Page 1

Page 2

COPY RIGHT NO TICE

This manual is a publication of Maple Systems, Inc., and is provided for use by its customers only. The contents of the

manual are copyrighted by Maple Systems, Inc.; reproduction in whole or in part, for use other than in support of Maple

Systems equipment, is prohibited without the specific written permission of Maple Systems.

The copyright of EasyBuilder-5000 and its related software belongs to Weintek Labs, Inc.

WAR RANTY

Maple Systems warrants each product to be free from electrical and mechanical defects in materials and workmanship for a

period of two years from the date of shipment. This warranty does not apply to defects in the Products caused by abuse,

misuse, accident, casualty, alteration, negligence, repair not authorized by Maple Systems, use on current or voltages other

than specified by Maple Systems, or application or installation not in accordance with published instruction manuals. This

warranty is in lieu of any other warranty either expressed or implied.

Maple Systems’ liability is limited to the repair or replacement of the Product only, and not costs of installation, removal, or

damage to user’s property or other liabilities. If Maple Systems is unable to repair or replace a nonconforming Product, it

may offer a refund of the amount paid to Maple Systems for such Product in full satisfaction of its warranty obligation.

Maximum liability of Maple Systems is the cost of the Product.

Information furnished by Maple Systems, Inc., is believed to be accurate and reliable. However, no responsibility is assumed

by Maple Systems for the use of this information nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication, or otherwise, under any patent or patent rights of Maple

Systems, Inc. Maple Systems retains the right to revise or change its products and documentation at any time without notice.

IF SER VICE IS RE QUIRED

Contact Watlow Customer Service at (507) 454-5300 for instructions on how to return a product and how to obtain a Return

Materials Authorization (RMA) number.

Package the unit in its original packaging container or, if unavailable, any suitable rigid container. If a substitute container is

used, surround the unit with shock absorbing material; damage in shipment is not covered by the warranty. Include a letter

with the unit describing the difficulty and designating a contact person.

All returns will be tested to verify customer claims of noncompliance with the product warranty. Improper return packaging,

which makes verification impossible, will void the warranty. Products passing the tests will be returned “AS IS” to the

customer.

If noncompliance is verified and is not due to customer abuse or the other exceptions described with product warranty, Maple

Systems will, at its option, repair or replace the Product returned to it, freight prepaid , which fail to comply with the

foregoing warranty, provided Maple Systems is notified of such noncompliance within the two-year warranty period.

AP PLI CA TIONS AS SIS TANCE

This man ual is de signed to pro vide the nec es sary in for ma tion for trou ble-free in stal la tion and op er a tion of your new Op er a tor

In ter face Ter mi nal (OIT). How ever, if you need as sis tance, please call Watlow at (507) 494-5656 between 7 a.m. and 5 p.m.

Central Standard Time (CST). Ask for an Applications Engineer. Or you may e-mail your questions to

wintechsupport@watlow.com .

