Marantec EX-2005, EX-2007 Instructions Manual

Access Systems

Automatically The Best Choice

Marantec America Corporation

675 Heathrow Drive Lincolnshire, IL 60069 U.S.A.

Phone 1-888-622-2489 • Fax 847-478-0348

www.marantecamerica.com

Garage Door Opener System

Installation and Operating Instructions

Deluxe EX-2005

Elite EX-2007

Digital Intelligence for the Garage

OWNER’S MANUAL CONTENTS

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. ADVANCED FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. IMPORTANT SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

GARAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5.

6. OPENER PACKAGE CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION STEPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.

8. OPENER PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9. TRANSMITTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10. OPERATION OF YOUR OPENER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11. TEST SAFETY REVERSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12. TENSION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

13. RAIL LENGTH ADJUSTMENT—FOR PROFESSIONAL USE ONLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14. RAIL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

15. POWER HEAD ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

16. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

17. EXTERNAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

18. TROUBLESHOOTING—FOR PROFESSIONAL INSTALLER ONLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

19. ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

20. TECHNICAL SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

21. MAINTENANCE AND ADJUSTMENTS RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1. INTRODUCTION

Congratulations on purchasing your Marantec®Professional Series Garage Door Opener System, the most innovative opener available today. This stylishly designed digital opener with a wide range of accessories is engineered to provide the smoothest, quietest and safest operation to compliment any home. Advanced

technology results in the opener being capable of easily moving almost any properly balanced residential

garage door, and at the same time providing state-of-the-art safety features to detect obstructions and to

stop and reverse the door, thus helping to protect persons and property near the door.

2. ADVANCED FEATURES

This opener includes numerous state-of-the-art features to provide you, the user, with years of

trouble-free, convenient, and safe use of your automatic garage door opener.

■ Precision Controlled DC Motor, Complete with Automatic Soft Start and Soft Stop Feature:

The opener automatically detects when your door is almost fully closed or fully opened, and gradually slows

the door down before it reaches its fully closed or opened position. During start-up, the door starts moving

slowly and gradually ramps up to full speed for the full travel of your door. This reduces the possible

damaging effects of the sudden starts and stops associated with some other openers, and results in the

smooth operation and increased life of your door and hardware.

■ Built-In Safety Features: Including patented drive system that delivers only the optimum power needed to

move your door safely — Every time!

■ Modular Receiver Concept (patented): Plug-in your choice of frequency module.

■ Photo Eye (Infrared) Safety System: State-of-the-art infrared beam system helps detect obstructions in

the path of your door and automatically reverses closing door travel, helping to protect persons and

property near the door.

2

3. IMPORTANT SAFETY INFORMATION

This manual is essential to the safe and pr

oper installation, operation, and maintenance of your opener. Read

and follow all guidelines and operating instructions before the first use of this product. Store the manual in a

safe, easily accessible location.

IMPORTANT SAFETY INSTRUCTIONS

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

1. READ

2.

3.

4.

5.

6.

7. KEEP GARAGE DOORS PROPERLY BALANCED. See Garage Door

8.

AND FOLLOW ALL INSTRUCTIONS CAREFULLY.

Never let children operate or play with door controls. Keep the remote control away

om children.

fr

Always keep the moving door in sight and away from people and objects until it is completely

closed.

NEVER GO UNDER A STOPPED, P

Test door opener monthly. The garage door MUST reverse on contact with a 40mm (1-1/2") high

object on the floor

Failur

If possible, use the emergency release only when the door is closed. Use caution when using this

r

sever

balanced door could cause severe injury or death. Have a qualified service person make repairs to

cables, spring assemblies, and other har

Disconnect the electrical power to the garage door opener before making any repairs or removing the housing cover

NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

ARTIALLY OPEN DOOR.

. After adjusting either the force or the limit of travel, retest the door opener.

e to adjust the opener properly may cause severe injury or death.

elease with the door open. Weak or broken springs may allow the door to fall rapidly, causing

e injury or death.

Owner's Manual. An improperly

dware.

.

IMPORTANT INSTALLATION INSTRUCTIONS

1. Check with the door manufacturer to determine if additional reinforcement is required to support the door prior to installation of the garage door opener.

2. Install garage door opener only on a properly balanced garage door. An improperly balanced

door could cause serious injur

cables, spring assemblies, and other har

Remove all ropes and remove or make inoperative all locks connected to the garage door before

3.

installing opener

If possible, install the door opener 2.1m (7 Ft) or more above the floor. Adjust the emergency

4.

release cord so that knob hangs 1.8m (6 Ft) above the floor.

5. Do not connect the opener to source of power until this manual instructs you to do so.

6. Locate the wall control panel or wall button: (a) within sight of door, (b) at a minimum height

of 5 feet above the gr

of the door.

7. The Emergency Release T

8. After installing the opener

40mm (1-1/2”) high object on the floor

.

ound so small children cannot reach it, and (c) away from all moving parts

SAVE THESE INSTRUCTIONS for future safety, adjustment, and maintenance purposes.

y. Have a qualified service person make repairs to garage door

dware before installing the opener.

ag must remain on the emergency release cord.

, test Safety Reversal System. Door MUST

.

