Maple Systems HMC3-M0808P0401T, HMC3-M0808Y0401T, HMC3-M1210P0201, HMC3-M1210Y0201, HMC3-M1614Y User Manual

...Page 1

Your Industrial Control Solutions Source

_____________________

www.maplesystems.com

Maple Systems, Inc. | 808 134th St. SW, Suite 120, Everett, WA 98204 | 425.745.3229

I/O Module Guide

For the HMC3000 Series

For use with the following:

• HMC3000 Series

• Digital and Analog

I/O Modules

Page 2

Introduction 2

HMC3000 Series I/O Module Guide 2

COPYRIGHT NOTICE

This manual is a publication of Maple Systems, Inc., and is provided for use by its customers only. The contents

of the manual are copyrighted by Maple Systems, Inc.; reproduction in whole or in part, for use other than in

support of Maple Systems equipment is prohibited without the specific written permission of Maple Systems.

WARRANTY

Warranty Statements are included with each unit at the time of purchase and are available at

www.maplesystems.com.

TECHNICAL SUPPORT

This manual is designed to provide the necessary information for trouble-free installation and operation of your

I/O module(s). However, if you need assistance, please contact Maple Systems:

• Phone: 425-745-3229

• Email: support@maplesystems.com

• Web: www.maplesystems.com

Page 3

Introduction 3

HMC3000 Series I/O Module Guide 3

Table of Contents

COPYRIGHT NOTICE .......................................................................................................................................2

WARRANTY ...................................................................................................................................................2

TECHNICAL SUPPORT .....................................................................................................................................2

Introduction ..................................................................................................................................................5

I/O Expansion Module Overview ....................................................................................................................6

Installing I/O Modules ...........................................................................................................................................6

Configuring the I/O Modules .................................................................................................................................6

Common Terms and Definitions......................................................................................................................... 10

Configuring High-speed Counters ...................................................................................................................... 12

Configuring Pulse Width Modulation (PWM) Outputs ...................................................................................... 14

HMC3-M0808P0401T ................................................................................................................................... 19

Specifications ..................................................................................................................................................... 19

Configuration ...................................................................................................................................................... 21

Wiring: ................................................................................................................................................................ 23

HMC3-M0808Y0401T ................................................................................................................................... 27

Specifications ..................................................................................................................................................... 27

Configuration ...................................................................................................................................................... 29

Wiring: ................................................................................................................................................................ 31

HMC3-M1212P0200 ..................................................................................................................................... 35

Specifications ..................................................................................................................................................... 35

Configuration ...................................................................................................................................................... 37

Wiring: ................................................................................................................................................................ 39

HMC3-M1212Y0200 ..................................................................................................................................... 42

Specifications ..................................................................................................................................................... 42

Configuration ...................................................................................................................................................... 44

Wiring: ................................................................................................................................................................ 46

HMC3-M1210P0201 ..................................................................................................................................... 49

Specifications ..................................................................................................................................................... 49

Configuration ...................................................................................................................................................... 51

Wiring: ................................................................................................................................................................ 53

HMC3-M1210Y0201 ..................................................................................................................................... 57

Page 4

Introduction 4

HMC3000 Series I/O Module Guide 4

Specifications ..................................................................................................................................................... 57

Configuration ...................................................................................................................................................... 59

Wiring: ................................................................................................................................................................ 61

HMC3-M1614Y............................................................................................................................................. 64

Specifications ..................................................................................................................................................... 64

Configuration ...................................................................................................................................................... 65

Wiring: ................................................................................................................................................................ 66

HMC3-M1616P ............................................................................................................................................ 68

Specifications ..................................................................................................................................................... 68

Configuration ...................................................................................................................................................... 69

Wiring: ................................................................................................................................................................ 70

Page 5

Introduction 5

HMC3000 Series I/O Module Guide 5

Introduction

The HMC3000 HMI + PLC Series supports the following I/O expansion modules. These modules are not

compatible with the HMC7000 Series. These modules provide digital and/or analog I/O (inputs and outputs) for

an electrical control system. All of the I/O Modules are CE and UL Certified.

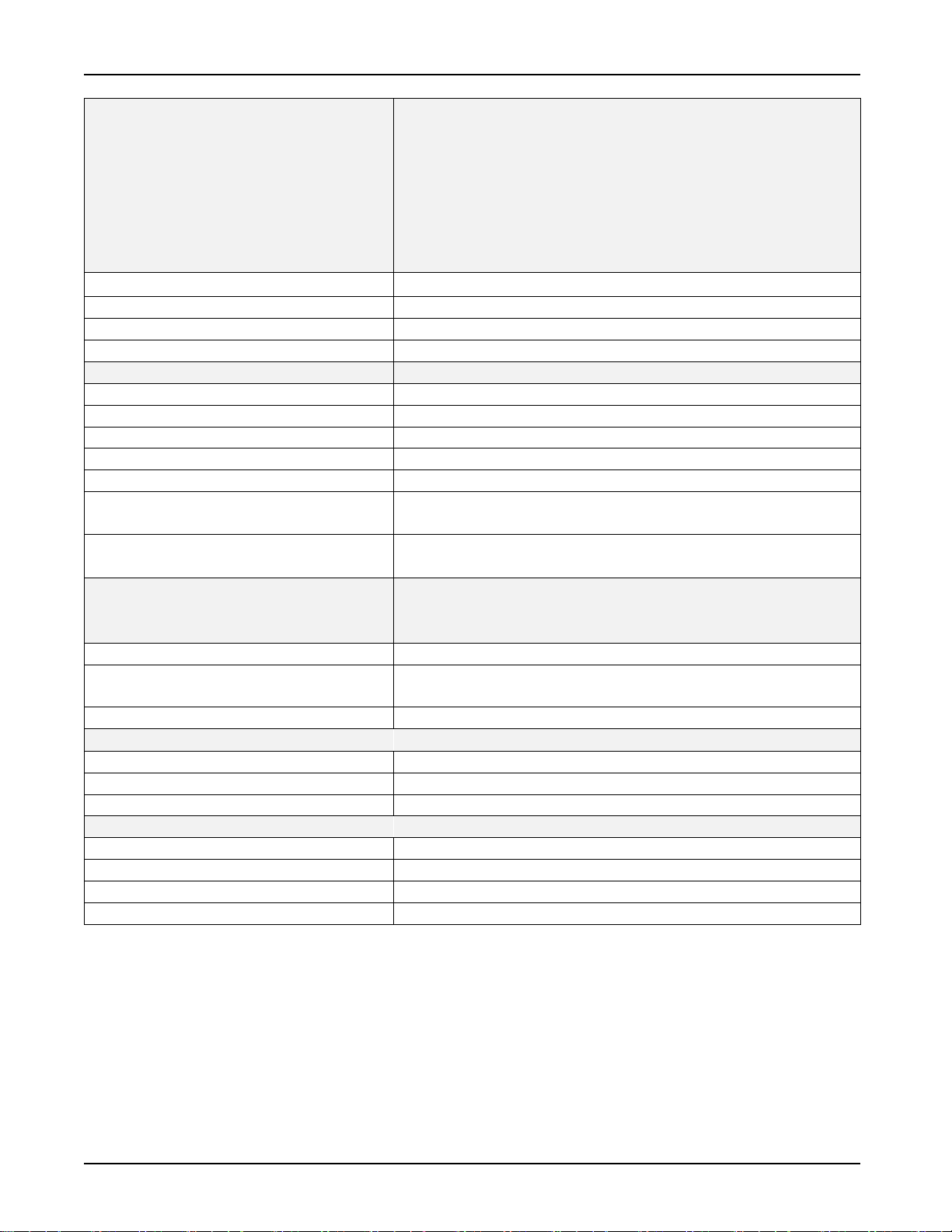

I/O Module Part No.

Description

HMC3-M0808P0401T

8 Digital Inputs (2 high-speed pairs, up to 200kHz)

8 Digital Outputs (2 PWM, up to 200kHz)

4 Analog Inputs (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA, Thermocouple, RTD)

1 Analog Output (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA)

HMC3-M0808Y0401T

8 Digital Inputs (2 high-speed pairs, up to 200kHz)

8 Digital Outputs (6 Relay, 2 PWM, up to 200kHz)

4 Analog Inputs (Voltage: 0-5V, 0-10V, Current: 0-20mA, 4-20mA, Thermocouple, RTD)

1 Analog Output (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA)

HMC3-M1212P0200

12 Digital Inputs (2 high-speed pairs, up to 200kHz)

12 Digital Outputs (2 PWM, up to 1kHz)

2 Analog Inputs (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA)

HMC3-M1212Y0200

12 Digital Inputs (2 high-speed pairs, up to 200kHz)

12 Digital Outputs (10 Relay, 2 PWM, up to 1kHz)

2 Analog Inputs (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA)

HMC3-M1210P0201

12 Digital Inputs (2 high-speed pairs, up to 200kHz)

10 Digital Outputs (2 PWM, up to 1kHz)

2 Analog Inputs (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA)

1 Analog Output (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA)

HMC3-M1210Y0201

12 Digital Inputs (2 high-speed pairs, up to 200kHz)

10 Digital Outputs (8 Relay, 2 PWM, up to 1kHz)

2 Analog Inputs (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA)

1 Analog Output (Voltage: 0-5V, 0-10V Current: 0-20mA, 4-20mA)

HMC3-M1614Y

16 Digital Inputs (2 high-speed pairs, up to 200kHz)

14 Digital Outputs (12 Relay, 2 PWM, up to 1kHz)

HMC3-M1616P

16 Digital Inputs (2 high-speed pairs, up to 200kHz)

16 Digital Outputs (2 PWM, up to 1kHz)

Page 6

I/O Expansion Module Overview 6

HMC3000 Series I/O Module Guide 6

I/O Expansion Module Overview

Each I/O terminal is labeled for easy identification on the modules. ‘COM’ is the common ground terminal. A

terminal with an ‘X’ followed by a number is an input terminal and a terminal with a ‘Y’ followed by a number is

an output terminal. The number refers to the position associated with each terminal on the I/O module.

When a project is created in MAPware-7000, bit/register memory addresses are assigned for each terminal on

the expansion module. MAPware-7000 provides the option to allow the software to do this automatically. In this

case, it will assign memory addresses according to the position and expansion slot in which the I/O module is

located.

In addition, many of the I/O modules have a two-pin connector that is used to connect a voltage source (usually

+24VDC). This voltage source drives the output terminals of the I/O modules.

Installing I/O Modules

The expansion modules for the HMC3000 base units attach onto the back of the HMC3000 via expansion slots

and are secured with a Phillips screw on the top-right and bottom-left corners of the module. The HMC3043A-M

supports one expansion module. The HMC3070A-M supports up to three modules, while the HMC3102A-M unit

supports up to five modules. Modules connected to the HMC3043A-M are attached horizontally to the rear

housing, while the other HMC3000 units allow for vertical mounting of the modules to the rear housing.

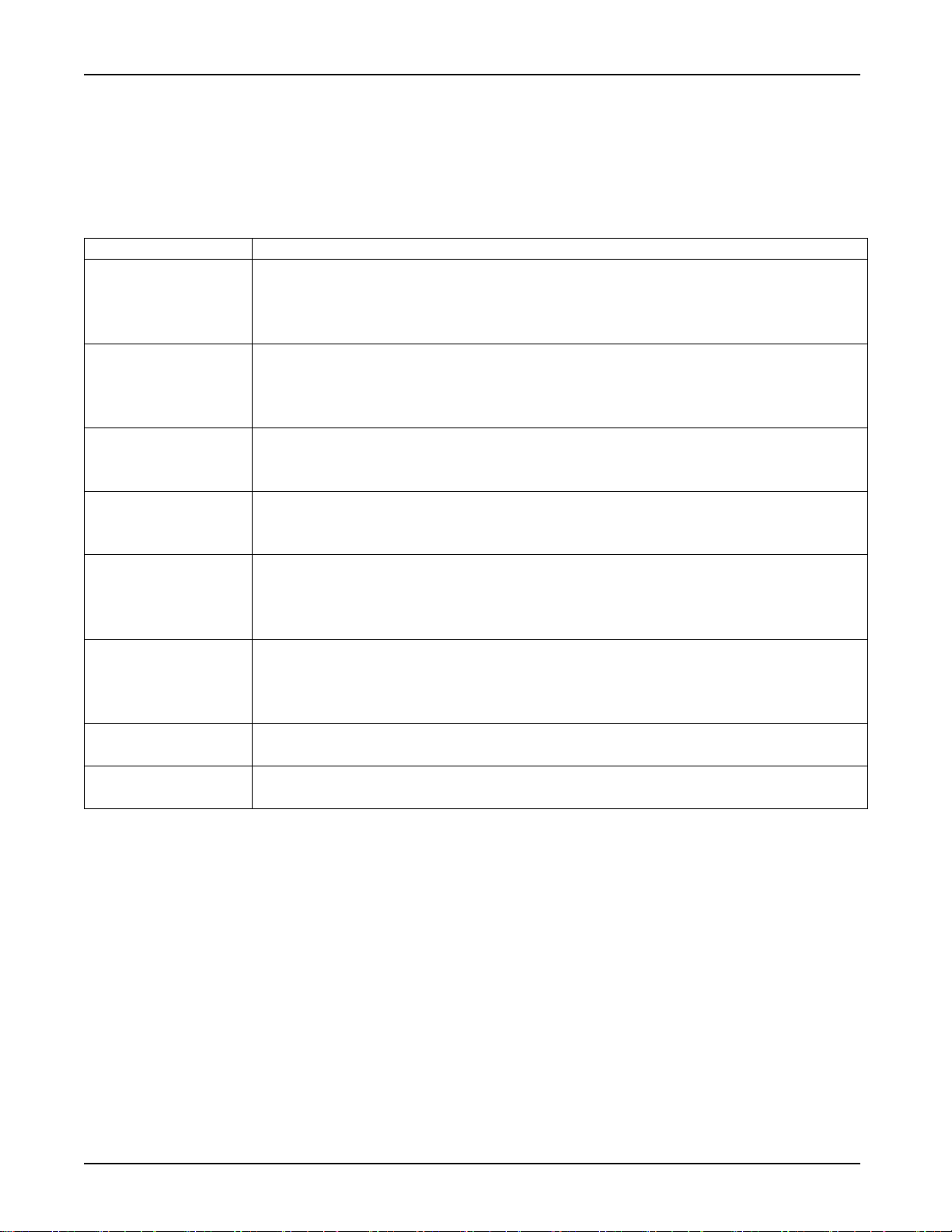

Configuring the I/O Modules

The I/O expansion modules for the HMC3000 Series are assigned to the proper slot using MAPware-7000. Note

that any project downloaded into a HMC3000 with modules that do not match the physical configuration of the

unit will not run. Therefore, it is important to correctly identify the I/O modules in the MAPware-7000 project.

Regardless of the particular HMC3000 model used, the steps to configure the I/O modules are very similar:

1. Open a new project and select the appropriate HMC3000 model. Click OK.

2. In the Project Information Window, click the IO Allocation folder, then click the Expansion folder.

Page 7

I/O Expansion Module Overview 7

HMC3000 Series I/O Module Guide 7

3. Double-click Slot 1 to display the IO Allocation dialog:

4. Select the particular I/O expansion module installed in Slot 1 of the HMC3000 from the drop-down

Model selection menu. When the checkbox to ‘Add tags for XW, YW, and MW’ option is checked,

MAPware-7000 automatically assigns tags to the Tag Database for the I/O module. The tags configured

are based upon the module and the slot location. Click OK to close the IO Allocation window, or click the

Configure button to pre-configure the module’s input and output channels.