Page 3

Ta ble of Con tents

EZware-5000 Sup port ...............1

OIT Mod els Sup ported ............1

PLCs Sup ported .................1

About Your Doc u men ta tion............1

Con ven tions ...................1

What You Need .................2

OIT Ba sics ........................2

What is a Sil ver Se ries OIT? ........4

List of Fea tures..................5

Chap ter 1 - In stal la tion of OITs ............7

Un pack ing the Unit ..............7

Man ag ing Elec tro static Dis charge ....7

CE Com pli ance .................7

NEMA Rat ing ...................7

En vi ron men tal Con sid er ations ......7

Safety Pre cau tions ...............8

Con trol Panel De sign Guide lines........8

Con trol Panel Ground ing ..........9

Con nect OIT Chas sis Ground to Con trol

Panel.........................9

Power Sup ply Se lec tion............11

Ca ble Rout ing and Noise Im mu nity...11

In stal la tion........................12

Con nect the OIT to Power .........12

Panel Prep a ra tion ...............14

Mount the OIT to the Panel.........14

Con fig u ra tion Wir ing ................15

Con nect the OIT to the PC for

Con fig u ra tion ..................15

Chap ter 2 - OIT Lo cal Setup...............17

Fac tory Con fig u ra tion................17

Cal i brat ing the Touchscreen ........17

Get ting into Lo cal Setup ...........17

Chang ing the Sys tem Set tings .......18

View ing Sys tem In for ma tion ........22

Trans fer ring Pro jects and Data from

USB/CompactFlash ..............23

Chap ter 3 - Con nect the OIT to the PLC or

Con trol ler ............................25

COM Ports for the

HMI5080/HMI5104/HMI5121 ......26

COM Ports for the HMI5056 .......27

Con nect ing to COM1 and COM3 on

Port A ........................28

Con nect ing to COM1 and COM2 on

Port B ........................32

Con nect ing mul ti ple PLC/con trol lers

se ri ally us ing daisy chain ing ........33

Con nect ing one or more PLC/con trol lers

via Ethernet ....................33

Chap ter 4 - Cre at ing Your First Pro ject ......35

Be fore You Be gin ...................35

Con nect ing OIT to Com puter ..........35

Start ing EZware-5000 ...............35

Cre at ing a Sam ple Pro ject ............36

Set ting the Sys tem Pa ram e ters ......36

Cre at ing a Popup Win dow .........40

Cre at ing a Startup Win dow ........48

Fin ish ing Up ......................54

Chap ter 5 - Sim u la tor Mode ..............59

The Sim u la tion Screen ...............59

Chap ter 6 - Us ing EZware-5000 ...........61

Over view .........................60

The Pro ject Man ager ................60

Com mu ni ca tions & Pass word Set tings . 62

Ed i tor Set tings ..................63

Trans fer Set tings ................63

Sim u la tion Set tings...............63

View ing Data Log................65

Easy Printer ....................70

Con vert ing Data/Event Log.........70

Rec ipe Ex tended Mem. Editor .......71

Pass Through Mode ..............76

The EasyConverter Ap pli ca tion .........76

Man ag ing Pro jects ...............78

Ed it ing and Cre at ing Screen Ob jects..82

Ba sic Ed it ing Commands ..........86

Group ing Ojects ................90

Lay er ing Objects ................91

Nudg ing Objects ................93

Mak ing Ob jects Same Size .........97

Mak ing Ob jects Same Color........98

Gen eral Set tings ................101

Au to mat i cally Re boot OIT .............112

Save and Com pile the Pro ject ..........112

Chap ter 7 - Cre at ing Win dows ............116

Win dow Fun da men tals ...............117

Open ing a Win dow ..............117

Cre at ing a New Win dow ..........117

As sign ing Un der lay Win dows .......121

How to Dis play Un der lay Win dows ...122

Rules That Ap ply to Un der lay

Win dows ......................122

De let ing a Win dow ..............123

Us ing Base Win dows ................123

How to Dis play Base Win dows ......123

Us ing the Com mon Win dow ...........129

Chang ing the Ac tive Com mon

Win dow.......................132

Us ing the Fast Se lec tion Win dow........133

Us ing the Fast Se lec tion Key ........135

Chang ing screens us ing the Fast

Se lec tion win dow ................136

Sys tem Mes sage Win dow ..........138

Chap ter 8 - Cre at ing Graphic Ob jects .......140

Draw ing Ob jects ...................140

Us ing the Draw ing Tools ..........140

Us ing Text .....................144

Page 4

ii Sil ver Se ries In stal la tion & Operation Man ual

Pre de fined Shapes and Pic tures.........146

Us ing a Pre de fined Shape ......146

Us ing a Pre de fined Pic ture ......148

Graphics Li brar ies ..................150

What are ‘states’? ............150

Us ing Shape Li brar ies .........150

Us ing Pic ture Li brar ies .........154

Us ing Group Li brar ies .........157

Us ing Sound Li brar ies .........160

Chap ter 9 - Cre at ing and Us ing Da ta bases and

Lan guages ............................164

Cre at ing and Us ing the Tag Li brary .....164

Im port ing and Ex port ing the Tag

Li brary.....................165

Us ing the Tag Li brary..........165

Cre at ing the La bel Li brary ............166

Set ting Dif fer ent Fonts for Dif fer ent Lan -

guages ....................168

Im port ing and Ex port ing the La bel

Li brary.....................169

Us ing the La bel Li brary...............169

Us ing Lan guages with the La bel

Li brary.....................170

Chap ter 10 - Rep re sent ing Data with Graphics

Ob jects...............................172

Gen eral Prop er ties of Objects ..........172

Us ing In dex Registers ................182

Us ing In ter nal Data Mem ory of OIT .....184

Rep re sent ing PLC Coil Reg is ters ........192

The Bit Lamp Ob ject ..........192

The Set Bit Ob ject ............196

The Tog gle Switch Ob ject .......197

Rep re sent ing PLC Data Reg is ters ........199

The Word Lamp Ob ject ........199

The Set Word Ob ject ..........202

The Slider Ob ject .............203

The MultiState Switch Ob ject.....205

The Nu meric Dis play Ob ject.....209

The Nu meric In put Ob ject ......211

The ASCII Dis play Ob ject .......216

The ASCII In put Ob ject.........217

The Mov ing Shape Ob ject ......218

The An i ma tion Ob ject .........222

The XY Plot Ob ject ............224

Chap ter 11 - Us ing and Cre at ing Keypads ...240

How to Cre ate a Key pad .............240

Dis play ing and Us ing a Key pad ........241

Chap ter 12 - Bar Graphs, Me ters and Trends . 246

Cre at ing Bar Graphs ................246

Cre at ing Me ter Dis plays ..............248

Cre at ing Trend Dis plays & Data Sam pling

Ob jects ..........................251

His tory Data Dis play Part .......258

Chap ter 13 - Cap tur ing Alarms and Events ...264

Us ing Alarms ......................264

Mon i tor ing Alarms with the Alarm/Event

Log .............................263

Dis play ing Alarms/Alarm Dis play Ob ject ..266

Dis play ing Alarms us ing the Alarm Bar

Ob ject.....................267

Us ing Events ................269

Mon i tor ing Events With the Event Log

Ob ject.....................269

Dis play ing Events Us ing the Event

Dis play Ob ject ...............269

Chap ter 14 - Data and Rec ipe Trans fer Ob jects 272

Us ing the Data Trans fer Ob ject.........271

Us ing the Rec ipe Trans fer (Data Trans fer, Trig -

ger Based) Ob ject ..................272

Cre at ing a Rec ipe ............273

Backup Part .................274

Chap ter 15 - Mac ros ....................277

Us ing Mac ros .....................277

Macro Sam ple and

Im ple men ta tion .............277

Vari ables, Dec la ra tions and Mem ory

Us age ...........................278

Mem ory Us age: .............278

Vari able Dec la ra tions..........279

Vari able Ini tial iza tion ..........279

Ar ray ini tial iza tion ............280

Re served Words ..............281

Op er a tor...................281

Or der of Pre ce dence ..........282

Main Func tions and Sub-

func tions ...................282

Lo cal and Global Vari ables .....282

Cre at ing Vari able Ar rays .......283

Us ing Mac ros Within Rec i pes ....283

State ments, Con di tions &

Ex pres sions .................284

Func tion Calls and Pass ing Pa ram e ters

246

Read ing & Writ ing Ex ter nal Reg is ters in

a Macro ...................286

Pre cau tions, Tips & Tricks when Us ing

Mac ros ....................288

Com piler Er rors & Er ror Codes .........288

Chap ter 16 - Mis cel la neous Objects.........291

Misc. Objects ......................291

Sched uler Object ............293

Time Set Tab ................293

Pro hibit Tab .................295

Me dia Player ................296

In dex ................................303

1010-1007, Rev 06

Page 5

Sil ver Se ries In stal la tion & Op er a tion Man ual

iii

1010-1007W, Rev 06

Page 6

Introduction 1

Introduction - Welcome

Welcome to the Maple Systems’ Silver Series Operator Interface Terminals (OITs) from Watlow. Using graphic OITs has

never been easier. This powerful family of graphics operator interface terminals connect to Watlow controllers and other

devices such as programmable logic controllers (PLCs) to provide the human-machine interface in industrial applications.

The Silver Series has several features not found in other graphic OITs. This manual explains the operation of the Silver

Series OITs and how to implement the many available features using the EZware-5000 Configuration Software.

