Page 1

Page 2

COPY RIGHT NO TICE

This manual is a publication of Maple Systems, Inc., and is provided for use by its customers only. The contents of the

manual are copyrighted by Maple Systems, Inc.; reproduction in whole or in part, for use other than in support of Maple

Systems equipment, is prohibited without the specific written permission of Maple Systems. HMI600 and Ivory Series are

trademarks of Maple Systems, Inc. IBM, PC/AT, and PS/2 are trademarks of International Business Machines Corporation.

Windows CE, Windows XP Embedded and ActiveSync are trademarks of Microsoft Corporation. WebStudio is a trademark

of Indusoft Corporation. All other brand and product names mentioned herein are trademarks or registered trademarks of

their respective holders.

LIM I TA TIONS OF USE

The XPe device may not be used in any device or system in which a malfunction of the operating system would result in

foreseeable risk of personal injury, death to the operator of the device or system, or to others, or severe physical or

environmental damage.

WAR RANTY

Maple Systems warrants each product to be free from electrical and mechanical defects in materials and workmanship for a

period of two years from the date of shipment. This warranty does not apply to defects in the Products caused by abuse,

misuse, accident, casualty, alteration, negligence, repair not authorized by Maple Systems, use on current or voltages other

than specified by Maple Systems, or application or installation not in accordance with published instruction manuals. This

warranty is in lieu of any other warranty either expressed or implied.

Maple Systems’ liability is limited to the repair or replacement of the Product only, and not costs of installation, removal, or

damage to user’s property or other liabilities. If Maple Systems is unable to repair or replace a nonconforming Product, it

may offer a refund of the amount paid to Maple Systems for such Product in full satisfaction of its warranty obligation.

Maximum liability of Maple Systems is the cost of the Product.

Information furnished by Maple Systems, Inc., is believed to be accurate and reliable. However, no responsibility is assumed

by Maple Systems for the use of this information nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication, or otherwise, under any patent or patent rights of Maple

Systems, Inc. Maple Systems retains the right to revise or change its products and documentation at any time without notice.

IF SER VICE IS RE QUIRED

Package the unit in its original packaging container or, if unavailable, any suitable rigid container. If a substitute container is

used, surround the unit with shock absorbing material; damage in shipment is not covered by the warranty. Include a letter

with the unit describing the difficulty and designating a contact person. Send to the following address: Maple Systems, Inc.,

808 134th Street SW, Suite 120, Everett, WA 98204-7333.

Only Products that have been issued a Return Material Authorization (RMA) number from Maple Systems may be returned.

All RMAs must be accompanied with a written purchase order for tracking purposes or, in the case of out-of-warranty

repairs, for repair charges on a time and material basis.

All returns will be tested to verify customer claims of noncompliance with the product warranty. Improper return packaging,

which makes verification impossible, will void the warranty. Products passing the tests will be returned “AS IS” to the

customer.

If noncompliance is verified and is not due to customer abuse or the other exceptions described with product warranty, Maple

Systems will, at its option, repair or replace the Product returned to it, freight prepaid, which fail to comply with the

foregoing warranty, provided Maple Systems is notified of such noncompliance within the two-year warranty period.

AP PLI CA TIONS AS SIS TANCE

This man ual is de signed to pro vide the nec es sary in for ma tion for trou ble-free in stal la tion and op er a tion of your new Ivory

Series Panel PC; how ever, if you need as sis tance, please call Ma ple Sys tems at 425-745-3229 or visit our web site at

www.ma plesystems.com.

Page 3

Ta ble of Con tents

About Your Doc u men ta tion ..........1

Con ven tions...................1

What You Need ................2

What is an Ivory Se ries Panel PC?...2

Win dows CE Ba sics.................3

Win dows XPe Ba sics ................3

List of Fea tures....................3

Con nect ing to a PC ................3

Chap ter 1 - In stal la tion In struc tions.........5

Be fore You Be gin ..................5

Un pack ing the Unit .............5

Man ag ing Elec tro static Dis charge ...5

CE Com pli ance ................5

NEMA Rat ing ..................5

FCC Class A Rat ing .............5

En vi ron men tal Con sid er ations .....5

Safety Pre cau tions ..............6

Con trol Panel De sign Guide lines ......7

Con trol Panel Ground ing .........7

Con nect Panel PC Chas sis Ground to

Con trol Panel..................8

Power Sup ply Se lec tion ..........8

Ca ble Rout ing and Noise Im mu nity . 9

In stal la tion.......................9

Con nect the Panel PC to Power ....9

Panel Prep a ra tion ..............11

Mount the Panel PC to the Panel ...12

Com mu ni ca tions ..................13

COM1 [RS232]/COM2 [RS232] ....13

COM1 [RS-485 2/4 W] Port ,

COM3[RS485], COM3[RS232] Port..14

Con nect ing to the Panel PC Us ing

Ethernet ......................14

USB Host Port .................15

USB Cli ent Port ................15

Com pact Flash ....................15

Print ing - Win dows CE ..............15

Print ing - Win dows XPe .............16

Us ing a Net worked Printer - Win dows CE

and Win dows XPe .................16

Fac tory Con fig u ra tion...............17

What Co mes with the Ivory Se ries Panel

PC? .........................17

Dip Switch Set tings..............17

Chap ter 2 - Us ing Win dows CE.net & Win dows

XPe..................................19

What is Win dowsTM CE.net 5.0? ......19

Util i ties .........................19

Soft Key board .................19

Sys tem Set tings ................20

NorFlash .....................24

Start Up ......................24

Re mote Desk top Con nec tion ......25

About Win dows XPe ................26

Chap ter 3 - Net work ing..................27

Net work ing Via Ethernet Us ing

Win dows CE......................27

Net work ing Via Ethernet Us ing

Win dows XPe .....................27

Net work ing via Se rial Port Us ing

Win dows CE......................27

In stall ing Ac tive Sync ............27

Web Browser .....................29

Chap ter 4 - De vel op ing Ap pli ca tions ........31

Win dows CE......................31

Microsoft Vi sual Stu dio 2008 ......31

Microsoft eM bed ded Vi sual C++ 4.0 31

Ivory Se ries SDK................31

Win dows XPe .....................31

Chap ter 5 - Us ing Third Party Soft ware to

Con fig ure the Ivory Se ries Panel PCs ........33

Indusoft WebStudio ................33

Other HMI Con fig u ra tion Soft ware.....33

Chap ter 6 - Main te nance and Sys tem

Con fig u ra tion .........................35

Fuse Main te nance .................35

Clean ing the Over lay ...............35

Cal i brat ing the Touchscreen..........35

Sys tem Con fig u ra tion ...............37

Page 4

Introduction 1

Introduction - Welcome

Welcome to the Maple Systems' Ivory Series of Panel PCs. This powerful family of Panel PCs can be configured with any

Windows CE or Windows XP Embedded compatible HMI software, such as WebStudio, to connect to programmable logic

controllers (PLCs) and motion controllers to provide the human-machine interface in industrial applications. This manual

explains the installation and operation of the Ivory Series.

About Your Doc u men ta tion

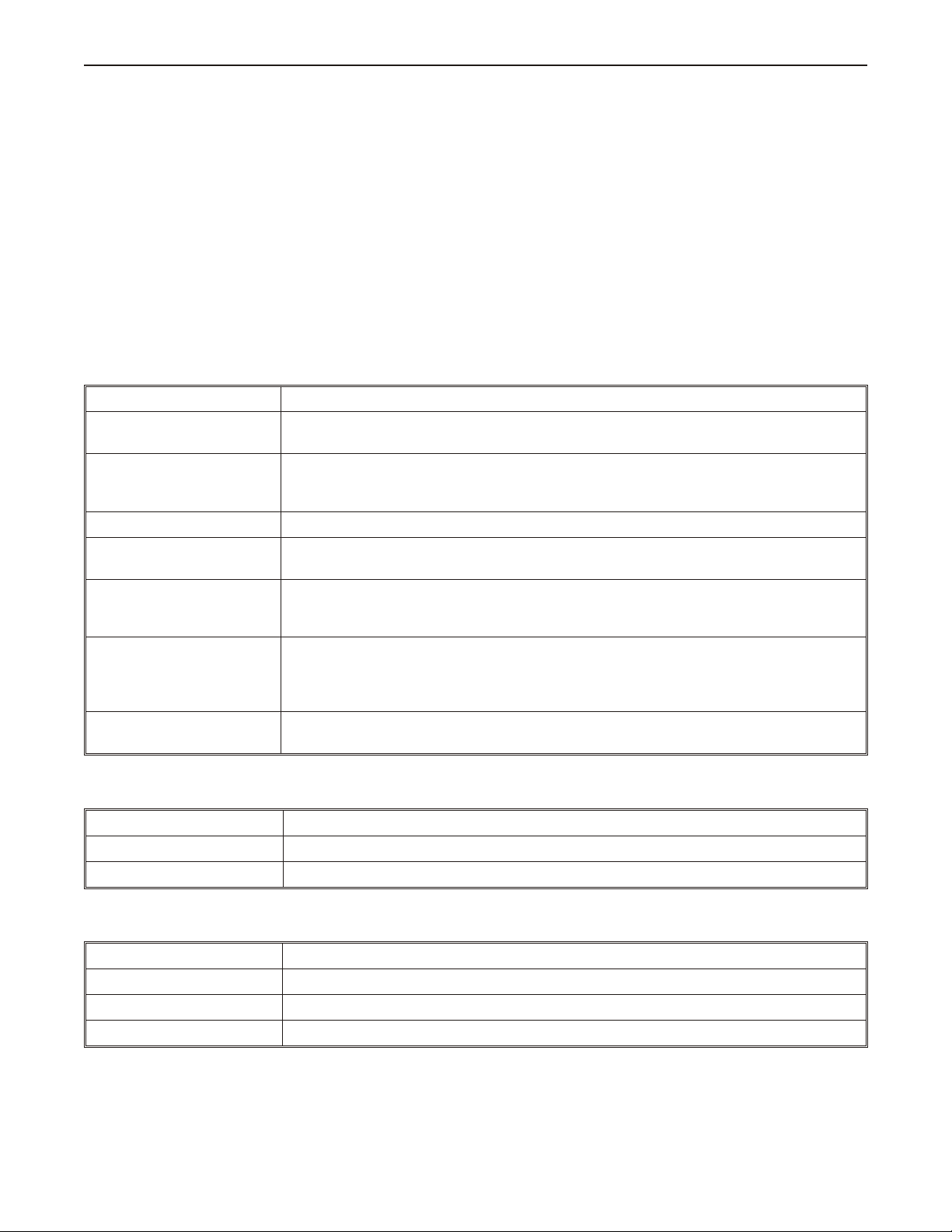

Con ven tions

In most cases, we will describe each method when the task is first discussed. The menu method is then used whenever the

task is used in later procedures. Other conventions used in this book are listed in the following table.

Convention Meaning

Bold

Italic

ALL CAPITALS Directory names, file names, key names, and acronyms

KEY1+KEY2

click

Double-click

Right-click

Characters that you must type exactly as they appear. For example, if you are directed to

type a:\setup, you should type all the bold characters exactly as they are printed.

Placeholders for information you must provide. For example, if you are directed to type

filename, you should type the actual name for a file instead of the word shown in italic

type. Italics are also used to indicate a glossary term.

A plus sign (+) between key names means to press and hold down the first key while you

press the second key.

When referring to the touch screen, click means to tap icon onscreen once with either a

finger or stylus. When referring to a computer with a mouse, click refers to clicking the

left mouse button once.

When referring to the touchscreen, this refers to quickly tapping an onscreen icon twice in

rapid succession with either a finger or a styles. When discussing a computer with a

mouse, refers to quickly clicking the primary mouse button (usually the left mouse button)

twice.

