Marantec 280, 260, 270 User Manual

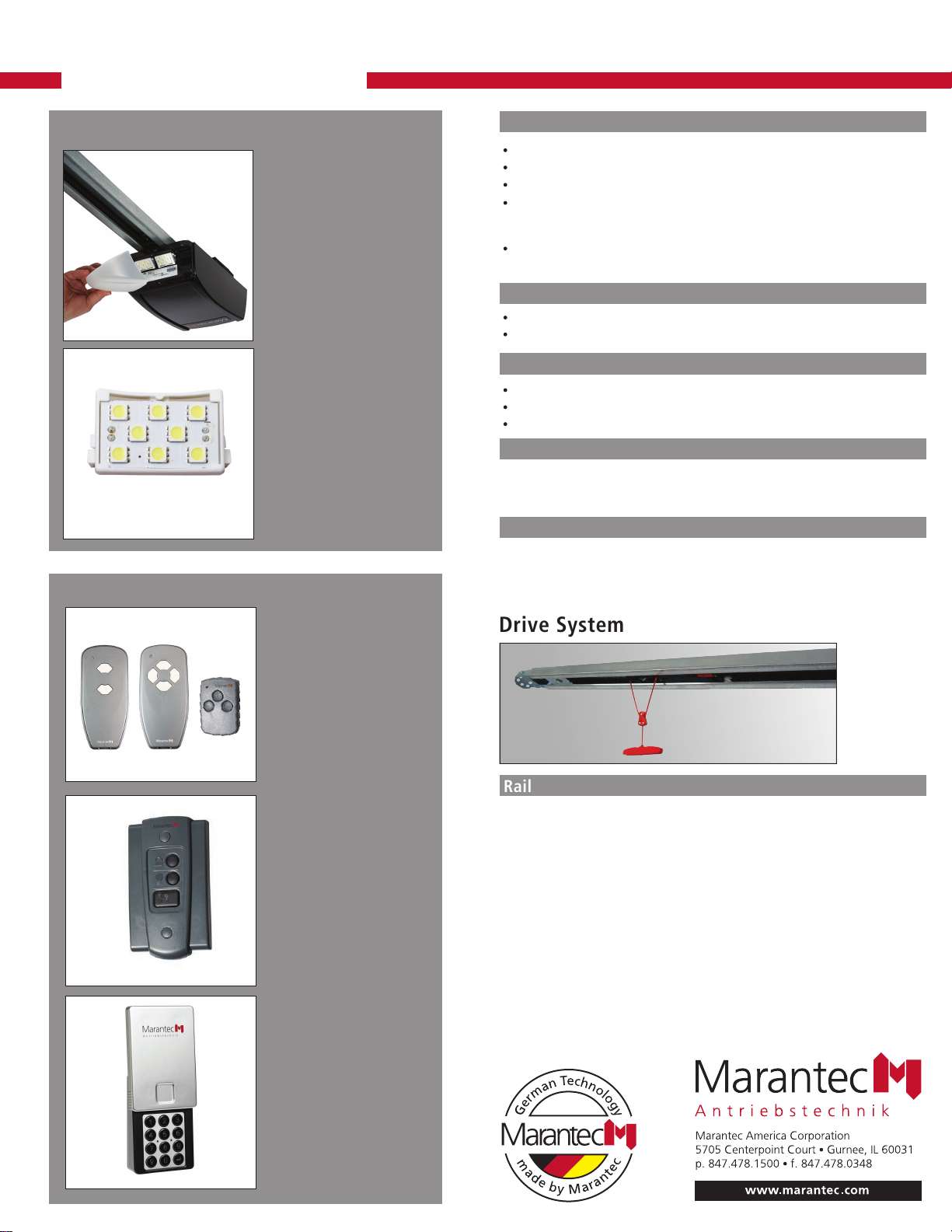

Synergy 260

The new Synergy Collection of garage door openers.

Faster, Brighter, Smarter, Stronger, Ultra Quiet.

The Synergy 260 is a feature-rich garage door operator system, built to last and

guaranteed to provide years of smooth, trouble-free performance. Innovative LED

lighting and reduced stand-by consumption make the Synergy 260 the most

efficient residential garage door opener available, while the direct current (DC)

Smart Motor , coupled with a chain or belt drive system, ensures an amazingly

quiet operation.

Limited Lifetime Warranty

on Motor, Gear Assembly

and Rail System. 2-year

Limited Parts Warranty

Part #120124 Version: 11/16

®

Synergy 260 Specifications

LED Lighting System

Accessories

Integrated seamlessly into

the motor housing, LED

lighting comes standard with

every Synergy operator. The

lens covers are completely

enclosed, meaning no

unsightly dirt and bugs under

the light covers

• LED lighting 80% – more

efficient than incandescent

light bulbs

• Longevity – LEDs have a

lifespan of over 30,000

hours.

• Cool Operation – LED

modules create more light,

while emitting less heat.

Transmitters

Two styles of digital remote

control transmitters in three

different configurations:

2-channel MINI, 4-channel

MINI (optional), and

3-channel MICRO (optional)

remotes for controlling other

devices. Unique and

extremely secure multi-bit

code technology.

Modular Multi-Function

Wall Station

Provides door operation and

convenience from inside the

garage. Compact, stylishly

designed to fit in a standard

single gang electrical box.

Illuminated push-button.

Security vacation/lock switch.

Light control. Individual

control stations can be

combined into one solid panel.

Wireless Keyless Entry

System (optional)

Convenient, 4-digit PIN.

Controls up to 4 different

garage doors. Code security.

Weather resistant.

Can be programmed to

provide temporary access

to authorized visitors or

service personnel.

Operator Features

DC motor provides for amazingly quiet operation

Opening and Closing Speed: 6.3 in/sec max

Push & Pull Force: 550 Newton (1/2 HPCS

Garage door opener is self-learning the operating force necessary to open and

close the garage door. Independently from the operating force, the opener

system monitors for obstructions during door travel.

Sealed motor gear case provides continuous lubrication to ensure a long service

life and and smooth, trouble-free operation.

™

)

Radio Controls

Frequency: 315MHz, Homelink® compatible

Technology: Multibit code

Lighting System

LED lighting system (included)

378 lumens expandable to approximately 756 lumens

Time controlled - lighting duration is programmable

Photo Eyes Safety System

State-of-the-art photo eye safety system detects obstructions in the path

of the door and automatically stops and reverses the downward door

travel. Safety when you need it most.

Warranty

Limited Lifetime Warranty on Motor, Gear Assembly and Rail System.