reverse when it contacts a

3

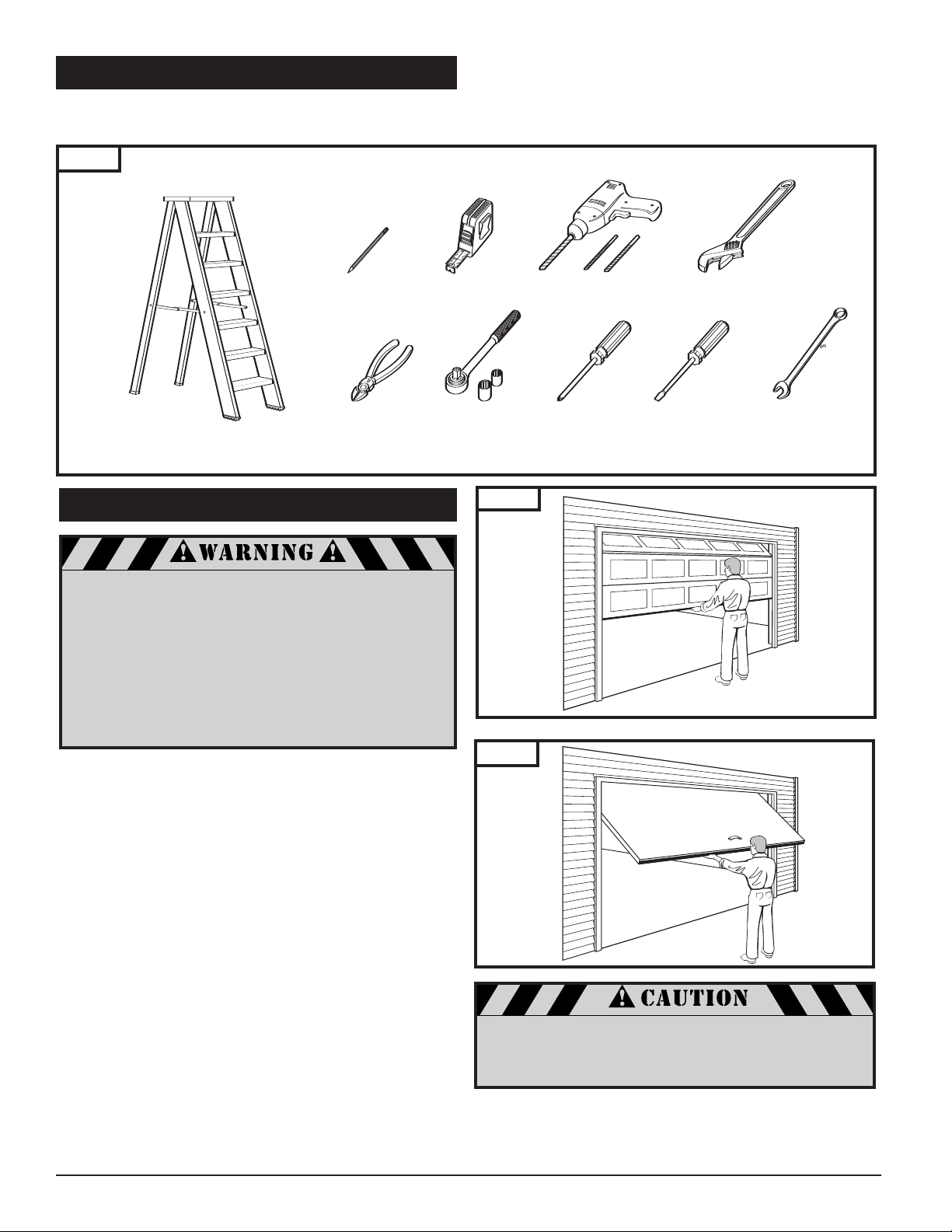

Pencil Tape Measure

D

rill and Drill Bits

Adjustable Wrench

Wire Cutters

R

atchet and Sockets

(

1/2”, 7/16”)

Phillips

Screwdriver

F

lat-Tip

S

crewdriver

7

/16”

W

rench

S

tepladder

4. TOOLS

One-Piece Door

Sectional Door

The instructions will refer to the tools shown below for proper installation, adjustment, and maintenance of the garage

door opener. Additional tools may be required depending on your particular installation.