Refers to clicking the secondary mouse button (usually the right mouse button) once.

Right-clicking usually opens shortcut menus.

The following terminology will be used when referring to computers and PCs:

Term Meaning

Panel PC Refers to the Ivory Series Panel PC

PC Refers to a desktop PC - not the Ivory Series Panel PC

The following table identifies symbols and margin icons.

Icon Meaning

4 Identifies a procedure.

4 Indicates a reference to additional information.

Indicates an important note.

1010-1010 Rev 02

Page 5

2 Ivory Se ries In stal la tion & Operation Man ual

What You Need

The following items are needed to configure and operate your Panel PC.

Configuration Software WebStudio or other CE or Windows XP Embedded (XPe)-compatible HMI software.

Configuration Cable

(Panel PC to PC)

Personal Computer

1

7431-0106

User Provided

Power Cable 6030-0009

24VDC Power Supply User Provided (for details refer to Appendix A: Specifications)

PLC User Provided

1PC requirements include at least a Pentium IV-compatible PC; 256MB RAM; 500MB available hard disk space; VGA or

SVGA display adapter; Microsoft Windows 2000, XP, Vista, 2003/2008 server or NT, and one available RS-232 serial port.

What is an Ivory Se ries Panel PC?

The Ivory Series is a compact Panel PC designed to operate in an industrial environment. The Ivory Series employs a

RISC-based ARM processor and Flash technology embedded with the Microsoft® Windows® CE.net™ or Microsoft

Windows XPe operating system. These models include the following key features:

• All-in-one platform: The CPU, DRAM and even Windows CE or XPe are integrated. The Ivory Series is

a plug-and-play machine.

• Slim but robust: The Ivory Series is very thin (50mm thickness); nevertheless, its plastic bezel provides

protection in harsh industrial environments - protecting against dust and water, and providing resistance to

chemicals.

• EMI protection: The Ivory Series meets standards for electrical noise emissions and immunity according

to the European CE directives.

• Excellent display characteristics: The Ivory Series uses 65K color TFT displays for high brightness and

contrast clarity.

• Fanless operation: The low power consumption and fanless design provide reliable operation and longer

lifespan.

• Powerful communications capability: The Ivory Series provides serial ports, Ethernet port, USB ports

and sound and IDE expansion ports (HMI 615X, HMI612X, HMI610X and HMI608T models). Compact

flash is available on T models only.

• Windows CE or Windows XPe Support: The Ivory Series offers platform support for either Windows

CE.net (5.0) or Windows XPe. These operating systems allow the user to develop his own application

software or use a number of available third-party applications.

There are currently EIGHT models in the Ivory Series:

Model

Display

Size

Resolution

HMI606T 5.7" 320x234

HMI608T 8.8" 640 x480

HMI610X-CE 10.4" 640x480

HMI610X-XP 10.4" 640x480

HMI612X-CE 12.1" 800x600

HMI612X-XP 12.1" 800x600

1010-1010 Rev 02

LCD

Type

65K-color

TFT

65K-color

TFT

65K-color

TFT

65K-color

TFT

65K-color

TFT

65K-color

TFT

Brightness

(cdm2)

Contrast Ethernet

Compact

Flash

500 250:1 Yes Yes CE

400 250:1 Yes Yes CE

400 300:1 Yes No CE

400 300:1 Yes No XPe

450 600:1 Yes No CE

450 600:1 Yes No XPe

Operating

System

Page 6

Introduction 3

HMI615X-CE 15" 1024x768

HMI615X-XP 15" 1024x768

65K-color

TFT

65K-color

TFT

350 700:1 Yes No CE

350 700:1 Yes No XPe

Win dows CE Ba sics

The Ivory Series comes preloaded with either MicrosoftÒ WindowsÒ CE.netÔ 5.0 or Windows XPe. Windows CE.net is a

real-time embedded operating system for use in small foot print and mobile devices. With a complete operating system

feature set and comprehensive development tools, Windows CE.net contains the features developers need to build, debug,

and deploy customized Windows CE.net-based devices. Some basic benefits of Windows CE.net 5.0 include:

• Secure networking

• Enhanced real-time processing

• High-speed performance

• Multimedia and Web browsing capabilities

• Connectivity with PCs, Servers, PLCs, and other devices

Win dows XPe Ba sics

Windows XP for Embedded (Windows XPe) Systems is an edition of Windows XP that contains the full feature set of

Windows XP Professional, but has restrictions on licensing that requires that it be used in a process-specific application.

Some of the benefits of XPe include:

• Secure networking

• Enhanced real-time processing

• High-speed performance

• Multimedia and Web browsing capabilities

• Connectivity with PCs, Servers, PLCs, and other devices

• USB or Network Boot capability

• File sharing capability

List of Fea tures

The Ivory Series has a host of features that make it the ideal open-platform Panel PC for every application:

• One Ethernet port for networking or Internet connection

• Two device-ready USB ports on the HMI606 and three on the HMI615X/HMI612X HMI610X/HMI608T

• Two serial ports for RS232, RS422 or RS485 communications

• One RS232 port for downloading application software

• Built-in 32 MB Flash memory (T Models)

• Built-in 256 MB DOM (X models with CE)

• Built-in 2 G DOM (X models with XPe)

• 64 MB DRAM

• 256 MB DDR (all X models)

• Built-in compact flash port is available on T models

• Fanless, low-power operation

Con nect ing to a PC

To connect the Ivory Series to a PC for configuration, refer to Chapter 3, under Networking via Serial Port.

1010-1010 Rev 02

Page 7

4 Ivory Se ries In stal la tion & Operation Man ual

1010-1010 Rev 02

Page 8

In stal la tion Instructions 5

Chapter 1 - Installation Instructions

Be fore You Be gin

Please read the following for proper handling of your new Ivory Series Panel PC.

Un packing the Unit

Carefully unpack the Panel PC. Please read any instructions or cautions that appear on the shipping container.

Check all material in the container against the enclosed packing list. Maple Systems, Inc. will not accept

responsibility for shortages against the packing list unless notified within 30 days. The equipment and its

accessories were inspected and tested by Maple Systems before shipment; all of the equipment should be in good

working order. Examine the equipment carefully; if any shipping damage is evident, notify the carrier immediately.

You are responsible for claim negotiations with the carrier. Save the shipping container and packing material in

case the equipment needs to be stored, returned to Maple Systems, or transported for any reason.

Man aging Elec tro static Dis charge

It is best NOT to remove the rear enclosure of the Panel PC. When the rear part of the enclosure is removed, the

circuitry inside is exposed to possible damage by electrostatic discharge during handling. Minimize the possibility

of electrostatic discharge by:

• Discharging personal static by grounding yourself prior to handling the computer

• Handling the computer at a static-free grounded workstation

• Connecting the frame ground ( FG ) connector of the computer to a clean earth ground

• Placing the computer in an anti-static bag during transport

CE Com pli ance

The Ivory Series Panel PCs have been tested to conform to European CE requirements per Council Directive

89/336/EEC. The European Union created these requirements to ensure conformity among products traded in those

countries. Specifically, the Ivory Series Panel PCs meet or exceed the noise emissions and immunity requirements

as set forth in the EN50081 (Emissions) and EN50082 (Immunity) standards. These products are designed to

withstand electrical noise in harsh industrial environments. They also conform to requirements that limit electrical

emissions. However, this does not guarantee that the products will be totally immune from possible malfunction in

cases where severe electrical noise occurs. Therefore, we strongly recommend that you follow the guidelines

outlined in this chapter for proper wire routing and grounding to insure the proper operation of the Ivory Series

Panel PC.

NEMA Rat ing

The Ivory Series Panel PCs are rated for NEMA 4 (indoor). This means that when the Panel PC is properly

mounted to a panel or other enclosure, the front enclosure of the Panel PC will provide protection to the inside of the

panel from splashing water, wind blown dust, or hose-directed water. The computer must be installed according to

the instructions in this chapter to be properly sealed.

FCC Class A Rat ing

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency

energy. If not installed and used in accordance with this user’s manual, it may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at his own expense.

En vi ron men tal Con sid er ations

The Ivory Series is designed to operate in temperatures from 0-45° C. It is intended for indoor installations and not

designed for outdoor applications. Avoid installing the Ivory Series in environments with severe mechanical

1010-1010 Rev 02

Page 9

6 Ivory Se ries In stal la tion & Op er a tion Man ual

vibration or shocks. Do not install the computer in enclosures with rapid temperature variations or high humidity.

Either will cause condensation of water inside the device and eventual damage to the computer.

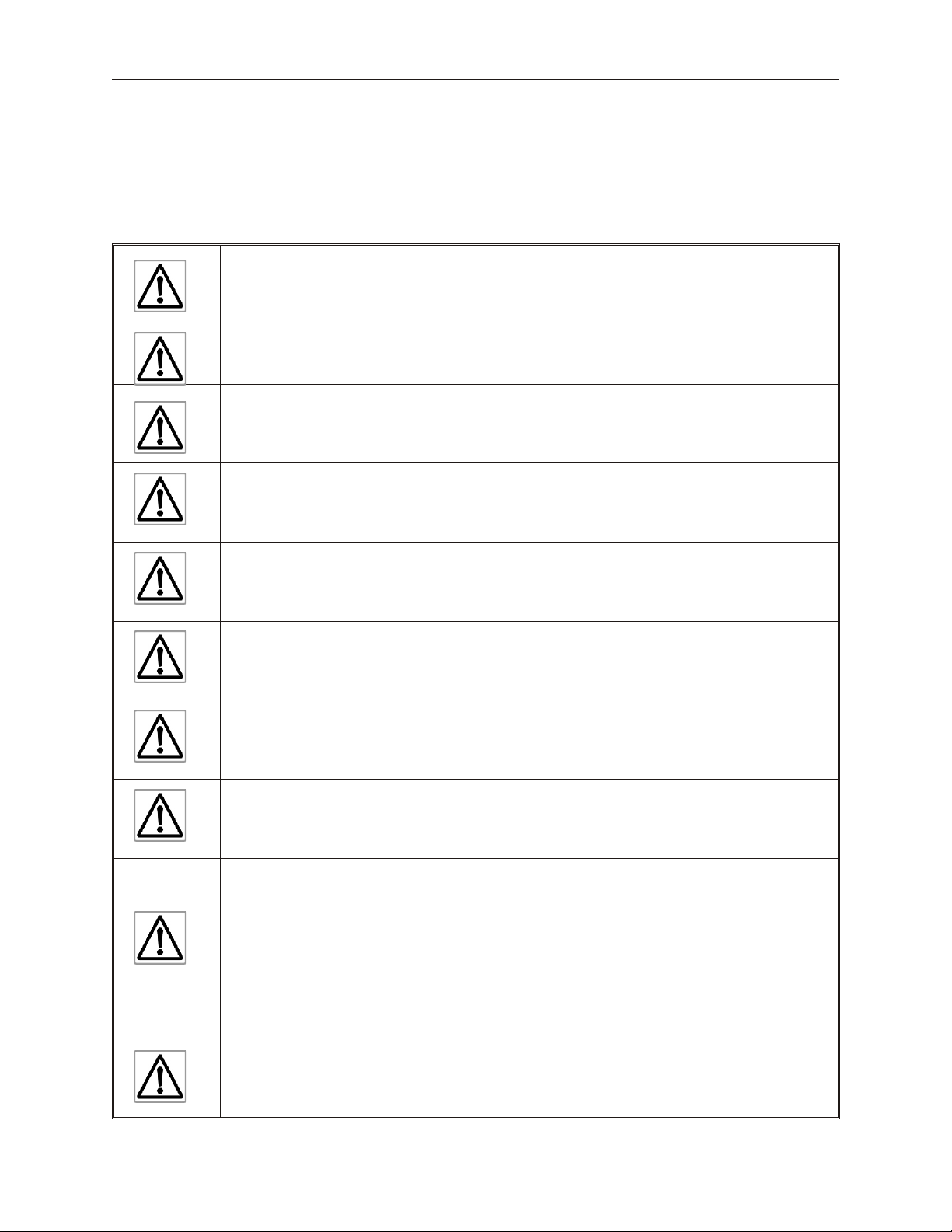

Safety Pre cau tions

Please observe the following precautions when installing the Ivory Series Panel PCs. Failure to comply with these

restrictions could result in loss of life, serious personal injury, or equipment damage.