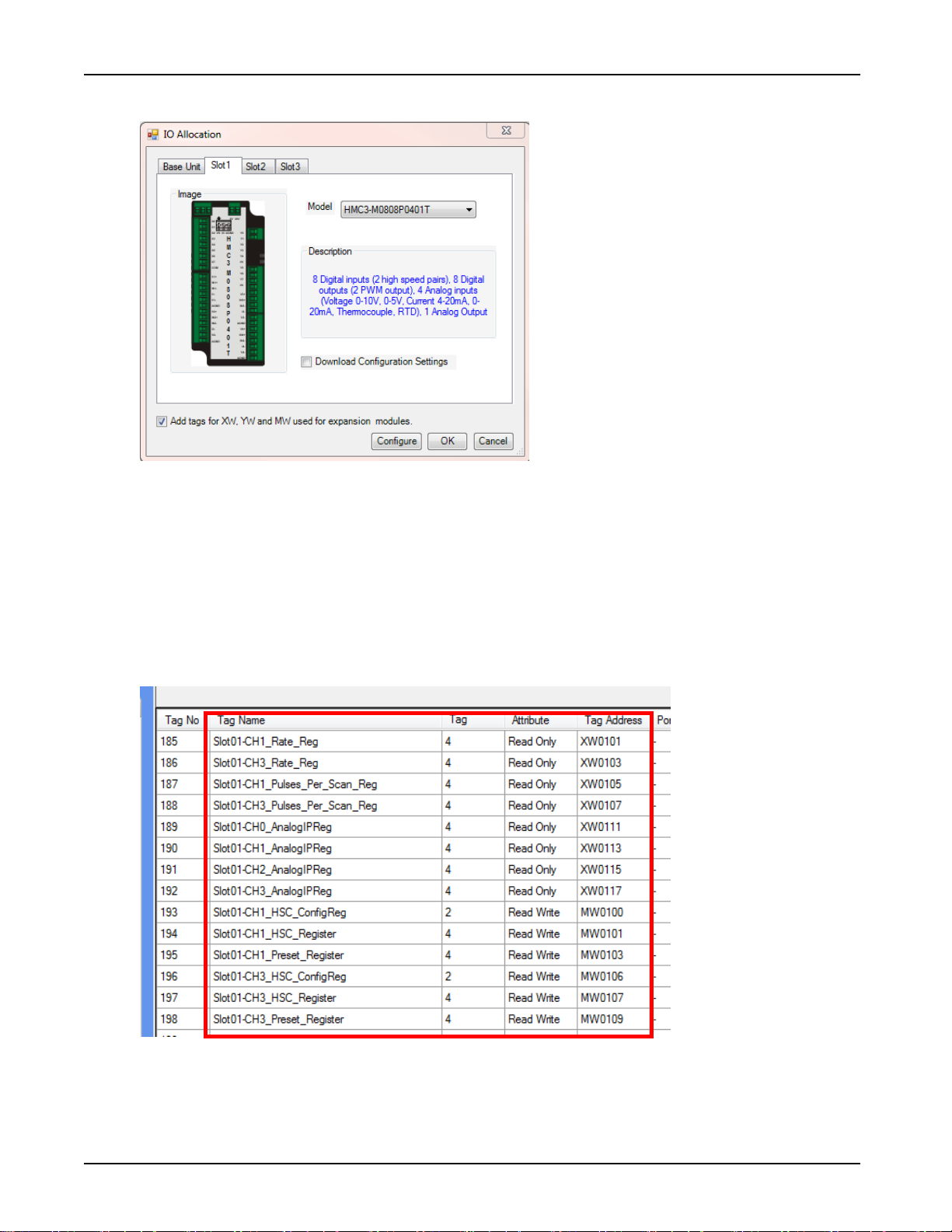

5. In this example, Slot 1 is identified with an I/O module, along with a description and memory address

allocation. The tags are available in the Tag Database as seen below. These tags can be used in the

project to address the I/O, or they can be preconfigured.

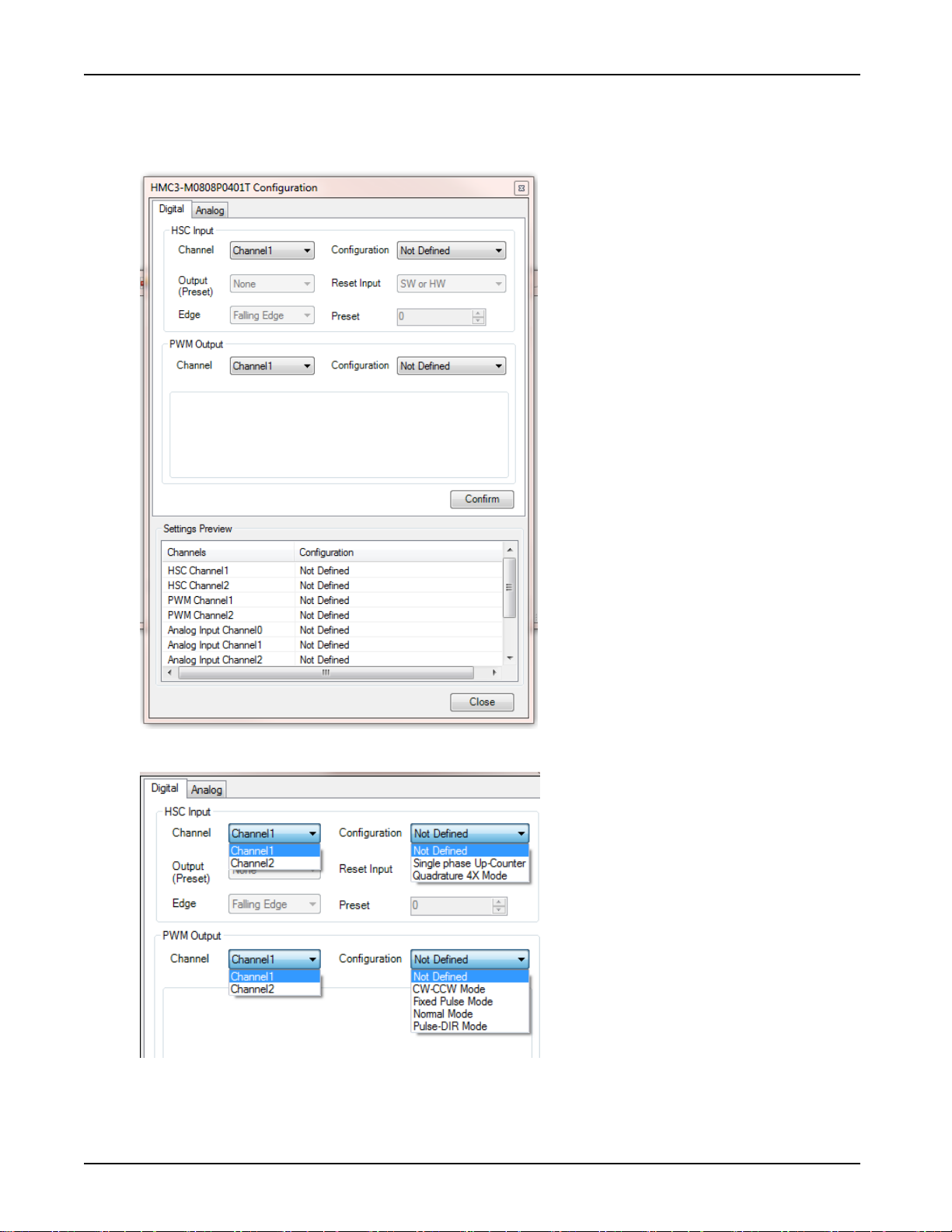

6. If pre-configuring the I/O modules, simply choose the appropriate Digital or Analog tab and set the

respective parameters of each input/output channel to your desired specifications. This will allow

configuration of the I/O module automatically, without the need to configure the module elsewhere in

Page 8

I/O Expansion Module Overview 8

HMC3000 Series I/O Module Guide 8

the project, such as from a window or via a power-up task. The available options will depend on the

module being configured. Select the channel and desired configuration, then click the Confirm button to

save the configuration.

7. The image below lists the digital configuration options for this specific module:

Page 9

I/O Expansion Module Overview 9

HMC3000 Series I/O Module Guide 9

8. For the Analog configuration of this module, the behavior is the same; choose the channel and the

configuration, then click the Confirm button to complete the configuration.

9. Options for the Analog configuration of this specific module:

Page 10

I/O Expansion Module Overview 10

HMC3000 Series I/O Module Guide 10

Common Terms and Definitions

This section defines some common terms used to describe various types of inputs and outputs. The terms

explained below are generic descriptions. Be sure to consult the datasheet for the specific requirements when

installing and wiring a module.

Digital Inputs and Outputs

Digital inputs provide physical connections and interpretations of input devices using discrete signals. The input

is represented in the PLC input registers as a 1 for the on state and 0 for the off state. Each digital input terminal

is associated with an internal Input Coil (X) in the tag database of the HMC3000. Similarly, each digital output

terminal is associated with an Output Coil (Y).

Analog Inputs and Outputs

Analog inputs provide physical connections and interpretations of input devices using analog signals. The input

range depends on the type of input device. Configure analog inputs to work with current or voltage sources.

Each analog input terminal is associated with an internal Input Register (XW) in the tag database of the

HMC3000. Similarly, each analog output terminal is associated with an Output Register (YW).

Sinking versus Sourcing

These terms refer to the type of digital inputs or outputs used. A sourcing I/O provides a voltage source, and a

sinking I/O provides a ground. Any module that is not bidirectional (meaning current can go in either direction)

requires that the circuit conduct current in a specific direction. In order to have current flow, each I/O terminal

on the expansion module must have a return path or a signal ground connection. In most modules, multiple I/O

terminals share the signal ground connection.

For a sourcing module, the current flows out of the expansion module terminal and into the common (signal

ground) terminal. The term source indicates the terminal on the expansion module provides the current to the

switch contact or load.

For a sinking module, the current flows into the expansion module terminal and out of the common terminal on

the I/O module. The term sink indicates the terminal takes in the current from the switch contact or load.

Note: Arrow indicates current flow direction

Page 11

I/O Expansion Module Overview 11

HMC3000 Series I/O Module Guide 11

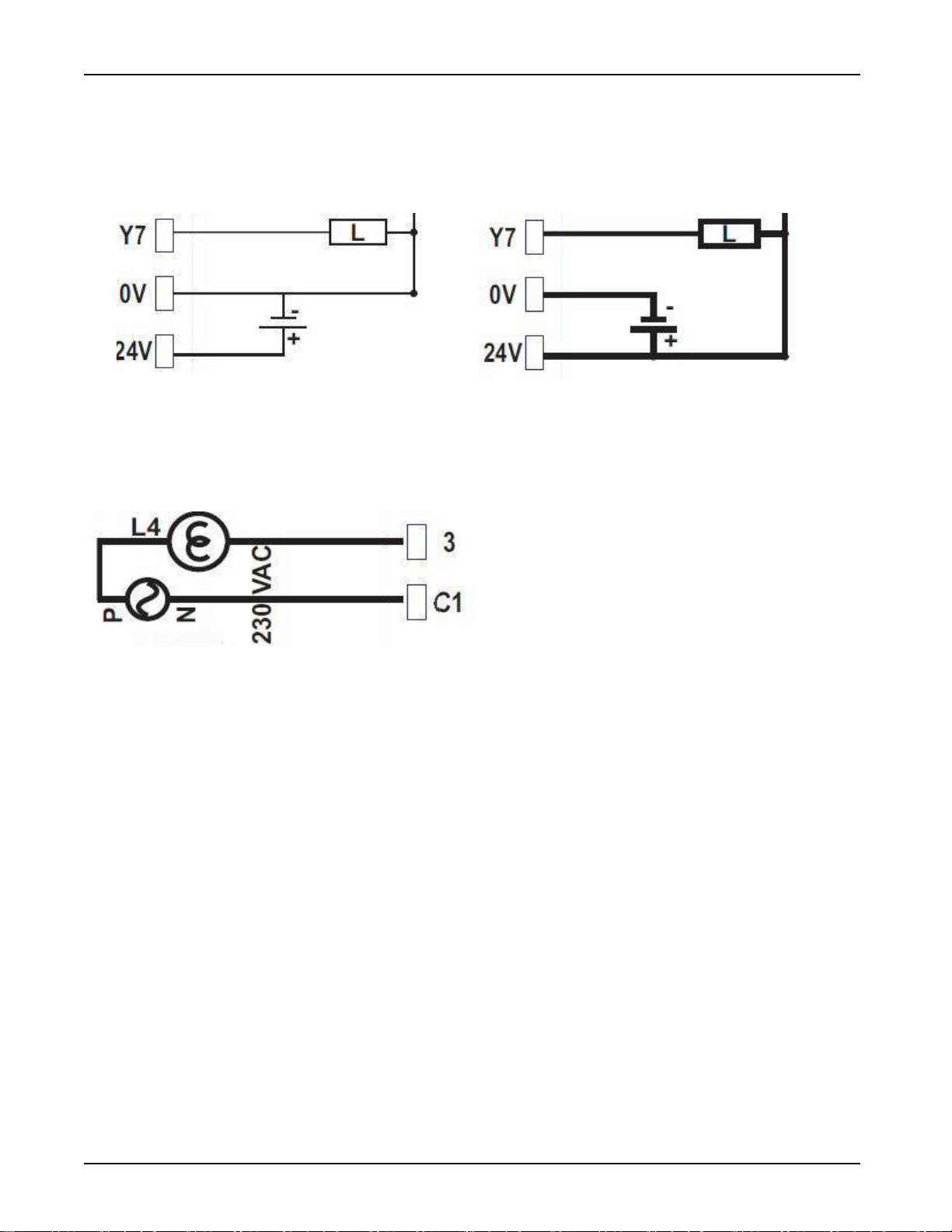

Digital Outputs (PNP or NPN type)

The output terminals of a digital I/O module use an optically isolated PNP or NPN transistor to energize the

connected load. PNP/NPN outputs are faster than relay outputs but can only work with low current DC loads

(typically 500mA max per terminal). PNP modules are sourcing modules, and NPN modules are sinking modules.

PNP-type connection (Source)

NPN-type connection (Sink)

Note: the above diagrams show that a PNP output is ‘sourcing’ current and the NPN output is ‘sinking’ current.

Digital Outputs (Relay type)

The output terminals of a relay-type digital module typically control loads that require an AC power source:

Use a Relay Output module to connect a DC load that requires more current than the maximum available when

using a PNP or NPN output. For AC loads, each relay output contact can handle up to 230VAC with a 2A load per

contact. For DC loads, each relay output contact can handle a 2A load per contact for up to 30VDC.

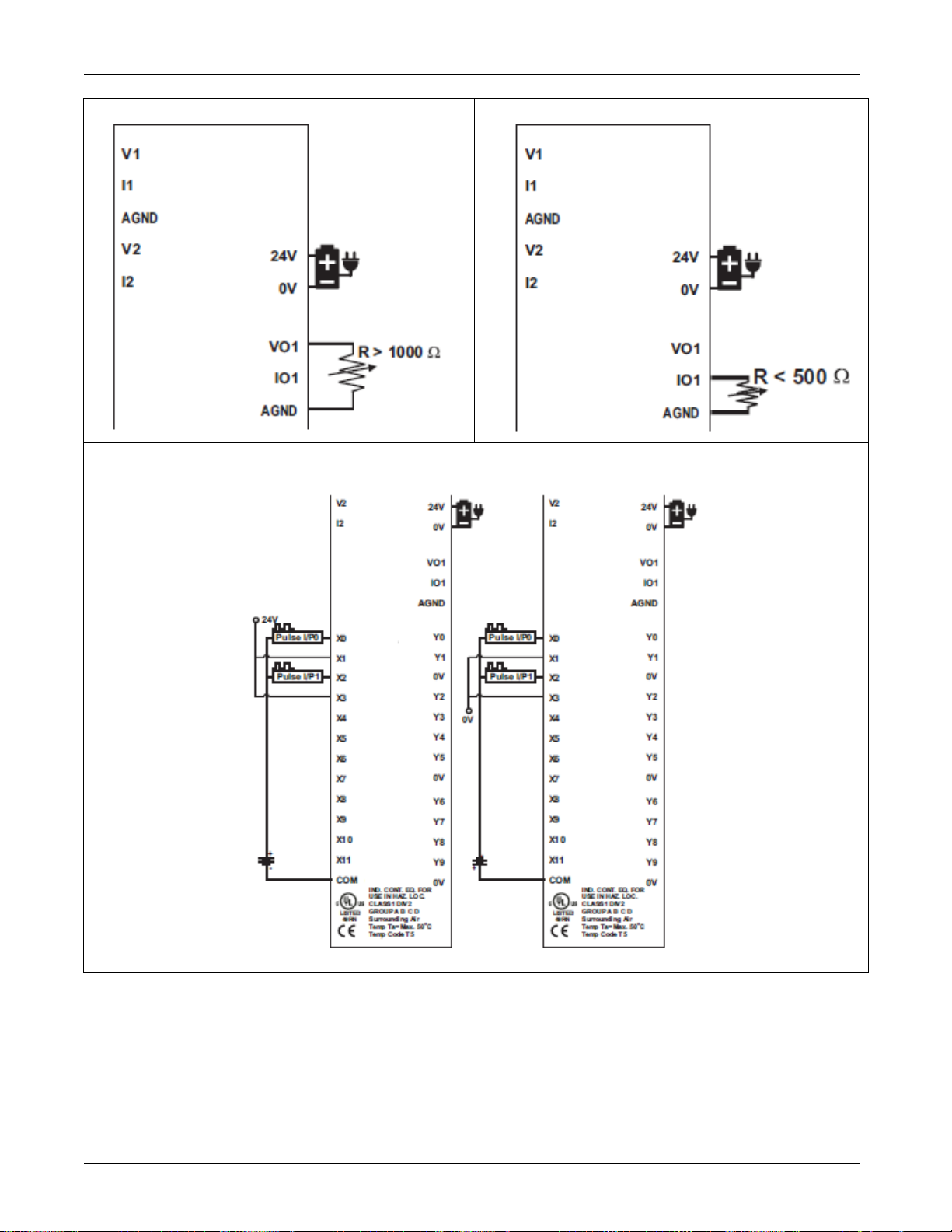

Analog Voltage

Analog voltage inputs can measure DC voltage ranges of 0-5 and 0 to 10 volts. With analog inputs, the analog

module writes a data value to the assigned register (XW) based upon the measured DC voltage at the input.

