Page 1

Introduction

OPEN HMI

OMI5000 Series

(Windows Embedded CE 6.0 Pro Edition)

Installation Guide

Thank you for purchasing a Maple Systems OMI5000 Series Open HMI

This booklet describes the steps necessary for installing the OMI5000

Series touchscreens.

For information on configuring the OMI, please refer to the OMI5000

Series Operations Manual (Windows CE Embedded 6.0 Professional

Edition) [Maple P/N 1010-1016] available for download at

www.maplesystems.com. For additional information, please refer to the

Support Center on the website. The Support Center provides links to

manuals, FAQs, technical notes, training videos, sample projects,

controller information sheets, and controller cables.

Static Awareness

Do NOT remove the rear cover of your OMI5000 Series product – doing

so will void your warranty. When the rear cover is removed the circuitry

inside is exposed to possible damage by electrostatic discharge during

handling. Minimize the possibility of electrostatic discharge by:

Discharging personal static by grounding yourself prior to

handling the OMI.

Handling the OMI at a static-free grounded workstation.

Connecting the frame ground ( ) connector of the OMI to a

clean earth ground.

Placing the OMI in an antistatic bag during transport.

Page 2

Unpacking the Unit

Packing List

Part Number

OMI5000 Series Touchscreen

Depends on model

Power Connector

2202-2021

Mounting Clamps

OMI5070B-CE

OMI5121A-CE

OMI5150A-CE

2202-3001 (Ver 1, Set of 6)

2202-3001 (Ver 1, 2 Sets of 6)

2252-1502X (Ver 2, Set of 10)

Spare Fuse, 1.0 A/250V

2202-0009

Carefully unpack the OMI. Please read any instructions or cautions that

appear on the shipping container. Check all material in the container

against the packing list. Maple Systems, Inc. will not accept

responsibility for shortages against the packing list unless notified within

30 days. The equipment and accessories were inspected and tested by

Maple Systems before shipment; all of the equipment should be in good

working order. Examine the equipment carefully; if any shipping damage

is evident, notify the carrier immediately. You are responsible for claim

negotiations with the carrier. Save the shipping container and packing

material in case the equipment needs to be stored, returned to Maple

Systems, or transported for any reason.

Warranty

Maple Systems warrants each product to be free from electrical and

mechanical defects in materials and workmanship for a period of one

year from the date of shipment for the LCD display and backlight, and

for a period of two years from the date of shipment for all other parts and

labor. This warranty does not apply to defects in the Products caused by

abuse, misuse, accident, casualty, alteration, negligence, repair not

authorized by Maple Systems, use on current or voltages other than

specified by Maple Systems, or application or installation not in

accordance with published instruction manuals. This warranty is in lieu

of any other warranty either expressed or implied.

1010-1017 Rev. 00 2

Page 3

Maple Systems liability is limited to the repair or replacement of the

Product only, and not costs of installation, removal, or damage to user’s

property or other liabilities. If Maple Systems is unable to repair or

replace a nonconforming Product, it may offer a refund of the amount

paid to Maple Systems for such Product in full satisfaction of its

warranty obligation. Maximum liability of Maple Systems is the cost of

the Product.

Information furnished by Maple Systems, Inc., is believed to be accurate

and reliable. However, no responsibility is assumed by Maple Systems

for the use of this information, or for any infringements of patents or

other rights of third parties which may result from its use. No license is

granted by implication, or otherwise, under any patent or patent rights of

Maple Systems, Inc. Maple Systems retains the right to revise or change

its products and documentation at any time without notice.

Installation of OMIs

CE Compliance

The OMI5000 Series Open HMIs have been tested to conform to

European CE requirements, which meet or exceed the noise emissions

and immunity requirements as set forth in the EN55022 (Emissions) and

EN55024 (Immunity) standards. The products are designed to withstand

electrical noise in harsh industrial environments. They also conform to

requirements that limit electrical emissions. However, this does not

guarantee that the products will be totally immune from possible

malfunction in cases where severe electrical noise occurs. Therefore, we

strongly recommend that you follow the guidelines outlined in this guide

for proper wire routing and grounding to insure the proper operation of

your Open HMI.