Warning: Disconnect this equipment from any AC outlet before cleaning. Do not use liquid

or spray detergents for cleaning. Use a damp cloth.

Warning: Keep this equipment away from humidity.

Warning: The openings on the enclosure are for air convection. Protect the equipment from

overheating. DO NOT COVER THE OPENINGS.

Warning: Make sure the voltage of the power source is correct before connecting the

equipment to the power outlet.

Warning: Position the power cord so that people cannot step on it. Do not place anything

over the power cord.

Warning: If the equipment is not used for a long time, disconnect it from the power source

to avoid damage by transient over-voltage.

Warning: Never pour any liquid into an opening. This could cause fire or electrical shock.

Warning: Never open the equipment. For safety reasons, the equipment should be opened

only by a qualified service technician.

Warning: If any of the following situations arise, get the equipment checked by qualified

service personnel

• The power cord or plug is damaged.

• Liquid has penetrated into the equipment.

• The equipment has been exposed to moisture.

• The equipment does not work well, or you cannot get it to work according to the

installation reference guide.

• The equipment has been dropped and damaged.

• The equipment has obvious signs of breakage.

1010-1010, Rev 02

DO NOT LEAVE THIS EQUIPMENT IN AN UNCONTROLLED ENVIRONMENT WHERE

THE STORAGE TEMPERATURE IS BELOW - 20°C (-4° F) OR ABOVE 60°C (140° F). IT

MAY DAMAGE THE EQUIPMENT.

Page 10

In stal la tion Instructions 7

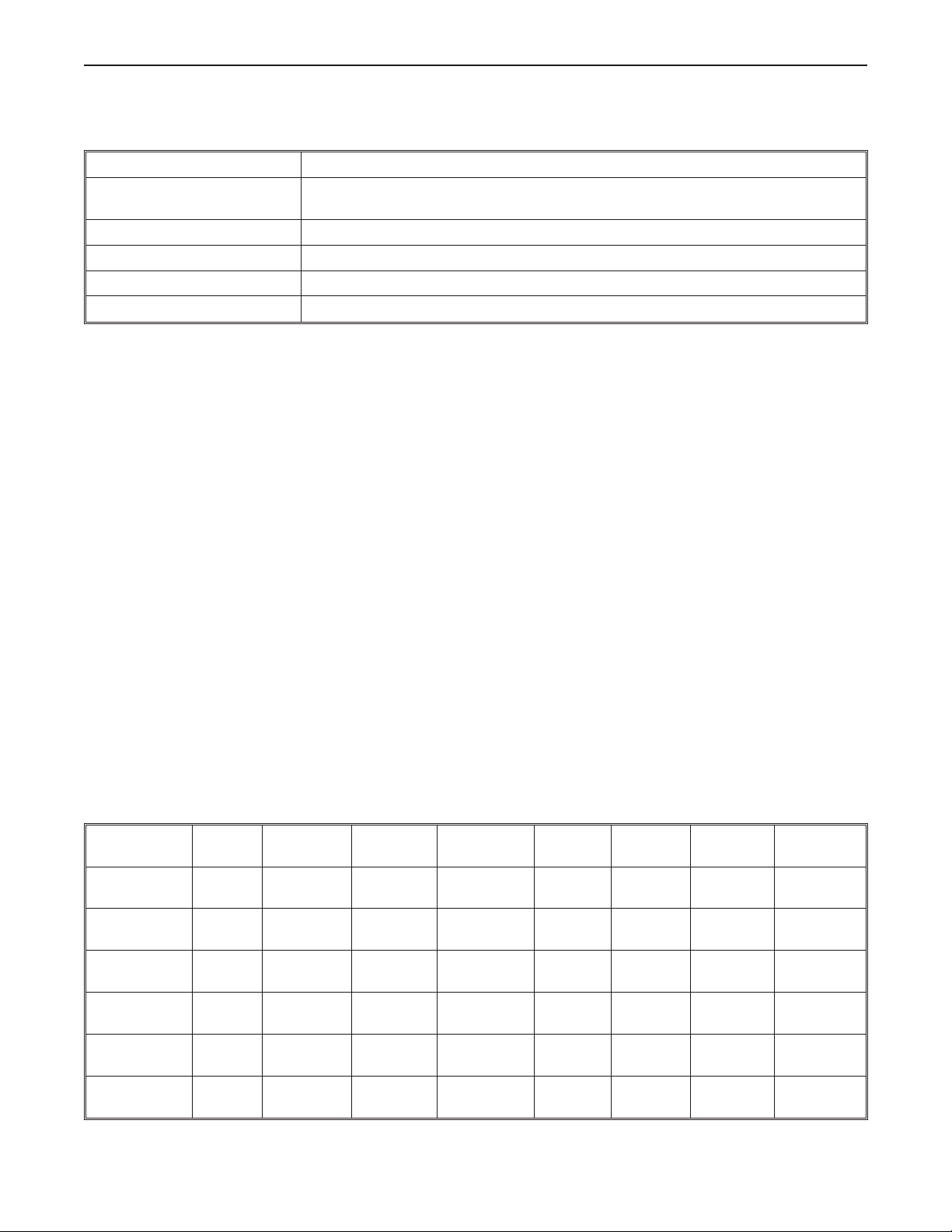

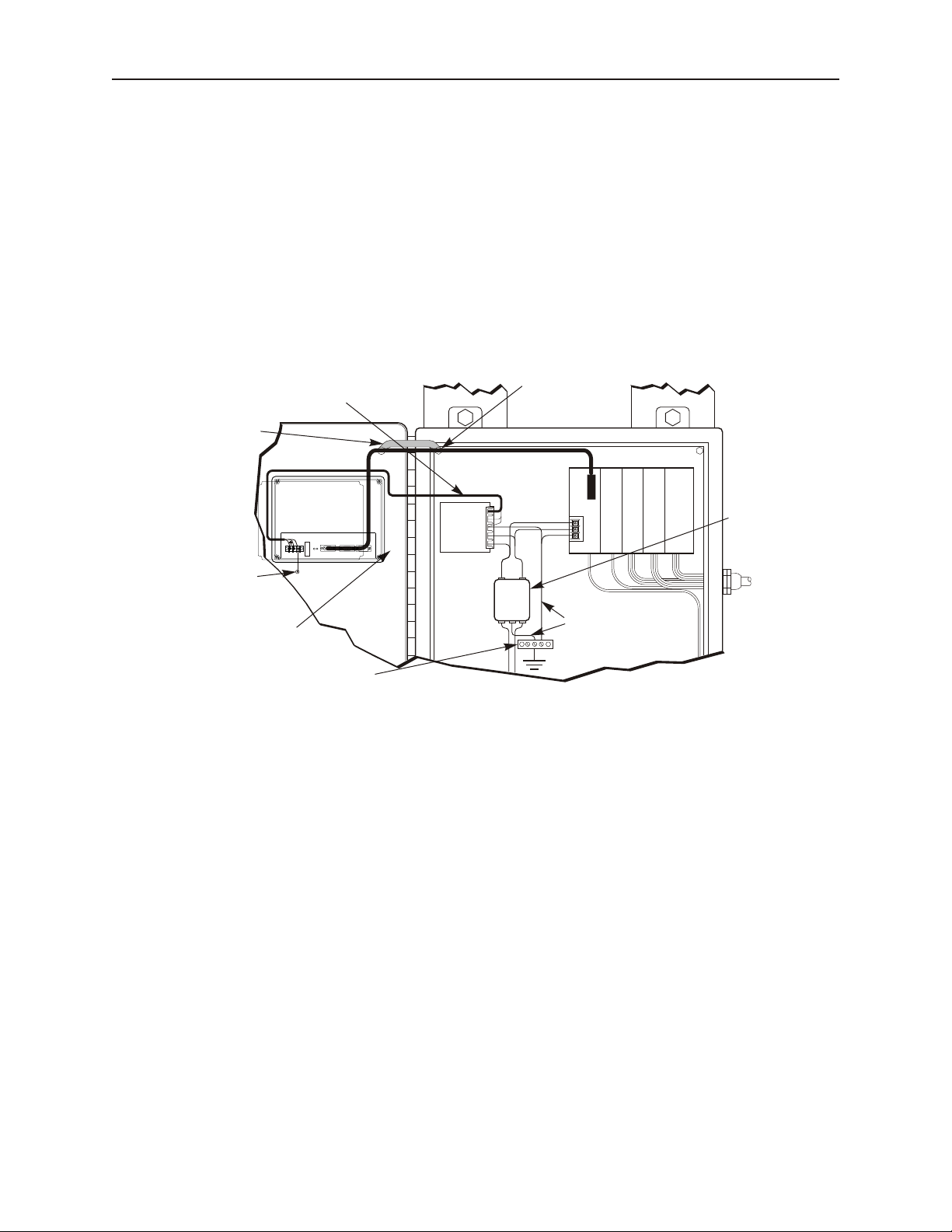

I / O control lines

PLC/Host

Ground wires

(rear side)

Panel PC is

grounded to

control panel

Ground

strap

Power

line

filter

Quiet ground

(isolated)

Quiet ground

Line

Filter

Power

Supply

Shielded power cable

Shielded

communication

cable

Control panel is

tied to a reliable

earth ground

Ivory Series

Panel PC

24V

GND

COM1 [RS-485 2/4W]

PLC [RS-232]

COM3 [RS-485]

COM3 [RS-232]

COM1 [RS-232]

COM2 [RS-232]

In addition, please observe all of the following safety precautions:

• Read these instructions carefully.

• Keep this installation reference guide for later reference.

• For pluggable equipment, the power outlet must be installed near the equipment and must be easily

accessible.

• Put this equipment on a reliable surface during installation. Dropping it or letting it fall could cause

damage.

• All cautions and warnings on the equipment should be noted.

Con trol Panel De sign Guide lines

Pay careful attention to the placement of system components and associated cable routing. These items can

significantly enhance the performance and integrity of your control application.

Con trol Panel Example

Con trol Panel Ground ing

The control panel should be connected to a good, high-integrity earth ground both for safety considerations and

shielding purposes. Maple Systems cannot overemphasize the importance of good grounding. If you fail to use

good grounding procedures during installation, sporadic malfunction of the Panel PC may occur:

· Connect the Panel PC's chassis ground terminal to a reliable earth ground with a low-resistance path.

· Route all earth ground wires that lead from the computer, the PLC, the power supply, and the line filter to a

central earth ground point such as a barrier strip. This will ensure that no ground current from one device

influences the operation of the other devices.

· Connect the Panel PC's chassis ground terminal to the control panel door using a heavy-gauge short braided

cable or ground wire to minimize resistance.

· Connect the power cable’s shield wire to the Panel PC’s chassis ground terminal.

· Connect the control panel to earth ground using a copper grounding rod close to the Panel PC and control

panel.

Hinged doors on control panels do not provide a long-term electrical connection to the rest of the enclosure.

