Page 1

Quick Start Guide

HMC3070A-M

Description:

HMC3070A-M 800x480 pixels, 7.0” color TFT, with three

expansion slots.

Contents:

—1 HMC3070A-M (in plastic bag with protective cover sheet

on the screen)

—1 plastic bag containing 4 mounting clamps (each clamp

consisting of cap nut, bolt, and clamp)

—1 three prong green power plug*

—Cardboard package inserts

—Quick Start Guide

*Note: Connector manufacturer may vary.

Programming software (MAPware-7000), cables, and power

supply purchased separately.

Panel Mounting and Panel Cutout:

HMC3070A-M

Tighten the mounting screws evenly to a torque between 0.4 Nm to

maintain water and dust resistance. Make sure the panel is not dirty

and warped and that it is strong enough to hold the unit.

Note: Maximum Panel thickness (on which unit is to be mounted)

should be 6.0 mm (Tolerance: +/-0.2 mm).

Doc. No. 1011-0302

Maple Systems, Inc. 808 134th St SW, Suite 120, Everett, WA 98204-7333 www.maplesystems.com

Specifications:

The HMC3070A-M is a combination operator-based HMI (Human

Machine Interface) with built-in PLC (Programmable Logic

Controller) operation. It communicates with external PLCs over

serial communications ports to read/write data. Three I/O

expansion modules can be attached.

Power: 24VDC +/- 15%, 20W (with 3

expansions)

Display: 7.0” TFT (800 x 480 pixels)

Color graphics display

Bezel: NEMA 4X (IP 66) rated

Touchscreen: 4-wire analog resistive

LEDs: Power indicator

CPU: 32-bit RISC, 454 MHz

Memory: 45 MB Max. Application Memory

Serial Comms (DE9S): Two serial ports

(RS232/RS485/RS422)

USB Slave (Micro Type B): Upload/download projects

USB Host (Standard Type A): Data storage

Ethernet (RJ45): 10/100 Mbps

SD card: Micro SD (high capacity- 4 to 32

GB)

Expansion ports: Three for optional HMC3 I/O

modules

Operating temp: 0 to 60° C

Humidity: 10% to 90% (non-condensing)

Dimensions (WxHxD): 7.32 x 5.43 x 1.22 inches

[186.0 x 138.0 x 31.0mm]

Panel cutout: 4.37 x 3.15 inches [111 x 80mm]

Mounting Module to Panel:

Step 2: Tighten clamps evenly to prevent warping. Continue to

tighten until a torque force of 0.4-0.5 Nm is obtained.

Step 3: HMC3070 should be aligned evenly with the cutout with

no warping present after clamps are tightened.

Port Details:

Note: connect shell to shield of cable.

Grounding:

The HMC3070 should have a good electrical connection to earth

ground via the power connector for safety and to reduce electrical

noise. The HMC unit should be grounded separately from other

high-power systems.

Note: Do not use a ground connection that has potential

impedance (such as painted screws) or is subject to vibration.

Expansion I/O Modules:

The HMC3070A-M has three expansion slots that you can use to

connect I/O modules. Below is a listing of modules currently

available (consult Maple Systems website for additional

information).

HMC3-M1616P: 16 digital input, 16 PNP-type digital

output

HMC3-M1614Y: 16 digital input, 14 digital output

(12 relay, 2 PNP-type)

HMC3-M1212P0200: 12 digital input, 12 PNP-type digital

output, 2 analog input

HMC3-M1212Y0200: 12 digital input, 12 digital output

(10 relay, 2 PNP-type), 2 analog

input

HMC3-M1210P0201: 12 digital input, 10 PNP-type digital

output, 2 analog input and 1 analog

output.

HMC3-M1210Y0201: 12 digital input, 10 digital output (8

relay, 2 PNP-type), 2 analog input,

and 1 analog output.

HMC3-M0808P0401T: 8 digital input, 8 PNP-type digital

output, 4 analog input and 1 analog

output.

