Page 1

Table Of Contents

GETTING STARTED .....................1

What You Will Need ..................1

Step 1: Install the MAPware 100

Configuration Software ................1

Step 2: Create Your First MAPware 100

Project.............................4

Step 3: Connect the Operator Interface

Terminal to the PC ....................6

Step 4: Send Your Project to the Operator

Interface Terminal ....................7

Step 5: Connect the Operator Interface

Terminal to the PLC ...................7

Conclusion .........................8

OPERATION...........................9

Menu Bar ..........................10

Tool Bar............................10

New Project ......................11

Open Existing Project ...............11

Print Project ......................12

Save Project......................12

Cut ............................13

Copy ...........................13

Paste ...........................13

Align Left, Center, Right .............13

Clear Current Message ............14

Blink ...........................14

Insert Special Character .............14

Register Monitor Editor..............16

Example Group Box .............17

Data Group Box................17

Field Attributes Group Box ........18

Limits Box ....................19

ASCII Table Button..............20

Go To Message ...................21

Configuration Editor ...............21

OIT - PLC Interface Settings

Group Box ....................22

OIT Options Group Box ..........22

Function Key Editor ................24

Communication Options ............25

Read from OIT ....................26

Send to OIT ......................27

Help ...........................28

OIT/PLC Identification .................28

Basic Screen Characteristics .............28

Message Editor ...................29

Message Scroll Bar.................29

General Options Group Box..........29

OIT Memory Used Group Box............30

Message Utilization ...................30

TROUBLE SHOOTING ...................32

MAPware 100 Does Not Transfer a

Project to the OIT..................32

OIT Screen is Blank and the OIT is

Beeping .......................32

The OIT Does Not Attach to the PLC..32

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of Maple Systems, Inc.

© 1997 Maple Systems, Inc.

Microsoft and MS-DOS are registered trademarks, and Windows is a trademark of Microsoft Corporation.

Page 2

MAPware 100 User's Guide 1

The MAPware 100 User’s Guide explains how to install and use the MAPware 100 configuration software

and how to get your MAP Family Operator Interface Terminal up and running. It also includes a trouble

shooting chapter that covers some of the most common problems encountered when configuring a MAP

Family Operator Interface Terminal. In addition, we recommend you read the following:

Installation Manual–Covers the installation requirements of your specific MAP Family Operator

•

Interface Terminal. Each member of the MAP Family has a manual written specifically to its unique

specifications (shipped with each OIT).

MAP Family Operation Manual (PLC Protocols)–Covers the general operation and features of the

•

MAP Family whenthe PLC protocolsare used (shippedwith the MAPware100 configuration software).

Protocol Guides–Covers information relating to the use of your MAP Family Operator Interface

•

Terminal specific to each protocol (shipped with the MAPware 100 configuration software).

GETTING STARTED

This chapter shows you how to install the MAPware 100 configuration software, how to

create your first MAPware 100 project, how to download your project to a MAP Family

Operator Interface Terminal, and how to connect your MAP Family Operator Interface

Terminal to your PLC. If you follow each step correctly, you will have a functioning MAP

Family Operator Interface Terminal. If you encounter any problems, please contact your

local distributor or Maple Systems Technical Support at 425-486-4477.

What You Will Need

The table, below, lists the items necessary to program a Maple Systems MAP Family Operator

Interface Terminal and then connect it to your PLC.

MAP460D MAP320D, MAP340D

Configuration Software MAPware 100 MAPware 100

Configuration Cable (OIT to PC) 7431-0048 7431-0049

Personal Computer* User Provided User Provided

Power Cable Not Required 7431-0050A

1/2 Amp, 24 VDC Power Supply** User Provided User Provided

Programmable Logic Controller User Provided User Provided

Communication Cable (OIT to PLC)

See the Selection Table for Cable Accessories in

the appropriate Installation Manual

* Computer requirements include at least a 486SX/33MHz PC, 4MB RAM, 4MB available

hard disk space,VGA graphics card,Microsoft Windows 3.1,and one availableserial port.

** The MAP340D require a fast start power supply.

Step 1: Install the MAPware 100 Configuration Software

1. Start Windows.

Note: If any application programs are running, shut them down and restart Windows before

installing the MAPware 100 configuration software.

1010-0089, REV00

2. Place the MAPware 100 Setup Disk into your 3.5-inch floppy drive.

3. From the File menu in the Windows Program Manager, choose Run (For Windows 95:

From the task bar, choose Start then Run).

Page 3

2 GETTING STARTED

4. Enter a:\setup (Substitute B for A if your 3.5-inch floppy drive is configured as a B

drive).

5. Choose the OK button.

6. The Setup program starts. Depending on your computer, this can take a few seconds.

7. Setup then prompts you for the location of the setup data files. Select the disk drive

which contains the setup disk (usually A:\).

8. Setup then prompts you for the destination directory for the MAPware 100 files. The

default is C:\MAPWARE.

1010-0089, REV00

9. If any other application programs are currently running under Windows, the

following message box will appear. It is strongly recommended that you shut down

any active programs (except video). If you do not, a setup error can occur.

Page 4

MAPware 100 User's Guide 3

10. Setup will then show you total space required and space available for installation of

MAPware 100. Choose the Continue button. If adjustment is needed select Exit

Setup.

11. The MAPware 100 Setup will now start to transfer files to selected areas on the hard

disk. It will create the subdirectory specified in step 8. It will also place files into the

WINDOWS and WINDOWS\SYSTEM subdirectories. A dialog box will indicate the

files being transferred and the percentage of the file transfer complete. A MAPware

100 program group and program items will be created. You can run MAPware 100

from this program group or move the icon to another group later. Finally, MAPware

100 makes use of Display Specific Fonts (DSF). In order for MAPware 100 to use

these fonts, they are transferred into the WINDOWS\SYSTEM subdirectory and your

Windows WIN.INI file is updated.

12. Once the installation is complete, you are asked if you want to restart the computer or

continue with the current Windows session. MAPware 100 will not operate correctly

until the computer is restarted. Choose the Reboot Computer button.

Note: In rare cases, your computer may not restart properly. If this happens, simply reboot

your computer.

13. A new Windows Program Group entitled Maple Systems MAPware 100 has been

created which contains MAPware 100 and MAPware Setup. Remove the floppy disk

and store it in a safe place.

1010-0089, REV00

Page 5

4 GETTING STARTED

Step 2: Create Your First MAPware 100 Project

1. Double click on the MAPware 100 icon in the Windows Program Manager.

2. MAPware 100 starts and, after a few seconds, the MAPware 100 dialog box appears

(see Figure 1). In the center of the MAPware 100 dialog box is a representation of the

OIT display. From the File menu, choose New.

Figure 1 MAPware 100 Dialog Box

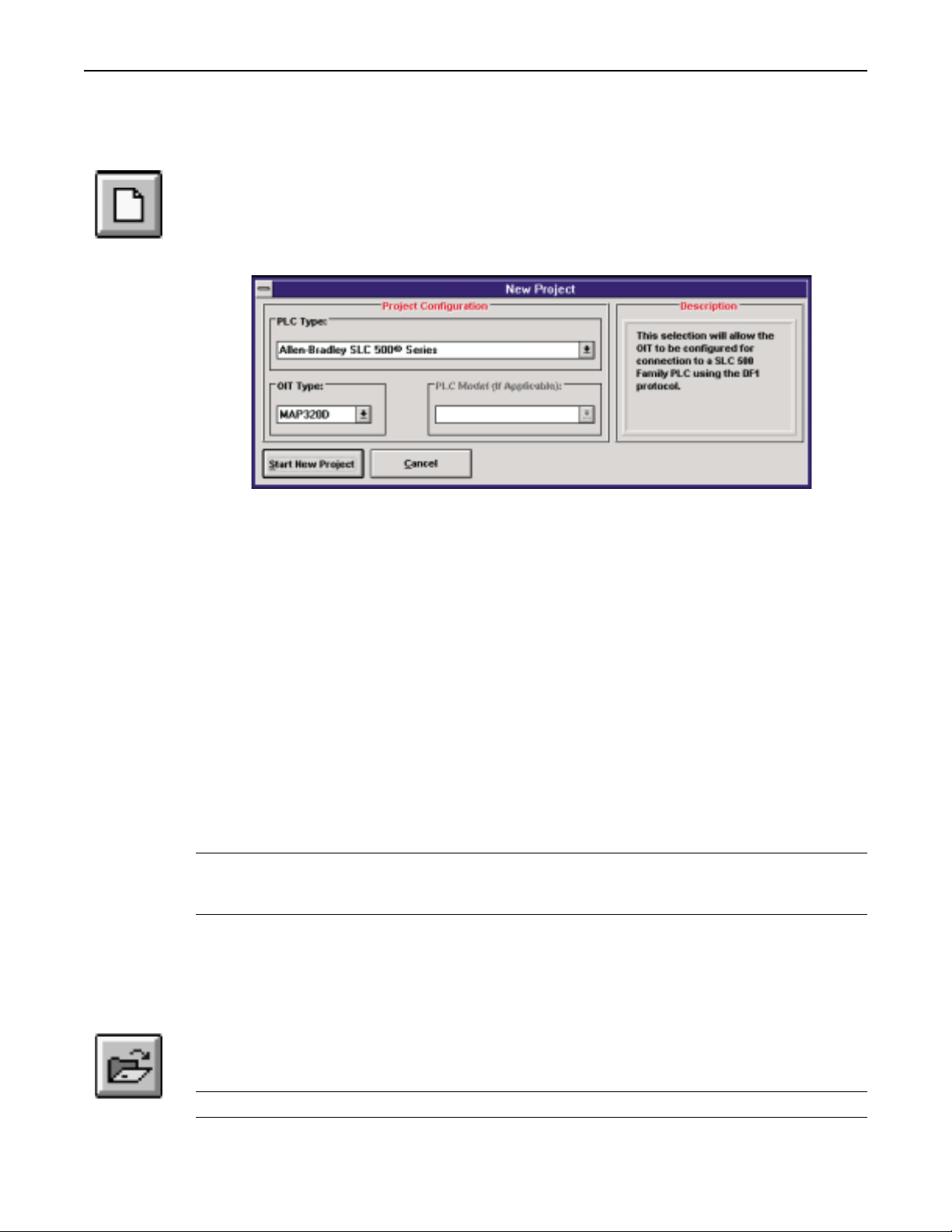

3. The New Project dialog box appears. Select the desired OIT and PLC from the OIT

Type and PLC Type list boxes (see Figure 2). It is very important to select the proper

OIT and PLC.