NEMA Rating

The OMI5000 Series is rated for NEMA 4/12 (indoor) or IP65

installations. This means that when the OMI is properly mounted to a

NEMA 4 panel or other NEMA 4 rated enclosure, the front enclosure of

the OMI will provide protection to the inside of the panel from splashing

water, wind-blown dust, rain, or hose-directed water. The OMI must be

installed according to the instructions in this manual to be properly

sealed.

1010-1017 Rev. 00 3

Page 4

Environmental Considerations

The OMI5000 Series is designed to operate in temperatures from 0° to

50°C (32° to 122°F). It is intended for indoor installations and may not

be suitable for use in certain outdoor applications. Avoid installing the

OMI5000 Series touchscreens in environments with severe mechanical

vibration or shocks. Do not install the OMI in enclosures with rapid

temperature variations or high humidity. Either will cause condensation

of water inside the device and eventual damage to the OMI.

Safety Precautions

Please observe the following precautions when installing the OMI.

Failure to comply with these restrictions could result in loss of life,

serious personal injury, or equipment damage.

Warning: Do not operate the OMI in areas subject to explosion

due to flammable gases, vapors, or dusts.

Warning: Do not connect the OMI to an AC power source. You

will cause permanent damage to the OMI.

Warning: Do not attempt to use a DC power supply that does

not meet OMI power requirements. You may cause malfunction

or permanent damage to the OMI.

Warning: Do not power the OMI with a DC power supply used

for inductive loads or for input circuitry to the programmable

logic controller. Severe voltage spikes caused by these devices

may damage the OMI.