HMC3-M0808Y0401T: 8 digital input, 8 digital output (6

relay, 2 PNP-type), 4 analog input,

and 1 analog output.

Rev 02, 06/25/2018

COM1 COM2

Pin

Number

Name D escription

1 RX- RS422 receive -

2 TX- RS422 transmit -

3 RX+ RS422 receive +

4 TX+ RS422 transmit +

5 GND Ground

6 RXD RS232 receive

7 TXD RS232 transmit

Pin

Number

Name D escription

1 TX+ RS422 transmit +

2 TXD RS232 transmit

3 RXD RS232 receive

4 RX+ RS422 receive +

5 GND Ground

6 NC No connection

7 NC No connection

8 TX- RS422 transmit -

9 RX- RS422 receive -

Page 2

Doc. No. 1011-0302

Rev 02, 06/25/20148Maple Systems, Inc. 808 134th St SW, Suite 120, Everett, WA 98204-7333 www.maplesystems.com

Getting Started:

Perform the following steps to configure and use the HMC3000

Series unit:

1. Install MAPware-7000 software.

2. Create your project.

3. Connect a programming cable (USB or Ethernet).

4. Save your project.

5. Download project to HMC3070 (note: you must select the

Download Firmware option for the initial download).

6. The HMC3000 unit is ready to use in the system.

PC Requirements for MAPware-7000:

Processor: 1 GHz Pentium-based processor or equivalent

Operating System: Microsoft Windows 7 or 10

RAM: 1 GB

Hard Disk: 800 MB (including 200 MB for the .NET Framework

Redistributable)

Display: 1024x768 high color 16-bit

Mouse/Keyboard: Required

USB or Ethernet port: for project downloads

Installing the Software:

1. Insert MAPware-7000 CD into CD-ROM drive and follow

instructions.

2. If software installation does not automatically start, click

\SETUP.EXE from CD directory.

PLC Connecting Cables:

Contact Maple Systems to order any PLC Communications

Cables or to download a cable pinout diagram.

Additional Resources:

Detailed instructions on the operation and installation of the

HMC3000 Series are available in the HMC3000 Programming

Manual that is included with the MAPware-7000 configuration

software. MAPware-7000 also includes help files that provide

detailed information on using the configuration software.

Other Sources (visit Maple Systems Support Center website):