Fig. 1

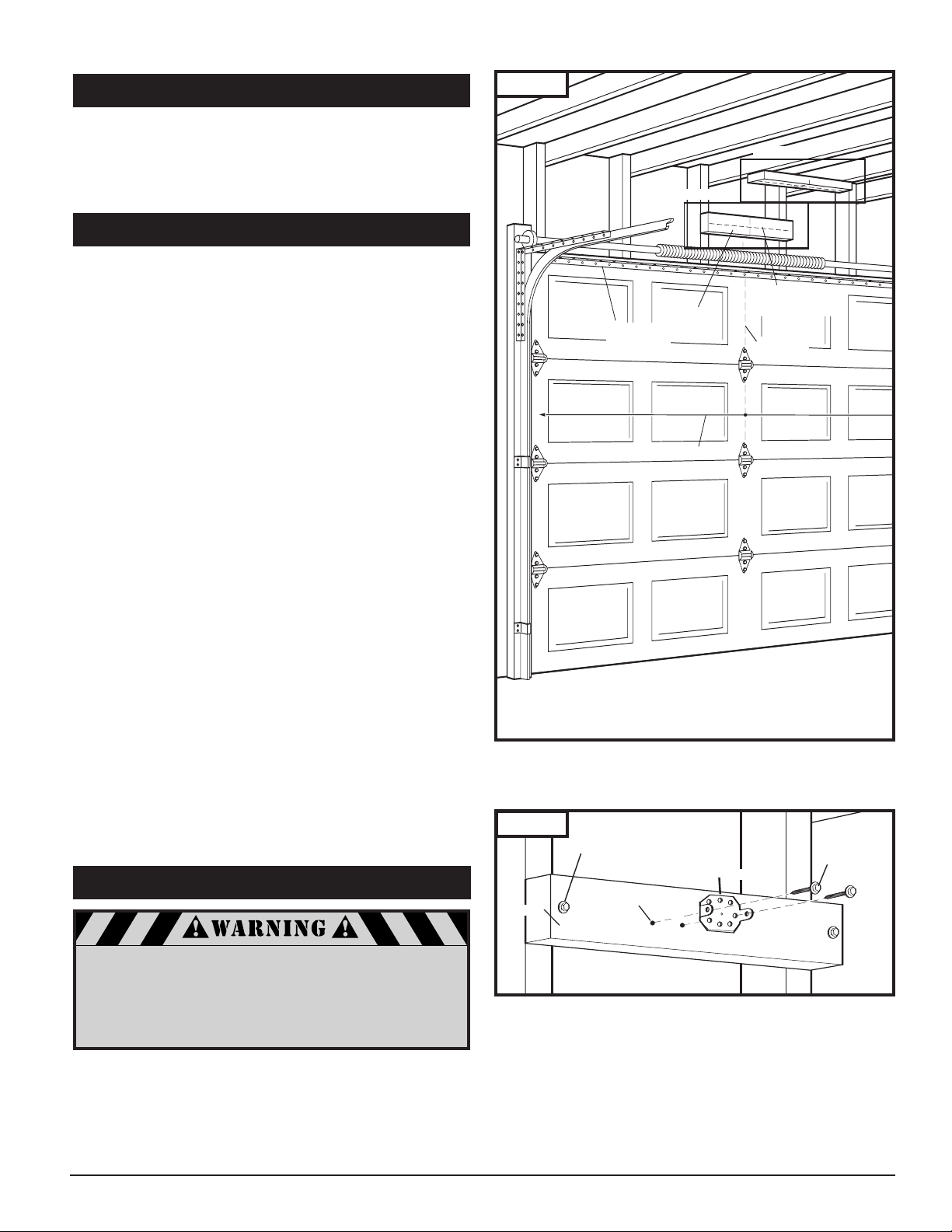

5. GARAGE

A garage door is a heavy moving object and can

cause serious injury or death. An unbalanced door

might not reverse when required, and can increase

the risk of injury. If your garage door is out of

balance, or if it binds or sticks, call for professional

garage door service. Garage doors, springs,

pulleys, cables, and hardware are under extreme

tension and can cause serious injury or death.

Do not try to adjust them yourself. Ropes left

on a garage door could cause someone to become

entangled and could kill them. Remove all ropes

connected to the door before installing your opener.

ake a moment to sur

T

■ Is ther

e an access door besides the garage door? If not,

you should install an emergency key release kit.

■ With the garage door closed, check alignment of door

and garage floor. The gap, if any, should be no more than

5mm (1/4"). If the gap is larger than this, repair floor or

door before installing opener.

■ The opener is intended for installation on a properly

balanced and adjusted garage door. DO NOT INSTALL IF

DOOR IS UNBALANCED OR BROKEN.

■ Check balance of door in mid travel and during full range

of opening and closing. Lift the door about half way,

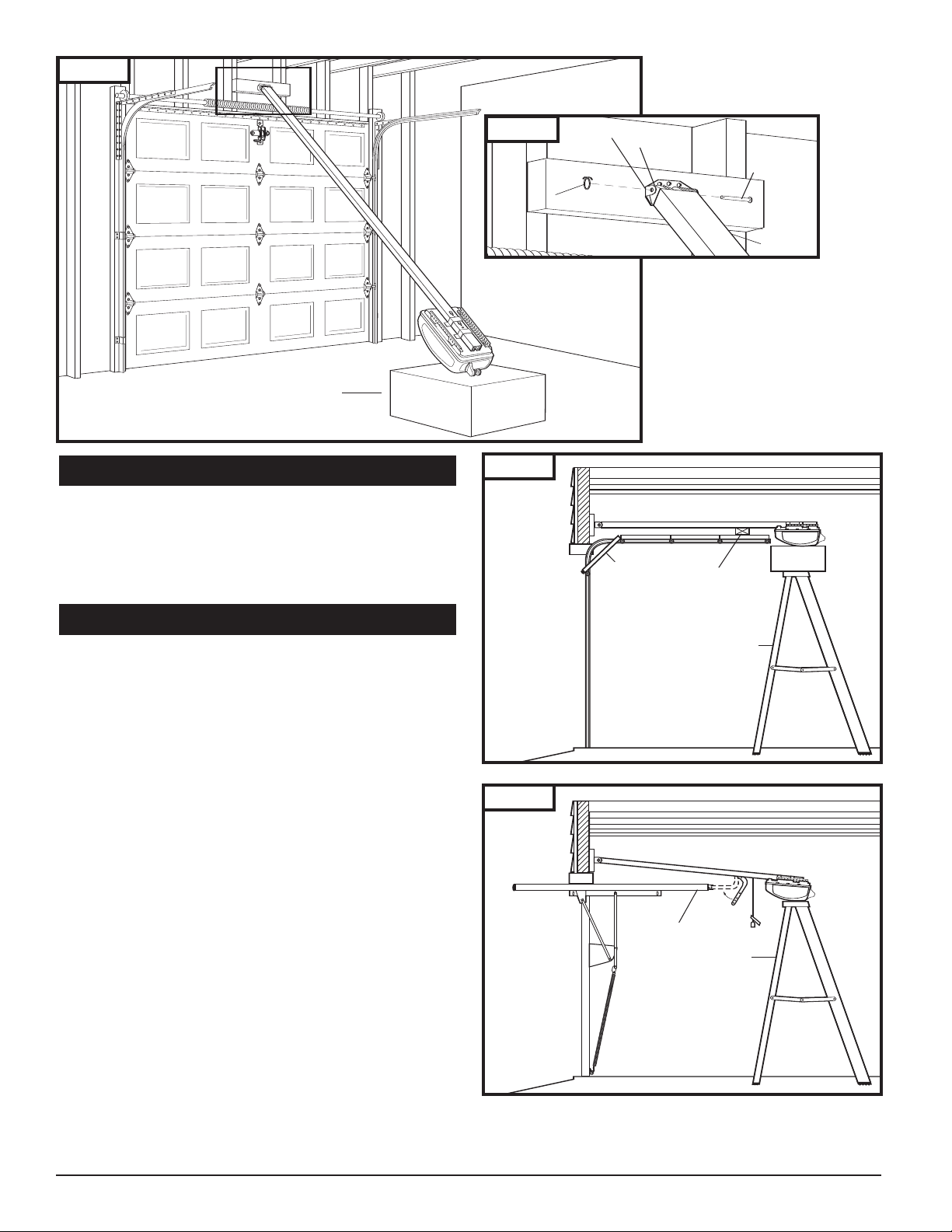

as shown in Fig. 2 & 3. Release the door. It should remain

in place, supported by its springs. Raise and lower the

door fully to check for binding or sticking.

■ If door is out of balance or needs repair, DO NOT ADJUST

IT YOURSELF. CALL A QUALIFIED GARAGE DOOR SERVICE

PROFESSIONAL to adjust your door.

■ If your door is over 2.1m (7 Ft) high, you will need a

longer rail. See section “6. Rail Assembly" on p. 6 of this

manual for availability of longer rails.

vey your garage and garage door.

Fig. 2

Fig. 3

event damage to steel, aluminum, fiberglass or

o pr

T

glass panel doors, always r

door both ver

tically and horizontally with steel or

angle ir

on bracing.