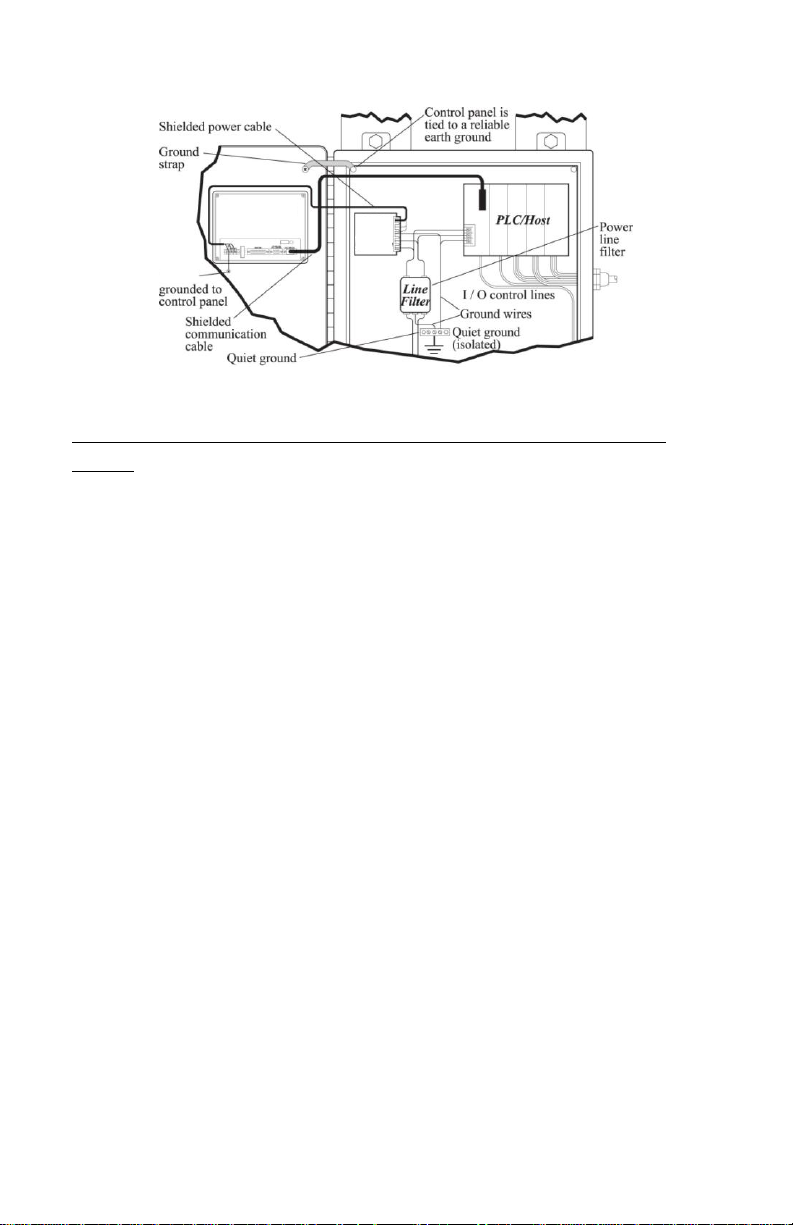

Control Panel Design Guidelines

Pay careful attention to the placement of system components and

associated cable routing. These items can significantly enhance the

performance and integrity of your control application.

1010-1017 Rev. 00 4

Page 5

Figure 1: Typical Panel Layout

OMI5000

(rear side)

OMI

Power

Supply

OMI is

Control Panel Grounding

The control panel must be connected to a good, high-integrity earth

ground both for safety considerations and shielding purposes. Maple

Systems cannot overemphasize the importance of good grounding. If you

fail to use good grounding procedures during installation, sporadic

malfunction of the OMI may occur:

Connect the OMIs chassis ground terminal to a reliable earth ground

with a low-resistance path.

Route all earth ground wires that lead from the OMI, the power supply,

and the line filter to a central earth ground point such as a barrier strip.

This will ensure that no ground current from one device influences the

operation of the other devices.

Connect the OMI chassis ground terminal to the control panel door using

a heavy-gauge short braided cable or ground wire to minimize resistance.

Connect the power cable’s shield wire to the OMI’s chassis ground terminal.

Connect the control panel to earth ground using a copper grounding rod

close to the OMI and control panel.

Hinged doors on control panels do not provide a long-term electrical

connection to the rest of the enclosure. Corrosion develops over time and

prevents good electrical contact. For this reason, a separate wire braid

should be installed from the hinged control panel to the rest of the

enclosure.

For a more in-depth overview of ground wiring techniques, refer to

1010-1017 Rev. 00 5

Page 6

Technical Note #1027, “OIT Ground Wiring and Electrical Noise

Reduction,” which you can find in the Support Center Technical Notes

section on our web site.

Connect OMI Chassis Ground to Control Panel

To reduce the possibility of electrical interference, connect the chassis

ground terminal of the OMI to a clean earth ground. If the control panel

is metal, make sure it is properly grounded. Then connect a short heavygauge wire (#14 AWG) from the chassis ground terminal of the OMI to a

mounting bolt on the control panel door. The mounting bolt must have

good electrical contact to the control panel; scrape away any paint that

may be covering the panel to provide a good connection.

NOTE: If the control panel is made of a non-conductive material, it is

essential that you connect the chassis ground terminal of the OMI to a

clean earth ground point located close to the panel.

Figure 2: Chassis Ground Connection

Power Supply Selection

The power supply used to power the OMI should provide an output of

+24 VDC ±20% measured at the HMI power terminal block. A 24VDC

regulated power supply dedicated to the OMI is recommended. Use a

power supply with adequate current rating based upon your particular

model (visit the Support Center Specifications page on our website).