Analog outputs can provide 0 to 5VDC and 0 to 10 VDC with a minimum resistance of 1000 ohms depending

upon the value in the assigned register (YW). Input resolution is 16-bits and Output resolution is 12-bits.

Analog Current

Analog current inputs can measure DC current ranges from 0 to 20mA and 4 to 20mA. With analog inputs, the

analog module writes a data value to the assigned register (XW) based upon the measured DC current at the

input. The analog outputs can provide 0 to 20mA and 4 to 20mA. Analog outputs can deliver a DC current of up

to 20mA to a load with a maximum resistance of 500 ohms based upon the data value in the assigned register

(YW). Input resolution is 16-bits and Output resolution is 12-bits.

Page 12

I/O Expansion Module Overview 12

HMC3000 Series I/O Module Guide 12

Configuring High-speed Counters

Maple Systems’ HMC modules have built-in High-Speed counters that link directly to specific inputs and outputs.

Specific registers and bits are predefined for setup and control of these counters. No logic is required to run the

counters, other than logic that may be used for configuration and control.

Two inputs on the module are used as the Triggers for the High-Speed counters, and two outputs are used as

the Done bits. The inputs support a maximum speed of 200 KHz.

The following bits and registers are associated with a High-Speed counter:

Register/ Bit

Description

Configuration

Register

The 16-bit register that controls how the High-Speed counter operates.

Current Count

Register

The 32-bit register that counts the number of times that the Trigger has

transitioned. The specified register is the Least Significant Word (LSW); the next

consecutive register is the Most Significant Word (MSW).

Preset Register

The 32-bit register that defines the number of counts at which the Done bit will be

set (see description of Done Bit below). The specified register is the Least Significant

Word (LSW); the next consecutive register is the Most Significant Word (MSW).

Trigger Bit

The input bit that triggers the count. The counter will increment by one on each bit

transition. The counter can operate on a falling (default) or rising edge.

Enable Bit

The counter will not run unless this bit is set. If this bit is reset while the counter is

running, the current values will be maintained, but the Trigger bit will have no

effect. The Done bit is reset if the Enable bit is reset. If the Current Count value is

greater than or equal to the Preset value, the Done bit is set after the Enable bit is

set again.

Reset Bit

When this bit goes from false to true, the current count will reset to 0 and the Done

bit is reset. The reset occurs even when the Enable bit is reset. The reset is

accomplished by an internal bit or a physical input.

Done Bit

The physical output that turns on when the Current Count is equal to or greater than

the Preset value. The bit remains set until the Reset bit goes true, even if the

counter counts beyond the preset. If the Enable bit is reset, the Done bit will reset. If

the Enable bit is set while the Current Count is equal to or greater than the Preset,

the Done bit is set.

Reference the tables below when configuring each HSC Configuration Register:

Input Mode

Output Mode

Register Value

Normal Input

N/A

0

High Speed,

Single Phase,

Up/Down Counter

Output ON when preset is reached

2

Output ON when counter is enabled,

OFF when preset is reached

258

Quadrature 4X

Output ON when preset is reached

131

Output ON when counter is enabled,

OFF when preset is reached

387

Page 13

I/O Expansion Module Overview 13

HMC3000 Series I/O Module Guide 13

HSC Configuration Register Bit table

Bits

Function

15-12

Not used

11-10

00: Reset counter if SW Reset bit or physical I/Preset bit goes from 0 to 1

01: Reset counter if the SW reset bit goes from 0 to 1

11: reserved for future use

9

Forced Output Configuration

0: Forced output ON for Preset 1

1: Forced output ON when enabled and OFF when Preset 1 reached

8

Forced Output Control

0: Forced Output Disabled

1: Forced Output Enabled

7-6

Quadrature mode

00: Reserved

01: Reserved

010: 4X Quadrature mode

4-5

HSC

00: Single Phase Up counter

3

0: Falling Edge

1: Rising Edge

2, 1, 0

Module Operating Mode

000: Normal Operation

010: Up Counter HSC

011: Quadrature

To Implement High-speed Counter Operation

1. Connect a device that will provide the high-speed pulses to one of the high-speed inputs on the

expansion module.

2. Configure the HSC using the configuration register for that channel.

Note: You can write to the configuration register value using the Power-Up logic block or in a Power-Up

Task.

3. Write the HSC preset count value in that channel’s Preset Register.

4. Enable the HSC by setting the HSC Enable Bit for that channel.

5. HSC increments the current value register for that channel until the preset value is reached.

6. Enable the HSC Reset Bit for that channel. This will cause the HSC current value to reset back to 0.

7. To start the process again, simply reset (clear) the HSC Reset Bit and set the HSC Enable Bit.

Note: if the HSC Enable Bit is still ON, you must reset (clear) this bit, and then set it again.

Page 14

I/O Expansion Module Overview 14

HMC3000 Series I/O Module Guide 14

Specific High-speed Counter Registers

The registers and I/O associated with the High-Speed Counter can be found below.

Function

Counter 1

(Channel 0)

Counter 2

(Channel 1)

Trigger Bit

Xnn000

Xnn002

Enable Bit

Mnn080

Mnn176

Reset Bit

Mnn081

Mnn177

Configuration Register

MWnn00

MWnn06

Current Count Register (LSW, MSW)

MWnn01, MWnn02

MWnn07, MWnn08

Preset Register (LSW, MSW)

MWnn03, MWnn04

MWnn09, MWnn10

Note: nn is the slot in which the module is installed (slot 1 is 01, slot 2 02, etc.)

For example, a module installed in Slot 3 has the following assignments:

Function

Counter 1

(Channel 0)

Counter 2

(Channel 1)

Trigger Bit

X03000

X03002

Enable Bit

M03080

M03176

Reset Bit

M03081

M03177

Configuration Register

MW0300

MW0306

Current Count Register (LSW, MSW)

MW0301, MW0302

MW0307, MW0308

Preset Register (LSW, MSW)

MW0303, MW0304

MW0309, MW0310

Configuring Pulse Width Modulation (PWM) Outputs

Maple Systems’ HMC3000 I/O modules have built-in Pulse Width Modulation functionality. Specific registers and

bits are predefined for setup and control of these functions. No logic is required to run the PWM, other than

logic that may be used to configure and control them.

There are four modes of PWM: Normal, CW/CCW, Pulse/Direction and Fixed Pulse. Use the information below

to configure the desired PWM output mode.

Note: For each table below, nn is the slot in which the module is installed (slot 1 is 01, slot 2 02, etc.)

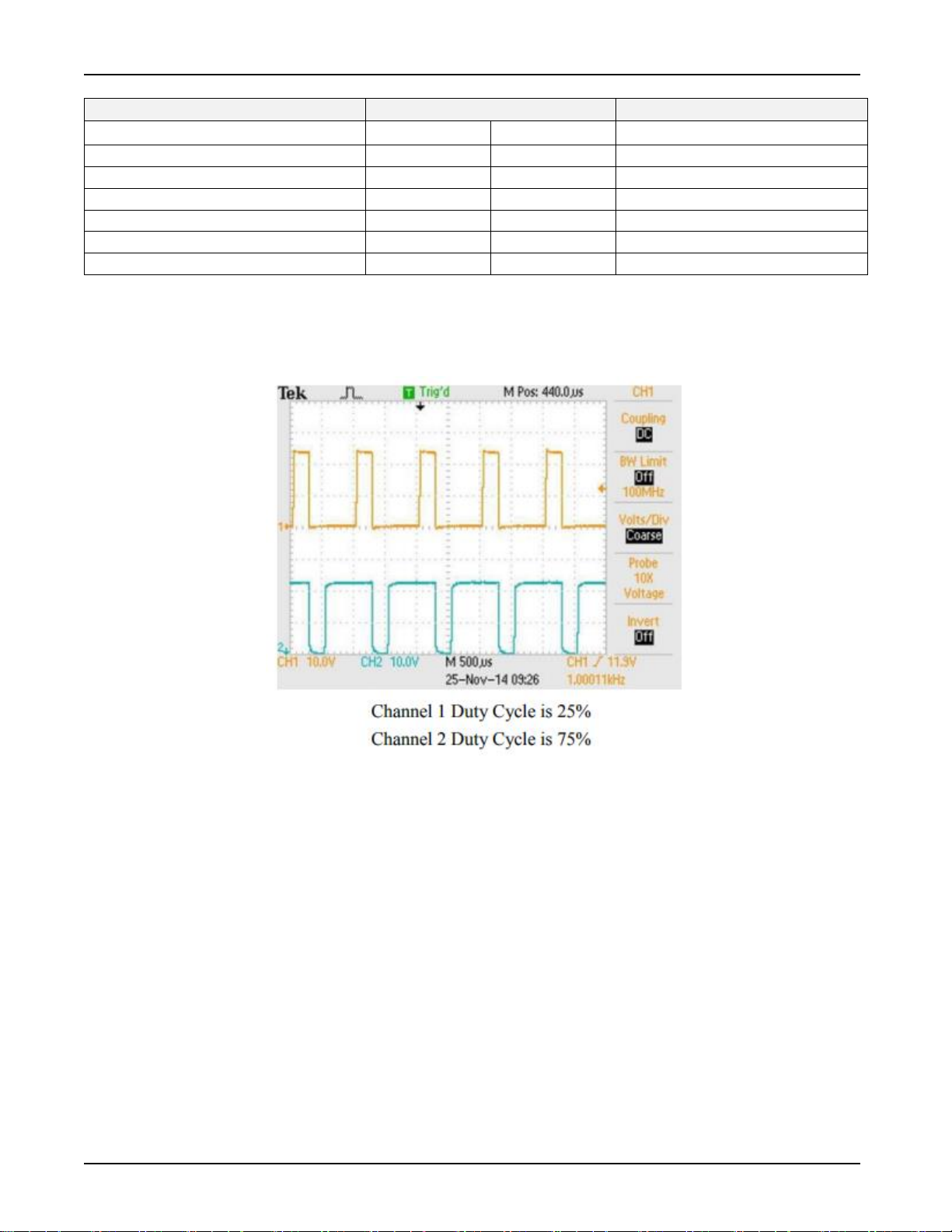

Normal PWM

The frequency must be the same for channel 1 and channel 2, but the Duty Cycle is independently adjustable for

each channel. Duty Cycle can be adjusted while the output is running. The valid range is 0 to 100%, but the

effective range will vary depending on the device being controlled. The frequency can be adjusted while running

(place a 2 in the Config register). The Channel 1 and Channel 2 outputs can be enabled and disabled

independently.

Page 15

I/O Expansion Module Overview 15

HMC3000 Series I/O Module Guide 15

Function

Register

Description

Output, PWM Pulse

Y0 (Channel 1)

Y1 (Channel 2)

Physical Output

Configuration Register

MWnn24

MWnn30

Value = 1 for this mode

Frequency Setting Register

MWnn25

MWnn31

Range = 1 to 200000

ON Duty Setting Register (Duty Cycle)

MWnn27

MWnn33

Range = 0 to 100

Pulse Enable Flag

Mnn576

Mnn577

Output enabled when ON

ON Duty Setting Error Flag

Mnn466

Mnn471

ON = error (resets automatically)

Frequency Setting Error Flag

Mnn467

Mnn472

ON = error (resets automatically)

Page 16

I/O Expansion Module Overview 16

HMC3000 Series I/O Module Guide 16

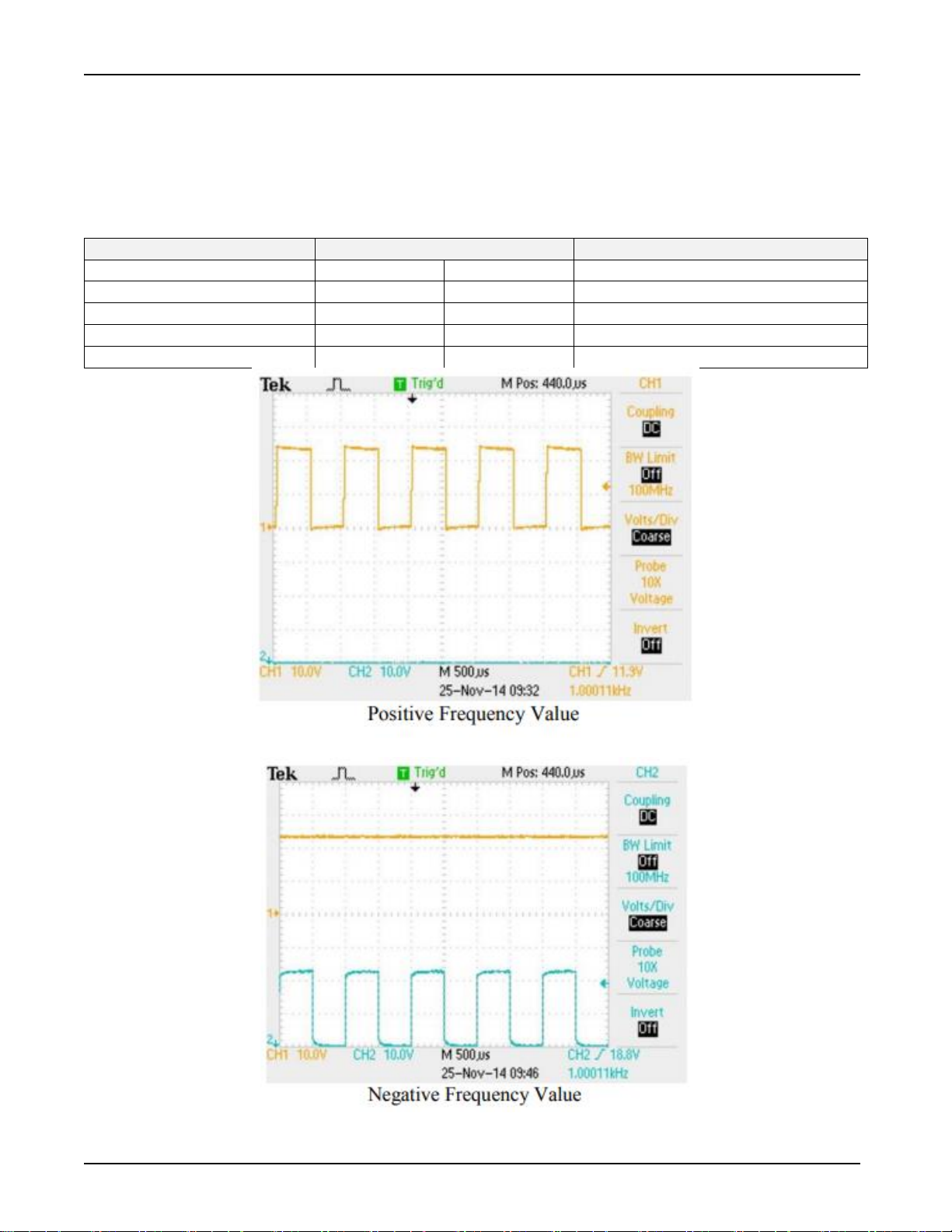

CW/CCW

When the frequency is positive, the output signal is generated on Channel 1, and Channel 2 is not used. When

the frequency value is negative, the output signal is generated on Channel 2, and Channel 1 is not used. The

frequency can be adjusted while running (place a 4 in the Config register instead of 3), and the Duty Cycle is

fixed at 50%.