Watlow and Maple Systems have worked together to bring you this product. Please contact Watlow for support, and be sure

to utilize any resources referenced in this manual on the Watlow website (www.watlow.com) and the Maple Systems

Website (www.maplesystems.com).

EZware-5000 Sup port

OIT Mod els Sup ported

For the latest list of Silver Series Models supported by Watlow, please visit the Watlow website at www.watlow.com.

PLCs Supported

For the latest list of PLCs and controllers supported by the Silver Series OITs, please visit our website.

About Your Doc u men ta tion

Maple Systems provides many resources to allow you to get the most out of your Silver Series OIT.

· Silver Series Operation Manual (shipped with EZware-5000 as a PDF file) - describes installation, general operation

and features of the Silver Series using EZware-5000 configuration software..

· Watlow Silver Operator Interface Terminal Manual Addendum - contains specific instructions and examples on

communicating with and creating interfaces for Watlow controllers.

· Controller Information Sheets - important information specific to each supported protocol.

· EZware-5000 On-line Help - covers the operation of EZware-5000. Always available by clicking HelpTopics from

the Help menu in EasyBuilder, or press F1 from any dialog.

For more information about these and other training sources, visit the Maple Systems website.

Con ven tions

When using EZware-5000, there are usually several ways to perform a task. For example, if you want to copy a graphics

object, you can:

· Click the Copy command on the Edit menu.

· Click the Copy button on the Standard toolbar.

· Press the CTRL + C keys on your com puter.

1010-1007W, Rev 06

Page 7

2 Sil ver Se ries In stal la tion & Operation Man ual

In most cases, we will describe each method when the task is first discussed. The menu method is then used whenever the

task is used in later procedures. Other conventions used in this manual are listed in the following table.