A power line filter installed at the AC input to the OMI power supply is

highly recommended as a safeguard against conducted RF noise, which

is often present on factory power lines. The wires connecting the output

of the power line filter to the power supply should be kept as short as

possible to minimize any additional noise pickup. The case of the power

line filter should be connected to a quiet earth ground. The power line

filter should have a current rating of at least 3 Amps with common mode

1010-1017 Rev. 00 6

Page 7

and differential mode attenuation. In applications that may have high

frequency noise present, we also recommend using a resistor (~1 MΩ)

and capacitor (~4700 pF) in parallel to clean earth ground on the DC

output of the power supply.

Do not use the power supply used to provide power to the OMI to power

switching relays, solenoids, or other active devices.

Figure 3: Power Line Filter Connection

Cable Routing and Noise Immunity

Follow these guidelines when routing cables to the OMI:

Always route the OMI communication cable and the power cable

away from any AC voltage or rapidly switching DC control

lines.

Never bundle the OMI cables together with 120VAC power

wires or with relay wiring.

Try to keep at least 8 inches (20 cm) of separation between the

OMI cables and other power wiring. If voltages greater than

120VAC are used in the system, greater separation is required.

If the OMI cables must come near AC wiring, make sure they

cross at 90 degrees.

Run AC power wires in a separate grounded conduit to reduce

electrical noise interference.

Keep the cable lengths for the OMI as short as possible. Do not

coil excess cable and place it next to AC powered equipment.

Cover any equipment used in the enclosure that operates at high

frequency or high current levels with a grounded metal shield.

1010-1017 Rev. 00 7

Page 8

Installation

It is necessary to follow all installation procedures described in this

chapter for electrical noise immunity and CE compliance.

Your Maple Systems OMI is designed to connect easily to your

Controller. External rear connectors provide quick connections for

power, communications and programming wiring.

Connect the OMI to Power

Use the separate 3-position terminal block supplied with the OMI to

provide power to the OMI.

The power cable for the OMI should be 18AWG, 2-conductor wire with

a shield drain wire and protective shield (foil/braid). You may buy cable

P/N 6030-0009 by the foot from Maple Systems to make your own

power cable.

Always run the DC ground wire directly back to the signal return of the

power supply. Do not use the chassis ground wire as your signal return.

Caution: To prevent possible damage to the OMI, we

recommend waiting ten seconds after removing power to the

OMI before applying power again.

Figure 4: OMI Power Wiring

1010-1017 Rev. 00 8

Page 9

To connect the OMI to power:

Color

Power Supply

OMI

Red

+Output/+24V DC

+24 V

Black

–Output/+24V DC return

GND

Shield

Case ground

FG or

1. Connect the power cable to the OMI.

a. Strip the power cable shield to expose 2” of the black and

red wires.

b. Strip about ¼” of insulation from the black and red wires.

c. Connect the red wire to the 24V DC positive (+) input of the

OMI power terminal block.

d. Connect the black wire to the 24V DC negative (–) input of

the OMI power terminal block.

e. Connect the power cable shield wire to the OMI power

terminal block’s chassis ground input.

2. Route the power cable to the OMI power supply. The power

cable should not be any longer than necessary.

3. Install the power supply wires as follows (with colors shown for

Maple Systems cable P/N 6030-0009):

NOTE: The power connector on the OMI5000 Series uses a 3-position

terminal block with screw-down clamps. Lugs are not required.

Panel Preparation

A metal panel or mounting surface with a minimum thickness of 15

gauge (0.059 in/3.3 mm) if cold-rolled steel or hardened steel, or 10

gauge (0.101 in/2.6 mm) if aluminum alloy (6061-T6 preferred) is

required. Thinner panels or surfaces may bow between the mounting

clamps and not form a seal with the gasket. Make sure all supplied

mounting clamps are used and that the panel does not flex or bow more

than 0.010 in. to ensure a proper seal.

1010-1017 Rev. 00 9

Page 10

The OMI should be mounted into a panel with a depth of at least 4 in.

