MAQ SONAR 60KHz, 90KHz, 22KHz Installation Manual

MAQ SONAR COMPANY

div of Helo Enterprises Inc.

Technical and

Installation Manual

© 2014 MAQ Sonar Company

Division of Helo Enterprises

9 Church Street, Finch, Ontario

Canada K0C 1K0

Phone 613-984-9000

Fax 613-984-0909

www.maqsonar.com

info@maqsonar.com

Revised: June 2014

No part of this document may be reproduced without express written permission

from MAQ Sonar.

MAQ Sonar is not legally responsible for any errors or omissions in this document

or for any damage or injury as a result of the operation of the system.

The information contained herein is subject to change without notice.

Notes:

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

i

Notes:

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

ii

PREFACE

Note:

MAQ Sonar makes every effort to ensure the information contained within this document

is correct. However, our equipment is continuously updated, so we cannot assume

liability for errors, which may occur.

Warning:

MAQ Sonar disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

References:

This Technical Manual is intended as a reference only. The information contained in this

document is to be used in conjunction with the shipyards own vessel drawings,

documentation and engineers. Standards for installation are to be certified by the

installing shipyard, engineers and dealers. Further information about MAQ Sonar can be

found in the MAQ Sonar Operators Manual.

Manuals:

This manual must be kept aboard the vessel at all times. The information contained

herein is subject to change without notice.

Introduction:

The main purpose of this manual is to provide the information and basic drawings

required for installation of the MAQ Sonar system. In addition this manual contains

technical information which may be required in the future.

The MAQ Sonar electronics is capable of driving three different frequency transducers.

This is a generalized manual for all three types of transducers.

Responsibilities:

The installer is responsible for the equipment during the installation. The warranty is only

valid when the installation is made in accordance with this manual.

iii

Intentionally left blank for future use

iv

Table of contents

Chapter 1 Installation requirements Pages 1-2

Sea-Chest Installation References Pages 3-5

Hoist and Transducer Illustrations Pages 6-10

Chapter 2 Mechanical drawings Pages 11-30

Installation Wiring Diagrams Pages 31-36

Chapter 3 Inclinometer Setup Procedure Pages 37-38

Chapter 5 System Power UP Pages 39-40

Screen Layout Pages 41-46

Chapter 5 System Setup Pages 47-54

Navigation Setup NMEA Sentences Pages 55-56

Chapter 6 Basic Operation Pages 57-58

Chapter 7 Menu Panels

RAW Rawdata Panel Pages 57-58

TIM Time Panel Pages 59-60

AFL Automatic Fault Locator Panel Pages 61-62

NAV Navigation Panel Pages 63-68

SYS Systems Panel Pages 69-74

Chapter 8 Electronic Descriptions Pages 69-71

Troubleshooting Electronics Pages 72-74

Chapter 9 Standard Maintenance Checks Pages 81-82

EU Declaration of Conformity Page 83

v

Intentionally left blank for future use

vi

MAQ SONAR COMPANY

DIVISION OF HELO ENTERPRISES INC.

Chapter 1

Requirements

Basic Installation Requirements

Sea Chest Installation Requirements

Hoist and Transducer Illustrations

P.O BOX 199, 9 CHURCH STREET, FINCH, ONTARIO, CANADA K0C 1K0

Phone: (613) 984-9000 Fax: (613) 984-0909 E-Mail: info@maqsonar.com

Installation Requirements

1) Approvals: Sea-Chest installations must be approved on a case-by-case basis with regard

to the vessel’s national registry and corresponding maritime authority. The ship owner

and shipyard performing the installation are responsible for obtaining installation

approval.

2) Power supply: For the Processor Units AC Power we recommend the use of an

Uninterruptible Power Supply (UPS). The UPS should have the ability to maintain power

for 10 minutes; This allows shut off of the equipment in the case of a AC power failure.

This also prevents shut off due to power surges/loses due to other vessel equipment.

Many Vessels are equipped with AC inverts. These must be Pure Sine Inverters with

sufficient power to support the system. Hoist DC power must be supplied from Vessel

Power sources. 22KHz will also require AC power for the Motor.

3) Dry Dock: Ensure proper clearance under Sea-Chest for sonar installation. Avoid placing

supporting blocks in the area of the Sea-Chest. In the Note section of this manual, log the

position of the Sea-Chest for future reference.

4) Wiring: All cables must be supported or protected along its entire length. Conduit or

cable trays should be used. Cables must be installed so as not to run in the areas of highpower supplies, antenna cables or other sources of interference.

5) Vibration: Vibration on any of the equipments must be monitored. Excessive vibration

will require dampeners to be installed. Improper installation on Transducer Guides can

result in Flow related vibration.

6) Temperature and Humidity: All equipment, unless otherwise specified, must be

protected from extremes in temperature and humidity.

7) Warranty: The warranty is only valid when the installation is made in accordance with this

manual. Note that the Warranty Registration Card must be returned by the vessel to MAQ

SONAR within 30 days of the installation to be validated (see the example below).

1

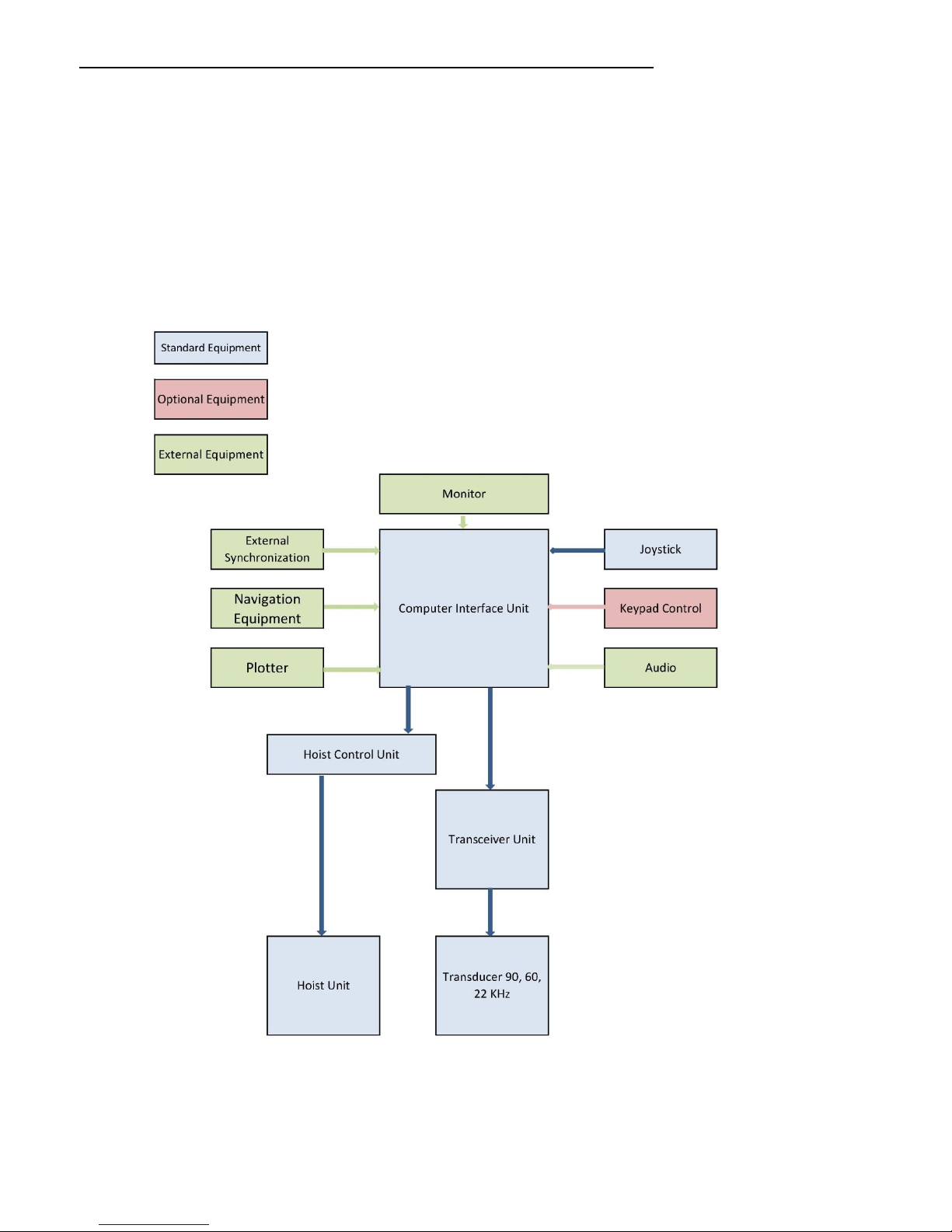

The MAQ Sonar system consists of the following components:

