

marathon 550 SL, 800 SL, 1100 SL

Installation and Operating Instructions Page 17 - 33

GB

17

Contents

Symbols

Foreword

Indicates a potential risk. Failure to follow instructions may

result in serious injuries.

A.1 (1)

Information, useful advice.

Refers to the relevant illustration in the introduction or main

text.

Safety Instructions

Foreword 17

Symbols 17

Safety Instructions 17

Normal Use 18

Technical Data 18

EU Manufacturers' Declaration 18

Rating Plate 18

Installation 19

marathon SL Control Unit 22

Radio Receiver 868.8 MHz 24

Initial Operation 25

Additional Functions 26

Operation and Handling 28

Accessories 29

Maintenance and Care 30

Disassembly 31

Warranty and After-sales Service 31

Troubleshooting 31

General Safety Instructions

• These Installation and Operating Instructions (MBA) must be read,

understood and observed by the person installing, operating or

maintaining the drive mechanism.

• The manufacturer accepts no liability for damage or malfunctions caused

by failure to follow theses Operating Instructions.

• Make sure that these Operating Instructions are readily accessible in the

garage.

• Observe and comply with the locally applicable accident prevention

regulations and EC standards.

Our new garage door drive mechanisms 'marathon 550 SL' 'marathon 800

SL' and 'marathon 1100 SL' combine reliability with innovation. The new

'marathon 550 SL' range replaces the current 'marathon S 550 N',

marathon S 800 N' and 'marathon S 1100 N' models whilst offering new

functions and connecting options (e.g. soft run, 2nd button, interface for

TorMinal, etc.).

As the connection set-up of the 'marathon 550 SL' control unit is not

compatible with the current 'marathon' models, the latter can only be

upgraded to 'marathon SL' models by replacing the control unit as a whole

or converting the control unit housing.

Furthermore, the new drive is supplied with our new radio control system

based on a frequency of 868.8 MHz, which offers enhanced security

standards. The system features rolling code technology, where the code is

changed for each new radio command, thus offering optimum security.

• Only install the drive mechanism to correctly aligned and weightbalanced doors. An incorrectly aligned door could cause serious injury or

damage to the drive mechanism.

• Doors that operate automatically by means of the drive mechanism must

comply with the following standards: EN 12604, EN 12605.

• Installation, connection and initial operation of the drive mechanism may

only be carried out by qualified specialists.

• Always disconnect the drive mechanism from the power supply before

carrying out any work.

• Only use the manufacturer's original spare parts, accessories and

fastening materials.

Storage Tips

• The drive mechanism may only be stored indoors, in a dry, sealed

environment at an ambient temperature of between -20°C and +50°C.

• The drive mechanism should be stored horizontally.

Operation-related Safety Instructions

• The drive mechanism may only be operated if a risk-free force tolerance

has been set. The force tolerance must be set as low as is required to

ensure that the door's closing force does not constitute a danger

(see 'Force Setting' section).

• Keep your hands clear of any moving door or any moving parts.

• Keep children, disabled persons and animals away from the door.

• Only drive into and out of the garage when the door is fully opened.

• Closing edges and workings of the door pose risk of injury.

Safety Instructions for Radio-controlled

Operation

• The radio remote control may only be used for equipment and systems in

which defective remote operation of the transmitter or receiver does not

constitute a risk to people, animals or objects, or in cases where this risk

is eliminated by means of additional safety facilities.

•

Use of the radio remote control in conjunction with equipment or systems

subject to an enhanced risk of accident (e.g. crane systems) is prohibited!

• To ensure safe operation, local safety regulations relevant to the

equipment concerned must be observed! Information regarding this can

be obtained from electricity suppliers, the VDE and employers' liability

insurance associations.

• The user must be made aware of the fact that the remote control of

equipment with accident risk potential may only occur, if at all, when the

equipment concerned is clearly visible.

• Radio remote control may only be used if movement of the door can be

supervised and there are no persons or objects in the area of movement.

• Store the manual remote control such that there is no risk of it being

accidentally operated by, for instance, children or animals.

GB

18

Rating Plate

EU Manufacturers' Declaration

The rating plate is located on the cover of the control unit housing.

The following is an example of a rating plate:

Technical Data

Important to note!