2 - year Limited Parts Warranty

5-year Limited Warranty on LED Lighting System

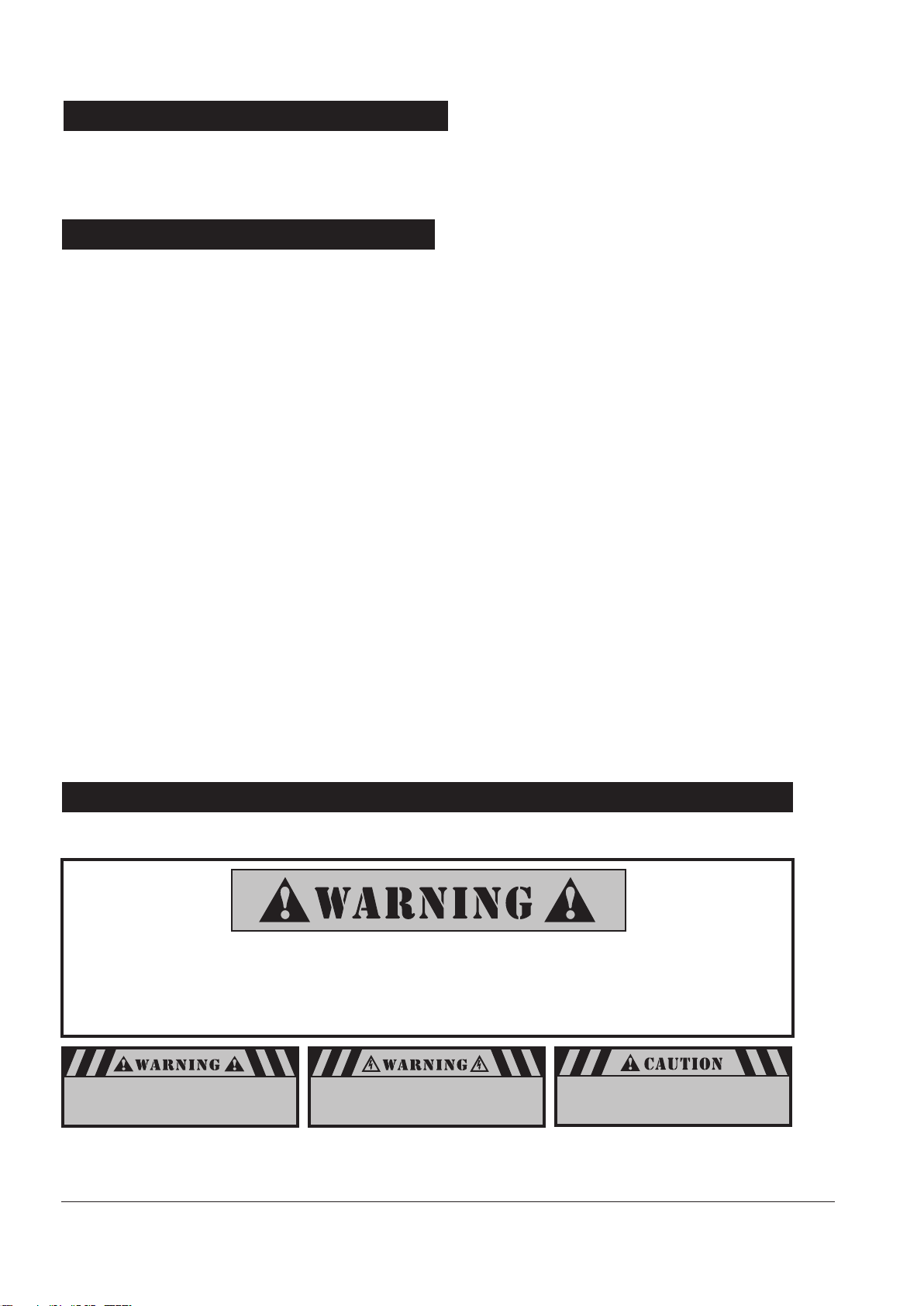

Drive System

Rail

The best in advanced engineering and materials. One piece

semi-closed fully assembled drive system with a high strength

galvanized steel finished C-rail, available with a steelreinforced belt or a full steel chain. A revolutionary trolley

release mechanism helps to prevent garage break ins.

Drive system’s overall length with attached operator 7ft. door: 10’- 6.25”

Door Heights Supported: 7ft, 8ft

Headroom Clearance Required: 1.25 inches

Trolley: Includes emergency release, easy reconnect, vault release compatibility

Owner’s Manual contains:

Installation, operating,

maintenance & warranty

instructions.

Synergy 260, 270, 280

Marantec America Corporation

5705 Centerpoint Court, Gurnee, IL 60031 U.S.A.

Phone 1-888-622-2489

Fax 847-478-0348

OWNER’S MANUAL CONTENTS

1. INTRODUCTION 3

2. ADVANCED FEATURES 3

3. IMPORTANT SAFETY INFORMATION 3

4. TOOLS 4

5. GARAGE 4

6. OPERATOR PACKAGE CONTENTS 6

7. IMPORTANT INSTALLATION INSTRUCTIONS 7

8. INSTALLATION STEPS 8

8-1. MEASURE AND MARK DOOR AREA 8

8-2. INSTALL HEADER BRACKET 8

8-3. INSTALL DOOR BRACKET TO DOOR 9

8-4. RAIL ASSEMBLY 10

8-5. ATTACH RAIL TO OPERATOR HEAD 11

8-6. ATTACH RAIL TO HEADER BRACKET 11

8-7. POSITION OPERATOR FOR MOUNTING 12

8-8. MOUNT OPERATOR TO CEILING 13

8-9. CONNECT ARM TO DOOR AND TROLLEY 13

8-10. RAIL BUMPER INSTALLATION 14

8-11. CHECK EMERGENCY RELEASE 14

8-12. INSTALL PHOTO EYE SAFETY SYSTEM 15

8-13. INSTALL WALL CONTROL PANEL 16

8-14. CONNECTING WIRES TO OPERATOR 16

9. CONTROL UNIT CONNECTIONS 17

10. CONNECT TO POWER 18

11. SYSTEM SET UP 19

12. ADVANCED SETTINGS 21

13. REMOTE CONTROLS 25

13-1. TRANSMITTER 25

13-2. WIRELESS KEYLESS ENTRY SYSTEM (OPTIONAL ACCESSORY) 26

14. OPERATION OF YOUR OPERATOR 27

15. HOMELINK® TRANSCEIVER 28

16. TEST SAFETY REVERSAL 29

17. ALIGN AND TEST PHOTO EYE SENSORS 29

18. APPLY LABELS TO INSIDE OF GARAGE 30

19. ATTACH OWNER’S MANUAL TO WALL 30

20. IMPORTANT SAFETY INSTRUCTIONS 30

21. TENSION ADJUSTMENT 31

22. RAIL LENGTH ADJUSTMENT - FOR PROFESSIONAL INSTALLERS ONLY 31

23. RAIL ASSEMBLY PARTS 32

24. ACCESSORIES 33

24-1. LED EL 200 33

24-2. EXTENSION BRACKET KIT 34

24-3. PERMANENT WIRING 35

25. TROUBLESHOOTING - FOR PROFESSIONAL INSTALLERS ONLY 36

26. MAINTENANCE AND ADJUSTMENTS 38

27. LIMITED PARTS WARRANTY 38

28. WARRANTY LIMITATIONS, CLAIMS AND SERVICE 40

29. REGISTRATION 40

30. WARRANTY SERVICE 40

C

Copyright 2015 All Rights Reserved.

1. INTRODUCTION

Congratulations on purchasing your Marantec® Synergy Garage Door Operator System, the most innovative operator available today.

This stylishly designed digital operator with a wide range of accessories is engineered to provide the smoothest, quietest and safest operation to

compliment any application. Advanced technology results in the operator being capable of easily moving almost any properly balanced sectional

door, and at the same time providing state-of-the-art safety features to detect obstructions and to stop and reverse the door, thus helping to

protect persons and property near the door.

2. ADVANCED FEATURES

This operator includes numerous state-of-the-art features to provide you, the user, with years of trouble-free, convenient, and safe use of

your automatic garage door operator.

Advanced Digital Operating System EOS (Easy Operating System): The EOS digital system provides an user friendly

system set up. The EOS system requires only the initial set up parameters. All other operating parameters are learned and set

automatically by the system. In addition, the system optimizes all parameters with every cycle for a more efficient operation by

the GDO. This shorter parameter set up provides a quicker and more efficient installation.

New LED Lighting System: Provides a green energy efficient lighting approach to conventional incandescent lighting.

Added convenience requires no light bulb replacement.

Precision Controlled DC Motor, Complete with Automatic Soft Start and Soft Stop Feature: The operator

automatically detects when your door is almost fully closed or fully opened, and gradually slows the door down before it

reaches its fully closed or opened position. During start-up, the door starts moving slowly and gradually ramps up to full

speed for the full travel of your door. This reduces the possible damaging effects of the sudden starts and stops associated

with some other operators, and results in the smooth operation and increased service life of your door and hardware.

Quiet, Smooth Operation: Precision engineering and carefully selected materials result in extremely smooth and quiet

operation, unmatched by conventional garage door operators.

Modular Antenna Concept (patented): Plug-in your choice of frequency module.

Built-In Safety Features: Including patented drive system that delivers only the optimum power needed to move your door

safely - Every time!

Photo Eye (Infrared) Safety System: State-of-the-art infrared beam system helps detect obstructions in the path of

your door and automatically reverses closing door travel, helping to protect persons and property near the door.

LCD Display System Control: Easy navigation through levels and menus.

Convenient Status Display: To indicate the status of your door operator at any time. Especially useful if troubleshooting is necessary.