1) Computer interface unit (Processor) with Joystick unit. (An optional Keypad Control is

Available)

2) Hoist with Hoist Control unit (60 KHz and 90 KHz unit the same hoist system)

3) Transceiver Unit

4) Optional RDT Transmitter Unit (not Shown)

5) Transducer (90 KHz, 60 KHz or 22 KHz)

6) Monitor (not supplied by MAQ Sonar)

2

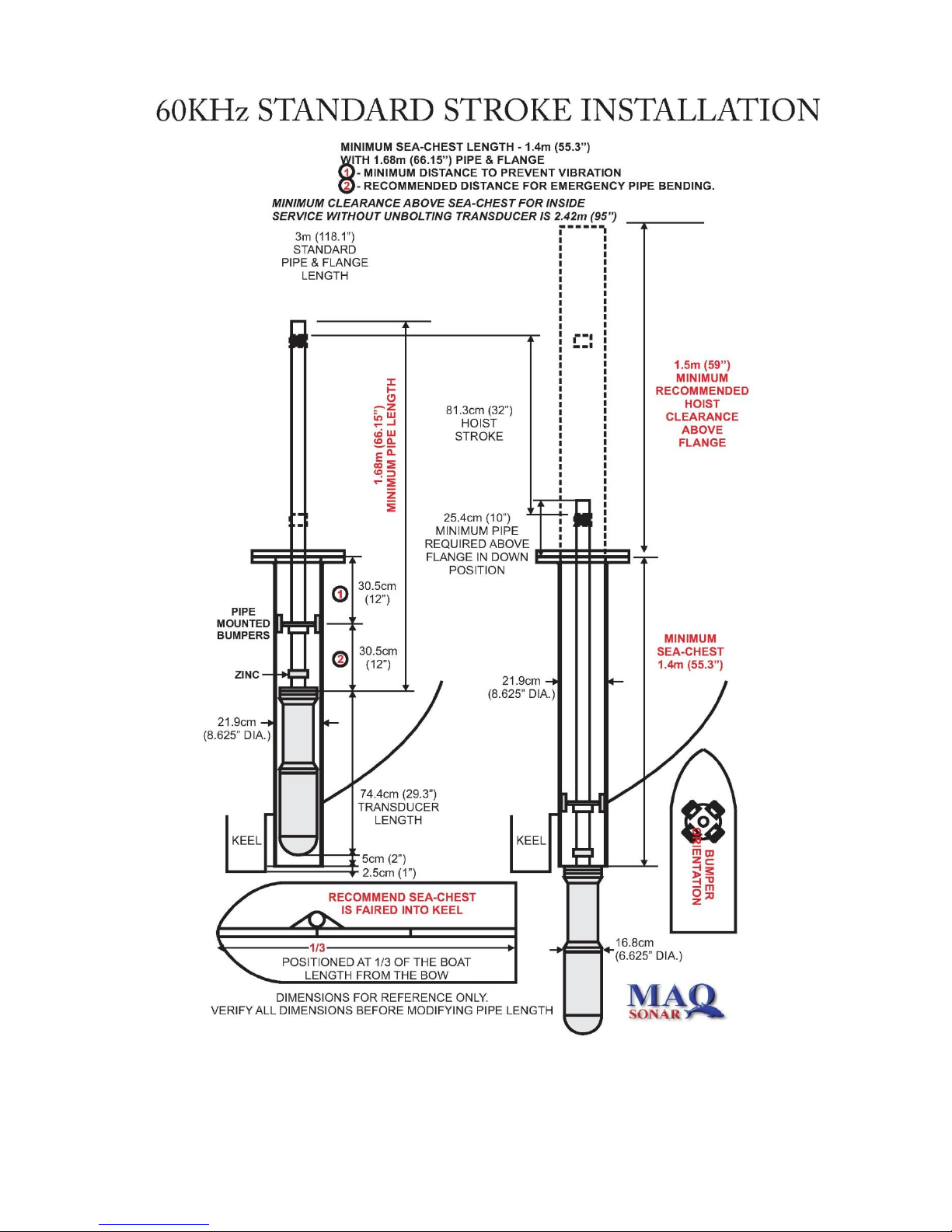

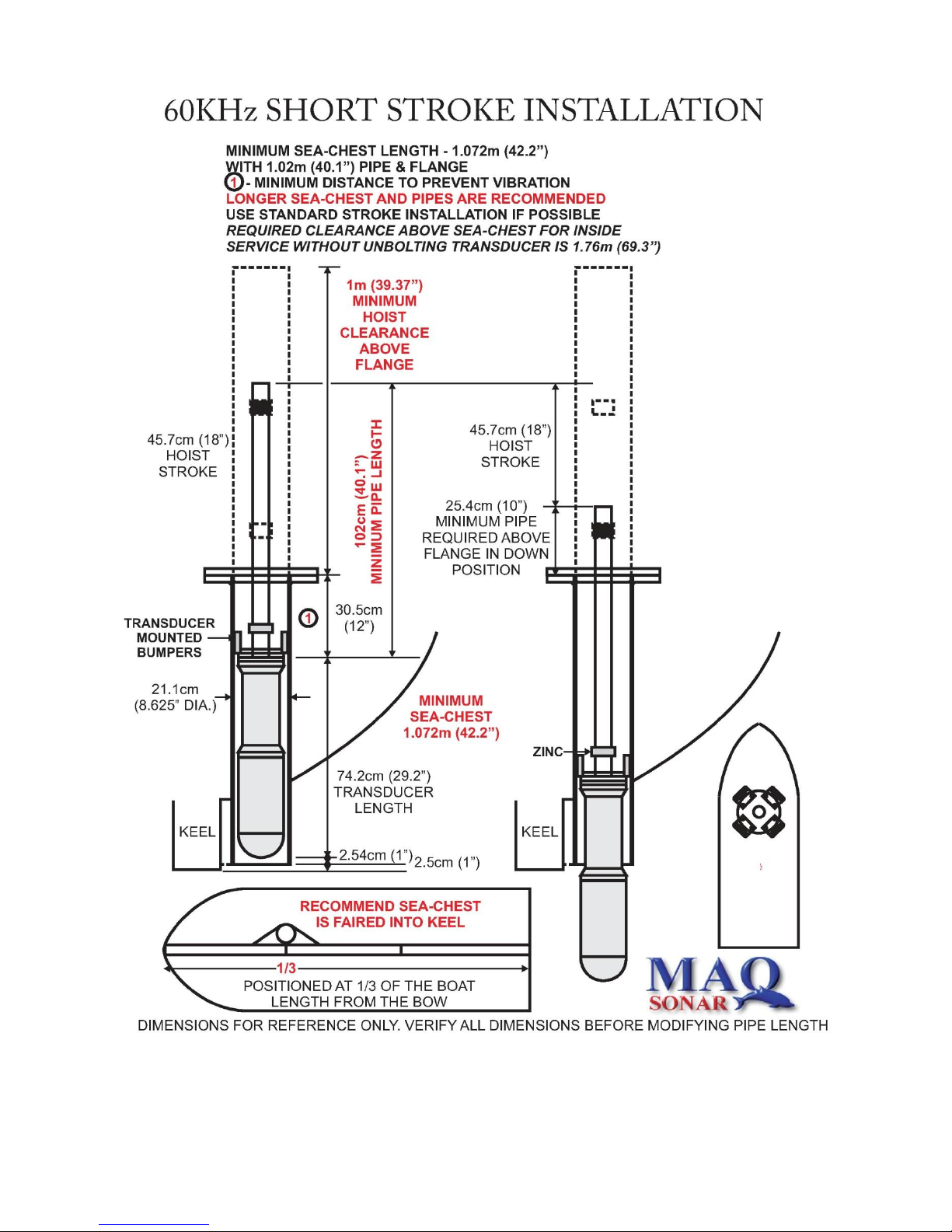

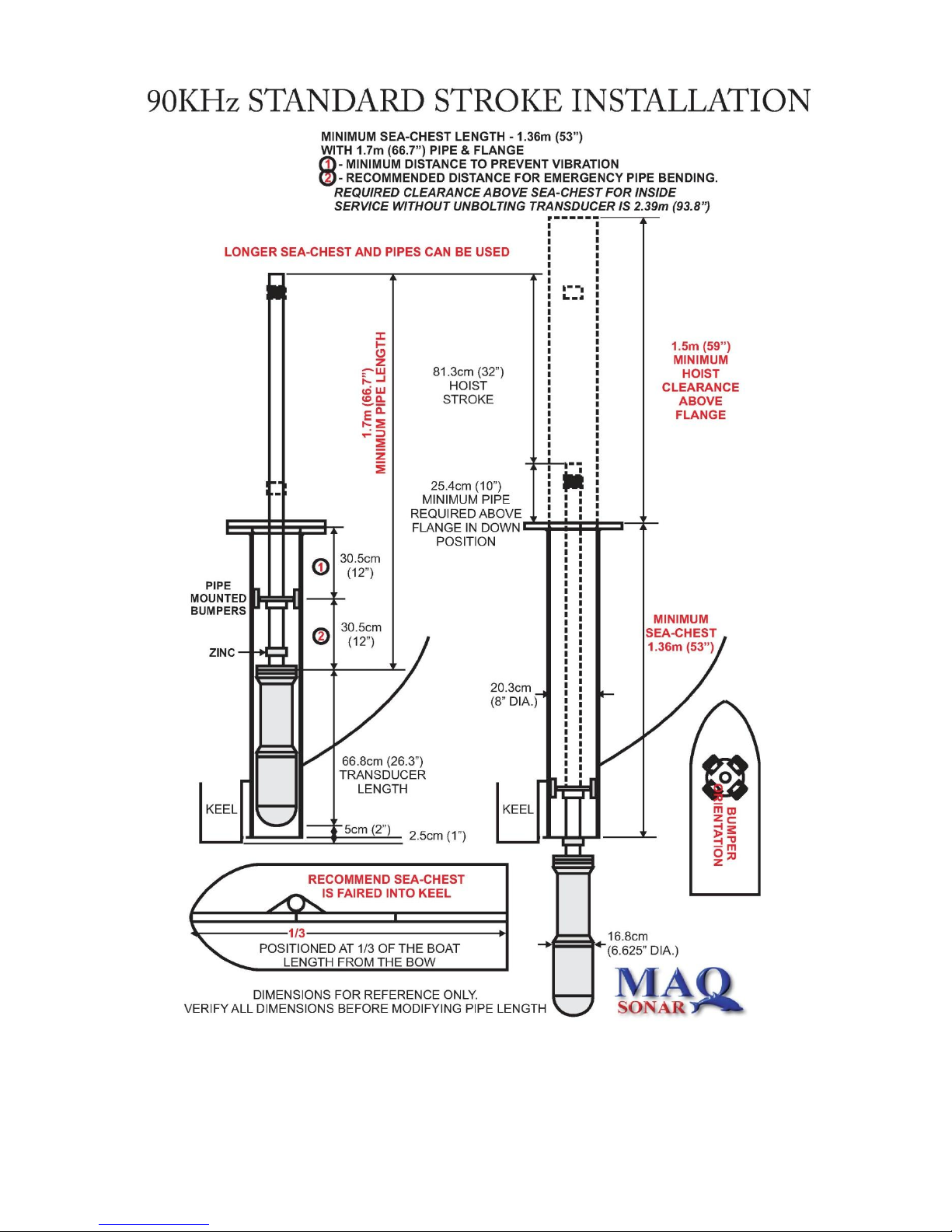

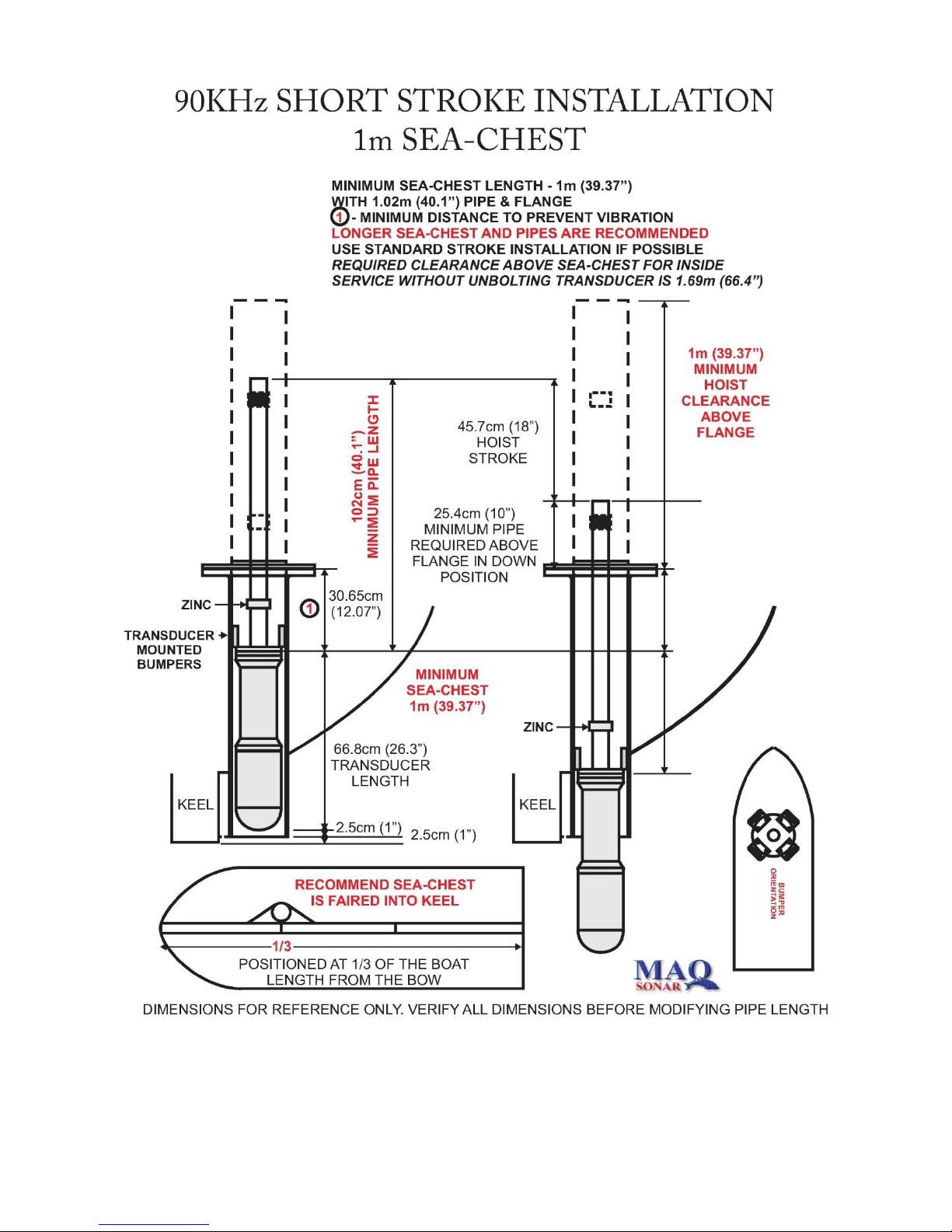

MAQ Sonar Sea-Chest Installation References

Approvals:

Sea-Chest installations must be approved on a case-by-case basis with regard to the vessel’s national

registry and corresponding maritime authority. The ship owner and shipyard performing the installation

are responsible for obtaining installation approval.

Dry Dock:

Ensure proper clearance under Sea-Chest for Sonar installation. Avoid placing supporting blocks in the

area of the Sea-Chest. Ensure you record the position of the Sea-Chest for future reference. Sonar have

been installed in existing Sea-Chest without placing the vessel in Dry Dock but this is at the discretion of

the vessel owners and Dealers.

Sea-Chest:

MAQ Sonar is one of the simplest and fastest Omni Sonar to install. This Sonar was designed to fit on

vessels with existing Sea-Chests and can be installed in as little as one day.