Corrosion develops over time and prevents good electrical contract. For this reason, a separate wire braid should be

installed from the hinged control panel to the rest of the enclosure.

1010-1010, Rev 02

Page 11

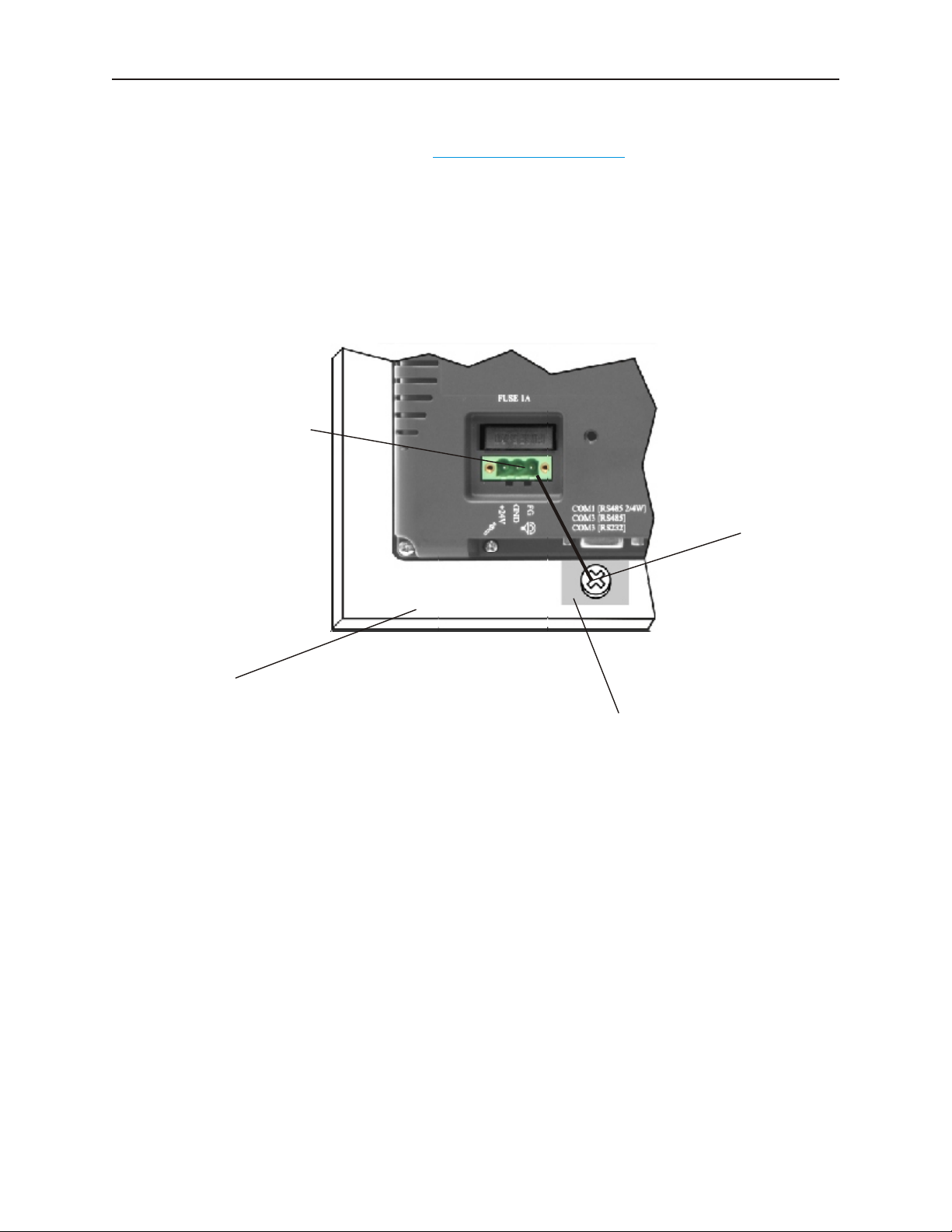

8 Ivory Se ries In stal la tion & Op er a tion Man ual

Frame ground (marked FG)

Area on panel free of paint.

Stud or screw

Control Panel

For a more in-depth overview of ground wiring techniques, refer to technical note #1027, “HMI Ground Wiring and

Electrical Noise Reduction,” which you can find at http://www.maplesystems.com in the Support Center section.

Con nect Panel PC Chas sis Ground to Con trol Panel

To reduce the possibility of electrical interference, connect the chassis ground terminal of the computer to a clean

earth ground. If the control panel is metal, make sure it is properly grounded. Then connect a short heavy-gauge

wire (#18 AWG) from the chassis ground terminal of the computer to a mounting bolt on the control panel door.

The mounting bolt must have good electrical contact to the control panel; scrape away any paint that may be

covering the panel to provide a good connection.

If the control panel is made of a non-conductive material, it is essential that you connect the chassis ground terminal

of the computer to a clean earth ground point located close to the panel.

Power Sup ply Se lec tion

The power supply used to power the computer should provide an output of +24 VDC 5% measured at the Panel PC

power terminal block. A 24VDC regulated power supply dedicated to the computer is required.

The power cable for the computer should be 18AWG, 2-conductor wire with a shield drain wire and protective

shield (foil or braid). The shield drain wire must be connected to earth ground at both ends of the cable. Please refer

to the “Connect the Panel PC to Power” section for more information.

A power line filter installed at the AC input to the computer power supply is highly recommended as a safeguard

against conducted RF noise, which is often present on factory power lines. The wires connecting the output of the

power line filter to the power supply should be kept as short as possible to minimize any additional noise pickup.

The case of the power line filter should be connected to a quiet earth ground. The power line filter should have a

current rating of at least 3 Amps with common mode and differential mode attenuation.

1010-1010, Rev 02

Panel PC Chas sis Ground connection

Page 12

In stal la tion Instructions 9

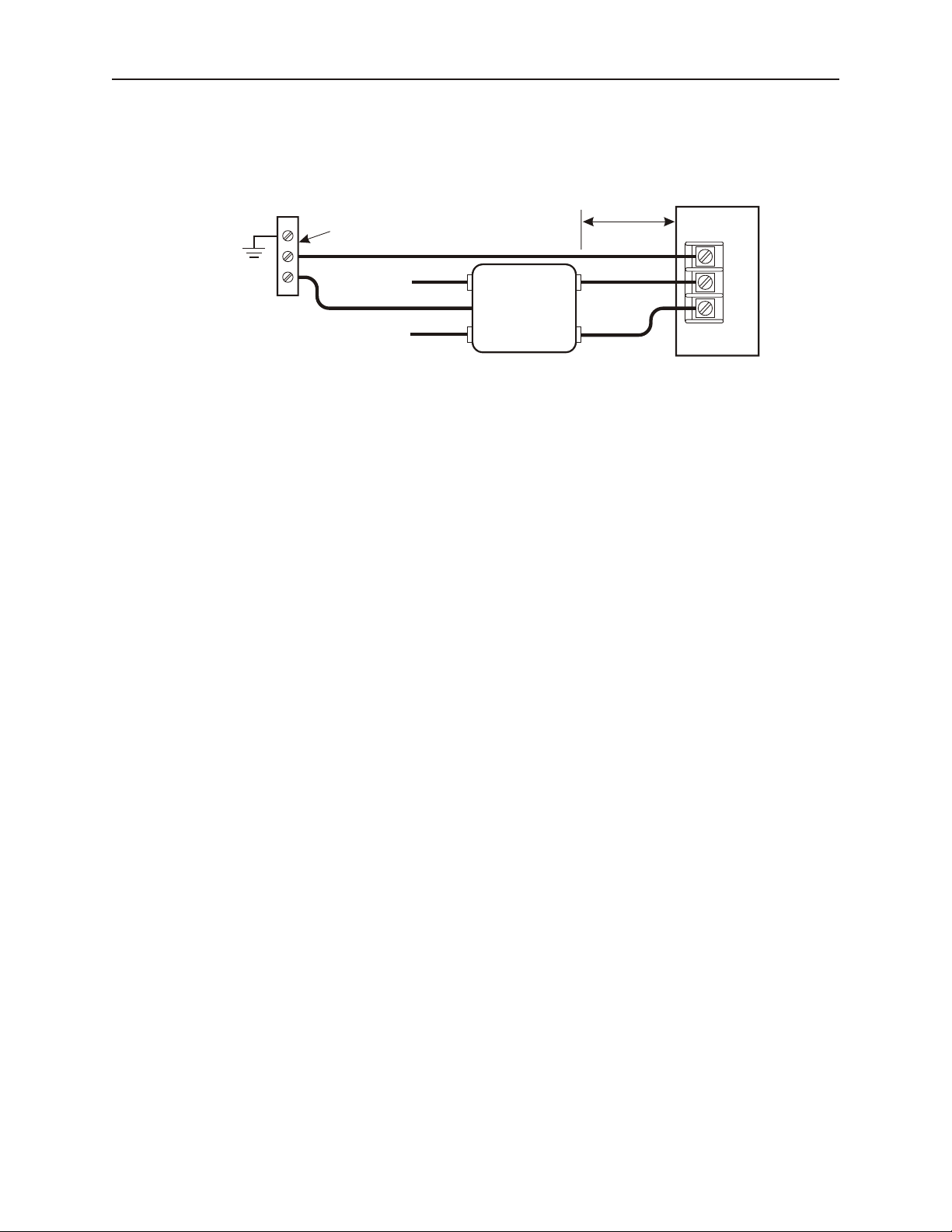

AC

AC

GND

N

L

White

Black

N

L

G

AC

Line Filter

Green

White to

110Vac neutral

Black to

110Vac load (hot)

To earth

ground

"Quiet”

ground

Bus bar

Power

Supply

Keep short

Do not use the power supply used to provide power to the computer to power switching relays, solenoids, or other

active devices.

Power Line Fil ter Connection

Ca ble Routing and Noise Im mu nity

Follow these guidelines when routing cable to the computer:

· Always route the Panel PC communication cable and the power cable away from any AC voltage or rapidly

switching DC control lines.

· Never bundle the Panel PC cables together with 120VAC power wires or with relay wiring.

· Try to keep at least 8 inches (20 cm) of separation between the Panel PC cables and other power wiring. If

voltages greater than 120VAC are used in the system, greater separation is required.

· If the Panel PC cables must come near AC wiring, make sure they cross at 90 degrees.

· Run AC power wires in a separate grounded conduit to reduce electrical noise interference.

· Keep the cable lengths for the Panel PC as short as possible. Do not coil excess cable and place it next to

AC powered equipment.

· Cover any equipment used in the enclosure that operates at high frequency or high current levels with a

grounded metal shield.

In stal la tion

It is necessary to follow all installation procedures described in this chapter for electrical noise immunity and CE

compliance.

Your Maple Systems Panel PC is designed to connect easily to your PLC. External rear connectors provide quick

connections for power, communications and programming wiring.

There are two serial port connections on the rear of the Panel PC. These are D-subminiature 9-pin connectors. The

female connector can be used for RS232 or RS485 connection to a PLC. The male connector can be used for

RS232 connections to a PLC or to the PC used for configuration.

Use the supplied separate 3-position terminal block to provide power to the Panel PC.

Con nect the Panel PC to Power

The power cable for the Panel PC should be 18AWG, 2-conductor wire with a shield drain wire and protective

shield foil. You may buy cable P/N 6030-0009 by the foot from Maple Systems to make these.