Numeric Parameter Display Setting: Provides easier and quicker setup.

Numeric Error Code Display: Provides quicker troubleshooting.

Maintenance and Service Scheduling: Optimizes operator service life and trouble-free performance.

The EOS platform unifies all Marantec Products by design.

Meets all UL 325 requirements.

3. IMPORTANT SAFETY INFORMATION

This manual is essential to the safe and proper installation, operation, and maintenance of your operator. Read and follow all

guidelines and operating instructions before the first use of this product. Store the manual in a safe, easily accessible location.

Operate the garage door operator at 120V, 60Hz to avoid operator damage.

Garage doors are heavy, moving objects. When coupled with an automatic operator, electrical power is also

present. If not properly installed, balanced, operated, and maintained, an automatic door can become

dangerous and cause serious injury or death. Please pay close attention to the WARNING and CAUTION notices

that appear throughout this manual. Failure to follow certain instructions may result in damage to the door or

door opener, or may result in severe injury or death to yourself or others.

WARNING means that severe injury

or death could result from failure

to follow instructions.

Mechanical

WARNING means that severe injury

or death could result from failure

to follow instructions.

Electrical

CAUTION means that property damage

or injury could result from failure

to follow instructions.

3

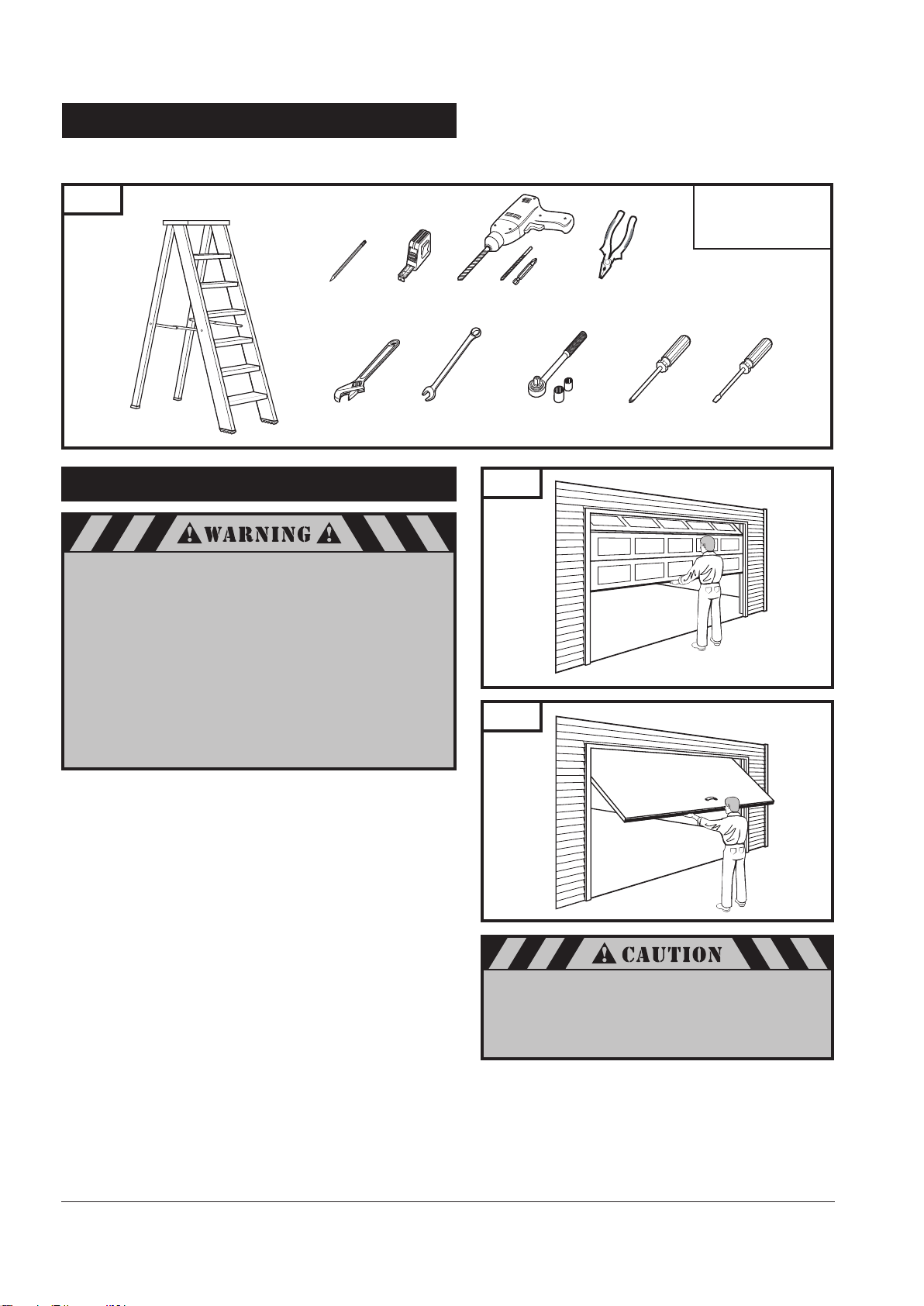

4. TOOLS

The instructions will refer to the tools shown below for proper installation, adjustment, and maintenance of the garage door

operator. Additional tools may be required depending on your particular installation.

Fig. 1

Stepladder

Pencil

Adjustable

Wrench

Tape Measure

7/16" Wrench

5. GARAGE

A garage door is a heavy moving object and can cause

serious injury or death. An unbalanced door might not

reverse when required, and can increase the risk of

injury. If your garage door is out of

balance, or if it binds or sticks, call for professional

garage door service. Garage doors, springs,

pulleys, cables, and hardware are under extreme tension

and can cause serious injury or death.

Do not try to adjust them yourself. Ropes left

on a garage door could cause someone to become

entangled and could kill them. Remove all ropes

connected to the door before installing your operator.

Drill,Drill Bits,

Phillips Power Bit

Ratchet and Sockets

(1/2", 7/16")

Fig. 2

Fig. 3

Pliers

Phillips

Screwdriver

Conversion:

1 foot = 305mm

1 inch = 25.4mm

Flat-Tip

Screwdriver

Sectional Door

One-Piece Door

Take a moment to survey your garage and garage door.

Is there an access door besides the garage door? If not, you

should install an emergency key release kit.

With the garage door closed, check alignment of door and

garage floor. The gap, if any, should be no more than

1/4" (6mm). If the gap is larger than this, repair floor or door

before installing operator.

The operator is intended for installation on a properly balanced

and adjusted garage door. DO NOT INSTALL IF DOOR IS

UNBALANCED OR BROKEN.

Check balance of door in mid travel and during full range of

opening and closing. Lift the door about half way, as shown in

Fig. 2 & 3. Release the door. It should remain in place,

supported by its springs. Raise and lower the door fully to

check for binding or sticking.

If door is out of balance or needs repair, DO NOT ADJUST IT

YOURSELF. CALL A QUALIFIED GARAGE DOOR SERVICE

PROFESSIONAL to adjust your door.

If your door is over 7 ft. (2.1m) high, you will need a longer

rail. See section 6 “Rail Assembly” on p. 6 of this manual for

availability of longer rails.

4

To prevent damage to steel, aluminum, fiberglass

or glass panel doors, always reinforce the inside of

the door both vertically and horizontally with steel

or angle iron bracing.

The best solution is to follow the instructions for your

particular garage door or contact the garage door

manufacturer for proper reinforcement instructions.