The Sea-Chest is probably the most important consideration when installing Sonar. For best performance

the transducer must extend properly out of the Sea-Chest in order that the active face is fully exposed

(Short Stroke). When it is extended farther below the keel it will not be exposed to air bubbles which

may be driven under the vessel which will reduce Sonar performance (Long Stroke). Many vessels do not

have an issue with air bubbles from the Bow of the vessel and short stroke installations are more than

adequate.

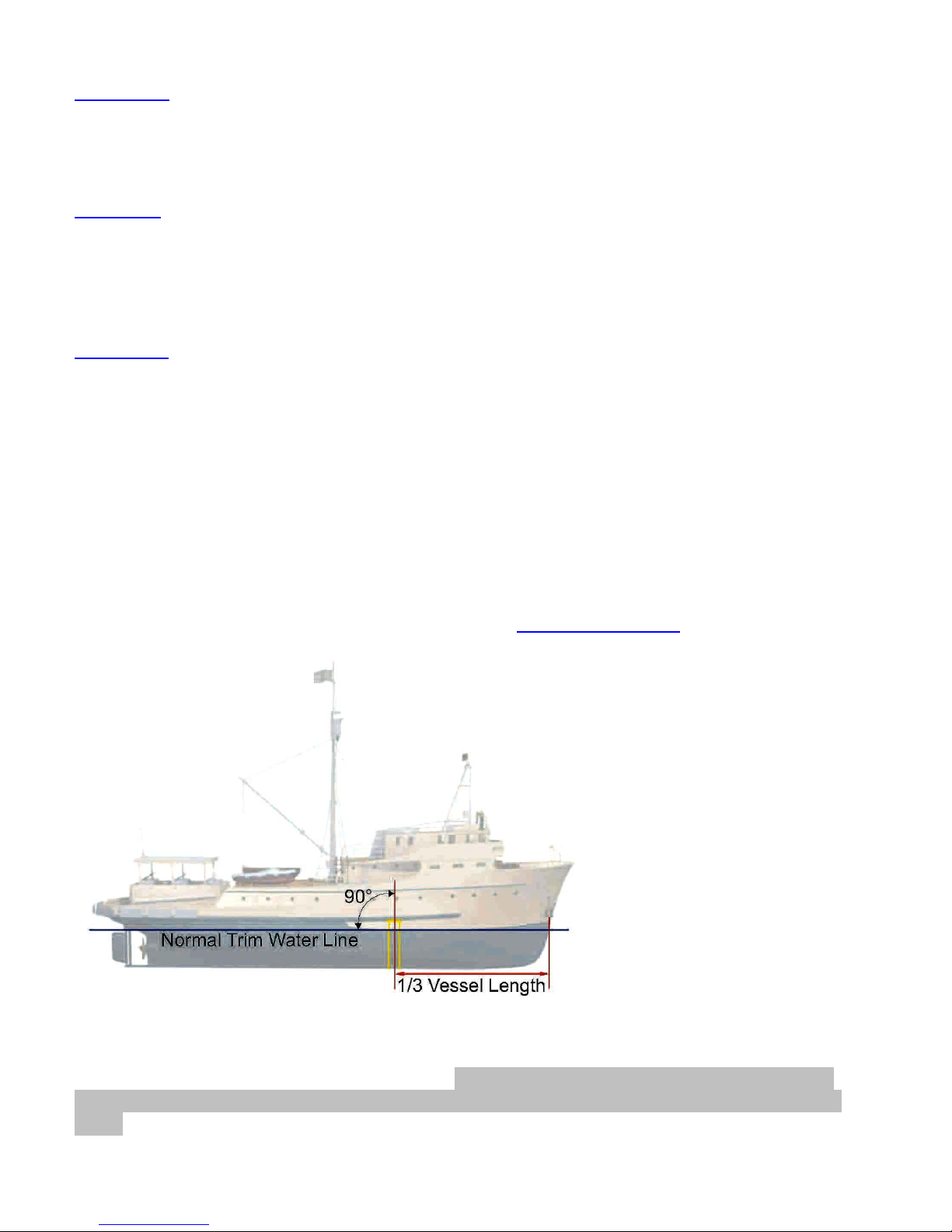

The recommended location for the Sea-Chest is 1/3 of the vessel length from the Bow and as close to the

keel as possible. For assistance Please contact the Factory tech@maqsonar.com .

There are several other

considerations for locating a SeaChest. When the vessel is already

equipped with Sonar these Sonar

may extend in front of or next to

the MAQ. If the equipment is in the

line of sight of the MAQ they will

create a shadow or block the

detection of the Sonar in this

direction.