Figure 2 New Project Dialog Box

4. Once the OIT and PLC have been selected, choose the Start New Project button.

1010-0089, REV00

Page 6

MAPware 100 User's Guide 5

5. The Configuration Editor dialog box appears (see Figure 3). This dialog box allows

you to tailor your MAP Family Operator Interface Terminal to your PLC. To accept

the default values, choose the Done button.

Figure 3 Configuration Editor Dialog Box

6. You are now back in the MAPware 100 dialog box. Type an appropriate message into

the Message text box (see Figure 4).

1010-0089, REV00

Figure 4 Message Text Box in MAPware 100 Dialog Box

7. In the General Options group box, select the Start Up Message check box.

8. From the File menu, choose Save As.

Page 7

6 GETTING STARTED

9. The Save As dialog box appears. Type firstoit.mwr into the File Name text box.

Figure 5 Save As Dialog Box

10. Choose the OK button. You have now created your first MAPware 100 project.

Step 3: Connect the Operator Interface Terminal to the PC

PC

OIT

Port 1 Power

7431-0050A

Port 1

Power

OIT

7431-0048

/

MAP320D

MAP340D

MAP460D

OIT Power

Supply

+

GND

-

OIT Power

Supply

+

GND

-

Com2

PC

Com2

Pr int er

Pr int er

Com1

Maple Systems

OIT to PC cable

(If mouse is using

Com 1, use Com2)

Com1

(If mouse is using

Com 1, use Com2)

(Rear of

OIT)

7431-0049

(Rear of

OIT)

Maple Systems

OIT to PC cable

1010-0089, REV00

Figure 6 OIT to PC Wiring Configurations

Page 8

MAPware 100 User's Guide 7

Step 4: Send Your Project to the Operator Interface Terminal

1. Apply 24 VDC to the OIT. At this point the OIT will display the following messages:

***System is not configured!*** and Press ANY key to enter download mode.

Press a key on the OIT keypad. The message indicates that the OIT is ready to receive

a project from MAPware 100.

2. In MAPware 100, from the Transfer menu, choose Send to OIT.

3. The Send To OIT dialog box appears (see Figure 7). If you are using a serial port other

than COM 1, choose the Options button.

4. The Communication Options dialog box appears (see Figure 7). In the PC Serial Port

group box, select the option button for the COM port you are connected to and then

choose the Done button.

Figure 7 Send to OIT & Communication Options Dialog Box

5. You are now back in the Send to OIT dialog box. Choose the OK button.

6. MAPware 100 will now send the entire OIT project file to the OIT. The project

transfer will take a couple of minutes. When the transfer is complete MAPware 100

will restart the OIT. The OIT will then attempt to attach to the PLC.

Step 5: Connect the Operator Interface Terminal to the PLC

1. Connect the OIT to your PLC as per the installation manual supplied with your OIT.

2. Make sure you use the correct cable to connect the OIT to your PLC. Contact your

local distributor or Maple Systems Technical Support if you need assistance in

choosing the appropriate cable.

3. When the OIT attaches to the PLC, the startup screen you created in your first project

appears on the screen.

1010-0089, REV00

Page 9

8 GETTING STARTED

PLC

OIT

Port 1

Power

MAP320D

OIT Power

Com Port

(Rear of

OIT)

Supply

MAP340D

GN D

+

-

Maple Systems

OIT to PLC cable

7431-0050A

MAP460D

Conclusion

You have now created your first MAP Family Operator Interface Terminal project. Please

take the time to review all the documentation provided, as we are sure you will want to

explore all the capabilities of your new MAP Family Operator Interface Terminal. If you

encountered any difficulties or questions downloading your MAP Family Operator Interface

Terminal project, please contact your local distributor or Maple Systems Technical Support

at 425-486-4477.

PLC

Com Port

OIT Power

Supply

+

GN D

-

Figure 8 OIT to PLC Wiring Configurations

Maple Systems

OIT to PLC cable

(Rear of

OIT)

OIT

Port 1

Power

/

1010-0089, REV00

Page 10

MAPware 100 User's Guide 9

OPERATION

Since MAPware 100 has been designed to run under the MicrosoftWindows environment, it

conforms to the Windows user interface standard. Many of the tools on the tool bar are

identical to other software packages such as Microsoft Word and Excel. The pull down

menus all operate according to the Windows standard, they may be selected using the mouse

or through the appropriate Alt sequence (i.e. Alt+F for the File menu).

As with many Windows programs, depending on the options selected at any one time, some

functions are no longer valid. These functions are deselected or grayed out so that they are

not accessible when their use is not appropriate. For example, on the main MAPware 100

dialog box, if the Chain check box is selected in the Extensions group box the Message box is

activated. If the Chain check box is disabled, the Message box is grayed out.

The illustration below outlines the major features of the main MAPware 100 dialog box:

Title Bar

Menu Bar

Tool Bar

OIT Identification

PLC Identification

Message Editor

Message Scroll Bar

General Options

Group Box

•

Title Bar: Identifies the file name for the current project.

•

Menu Bar: Provides pull-down menus for accessing functions (pg. 10).

•

Tool Bar: Provides buttons that can be used as shortcuts to choosing functions from the

OIT Memory Used

Group Box

menus (pg. 10).

•

OIT Identification: Identifies the OIT model selected for the current project (pg. 28).

•

PLC Identification: Identifies the PLC model the OIT is being configured to work with

for the current project (pg. 28).

•

Message Editor: Area used to enter OIT text and register monitors for each stored

message (pg. 29).

•

Message Scroll Bar: Scrolls through the stored messages (pg. 29).

•

General Option Group Box: Grouping of options that can beapplied to stored messages

(pg. 29).

•

OIT Memory Used Group Box: Indicates the amount of OIT configuration memory

remaining and the correct date and time. (pg. 30)

1010-0089, REV00

Page 11

10 OPERATION

Menu Bar

The menu bar contains all of the menus that can be used to navigate through the program.

Accessing the menusis simple: either pointto one with themouse and click onit, or pressand

hold the Alt key while pressing the first character in the menu name (example: F for File).

Many of the items in the menus may be accessed directly using the associated control keys as

indicated to the right of the menu item. Once the menu drops down, use the mouse or cursor

keys to point to the desired menu item, then click on the item with the mouse, or press Enter

on the keyboard to select the menu item.

Tool Bar

The tool bar contains tools, or buttons, that provide a much quicker way of performing

functions than using the pull-down menus. Some examples include cutting and pasting

screen information, saving the current project, and placing register monitors onto the screen.

Hints explaining a button’s purpose appear if the cursor is placed over a button.

New

Project

Open

Existing

Project

Print

Project

Clear Current

Align

Right

Screen

Insert Special

Character

Register Monitor

Blink

Paste

Cut

Copy

Save

Project

•

New Project: Creates a new project (pg. 11).

•

Open Existing Project: Opens existing project (pg. 11).

•

Print Project: Sends project to printer for hard copy output (pg. 12).

•

Save Project: Saves changes made to active project (pg. 12).

•

Cut: Cuts selected text or objects from the active message (pg. 13).

•

Copy: Copies selected text or objects from the active message (pg. 13).

•

Paste: Pastes previously cut or copied text or objects into the active message (pg. 13).

•

Align: Aligns text to the left margin, right margin, or centered in the display (pg. 13).

•

Clear Current Screen: Clears all information from the active message (pg. 14).

•

Blink: Controls blinking feature (pg. 14).

•

Insert Special Character: Allows special OIT-dependent characters to be inserted onto

Align

Center

Align

Left

Editor

Go To

Message

Configuration

Function Key

Editor

Editor

Read

from OIT

Send to

Communication

Options

message (pg. 14).

•

Register Monitor Editor: Enables PLC register monitors to be attached to the active

message (pg. 16).

•

Go To Message: Finds desired message (pg. 21).

•

Configuration Editor: Sets up system-wide parameters (pg. 21).

•

Function Key Editor: Enables configuration of the function keys (pg. 24).

•

Communication Options: Configures parameters of communication between

MAPware and the OIT (pg. 25).

•

Read from OIT: Reads a project from the OIT (pg. 26).

Help

OIT

1010-0089, REV00

Page 12

MAPware 100 User's Guide 11

Send to OIT: Sends a project from MAPware 100 to the OIT (pg. 27).

•

Help: Context-sensitive help (pg. 28).

•

New Project

The New Project button is the shortcut for the File/New menu item. Clicking on this button with

the mouse will cause MAPware 100 to start a new project. If a project is currently loaded and it

has changed, you will be asked if you wish to save the existing project before starting a new one.

If you select NO, the edited project will be lost. The following dialog box will appear:

Select the PLC that the OIT will be connected to using the select box in the PLC Type group.