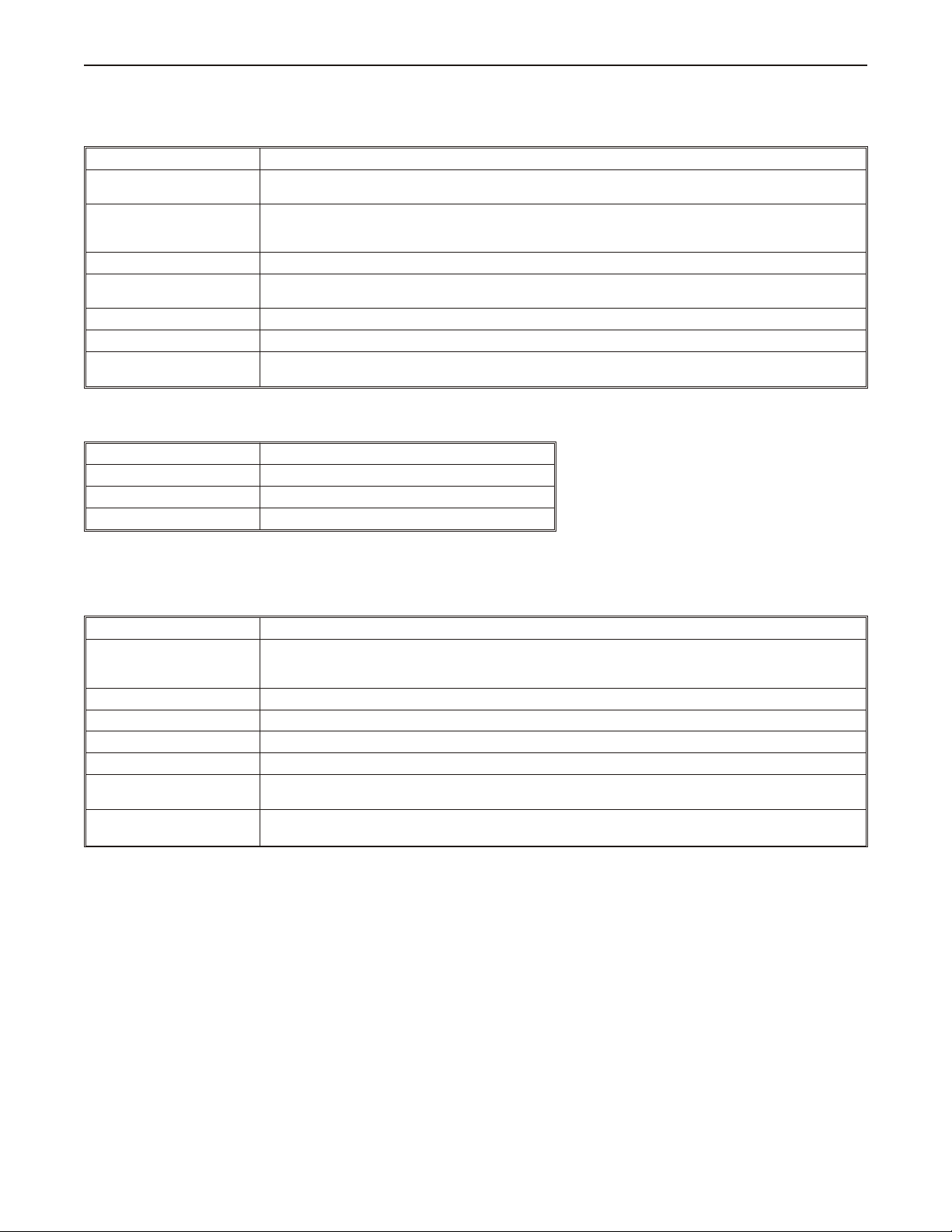

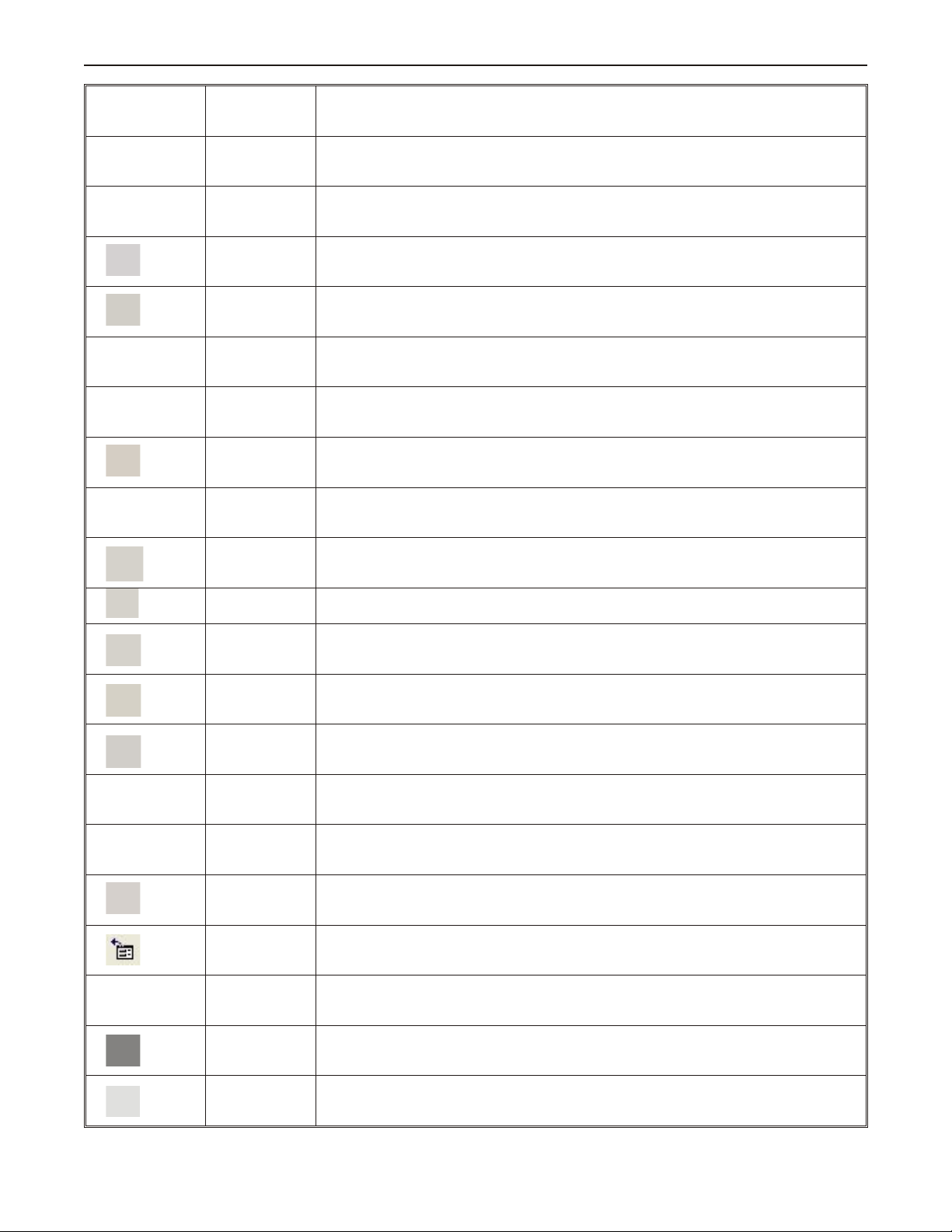

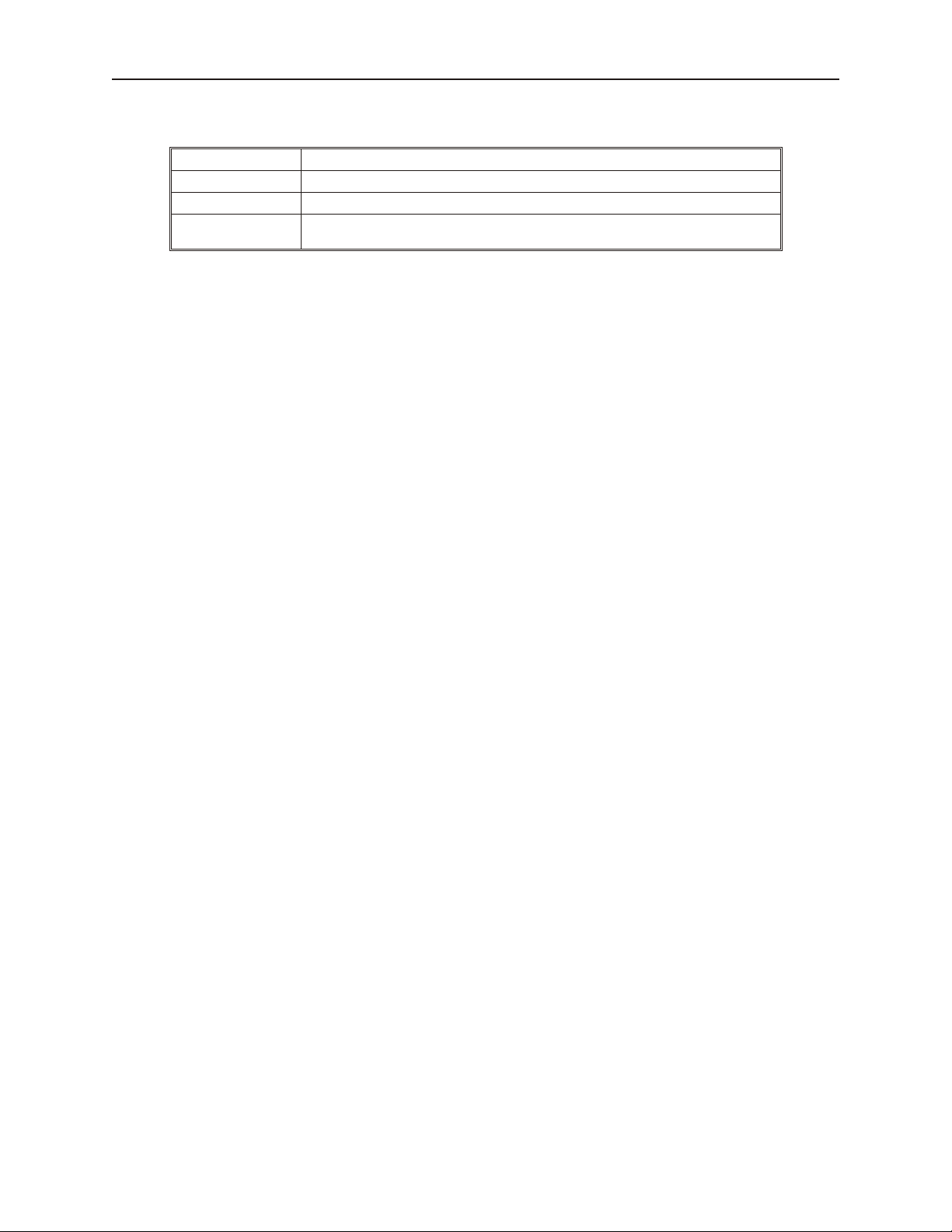

Convention Meaning

Bold

Italic

ALL CAPITALS Directory names, file names, key names, and acronyms

KEY1+KEY2

click Refers to clicking the primary mouse button (usually the left mouse button) once.