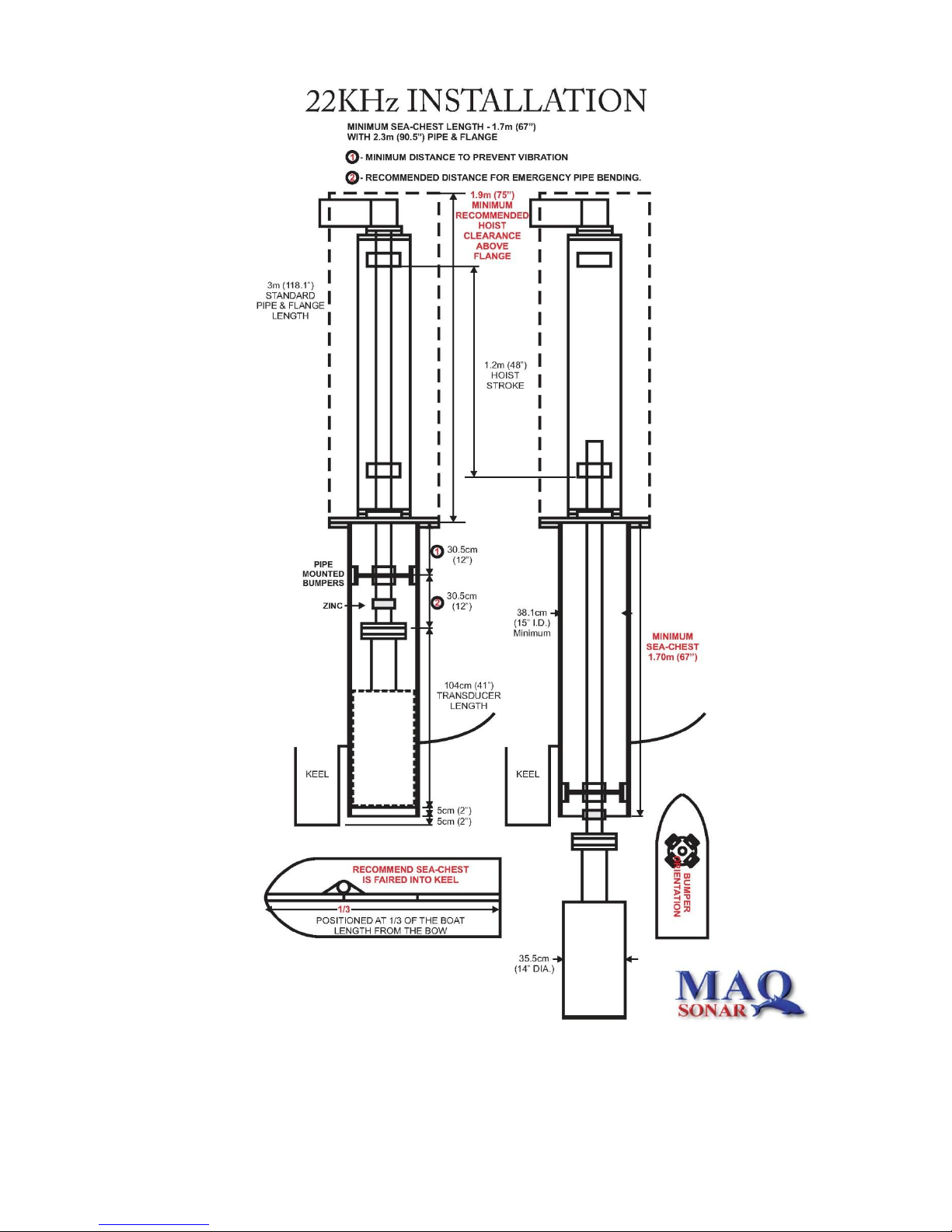

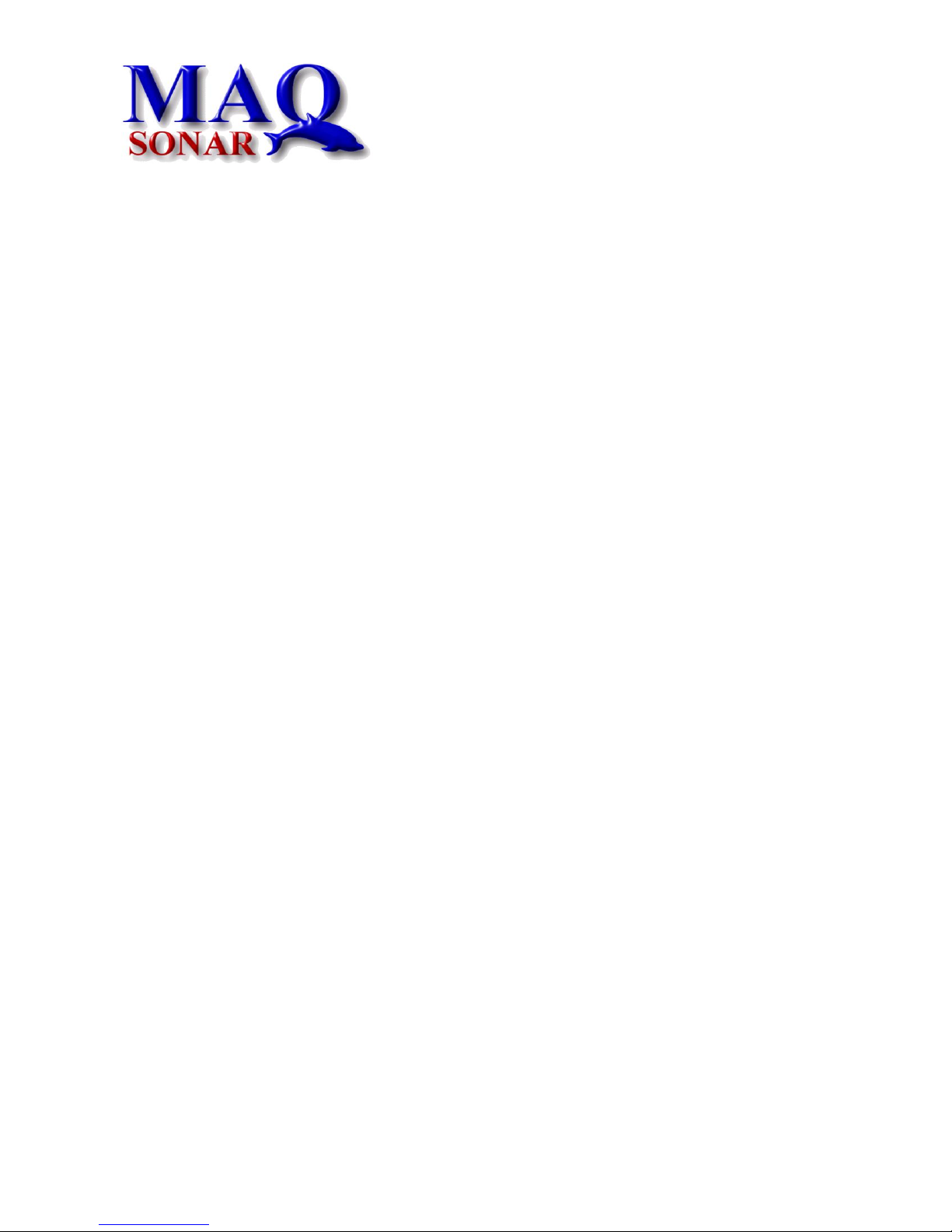

Although MAQ Sonar will fit in any 8” (90KHz and 60KHz) or 18” (22KHz) Sea-Chest, Sea-Chest extensions

may have to be added to accommodate the MAQ. It is critical that the I.D. of a Sea-Chest extension

matches the original Sea-Chest I.D. and that the extension is aligned properly with the original SeaChest.

Before proceeding with the installation, please reference the attached Installation drawings and

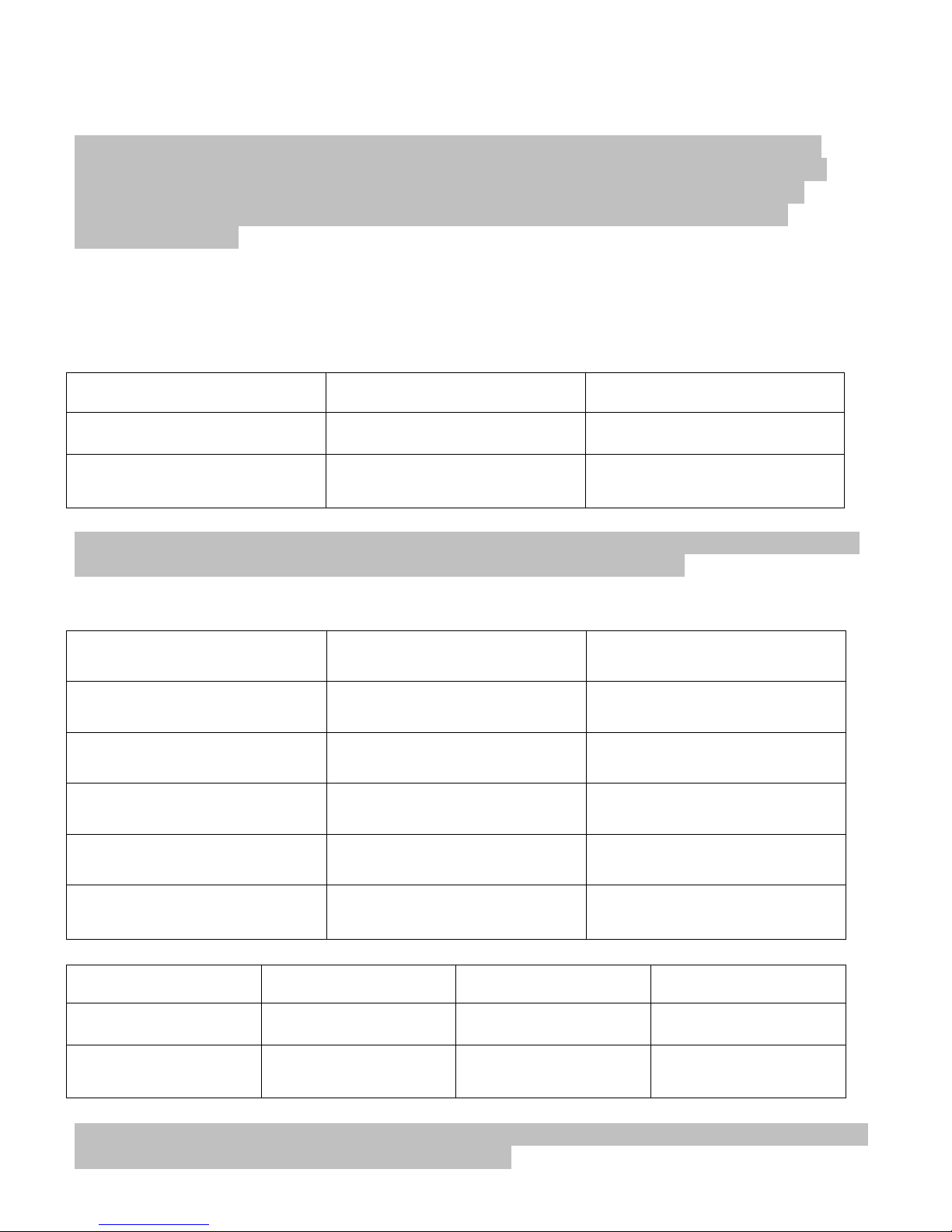

MODEL

60/90KHz

22KHz

Sea Chest Size

8”

18” pipe (Flange 16”)

Inside Diameter

Sea Chest Pipe

7.625” (194mm) to

7.981” (203mm)

16.8” (427mm) to

18” (406mm)

FLANGE

60/90KHz

22KHz

Outside Diameter

13.7” (348mm)

23.6” (600mm)

Bolt Circle

Diameter

11.7” (297mm)

21.25” (540mm)

Flange Hole

Diameter

0.875” (22mm)

1.125” (28mm)

Number of Holes

8

16

Mounting Bolts

60/90KHz3/4”-10 x 3” SS

M18-2.5 x 70mm SS

1”-8x 4” SS

M24-3 x 120mm SS

HOIST

Short Stroke

60/90kHz

22kHz

Stroke

18” (457mm)

32” (813mm)

47.25” (1200mm)

Hoist Height

Above Flange

40” (1016mm)

52” (1320mm)

75” (1900mm)

diagrams. These drawing show typical lengths and dimensions for short stroke and standard stroke hoist

installations of the 90KHz, 60KHz and 22KHz Sonar.