To do this, place the cursor on the down arrow and click on the left mouse button. The Select

box will drop and display a list of the currently supported PLCs from which you can choose.

Using the mouse, scroll through the selection and double click on the desired PLC protocol

driver. Some PLC families have models with varying memory configurations. If this is the

case on the selected PLC protocol driver, the Model group will be enabled. In a similar

fashion to selecting a PLC protocol driver, use the mouse to select the specific PLC model

the OIT will be connected to.

As various PLC protocol drivers are selected, a description of the protocol and PLC family

will appear on the Description group. This is information only and may be used to help

identify the proper protocol driver for a particular PLC. More information about the PLC

protocol driver specifics may be found by clicking on the Help button.

Once you are satisfied with the selected PLC protocol driver, click on the Start New Project

button to begin a new project file. If you do not wish to change protocol drivers at this time,

click on the Cancel button.

Note: The MAPware 100 software always starts up with a default protocol selected.

Therefore, it is important to select the New button and choose the appropriate PLC

protocol before screen data is entered.

Since screen data information varies with the PLC protocol used, any project created for a

particular PLC protocol cannot be transferred to another project using a different PLC

protocol.

Open Existing Project

The Open Existing Project button is the shortcut for the File/Open menu item. This button is

used to load from disk a previously saved project file.

Note: All projects use the .mwr extension.

1010-0089, REV00

Page 13

12 OPERATION

Project files may be stored anywhere on your computer system. Use the Drives and

Directories box for selecting the proper path. Projects that have previously been saved in the

selected directory will be displayed in the File Name list box. Use the mouse to select a file

name and click on the OK button to load the project. Click on the Cancel button to abort

loading a project file.

Note: MAPware 100 remembers your last 4 projects.

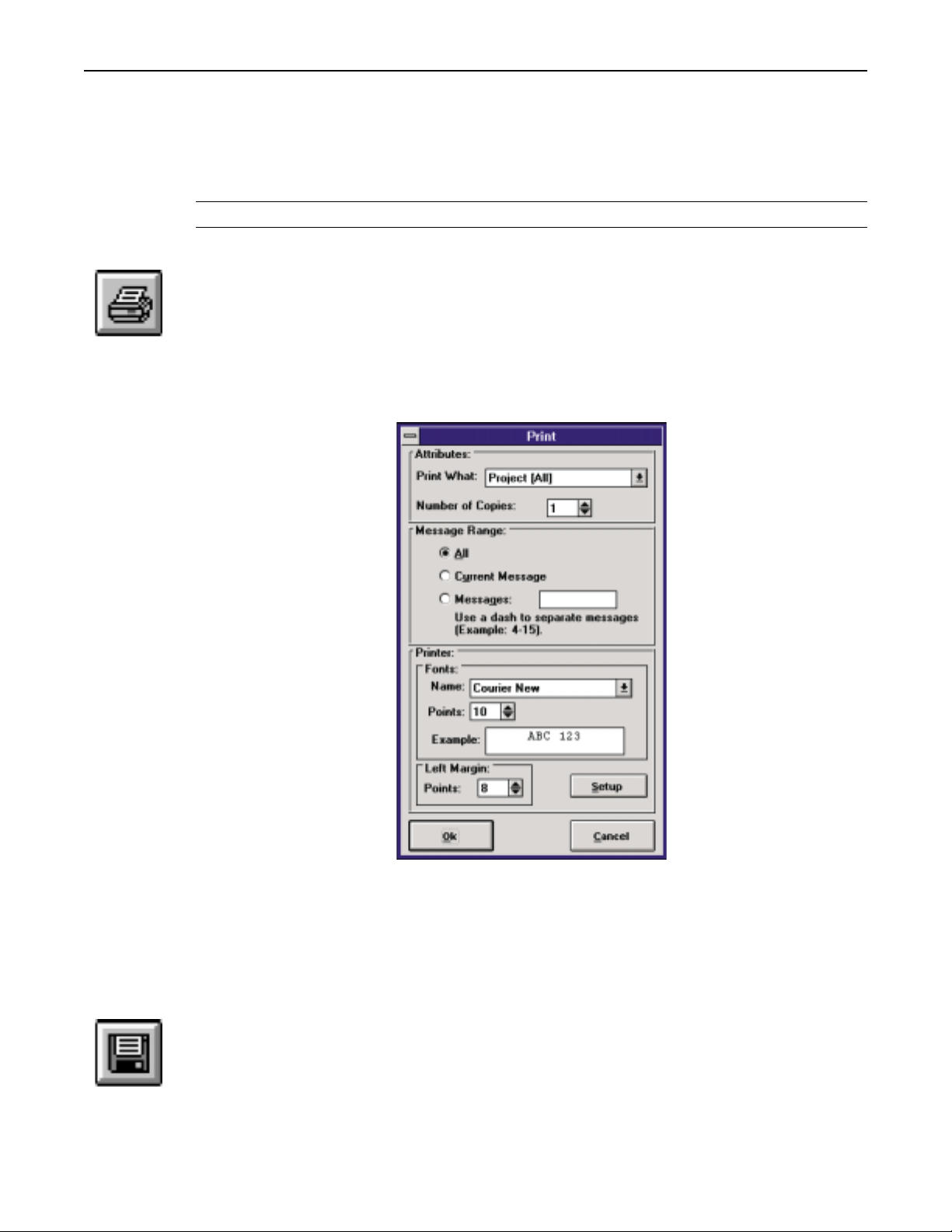

Print Project

The Print Project button is the shortcut for the File/Print menu item. This button allows you

to print the currently loaded project. All of the PLC communication parameters and message

text are printed. The message text is printed in the order that the messages are chained so that

the listing may be used for debugging the system.

The Print dialog box only appears if the File/Print menu item is selected. The Print dialog

box does not appear if the Print Project button is chosen.

Save Project

1010-0089, REV00

Upon the starting of MAPware 100 for the first time, the software will detect if there is a

MAPware 100 INI file (there will not be). The software will then search the system for the

font closest to Courier and default to that (Courier is recommended since it is a TrueType

font). The margin will default to 10 points. Subsequent activation will pull the font and

margin in from the MAPWARE.INI file.

The Save Project button is the shortcut for the File/Save menu item. This tool button will

save the current project. If the projecthas previously been saved, theSave button will simply

update the contents of the project file on disk. If this is the first time for the file to be saved,

you will be presented with a screen that allows you to enter the project’s name as well as the

location to save the file to.

Page 14

MAPware 100 User's Guide 13

While you are working on a project, all of the data entered is temporarily saved within the

PC’s memory. Nothing is saved permanently until the Save or Save As command is

executed. You should save often to ensure that you don’t lose valuable information.

Cut

The Cut button is the shortcut for the Edit/Cut menu item. The Cut button will clip out the

highlighted area on the message entry window and place it onto a clipboard so that it may be

pasted at a later time. To highlight an area of the message, use the mouse to place the cursor

on the message and press the left mouse button. While holding the button, drag the mouse

across the area you wish to cut or remove from the message. The selected message area will

become highlighted as the mouse is moved. Release the left mouse button to stop selecting.

Clicking on the Cut button will now remove the selected message information and place it

onto the clipboard for later pasting. Only the last cut section of the message may be pasted

onto the same message or another.

Since register monitors on the message are objects, entire register monitors must be

highlighted before they can be cut.

Copy

The Copy button is the shortcut for the Edit/Copy menu item. The Copy button will place a

copy of the highlighted area of the message entry window onto a clipboard so that it may be

pasted at a later time. To highlight an area of the message, use the mouse to place the cursor

on the message and press the left mouse button. While holding the button, drag the mouse

across the area you wish to copy from the message. The selected message area will become

highlighted as the mouse is moved. Release the left mouse button to stop selecting. Clicking

on the Copy button will now copy the selected message information and place it onto the

clipboard for later pasting. As with cutting text, only the last copied section of the message

may be pasted onto the same message or another.

Register monitors are objects on the message. Only by highlighting the entire register

monitor will it be copied to the clipboard when executing this command.

Paste

The Paste button is the shortcut for the Edit/Paste menu item. The Paste button is used in

conjunction with the Cut or Copy buttons to move data on the message or to repetitively place

identical copies of text and register monitors onto any number of OIT messages. Text and register

monitors that are cut or copied are placed on the clipboard which may be pasted at will. Pasted text

and register monitors will appearstarting at the cursor location andmay be pasted multiple times.

Register monitors that are pasted to the message will create a duplicate, but unique, register

monitor on the current message. Changes made to the new register monitor(s) will not affect

the copied register monitors.

Align Left, Center, Right

The Align Left, Align Center, and Align Right buttons are the shortcuts for the Edit/Align

Left, Edit/Align Center, and Edit/Align Right menu items. These buttons allow aligning a

line on the project. Click on the alignment desired—left, centered, or right alignment—and

the MAPware 100 software will move the text and Register Monitors accordingly.

1010-0089, REV00

Page 15

14 OPERATION

Clear Current Message

The Clear Current Message button is the shortcut for the Edit/Clear Message menu item. The

Clear Current Message button is used to clear the entire contents of the current message. All

text, attributes and register monitors will be deleted from the message.

Blink

The Blink button is the shortcut for the Edit/Blink menu item.Each character on the message

may have its blink attribute enabled causing the character to blink at a rate of once per

second. In addition to characters on the message, some register monitors can also have the

blink attribute enabled.

Using the mouse, placethe cursor on the character to enable blinking on, or highlight the area

of text to blink. Click on the Blink button and notice that the blink attribute is enabled on the

selected characters (they will all blink). To enable the blink attribute on a register monitor

field, select all of the characters within the register monitor field and click on the Blink

button. Disabling the blink attribute is done the same way. Use the mouse to highlight the

characters that have the blink attribute enabled and click on the Blink button again.