Function

Register

Description

Output, PWM Pulse

Y0 (Channel 1)

Y1 (Channel 2)

Physical Output

Configuration Register

MWnn24

MWnn30

Value = 3 for this mode

Frequency Setting Register

MWnn25

MWnn31

Range = -100000 to -1 and 1 to 100000

Pulse Enable Flag

Mnn576

Mnn577

Output enabled when ON

Frequency Setting Error Flag

Mnn467

Mnn472

ON = error (resets automatically)

Page 17

I/O Expansion Module Overview 17

HMC3000 Series I/O Module Guide 17

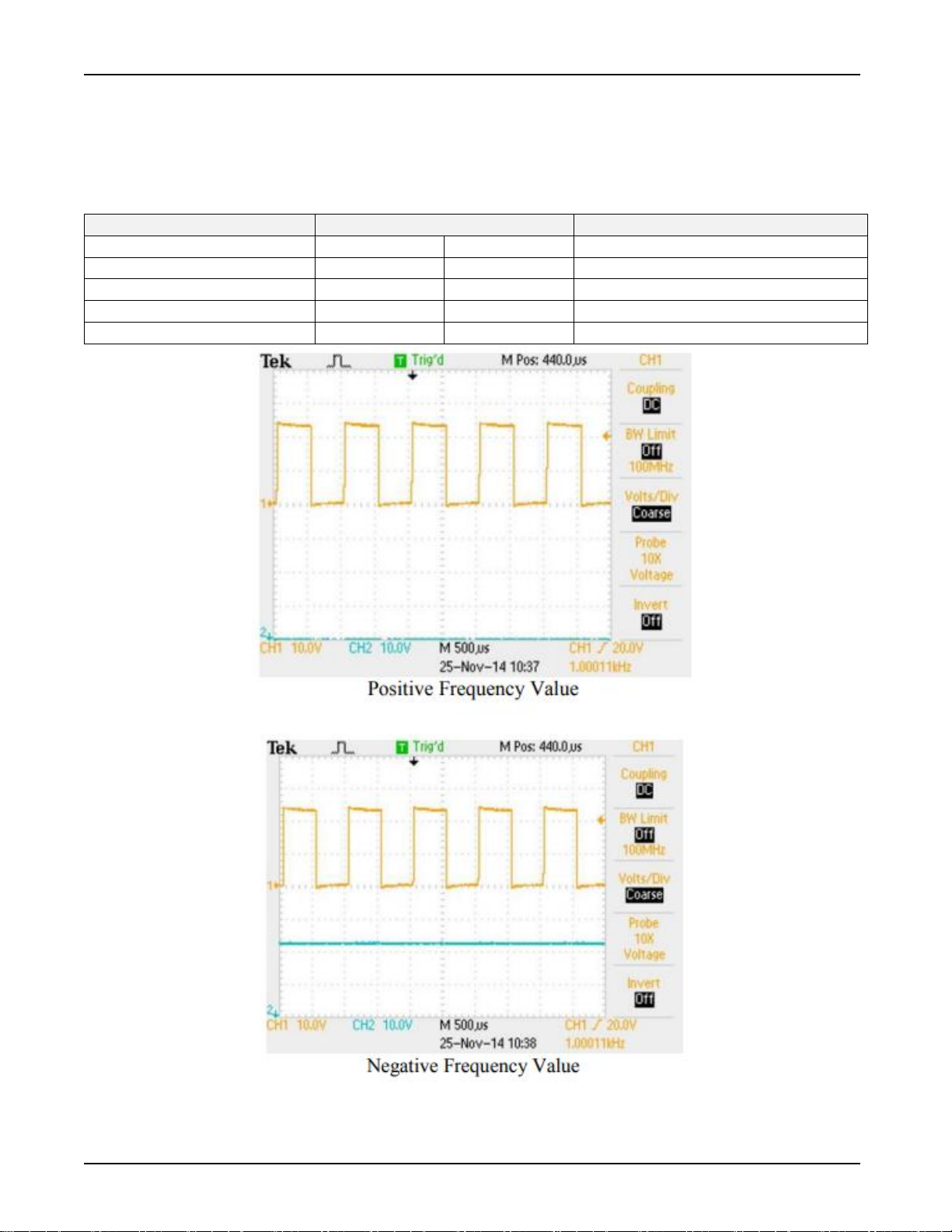

Pulse/Direction

The output signal is generated on Channel 1. If the frequency value is positive, Channel 2 is held low. If the

frequency value is negative, Channel 2 is held high. The frequency can be adjusted while running (place an 8 in

the configuration register), and the Duty Cycle is fixed at 50%.

Function

Register

Description

Output, PWM Pulse

Y0 (Channel 1)

Y1 (Channel 2)

Physical Output

Configuration Register

MWnn24

MWnn30

Value = 7 for this mode

Frequency Setting Register

MWnn25

MWnn31

Range = -100000 to -1 and 1 to 100000

Pulse Enable Flag

Mnn576

Mnn577

Output enabled when ON

Frequency Setting Error Flag

Mnn467

Mnn472

ON = error (resets automatically)

Page 18

I/O Expansion Module Overview 18

HMC3000 Series I/O Module Guide 18

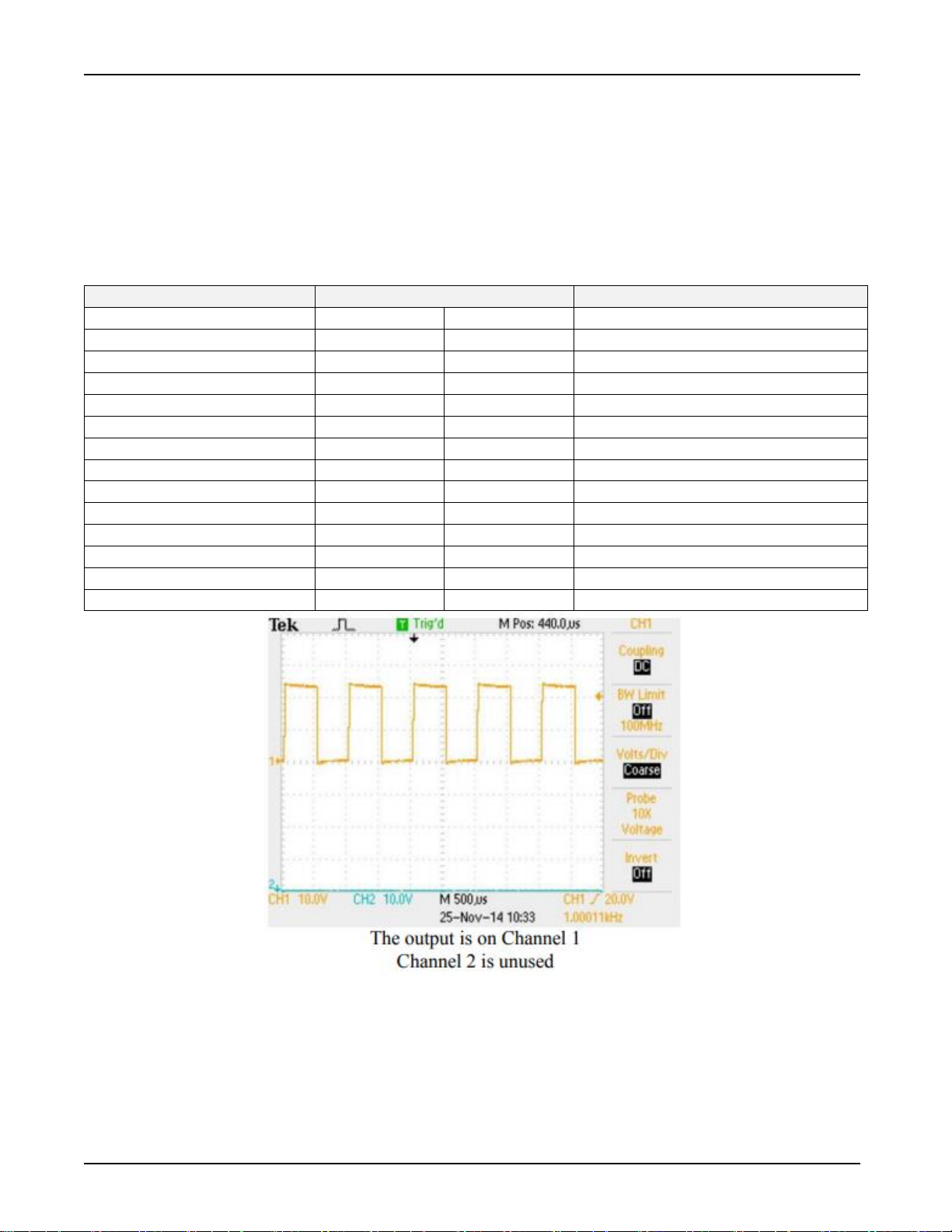

Fixed Pulse Mode

The output signal is generated on Channel 1. The frequency ramps up from the minimum frequency to the

maximum frequency in the interval specified by acceleration time. The output signal is generated until the

specified number of pulses has been sent. As the number of pulses approaches the specified count, the

frequency ramps down from the maximum frequency to the minimum frequency in the interval specified by the

deceleration time. When the specified number of pulses is reached, the output signal stops but remains

enabled. The Duty Cycle is fixed at 50%.

Function

Register

Description

Output, PWM Pulse

Y0 (Channel 1)

Y1 (Channel 2)

Physical Output

Configuration Register

MWnn24

MWnn30

Value = 9 for this mode

Minimum Frequency Register

MWnn25

MWnn31

Range = 1 to 100000

Maximum Frequency Register

MWnn27

MWnn33

Range = 1 to 100000

Acceleration Time Register

MWnn37

MWnn38

Range: 0 to 65535

Deceleration Time Register

MWnn39

MWnn40

Range: 0 to 35536

Total Pulses Register

MWnn41

MWnn43

0 to 4294967295

Elapsed Pulses Register

MWnn45

MWnn47

0 to 4294967295

Pulse Enable Flag

Mnn576

Mnn577

Output enabled when ON

Frequency Setting Error Flag

Mnn467

Mnn472

ON = error (resets automatically)

Acceleration Time Error Flag

Mnn468

Mnn473

ON = error

Deceleration Time Error Flag

Mnn469

Mnn474

ON = error

Total Pulses Setting Error Flag

Mnn470

Mnn475

ON = error

Total Pulses Reached

Mnn784

Mnn785

ON when Total Pulses have been sent

To Implement PWM Operation:

1. Configure the PWM output using the configuration register for that channel and mode.

2. Set the parameter values for the selected mode. Monitor the error flags for the parameters.

3. Enable the output by setting the Enable Output bit for that channel.

Page 19

HMC3-M0808P0401T 19

HMC3000 Series I/O Module Guide 19

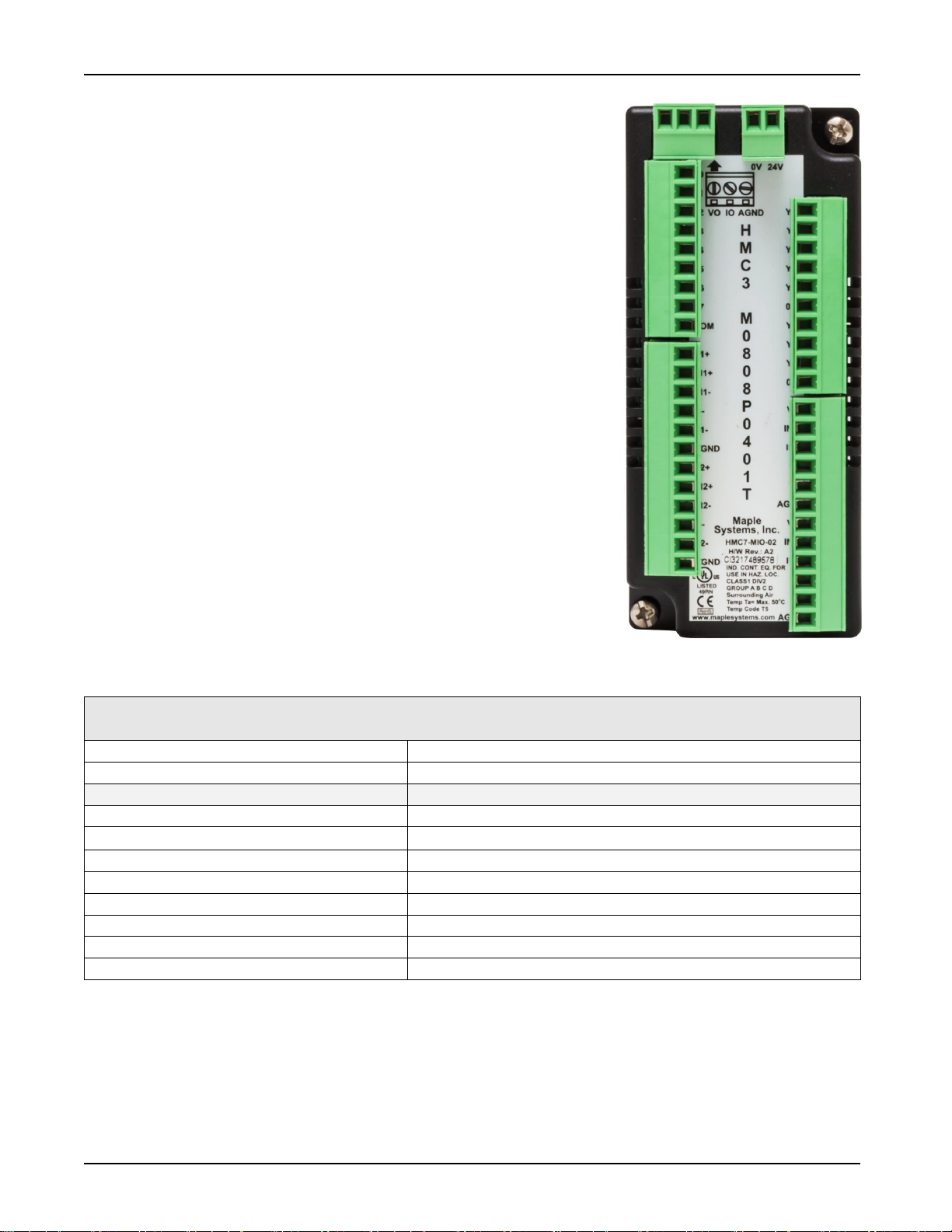

HMC3-M0808P0401T

8 Digital Inputs (2 high-speed pairs up to 200kHz)

8 Digital Outputs (2 PWM up to 200kHz)

4 Universal Analog Inputs

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

• Thermocouple

• RTD

1 Analog Output

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

This module is an input/output module for the HMC3000 Series models. It

has eight bidirectional inputs, two pairs of which are high-speed inputs. It

also has eight digital sourcing (PNP) outputs, two of which can be

configured for PWM operation.

This module also has 4 universal analog inputs

(Voltage/Current/Thermocouple/RTD) as well as one analog output

(Voltage/Current).