The best solution is to follow the instr

Sectional Door

One-Piece Door

ce the inside of the

einfor

uctions for your partic-

ular garage door or contact the garage door manufactur

oper reinforcement instructions.

for pr

er

4

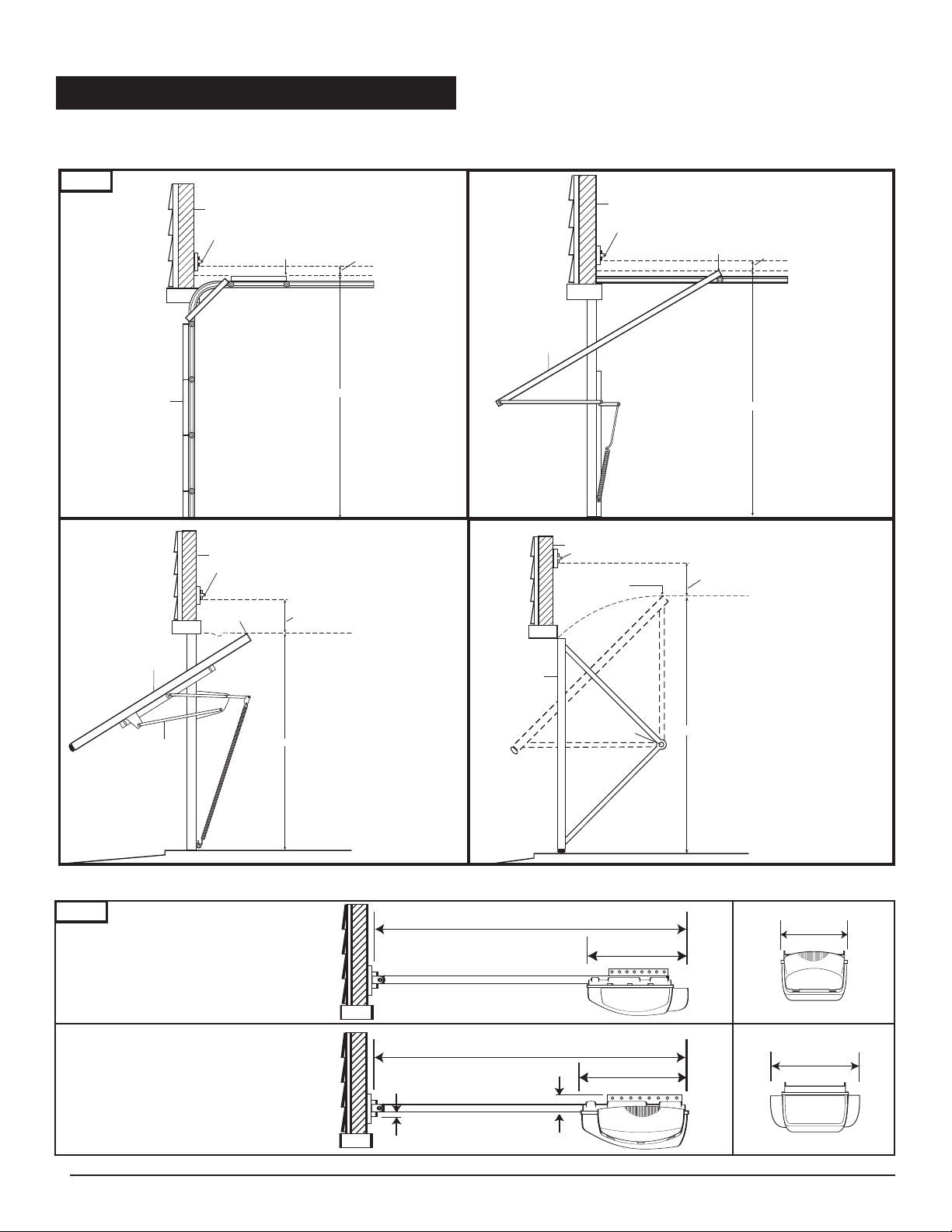

5. GARAGE (

Header Wall

Header Bracket

30mm (1-1/4”) Clearance

Highest Point of

Door T

ravel

Door

Distance

Header Wall

1-1/4”

Clearance

Highest Point of

Door Travel

D

oor

H

eader Bracket

D

istance

Header Wall

3-3/4” Clearance

Highest Point of

Door Travel

Door

Jamb

Hardware

Header Bracket

Distance

Header Wall

3-3/4”

Clearance

Highest Point of

Door Travel

D

Door

Pivot

H

eader Bracket

Distance

10' 10"

18"

10' 6 1/2"

14 1/2"

1/2" 1 3/8"

8 1/2"

14 1/2"

cont’d)

Check the type of door construction you have. The information contained in the figures below will be referred to later

in the manual for pr

Fig. 4

oper installation on the different door types.

Sectional Door

with Curved Track

One-Piece Door

with Jamb Har

e without Track

dwar

with Pivot Har

95mm (3-3/4”)

Clearance

One-Piece Door

with Horizontal T

30mm (1-1/4”)

Clearance

One-Piece Door

dwar

Track

e without

rack

95mm (3-3/4”) Clearance

GARAGE DOOR OPENER SYSTEM OVERALL DIMENSIONS 2.1m (7Ft) DOOR

Fig. 5

One Light Opener

Two Light Opener

3.3m (10’ 10”)

3.2m (10’ 6-1/2”)

460mm (18”)

370mm (14-1/2”)

215mm

(8-1/2”)

370mm

(14-1/2”)

13mm

(1/2”)

35mm

(1-3/8”)