Insert Special Character

The Insert Special Character button is the shortcut for the Insert/Special Character menu

item. The OITdisplay is capableof displaying manymore characters thanmay be enteredvia

the PC keyboard. The Insert Special Character button is used to access the other characters

that cannot be typed in. These characters include special symbols and foreign characters.

Note: The Special Character sets vary depending on the OIT model. Please refer to the figures

at the end of this section for the special characters available on your OIT.

To insert aspecial character, click onthe Insert SpecialCharacter button with themouse. The

following dialog box will appear:

1010-0089, REV00

Page 16

MAPware 100 User's Guide 15

Characters can be selected in two ways: By double-clicking on the desired character, or by

clicking once on the desired character and then clicking on the Add to List button. The

selected character will be displayed in the text box located at the bottom of the window.

You may enter standard text by clicking in the Add To List box. This allows you to enter

foreign words without having to switch from the main screen to the Insert Special Character

screen (such as in a German word with an umlaut).

The Zoom button displays a highlighted character at several times its normal size for

simplified viewing. Click on the done button in the zoom window to close the window (or

use the right mouse button).

Click on the Done button to add the selected characters to the current OIT message. To

abandon inserting the characters into the message, click on the Cancel button.

The following illustrations represent the Special Character screens for the MAP320D,

MAP460D and MAP340D respectively.

1010-0089, REV00

MAP320D Special Character Set

MAP460D Special Character Set

Page 17

16 OPERATION

MAP340D Special Character Set

Register Monitor Editor

The Register Monitor Editor button is the shortcut for the Insert/PLC Register Monitor menu

item. Register monitors are objects that are placed on the message and represent registers or

coils within thePLC that are readand updated inreal-time. Up to 10register monitors maybe

placed on eachmessage. Everything about the registermonitor format may beadjusted, from

its width to the type of data presented on the message. Clicking on the Register Monitor

Editor button opens the following window:

1010-0089, REV00

Page 18

MAPware 100 User's Guide 17

Notes: Double clicking on a current Register Monitor (or pressing the Register Monitor Editor

button with the monitor highlighted) enables you to edit an existing Register Monitor.

Example Group Box

This box contains a sample of what the data on the message will look like. Refer back to this

box when making changes to examine how the register monitor will look on the message

when you are finished. The register monitor will occupy the same number of characters on

the message when you click on the Add button. Nothing within the Example box may be

changed; it is for reference only.

Data Group Box

This is the box where you specify the actual PLC register information, the PLC register type,

the address, the sub-element and the format. Depending on the type of PLC selected,

additional information may appear in this box. In the example above, the Allen-Bradley PLC

has been selected. In this particular case, the PLC register type, address, and sub-element are

used to specify a coil within the PLC.

Format

The following formats can be selected in the Format box:

Signed—This format is used to represent a 16-bit register in the PLC as a signed integer

•

value with a range of -32,768 to +32,767.

Decimal—This format is used to represent a 16-bit register in the PLC as an unsigned

•

integer value with a range of 0 to 65,535.

•

Long—This format is used to represent a 32-bit register in the PLC as a signed long

integer value with a range of -2,147,483,648 to +2,147,483,647.

•

4-Digit BCD—This format is used to represent a 16-bit register in the PLC as a BCD

value with a range of 0 to 9,999. If the value in the PLC register is not in BCD format, then

the OIT will display the value as hexadecimal.

•

8-Digit BCD—This format is used to represent a 32-bit register in the PLC as a BCD

value with a range of 0 to 99,999,999. If the value in the PLC register is not in BCD format,

then the OIT will display the value as hexadecimal.

•

1/0 Coil—This format is used to represent a single coil in the PLC as a binary value with

‘0’ indicating the coil is off and ‘1’ indicating that the coil is on.

•

On/Off Coil—This format is used to represent a single coil in the PLC as a binary value

with ‘Off’ indicating the coil is off and ‘On’ indicating that the coil is on.

•

Bank 8—This format is used to represent eight consecutive coils in the PLC as binary

values with ‘0’ indicating that the coil is off and ‘1’ indicating that the coil is on. The

highest addressed coil is always displayed in the left-most position.

•

Bank 16—This format is used to represent 16 consecutive coils in the PLC as binary

values with ‘0’ indicating that the coil is off and ‘1’ indicating that the coil is on. The

highest addressed coil is always displayed in the left-most position.

•

ASCII Char—This format is used to represent a 16-bit register in the PLC as a

corresponding ASCII character. If the Number of Digits Attribute is set to 2, then the OIT

will read the 16-bit register as two 8-bit ASCII charactersand display them. If the Number

of Digits Attribute is set to 1, then the OIT will read the lowest eight bits of the 16-bit

register and display one ASCII character. If the value in the PLC register does not

1010-0089, REV00

Page 19

18 OPERATION

correspond to a displayable ASCII character, then the OIT will continue to show the last

displayable ASCII character that was in the PLC register, or if there never was one, then a

space will be shown.

ASCII String—This format is used to represent a single coil in the PLC as a binary value

•

with user-definable strings that will indicate whether the coil is on or off. The strings can

be up to eight characters in length. When this format is selected, the ASCII Text box in

Field Attributes becomes enabled. Use this field to select the ASCII string which will

represent value 0, and the ASCII string which will represent value 1. The ASCII Table

command button is used to create the ASCII strings (maximum of 30).

Time (12 hour)—This format is used to represent the time of the built-in clock of the OIT

•

in 12-hour (a.m./p.m.) format. It does not require the use of a PLC register.

Time (24 hour)—This format is used to represent the time of the built-in clock of the OIT

•

in 24-hour (military time) format. It does not require the use of a PLC register.

Date (US)—This format is used to represent the date of the built-in clock of the OIT in

•

MM/DD/YY (US) format. It does not require the use of a PLC register.

Date (Euro)—This format is used to represent the date of the built-in clock of the OIT in

•

DD/MM/YY (European) format. It does not require the use of a PLC register.

Note: The Time/Date formats are available for the MAP460D only. Each screen of the OIT is

capable of displaying a maximum of two time/date registers.

Field Attributes Group Box

The Field Attributes box is used to alter how the register monitor is displayed. All changes

made within this box are reflected in the Example box at the top of the window.

Access

The register monitor can be configured as a read-only register or a read/write register.

Read-only register monitors only allow the operator to view their contents. Read/write

register monitors allow the operator to alter the data within the PLC’s register or coil.

Attributes

The width of the register monitor is adjusted using the Number of Digits box. The actual

width may be directly typed in, or you may use the mouse to scroll through the available list

of options usingthe spin buttons (up anddown arrows located adjacent tothe data entry box).

It is important to note that this entry only controls the number of digits that are displayed

(including the sign), not the actual field width. If commas or a decimal are added, the field

width will be wider than Number of Digits. Field width is governed by the register monitor

format.

A decimal may be placed anywhere within the register monitor field. Adding a decimal

place to the register monitor formats the PLC register information prior to displaying it on

the OITs display. For example, if a register within the PLC contains 32768, this data may

be displayed as 327.68 or 3.2768 depending on what the register represents. The location

of the decimal point is completely controlled via the system programmer. Enter the correct

decimal location within the Decimal Location: box, select 0 to disable the decimal point

altogether. The decimal location value increases as the decimal point moves from right to

left (i.e. 1=3276.8, 2=327.68, 3=32.768, etc.).

1010-0089, REV00

Page 20

MAPware 100 User's Guide 19

Special Effects

Commas make the data easier to read by a human by simply inserting a comma in every

1,000th place (every 3 digits). For example, instead of displaying 60000, the OIT will

display 60,000 when Commas is enabled. Note that depending on where the decimal is

placed and what format of register monitor is being used, commas may not actually be

displayed. A simple example of this would be to select the decimal format which is five

characters in length. If the decimal is placed at the second character or farther, there aren’t

three characters to the left of the decimal to enable the comma insertion.

Linear scaling is more complicated. Linear scaling is used to convert one set of units to

another (millimeters to inches, etc.). When the Linear Scaling check box is checked, the

register monitor data is converted prior to being displayed. When the operator enters data,

the data is converted back to PLC units prior to being sent to the PLC. In this manner, the OIT

allows the operator to speak in units he is familiar with while still providing the PLC with

units that are required for proper operation. Some examples are converting an A/D value to

temperature, converting the number of clicks from a rotary encoder to length (inches, feet,

etc.), or converting a counter to gallons per minute.

Linear conversion data is entered in the Linear Scaling Parameters box using three

parameters: the range scalar, the offset, and the presets. The range scalar is represented by

the two entries preceding X, while the offset data is represented by the last entry. The range

scalar is entered in the Linear Scaling parameter box in two parts which allows either

expansion of the range, or reduction of the range. The Presets button allows the system

operator to select one of the commonly used preset linear scaling conversion factors. Simply

press on the Presets button and then select one of the presets by double-clicking on it withthe

mouse. The correct values will be automatically entered into the equation for you.

Leading Zeros, when checked, causes the OIT to display zeros in the left-most positions of

the Register Monitor. For example, if the Field Width is set to 6, and the data is only three

characters long the 3 left-most positions would contain zeros.

Note: Available only on Register Types Decimal, 4-Digit BCD, and 8-Digit BCD, and with

Commas and Linear Scaling off.

Hide Data Entry, when checked, will cause the OIT to display asterisks (*) instead of

numeric data for the Register Monitor. This option is available on Read/Write Register

Monitors of format Signed, Decimal, 4-Digit BCD, 8-Digit BCD, and Long.