1010-1010, Rev 02

Page 13

10 Ivory Se ries In stal la tion & Op er a tion Man ual

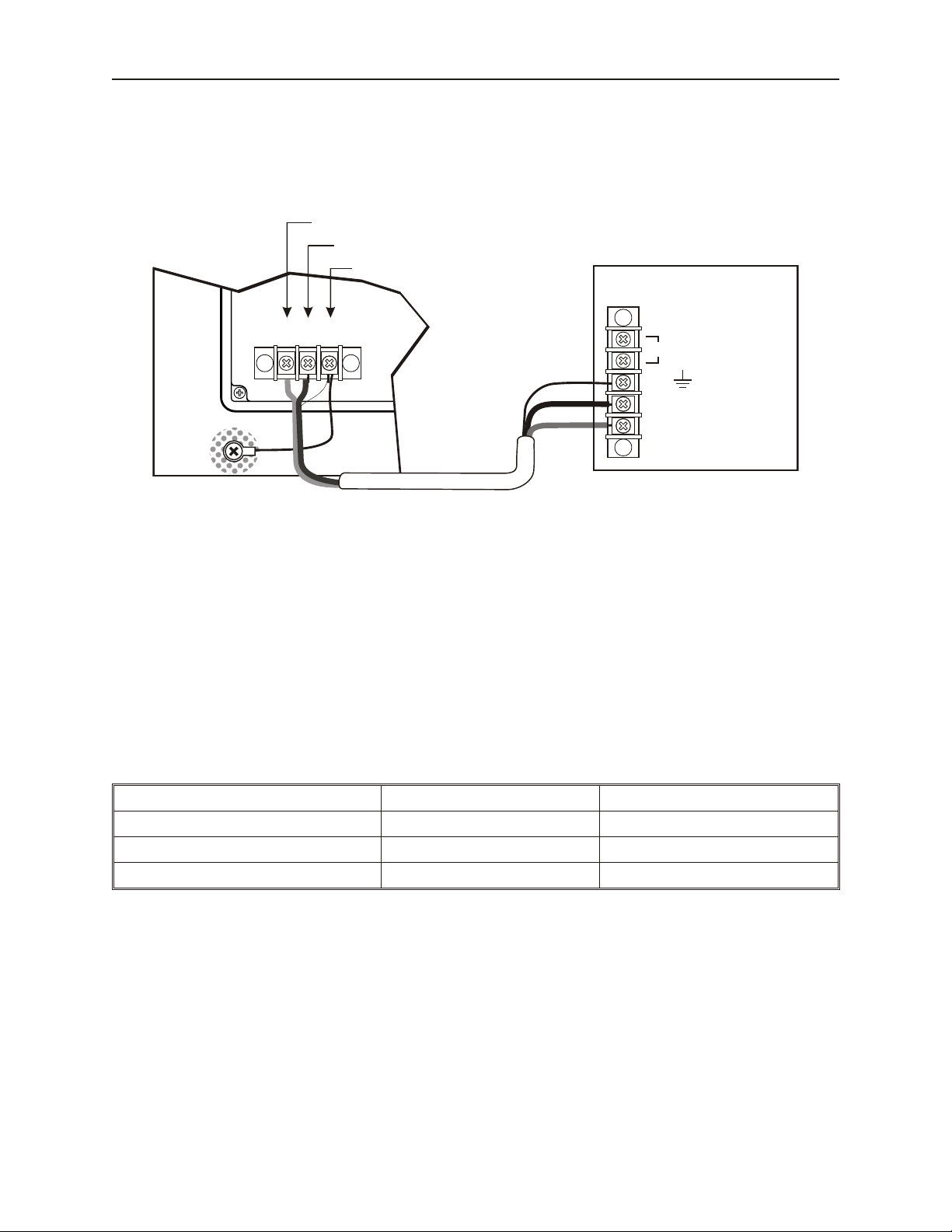

Panel PC

(rear side)

24Vdc

power supply

Control

panel

Shield wire (bare)

Black wire (-)

Red wire (+)

24V

120Vac

Black

Shield drain

Red

FG

DC Output -V (Gnd)

DC Output +V (+24V)

(+)

GND

(-)

FG

Always run the DC ground wire directly back to the signal return of the power supply. Do not use the chassis

ground wire as your signal return! Maple Systems recommends using an axial ferrite coil with each Panel PC to

further reduce the electrical interference that may be conducted on the power lines. Thread the positive and negative

wires of the power cable through the ferrite coil so that the coil is no more than two inches from the Panel PC’s

power input.

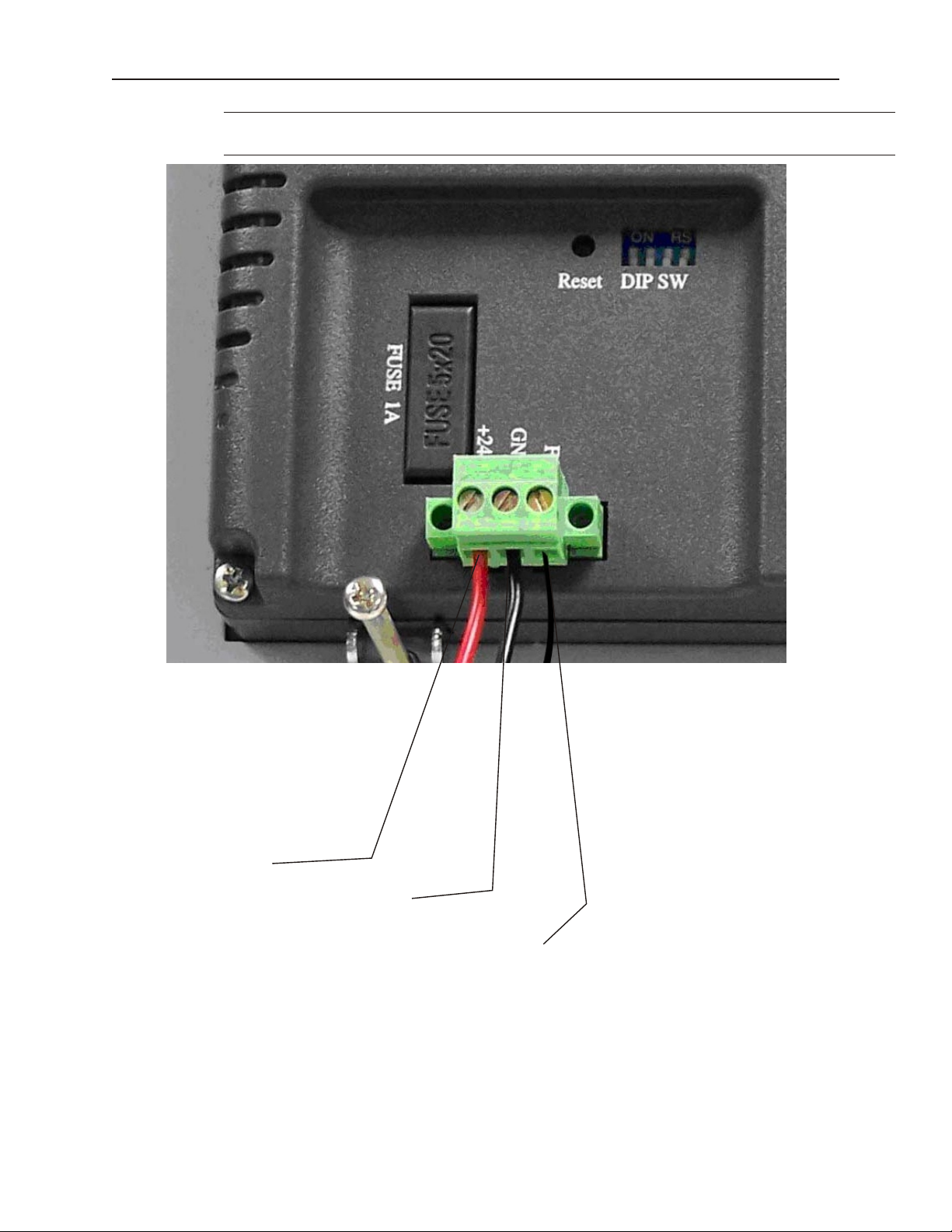

Panel PC Power Inputs

4To connect the Panel PC to power:

1. Connect the power cable to the Panel PC

a. Strip the power cable shield to expose 2” of the black and red wires.

b. Strip about ¼” of insulation from the black and red wires.

c. Thread the black and red wires through the ferrite core. The shield wire must be outside.

d. Connect the red wire to the DC positive (+) input of the Panel PC power terminal.

e. Connect the black wire to the DC negative (-) input of the Panel PC power terminal.

f. Connect the power cable shield wire to the Panel PC power terminal’s chassis ground

input.

2. Route the power cable to the Panel PC power supply. The power cable should not be any

longer than necessary.

3. Install the power supply wires as follows (with colors shown for Maple Systems cable P/N

6030-0009):

Color Power Supply Panel PC

Red +Output/+24 Vdc +24V

Black -Output/+24 Vdc return GND

Shield Case ground FG

1010-1010, Rev 02

Page 14

In stal la tion Instructions 11

24+VDC

0V

FG

The power connector on the Ivory Series is a terminal block with wire clamps. Lugs are

not required.

Ivory Se ries Power Wiring

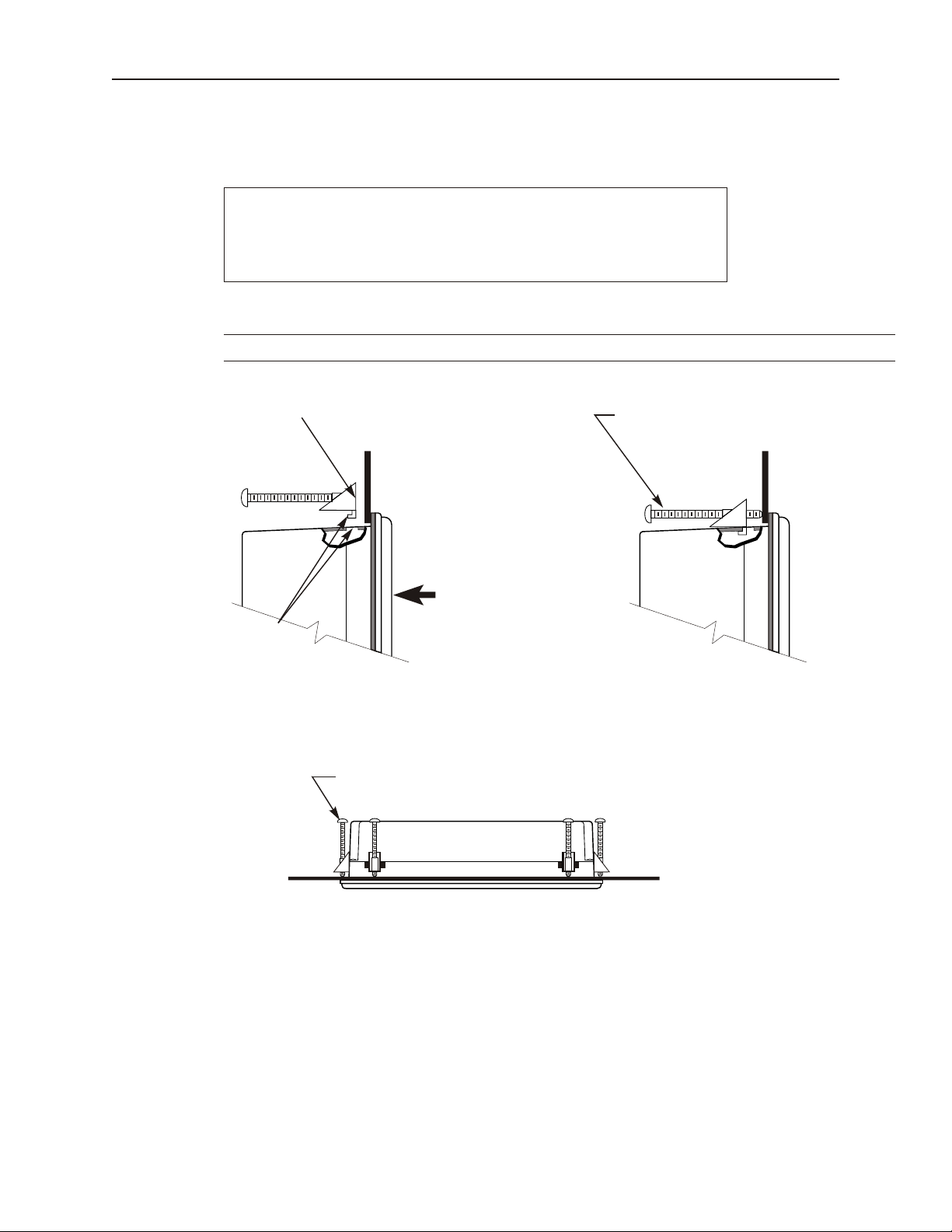

Panel Prep a ra tion

A metal panel or mounting surface with a minimum thickness of 15 gauge (0.059 inch/3.3mm) if cold-rolled steel or

hardened steel, or 10 gauge (0.101 inch/2.6mm) if aluminum alloy (6061-T6 preferred) is required. Thinner panels

or surfaces may bow between the mounting clamps and not form a seal with the gasket.