5

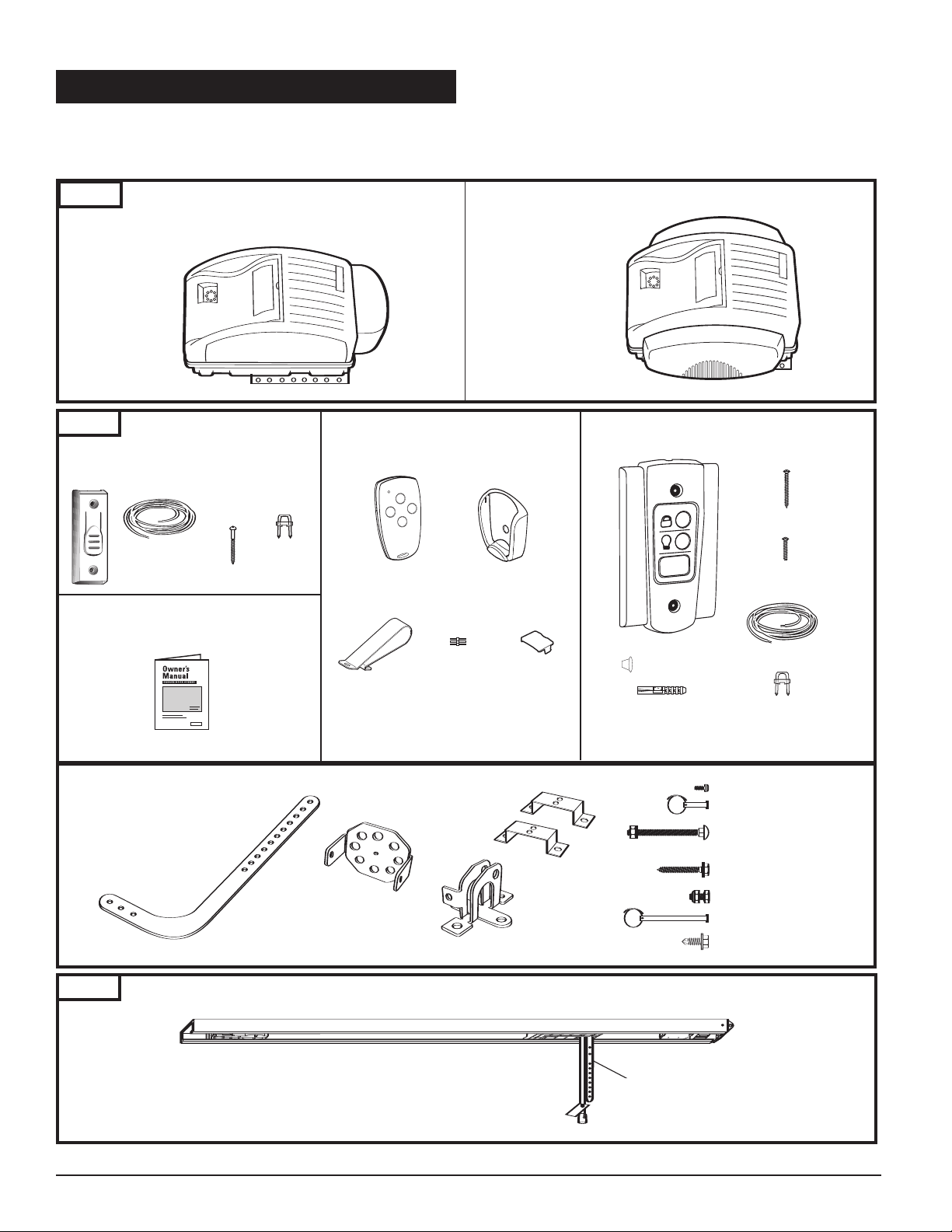

6. OPENER PACKAGE CONTENTS

M-Line

®

S

eries M-4500

(

Power Head with

1

Light Lens)

Hex Head T

“C” Brackets (2)

Curved Door Arm

Door Bracket

Header Bracket

Plastite Screw (4): 6 x 14

Clevis Pin (1): 5/16” x 7/8”

Cotter Ring (1)

Carriage Bolt (2): 1/4”-20 x 2”

Lock Washer (2): 1/4”

Hex Nut (2): 1/4”-20

Lag Screw (2): 5/16” x 1-5/8”

Hex Bolt (2): 5/16”-18 x 3/4”

Lock Nut (2): 5/16”-18

Header Clevis Pin (1): 1/4” x 3-1/4”

Cotter Ring (1)

ek Screw (2): 1/4 x 3/4”

Straight Door Arm

Drywall Anchors (2)

Staples (10)

T

apered-Head Screws

(2)

30 Ft. 2-Conductor

Wire

Screw Caps (2)

Machine screws

(

2)

Warranty

Card

Staples (10)

Round Head Screws (2)

30 Ft. 2-Conductor

Wire

C

over

Programming

Connector

Cover

Visor

Clip

Cover

Programming

The following items ar

e included with your Garage Door Opener. All hardware components located in GDO carton.

The accessories are packaged with their respective hardware in separate packs for ease of identification and use.

Items shown not actual size.

Fig. 6

EX-2005

(One Light

Powerhead)

Fig. 7

Pushbutton

For EX-2005 (with Hardware Kit)

POWERHEADS

ACCESSORIES

9m (30Ft) 2-Conductor

Wire

4-Channel

Mini Transmitter

ransmitter

T

EX-2007

(Two Light

Powerhead)

Wall Control Panel

For EX-2007 (with Hardware Kit)

Mounting Plate

6

Garage Door Opener Manual

Hardware Kit

Fig. 8

Models (per application)

2.1m (7’) Door ML-807B ML-807C

2.4m (8’) Door ML-808B

3m (10’) Door ML-810B ML-810C

RAIL ASSEMBLY

(packaged in separate carton)