Double-click Refers to quickly clicking the primary mouse button (usually the left mouse button) twice.

Right-click

Characters that you must type exactly as they appear. For example, if you are directed to type a:\setup,

you should type all the bold characters exactly as they are printed.

Placeholders for information you must provide. For example, if you are directed to type filename, you

should type the actual name for a file instead of the word shown in italic type. Italics are also used to

indicate a glossary term.

A plus sign (+) between key names means to press and hold down the first key while you press the second

key.

Refers to clicking the secondary mouse button (usually the right mouse button) once. Right-clicking

usually opens shortcut menus.

The following table identifies symbols and margin icons.

Icon Meaning

4 Identifies a procedure.

4 Indicates a reference to additional information.

Indicates an important note.

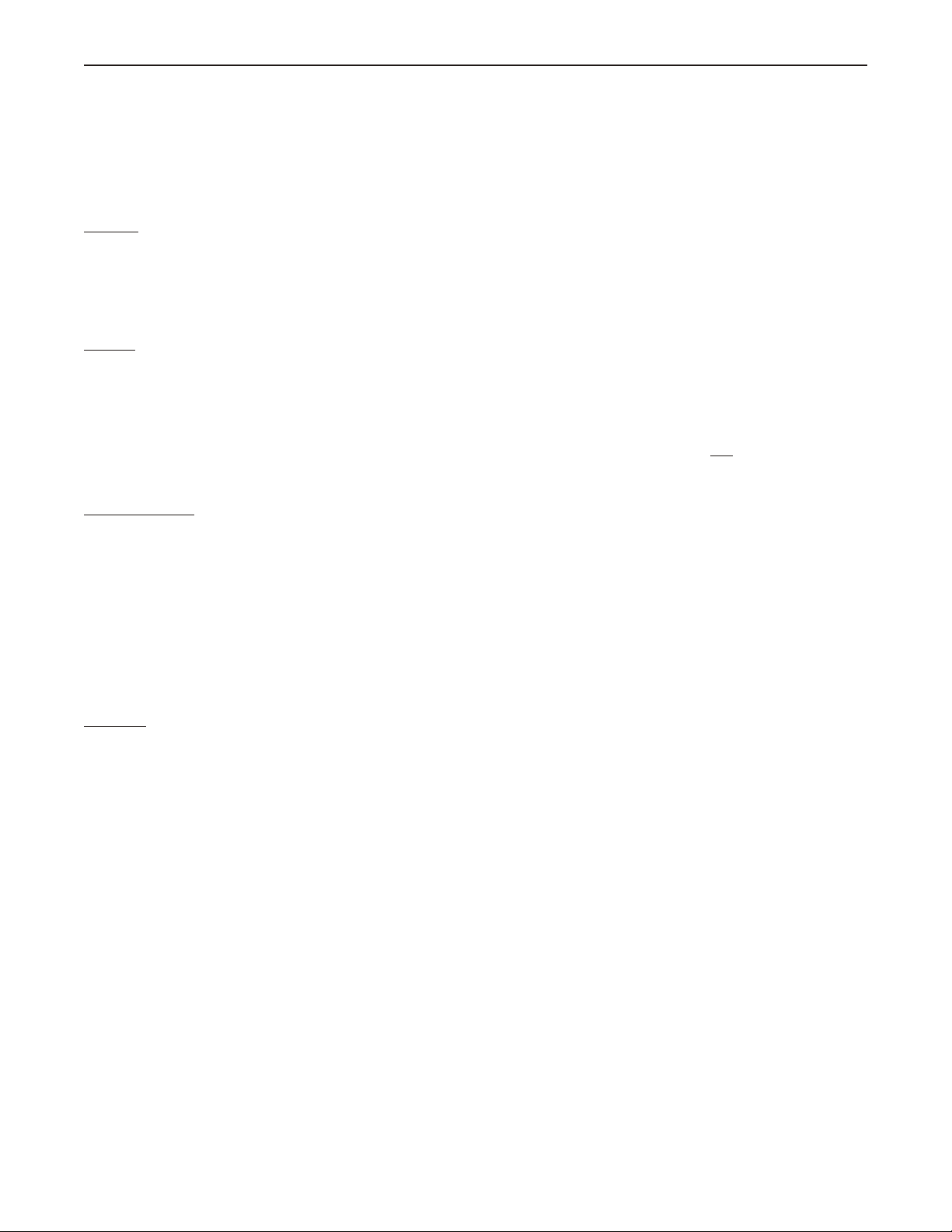

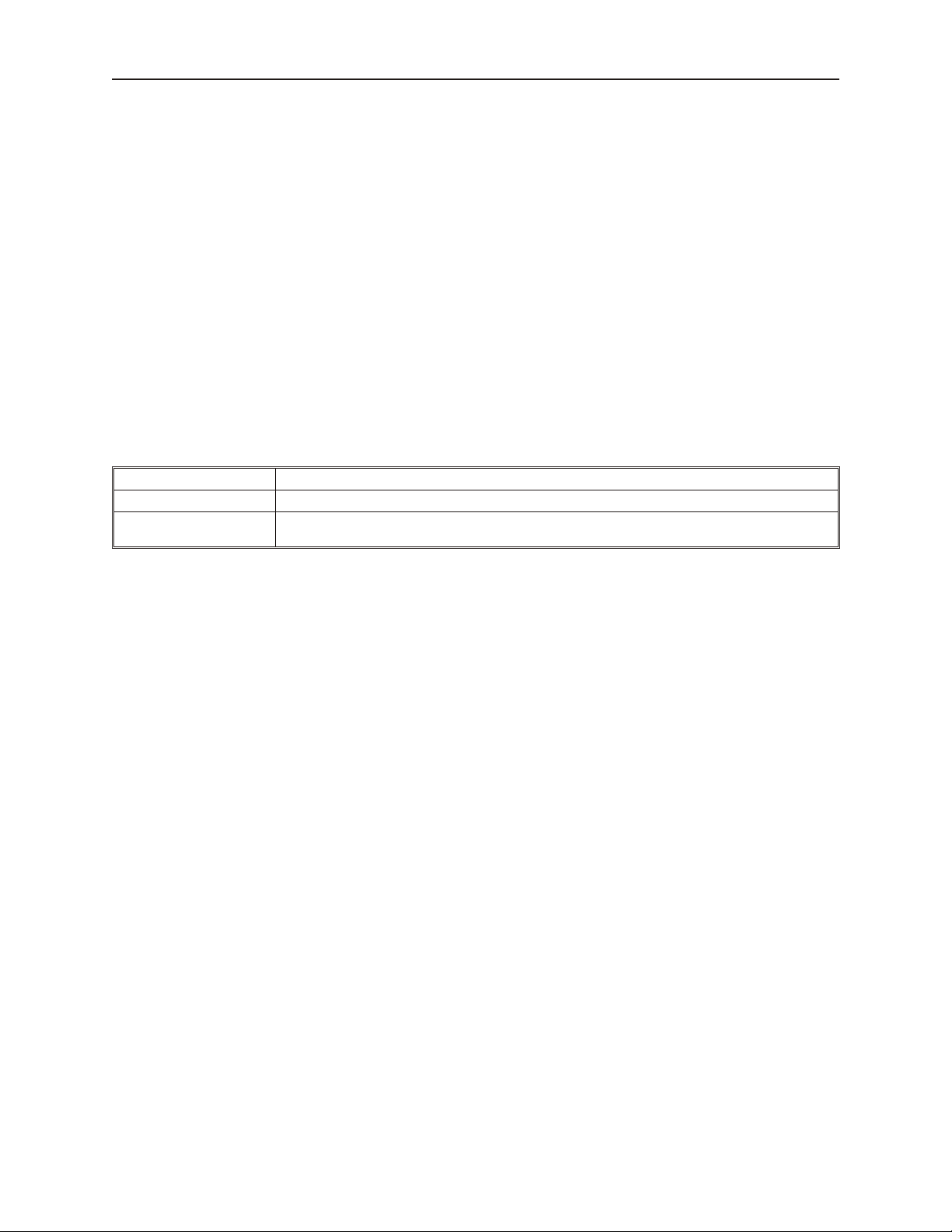

What You Need

The following items are needed to configure and operate your OIT.

Configuration Software EZware -5000

Configuration Cable

Personal Computer

Power Cable 6030-0009 2-conductor 18 AWG, shielded, no connectors

24VDC Power Supply User Provided

PLC User Provided

Controller Information Sheet

Communication Cable

(HMI to PLC)

1

Al lows you to con nect OIT directly to PC Ethernet port or to USB port to download/upload projects into the OIT.

2

Computer requirements include a Pentium 1.7 GHz or higher processor, 512 MB RAM, 200 MB available Hard Disk

1

2

7431-0104 ( Ethernet Crossover cable for HMI5056T, HMI5080T, HMI5104T/XH, HMI5121T/X, HMI5150X

models)

7431-0115 (USB download cable for HMI5043N, HMI 5056N, HMI5070NH/TH and HMI5100N/T models)

User Provided

Maple Systems provides Controller Information Sheets which contain important information specific to each

PLC. Please locate the sheet that corresponds to your PLC on our website.

Refer to our web site (www. maple-systems.com) for a list of available cables.

Space, SVGA or higher resolution monitor, Keyboard and Mouse, available Ethernet port or USB port (for downloading

project), at least one RS232 port for online simulation, Windows XP, 2000 or Vista.

OIT Ba sics

Operator Interface Terminals (OITs) provide much more versatility than traditional mechanical control panels. An OIT

allows a plant floor operator to monitor current conditions of a control system and, if necessary, to initiate a change in the

operation of the system. OITs connect to programmable logic controllers (PLCs) typically through the PLC’s serial