If the drive mechanism is installed by a company qualified to do

so, the company concerned must carry out an acceptance/

transfer test and fit a rating plate to the door. A copy of the test

protocol and the drive mechanism's Installation and Operation

Instructions should be kept by the operator.

• Doors that operate automatically by means of the drive mechanism must

comply with the following standards: EN 12604, EN 12605.

• The drive mechanism is intended for the exclusive purpose of opening

and closing the doors. Any other use does not constitute normal use.

• The manufacturer accepts no liability for damage resulting from use other

than normal use. The user accepts sole responsibility for any risk thereby

incurred.

• The drive mechanism may only be used if it is in a technically perfect

condition and in compliance with these Installation and Operating

Instructions (MBA) particularly regarding correct and responsible usage.

• Any defects that may impair the safe operation of the equipment should

be eliminated without delay.

• The gate wings must be stable and warp-proof, i.e. they should not bend

or warp during opening or closing operations.

• The drive mechanism is unable to compensate for any defects in the

door or for its incorrect installation.

• Only use the drive mechanism in a dry, indoor environment where there

is no risk of explosion.

• The ambient temperature for drive mechanism operation and storage is

between -20°C and +50°C. Should extreme weather conditions prevail,

consult your local stockist for advice.

Maximum door dimensions:

550 SL 800 SL 1100 SL

- max. width: 3500 mm 6000 mm 8000 mm

- max. height of canopy doors:

2600 mm 2600 mm 2600 mm

- max. height of vertical sectional doors:

2350 mm 2350 mm 2350 mm

With taller doors, corresponding rail extensions need to be installed - see

'Accessories' section.

- duty cycle: 40 % 40 % 40 %

Any other or non-compliant usage is deemed to be incorrect. The

manufacturer is not liable for any damage occurring as a result. The user is

responsible in such cases. Any warranty entitlement lapses.

Normal Use

Messrs.

SOMMER Antriebs- und Funktechnik GmbH

Hans-Böckler-Straße 21-27

D-73230 Kirchheim/Teck

hereby declares that the machine component designated below is intended

to be fitted into a gate mechanism and that commissioning is prohibited

until it has been ascertained that the installation in which this equipment is

to be fitted complies with all the relevant provisions of the applicable EU

directives.

Designation of machine component:

- marathon 550 SL garage door drive mechanism

- marathon 800 SL garage door drive mechanism

- marathon 1100 SL garage door drive mechanism

The relevant directives and standards are as follows:

- Machine Directive 98/37/EG

- Low Voltage Directive 73/23/EEC, Machine Directive 89/392/EEC

- EU Electromagnetic Compatibility Directive 89/336/EEC

Kirchheim, 01.07.2001 Uwe Sommer

Managing Director

marathon 550 SL 800 SL 1100 SL

Rated voltage: 230 230 230 V/AC

Rated frequency: 50/60 50/60 50/60 Hz

Maximum traction and

pressure force: 550 800 1100 N

Rated traction: 165 240 330 N

Rated current consumption: 0,7 0,8 0,9 A

Rated power consumption: 150 160 190 W

Maximum speed: 180 130 130 mm/s

Power consumption (stand-by): ~ 2 ~ 2 ~ 2 W

Operating temp. Range: -20 - +50 -20 - +50 -20 - +50 °C

Weight: 18 18,5 19 kg

Workplace-specific emission value < 75 dBA - drive only

Model : marathon 550 SL, FM 868 MHz

Manufacturer: SOMMER Antriebs- und Funktechnik GmbH

D-73230 Kirchheim/Teck

Article no.: 4200V000

Year built: 07/2001

Serial no.: ?

230V~ 50/60 Hz

150W/0.7A at 165N rated traction; max. 550N traction and pressure force

Operating temp. Range -20°C - +50°C

After-run distance <30mm; ED: 40% S3

Nur für trockene Räume

Use only in dry rooms

Seulement pour les chamdres séches

Safety Instructions for Authorised

Radio-controlled Operation

• The operator of this radio-controlled equipment is in no way protected

from interference from other telecommunications systems and facilities

(e.g. other radio-controlled equipment that is licensed to operate at the

same frequency range). Should serious interference be encountered,

please contact your nearest telecommunications office with interference

measuring facilities (radio signal localisation)!

• Under no circumstances may this radio-controlled equipment be linked to

any other telecommunications system without the express authorisation

of the relevant licensing authorities.