Justification

Each register monitor on the screen may have different justification: either right or left.

Justification is the term used to describe placing all of the characters against the right- or

left-handed margin, regardless of the actual number of characters displayed. Using the

MAPware 100 software, you may select either left or right justification.

Limits Box

When a register monitor has been selected to be a read/write monitor, values may be set that

restrict data entry to predetermined limits. This will keep the operator from being able to

enter invalid data into a register or coil within the PLC. The maximum and minimum values

for data entry default to the maximum and minimum values allowed for the format. If the

1010-0089, REV00

Page 21

20 OPERATION

operator attempts to enter data outside the bounds, he will be notified with an error screen

indicating that the data is not within bounds. Data will not be sent to the PLC unless it falls

within the preset bounds.

Remember when linear scaling is set, the limits must be set in terms of the operator’s units

since the OIT converts the entered data into units the PLC is capable of dealing with. For

example, if the operator is to enter the temperature in degrees C,then the limits must be set in

degrees, not in A/D or D/A units that the PLC will actually use.

ASCII Table Button

When a register monitor is formatted as a binary ASCII string, a coil from the PLC is read

and, depending on the value of the coil, one of two ASCII strings will be displayed. This

allows the system programmer to customize the OIT to the particular application; instead of

simple On/Off indicators, the OIT may now display Running, or Stopped, or anything else

the system programmer thinks of. The OIT can store up to 30 ASCII strings, each of which

may be up to eight characters in length.

The method of cross-referencing the ASCII strings to coil values is fairly simple. The OIT

has a programmed table of 30 ASCII strings, each one unique. When a register monitor is

configured, use the ASCII Text box to select which string is displayed for a coil state of 0 and

1. The number of the ASCII string to be displayed is programmed into the OIT, so each

ASCII string may be used more than once and even to represent different coil states. The

following sample ASCIIstring table illustrateshow the cross-referencingis accomplished.

1010-0089, REV00

The ASCII Table Editor allows the system programmer to enter custom ASCII strings that

represent the ‘0’ or ‘1’ states for any coil within the system. Since it is table-based (there is no

direct correlation between the coil state and a string), this allows the 30 strings to be

effectively used on many more than 30 coils. In many cases the system programmer has only

a few ‘off’ states such as stopped or off. This would only require one entry into the database,

leaving 29 entries for the ‘on’ state.

Page 22

MAPware 100 User's Guide 21

Go To Message

The Go To Message button is the shortcut for the Edit/Go To Message menu item. This

button gives the system programmer the ability to randomly jump to any message within the

system. Once the Go To Message button has been pressed, the following dialog box will

appear:

Enter the desired message number and either press Enter or click on the Go To Message

button. If you don’t desire to change messages, click on the Cancel button to return to the

previous message.

Configuration Editor

The Configuration Editor button is the shortcut for the Tools/Configuration Editor menu

item. This button is used to set up the system wide parameters: PLC addresses,

communication parameters, display viewing angle, passwords.

In all cases, the Default button will select the manufacturers recommended settings for a

given PLC model. Even though some settings for baud rate, parity, and data bits/stop bits

may not work properly with all PLCs, Maple Systems has allowed all settings to be user

adjustable in the event that the PLC manufacturers change the operation of the PLCs.

1010-0089, REV00

Page 23

22 OPERATION

Note: If you are experiencing problems with communicating with the selected PLC, first

verify that the communication parameters are set to the default by clicking on the

Default button on the mouse.

OIT - PLC Interface Settings Group Box

This group box is used to set all of the addresses for communicating with the PLC. There are

three registers that are required for the OIT to operate: The Message Request Register, the

Function Key Coils, and the Status Coils.

The message request register (MRR) address is set in the text box in the Message group box. This

register is used by the PLC to inform the OIT of messages to display or command codes. This

register is read up to five times per second to receive information from the PLC. The value within

the MRR must change before the OIT will acknowledge that a new message or alarm must be

displayed. Checking the BCD Format check box causes the OIT to interpret the value in the

Message Request Register as a Binary Coded Decimal (BCD) value. If this box is not checked, the

value is interpreted as a Decimal number.

The function key coils are used by the OIT to write information about function key activity to

the PLC. The function key coils are continuously read by the PLC ladder logic program to

determine what action to take when a key is pressed or released. The OIT updates this

register upon key activation. The function key coils address is set in the text box in the

Function Key Coilsgroup box. Checking the Retentive check boxcauses the OITto read and

return the values of the Function Key Coils when the OIT powers up. If this box is not

checked, all of the Function Key Coils are reset when the OIT powers up.

The status bit coils are used by the OIT and PLC to communicate status information between

the devices. The use of each status bit is explained in the “Operation” chapter of the OIT

Family Operation Manual. The status bit coils address is set in the text box in the Status Coil

group box.

The Address group box is used to specify the PLC address. Some PLCs require that a PLC address

be used in order to communicate with them.

The Source and Destination group boxed are only used in selected PLC protocols. Refer to

the Protocol Guides for more information.

The PLC password may be set in the Password group box. Several PLCs require the

password to be entered prior to any register or coil transaction.

OIT Options Group Box

Three items exist within the Options box: screen saver settings, supervisor settings, and

passwords.

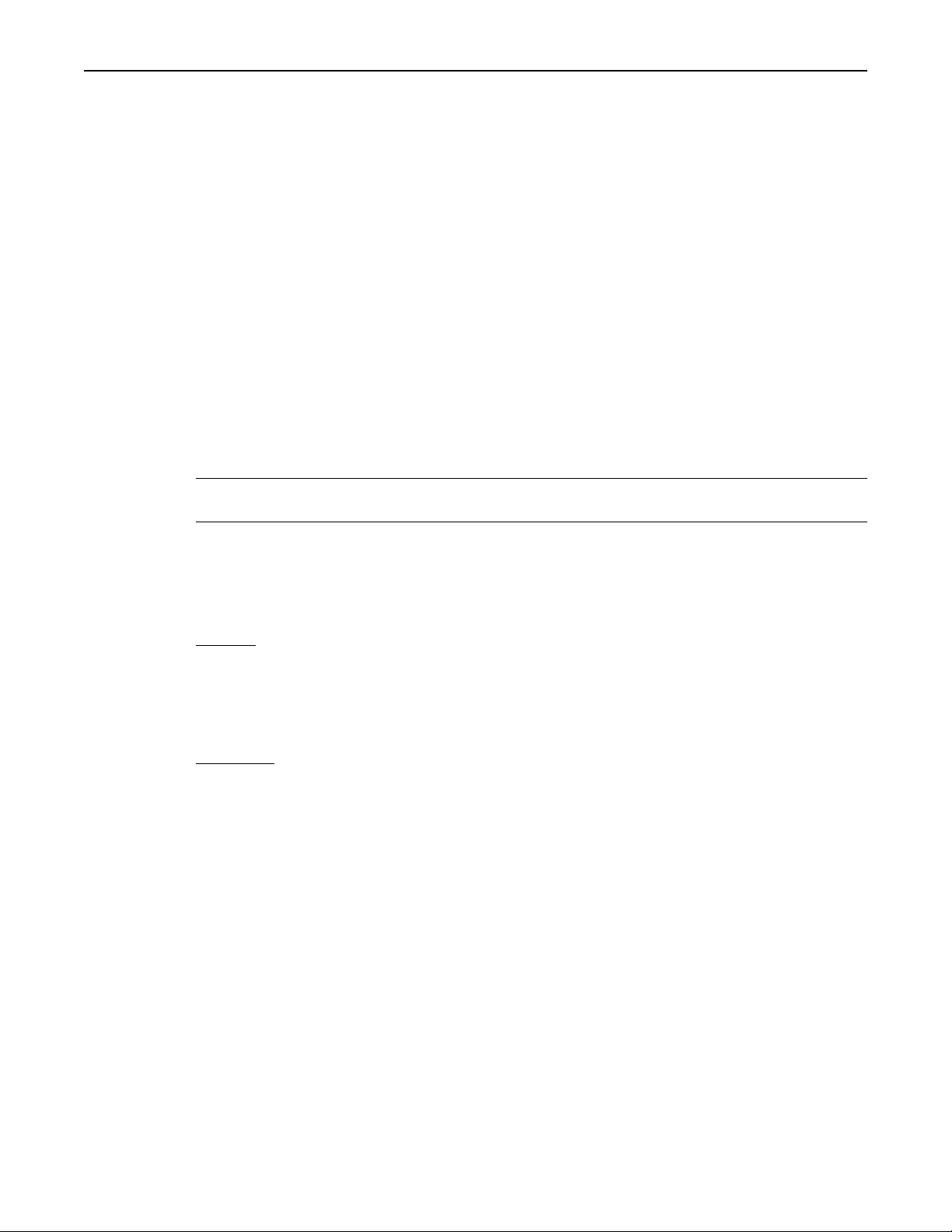

Screen Saver Editor

Use of the screen saver will extend the life of the vacuum florescent display used in the

MAP340D. Maple Systems recommends the use of the screen saver on these models. To

enable the screen saver, check the Enable box and click on the Define button within the

Screen Saver box. The following window will be displayed:

1010-0089, REV00

Page 24

MAPware 100 User's Guide 23

The Delay box is used to select the time that must elapse since the last keypress on the OIT or

the last message received from the PLC before the screen saver is enacted. The range is from

5-60 minutes. The Text box is used to enter the single line screen that will scroll across the

OIT display when the screen saver is active. Note that the extended characters can also be

used here. When finished, click on the Done button to go back to the prior screen.

The Insert Special Character and Clear Current Screen buttons from the main tool bar are

repeated here for convenience.