communications port. The OIT can be programmed to monitor and/or change current values stored in the data memory of the

PLC.

OITs can have either text-based or graphics-based displays. A text-based OIT can display printable text characters but no

graphics. Some text-based OITs can display text characters in various sizes. A graphics-based OIT can display printable text

characters of varying fonts and sizes and graphics shapes such as icons, bitmaps, or pictures. Using pictures instead of words

or characters often greatly simplifies the operation of the OIT, making the OIT much more intuitive to use.

1010-1007W, Rev 06

Page 8

Introduction 3

Some OITs use touchscreen displays while others use a membrane-style keypad. Membrane-style keyboards are best used in

applications in which the keypad is likely to become dirty. Touchscreen displays are placed over the OIT screen thus

providing much more flexibility than typical membrane-style keypads. Because of this, switches can be created on a

touchscreen that appear only when needed.

The Maple Systems Silver Series OITs are graphics-based touchscreen OITs. Before we get any further into the operation of

these OITs, it is necessary to define some terms that will be used throughout this manual.

Projects

The OIT has two basic segments of internal memory. The code memory contains the information required by the OIT that

controls how it operates such as the features supported and how it communicates to a PLC. The OIT programmer does not

have the ability to change code memory. The project memory pertains to all of the window screens created and any other

features that the OIT programmer can create using the EZware-5000 configuration software. Therefore, the term project is

used to designate the file that is sent to the OIT from the EZware-5000 software.

Objects

An object is any action that the OIT performs while it is communicating to the PLC. In order to get the operator interface

terminal to ‘do anything’, you must program the OIT with objects. Objects perform actions such as display text or graphics,

write a value to a PLC register, or display an alarm. Objects most often are graphics shapes that are to be displayed on the

OIT screen. For example, a Text Object is used to display text on the OIT. But objects are also used to configure the OIT to

perform some action. For example, a PLC Control Object tells the OIT to continuously monitor a PLC register that is used

by the PLC to request a new window. Some objects can display a graphics shape on the OIT screen and

perform some

action. For example, a Toggle Switch Object creates a graphic object on the OIT that when pressed, activates a bit in the

PLC.