• Do not use the manually-operated remote control near locations or

installations that are susceptible to radio interference

(airports, hospitals).

GB

19

Door Types and Special Accessories*

* Accessories are not included in the delivery specification.

Door type Accessories

Up-and over, No special accessories required

Tracked door

Vertical sectional door with Vertical sectional door

single runner rail fitting with boomerang *

Vertical sectional door with Vertical sectional door

double runner rail fitting without boomerang *

Shutter-type door No accessories required

Canopy and non-protuding door Bow arm convertor system*

Swing door Swing-door fitting *

Side-opening sectional door Please consult specialist retailer

Installation Tips

• Check that all the parts have been supplied before you start installation

work in order to save time and unnecessary work if a part is missing.

• The drive mechanism can be installed to one side of the door if it cannot

be installed at the centre. It is important to note that the door does not

bend as a result and jam in the guide rails.

Check

Open and close the door several times by hand holding it at the point

where you intend fitting the drive mechanism. If the door can be moved

in this way without difficulty (in compliance with the above forces), then

the drive mechanism can be fitted at this point.

• Emergency Release

In the case of a garage without a separate entrance (e.g. slip door), the

emergency release of the drive mechanism must be operable from the

outside. To this end, you should fit a Bowden wire or a release lock,

accessible from the outside. See 'Accessories' section.

• Door lock

With doors supplied without the current door locking system, opening

approximately 50 mm by hand, this should be replaced by a spring latch.

This spring latch can be connected across the locking set to the drive, so

that when the door opens the spring latch locks first and then the drive

starts to open the door. Spring latches can be built onto the left, right or

middle of the door. Ask your dealer for details.

• Canopy doors

As the mechanical lock of a door with a drive mechanism has to be

dismantled or activated, it is possible to open the door manually up to

approx. 50mm depending on the door construction.

In order to accommodate this, spring latches that lock the door in

addition to the drive can be mounted. These spring latches are

connected to the drive via a locking set in order to first unlock the spring

latches before a drive opens the door when opening the door.

• Installation should be carried out quickly and safely by two persons

• All-round or side-sectional door

The polarity of wires 12 + 13 of drives that have to push one the

above-mentioned doors open has to be changed. See marathon SL

Control Unit fig. 29.1 terminal 12 + 13.