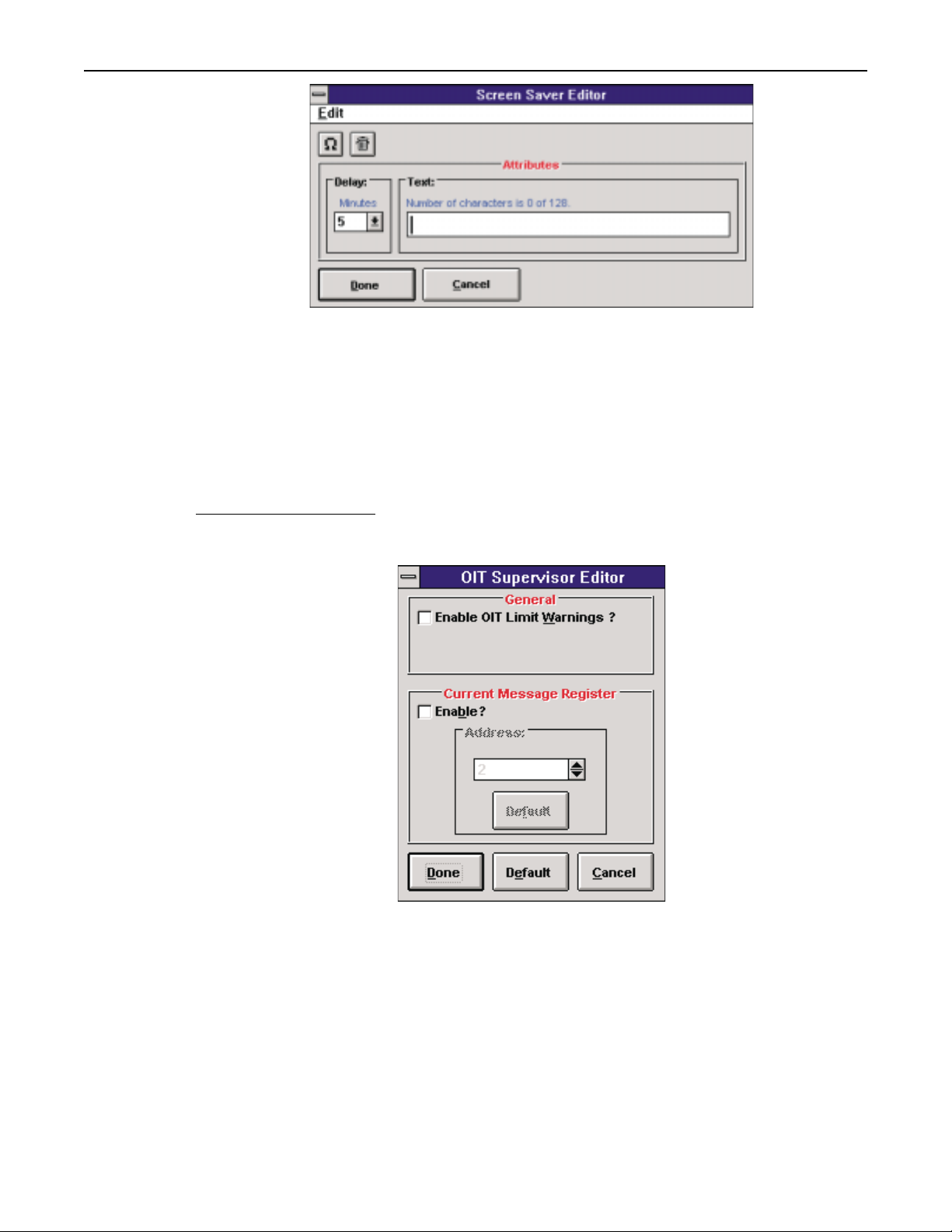

OIT Supervisor Editor

This feature isselected from within theConfiguration Editor and the following screen appears:

The OIT SupervisorEditor allows theenabling or disablingof certain featureson the OIT.

General Group Box:

When the Enable OIT Limit Warnings check box is checked, the OIT displays the high or

low limit for the Register Monitor whose value is being entered out-of-range. Otherwise, the

OIT displays a message indicating that the value being entered is out-of-range.

1010-0089, REV00

Current Message Register Group Box:

When the Enable ? check box is checked, the OIT will place the number of the last message

currently displayed on the OIT into the Current Message Register. This register can then be

used by the PLC to determine which message is shown on the OIT.

Page 25

24 OPERATION

If the Current Message Register is enabled, an address must be specified in the Address text

box. Pressing the Default button, resets the address to the default address which is two

greater than the address set in the Message group box in the Configuration Editor.

The value in the Current Message Register will either be in decimal or BCD format. It

depends on whether the BCD Format check box in the Message group box in the

Configuration Editor is checked.

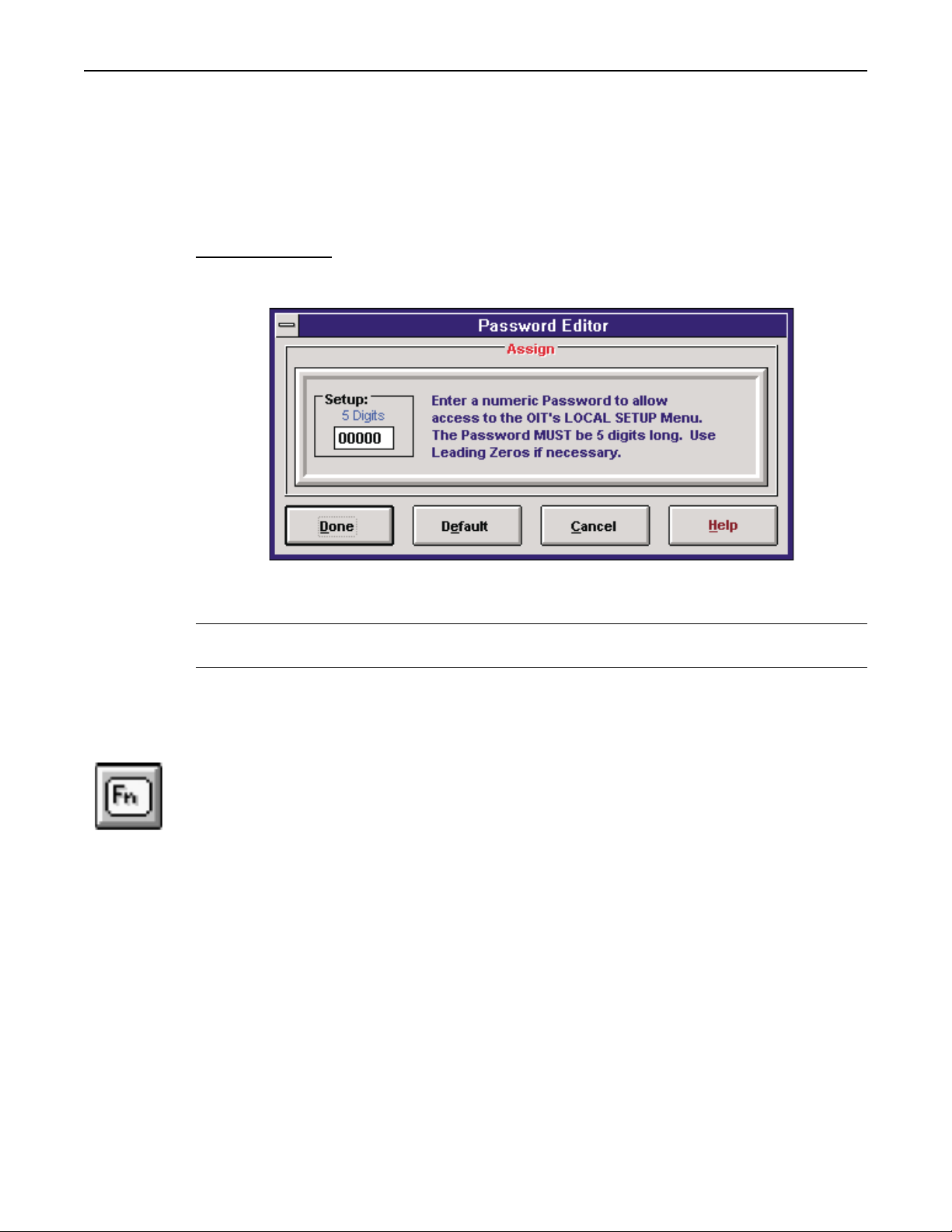

Password Editor

Clicking on theEditor button withinthe Passwords boxwill display thefollowing window:

The setup password is used to gain access to the OIT’s setup menu where local parameters

may be set as well as downloading from the PC.

Note: Make sure you remember the setup password! If you lose it, you will be unable to

download new configuration data or firmware to the OIT!

If the default setting (00000) is selected for the setup password, the operator can enter the

setup menu byentering five 0’s,or using ashortcut which issimply pressing theEnter key.