Specifications

Power

12V and 3.3VDC from base

Certifications

CE, UL

Digital Inputs

8 bidirectional inputs (2 high-speed pairs)

Rated Input Voltage

24 VDC

Rated Input Current

Up to 5mA (per contact)

Input Impedance

3K ohms

Minimum ON voltage

15 VDC

Maximum OFF voltage

5 VDC

Turn ON Time

10 mSec

Turn OFF Time

10 mSec

Isolation

Optically isolated from internal circuit

Page 20

HMC3-M0808P0401T 20

HMC3000 Series I/O Module Guide 20

Analog Inputs

4 Inputs, each configurable as:

• 0 to 50mV, 0 to 100 mV; 0 to 10V, 0 to 5V;

• 0 to 20mA, 4-20mA;

• PT100 RTD, alpha1 [0.00385 Ω/Ω°C] (-200 to 850 C);

• PT100 RTD, alpha2 [0.003926 Ω/Ω°C] (-100 to 457 C);

• PT1000 RTD (-200 to 850 C);

• Type J Thermocouple (-210 to 1200 C);

• Type K Thermocouple (-200 to 1373 C)

Input Resolution

16 bit

Input Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Digital Outputs

8 sourcing outputs (PNP-type), 2 of which are PWM

Maximum PWM Output Frequency

200KHz

Minimum ON Output Voltage

22 VDC

Maximum ON Output Voltage

30 VDC

Minimum OFF Output Voltage

0.2 VDC

Maximum OFF Output Voltage

1 VDC

Rated Load

250mA @ 24VDC

Nominal load

96 6W (resistive) @ 24VDC

6VA (inductive, UPF)

Analog Outputs

1, configurable as:

• 0 to 5V, 0 to 10V;

• 0 to 20mA, 4-20mA

Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Load

1 KΩ (Min) for V;

500Ω (Max) for mA

Output Resolution

12 bit

High-speed Channels

No. of inputs

2 channel pairs (X0/X1 and X2/X3)

Maximum Input Frequency

200 KHz

Maximum Input Count

4,294,967,295 (32-bit)

General

Connection method

Removable terminals (3.81 mm pitch)

Operating Temperature

0 to 55°C

Operating Humidity

10% to 90% (non-condensing)

Mechanical Dimension (W x H x D)

1.88 x 4.25 x 1.61 inches [48x108x41mm]

Page 21

HMC3-M0808P0401T 21

HMC3000 Series I/O Module Guide 21

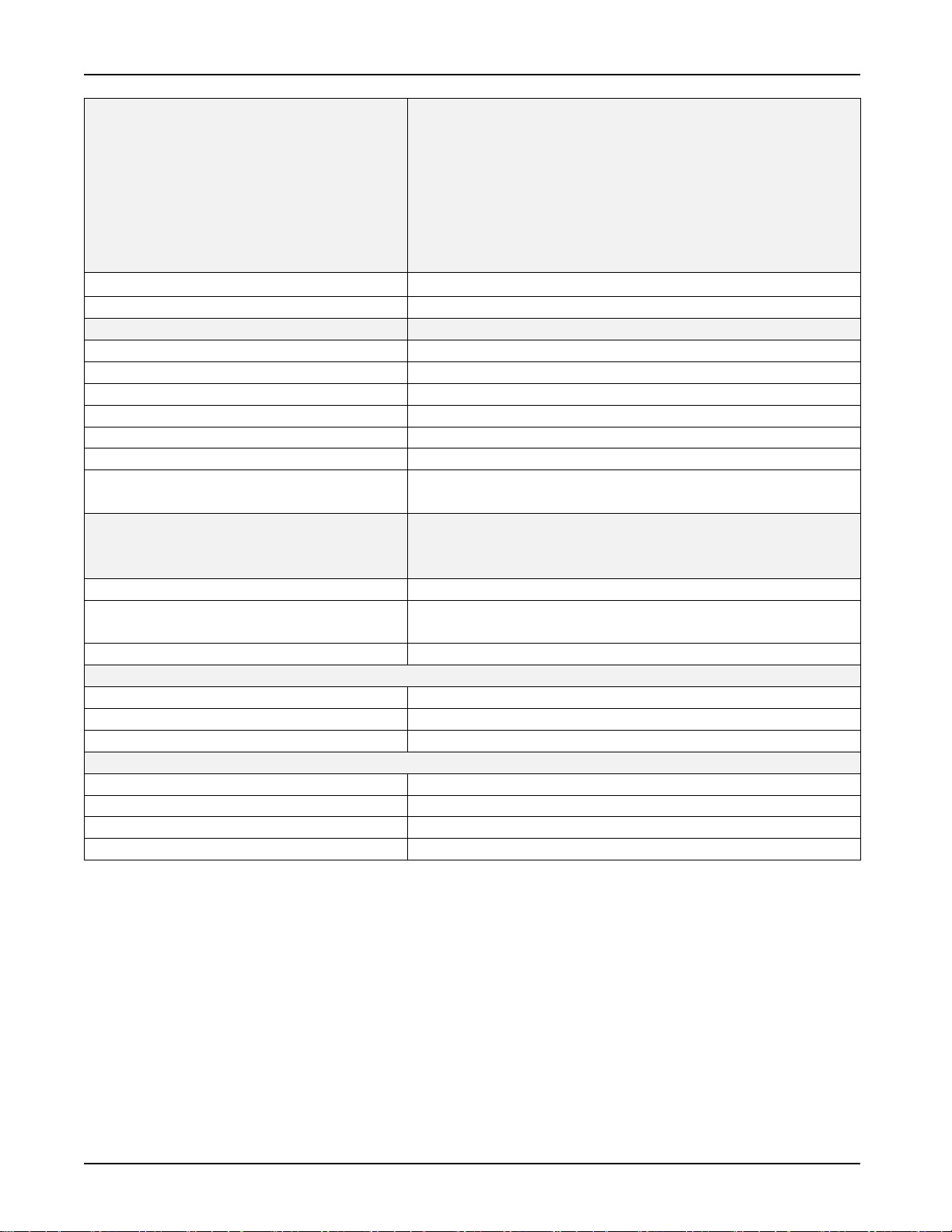

Configuration

Use MAPware-7000 to assign input (X and XW), output (Y and YW) and configuration (M and MW) memory

addresses to the module. These addresses are created according to the slot location of the module, where nn

refers to the slot number (ex. 01…05):

Function

Register

Access

X0-X7 Digital Inputs

Xnn000-007 (XWnn00)

Read Only

Y0-Y7 Digital Outputs

Ynn000-007 (YWnn00)

Read/Write

High-speed Counter Option

HSC Channel 1

HSC Channel 2 HSC Input Pin

X0

X2

Read Only

Quadrature Inputs

Pair 1

Pair 2 Counter Inputs

X0, X1

X2, X3

Read Only

HSC Configuration Register

MWnn00

MWnn06

Read/Write

HSC Counter Register (Current Value)

MWnn01

MWnn07

Read/Write

HSC Preset Register

MWnn03

MWnn09

Read/Write

HSC Enable Bit

Mnn080

Mnn176

Read/Write

HSC Reset Bit

Mnn081

Mnn177

Read/Write

Output Flag

Y2

Y3

PWM Outputs

Channel 1

Channel 2

Output

Y0

Y1

Read Only

PWM Configuration Register

MWnn24

MWnn30

Read/Write

Frequency Setting Register

MWnn25

MWnn31

Read/Write

ON Duty Setting Register (Duty Cycle)

MWnn27

MWnn33

Read/Write

Pulse Enable Flag

Mnn576

Mnn577

Read/Write

ON Duty Setting Error Flag

Mnn466

Mnn471

Read Only

Frequency Setting Error Flag

Mnn467

Mnn472

Read Only

Analog Inputs

Register

Input Channel 0 Data

XWnn11

Read Only

Input Channel 1 Data

XWnn13

Read Only

Input Channel 2 Data

XWnn15

Read Only

Input Channel 3 Data

XWnn17

Read Only

Input Channel 0 Config Register

MWnn60

Read/Write

Input Channel 1 Config Register

MWnn61

Read/Write

Input Channel 2 Config Register

MWnn62

Read/Write

Input Channel 3 Config Register

MWnn63

Read/Write

Analog Outputs

Register

Output Channel 0 Data (Voltage)

YWnn01

Read/Write

Output Channel 0 Data (Current)

YWnn02

Read/Write

Output Channel 0 Config Register

MWnn68

Read/Write

Page 22

HMC3-M0808P0401T 22

HMC3000 Series I/O Module Guide 22

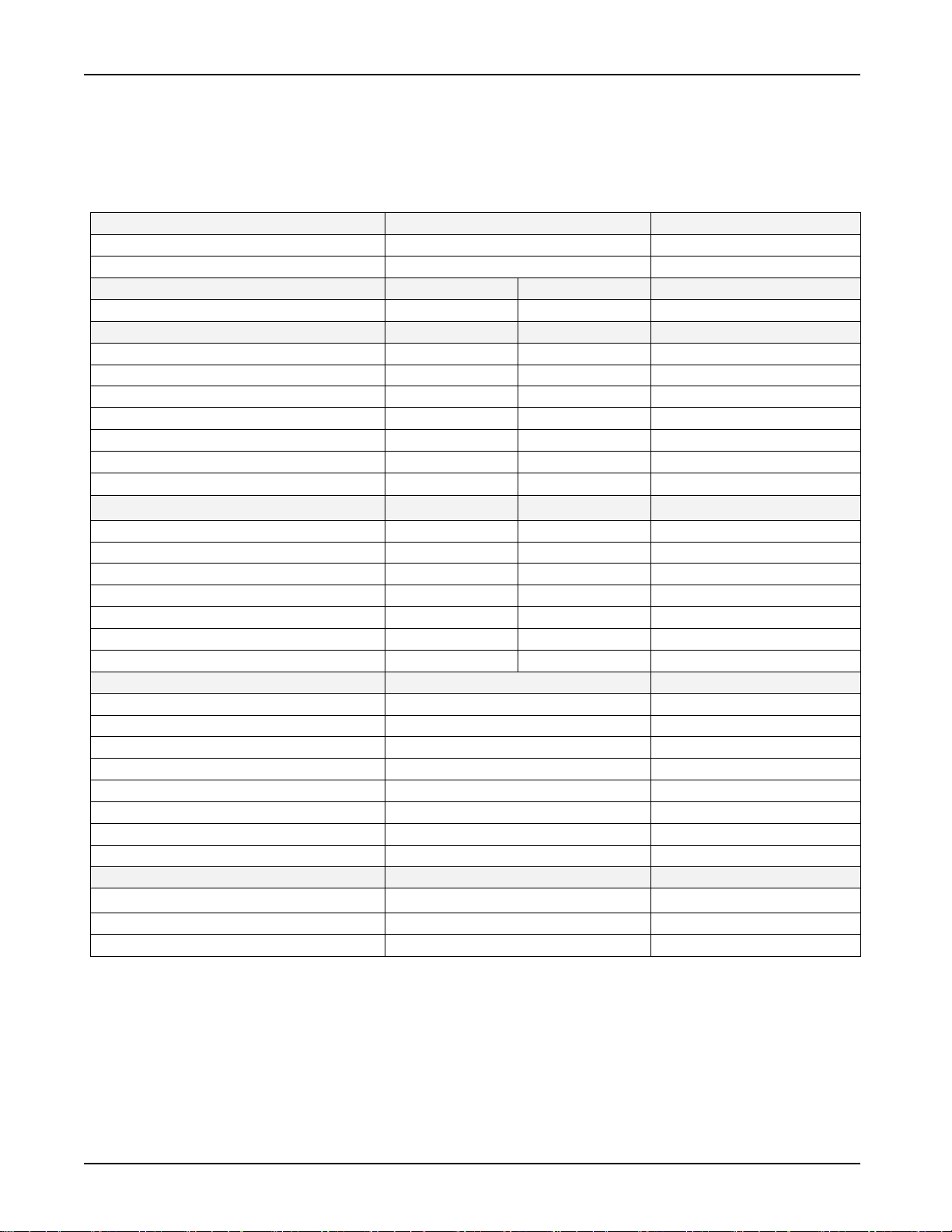

Reference the table below when configuring each HSC Configuration Register:

Input Mode

Output Mode

Register Value

Normal Input

N/A

0

High Speed,

Single Phase,

Up/Down Counter

Output ON when preset is reached

2

Output ON when counter is enabled,

OFF when preset is reached

258

Quadrature 4X

Output ON when preset is reached

131

Output ON when counter is enabled,

OFF when preset is reached

387

Reference the table below when configuring the PWM Configuration Registers:

Output Mode

Register Value

Normal PWM (fixed frequency)

1

Normal PWM (variable frequency)

2

CW/CCW (fixed frequency)

3

CW/CCW (variable frequency)

4

Pulse/Direction (fixed frequency)

7

Pulse/Direction (variable frequency)

8

Trapezoidal (Fixed Pulse Mode)

9

Reference the table below when configuring each Analog Input Configuration Register (MWnn60-MWnn63):

Input Signal Type

Register Value

Voltage, 0 to 10V

1

Voltage, 0 to 5V

6

Voltage, 0 to 50mV

5

Voltage, 0 to 100mV

4

Current, 4 to 20mA

2

Current, 0 to 20mA

3

RTC and Thermocouple

For °C

For °F

RTD, PT100, alpha1 1

7

19

RTD, PT100, alpha2 1

8

20

RTD, PT1000

9

21

Thermocouple, Type J 2

14

26

Thermocouple, Type K 2

15

27

Notes:

1. alpha1= 0.00385 Ω/Ω°C, alpha2=0.003926 Ω/Ω°C

2. 15-minute module warm-up time recommended

The values in the appropriate analog input register range from 0-65535.

Expansion Module

Reg Value

Input Values

0 to 20mA

4 to 20mA

0 to 10V

0 to 5V

0 to 100mV

0 to 50mV

0

0mA

4mA

0V

0V

0mV

0mV

16384

5mA

8mA

2.5V

1.25V

25mV

12.5mV

32768

10mA

12mA

5V

2.5V

50mV

25mV

49152

15mA

16mA

7.5V

3.75V

75mV

37.5mV

65535

20mA

20mA

10V

5V

100mV

50mV

Page 23

HMC3-M0808P0401T 23

HMC3000 Series I/O Module Guide 23

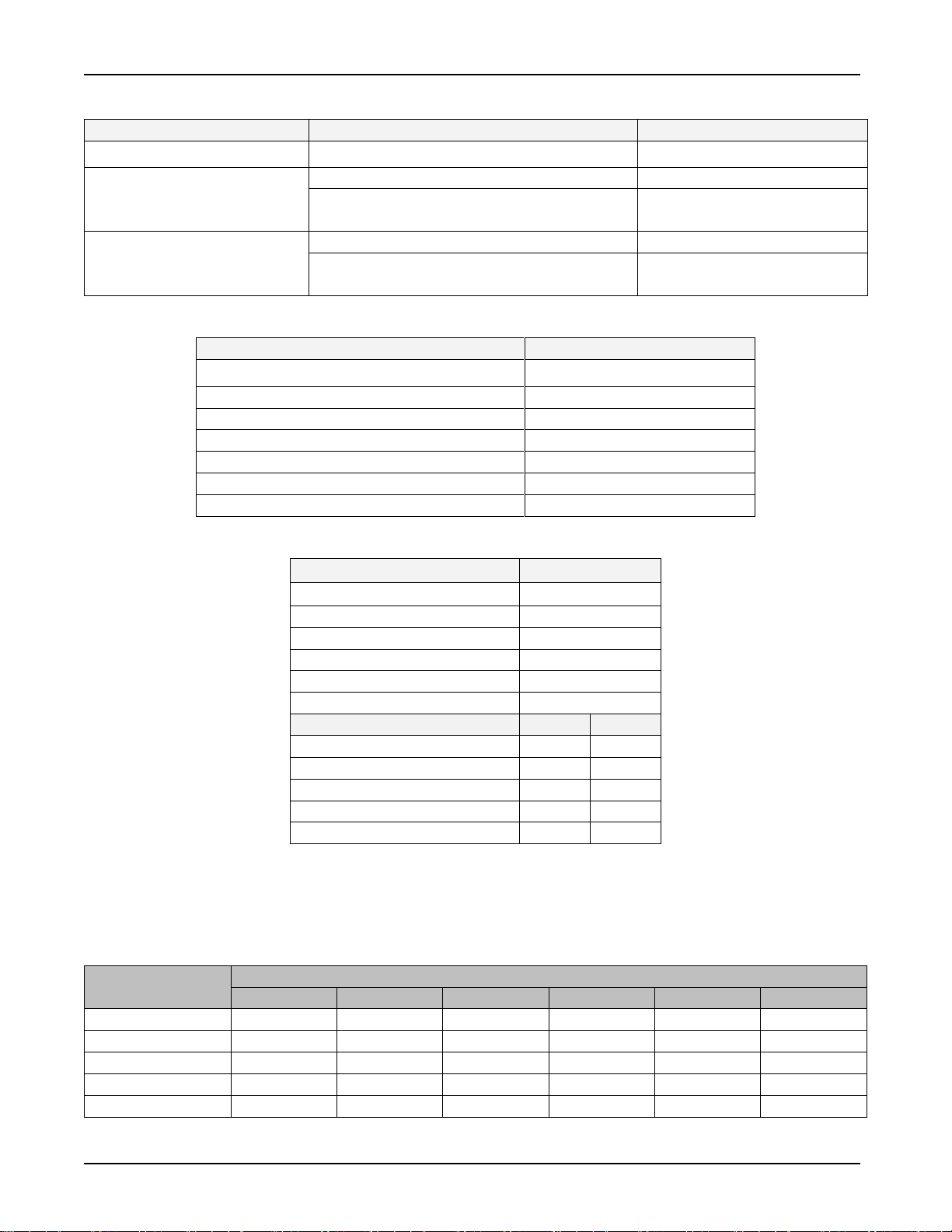

Reference the table below when configuring the Analog Output Configuration Register (MWnn68):

Output Signal Type

Register Value

Voltage, 0 to 10V

2

Voltage, 0 to 5V

1

Current, 4 to 20mA

5

Current, 0 to 20mA

6

Analog expansion modules have an analog output resolution of 12 bits with values ranging from 0-4095.