7

6

5

4

4

4

3

Installation

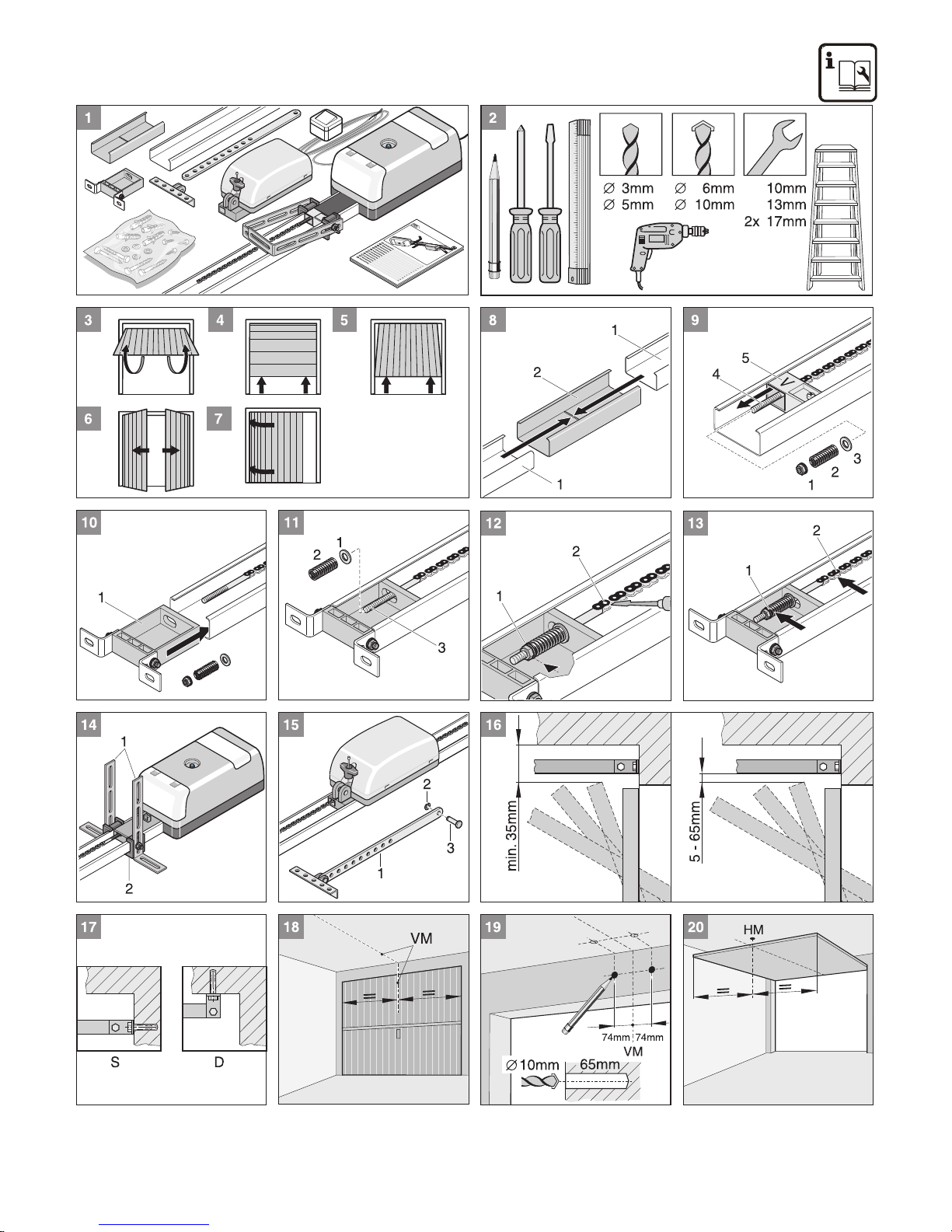

Supplied Parts and Components

C-rails, chain with bogie unit and drive shaft

Control unit in housing, push-button cable, mains cable

Connecting element

Lintel fitting

Ceiling mounting

Installation accessories in bag comprising:

1 push-button

5 hexagon-head, self-tapping screws 6.5 x 19

4 wood screws 8 x 60

4 plugs S10

4 plain washers 8.4

Installation and Operating Instructions

Tools Required

See Figure

Safety Tips

• Installation, connection and initial operation of the drive mechanism may

only be carried out by qualified specialists.

• Do not operate the door when people, animals and/or objects are in its

area of movement.

• Keep children, disabled persons and animals away from the door.

• Door installation should be carried out by two persons, thus ensuring

safe and fast completion of the work involved.

• Safety goggles should be worn when drilling the mounting holes.

• Cover the drive mechanism up when drilling to ensure it does not get

soiled.

Before Installation

Very important to note!

The walls and ceiling must be firm and stable. Only fit the

drive mechanism to a correctly aligned door. A door that has

not been aligned correctly can cause serious injuries.

• Doors that operate automatically by means of the drive mechanism must

comply with the following standards: EN 12604, EN 12605.

• Doors must be stable because they are subjected to high tensile and

compressive forces. Light doors made of plastic or aluminium must be

strenghtened before installation if necessary. Ask your specialist retailer

for advice.

• Remove door locking system or disable same.

• Check that the door runs easily.

• The door must be balanced.

Test :

Manually open the door half-way. It must stay still in this position. If the

door moves downards or upwards, mechanically readjust it. Ask your

specialist retailer for advice.

• If the drive mechanism requires a rail extension to be installed, it is

essential that the second ceiling mounting be fitted for this purpose.

• Check the clearance between the door's highest up-position (THP, see

fig. 16) and the ceiling. The minimum clearance is 35 mm and the

maximum 100 mm, whereby the drive arm can only be at an angle of

max. 30°. If the clearance is less than is permissible, the drive

mechanism has to be moved back and an extended drive rail fitted.

Ask your local stockist for advice.

2

1

• Insert plug (1). Fit two screws (2) with plain washers (3). Tighten

screws securely.

• Align C-rail (4) at correct height. If necessary, move screws (5).

Tighten screws (5).

• Mount drive shaft (1):

Insert bolt (2) and push on retainer (3).

• Pull once on emergency release wire (N), thus disengaging bogie

unit (1). Tighten screw (8) on lintel fitting.