Hold the OMI against

the panel until all screw

clamps are in position

(105 mm). Allow a clearance of at least 1 in. (25 mm) on each side for

mounting hardware. Consider proper clearance for cable connections

when mounting.

NOTE: Cutout dimensions for each particular OMI model are readily

available for download from the Support Center-Dimensional Drawings

section of the Maple Systems website.

The area of the panel or mounting surface where the gasket comes into

contact must be flat and free of scratches, pits, and other features that

prevent the gasket from sealing properly. If the panel or mounting

surface is not uniform, thick, flat, stiff, or smooth enough, then a sealant

such as silicone may be required.

NOTE: Clean and deburr the panel cutout before the OMI is installed.

Warning: The OMI requires a stiff, flat, smooth mounting

surface free of blemishes to seal properly to NEMA 4.

Mount the OMI to the Panel

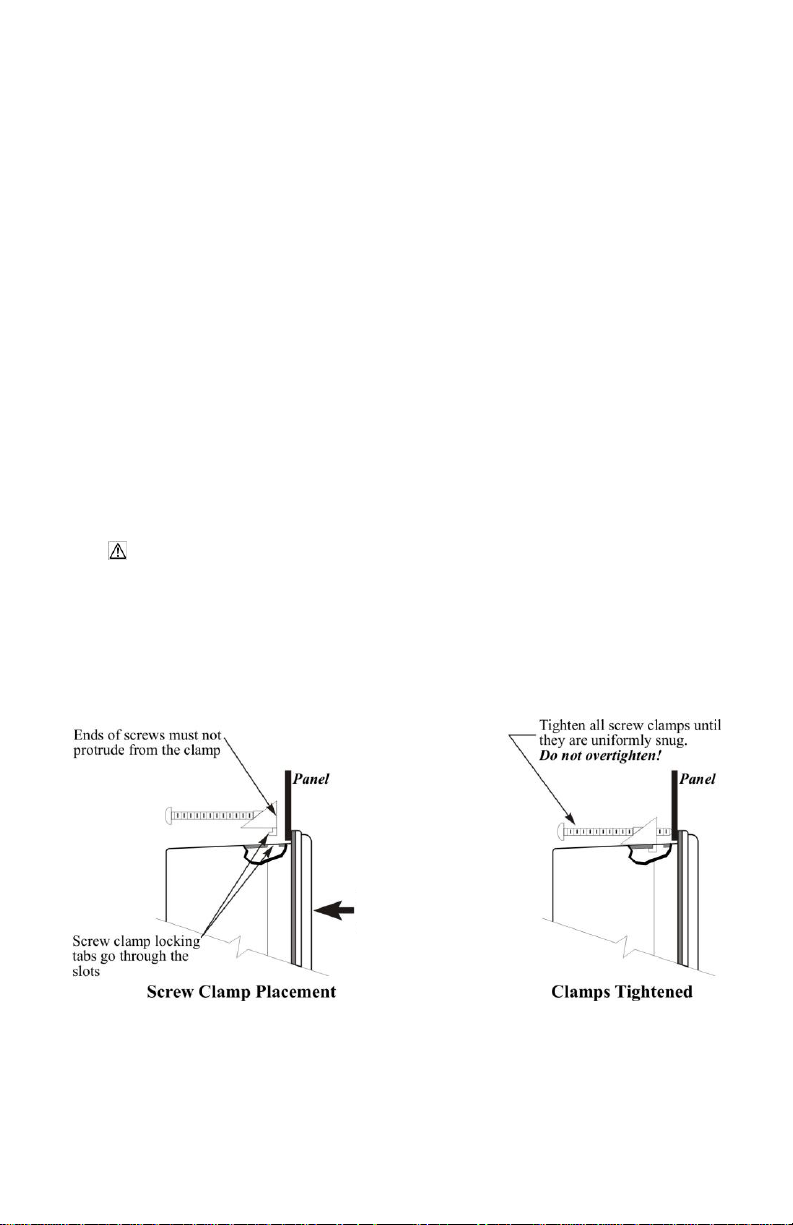

Figure 5: Installing Screw Clamps to the OMI

Note: The clamps for your model may be slightly different than shown

here, but essentially work in the same way.