Expansion Module

Reg Value

Output Values

0 to 10V

4 to 20mA

0 0 4mA

1024

2.5V

8mA

2048

5V

12mA

3072

7.5V

16mA

4095

10V

20mA

Wiring:

Digital Inputs

Digital Outputs

Page 24

HMC3-M0808P0401T 24

HMC3000 Series I/O Module Guide 24

Analog Input (Voltage)

Analog Input (Current)

Analog Input (mV / Thermocouple)

Analog Input (RTD)

Page 25

HMC3-M0808P0401T 25

HMC3000 Series I/O Module Guide 25

Analog Output (Voltage)

Analog Output (Current)

HSC Single Phase Up Counter

HSC Single Phase Down Counter

HSC Quadrature

Page 26

HMC3-M0808P0401T 26

HMC3000 Series I/O Module Guide 26

Page 27

HMC3-M0808Y0401T 27

HMC3000 Series I/O Module Guide 27

HMC3-M0808Y0401T

8 Digital Inputs (2 high-speed pairs up to 200kHz)

8 Digital Outputs (6 Relay, 2 PNP w/ PWM up to 200kHz)

4 Universal Analog Inputs

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

• Thermocouple

• RTD

1 Analog Output

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

This module is an input/output module for the HMC3000 Series models. It

has eight bidirectional inputs, two pairs of which are high-speed inputs. It

also has eight outputs, two sourcing (PNP) which can be configured for

PWM operation and the other 6 are relay type.

This module also has 4 universal analog inputs

(Voltage/Current/Thermocouple/RTD) as well as one analog output

(Voltage/Current).

Specifications

Power

12V and 3.3VDC from base

Certifications

CE, UL

Digital Inputs

8 bidirectional inputs (2 high-speed pairs)

Rated Input Voltage

24 VDC +/- 15%

Rated input current

Up to 5mA (per contact)

Input impedance

4.9K ohms

Minimum ON voltage

15 VDC

Maximum OFF voltage

5 VDC

Turn ON Time

10 mSec

Turn OFF Time

10 mSec

Isolation

Optically isolated from internal circuit

Page 28

HMC3-M0808Y0401T 28

HMC3000 Series I/O Module Guide 28

Analog Inputs

4 Inputs, each configurable as:

• 0 to 50mV, 0 to 100 mV; 0 to 10V, 0 to 5V;

• 0 to 20mA, 4-20mA;

• PT100 RTD, alpha1 [0.00385 Ω/Ω°C] (-200 to 850 C);

• PT100 RTD, alpha2 [0.003926 Ω/Ω°C] (-100 to 457 C);

• PT1000 RTD (-200 to 850 C);

• Type J Thermocouple (-210 to 1200 C);

• Type K Thermocouple (-200 to 1373 C)

Input Resolution

16 bit

Input Impedance

3 KΩ

Maximum Input

+/- 30VDC, 30mA

Input Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Digital Outputs

8 outputs: 6 Relay, 2 Sourcing (PNP-type) / PWM

Maximum PWM Output Frequency

200KHz

Minimum ON Output Voltage

22 VDC

Maximum ON Output Voltage

30 VDC

Minimum OFF Output Voltage

0.2 VDC

Maximum OFF Output Voltage

1 VDC

Rated Load

250mA @ 24VDC

2A @230VAC

Nominal load

96 6W (resistive) @ 24VDC

6VA (inductive, UPF)

Analog Outputs

1, configurable as:

• 0 to 5V, 0 to 10V;

• 0 to 20mA, 4-20mA

Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Load

1 KΩ (Min) for V;

500Ω (Max) for mA

Output Resolution

12 bit

High-speed Channels

No. of inputs

2 channel pairs (X0/X1 and X2/X3)

Maximum Input Frequency

200 KHz

Maximum Input Count

4,294,967,295 (32-bit)

General

Connection method

Removable terminals (3.81 mm pitch)

Operating Temperature

0 to 55°C

Operating Humidity

10% to 90% (non-condensing)

Mechanical Dimension (W x H x D)

1.88 x 4.25 x 1.61 inches [48x108x41mm]

Page 29

HMC3-M0808Y0401T 29

HMC3000 Series I/O Module Guide 29

Configuration

Use MAPware-7000 to assign input (X and XW), output (Y and YW) and configuration (M and MW) memory

addresses to the module. These addresses are created according to the slot location of the module, where nn

refers to the slot number (ex. 01…05):

Function

Register

Access

X0-X7 Digital Inputs

Xnn000-007 (XWnn00)

Read Only

Y0-Y7 Digital Outputs

Ynn000-007 (YWnn00)

Read/Write

High-speed Counter Option

HSC Channel 1

HSC Channel 2 HSC Input Pin

X0

X2

Read Only

Quadrature Inputs

Pair 1

Pair 2 Counter Inputs

X0, X1

X2, X3

Read Only

HSC Configuration Register

MWnn00

MWnn06

Read/Write

HSC Counter Register (Current Value)

MWnn01

MWnn07

Read/Write

HSC Preset Register

MWnn03

MWnn09

Read/Write

HSC Enable Bit

Mnn080

Mnn176

Read/Write

HSC Reset Bit

Mnn081

Mnn177

Read/Write

Output Flag

Y2

Y3

PWM Outputs

Channel 1

Channel 2

Output

Y0

Y1

Read Only

PWM Configuration Register

MWnn24

MWnn30

Read/Write

Frequency Setting Register

MWnn25

MWnn31

Read/Write

ON Duty Setting Register (Duty Cycle)

MWnn27

MWnn33

Read/Write

Pulse Enable Flag

Mnn576

Mnn577

Read/Write

ON Duty Setting Error Flag

Mnn466

Mnn471

Read Only

Frequency Setting Error Flag

Mnn467

Mnn472

Read Only

Analog Inputs

Register

Input Channel 0 Data

XWnn11

Read Only

Input Channel 1 Data

XWnn13

Read Only

Input Channel 2 Data

XWnn15

Read Only

Input Channel 3 Data

XWnn17

Read Only

Input Channel 0 Config Register

MWnn60

Read/Write

Input Channel 1 Config Register

MWnn61

Read/Write

Input Channel 2 Config Register

MWnn62

Read/Write

Input Channel 3 Config Register

MWnn63

Read/Write

Analog Outputs

Register

Output Channel 0 Data (Voltage)

YWnn01

Read/Write

Output Channel 0 Data (Current)

YWnn02

Read/Write

Output Channel 0 Config Register

MWnn68

Read/Write

Page 30

HMC3-M0808Y0401T 30

HMC3000 Series I/O Module Guide 30

Reference the table below when configuring each HSC Configuration Register:

Input Mode

Output Mode

Register Value

Normal Input

N/A

0

High Speed,

Single Phase,

Up/Down Counter

Output ON when preset is reached

2

Output ON when counter is enabled,

OFF when preset is reached

258

Quadrature 4X

Output ON when preset is reached

131

Output ON when counter is enabled,

OFF when preset is reached

387

Reference the table below when configuring the PWM Configuration Registers:

Output Mode

Register Value

Normal PWM (fixed frequency)

1

Normal PWM (variable frequency)

2

CW/CCW (fixed frequency)

3

CW/CCW (variable frequency)

4

Pulse/Direction (fixed frequency)

7

Pulse/Direction (variable frequency)

8

Trapezoidal (Fixed Pulse Mode)

9

Reference the table below when configuring each Analog Input Configuration Register (MWnn60-MWnn63):

Input Signal Type

Register Value

Voltage, 0 to 10V

1

Voltage, 0 to 5V

6

Voltage, 0 to 50mV

5

Voltage, 0 to 100mV

4

Current, 4 to 20mA

2

Current, 0 to 20mA

3

RTC and Thermocouple

For °C

For °F

RTD, PT100, alpha1 1

7

19

RTD, PT100, alpha2 1

8

20

RTD, PT1000

9

21

Thermocouple, Type J 2

14

26

Thermocouple, Type K 2

15

27

Notes:

3. alpha1= 0.00385 Ω/Ω°C, alpha2=0.003926 Ω/Ω°C

4. 15-minute module warm-up time recommended

The values in the appropriate analog input register range from 0-65535.

Expansion Module

Reg Value

Input Values

0 to 20mA

4 to 20mA

0 to 10V

0 to 5V

0 to 100mV

0 to 50mV

0

0mA

4mA

0V

0V

0mV

0mV

16384

5mA

8mA

2.5V

1.25V

25mV

12.5mV

32768

10mA

12mA

5V

2.5V

50mV

25mV

49152

15mA

16mA

7.5V

3.75V

75mV

37.5mV

65535

20mA

20mA

10V

5V

100mV

50mV

Page 31

HMC3-M0808Y0401T 31

HMC3000 Series I/O Module Guide 31

Reference the table below when configuring the Analog Output Configuration Register (MWnn68):

Output Signal Type

Register Value

Voltage, 0 to 10V

2

Voltage, 0 to 5V

1

Current, 4 to 20mA

5

Current, 0 to 20mA

6

Analog expansion modules have an analog output resolution of 12 bits with values ranging from 0-4095.

Expansion Module

Reg Value

Output Values

0 to 10V

4 to 20mA

0 0 4mA

1024

2.5V

8mA

2048

5V

12mA

3072

7.5V

16mA

4095

10V

20mA

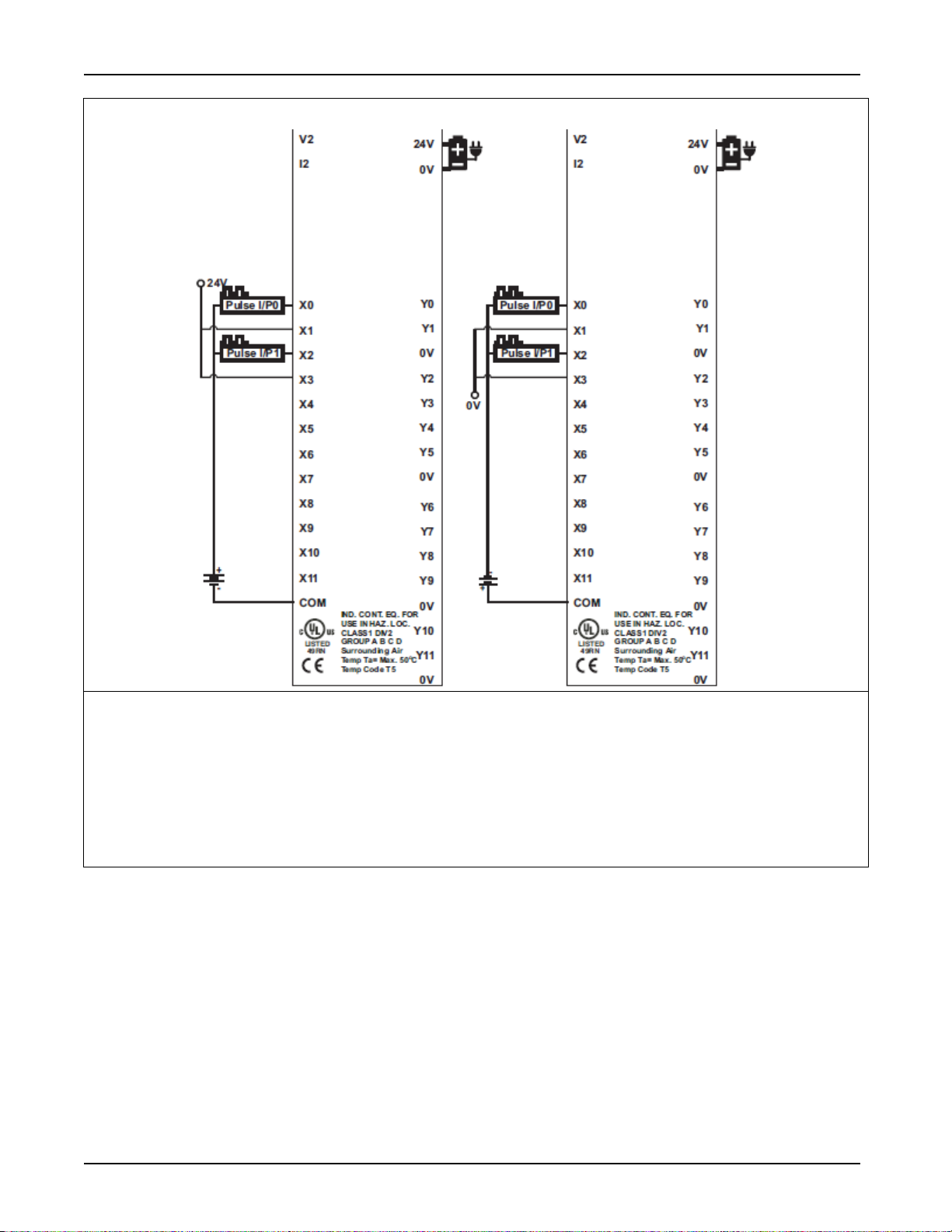

Wiring:

Digital Inputs

Digital Outputs

Page 32

HMC3-M0808Y0401T 32

HMC3000 Series I/O Module Guide 32

Analog Input (Voltage)

Analog Input (Current)

Analog Input (mV / Thermocouple)

Analog Input (RTD)

Page 33

HMC3-M0808Y0401T 33

HMC3000 Series I/O Module Guide 33

Analog Output (Voltage)

Analog Output (Current)

HSC Single Phase Up Counter

HSC Single Phase Down Counter

HSC Quadrature

Page 34

HMC3-M0808Y0401T 34

HMC3000 Series I/O Module Guide 34

Page 35

HMC3-M1212P0200 35

HMC3000 Series I/O Module Guide 35

HMC3-M1212P0200

12 Digital Inputs (2 high-speed pairs up to 200kHz)

12 Digital Outputs (2 PWM up to 1kHz)

4 Universal Analog Inputs

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

This module is an input/output module for the HMC3000 Series models. It

has twelve digital inputs, two of which are high-speed pairs and 12

sourcing digital outputs. Two of those digital outputs are configurable as

PWM.

This module also has two analog inputs, each measuring Voltage or

Current.