Before installing the Sea-Chest or Sonar it is IMPORTANT to measure the angle of a vessel during

typical search and catch situations as well as pitch and Roll measurements. Sea-Chests, that were

angled as much as 10° off the typical vessel angles during standard Sonar operation have been

observed in the past. This will make operation of OMNI Sonar very difficult and also reduces

performance greatly.

These issues should all be considered on installations in new or existing Sea-Chests.

Sea Chest and Hoist Size Listings

CONSULT FACTORY FOR MINIMUM SEA CHEST LENGTHS AS SHORT SEA CHEST MAY CAUSE EXCESSIVE

VIBRATION. CONSULT FACTORY WITH SEA CHEST DIMENSIONS FOR APPROVAL

INSTALLATION OF 22 KHz TRANSDUCERS IN 16” SEA CHESTS IS NOT RECOMMENDED. PLEASE CONSULT

FACTORY WITH SEA CHEST DIMENSIONS FOR APPROVAL

Grounding and Zinc Anodes:

MAQ Sonar’s Transducer Pipe, Transceiver and Processor Units must be

electrically connected to the ships main ground.

Zinc Anodes must be installed on Transducer pipes and inspected and

replaced yearly.

Poor grounding will cause excessive zinc erosion.

MAQ SONAR COMPANY

DIVISION OF HELO ENTERPRISES INC.