1010-1010, Rev 02

Page 15

12 Ivory Se ries In stal la tion & Op er a tion Man ual

Screw clamp locking

tabs go through the

slots

Tighten all screw clamps until

they are uniformly snug

Ends of screws must not

protrude from the clamp

Screw Clamp Placement Clamps Tightened

Hold the Panel PC against

the panel until all screw

clamps are in position

PanelPanel

Position screw clamps 6 places in slots provided:

2 screw clamps each side and one top and bottom

Panel

Side View

The area of the panel or mounting surface where the gasket comes into contact must be flat and free of scratches,

pits, and other features that prevent the gasket from sealing properly. If the panel or mounting surface is not

uniform, thick, flat, stiff, or smooth enough, then a sealant such as silicone may be required.

WARNING

The Panel PC requires a stiff, flat, smooth mounting surface free

of blemishes to seal properly to NEMA 4.

The diagrams in Appendix B show the dimensions of the panel cutout required for proper installation of the all

models.

Clean and deburr the panel cutout before the Panel PC is installed.

Mount the Panel PC to the Panel

1010-1010, Rev 02

In stall ing Screws on the Panel PC

Po si tion of the Six Screw Clamps for Mount ing the

HMI615/612/610

Page 16

In stal la tion Instructions 13

Position 4 screw clamps

(2 each side)

Panel

Po si tion of the Four Screw Clamps for Mount ing the HMI606/608

STEPS:

1. Prepare the four screw clamps for the HMI606/608 or the six screw clamps for the HMI615/612/610 by

positioning the metal brackets at the midpoints of the screws. Position the screws so that the ends don’t

protrude from the plastic portions.

2. Set the Panel PC in the panel cutout and hold it in place until all clamps are in position.

3. Tighten the screw clamps until all are uniformly snug.

CAUTION: Do not over-tighten the screws beyond snugness, or you may damage the housing.

REINSTALLATION: Because the gasket will take a “set” to the panel, be sure to reinstall the Panel PC to the same

panel cutout when a NEMA 4 seal is required. For best results, also replace the gasket itself.

Com mu ni ca tions

The Ivory Series have 2 DE9 connectors for serial devices.

• The male connector is designated COM1[RS232]/COM2[RS232]

• The female connector is designated COM1[RS485 2/4W]/COM3[RS485]/COM3[RS232].

• The COM1 port can be used in RS232, RS485, or RS422 modes.

• The COM3 port can be used in RS232 or RS485 modes.

• The COM2 port can only be used in RS232 mode.

The ports are set up us ing the CECP util ity’s Set Se rial Port Mode op tion. Note that al though the com port num ber

set ting is the same, dif fer ent con nec tions are re quired for us ing RS232 or RS422/485. The pinouts for each port are

shown.

Restrict cable length to less than 500 feet (150m) for RS-422/RS485 devices and less

than 50 feet (15m) for RS-232 devices in order to avoid communication problems.

COM1 [RS232]/COM2 [RS232]

Pinout of DE9P (male) con nec tor

Pin # Symbol COM1[RS232] COM2[RS232]

1 Not Used

2 RxD Received Data

3 TxD Transmit Data

1010-1010, Rev 02

Page 17

14 Ivory Series Installation & Operation Manual

4 TxD Transmit Data

5 GND Signal Ground

6 RxD Receive Data

7 RTS Ready to send output

8 CTS Clear to send input

9 Not Used

COM1 [RS-485 2/4 W] Port , COM3[RS485], COM3[RS232] Port

Pinout of DE9S (female) connector

Pin# Symbol COM1 [RS485 2W] COM1 [RS485 4W] COM3[RS485 2w] COM3[RS232]

1 Rx- RS485 Receive Data - RX -

2 Rx+ RS485 Receive Data + RX +

3 Tx- RS485 Transmit TX -

4 Tx+ RS485 Transmit TX +

5 GND Signal Ground

6 Data- Data -

7 TxD RS232 Transmit Transmit Data

8 RxD RS232 Receive Receive Data

9 Data+ Data +

Connecting to the Panel PC Using Ethernet - Windows CE

The Ivory Series comes equipped with a 10/100BaseT Ethernet port. By default, the Ivory Series' Ethernet port is

set to get an IP address from a DHCP server.

4To change the static IP address:

1. From the Windows CE.net desktop, click the Start button.

2. Click Settings.

3. Click Network and Dial-up Connections.

4. Double-click CS89501.

5. Select the IP Address tab.

6. Click the Specify an IP address option button.

7. Enter an IP Address and Subnet Mask. Make sure that the IP Address and Subnet mask are

consistent with the IP addresses that the Panel PC will be connected to.

8. Enter a Default Gateway if needed.

9. Select the Name Servers tab.

10. If required, enter the IP addresses of the Primary and Secondary Domain Name Service

servers.

11. If required, enter the IP addresses of the Primary and Secondary Windows Internet Naming

Service servers.

12. Click the OK button. Then close the Network Connections window.

1010-1010, Rev 02

Page 18

In stal la tion Instructions 15

13. Select the CECP icon from the system tray.

9. Select the Save tab from the System Settings dialog box.

10. Click Save registry.

11. Click OK.

12. Reboot the Panel PC to make settings take effect.

Con nect ing to the Panel PC Us ing Ethernet - Win dows XPe

4To connect to a network on an Windows XPe unit:

1. Click Start - Network Connections.

2. Double-click Local Area Connection (RealTek RTL8139).

3. Under This connection uses the following items, double click Internet Protocol (TCP/IP).

4. On the General tab, select Obtain an IP address automatically if your network uses a

DHCP server; otherwise, select Use the following IP address and then enter the appropriate

information.

5. Click OK on each dialog to accept the new settings.

USB Host Port

The USB Host Port has the following uses:

• Connect to USB mouse.

• Connect to USB keyboard.

• Connect to USB mass storage device that has been connected to an external power source.

The USB Host port supports a USB 2.0 full-speed host at 12 Mbps.

USB Cli ent Port

The Windows XPe units support the USB client ports and work with plug and play devices. Windows CE units do

not support USB Client Port.

Com pact Flash

The Ivory Series can accommodate a standard Type 1 Compact Flash (CF) card. When installed, the CF card will

be recognized as StorageCard by the Ivory Series’ Windows CE operating system. Files and folders can be

manipulated on the card just like any other device. The CF card is also the mechanism by which the WindowsCE

operating system is repaired or reinstalled. Windows XPe Panel PCs do not support CompactFlash.

1010-1010, Rev 02

Page 19

16 Ivory Se ries In stal la tion & Op er a tion Man ual

Print ing - Win dows CE

The Ivory Series Windows CE Panel PCs support HP PCL printers. The printer connection can be obtained via USB

Host port or network connection to a shared printer.

4To print:

1. From the Internet Explorer or User's Application menu, select File-Print…and follow the

onscreen prompts to select print settings.

2. Printer: Use drop-down menu to select printer type.

3. Port: Use drop-down menu to select COM port.

4. Net Path: If printer selected is a network printer, enter network path.

5. Print Range: Select All for entire document or Selection to print selected area.

6. Orientation: Select Portrait or Landscape.

7. Margins: Set margins here.

Print ing - Win dows XPe

XPe supports any plug and play printer.

1010-1010, Rev 02

Page 20

In stal la tion Instructions 17

Us ing a Net worked Printer - Win dows CE and Win dows XPe

4 To share a network printer connected to a desktop PC:

1. On your desktop PC, select Start-Settings-Printers and Faxes.

2. Right click on the printer you wish to set as the network computer, then select Properties.

The printer properties dialog appears.

3. Select the Sharing tab and select Share this Printer. Assign a name to the printer.

4. Click OK.

1010-1010, Rev 02

Page 21

18 Ivory Se ries In stal la tion & Op er a tion Man ual

Fac tory Con fig u ra tion

What Co mes with the Ivory Se ries Panel PC?

The Ivory Series Panel PC arrives from the factory with the following components:

• One Ivory Series Panel PC, preloaded with Microsoft Windows CE.net 5.0 or Windows XPe.

• CD containing Ivory Series Installation and Operation Manual, Windows CE/XPe image files,

and the software development kit (SDK) for the Ivory Series.

Not included with the Ivory Series Panel PC:

• HMI configuration software must be purchased separately. The Ivory Series can be configured

with any CE or XPe-compatible HMI configuration software. We recommend WebStudio.

• Power supply and cabling must be purchased separately. Contact Maple Systems for more

information.

• Development tools for creating Windows CE/XPe applications.

Dip Switch Set tings

The following table shows factory-configured dip switch settings of the Ivory Series.

Calibration Mode

SW1 SW2 SW3 SW4 Mode

ON OFF OFF OFF Touchscreen

OFF ON OFF OFF Reserved

OFF OFF ON OFF Boot loader mode

OFF OFF OFF ON Reserved

OFF OFF OFF OFF Normal Operation

Boot Loader Mode

This mode allows users to load a new Windows CE or Windows XPe image file.

4 To load a new image file from compact flash:

1. Turn off Panel PC.

1010-10010, Rev 02

Page 22

In stal la tion Instructions 19

2. Load the image onto compact flash

3. Insert Compact Flash into unit or Compact Flash reader.

4. Set dip SW3 to ON.

5. Reapply power to the Ivory Series Panel PC. Panel PC will boot in boot loader mode.

6. The image file will automatically load and Panel PC automatically reboots when the

download is complete. While loading the CPU LED will flash continuously. The download

takes approximately 10 minutes to complete.

7. Be sure to reset all dip switches to OFF before turning on the Panel PC the next time, or it

will load in Boot Loader Mode.

Contact Maple Systems for information on the operating system image files.

1010-1010, Rev 02

Page 23

20 Sil ver Se ries In stal la tion & Op er a tion Man ual

1010-1010, Rev 02

Page 24

Us ing Win dows CE.net and Win dows XPe 21

Chapter 2 - Using Windows CE.net & Windows XPe

What is Win dowsTM CE.net 5.0?

The Ivory Series Panel PC is designed to be a Windows CE or Windows XPe platform. MicrosoftÒ WindowsÒ

CE is a compact operating system that occupies less storage space or system resources than other operating systems.

By its modular nature, it is possible to choose those functions that are useful for specific applications, not only

reducing the system resources required, but also reducing start-up time. In the field of industrial automation or for

operator interface terminal, this is an appealing feature because the impact of downtime is minimized. Furthermore,

the small storage space it needs makes operating systems on solid-state disk possible.