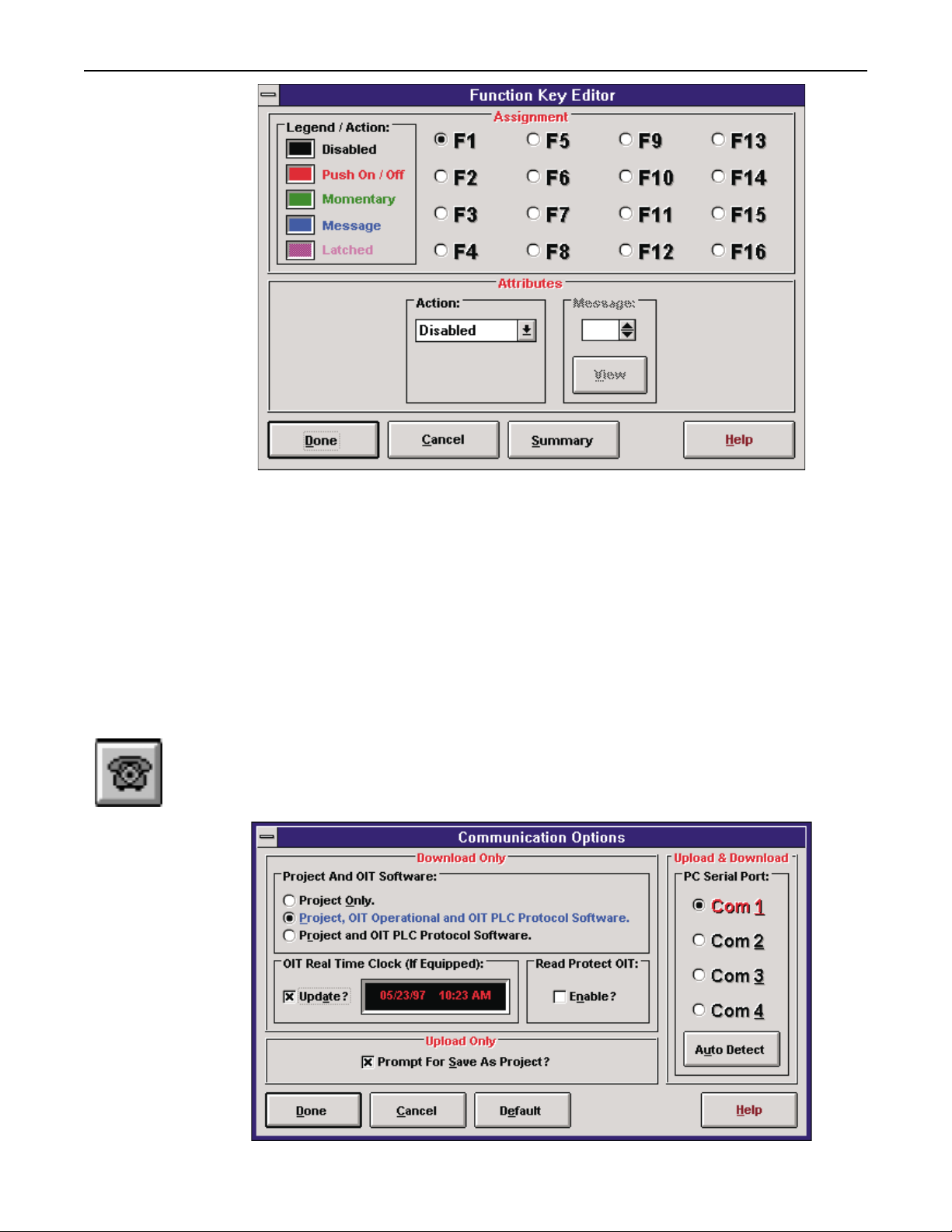

Function Key Editor

The Function KeyEditor button is theshortcut for the Tools/FunctionKey Editor menu item.

The OIT has 12 or 16 programmable function keys, depending on the model. Each key has

the ability to be programmed as disabled, push on-push off, momentary, message display, or

latched. See the MAP Family Operation Manual for a description of each Function Key

mode. Clicking on the Function Keys button will display the function key editor screen:

1010-0089, REV00

Page 26

MAPware 100 User's Guide 25

The Action box is used to dictate the operation of each key. To select a key, use the mouse to click

on a function key in the Status box. The selected function key will darken and its attributes will be

displayed in the Attributes box on the lower half of the screen. Using the mouse, click on the down

arrow in the Action box to display a list of available function key operations. Select one with the

mouse to alter this function key’s operation. As a shortcut, the key can also be configured by

clicking on the appropriate colored square in the Legend/Action box or double clicking over the F

Key orby using the right mouse button. If a function key is configured to display amessage when it

is pressed, the Message box will darken, indicating that it is now valid and will accept data entry.

Set the message number to display using the Message box. The View button will allow you to

browse through the messages to ensure that the proper message has been selected.

Communication Options

The Communication Optionsbutton is theshortcut for theTransfer/Communication Options

menu item. The communication parameters between the MAPware 100 software and the

OIT are configured using the following screen:

1010-0089, REV00

Page 27

26 OPERATION

Notice that COM Ports 1 through 4 are supported, although most machines typically have

COM1 and COM2. The port needs to be set once.

Three options are availableto determinehow theproject informationis to be sent to the OIT. The

Project, Operational, and PLC Protocol option must be used when the OIT is configured for the

first time (default). This selection will send the primary OIT operational software, the PLC

protocol driver, and the project data configuration file to the OIT. The Project and PLC Protocol

option should be used when a previously configured OIT is being configured to attach to a

different PLC. The Project Only option should be used mostoften, after the OIT has been initially

configured and the PLC protocol has already been selected. This option sends the project data

configuration file only and does not send the primary OIT operational software or the PLC

protocol driver. The project data configuration file is everything the system programmer has

created for the OIT using the MAPware 100 software. (For example, messages, function key

configuration, PLC communications parameters, etc.) The Project Only option dramatically

reduces the download time of the OIT. The MAPware 100 software will check to see if the

primary OIT operational software and the PLC protocol driver inthe OIT match what is currently

used in the project and give a warning message if there is a mismatch.

If you select Auto Detect, MAPware 100 will ascertain if the OIT is connected to the

computer correctly and which serial port is attached to the OIT. To use this feature, connect

the OIT to the PC and place the OIT in upload/download mode. MAPware 100 will then

search the PC’s serial communications ports. If an OIT was detected, the serial port will be

set on the Communication Options screen (and saved and restored each time you use

MAPware 100) and the OIT will be reset.

Note: If the Read Protect switch is set then the MAPware will be unable to read from the OIT.

Use caution when using this switch. Note that it is project related and if you set this

switch for the current project, a new project will not have this switch set.

Read from OIT

The Read from OIT button is the shortcut for the Transfer/Read from OIT menu item. The

Read from OIT button allows you to read a project stored in the OIT (refer to the

Communications Options screen). To use this feature, make sure that the OIT is connected to

the PC, is powered up, and that the OIT is in upload/download mode. Select either Transfer

Read from OIT (F11) or the Read from OIT button.

Once selected, the following screen appears:

1010-0089, REV00

Page 28

MAPware 100 User's Guide 27

If you select Options, the Communications Options screen appears.

Note: If you have Prompt for Save As enabled (default), you will be prompted for a file name

to save the project as read from the OIT.

Select OK. If the Prompt for Save As is active, the Save As dialog box will appear.

Note: If the OIT does not have a valid project, the read will terminate. MAPware 100 will then

ascertain if the OIT is read protected. If it is, the read will terminate. Refer to the Read

Protect section for details.

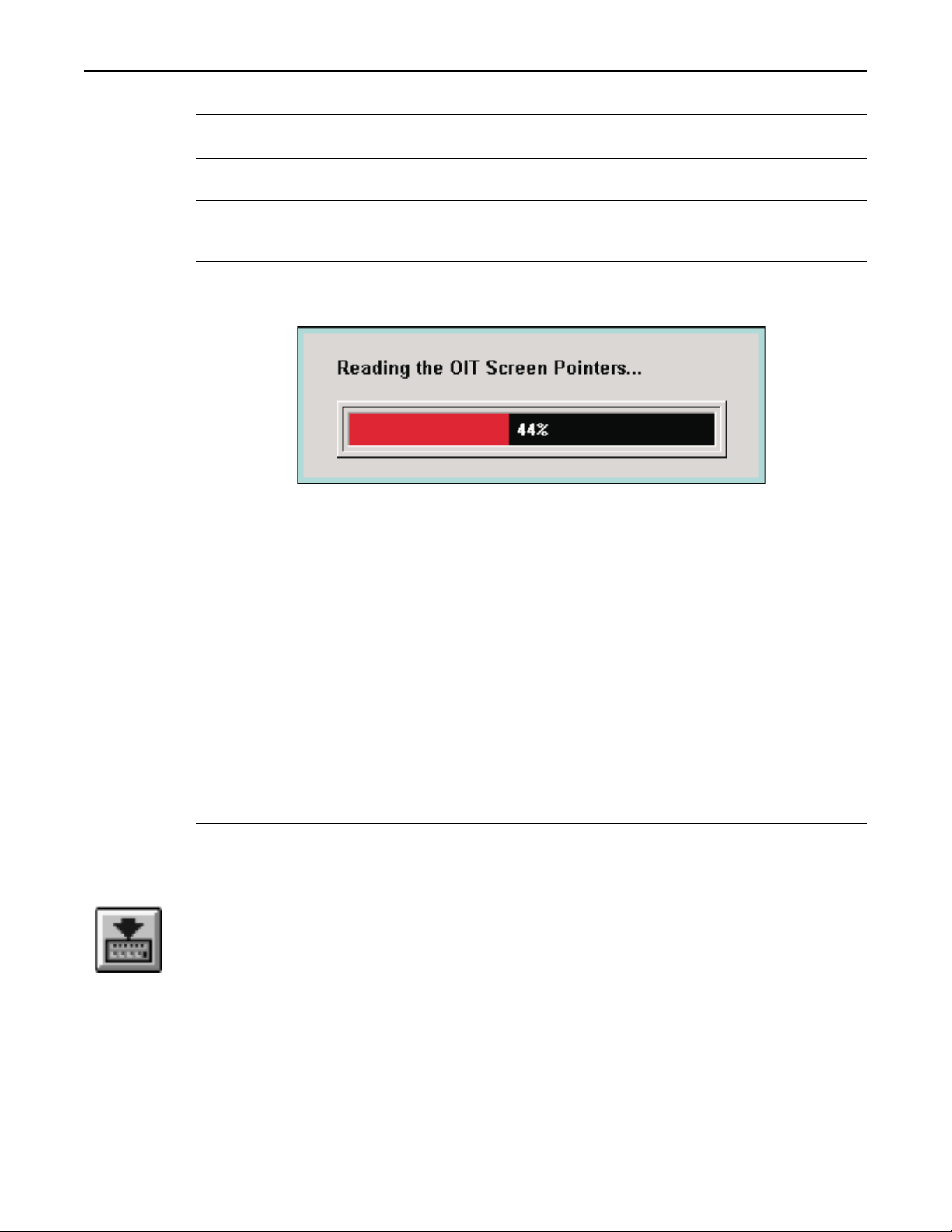

The OIT will now be read by MAPware 100. You can track the status of the read by the “gas

gauge” displayed:

When the read is complete, the OIT will be restarted, and the project you read will be present

on the MAPware 100 screens.