Chapter 2

Drawings and Diagrams

Mechanical Drawings

Installation Wiring Diagrams

P.O BOX 199, 9 CHURCH STREET, FINCH, ONTARIO, CANADA K0C 1K0

Phone: (613) 984-9000 Fax: (613) 984-0909 E-Mail: info@maqsonar.com

60/90KHz Sea-Chest

22KHz Sea-Chest

11

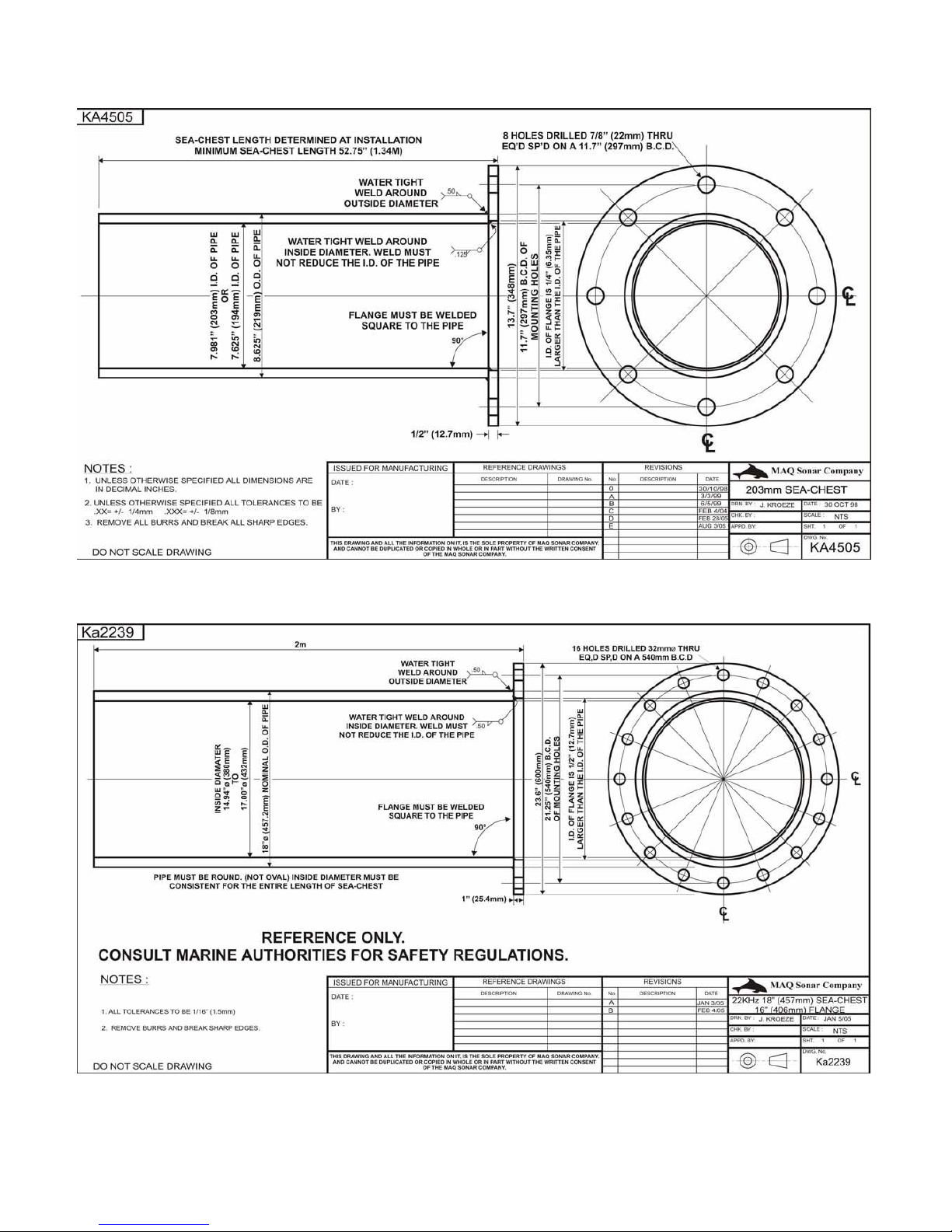

GM4501 - 60/90kHz Transducer Pipe with Flange