Util i ties

There are several useful utilities that come with the Windows CE.net v. 5.0 operating system of the Ivory Series.

Soft Key board

There are two options available on the Ivory Series for keyboard input - a separate keyboard that can be connected

to the USB port or a built-in ‘software keypad’ that can be activated and displayed on the touchscreen of the Panel

PC.

To use the soft keyboard, click on the small keyboard icon located on the right side of the Task bar. Soft keyboard

options include smaller or larger keys and the use of "gestures" for space, backspace, shift and enter.

4To access keyboard options

1. Click Start…Settings..Control Panel.

2. Double click on the Input Panel icon. The Input Panel ialog box appears.

1010-1010 Rev 02

Page 25

22 Ivory Se ries In stal la tion & Op er a tion Man ual

3. Click Options…

Sys tem Set tings

Several system components can be configured using CE.net system settings.

Whenever a change is made, the settings must be saved to the registry. See Save

Settings section later in this chapter.

Backlight Set tings

The backlight can be con fig ured to op er ate in backlight saver mode, which di rects the backlight to turn off af ter a

cer tain pe riod of in ac tiv ity.

4 To configure the backlight

1. From the desktop, double click on the CECP icon. This will display the System settings

dialog.

2.. Click on the LCD Settings tab.

3. Select the backlight setting option you desire in the dropdown box for Turn off backlight if

device not used for.

4. Click OK.

MAC Ad dress

4 To view the Media Access Controller Address (MAC Address):

1010-1010, Rev 02

Page 26

Us ing Win dows CE.net and Win dows XPe 23

1. Double-click on the CECP icon on desktop.

2. The system setting dialog box appears. Select the MAC Address tab.

3. The network MAC address shows in the block.

Save Settings

It is possible to save current registry data so that CE.net will use it the next time the computer is booted. It is

important to save the registry whenever a change is made to the Panel PC's configuration.

4 To save the registry :

1. Double click CECP icon on desktop.

2. The system setting dialog box appears. Use the arrow key to scroll to the Save tab.

3. Click Save Registry.

4. Click OK.

1010-1010, Rev 02

Page 27

24 Ivory Se ries In stal la tion & Op er a tion Man ual

Sys tem Ver sion

Displays information about the Panel PC’s installed software.

4 To view the current CE image version:

1. Double click the CECP icon on desktop.

2. The system setting dialog box appears. Use the arrow key to scroll to the System Version

tab. The current system version information will be displayed.

3. Select OK.

Set Se rial Port Mode

This setting allows you to set COM1 for RS232, RS485, or RS422 and COM3 for RS232 or RS485.

4 To set serial port mode:

1. Double click the CECP icon on desktop.

1010-1010, Rev 02

Page 28

Us ing Win dows CE.net and Win dows XPe 25

2. The system setting dialog box appears. Use the arrow key to scroll to the Set Serial Port

Mode tab.

3. Select COM1 mode from the drop down box.

4. Select COM3 mode from the drop down box.

5. Click OK.

Home Di rec tory Change

When the Panel PC is configured as a Web Server, this sets the local folder where HTML files are stored.

4 To change the Home Directory:

1. Double click the CECP icon on desktop.

2. The system setting dialog box appears. use the arrow key to scroll to the Home Directory

Change tab.

3. Enter the new directory.

4. Select OK.

5. Reboot the computer so that changes take effect.

1010-1010, Rev 02

Page 29

26 Ivory Se ries In stal la tion & Op er a tion Man ual

Con trast

This setting sets the display contrast.

4 To adjust LCD contrast:

1. Double click the CECP icon on desktop.

2. The system setting dialog box appears. Use the arrow key to scroll to the Contrast tab.

3. Slide control to desired contrast level.

4. Select OK.

NorFlash

NorFlash serves as a small-capacity non-volatile hard disk that allows storage of critical application files and data in

Flash ROM. This can prevent loss of important data due to power failure. When the registry is backed up using

system utilities, it is stored in the NorFlash folder. The NorFlash folder can be located by double clicking My

Device from the desktop.

Start Up

The start up function automatically boots on system boot up. Start up functions are stored in the NorFlash directory.

4 To create a customized start up function:

1. Double click the My Device icon from the Windows CE desktop.

1010-1010, Rev 02

Page 30

Us ing Win dows CE.net and Win dows XPe 27

2. Double click on the NorFlash folder.

3. Create a new directory and call it start up.

4. Copy executable files to the Startup directory.

Re mote Desk top Con nec tion

This feature allows users to use the Ivory Series Panel PC to connect remotely to another PC. To use the remote

desktop connection, the remote PC (which will be controlled by the Ivory Series) must have Windows XP

Professional installed on it.

4 To enable Remote Desktop Connection on the Panel PC:

1. Log onto the remote PC as an administrator.

2. Click the Remote Desktop icon, if available. If not, choose Start - My Computer - View

System Information. The System Properties Dialog appears. Select the Remote tab.

1010-1010, Rev 02

Page 31

28 Ivory Se ries In stal la tion & Op er a tion Man ual

3. Check the Allow users to connect remotely to this computer checkbox, and then click Select

Remote Users… The remote users dialog appears.

4. Click Add.. and add the host computer. Click OK.

4 To connect to the remote PC using the Ivory Series Panel PC:

1. Click on Remote Desktop Connection. The Logon to Windows dialog appears.

2. Type user name, password and domain, if required. Click OK.

About Win dows XPe

Windows XP for Embedded (Windows XPe) Systems is an edition of Windows XP that contains the full feature set

of Windows XP Professional, but has restrictions on licensing that requires that it be used in a process-specific

application. XPe works in much the same fashion as Windows XP depending on the features provided by the

developer (Maple Systems). Discussion of Windows XP operations is beyond the scope of this manual. For

information on using XPe, visit Microsoft's website:

http://www.microsoft.com/windows/embedded/products/wexpe/default.mspx.

1010-1010, Rev 02

Page 32

Networking 29

Chapter 3 - Networking

Net work ing Via Ethernet Us ing Win dows CE

The Ivory Series Panel PCs are equipped with an Ethernet 10/100Base-T port. The port comes already activated

and set to obtain an IP address via DHCP.

4To specify an IP address on a Windows CE Unit:

1. Click the Start button on the Windows Task Bar.

2. Click Settings and then click Network and Dial-Up Connections.

3. Double-click on the CS89501 icon. The EP9312 Ethernet Driver Settings dialog box

displays.

4. Under the IP Address tab, select Specify an IP address, then fill in the correct IP address

information for your network.

5. To make the change permanent, the settings must be saved to the registry as described in the

previous chapter under Save Settings.

Net work ing Via Ethernet Us ing Win dows XPe

4To connect to a network on an Windows XPe unit:

1. Click Start - Network Connections.

2. Double-click Local Area Connection (RealTek RTL8139).

3. Under This connection uses the following items, double click Internet Protocol (TCP/IP).

4. On the General tab, select Obtain an IP address automatically if your network uses a

DHCP server; otherwise, select Use the following IP address and then enter the appropriate

information.

5. Click OK on each dialog to accept the new settings.

Net work ing via Se rial Port Us ing Win dows CE

The Ivory Series with built-in Windows CE supports serial connections to host computers. The host computer must

install the Microsoft ActiveSync service offered by Microsoft. Use Maple Systems’ cable 7431-0106 to connect the

serial ports of the host computer and the Panel PC. Then activate ActiveSync service on the host computer. See the

next section for information about setting up communications. The cable drawing can be downloaded here:

http://www.maplesystems.com/1029/10290106.pdf

In stall ing Ac tive Sync

ActiveSync is a Microsoft product for connecting to Windows CE devices.

The first ActiveSync connection to the Ivory Series must be made via the serial port. Once ActiveSync has been

properly installed and opened:

1. Connect the RS232 ActiveSync cable between the PC and the Ivory Series Panel PC's

COM1/COM2 port.

2. On the Ivory Series Panel PC, click the Start button, then select Run. The Run dialog box

appears.

3. Enter repllog. Do not click the OK button yet.

4. On the PC, click the Next button in the Get Connected dialog box.

5. On the Ivory Series Panel PC, click the OK button in the Run dialog box.

6. ActiveSync should recognize the Ivory Series Panel PC.

7. On the Ivory Series Panel PC, use the CECP utility to save the registration so that the Panel

PC will remember the partnership. Double click the CECP icon. This will start the Panel

PC’s configuration utility.

.

1010-1010, Rev 02

Page 33

30 Ivory Se ries In stal la tion & Op er a tion Man ual

8. Select the Save tab.

9. Click the Save registry button.

10. When the registry has been saved, OK.

ActiveSync takes several seconds to scan each serial port. The higher the serial port

number (COM1, COM2, COM3, etc.), the longer it will take ActiveSync to recognize

the Panel PC.

4If ActiveSync fails to connect to the Ivory Series Panel PC:

1. From ActiveSync’s File menu, select Connection Settings.

2. Check the Allow serial cable or infrared connection to this COM port box, and select the

COM port to which the cable is connected.

3. Uncheck the Allow USB… and Allow Network… boxes. The Panel PC does not support

ActiveSync via USB because it is a USB Host itself, not a USB client. ActiveSync via

network connection is supported, but a serial connection must be established first.

4. Click the Get Connected button, and follow the on-screen instructions. ActiveSync will

begin looking for the Panel PC.

5. On the Ivory Series Panel PC, click the Start-Run.

6. In the dialog that is displayed, enter repllog, and click OK. ActiveSync should recognize the

Panel PC and connect.

7. On the Ivory Series Panel PC, use the CECP utility to save the registration so that the Panel

PC will remember the partnership. Double click the CECP icon. This will start the Panel

PC’s configuration utility.

8. Select the Save tab.

9. Click the Save registry button.

10. When the registry has been saved, OK.

1010-1010, Rev 02

Page 34

Net work ing 31

Once ActiveSync has established a partnership, a network connection can be set up (the IP addresses of the Panel

PC and the PC must be on the same subnet):

1. Disconnect the RS232 cable.

2. Open ActiveSync.

3. Select Connection Settings… from the File menu.

4. Check the Allow network (Ethernet) and Remote Access Service (RAS) server

connection with this desktop computer box.

5. Uncheck the Allow Serial… and Allow USB… boxes.

6. Click the Get Connected button, and follow the on-screen instructions. ActiveSync will

begin looking for the Ivory Series Panel PC.

7. On the Panel PC, click the Start button, then Run.

8. In the dialog that is displayed, enter repllog /remote, and click the OK.

9· In the next dialog, select Network Connection, and the name of the computer to establish the

connection with. Click Connect.

The Ethernet connection between the PC and the Panel PC should now be established.

Once a connection (serial or Ethernet) has been established, ActiveSync provides a mechanism for transferring files

between the Panel PC and the PC.

4 To transfer files between the Panel PC and PC:

1. On the ActiveSync window, click the Explore button. An explorer window will be

displayed, showing all the files and folders on the Ivory Series.

2. Files and folders can be dragged and dropped, copied, deleted, renamed, etc., just like any

other folder.

Web Browser

The Microsoft Windows CE operating system included with the Ivory Series has a built-in web browser called

Microsoft Pocket Internet Explorer. With Internet Explorer, you can connect to the internet and browse web pages

via LAN or dial-up connection.

Windows XPe comes with a full version of Internet Explorer for Internet browsing. To access, click the Internet

Explorer icon on the desktop or select Start-Internet.

1010-1010, Rev 02

Page 35

32 Ivory Se ries In stal la tion & Op er a tion Man ual

.