Read Protect

Sometimes it is desirable to read protect the OIT to keep any unauthorized individuals who

have access to MAPware 100 from reading the project stored in the OIT. You can read

protect the OIT in either of two ways:

•

Select the Transfer Read Protect OIT command from the MAPware main menu, under the

Transfer Menu item. When you select this command you must place the OIT in

upload/download mode and insure that the OIT is attached to the PC.

•

Select Read Protect OIT in the Communications Options screen. This switch is project

related. That is, if you select this feature on a particular project, the switch will be set every

time you recall that project. The OIT is read protected as soon as the project is sent to the

OIT.

Note: Once the OIT is read protected, you cannot disable this feature. You may disable this

feature only when a new project is sent to the OIT.

Send to OIT

The Send to OIT button is the shortcut for the Transfer/Send to OIT menu item. This button is

used to actually send a project to the OIT. Before using this command, make sure the OIT is

connected to the correct COM port on the PC. The OIT must be in the local setup menu at the

Download/Upload OIT Project? YES prompt. Select YES by pressing the Enter key on the

OIT. The Computer Communications Mode screen will appear at which time the OIT is ready

to accept information from the PC. The computer candownload the entire project tothe OIT or

the data files only. The entire project would consist of the latest OIT operating code, the latest

PLC protocol driver used by the OIT, and all of the data and screens configured using the

MAPware 100 configuration software. If data files only is selected, the MAPware 100

software will still check the OIT operating code and the PLC protocol driver to ensure that the

1010-0089, REV00

Page 29

28 OPERATION

OIT is using the latest revisions, then proceed to download all of the data and screens created

using the MAPware 100 configuration software. While the OIT internal FLASH EPROM is

being updated, the dialog box that appears will display the percentage of completion.

Depending on how many messages, register monitors, etc. you have programmed into the

project, the download time will vary. Once the project has been downloaded into the OIT, the

configuration of theOIT is permanent; nobatteries are needed to maintain the configuration.

Help

The Help button executes the Windows Help system. Within the help system, you may

search for help on any topic, or read information based on a topic. Keywords have been

entered to make the searching easier on you. At any time, clicking on the Help buttons on a

screen will call up context sensitive help, help about the screen currently displayed, and its

associated features.

OIT/PLC Identification

The information box displays the Maple OIT model currently being programmed on the left

hand side of the screen. The right hand side ofthe information box displays the PLC protocol

which the OIT will use to communicate to the PLC. The OIT programmer should check that

the PLC protocol listed correctly matches the PLC being used before any data screens are

created since all data screens created will be erased if a new PLC protocol is selected. The

center of the information box is used to display the message number of the current message

being edited.

Basic Screen Characteristics

The MAP Family of OITs is line-based instead of screen-based. This means that a message

occupies a single line on the OIT display.

A message screen is used to convey information to the operator. Messages can be text only or

contain PLC register monitors. PLC registers can be placed on the message so that the

operator can see what is happening inside the PLC in real-time. Messages can be chained or

connected to other messages within the system. Chaining allows the OIT programmer to

increase the OIT screen size by creating several pages of messages which are linked to each

1010-0089, REV00

Page 30

MAPware 100 User's Guide 29

other. To enable chaining, click on the Chain check box and enter the message number to

connect to. When the OIT is functioning, the operator presses the Right Arrow key to scroll

through the chained messages.

A message can be displayed in several ways: the PLC may request it, the press of a function

key may display it, or another message may be chained to it.

Message Editor

The message editor is the portion of the screen used to enter information used for the

messages. It is accessed simply by placing the cursor on a portion of the message and

beginning typing. To delete characters from the message, either press the backspace key on

the keyboard or highlight a range of characters and press the delete key on the keyboard. To

highlight a range of characters, use the mouse to move the cursor to one of the desired

characters. Press and hold the left mouse button. Drag the mouse and notice that part of the

message changes color (becomes highlighted). Once the desired characters have been

highlighted, release the left mouse button.

Selected characters and register monitors may be cut, copied, and pasted onto the same

message or other messages. Cutting removes the text or register monitors from the message,

while copying simply makes a copy of the highlighted text and register monitors. After

cutting or copying the desired item, move the cursor to the desired location within the same

message or another message or click on the left mouse button. An outline cursor will appear

on the display. Use the mouse to click on the Paste button on the tool bar. The cut or copied

text will beplaced at the selectedarea of themessage. A right mousebutton menu is available

when the cursor is over the Message Editor area.

Message Scroll Bar

The scroll bar to the right of the message editor is use to move easily between messages

during the editing process. To jump directly to a given screen, use the Edit/Go To Message

menu or press the Control G shortcut key.

General Options Group Box

Line Number (1 to 2)

The Line Number is used to specify which line of the OIT display the message will display

on.

Start-up Message

The startup message is used to select a message which will always be displayed when the

OIT is initialized. Only one messagecan be selected as the startup message. If no message is

selected, then the OIT will initialize and display a blank screen.

Extensions

The Chain feature allows the message being edited to chain to another message specified in

the Message box.

1010-0089, REV00

Page 31

30 OPERATION

OIT Memory Used Group Box

OIT Memory Used is an indicator that displays the amount of memory that has been

consumed. No more configuration data may be stored once the OIT Memory Used shows

100%.

The amount of memory required for a project varies depending upon how the system is set

up. There aren’t really any hard boundaries for how many register monitors may be

programmed. The actual number is determined by how much memory is consumed during

configuration. The reserved memory space is dynamically allocated; that is, messages don’t

all require the same amount of space. Maple Systems has invested a lot of effort in ensuring

that maximum efficiency is attained with the memory that is available. Therefore, the

amount of memory required for a message depends on a number of things: how many

blinking characters there are, how many register monitors there are, and what type of register

monitors are stored on the message. Because there aren’t any pre-defined limits on the

configuration database, the OIT Memory Used was added to the main screen as an indicator

of the amount of remaining free memory.

Message Utilization

From the Tools menu, select Message Utilization (or Control + U). The Message Utilization

screen appears. This screen displays the amount of messages used in the project, their type,

and their location within the project. The screen shows 250 messages at a time. You may

select 1–250 or 251–500.

1010-0089, REV00

Page 32

MAPware 100 User's Guide 31

If you use the mouse, you can click on any of the displayed messages. In the Characteristics

area located at the bottom of the screen, the message you are reviewing will have relevant

characteristics displayed (such as chaining, etc.). The caret will move along with the mouse

click. When you move the mouse over the screen suite, the message you are over is displayed

in red in the lower left corner.

Each of the messages displayed will have a different color, based on the line number. To

view the message, click on the message you want to view, then select the View button. To go

to the message,either double clickon the messageor click andthen press GoTo Message.

1010-0089, REV00

Page 33

32 MAPware 100 User's Guide

TROUBLE SHOOTING

MAPware 100 Does Not Transfer a Project to the OIT

If MAPware 100 halts during a download or indicates that the OIT is not connected:

1. Make sure that the serial cable is connected to the right PC and OIT ports.

2. Make sure that the OIT is powered and is in download mode.

3. Make sure that MAPware 100 is configured for the correct serial port.

4. Check cable connections and pinouts to ensure proper configuration.

5. If all else fails, save your project and then try rebooting your computer.

OIT Screen is Blank and the OIT is Beeping

If the OIT has a blank screen and is beeping, this indicates that an MAPware 100 project was

not completely transferred to the OIT. However, there is nothing wrong with the OIT.

The OIT is in download mode. Simply resend the project from MAPware 100 and the OIT will

restart normally.

The OIT Does Not Attach to the PLC

If the OITis displaying a message indicatingthat it is attemptingto attach to the PLC(and the

attachment successful message never appears), the OIT is not correctly programmed to

communicate with the PLC.

1. Make sure that the serial cable is connected to Port 1 on the OIT.

2. Look at your MAPware 100 project. The PLC selected using Start New Project is

displayed in the right hand corner of the screen. If the PLC selected is incorrect you

must start a new project. Refer to Step 3.

1010-0089, REV00

MAPware 100 Main Screen

Page 34

TROUBLE SHOOTING 33

3. Power is not being supplied to the PLC. Check power supply and cabling to ensure a

successful power connection.

4. The default values in the Configuration Editor may not be appropriate for the

requirements of the PLC you are using. The default values are designed to work with the

chosen PLC in most cases, but may not work in all cases, especially if ladder logic values

have been changed drastically. Adjust the Configuration Editor parameters and resend the

project to the PLC. If this does not work, refer to the appropriate Maple Systems PLC

Protocol Guide for more information or contact Maple Systems Technical Support at

425-486-4477.

1010-0089, REV00

Loading...

Loading...