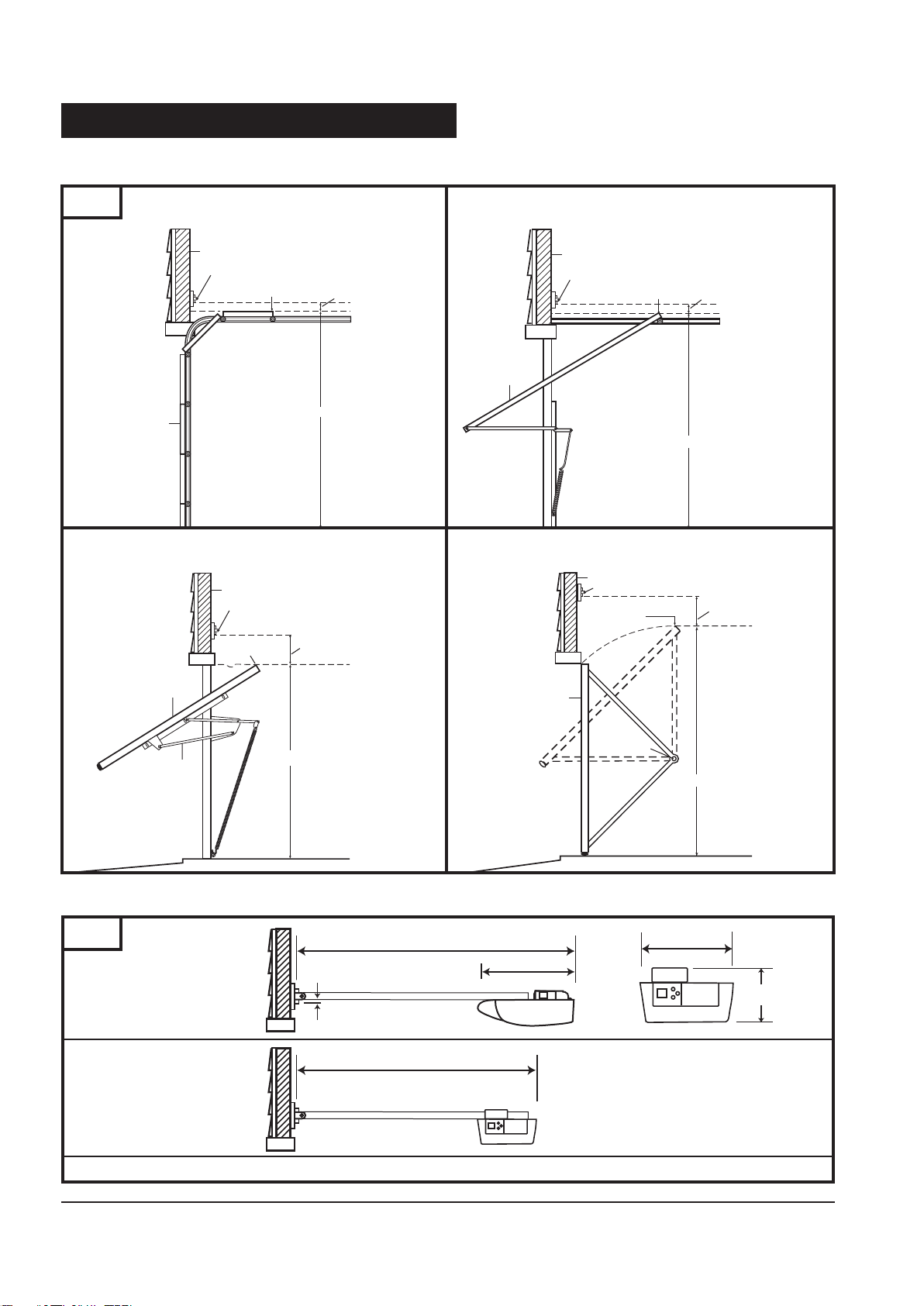

5. GARAGE (cont’d)

Header Wall

Check the type of door construction you have. The information contained in the figures below will be referred to later in the

Check the type of door construction you have. The information contained in the figures below will be referred to later in the

manual for proper installation on the different door types.

manual for proper installation on the different door types.

Fig. 4

Door

Header Wall

Header Bracket

Highest Point of

Header Wall

Header Bracket

Highest Point of

Door Travel

Sectional Door

with Curved Track

Door Travel

1-1/4” (30mm) Clearance

Distance

One-Piece Door

with Jamb Hardware without Track

3-3/4” (95mm) Clearance

Door

Header Wall

Header Bracket

Header Bracket

Highest Point of

Door Travel

Highest Point of

Door Travel

One-Piece Door

with Horizontal Track

1-1/4” (30mm) Clearance

Distance

One-Piece Door

with Pivot Hardware without

Track

3-3/4” (95mm) Clearance

Door

Jamb

Hardware

Distance

Door

GARAGE DOOR OPERATOR SYSTEM OVERALL DIMENSIONS 7' DOOR (2.1m)

Fig. 5

Standard Application

Space Saver Application

10' 6-1/4" (3.21m)

14-1/4" (360mm)

1/2" (13mm)

10' 3/4" (3.07m)

Pivot

Distance

7-1/2" (190mm )

5" (125mm )

Headroom Clearance - 1-1/4” (32mm)

5

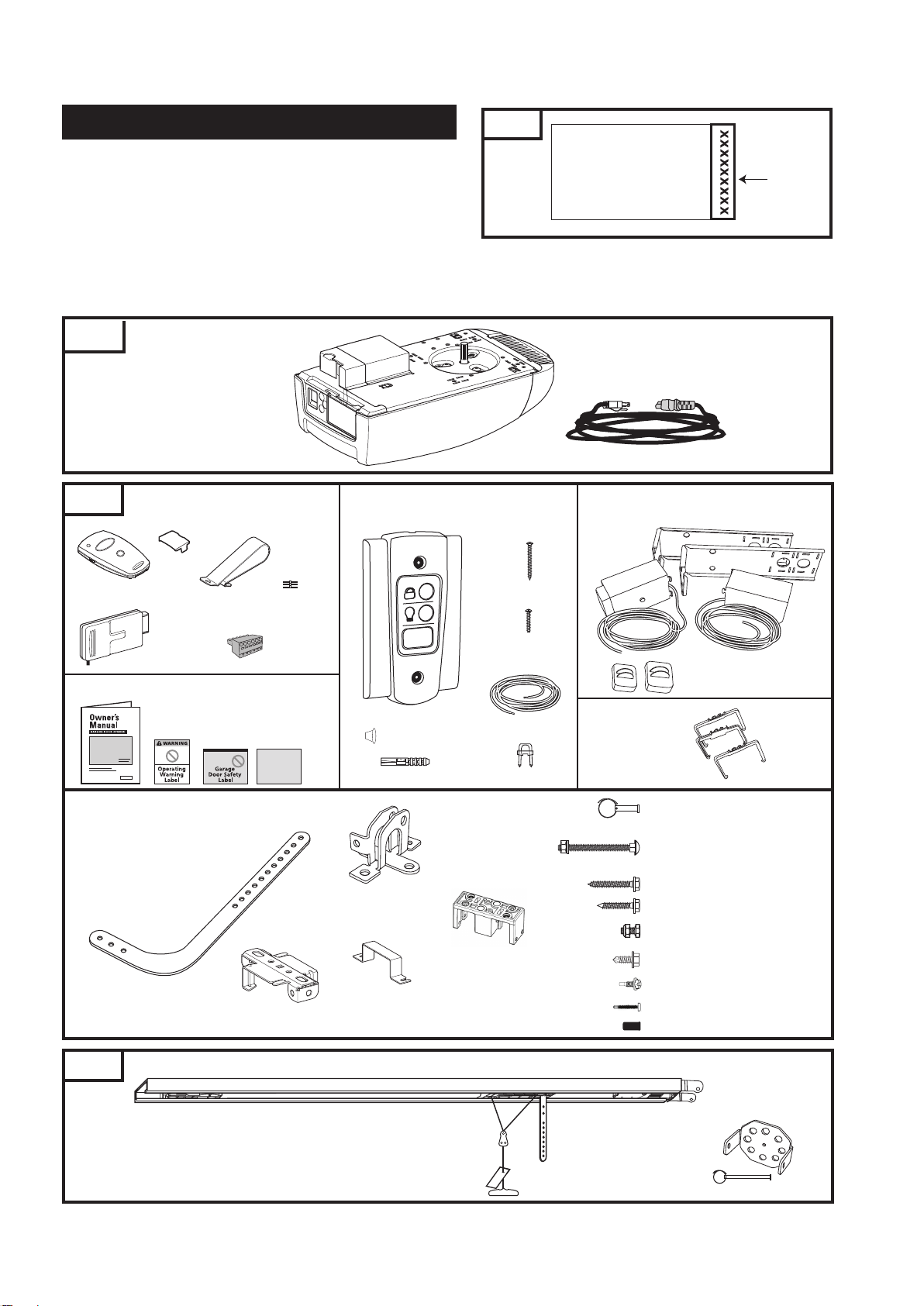

6. OPERATOR PACKAGE CONTENTS

Fig. 6

Remove one of the serial number labels located on both sides

of operator carton and apply to the front page of owner’s

manual. See Fig. 6.

