Page 1

CONTROLLER INFORMATION SHEET

Maple Model(s) PLC or Controller

Graphic HMIs Siemens S7-200 SMART (PPI)

P/N: 1036-0203

Rev. 01 Date: 10/11/2015

WARNING If your communications cable is not wired exactly as shown in our cable

assembly instructions, damage to the HMI or loss of communications can

result.

The PLC station number cannot be the same as the HMI station number.

Summary

Maple Systems Graphic HMIs communicate with Siemens S7-200 SMART modules via PPI.

When configured with EZware, the Graphic HMI is the master in a point-to-point single

master, single slave format. Please refer to the Installation and Operations Manual for

information on connecting multiple Graphic HMIs to a single PLC port.

Communications

The Graphic HMI should be connected to the controller’s PPI port. A list of communications

cables offered by Maple Systems as well as cable assembly instructions to assist you in

assembling your own communications cable are available on our website at

www.maplesystems.com.

PLC Controller Settings

Cab

le

. Maple Systems Inc., 808 134th Street SW, Suite 120, Everett, WA 98204-7333 – www.maplesystems.com

1036-0203 Page 1 of 4 Rev. 01, 10/11/2015

Page 2

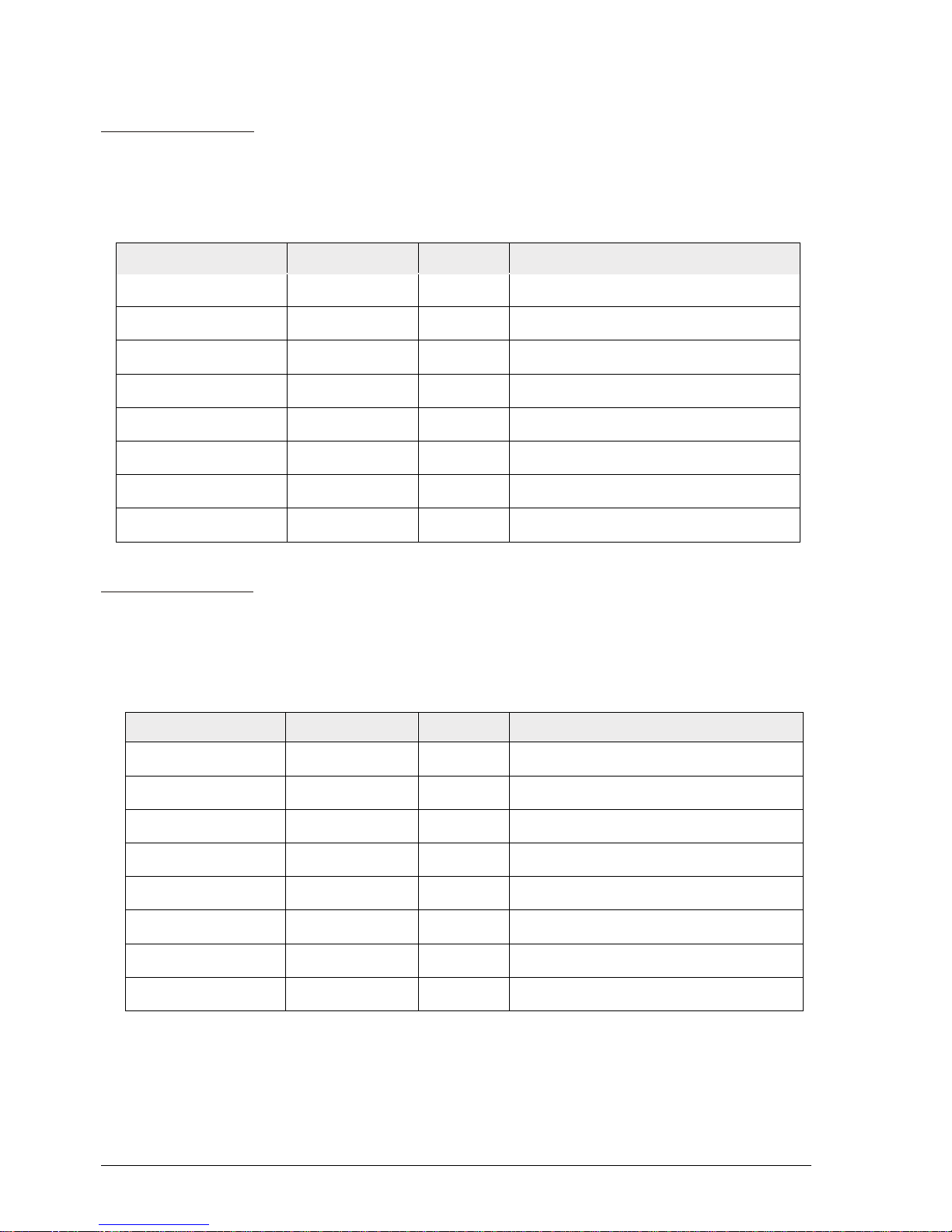

Accessible

PLC Register Type

Address Range

Format

PLC Register Description

MW

0-30

dd

Word Memory

VW

0-20478

ddddd

V Memory

SMW

0-1534

dddd

Special Memory

T

0-255

ddd

Timer

C

0-255

ddd

Counter

AIW

0-110

ddd

Analog Input

AQW

0-110

ddd

Analog Output

VD

0-20476

ddddd

V Memory (Double Word)

PLC Bit Type

Address Range

Format

PLC Bit Description

I

00-317

ddo

Input Bit (Read Only)

Q

00-317

ddddo

Output Bit

M

00-317

dddddo

Bit Memory

V

00-204797

dddddo

V Memory Bit

S

00-317

ddo

SCR

SM

00-15357

ddddo

Special Memory Bit

Timer

0-255

ddd

Timer

Counter

0-255

ddd

Counter

PLC

Mem

ory

Register Memory

The following table lists the PLC’s register memory ranges that the Graphic HMIs are able to

access. Please note that your PLC’s memory range may be smaller or larger than that

supported by these HMIs. The following register memory can be displayed in 16-bit or 32-bit

format on the Maple HMI.

(Note: d=decimal )

Discrete Memory

The following table lists the PLC’s discrete memory ranges that the Graphic HMIs are able to

access. Please note that your PLC’s memory range may be smaller or larger than that