Specifications

Power

12 VDC from base

Certifications

CE, UL

Digital Inputs

12 bidirectional inputs (2 high-speed pairs)

Rated Input Voltage

24 VDC +/- 15%

Rated input current

Up to 5mA (per contact)

Input impedance

4.9K ohms

Minimum ON voltage

15 VDC

Maximum OFF voltage

5 VDC

Turn ON Time

10 mSec

Turn OFF Time

10 mSec

Isolation

Optically isolated from internal circuit

Analog Inputs

2 Inputs, each configurable as:

• 0 to 10V, 0 to 5V;

• 0 to 20mA, 4-20mA

Input Resolution

16 bit

Input Impedance

3 KΩ

Maximum Input

+/- 30VDC, 30mA

Input Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Page 36

HMC3-M1212P0200 36

HMC3000 Series I/O Module Guide 36

Digital Outputs

12 sourcing outputs (PNP-type), 2 PWM

Maximum PWM Output Frequency

1KHz

Minimum ON Output Voltage

22 VDC

Maximum ON Output Voltage

30 VDC

Minimum OFF Output Voltage

0.2 VDC

Maximum OFF Output Voltage

1 VDC

Rated Load

250mA @ 24VDC

Nominal load

96 6W (resistive) @ 24VDC

6VA (inductive, UPF)

High-speed Channels

No. of inputs

2 channel pairs (X0/X1 and X2/X3)

Maximum Input Frequency

200 KHz

Maximum Input Count

4,294,967,295 (32-bit)

General

Connection method

Removable terminals (3.81 mm pitch)

Operating Temperature

0 to 55°C

Operating Humidity

10% to 90% (non-condensing)

Mechanical Dimension (W x H x D)

1.88 x 4.25 x 1.61 inches [48x108x41mm]

Page 37

HMC3-M1212P0200 37

HMC3000 Series I/O Module Guide 37

Configuration

Use MAPware-7000 to assign input (X and XW), output (Y and YW) and configuration (M and MW) memory

addresses to the module. These addresses are created according to the slot location of the module, where nn

refers to the slot number (ex. 01…05):

Function

Register

Access

X0-X11 Digital Inputs

Xnn000-011 (XWnn00)

Read Only

Y0-Y11 Digital Outputs

Ynn000-011 (YWnn00)

Read/Write

High-speed Counter Option

HSC Channel 1

HSC Channel 2

HSC Input Pin

X0

X2

Read Only

Quadrature Inputs

Pair 1

Pair 2

Counter Inputs

X0, X1

X2, X3

Read Only

HSC Configuration Register

MWnn00

MWnn06

Read/Write

HSC Counter Register (Current Value)

MWnn01

MWnn07

Read/Write

HSC Preset Register

MWnn03

MWnn09

Read/Write

HSC Enable Bit

Mnn080

Mnn176

Read/Write

HSC Reset Bit

Mnn081

Mnn177

Read/Write

Output Flag

Y2

Y3

PWM Outputs

Channel 1

Channel 2

Output

Y0

Y1

Read Only

PWM Configuration Register

MWnn24

MWnn30

Read/Write

Frequency Setting Register

MWnn25

MWnn31

Read/Write

ON Duty Setting Register (Duty Cycle)

MWnn27

MWnn33

Read/Write

Pulse Enable Flag

Mnn576

Mnn577

Read/Write

ON Duty Setting Error Flag

Mnn466

Mnn471

Read Only

Frequency Setting Error Flag

Mnn467

Mnn472

Read Only

Analog Inputs

Register

Input Channel 0 Data

XWnn11

Read Only

Input Channel 1 Data

XWnn13

Read Only

Input Channel 0 Config Register

MWnn60

Read/Write

Input Channel 1 Config Register

MWnn61

Read/Write

Reference the table below when configuring each HSC Configuration Register:

Input Mode

Output Mode

Register Value

Normal Input

N/A

0

High Speed,

Single Phase,

Up/Down Counter

Output ON when preset is reached

2

Output ON when counter is enabled,

OFF when preset is reached

258

Quadrature 4X

Output ON when preset is reached

131

Output ON when counter is enabled,

OFF when preset is reached

387

Page 38

HMC3-M1212P0200 38

HMC3000 Series I/O Module Guide 38

Reference the table below when configuring the PWM Configuration Registers:

Output Mode

Register Value

Normal PWM (fixed frequency)

1

Normal PWM (variable frequency)

2

CW/CCW (fixed frequency)

3

CW/CCW (variable frequency)

4

Pulse/Direction (fixed frequency)

7

Pulse/Direction (variable frequency)

8

Trapezoidal (Fixed Pulse Mode)

9

Reference the table below when configuring each Analog Input Configuration Register (MWnn60-MWnn61):

Input Signal Type

Register Value

Voltage, 0 to 10V

1

Voltage, 0 to 5V

6

Current, 4 to 20mA

2

Current, 0 to 20mA

3

The values in the appropriate analog input register range from 0-64000, with over and under indications at

65000 and 65001.

Expansion Module

Reg Value

Input Values

0 to 20mA

4 to 20mA

0 to 10V

0 to 5V

0

0mA

4mA

0V

0V

16000

5mA

8mA

2.5V

1.25V

32000

10mA

12mA

5V

2.5V

48000

15mA

16mA

7.5V

3.75V

64000

20mA

20mA

10V

5V

65000

< 0mA

< 4mA

< 0V

< 0V

65001

> 20mA

> 20mA

> 10V

> 5V

Page 39

HMC3-M1212P0200 39

HMC3000 Series I/O Module Guide 39

Wiring:

Digital Inputs

Digital Outputs

Analog Input (Voltage)

Analog Input (Current)

Page 40

HMC3-M1212P0200 40

HMC3000 Series I/O Module Guide 40

HSC Single Phase Up Counter

HSC Single Phase Down Counter

Page 41

HMC3-M1212P0200 41

HMC3000 Series I/O Module Guide 41

HSC Quadrature

Page 42

HMC3-M1212Y0200 42

HMC3000 Series I/O Module Guide 42

HMC3-M1212Y0200

12 Digital Inputs (2 high-speed pairs up to 200kHz)

12 Digital Outputs (10 Relay, 2 PNP w/ PWM up to 1kHz)

4 Universal Analog Inputs

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

This module is an input/output module for the HMC3000 Series models. It

has eight digital inputs, two of which are high-speed pairs and 12 digital

outputs. Two of those digital outputs are sourcing (PNP), and can be

configured for PWM, and the other 10 outputs are relay type.

This module also has two analog inputs, each measuring Voltage or

Current.

Specifications

Power

12 VDC from base

Certifications

CE, UL

Digital Inputs

12 bidirectional inputs (2 high-speed pairs)

Rated Input Voltage

24 VDC +/- 15%

Rated input current

Up to 5mA (per contact)

Input impedance

4.9K ohms

Minimum ON voltage

15 VDC

Maximum OFF voltage

5 VDC

Turn ON Time

10 mSec

Turn OFF Time

10 mSec

Isolation

Optically isolated from internal circuit

Analog Inputs

2 Inputs, each configurable as:

• 0 to 10V, 0 to 5V;

• 0 to 20mA, 4-20mA

Input Resolution

16 bit

Input Impedance

3 KΩ

Maximum Input

+/- 30VDC, 30mA

Input Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Page 43

HMC3-M1212Y0200 43

HMC3000 Series I/O Module Guide 43

Digital Outputs

12 outputs: 10 Relay, 2 Sourcing (PNP-type) / PWM

Maximum PWM Output Frequency

1KHz

Minimum ON Output Voltage

22 VDC

Maximum ON Output Voltage

30 VDC

Minimum OFF Output Voltage

0.2 VDC

Maximum OFF Output Voltage

1 VDC

Rated Load

250mA @ 24VDC

2A @230VAC

Nominal load

96 6W (resistive) @ 24VDC

6VA (inductive, UPF)

High-speed Channels

No. of inputs

2 channel pairs (X0/X1 and X2/X3)

Maximum Input Frequency

200 KHz

Maximum Input Count

4,294,967,295 (32-bit)

General

Connection method

Removable terminals (3.81 mm pitch)

Operating Temperature

0 to 55°C

Operating Humidity

10% to 90% (non-condensing)

Mechanical Dimension (W x H x D)

1.88 x 4.25 x 1.61 inches [48x108x41mm]

Page 44

HMC3-M1212Y0200 44

HMC3000 Series I/O Module Guide 44

Configuration

Use MAPware-7000 to assign input (X and XW), output (Y and YW) and configuration (M and MW) memory

addresses to the module. These addresses are created according to the slot location of the module, where nn

refers to the slot number (ex. 01…05):

Function

Register

Access

X0-X11 Digital Inputs

Xnn000-011 (XWnn00)

Read Only

Y0-Y11 Digital Outputs

Ynn000-011 (YWnn00)

Read/Write

High-speed Counter Option

HSC Channel 1

HSC Channel 2

HSC Input Pin

X0

X2

Read Only

Quadrature Inputs

Pair 1

Pair 2

Counter Inputs

X0, X1

X2, X3

Read Only

HSC Configuration Register

MWnn00

MWnn06

Read/Write

HSC Counter Register (Current Value)

MWnn01

MWnn07

Read/Write

HSC Preset Register

MWnn03

MWnn09

Read/Write

HSC Enable Bit

Mnn080

Mnn176

Read/Write

HSC Reset Bit

Mnn081

Mnn177

Read/Write

Output Flag

Y2

Y3

PWM Outputs

Channel 1

Channel 2

Output

Y0

Y1

Read Only

PWM Configuration Register

MWnn24

MWnn30

Read/Write

Frequency Setting Register

MWnn25

MWnn31

Read/Write

ON Duty Setting Register (Duty Cycle)

MWnn27

MWnn33

Read/Write

Pulse Enable Flag

Mnn576

Mnn577

Read/Write

ON Duty Setting Error Flag

Mnn466

Mnn471

Read Only

Frequency Setting Error Flag

Mnn467

Mnn472

Read Only

Analog Inputs

Register

Input Channel 0 Data

XWnn11

Read Only

Input Channel 1 Data

XWnn13

Read Only

Input Channel 0 Config Register

MWnn60

Read/Write

Input Channel 1 Config Register

MWnn61

Read/Write

Reference the table below when configuring each HSC Configuration Register:

Input Mode

Output Mode

Register Value

Normal Input

N/A

0

High Speed,

Single Phase,

Up/Down Counter

Output ON when preset is reached

2

Output ON when counter is enabled,

OFF when preset is reached

258

Quadrature 4X

Output ON when preset is reached

131

Output ON when counter is enabled,

OFF when preset is reached

387

Page 45

HMC3-M1212Y0200 45

HMC3000 Series I/O Module Guide 45

Reference the table below when configuring the PWM Configuration Registers:

Output Mode

Register Value

Normal PWM (fixed frequency)

1

Normal PWM (variable frequency)

2

CW/CCW (fixed frequency)

3

CW/CCW (variable frequency)

4

Pulse/Direction (fixed frequency)

7

Pulse/Direction (variable frequency)

8

Trapezoidal (Fixed Pulse Mode)

9

Reference the table below when configuring each Analog Input Configuration Register (MWnn60-MWnn61):

Input Signal Type

Register Value

Voltage, 0 to 10V

1

Voltage, 0 to 5V

6

Current, 4 to 20mA

2

Current, 0 to 20mA

3

The values in the appropriate analog input register range from 0-64000, with over and under indications at

65000 and 65001.

Expansion Module

Reg Value

Input Values

0 to 20mA

4 to 20mA

0 to 10V

0 to 5V

0

0mA

4mA

0V

0V

16000

5mA

8mA

2.5V

1.25V

32000

10mA

12mA

5V

2.5V

48000

15mA

16mA

7.5V

3.75V

64000

20mA

20mA

10V

5V

65000

< 0mA

< 4mA

< 0V

< 0V

65001

> 20mA

> 20mA

> 10V

> 5V

Page 46

HMC3-M1212Y0200 46

HMC3000 Series I/O Module Guide 46

Wiring:

Digital Inputs

Digital Outputs

Analog Input (Voltage)

Analog Input (Current)

Page 47

HMC3-M1212Y0200 47

HMC3000 Series I/O Module Guide 47

HSC Single Phase Up Counter

HSC Single Phase Down Counter

Page 48

HMC3-M1212Y0200 48

HMC3000 Series I/O Module Guide 48

HSC Quadrature

Page 49

HMC3-M1210P0201 49

HMC3000 Series I/O Module Guide 49

HMC3-M1210P0201

12 Digital Inputs (2 high-speed pairs up to 200kHz)

10 Digital Outputs (2 PWM up to 1kHz)

4 Universal Analog Inputs

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

1 Analog Output

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

This module is an input/output module for the HMC3000 Series models. It

has twelve digital inputs, two of which are high-speed pairs and 10

sourcing (PNP) digital outputs. Two of those digital outputs are PWM.

This module also has two analog inputs (Voltage/Current) and one analog

output (Voltage/Current).

Specifications

Power

12 VDC from base

Certifications

CE, UL

Digital Inputs

12 bidirectional inputs (2 high-speed pairs)

Rated Input Voltage

24 VDC +/- 15%

Rated input current

Up to 5mA (per contact)

Input impedance

4.9K ohms

Minimum ON voltage

15 VDC

Maximum OFF voltage

5 VDC

Turn ON Time

10 msec

Turn OFF Time

10 msec

Isolation

Optically isolated from internal circuit

Analog Inputs

2 Inputs, each configurable as:

• 0 to 10V, 0 to 5V;

• 0 to 20mA, 4-20mA

Input Resolution

16 bit

Input Impedance

3 KΩ

Maximum Input

+/- 30VDC, 30mA

Input Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Page 50

HMC3-M1210P0201 50

HMC3000 Series I/O Module Guide 50

Digital Outputs

10 sourcing outputs (PNP-type), 2 PWM

Maximum PWM Output Frequency

1KHz

Minimum ON Output Voltage

22 VDC

Maximum ON Output Voltage

30 VDC

Minimum OFF Output Voltage

0.2 VDC

Maximum OFF Output Voltage

1 VDC

Rated Load

250mA @ 24VDC

Nominal load

96 6W (resistive) @ 24VDC

6VA (inductive, UPF)

Analog Outputs

1, configurable as:

• 0 to 5V, 0 to 10V;

• 0 to 20mA, 4-20mA

Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Load

1 KΩ (Min) for V;

500Ω (Max) for mA

Output Resolution

12 bit

High-speed Channels

No. of inputs

2 channel pairs (X0/X1 and X2/X3)

Maximum Input Frequency

200 KHz

Maximum Input Count

4,294,967,295 (32-bit)

General

Connection method

Removable terminals (3.81 mm pitch)

Operating Temperature

0 to 55°C

Operating Humidity

10% to 90% (non-condensing)

Mechanical Dimension (W x H x D)

1.88 x 4.25 x 1.61 inches [48x108x41mm]