Removable

serial number

Remove second serial number label and apply to the warranty card.

Operator’s manufacturing date is located under operator lens cover.

The following items are included with your Garage Door Operator (GDO). All hardware components are located in the GDO

carton. The accessories are packaged with their respective hardware in separate packs for ease of identification and use.

Items shown not actual size.

Fig. 7

Fig. 7A

Transmitter

OPERATOR

ACCESSORIES

Cover

Visor Clip

Modular

Receiver

Programming

Connector

Terminal

Block

Garage Door Operator Manual and Safety Labels

Warranty

Card

Wall Control Panel

(with Hardware Kit)

Screw Caps (2)

Drywall Anchors (2)

Tapered-Head Screws

(2)

Machine screws

(2)

30 Ft. (9.2m)

2-Conductor Wire

Staples (10)

6 Ft. (1.8m) Detachable Power Cord

Photo Eye Sensor Safety System

(with accessories)

Sensor (TX)

Sensor (RX)

Sensor Lens Cap Protectors (2)

Wire Holder Kit

Bracket (2)

5“

6“

5.5”

5“

6“

5.5”

5“

6“

Hardware Kit

Curved Door Arm

#8009466

Support Bracket (2)

#71865

Fig. 8

RAIL ASSEMBLY

(packaged in separate carton)

Models (per application)

Belt Chain

7’ (2.1m) Door M13-807B M13-807C

8’ (2.4m) Door M13-808B M13-808C

10’ (3m) Door M13-810B M13-810C

6

Door Bracket

#8030743

Rail Bracket (2)

#99082

Bumper

#102723

Clevis Pin (1): 5/16” x 7/8”

Cotter Ring (1)

Carriage Bolt (2): 1/4” - 20 x 2”

Lock Washer (2): 1/4”

Hex Nut (2): 1/4” - 20

Lag Screw (2): 5/16” x 1-3/4”

Lag Screw (4): 1/4” x 1-1/2”

Hex Bolt (2): 5/16” - 18 x 3/4”

Lock Nut (2): 5/16” - 18

Hex Head Tek Screw (2): 1/4” x 3/4”

Screw (4): M5x8.5mm

Screw (2): 3.9x32mm

Cap (2) #104740

Header Bracket Kit

#103238

(Clevis Pin 1/4” x 3 1/14”)

7. IMPORTANT INSTALLATION INSTRUCTIONS

IMPORTANT INSTALLATION INSTRUCTIONS

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

1. READ AND FOLLOW ALL WARNINGS AND INSTALLATION INSTRUCTIONS.

2. Check with the door manufacturer to determine if additional reinforcement is required to support the door prior to

installation of the door operator.

3. Install operator only on a properly balanced garage door. An improperly balanced door could cause serious injury.

Have a qualified service person make repairs to garage door cables, spring assemblies, and other hardware before

installing the operator.

4. Remove all ropes and disable all locks connected to the garage door before installing operator.

5. If possible, install the door operator 7 feet (2.1m) or more above the floor. For products having an emergency

release, adjust the emergency release cord for the handle to be within reach, but at least 6 feet (1.8m) above the

floor and avoiding contact with vehicles to avoid accidental release.

6. Do not connect the operator to source of power until this manual instructs you to do so.

7. Locate the wall control station: (a) within sight of door, (b) at a minimum height of 5 feet (1.5m) above the ground

so small children cannot reach it, and (c) away from all moving parts of the door.

8. Place the Operating Warning Label next to the wall control panel in a prominent location. Affix Safety Label on

inside of garage door. The Emergency Release markings molded on handle.

9. After installing the operator, test Safety Reversal System. Door MUST reverse when it contacts a 1-1/2 inch (40mm)

high object (or a 2x4 laid flat) on the floor.

10.

SAVE THESE INSTRUCTIONS

For Important Safety Instructions see page 30.

for future safety, adjustment, and maintenance purposes.

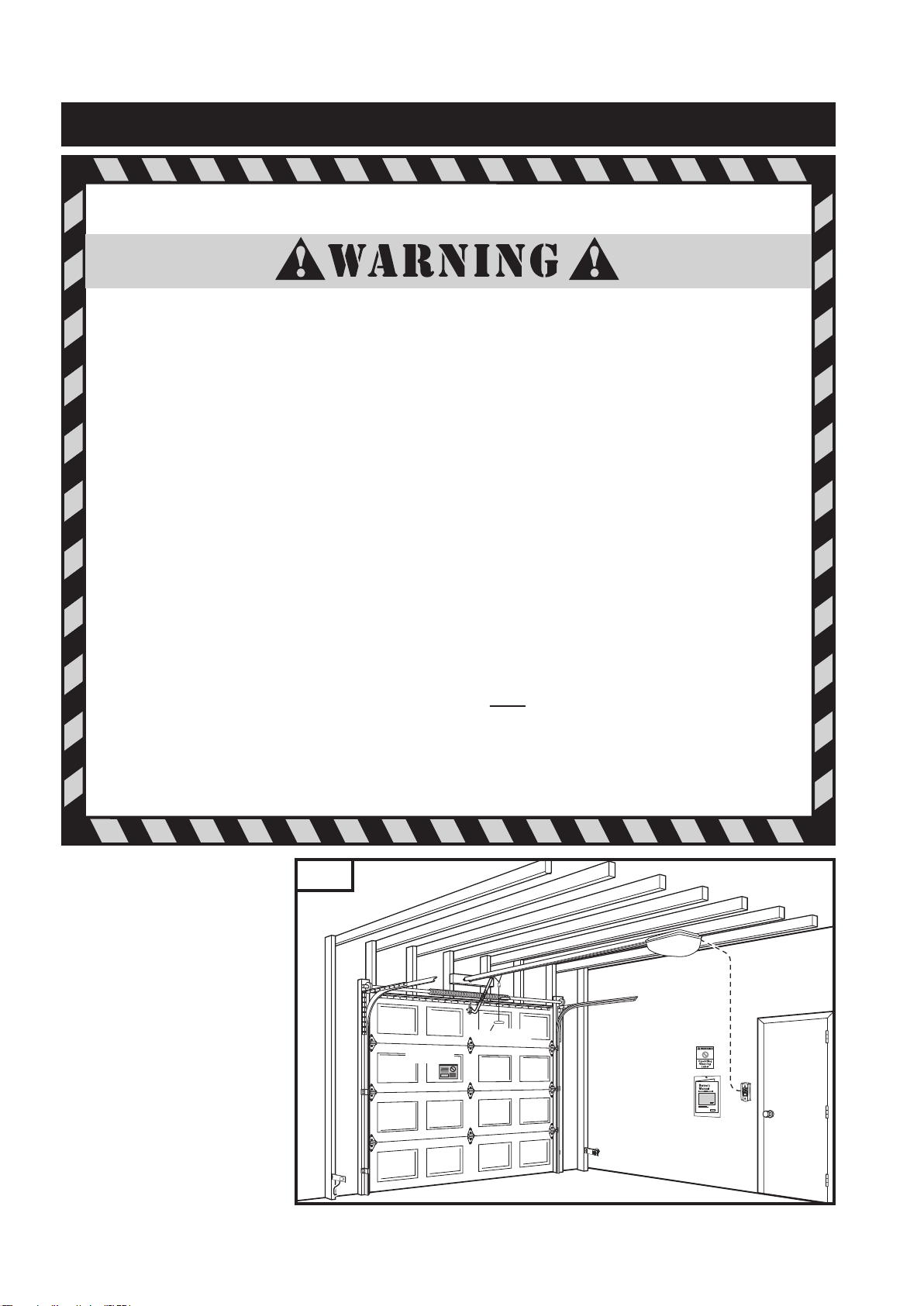

Fig. 9

Shown on the right is an

overall view of a completed

garage door operator system

installed on a sectional door.