• Use drive shaft (2) to push bogie unit (1) as far forward as possible

(3). If necessary, release cut-off buffer (4).

• Align door fitting bracket (5) to door centre and mark out 5 holes. Drill

5 holes (Ø 5 mm).

Use screws that are appropriate to the door material.

Wear safety goggles when drilling!

• Insert 5 hexagon-head screws (6) and tighten securely.

• Release cut-off buffer (4) and push right up to bogie unit (7).

• Tighten cut-off buffer screw (4) securely.

• Release rear cut-off buffer (1) and push right back to stop (2). Open

door (3) by hand.

Shorten projecting ceiling brackets (4).

• Push cut-off buffer (1) right up to bogie unit (5). Securely tighten

screw on cut-off buffer (1).

Installing Slip-door Facility or Release Lock

• If your garage door is fitted with a slip door but no slip-door safety facility,

you need to have one installed (see 'Accessories' instructions).

• If your door has no slip door and your garage has no separate entrance,

install a release lock or Bowden wire to facilitate drive mechanism

release from the outside (see 'Accessories' instructions).

Fitting and Connecting Push-button

Very important to note!

When operating the push-button, the user should not stand in

the door's area of movement and must have a clear view of

the door.

Never run the push-button cable along a power cable as this can cause the

control unit to malfunction. The push-button cable is supplied connected to

the control unit.

• Install push-button (1) in an appropriate, easily accessible location

inside the garage. Minimum height from floor - 1.6 m.

Do not install the push-button in the door's area of movement.

• Install connection cable (2) inside the garage.

Connect end of cable to push-button (1).

Useful Tip!

The Funkcody, a radio-operated interior switch and a key switch

are other possible pulse generators that could be used. No

connecting cable to the drive mechanism need be fitted with the

Funkcody and the radio-operated interior switch. Contact your

local stockist for advice.

27

26

25

24

GB

20

Pre-assembling the Drive Mechanism

• Remove the drive mechanism from its packaging.

Dispose of the packaging correctly in accordance with local

requirements.

• Slot two C-rails (1) into connecting element (2) and push together as

far as they will go.

• Remove nut (1), spring (2) and plain washer (3).

• Push securing bolt (4) through opening in cut-off buffer (3).

• Push in lintel fitting (1).

• Push plain washer (1) and spring (2) on to securing bolt (3).

• Tighten nut (1) as far as mark. Hold chain back with screwdriver to

prevent movement.

Do not press against chain joint (2)!

• Move securing bolt (1) and chain with chain case (2) outwards as far

as stop.

• Unscrew two steel angle irons with length adjustment holes (1) and

screw onto ceiling bracket (2) as shown.

• Dismantle drive shaft (1):

pull retainer (2) out

remove bolt (3).

Installation of Drive Mechanism

• Determine door's highest up-position (THP):

Open door and measure smallest clearance (min. 35 mm) between

top edge of door and ceiling. The distance between the highest

up-position and the bottom edge of the C-rails has to be min. 5 mm

and may be max. 65 mm, whereas the drive arm can be at an angle

of max. 30°!

• The drive mechanism can be mounted on lintel (S) or ceiling (D).

• Measure front centre point (VM) of door and mark on door and on

lintel or ceiling.

• Make a mark 74 mm to right and left of centre of door (VM) at same

height on lintel or ceiling (see fig. 16).

• Drill two holes (Ø 10 x 65 mm).

Caution! Wear safety goggles when drilling!

Check thickness of ceiling, particularly with prefabricated

garages!

• Open door. Transfer door centre mark (HM) on to ceiling. Close door.

• Insert plug (1). Lift up drive mechanism (2) at front. Secure lintel

fitting (3) at front with two screws (4) and plain washers (5).

Caution!

Protect control unit housing (6) from damage!

• Lift up drive mechanism at back.

• Align ceiling bracket (1). Its final location ought to be in area B

between 0 and 600 mm.

Use a non-slip, stable stepladder!

• Align drive mechanism horizontally to rear centre of door (HM). Mark

position of holes. Drill two holes (Ø 10 x 65 mm deep).

Caution! Wear safety goggles when drilling!

Check thickness of ceiling, particularly with prefabricated

garages!

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

Loading...

Loading...