Graphics Object

A graphics object is any text, icon, or picture that can be displayed on the OIT. Graphics objects are further defined by how

they are composed or created. A Text Object is a graphics object that displays text on the OIT screen. A Bitmap Object is a

graphics object that displays a bitmap on the OIT screen. Bitmaps are files stored in the OIT to display pictures. A Shape

Object is a graphics object that displays a shape on the OIT screen. Shapes are also files stored in the OIT to display

pictures. Shapes differ from bitmaps in that shapes are stored using a vector-based file format whereas bitmaps use a

pixel-based file format. Each format has its advantages and disadvantages. We will not go into any more detail about bitmap

objects and shape objects until later in this manual. For now, think of them as objects used to display pictures on the OIT

screen. Finally, a Group Object is the most complex type of graphics object. It is a combination of other objects. Briefly, a

group object consists of one or more objects that are ‘grouped’ together and stored as one object. A good example is a

keypad, which is really a combination of several keys each designed to perform a specific task. When grouped together, a

keypad can be stored as a group object for use in other projects or windows.

Windows

A window is a screen that can be displayed on the OIT. Windows can be full-sized to completely cover the OIT display or

partially sized. Any partially sized window is usually referred to as a popup window. Windows can appear on the OIT

display by a request from the PLC or by a press from the touchscreen. Windows can be configured to any size. Once a

window is displayed, it can be moved around the OIT display, removed from the display, or minimized to an icon. Windows

can even overlap each other. Each window can display graphics objects and there is no limit to the number of graphics

objects that can be placed on each window. The Silver Series is capable of storing up to 1999 windows , but the actual limit

is determined by the total amount of memory used for the application. A more in-depth discussion of windows is covered in

later chapters. For now, think of windows as screens that can be displayed on the OIT.

1010-1007W, Rev 06

Page 9

4 Sil ver Se ries In stal la tion & Op er a tion Man ual

What is a Silver Series OIT?

The Silver Series OITs by Maple Systems are graphics operator interfaces designed to connect to PLCs in an industrial

environment. The displays are covered with analog resistive touchscreens designed for harsh industrial environments. The

touchscreens use the latest in touchscreen technology enabling the OIT programmer to create switches that are very fine in

resolution. Unlike many other touchscreen OITs on the market, the Silver Series OITs are not limited to a fixed number of

cells in which switches can be created. The OIT programmer can create as many switches of varying sizes and shapes as he

wishes, limited only by the total amount of memory available for the project.

Three LED indicators are provided on the face of the Silver Series OITs to provide instant feedback to the OIT operator of

the current operating condition of the OIT.

LED Indicator Purpose

PWR LED (yellow) indicates if power is applied to the OIT

CPU LED (green) indicates if the OIT is operating correctly

COM LED (red) indicates communications activity on PLC port

The Silver Series OITs have three serial ports, which provide a connection to a PLC using RS-232 or

RS-485 communications and an Ethernet connection for PLC communication and project upload and download. The serial

ports also provide the ability to use the EZware-5000 configuration software in Simulation Mode enabling the OIT

programmer to test his project on the PC instead of downloading the project to the OIT.

The Silver Series is powered using +24VDC. Finally, a reset switch is provided on the back of the OIT to reinitialize the

OIT if an operational failure occurs. The Silver Series is designed for industrial environments and carries a NEMA 4X

(indoor only) rating as well as CE compliance for noise immunity and emissions.