The arrangement is similar for

a one-piece door (except for

differences described later in

this manual).

Garage Door

Safety Label

Emergency

Release Handle

Operating

Warning

Label

Owner’s

Manual

7

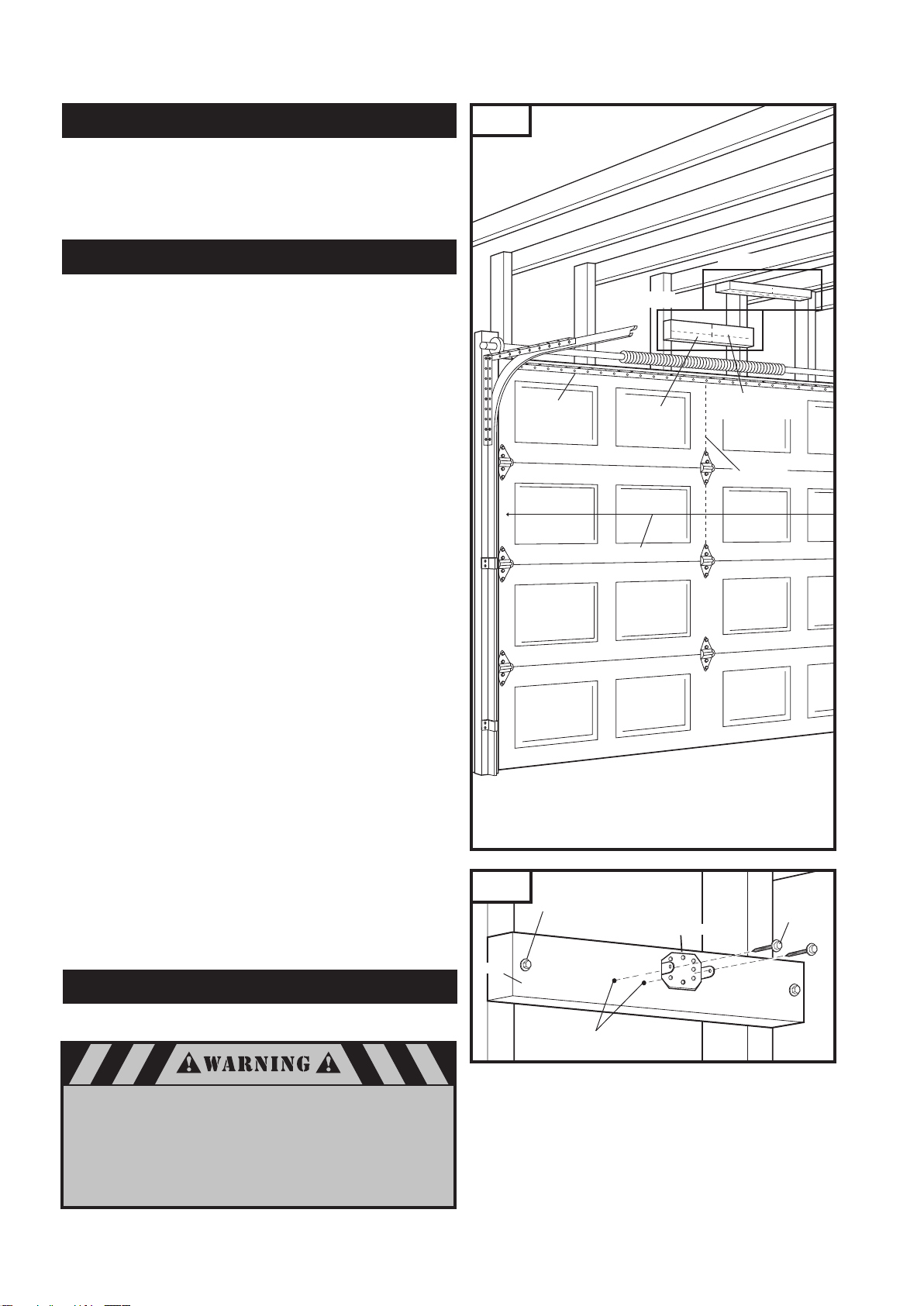

8. INSTALLATION STEPS

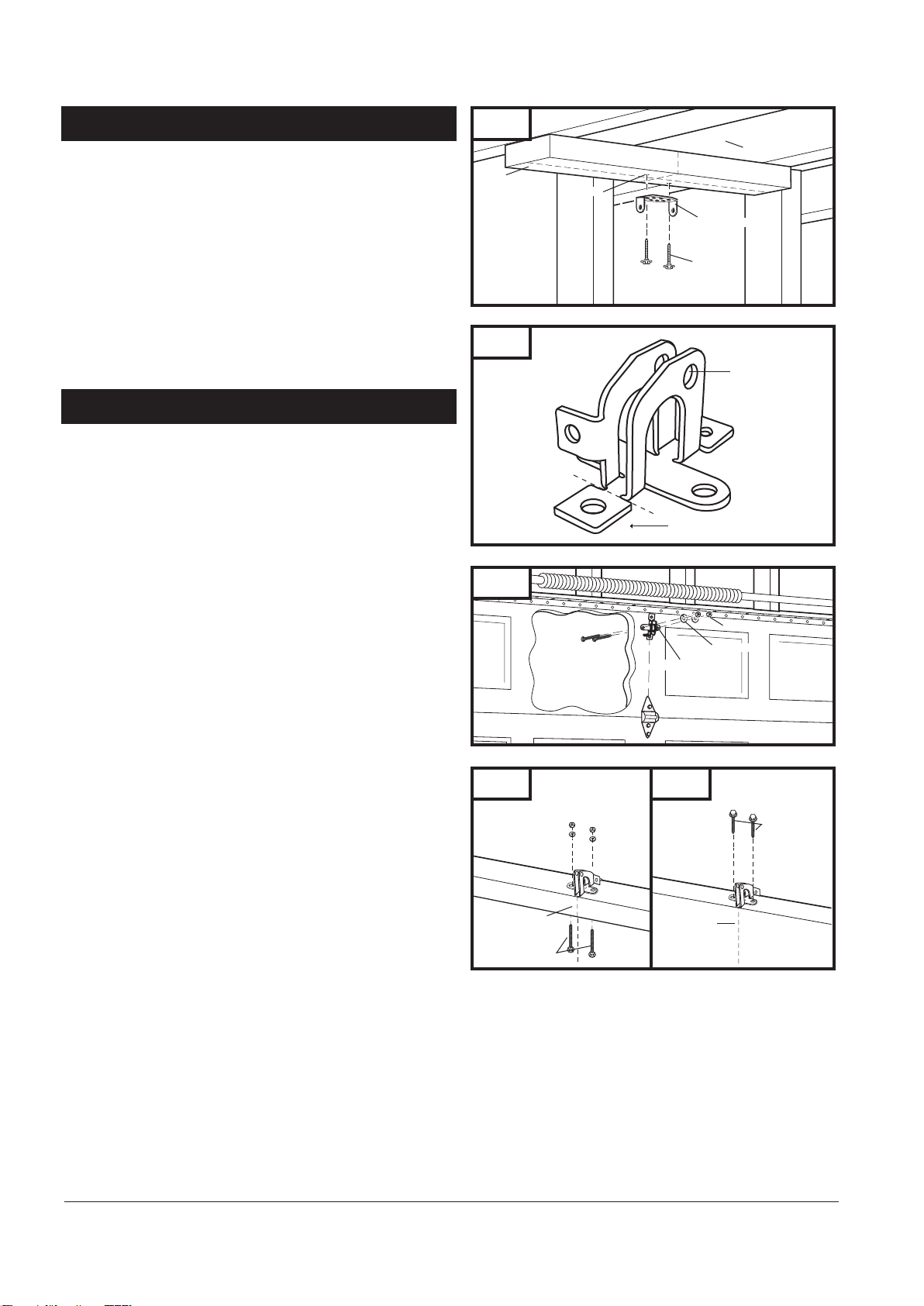

Identify a sound structural support on header wall above garage

door for header bracket mounting. See Fig. 11. If appropriate

header does not exist, replace or install a new support using a 2x4

(50mm x 100mm) or 2x6 (50mm x 150mm) board. Fasten it securely

using lag screws (not provided) to structural supports of garage.