Belt

Chain

ML-808C

9m (30Ft) 2-Conductor

Wire

See Fig. 11

See Fig. 10

Header

Doo

r Width

V

ertical

Center Line

Horizon

tal Line for

Header Bracket

Height

Horizontal

Reinforcement

Bracket

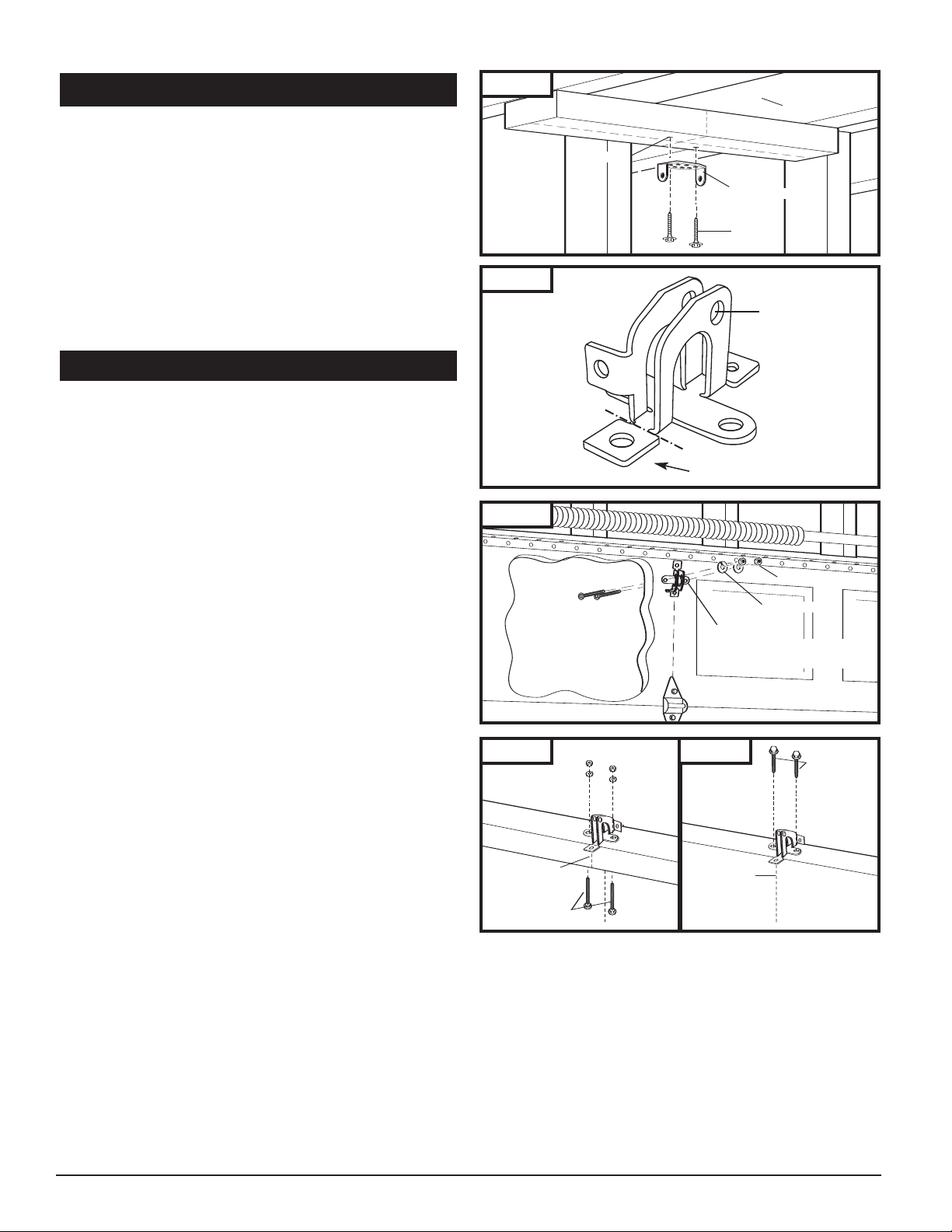

7. INST

Lag Screw for Header installation

if necessary (not provided)

Header Bracket

5/16 x 1-5/8”

Lag Screw

Pilot Hole

Header

ALLATION STEPS

Identify a sound structural support on header wall above

garage door for header bracket mounting. See Fig. 10. If

appropriate header does not exist, replace or install a new

support using a 50x100mm or 50x150mm (2x4 or 2x6) board.

Fasten it securely using lag screws (not provided) to

structural supports of garage.

7-1. MEASURE AND MARK DOOR AREA

Fig. 9

Before starting your installation, the door and the header

above the door must be measur

opriate brackets can be mounted at the correct locations

appr

avoiding installation and operating dif

ed and marked. This way, the

ficulties later.

MARK VERTICAL CENTER LINE:

■ Measure door width, then locate the center point (Fig.9).

■ Mark

a vertical line on the upper half of your door, on the

top edge of your door

, and on the header, through the

center point.

MEASURE DOOR’S HIGHEST TRAVEL POINT:

(Review Figs. on p. 5 for details)

■ Open door to its highest travel point and measure from

the garage floor to the top of door.

■ Write down this distance.

FOR SECTIONAL DOORS AND ONE-PIECE

DOORS WITH HORIZONTAL TRACK:

Add 30mm (1-1/4") to the door travel height (measured

above).

FOR ONE-PIECE DOORS

WITHOUT

TRACK:

Add 95mm (3-3/4") to the door travel height (measured

above).

MARK HORIZONTAL LINE FOR HEADER

BRACKET LOCATION:

■ Close door and measure the required distance (determined

above)

■ Mark a horizontal line, intersecting the ver

line, on header

from the garage floor to the header.

. This is the position at which the bottom

tical center

of the header bracket should be installed.

■ In case of minimal clearance above the door, the header

bracket may be mounted to the ceiling. In this case,

extend the vertical center line onto the ceiling, and mark

a horizontal line on the ceiling no further than 100mm

(4") from the header wall. The header bracket should be

mounted no farther than this distance from the header

wall.

7-2. INSTALL HEADER BRACKET

Fig. 10

If the header bracket is not rigidly fastened to a sound

structural support on the header wall or ceiling, the

safety reverse system may not work and could cause

serious injury or death. DO NOT move or adjust springs

or garage door hardware, as these parts are under

extreme tension and could cause injury or death.

7

7-2. INSTALL HEADER BRACKET (cont’d)

P

ilot Hole

C

eiling

Header Bracket

L

ag Screw

Insert 1/4-20 x 2”

Carriage Bolts

from outside of door

Door Bracket

Lock Washer

Wood Sectional

Doors

1/4-20 Nut

Garage Door

Center Line

Carriage Bolts

Garage Door

Center Line

Lag Screws

Fig.

11

■ Mark pilot holes location on header thr

lag screws will be inserted.

IMPORTANT: See Fig. 10 for

ough holes where

which header bracket holes to use.

■ Drill 3/16" pilot holes into header, and install bracket with

ews (5/16 x 1-5/8”) provided.

lag scr

■ Tighten lag screws firmly.

NOTE: Follow the same pr

uns vertically instead of horizontally and is the only

11) r

ocedure if header (shown in Fig.

option for mounting header bracket to header wall. In case

of minimal clearance above the garage door, the header

bracket may be mounted to the ceiling. Follow the same

steps above to ensure a sound surface for mounting.

7-3. INSTALL DOOR BRACKET TO DOOR

A. FOR SECTIONAL DOORS:

Wood Sectional Doors (Fig. 13)

■ Position door bracket (Fig. 12) along vertical center line of

door with pin hole facing top of the door and top edge of

the bracket 100mm (4”) to 125mm (5”) below top edge of

the door, or roughly at the same height as top rollers on

the door.