Page 51

HMC3-M1210P0201 51

HMC3000 Series I/O Module Guide 51

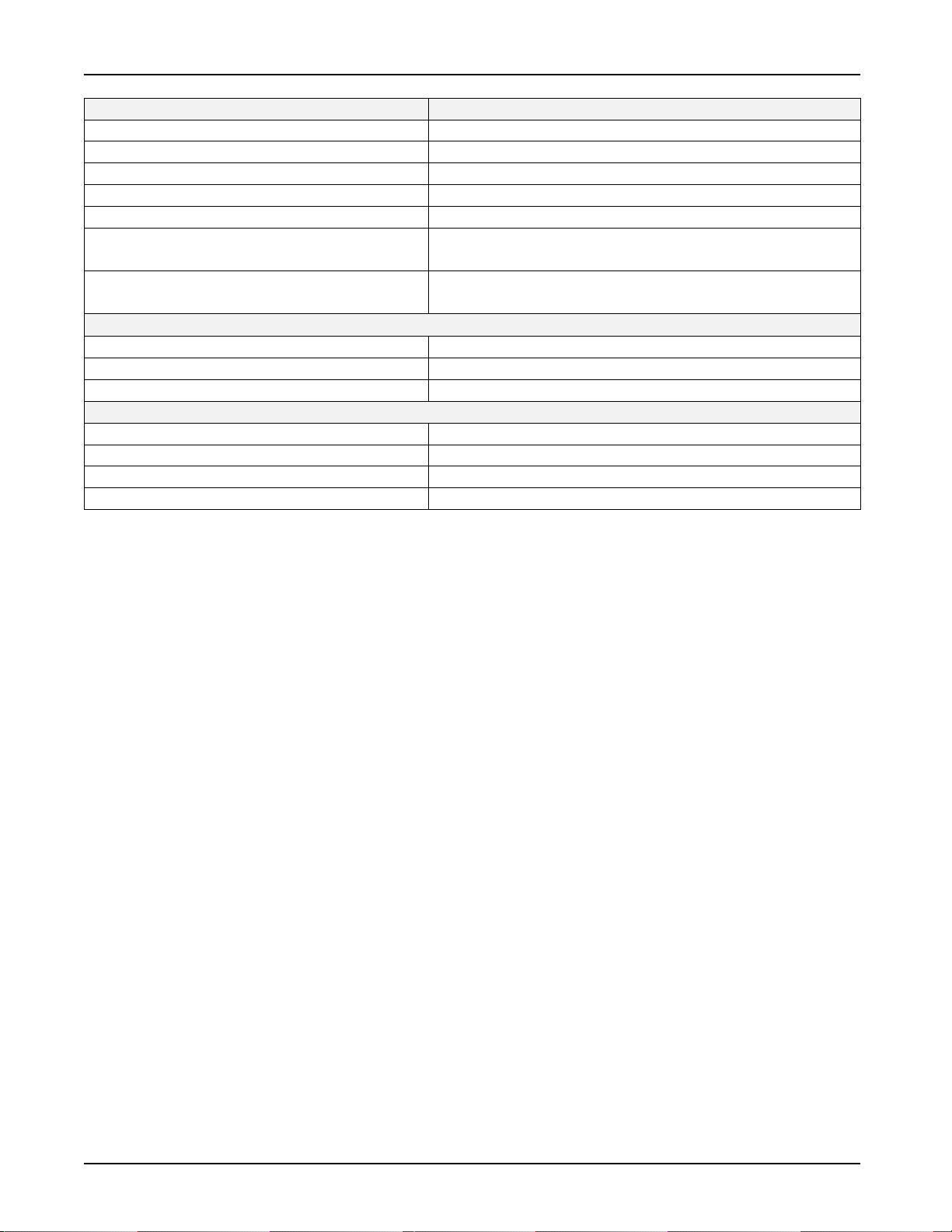

Configuration

Use MAPware-7000 to assign input (X and XW), output (Y and YW) and configuration (M and MW) memory

addresses to the module. These addresses are created according to the slot location of the module, where nn

refers to the slot number (ex. 01…05):

Function

Register

Access

X0-X11 Digital Inputs

Xnn000-011 (XWnn00)

Read Only

Y0-Y9 Digital Outputs

Ynn000-009 (YWnn00)

Read/Write

High-speed Counter Option

HSC Channel 1

HSC Channel 2

HSC Input Pin

X0

X2

Read Only

Quadrature Inputs

Pair 1

Pair 2

Counter Inputs

X0, X1

X2, X3

Read Only

HSC Configuration Register

MWnn00

MWnn06

Read/Write

HSC Counter Register (Current Value)

MWnn01

MWnn07

Read/Write

HSC Preset Register

MWnn03

MWnn09

Read/Write

HSC Enable Bit

Mnn080

Mnn176

Read/Write

HSC Reset Bit

Mnn081

Mnn177

Read/Write

Output Flag

Y2

Y3

PWM Outputs

Channel 1

Channel 2

Output

Y0

Y1

Read Only

PWM Configuration Register

MWnn24

MWnn30

Read/Write

Frequency Setting Register

MWnn25

MWnn31

Read/Write

ON Duty Setting Register (Duty Cycle)

MWnn27

MWnn33

Read/Write

Pulse Enable Flag

Mnn576

Mnn577

Read/Write

ON Duty Setting Error Flag

Mnn466

Mnn471

Read Only

Frequency Setting Error Flag

Mnn467

Mnn472

Read Only

Analog Inputs

Register

Input Channel 0 Data

XWnn11

Read Only

Input Channel 1 Data

XWnn13

Read Only

Input Channel 0 Config Register

MWnn60

Read/Write

Input Channel 1 Config Register

MWnn61

Read/Write

Analog Outputs

Register

Output Channel 0 Data (Voltage)

YWnn01

Read/Write

Output Channel 0 Data (Current)

YWnn02

Read/Write

Output Channel 0 Config Register

MWnn68

Read/Write

Reference the table below when configuring each HSC Configuration Register:

Input Mode

Output Mode

Register Value

Normal Input

N/A

0

High Speed,

Single Phase,

Up/Down Counter

Output ON when preset is reached

2

Output ON when counter is enabled,

OFF when preset is reached

258

Quadrature 4X

Output ON when preset is reached

131

Output ON when counter is enabled,

OFF when preset is reached

387

Page 52

HMC3-M1210P0201 52

HMC3000 Series I/O Module Guide 52

Reference the table below when configuring the PWM Configuration Registers:

Output Mode

Register Value

Normal PWM (fixed frequency)

1

Normal PWM (variable frequency)

2

CW/CCW (fixed frequency)

3

CW/CCW (variable frequency)

4

Pulse/Direction (fixed frequency)

7

Pulse/Direction (variable frequency)

8

Trapezoidal (Fixed Pulse Mode)

9

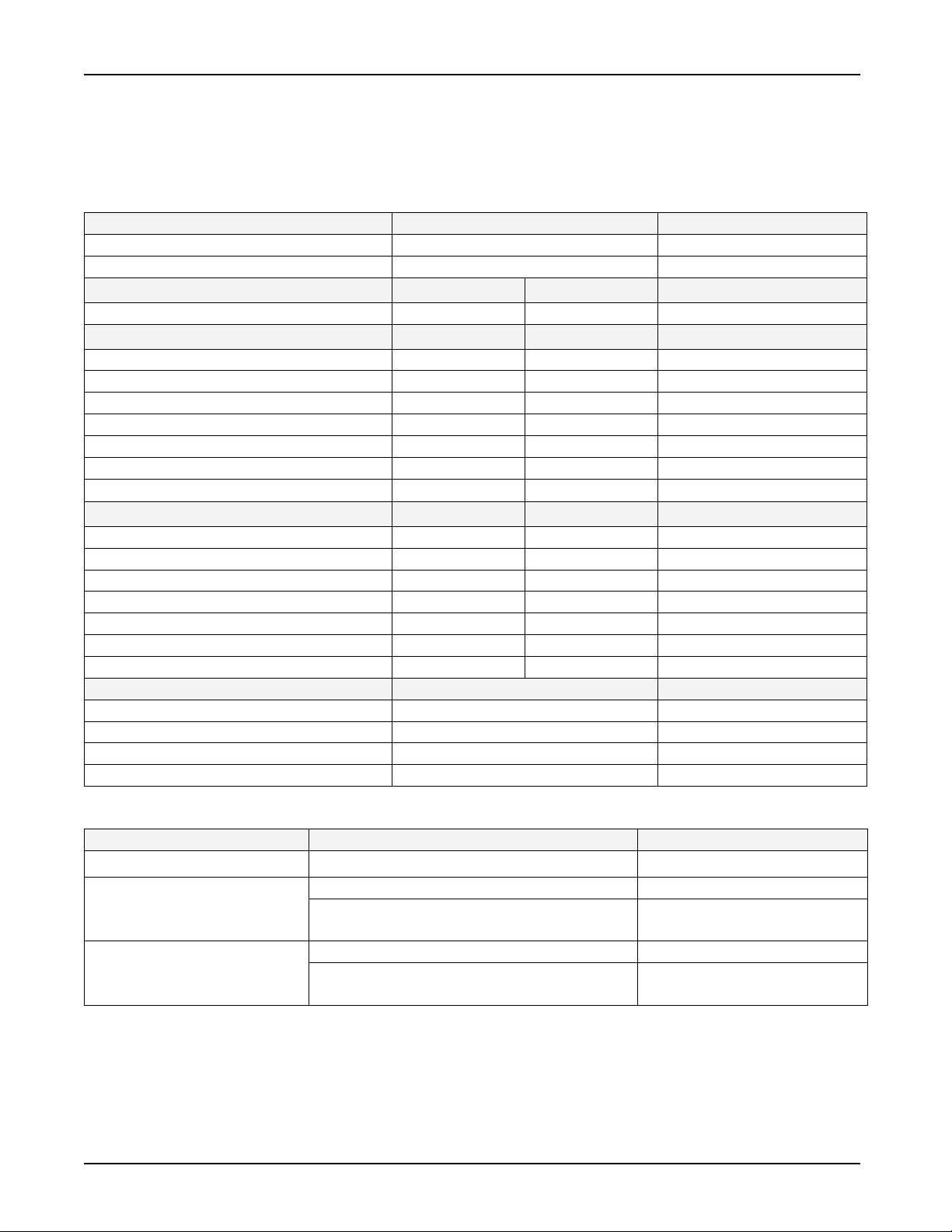

Reference the tables below when configuring each Analog Input and Output Configuration Register:

Input Signal Type

Register Value

Voltage, 0 to 10V

1

Voltage, 0 to 5V

6

Current, 4 to 20mA

2

Current, 0 to 20mA

3

The values in the appropriate analog input register range from 0-64000, with over and under indications at

65000 and 65001, while analog output register values range from 0-4095.

Expansion

Module Reg

Value

Input Values

0 to 20mA

4 to 20mA

0 to 10V

0 to 5V

0

0mA

4mA

0V

0V

16384

5mA

8mA

2.5V

1.25V

32768

10mA

12mA

5V

2.5V

49152

15mA

16mA

7.5V

3.75V

65535

20mA

20mA

10V

5V

65000

< 0mA

< 4mA

< 0V

< 0V

65001

> 20mA

> 20mA

> 10V

> 5V

Output Signal Type

Register Value

Voltage, 0 to 10V

2

Voltage, 0 to 5V

1

Current, 4 to 20mA

5

Current, 0 to 20mA

6

Expansion

Module

Reg Value

Output Values

0 to 10V

4 to 20mA

0 0 4mA

1024

2.5V

8mA

2048

5V

12mA

3072

7.5V

16mA

4095

10V

20mA

Page 53

HMC3-M1210P0201 53

HMC3000 Series I/O Module Guide 53

Wiring:

Digital Inputs

Digital Outputs

Analog Input (Voltage)

Analog Input (Current)

Page 54

HMC3-M1210P0201 54

HMC3000 Series I/O Module Guide 54

Analog Output (Voltage)

Analog Output (Current)

HSC Single Phase Up Counter

Page 55

HMC3-M1210P0201 55

HMC3000 Series I/O Module Guide 55

HSC Single Phase Down Counter

HSC Quadrature

Page 56

HMC3-M1210P0201 56

HMC3000 Series I/O Module Guide 56

Page 57

HMC3-M1210Y0201 57

HMC3000 Series I/O Module Guide 57

HMC3-M1210Y0201

12 Digital Inputs (2 high-speed pairs up to 200kHz)

10 Digital Outputs (8 Relay, 2 PNP w/ PWM up to 1kHz)

4 Universal Analog Inputs

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

1 Analog Output

• Voltage: 0-5V, 0-10V

• Current: 0-20mA, 4-20mA

This module is an input/output module for the HMC3000 Series models. It

has twelve digital inputs, two of which are high-speed pairs. There are 10

digital outputs, two are sourcing (PNP) with PWM ability and 8 are relay

type.

This module also has two analog inputs (Voltage/Current) and one analog

output (Voltage/Current).

Specifications

Power

12 VDC from base

Certifications

CE, UL

Digital Inputs

12 bidirectional inputs (2 high-speed pairs)

Rated Input Voltage

24 VDC +/- 15%

Rated input current

Up to 5mA (per contact)

Input impedance

4.9K ohms

Minimum ON voltage

15 VDC

Maximum OFF voltage

5 VDC

Turn ON Time

10 mSec

Turn OFF Time

10 mSec

Isolation

Optically isolated from internal circuit

Analog Inputs

2 Inputs, each configurable as:

• 0 to 10V, 0 to 5V;

• 0 to 20mA, 4-20mA

Input Resolution

16 bit

Input Impedance

3 KΩ

Maximum Input

+/- 30VDC, 30mA

Input Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Page 58

HMC3-M1210Y0201 58

HMC3000 Series I/O Module Guide 58

Digital Outputs

10 outputs: 8 Relay, 2 Sourcing (PNP-type) / PWM

Maximum PWM Output Frequency

1KHz

Minimum ON Output Voltage

22 VDC

Maximum ON Output Voltage

30 VDC

Minimum OFF Output Voltage

0.2 VDC

Maximum OFF Output Voltage

1 VDC

Rated Load

250mA @ 24VDC

2A @230VAC

Nominal load

96 6W (resistive) @ 24VDC

6VA (inductive, UPF)

Analog Outputs

1, configurable as:

• 0 to 5V, 0 to 10V;

• 0 to 20mA, 4-20mA

Accuracy

Overall Accuracy 0.2% of full scale@25°C (max)

Load

1 KΩ (Min) for V; 500Ω (Max) for mA

Output Resolution

12 bit

High-speed Channels

No. of inputs

2 channel pairs (X0/X1 and X2/X3)

Maximum Input Frequency

200 KHz

Maximum Input Count

4,294,967,295 (32-bit)

General

Connection method

Removable terminals (3.81 mm pitch)

Operating Temperature

0 to 55°C

Operating Humidity

10% to 90% (non-condensing)

Mechanical Dimension (W x H x D)

1.88 x 4.25 x 1.61 inches [48x108x41mm]

Page 59

HMC3-M1210Y0201 59

HMC3000 Series I/O Module Guide 59

Configuration

Use MAPware-7000 to assign input (X and XW), output (Y and YW) and configuration (M and MW) memory

addresses to the module. These addresses are created according to the slot location of the module, where nn

refers to the slot number (ex. 01…05):

Function

Register

Access

X0-X11 Digital Inputs

Xnn000-011 (XWnn00)

Read Only

Y0-Y9 Digital Outputs

Ynn000-009 (YWnn00)

Read/Write

High-speed Counter Option

HSC Channel 1

HSC Channel 2

HSC Input Pin

X0

X2

Read Only

Quadrature Inputs

Pair 1

Pair 2

Counter Inputs

X0, X1

X2, X3

Read Only

HSC Configuration Register

MWnn00

MWnn06

Read/Write

HSC Counter Register (Current Value)

MWnn01

MWnn07

Read/Write

HSC Preset Register

MWnn03

MWnn09

Read/Write

HSC Enable Bit

Mnn080

Mnn176

Read/Write

HSC Reset Bit

Mnn081

Mnn177

Read/Write

Output Flag

Y2

Y3

PWM Outputs

Channel 1

Channel 2

Output

Y0

Y1

Read Only

PWM Configuration Register

MWnn24

MWnn30

Read/Write

Frequency Setting Register

MWnn25

MWnn31

Read/Write

ON Duty Setting Register (Duty Cycle)

MWnn27

MWnn33

Read/Write

Pulse Enable Flag

Mnn576

Mnn577

Read/Write

ON Duty Setting Error Flag

Mnn466

Mnn471

Read Only

Frequency Setting Error Flag

Mnn467

Mnn472

Read Only

Analog Inputs

Register

Input Channel 0 Data

XWnn11

Read Only

Input Channel 1 Data

XWnn13

Read Only

Input Channel 0 Config Register

MWnn60

Read/Write

Input Channel 1 Config Register

MWnn61

Read/Write

Analog Outputs

Register

Output Channel 0 Data (Voltage)

YWnn01

Read/Write

Output Channel 0 Data (Current)

YWnn02

Read/Write

Output Channel 0 Config Register

MWnn68

Read/Write

Reference the table below when configuring each HSC Configuration Register:

Input Mode

Output Mode

Register Value

Normal Input

N/A

0

High Speed,

Single Phase,

Up/Down Counter

Output ON when preset is reached

2

Output ON when counter is enabled,

OFF when preset is reached

258

Quadrature 4X

Output ON when preset is reached

131

Output ON when counter is enabled,

OFF when preset is reached

387

Page 60

HMC3-M1210Y0201 60

HMC3000 Series I/O Module Guide 60

Reference the table below when configuring the PWM Configuration Registers:

Output Mode

Register Value

Normal PWM (fixed frequency)

1

Normal PWM (variable frequency)

2

CW/CCW (fixed frequency)

3

CW/CCW (variable frequency)

4

Pulse/Direction (fixed frequency)

7

Pulse/Direction (variable frequency)

8

Trapezoidal (Fixed Pulse Mode)

9