1010-1010, Rev 02

Page 36

De vel op ing Applications 33

Chapter 4 - Developing Applications

The Ivory Series comes with either the Microsoft Windows CE.net v. 5.0 or the Windows XP Embedded operating

system. Because of this, users can create their own application programs that can be installed onto the Panel PC.

Win dows CE

Tools for building Windows CE applications.

• Microsoft Visual Studio

• Microsoft eMbedded C++ 4.0

Microsoft Vi sual Stu dio 2008

This can be used to develop Windows CE 5.0 Compact Framework applications. For Ivory Series T models, the

target processor is an ARM v4i. The X Series target processor is the Intel x86.

Microsoft eM bed ded Vi sual C++ 4.0

Please refer to the Microsoft eMbedded Visual C++ 4.0 documentation for the specifics of application

programming.

Ivory Se ries SDK

The Ivory Series SDK provides developers with access to a set of functions that are specific to the Ivory Series

hardware.

4 To install Ivory Series SDK:

1. From the Ivory Series Utility CD, locate the EP931X_SDK.msi file in the \SDK folder.

Double click on the file icon to start the installation wizard.

2. Follow the onscreen instructions to install SDK.

4 To use SDK:

1. Open eVC++.

2. In the WCE configuration toolbars, select EP931X Device.

Win dows XPe

XPe has built in support for:

• .Net Framework 2.0

• Active Template Library

• Common Control Libraries Version 5

• Common Control Libraries Version 6 [6000]

• Common Control Libraries Version XPSP2

• Common File Dialogs

• Microsoft Visual C++ Run Time (Legacy)

1010-1010, Rev 02

Page 37

34 Ivory Se ries In stal la tion & Op er a tion Man ual

• Microsoft Visual C++ Run Time

• Visual Basic 50 Runtime Library

• Visual Basic 60 Runtime Library

• Visual C++ Runtime Libraries (Side X Side)

• Visual C++ Runtime Libraries Policy XPSP2

• Visual C++ Runtime Libraries XPSP2

• Visual Studio 2008

• Any other development tool that can target a Windows XP platform

Support for a number of other technologies is also included. Please contact Maple Systems for more information.

1010-1010, Rev 02

Page 38

Us ing Third Party Soft ware to Con fig ure the Ivory Se ries Panel PCs 35

Chapter 5 - Using Third Party Software to Configure the Ivory

Series Panel PCs

Indusoft WebStudio

Although you can use any application development software that is compatible with Windows CE.net 5.0 or

Windows XPe, Maple systems recommends WebStudio. For more information, visit our website at

www.maplesystems.com.

Other HMI Con fig u ra tion Soft ware

There are many companies that offer HMI configuration software that is compatible with Windows CE.net 5.0.

We have not tested any of this software with the Ivory Series Panel PCs. Below is a partial list:

• Iconics Embedded Genesis32

• Rockwell RSView Machine Edition

• GE Fanuc Proficy View Machine Edition

1010-1010 Rev 02

Page 39

36 Ivory Se ries In stal la tion & Op er a tion Man ual

1010-1010, Rev 02

Page 40

Main te nance and Sys tem Configuration 37

Chapter 6 - Maintenance and System Configuration

Fuse Main te nance

Fuse

The fuse used on Ivory Series Panel PCs is:

BUSSMANN GDBI

Fast Acting, Glass Tube

Rating: 250VAC, 1A

Size: 5x20mm

Make sure the power is off before replacing the fuse.

Do not replace the fuse with a fuse that has a different rating.

Clean ing the Over lay

Use a soft, lint-free cloth to gently wipe dust and debris off of overlay. Do not use alcohol or ammonia based

products to clean overlay. For hard-to-remove soil, use a damp soft cloth dipped in warm soapy water. Be certain

to wring out any excess fluid.

Cal i brat ing the Touchscreen

It is necessary to calibrate the touchscreen for use with Windows CE.

1010-1010, Rev 02

Page 41

38 Ivory Se ries In stal la tion & Op er a tion Man ual

4 To calibrate the touchscreen:

1. Double click the CECP icon.

2. Under the Touchscreen Settings tab, choose Calibrate.

3. The screen displays a "+" sign in the center.

1010-1010, Rev 02

Page 42

Main te nance and Sys tem Configuration 39

4. Touch and drag the "+" sign. It will begin to move on its own.

5. The + sign will now move to each corner, starting in the upper left and moving from corner to

corner in a counter-clockwise direction. When calibration is done, the + sign disappears.

Press the ENTER key or tap the screen to save settings.

6. Touchscreen parameters will be stored in the Panel PC's Flash.

Sys tem Con fig u ra tion

Like Windows for a desktop PC, Windows CE includes a number of applets for configuration.

Certificates

Lists and manages Digital Certificates for establishing safe and secure communications.

Date/Time

Sets the date and time for the unit.

Dialing

Set up the Dialing Rules used with modems and telephones.

Input Panel

Configures the pop-up keyboard used when an external keyboard is not available.

Internet Options

Set the Home and Search pages used by Internet Explorer, as well as connection and security settings.

Keyboard

Configures an external keyboard.

Mouse

Configures the mouse.

Network and Dial-up Connections

Configures additional network and dial-up connections.

Owner

Sets up user and network identification information.

Password

Configures passwords for power-up and/or screen saver.

1010-1010, Rev 02

Page 43

40 Ivory Se ries In stal la tion & Op er a tion Man ual

PC Connection

Lists the available connections for communicating with another PC.

Regional Settings

Set the number, date, time, and currency formats.

Remove Programs

Lists the installed applications, and allows their proper and complete removal.

Storage Manager

Configures how the Ivory Series' internal non-volatile memory is allocated.

System

Displays hardware and operating system information.

Volume and Sounds

Configures the sound volume, and whether sounds are played for various system events.

Windows XPe also has a number of applets:

MS Word Viewer

Allows viewing of word documents.

.NET Framework

Improves scalability and performance of applications with improved caching, application deployment and updating

with ClickOnce, support for a broad array of browsers and devices with ASP.NET 2.0 controls and services.

Administration Support Tools

Advanced Configuration and Power Interface (ACPI)

Common interfaces for hardware recognition, motherboard and device configuration and power management.

ASP.NET 2.0

A web application framework that programmers can use to build dynamic web sites, web applications and web

services.

Common Control Libraries Versions 5, 6 and XPSP2

Provides common user interface (UI) controls.

Common File Dialogs

Allows for viewing of files in easily recognizable formats such as thumbnails.

Communications Port

Support for communications ports.

Device Manager

Allows management of recognized devices.

DHCP Client Service

Manages network configuration by registering and updating IP addresses and DNS names.

1010-1010, Rev 02

Page 44

Main te nance and Sys tem Con fig u ra tion 41

Dial-up Networking Common Libraries

Provides support for the Dial-Up Networking Common Libraries. This component includes common resources that

are used by the Remote Access Service (RAS) client and the RAS Server.

Dial-up Server for Windows

Enables dial-up connection.

DirectMusic Core

Provides core functionality for applications using DirectMusic, including loading data and managing the

synthesizer.

DirectShow

A multimedia framework and API for software developers to perform various operations with media files or

streams.

File Sharing

Allows files to be shared between network users.

Generic USB Composite Device

Provides support for generic USB composite devices. This component supplies the USB Common Class Generic

Parent driver in the usbccgp.sys file. This driver represents the interfaces of a composite device as separate devices.

The interfaces of a composite device can then be separately managed by different drivers.

HTML Help Engine

The standard Help system for the Microsoft Windows platform. This component includes the run-time ActiveX

controls and executable files that are used to display compiled Help (.chm) files.

IIS Web Server

A group of Internet servers (including a Web or Hypertext Transfer Protocol server and a FTP server) with

additional capabilities for Microsoft’s XPe.

Internet Explorer

Microsoft's web browser.

IP Security Services

Internet protocol security.

Microsoft Foundation ClassLibrary (Legacy and MFC)

A library that wraps portions of the Windows API in C++ classes, including functionality that enables them to use a

default application framework.

Microsoft Visual C++ Run Time

Installs runtime components of Visual C++ Libraries required to run applications developed with Visual C++ on a

computer that does not have Visual C++ 2005 installed.

Offline Browsing for Internet Explorer

Provides the architecture needed to synchronize when your computer is offline and online with Internet Explorer.

Registry Editor

Allows editing of registries.

1010-1010, Rev 02

Page 45

42 Ivory Se ries In stal la tion & Op er a tion Man ual

Remote Registry Service

Enables remote users to modify registry settings on this computer. If this service is stopped, the registry can be

modified only by users on this computer. If this service is disabled, any services that explicitly depend on it will fail

to start.

Shockwave Flash

Views rich-media content on the web including animations, interactive presentations, and online entertainment.

TCP/IP Networking & Utilities

Enables use of TCP/IP protocol.

USB 20, 20 Common, Mass Storage Device, Printing Support and User Interface

Enables use of USB ports.

Visual Basic Runtime Library (50 & 60)

Allows Visual Basic applications to be run on the Panel PC.

Windows API-User

Application programming interfaces.

Windows Firewall Control Panel

Allows control of the firewall.

Windows Image Acquisition Core and User Interface

Provides both an application programming interface (API) and a device driver interface (DDI). It supports still

digital cameras and scanners.

Windows Installer Service

Allows installation of Windows applications.

1010-1010, Rev 02

Page 46

Index 43

Index

Installing the OIT ..................9

A

applets, Windows XPe...............40

B

Backlight Settings .................22

Boot Loader Mode.................18

C

Cable Routing ....................9

Cable Routing and Noise Immunity.........9

Calibrating the Touchscreen ............37

CE Compliance ...................5

Certificates .....................39

Compact Flash ..................15

connect the HMI to power .............10

Control panel grounding ..............7

Control panel, requirements.............7

D

Internet Explorer..................31

Internet Explorer .................31

Internet Options ..................39

IP address .....................14

IP address, static ..................14

Ivory Series CE Touchscreen Computer ......2

K

Keyboard......................39

L

LCD contrast....................26

M

MAC Address ...................23

Maintenance ....................37

Microsoft eMbedded Visual C++ 4.0 .......33

Microsoft support for XPe .............28

Mount the HMI to the Panel ............12

Date/Time .....................39

Dialing .......................39

Dip Switch Settings ................18

E

Electrostatic Discharge, managing .........5

Ethernet.....................14,29

Ethernet, Windows CE...............14

Ethernet, Windows XPe ..............15

F

FCC Class A Rating.................5

Fuse Maintenance .................37

G

Grounding ......................7

H

Home Directory ..................25

I

Indusoft WebStudio ................35

Installing Active Sync ...............29

N

NEMA rating ....................5

NEMA Rating ....................5

Network and Dial-up Connections.........39

Networking via Ethernet..............29

Noise Immunity ...................9

NorFlash ......................26

O

Owner .......................39

P

Panel Preparation .................11

PC Connection ...................40

Port wiring .....................9

Power Supply ....................8

Power supply requirements .............8

printer, networked .................16

Printing - Windows CE ..............16

Printing - Windows XPe..............16

1010-1010, Rev 02

Page 47

44 Ivory Se ries In stal la tion & Op er a tion Manual

printing, Windows CE ...............16

printing, Windows XPe ..............16

R

Regional Settings .................40

registry ......................23

Remote Desktop ..................27

S

Safety Precautions..................6

Save Settings....................23

Serial Port .....................24

Soft Keyboard ...................21

System Configuration ...............39

System Settings ..................22

System Version ..................24

T

transfer files ...................31

U

Unpacking......................5

USB Client Port ..................15

USB Master Port..................15

Utilities.......................21

W

Windows XP Embedded ..............3

Windows XPe ..................3,28

X

XPe .......................3,28

1010-1010, Rev 02

Loading...

Loading...