—Controller Information Sheets- specific information on

connecting a particular manufacturer's PLC to the HMC3000

—Cable Drawings- wiring diagrams to particular PLCs

—Technical Notes- Provides additional information and examples

not covered in the operations manual

—Software Upgrades- Upgrades to the MAPware-7000 software

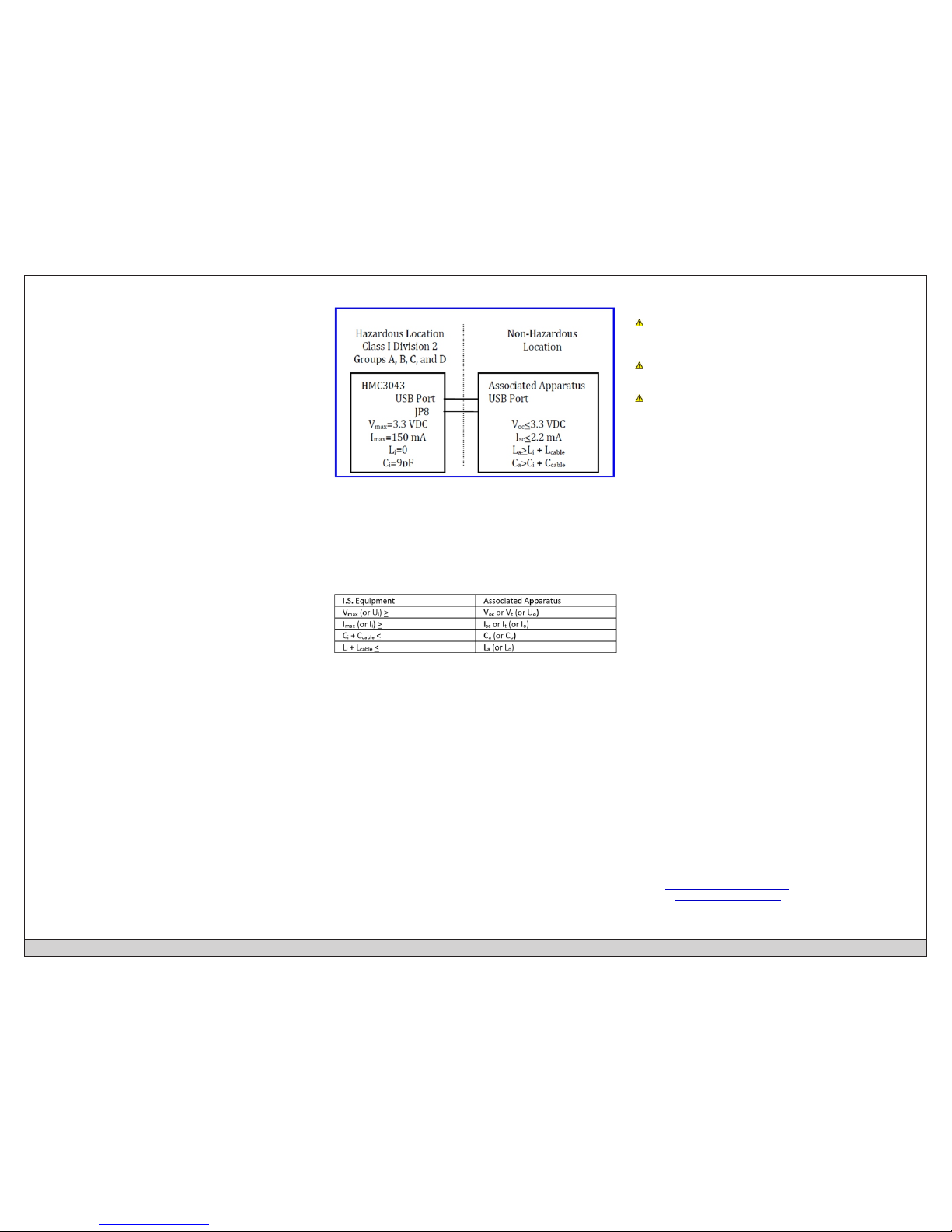

Class I Division 2 Wiring Considerations:

Capacitance and inductance of the field wiring from the

nonincendive equipment to the associated apparatus shall be

calculated and must be included in the system calculations as

shown in Table 1.

Where the cable capacitance and inductance per foot are not

known, the following values shall be used: Ccable = 60 pF/ft,

Lcable = 0.2 µH/ft.

TABLE 1:

Wiring method must be in accordance with ANSI/NFPA70.

This equipment is suitable for use in Class I, Division 2, Groups A,

B, C and D or non-hazardous locations only.

WARNING – EXPLOSION HAZARD – Do not disconnect

equipment unless power has been removed or the area is known

to be non-hazardous.

WARNING – EXPLOSION HAZARD - Substitution of

components may impair suitability for Class I, Division 2.

WARNING - CAUTION, battery may explode if mistreated. Do

not recharge, disassemble or dispose of in fire.

It is recommended that the user periodically inspect the sealed

devices used, check for any degradation of properties, and

replace as necessary.

For Technical Support:

Please contact Maple Systems if you have any questions

regarding this product. We ask that you provide us with the unit

serial number and firmware revision number written on the

product label of the unit.

Maple Systems Inc.

808 134th St. SW, STE 120

Everett, WA 98204

Tel: 425-745-3229

Fax: 425-745-3429

Email: support@maplesystems.com

Website: www.maplesystems.com

Loading...

Loading...