■ Mark locations of securement holes through door bracket.

■ Drill two 1/4" holes through door for securement of

door bracket.

riage bolts (1/4” x 2”) from the outside through

t car

■ Inser

door and bracket, then secur

om the inside.

fr

ighten nuts firmly.

■ T

Metal Sectional Doors

■ Attach door bracket with two teck scr

ecommendations.

door manufactur

er r

e with lock washers and nuts

ews (pr

ovided) per

Fig. 12

Fig. 13

f for one-piece

cut of

door only

Pin Hole

B. FOR ONE-PIECE DOORS:

Befor

mounting leg fr

om opposite side of pin hole.

ting the installation of the door bracket, cut off

e star

One-Piece Doors with Exposed Frames (Fig. 14)

■ Position center of door bracket on the center line on the

top edge of door.

■ Mark the position where carriage bolts will go through

bracket, and drill two 1/4" holes through top frame of

door.

■ Install carriage bolts from the bottom, through door

frame and bracket, and secure with lock washer and nut

from top.

■ Tighten nuts firmly.

One-Piece Doors without Exposed Frames (Fig. 14A)

■ For doors without exposed frames, use alternate method

of mounting door bracket.

■ Mark and drill two 3/16" pilot holes into top of frame,

then secure bracket with 5/16" x 1-5/8" lag screws

(not provided).

8

Fig. 14 Fig. 14A

One-Piece Door

with Exposed Frame:

Install with Carriage Bolts

One-Piece Door

without Exposed Frame:

Install with Lag Screws (not provided)

Correctly seated pin.

Incorrectly seated pin.

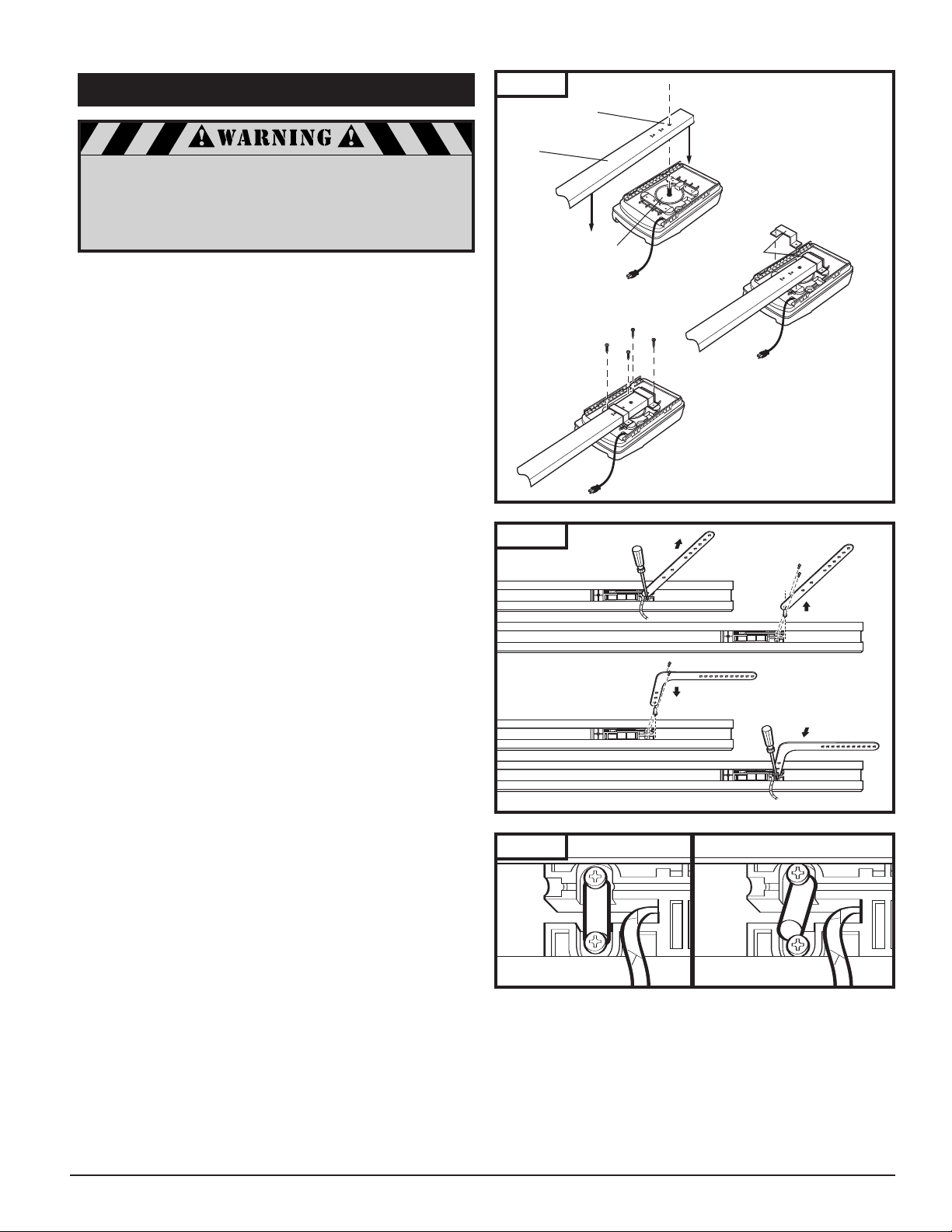

7-4. ATTACH RAIL TO OPENER HEAD

Rail Sprocket

Opening

Rail

Motor Head

Shaft

“C” Brackets

A. Place Rail

onto Chassis

B. Position “C”

Brackets

to Chassis

C. Secure “C”

Brackets

to Chassis

6x14

Screw

A. Loosen Scr

ews

C. Feed Pin through Curved

Door Arm Hole

B. Remove Pin

D. Reinsert Pin and Arm Firmly

and Squarely, Tighten Screws

When fastening the rail to the opener,

use only the screws provided. Use of any

other screws may result in opener falling

from ceiling and causing damage

to persons or pr

NOTE: Rail comes fully preassembled with straight door

arm already attached.

■ Unpack one-piece preassembled rail.

■ Leave straight door arm taped inside rail for safe and

convenient installation—it will be untaped and used later.