KA22005 - 22kHz Transducer Pipe with Flange

12

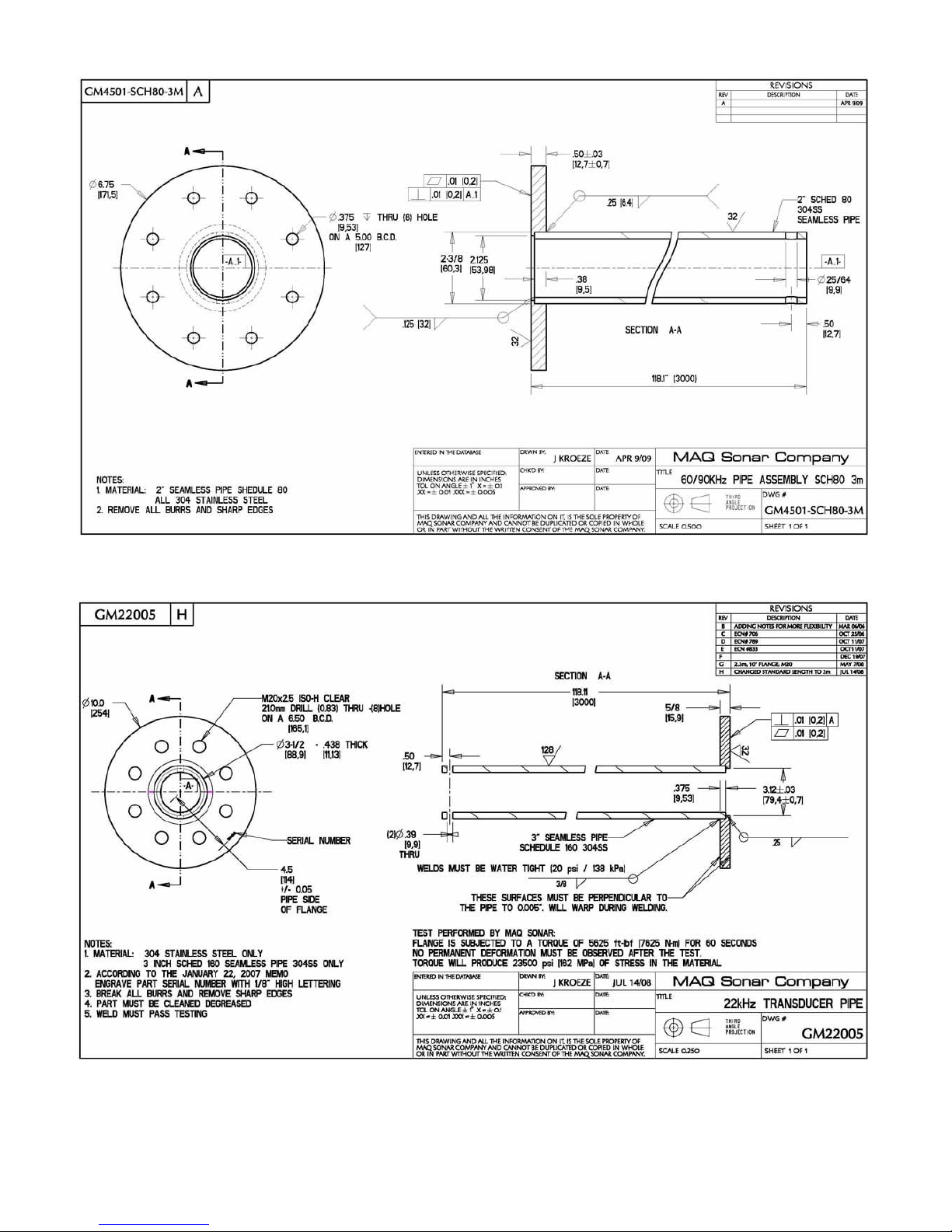

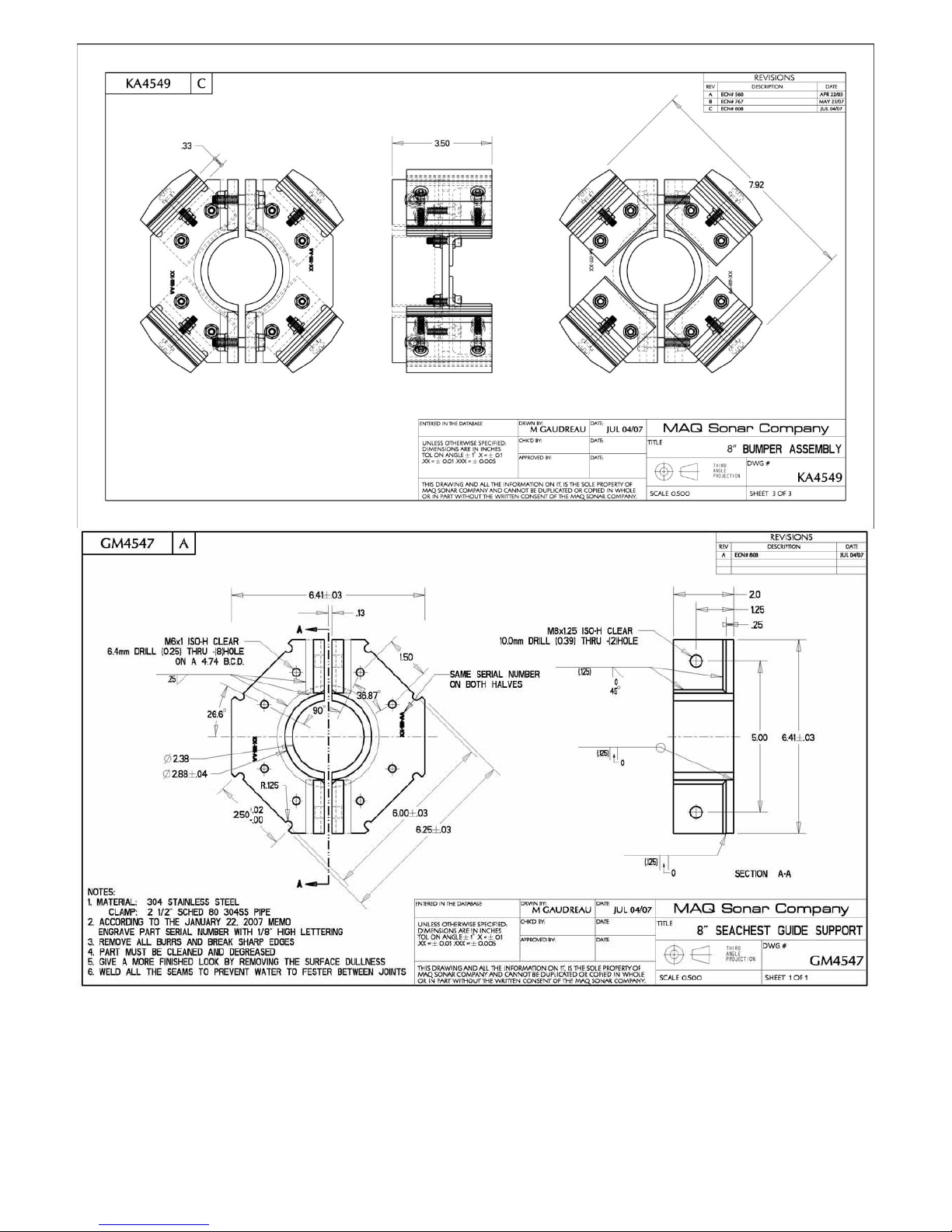

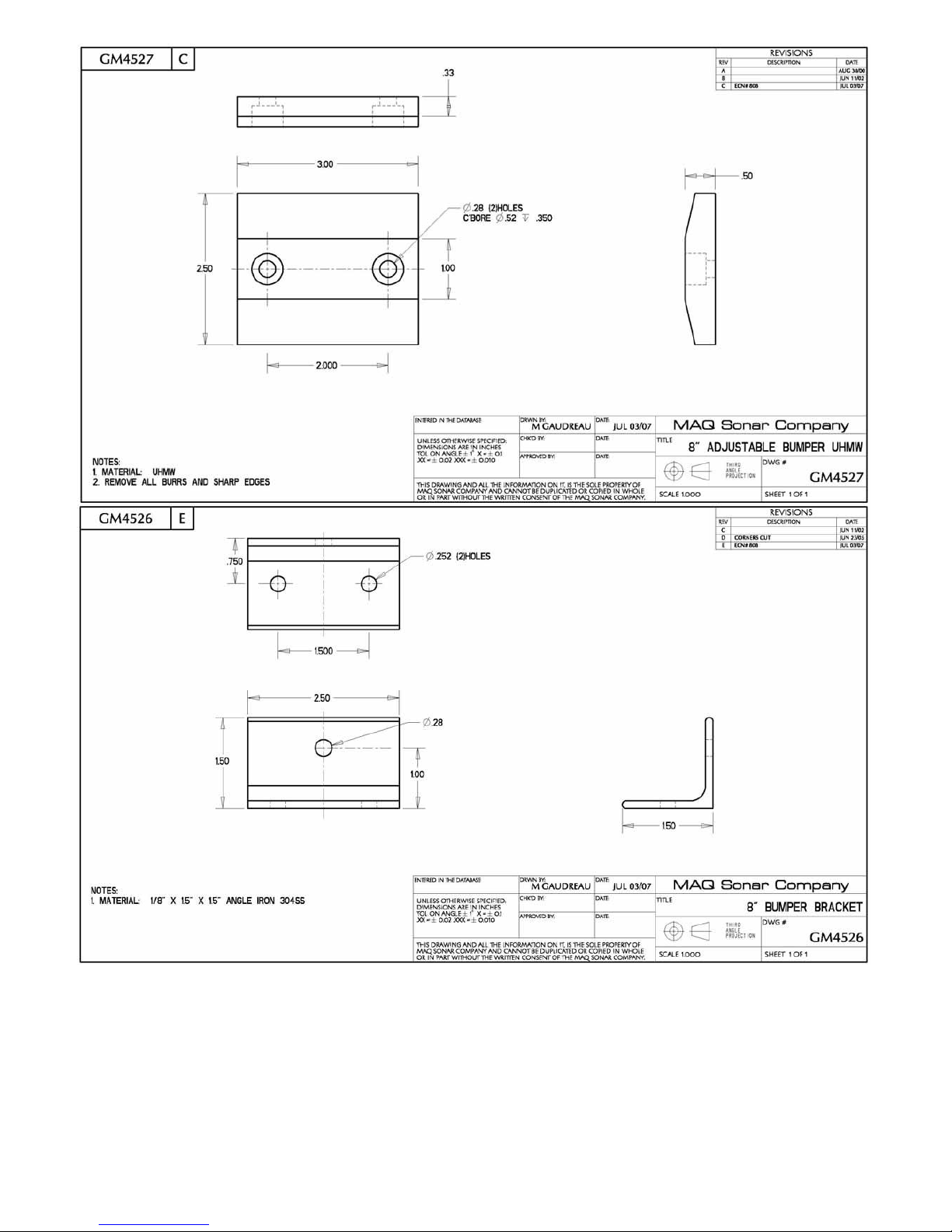

60/90KHz Sea-Chest Guides

13

14

15

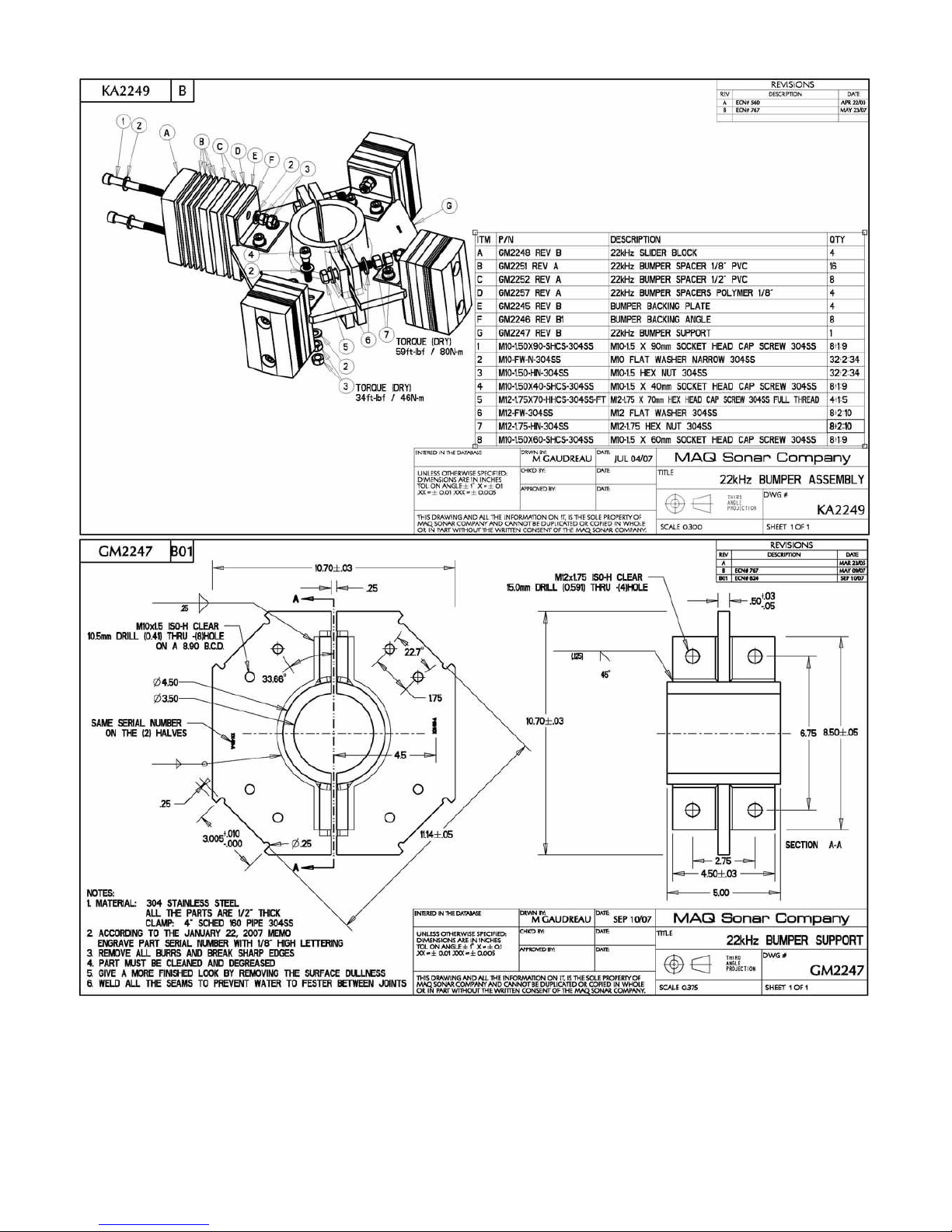

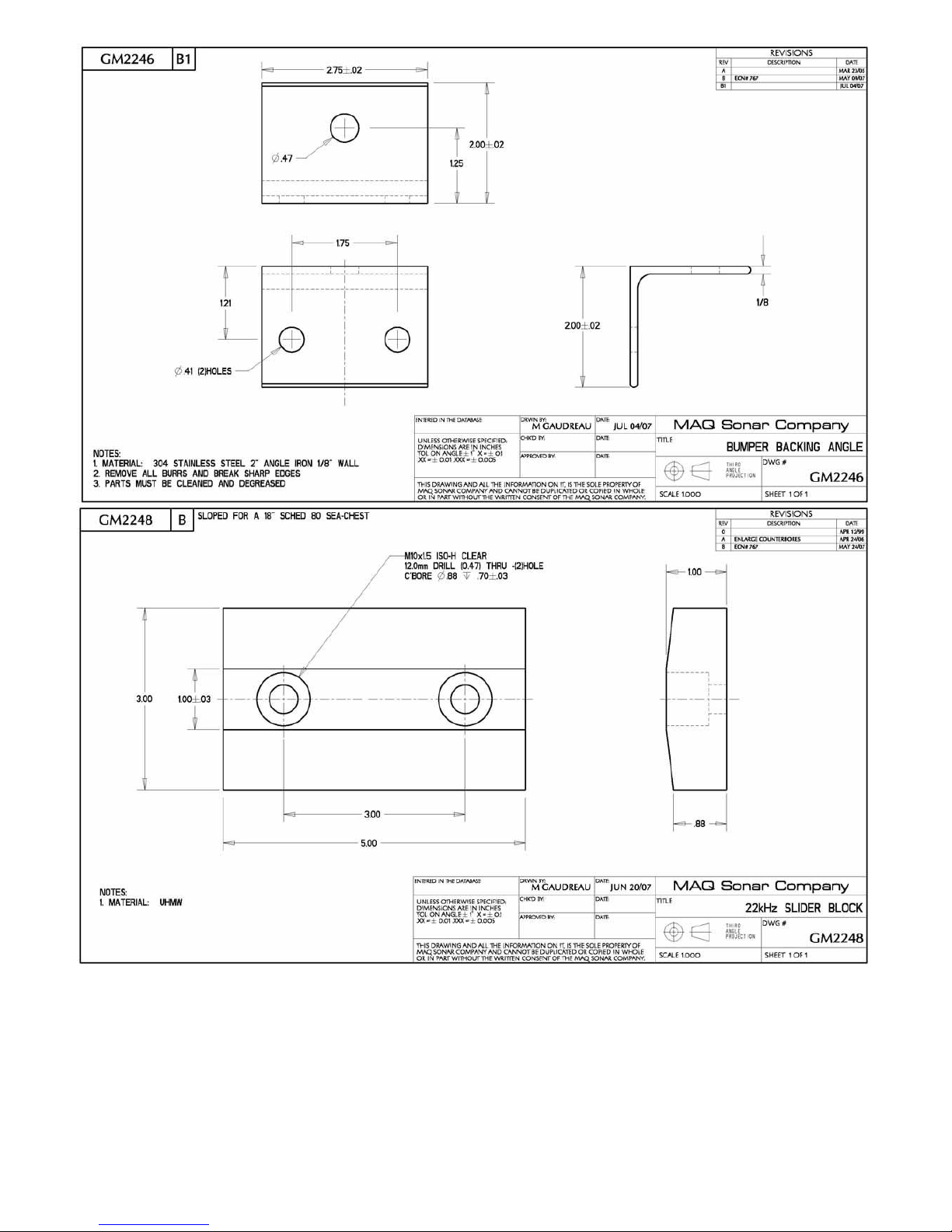

22KHz Sea-Chest Guides

16

17

18

Loading...

Loading...