1010-1017 Rev. 00 10

Page 11

STEPS:

Model

Left

Side

Right

Side

Top

Bottom

Supplied

OMI5070B-CE

1 1 2 2 6

OMI5121A-CE

3 3 3 3 12

OMI5150A-CE

2 2 3 3 10

1. Prepare the clamps for the OMI by inserting the screws into the

clamp as shown above. Position the screws so that the ends don’t

protrude through the clamp’s hole.

2. Set the OMI in the panel cutout and hold it in place until all

clamps are in position.

3. Tighten the screw clamps in an even pattern until all are

uniformly snug.

Caution: Do not over-tighten the screws beyond snugness or

you may damage the housing.

Mounting Clamp Placement

REINSTALLATION: If, at anytime, you are required to reinstall an

OMI into a panel, be aware that the gasket will take a ‘set’ to the panel

and may no longer provide an adequate NEMA 4 seal Therefore, for best

results, we recommend that you replace the gasket if reinstallation is

required.

Configuration Wiring

To install application software and upload/download files on your OMI,

you may wish to connect your computer to the Open HMI. Connection

can be done via the serial port, USB port or the Ethernet port.

USB

To transfer files via the USB client port on the OMI, you must purchase

a USB download cable (Maple P/N 7431-0115). You must also install a

USB device driver onto your computer that supports connection to the

OMI. Please follow the instructions located in your OMI5000

Operations Manual (Windows CE Embedded 6.0 Professional Edition)

[Maple P/N 1010-1016] to install the USB driver onto your computer.

1010-1017 Rev. 00 11

Page 12

Ethernet

SW1

SW2

SW3

SW4

Mode

ON

OFF

OFF

OFF

Touchscreen Calibration mode

OFF

ON

OFF

OFF

Reserved

OFF

OFF

ON

OFF

Force into Boot Loader mode

OFF

OFF

OFF

ON

Reserved

OFF

OFF

OFF

OFF

Normal operation

To connect your OMI to your computer via the10/100 Base-T Ethernet

port requires a standard Ethernet crossover cable (Maple P/N 7431-

0104). If you use a switch or router between the computer and the OMI,

use a straight-thru cable (Maple P/N 7431-0103).

Once a connection is made, you will need to install a data

synchronization program use as Microsoft's ActiveSync onto your

computer. ActiveSync provides the ability to manually transfer files to

the OMI5000 or download application software. ActiveSync is available

from Microsoft's support website for mobile applications.

Maintenance

Figure 6: DIP switch positions (power must be cycled on the OMI to enable the DIP

switch mode).

Touchscreen Calibration mode: This mode allows you to recalibrate

the touchscreen.

Boot Loader mode: This mode forces the OMI to not execute the

project. This mode is used when replacing or reinstalling the operating

system. Contact Maple Systems for more information.

Normal Operation: All DIP switches must be in the OFF position for

normal operation.