■ Position door opener head with control panel facing front

of garage. Rest opener head on cardboard or protective

surface on floor so opener does not get scratched. Chassis

side of opener (with motor shaft sticking out) facing up.

■ Position rail onto opener chassis by lining up rail sprocket

opening with motor head shaft (Fig. 15A). Make sure shaft

engages teeth inside rail sprocket. Press rail down firmly

onto shaft and opener chassis. DO NOT HAMMER.

■ Position 2 "C" brackets over rail and onto chassis. Flanges

on "C" brackets

MUST fit into cutout area on chassis

(Fig. 15B).

■ Insert screws 6 x 14 through bracket holes and into chassis

holes, and tighten screws firmly to hold rail to head

(Fig. 15C).

■ For sectional doors, proceed to step 7-5.

operty in the garage.

Fig. 15

Fig. 16

ADDITIONAL STEP FOR ONE-PIECE

DOORS ONLY:

IMPORTANT NOTE: For installation on One-Piece Doors

only, the straight door arm that is factory installed

onto the rail must be replaced by the curved door

arm supplied as part of hardware in powerhead box.

This must be done after attaching rail to powerhead,

before moving to step 7-5.

■ Turn rail and opener head over so that open channel in

rail faces up.

■ Untape straight door arm that is secured inside rail.

■ Remove and save the two phillips head screws that are

securing the door arm pin and straight door arm (Fig. 16).

■ Lift arm and pin straight out of slot in trolley, and remove

pin from straight door arm.

■ Insert pin into short side of curved door arm as shown.

■ Orient arm so that long side extends away from trolley.

■ Carefully insert pin and door arm into slot in trolley.

Push pin into slot with door arm so pin is fully seated into

trolley slot.

properly into recessed area in trolley. See Fig. 16A.

■ Secure pin and curved arm with the two phillips screws

which were removed from trolley—DO NOT use any

other screws. Tighten screws firmly.

■ Turn rail and powerhead over so that open channel

in rail faces down. Now proceed to Step 7-5.

IMPORTANT: Pin must be straight and seated

Fig. 16A

9

Stepladder

2x4 Laid Flat

Door

Stepladder

Door

Header Bracket

Rail End-Stop

C

otter Ring

1/4 x 3-1/4”

Clevis Pin

Rail

Fig. 17

Fig. 17A

Opener Box

7-5. ATTACH RAIL TO HEADER BRACKET

■ Support opener head slightly off the floor.

■ Lift the opposite end of the rail up to the header bracket.

■ Position rail end-stop within the openings in the header

bracket. Insert header clevis pin (1/4” dia.) through rail

end-stop and header bracket, then attach cotter ring to

end of pin. See Fig. 17A.

7-6. POSITION OPENER FOR MOUNTING

■ Once rail is attached to header bracket, support opener

powerhead on ladder, or use the assistance of another

person to support opener powerhead high enough so

door can open without hitting the rail.

A. SECTIONAL DOORS AND ONE-PIECE

DOORS WITH TRACK:

■ Open garage door to fully opened position, and place a

50mm board between the door and the rail. See Fig. 18.

■ The 2x4 pr

rect mounting height of the opener.

cor

ONE-PIECE DOORS WITHOUT TRACK:

B.

■ Disconnect tr

knob. Move tr

■ Open door all the way so that it is parallel to the floor

or slightly tilted towar

SHOULD NOT BE TILTED TOWARD THE BACK OF GARAGE.

■ Position opener so that top of opener head is level with

top of opened door.

■ To check for correct mounting height, temporarily position

curved door arm as if connecting to door bracket. See

Fig. 19. The long side of the arm should be parallel to the

floor when door is fully opened. Raise or lower

powerhead so that arm will be parallel to floor.

■ Temporarily support head at this height, and prepare to

mount the opener to ceiling.

ovides an easy method of ensuring the

olley by pulling down on emergency release

olley toward opener head.

d the front of the garage. DOOR

,

Fig. 18

50mm board

Fig. 19

10

7-7. MOUNT OPENER TO CEILING

Joists (may be

hidden behind

drywall)

Perforated

Angle

Rail

Support

Bracket

Angle

Fig. 20

If not pr

operly secured, the opener

could fall and injure someone.

e opener to structural supports or

Secur

framing. Do not mount to drywall, plaster,

or other such material.

■ Position opener head so that rail is lined up with center

line of open door.

■ Line up hanger brackets (not provided) with ceiling joists

or framing to locate wher

e brackets are to be fastened.

See Fig. 20.

■ Mark location for 5/16" lag screws (not provided), and

drill two 3/16" pilot holes.

■ Fasten hanger brackets to joists using lag screws.

■ If garage framing supports are not visible, attach a length

of perforated angle or a 50mm board to the ceiling, securing it to the hidden joists with lag screws long enough to

fasten firmly to garage framing (extra hardware items not

provided). Then, attach one end of hanger brackets to the

perforated angle or 50mm board mounted to ceiling.

Attach other end of hanger brackets to opener’s chassis

angle iron. See Fig. 21 for alternate mounting methods.

■ Once opener is securely fastened in position, remove

wood blocks and temporary supports and lower door.

Check door for proper operation and clearance by

manually moving door to full open and closed position.

If door hits rail at any point, raise opener head slightly

higher and re-mount in position.

Fig. 21

Fig. 22

NOTE: To provide additional support for rails 13’ length and

longer, use optional support bracket. (Accessories p.32)

■ Measure the rail’s overall span. Bracket is located on 1/3rd

of the overall rail span from the door header bracket end.

See Fig. 22

■ Place support bracket over rail (close side) on a diagonal.

Make sure support securement clamps clear rail sides.

■ Secure bracket onto rail by twisting support bracket as

indicated in Fig. 22A.

■ Attach mounting strap (not provided) to support bracket

and secure by fastening it to the ceiling.

7-8. CONNECT ARM TO DOOR AND TROLLEY

■ Make sure door is fully closed.

■ Remove tape from rail holding straight door arm

(sectional door only) and allow door arm to hang freely.

■ Pull the manual release cord on the trolley to disconnect

trolley from chain or belt connector. Slide trolley to

position it about 100mm (4") away from the door.

Fig. 22A

Fig. 23

11

Loading...

Loading...