Fig. 10

8-1. MEASURE AND MARK DOOR AREA

Before starting your installation, the door and the header above

the door must be measured and marked. This way, the appropriate brackets can be mounted at the correct locations avoiding

installation and operating difficulties later.

MARK VERTICAL CENTER LINE:

Measure door width, then locate the center point (Fig. 10).

Mark a vertical line on the upper half of your door, on the top

edge of your door, and on the header, through the center

point.

MEASURE DOOR’S HIGHEST TRAVEL POINT:

(Review Figs. on p. 5 for details)

Open door to its highest travel point and measure from the

garage floor to the top of door.

Write down this distance.

FOR SECTIONAL DOORS AND ONE-PIECE DOORS WITH

HORIZONTAL TRACK:

Add 1-1/4" (30mm) to the door travel height (measured above).

FOR ONE-PIECE DOORS WITHOUT TRACK:

Add 3-3/4" (95mm) to the door travel height (measured above).

Horizontal

Reinforcement

Bracket

See Fig. 11

Door Width

Header

See Fig. 12

Horizontal Line for

Header Bracket

Height

Vertical

Center Line

MARK HORIZONTAL LINE FOR HEADER BRACKET

LOCATION:

Close door and measure the required distance (determined

above) from the garage floor to the header.

Mark a horizontal line, intersecting the vertical center line, on

header. This is the position at which the bottom of the header

bracket should be installed.

In case of minimal clearance above the door, the header

bracket may be mounted to the ceiling. In this case, extend

the vertical center line onto the ceiling, and mark a horizontal

line on the ceiling no further than 4" (100mm) from the

header wall. The header bracket should be mounted no

farther than this distance from the header wall.

8-2. INSTALL HEADER BRACKET

Header bracket kit located in rail carton.

If the header bracket is not rigidly fastened to a sound

structural support on the header wall or ceiling, the

safety reverse system may not work and could cause

serious injury or death. DO NOT move or adjust springs

or garage door hardware, as these parts are under

extreme tension and could cause injury or death.

Fig. 11

Header

Lag Screw for Header installation

if necessary (not provided)

Header Bracket

Pilot Holes

5/16” x 1-3/4"

Lag Screw

8

8-2. INSTALL HEADER BRACKET (cont’d)

Mark pilot holes location on header through header bracket

holes where lag screws will be inserted.

IMPORTANT: See Fig. 11 for which header bracket holes to

use.

Drill 3/16" pilot holes into header, and install bracket with lag

screws (5/16” x 1-3/4”) provided.

Tighten lag screws firmly.

NOTE: Follow the same procedure if header runs vertically

instead of horizontally and is the only option for mounting

header bracket to header wall. In case of minimal clearance

above the garage door, the header bracket may be

mounted to the ceiling (Fig. 12). Follow the same steps

above to ensure a sound surface for mounting.

8-3. INSTALL DOOR BRACKET TO DOOR

A. FOR SECTIONAL DOORS:

Wood Sectional Doors (Fig. 14)

Position door bracket (Fig. 13) along vertical center line of

door with pin hole facing top of the door and top edge of

the bracket 4” to 5” (100mm - 125mm) below top edge of

the door, or roughly at the same height as top rollers on the door.

Mark locations of securement holes through door bracket.

Drill two 1/4" holes through door for securement of door

bracket.

Insert carriage bolts (1/4” x 2”) from the outside through

door and bracket, then secure with lock washers and nuts

from the inside.

Tighten nuts firmly.

Metal Sectional Doors

Attach door bracket with two teck screws (provided) per Door

manufacturer recommendations.

B. FOR ONE-PIECE DOORS:

Before starting the installation of the door bracket, cut off

mounting leg from opposite side of pin hole (Fig. 13).

One-Piece Doors with Exposed Frames (Fig. 15)

Position center of door bracket on the center line on the top

edge of door.

Mark the position where carriage bolts will go through

bracket, and drill two 1/4" holes through top frame of door.

Install carriage bolts from the bottom, through door frame

and bracket, and secure with lock washer and nut from top.

Tighten nuts firmly.

One-Piece Doors without Exposed Frames (Fig. 16)

For doors without exposed frames, use alternate method of

mounting door bracket.

Mark and drill two 3/16" pilot holes into top of frame, then

secure bracket with 5/16" x 1-5/8" lag screws (not provided).

Fig. 12

Header

Pilot Hole

Fig. 13

Cut off for one-piece

door only

Fig. 14

Insert 1/4”-20 x 2”

Carriage Bolts

from outside of door

Door Bracket

Fig. 15 Fig. 16

Garage Door

Center Line

Carriage Bolts

One-Piece Door

with Exposed Frame:

Install with Carriage Bolts

Garage Door

Center Line

without Exposed Frame:

Install with Lag Screws(not provided)

Ceiling

Header Bracket

Lag Screw

Pin Hole

1/4”-20 Nut

Lock Washer

Wood Sectional

Doors

Lag Screws

One-Piece Door

9

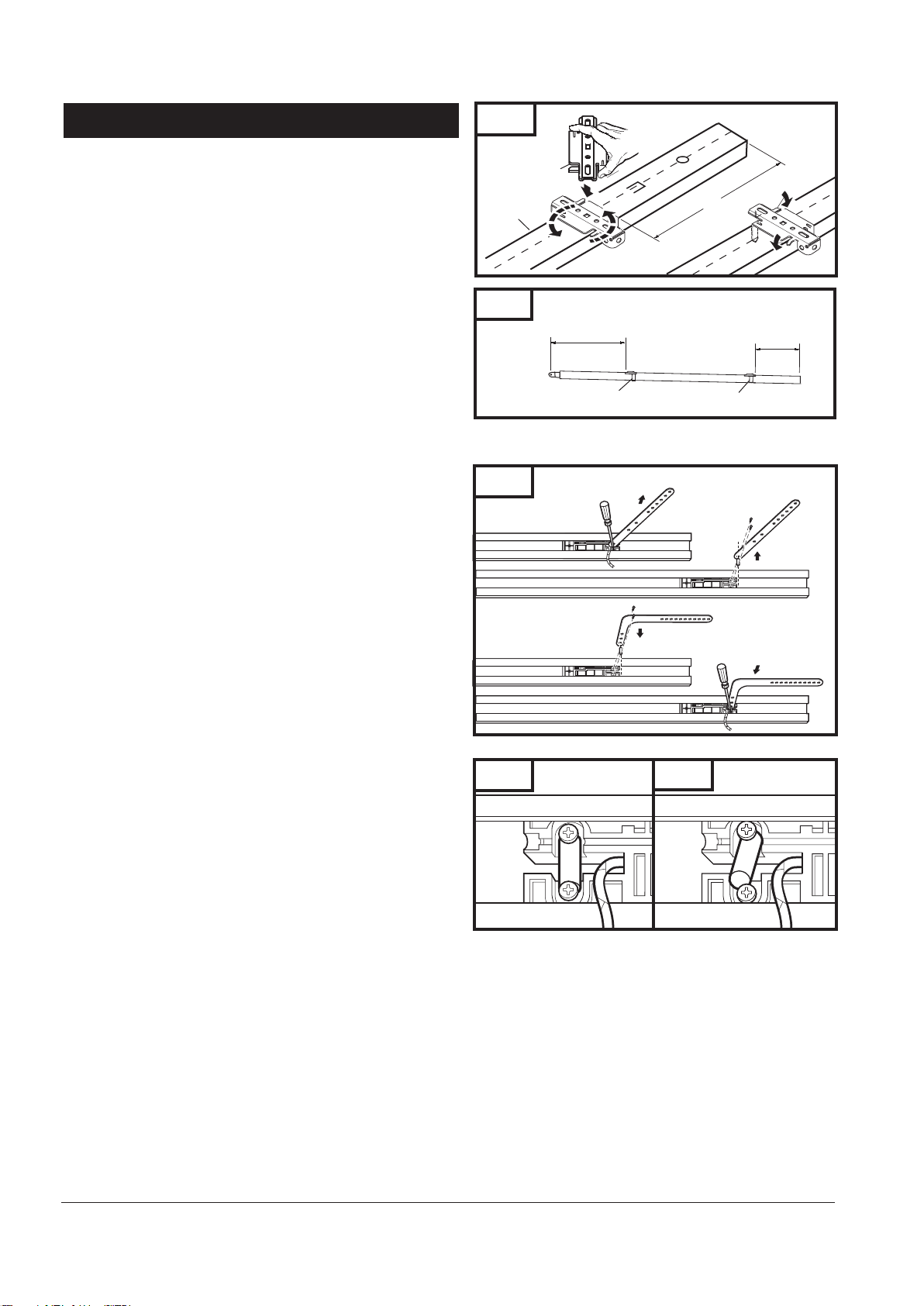

8-4. RAIL ASSEMBLY

NOTE: Rail comes fully preassembled with straight door arm

already attached.