1010-1017 Rev. 00 12

Page 13

Fusing Requirements

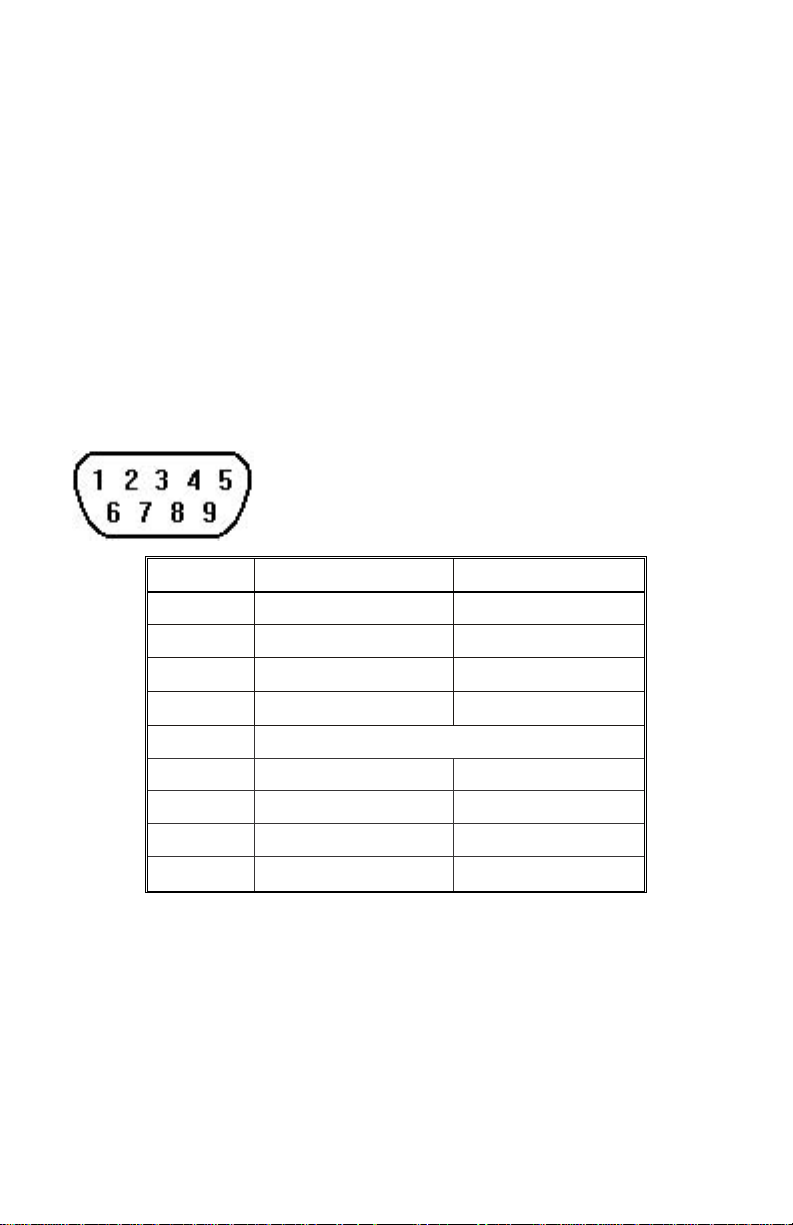

Pin #

COM1[RS232]

COM3[RS232]

1

2

RXD

3

TXD

4

5

Signal Ground

6

7

RTS

TXD

8

CTS

RXD

9

If the display does not come on within two seconds of power up, remove

power. An internal fuse will prevent damage if the polarity of the DC

power is incorrect. Check wiring to insure proper connections and try to

power up again.

Serial Port Connections

The diagrams below indicate the proper pin connections for the serial

ports of the OMIs.

Figure 7: Serial Port Pin outs

COM1 [RS-232]/COM3 [RS-232]

Pin out of DE9P (male) connector

1010-1017 Rev. 00 13

Page 14

COM1 [RS-485 2/4 W] Port, COM3[RS-485] Port

Pin#

COM1 [RS-485

COM1 [RS-485

COM3[RS-485

1

TX/RX -

RX -

2

TX/RX +

RX +

3

TX -

4

TX +

5

Signal Ground

6

TX/RX -

7

8

9

TX/RX +

Pin out of DE9S (female) connector

1010-1017 Rev. 00 14

Page 15

Page 16

Maple Systems Inc.

808 134th Street SW, Suite 120

Everett, WA 98204-7333

Phone: (425) 745-3229

Email: maple@maplesystems.com

Web: www.maplesystems.com

© 2012 Maple Systems Inc. All rights reserved.

Loading...

Loading...