supported by these HMIs. The following discrete memory is displayable in single-bit format

on the Maple HMI.

(Note: d=decimal, o=octal)

Phone: 425/745-3229 • Fax: 425/745-3429 • Email: support@maplesystems.com • www.maplesystems.com

1036-0203 Page 2 of 4 Rev. 01, 10/11/2015

Page 3

EZware Settings

Name

Recommended

Settings

Options

Important Notes

Name:

Siemens S7-200

Smart (PPI)

Description label

HMI or PLC

PLC

Location

Local

Local, Remote

Select Local if PLC directly

connected to HMI, Remote

if PLC connected thru

another HMI.

PLC type:

Siemens S7-200

Smart (PPI)

PLC I/F:

RS485 2W

RS-232,

RS-485 2W,

RS-485 4W

Must match the controller port

setting.

PLC default station

no.:

2

1-126

Must match the node address

assigned to the PLC.

Setting: COM:

COM1

COM1-COM3

Serial port of the HMI connected

to the controller.

Settings: Baud rate

9600

9600, 19200,

187.5K

Must match the PPI port

setting. Use the fastest

baud rate supported by the

controller.

Settings: Data Bits

8

7 or 8

Must match the PPI port setting.

Settings: Stop Bits

1

1 or 2

Must match the PPI port setting.

Settings: Parity:

Even

Even, Odd,

None

Must match the PPI port setting.

The following table lists the communications settings that must be configured in

EZware. These settings can be found in the Edit-System Parameters menu under the

Device Properties tab. Please note:

The Recommended Settings column provides the recommended setting

based upon the default settings most commonly used in Siemens modules.

The Options column lists EZware’s options; your PLC may not support

every option

. Maple Systems Inc., 808 134th Street SW, Suite 120, Everett, WA 98204-7333

1036-0203 Page 3 of 4 Rev. 01, 10/11/2015

Page 4

Name

Recommended

Settings

Options

Important Notes

Settings: Timeout

(sec)

1.0

0.1 to 25.5

Adjust if longer timeout is

required.

Settings: Turn around

delay (ms):

5

0-1000

Timeout period between HMI

polls.

Settings: Send Ack

Delay :

30

Settings: Reserved 1:

0 Not Applicable

Settings: Reserved 2:

0 Not Applicable

Settings: Reserved 3:

0 Not Applicable

Interval of block pack

(words):

5

0-512

Max. read-command

size (words):

16 Not Adjustable

Max. write-command

size (words):

2 Not Adjustable

Phone: 425/745-3229 • Fax: 425/745-3429 • Email: support@maplesystems.com • www.maplesystems.com

1036-0203 Page 4 of 4 Rev. 01, 10/11/2015

Loading...

Loading...