Unpack one-piece preassembled rail.

Leave straight door arm taped inside rail for safe and convenient

installation—it will be untaped and used later.

Place mounting bracket over rail (close side) on a diagonal.

Make sure support securement clamps clear rail sides.

Twist mounting bracket and secure onto rail 12” (305mm)

from spracket end side of rail as shown in Fig. 17.

Place second mounting bracket over the backside of the rail 33”

(840mm) from pin hole. See Fig. 17A.

Secure second bracket as shown on Fig. 17.

Fig. 17

Mounting Bracket

Rail

Fig. 17A

33”

(840mm)

12”

(305mm)

12”

(305mm)

ADDITIONAL STEP FOR ONE-PIECE DOORS ONLY:

IMPORTANT NOTE: For installation on One-Piece Doors only,

the straight door arm that is factory installed onto the rail

must be replaced by the curved door arm supplied as part

of hardware in the operator box.

Recommended: Replace arm after attaching rail to operator.

Turn rail over so that open channel in rail faces up.

Untape straight door arm that is secured inside rail.

Remove and save the two phillips head screws that are securing

the door arm pin and straight door arm (Fig. 18).

Lift arm and pin straight out of slot in trolley, and remove pin

from straight door arm.

Insert pin into short side of curved door arm as shown.

Orient arm so that long side extends away from trolley.

Carefully insert pin and door arm into slot in trolley.

Push pin into slot with door arm so pin is fully seated into trolley

slot. IMPORTANT: Pin must be straight and seated properly

into recessed area in trolley. See Figs. 18A and 18B.

Secure pin and curved arm with the two phillips screws which

were removed from trolley—DO NOT use any other screws.

Tighten screws firmly.

Mounting Bracket

Fig. 18

C. Feed Pin though Curved

Door Arm Hole

Fig. 18A

Correctly seated pin.

Mounting Bracket

A. Loosen Screws

D. Reinsert Pin and Arm Firmly

and Squarely, Tighten Screws

Fig. 18B

Incorrectly seated pin.

B. Remove Pin

10

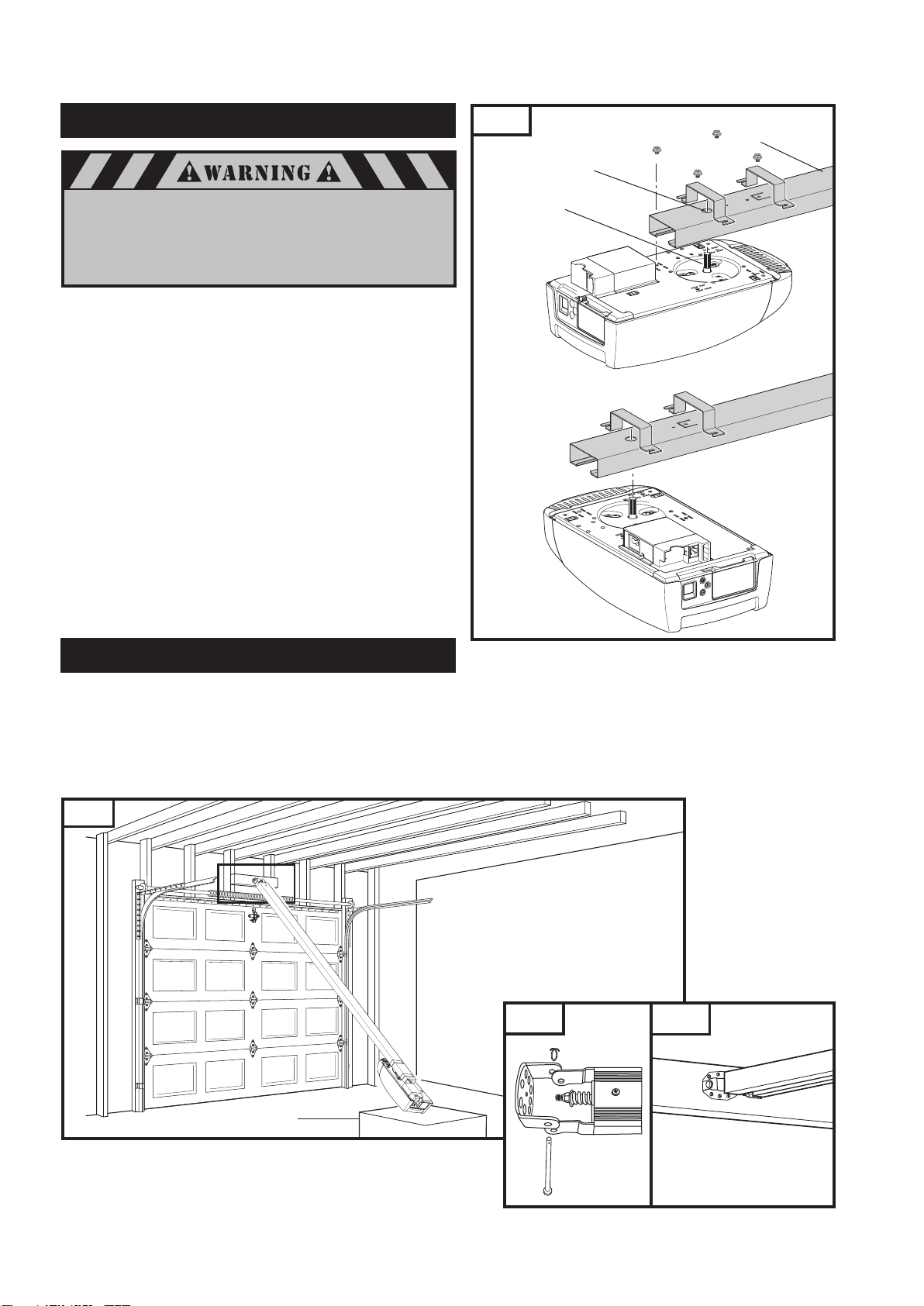

8-5. ATTACH RAIL TO OPERATOR HEAD

Fig. 19

Standard Application

Rail

Sprocket

Opening

When fastening the rail to the operator,

use only the screws provided. Use of any

other screws may result in operator falling

from ceiling and causing damage

to persons or property in the garage.

Position operator with control panel facing back of garage.

Rest operator head on cardboard or protective surface on floor

so opener does not get scratched.

Position rail onto operator chassis by lining up rail sprocket

opening with motor head shaft (Fig. 19). Make sure shaft

engages teeth inside rail sprocket. Press rail down firmly onto

shaft and opener chassis. DO NOT HAMMER.

Position the two rail brackets over rail as shown in Fig. 19.

Insert screws (M5 x 8.5) through bracket holes and into chassis

holes, and tighten screws firmly to hold rail to head.

Motor Head

Shaft

Alternate Rail Installation

(Space Saver Applications)

8-6. ATTACH RAIL TO HEADER BRACKET

Support operator head slightly off the floor.

Lift the opposite end of the rail up to the header bracket.

Position rail end-stop within the openings in the header

bracket. Insert header clevis pin (1/4” dia.) through header

bracket and rail end, then attach cotter ring to end

of pin. (See Fig. 20A)

Fig. 20

Fig. 20A Fig. 20B

Cotter Ring

Operator Box

1/4” x 3-1/4"

Clevis Pin

11

Loading...

Loading...