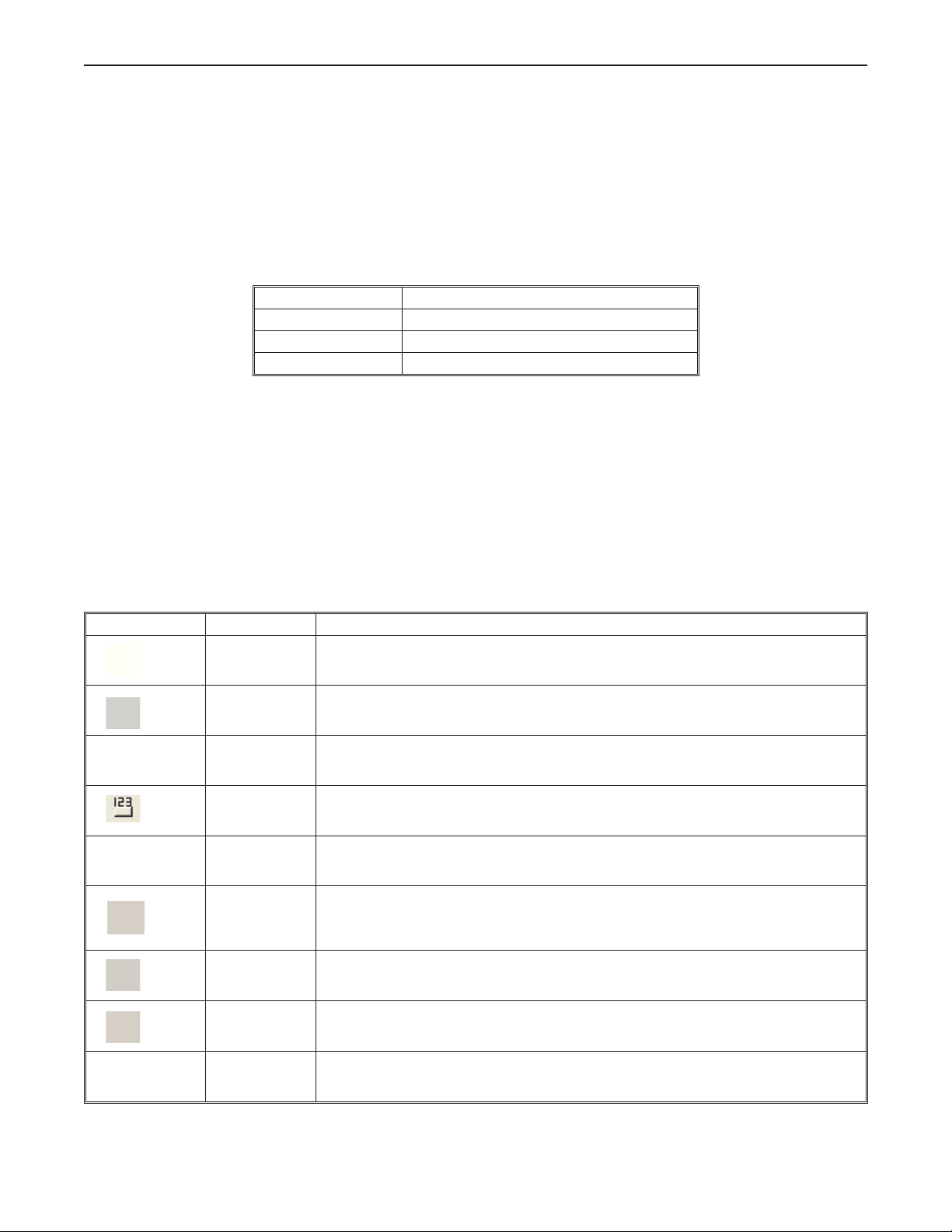

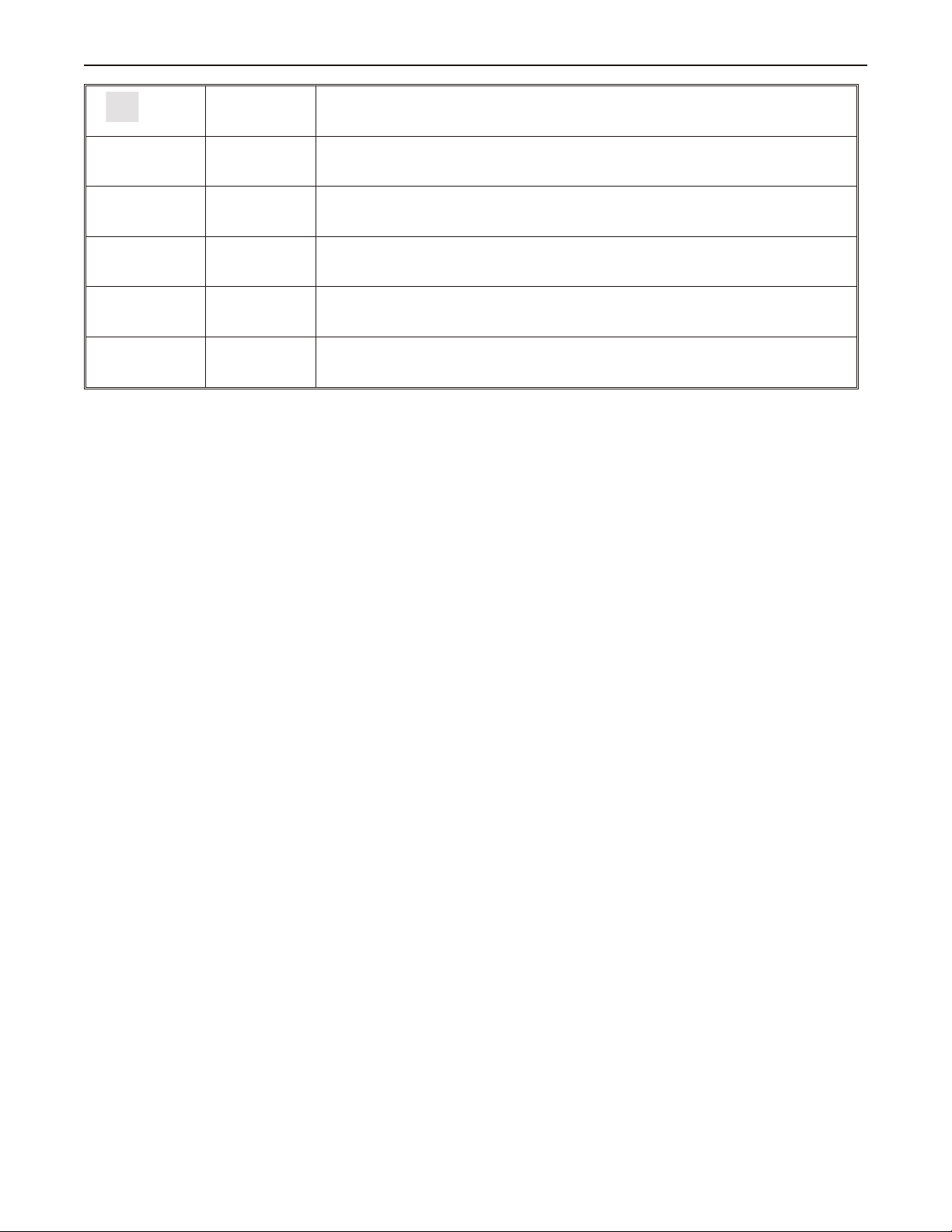

List of Fea tures

The next chapter will guide you through the creation of your first project. Before you proceed, you may wish to read this

brief list of some of the features offered in the Silver Series OIT.

Icon Name Description

Bit Lamp

Word Lamp Creates a graphics object to reflect the current state of a multi-state PLC data register.

Set Bit

Set Word

Toggle Switch

Slider Object

Multi-State

Switch

Creates a graphics object to reflect the current status of a PLC bit.

Creates a touchscreen graphics object that represents a two-state switch. When pressed it

sets/resets a PLC bit.

Creates a touchscreen graphics object that represents a multi-state switch. When pressed it can

place a constant value in a PLC register or jog the value.

Creates a touchscreen graphics object that represents a two-state switch changing state

(picture) based upon a PLC bit. When pressed, it can control another PLC bit.

Creates a touchscreen graphics object that changes the state according to the position of a

slider switch.

Creates a multi-state touchscreen graphics object that changes state (picture) according to the

value in a PLC data register. When pressed, it sends a value(s) to another PLC register.

1010-1007W, Rev 06

Function Key Creates a touchscreen graphics object or runs a macro.

Numeric Input

Displays a number stored in a PLC register. The number can be changed using a numeric

keypad.

Page 10

Introduction 5

Numeric Data

ASCII Input

ASCII Data Displays ASCII characters stored in a PLC register.

Moving Shapes

Animation

Indirect Window

Direct Window Displays a Window based on a bit in a PLC register.

Alarm Displays Creates alarms to display alarms sent from the Alarm/Event Log Object.

Alarm Bar Displays alarms detected by the Alarm/Event Log Object on a single horizontal scrolling line.

Displays a number stored in a PLC register.

Displays ASCII characters stored in a PLC register. Characters can be changed using an

alphanumeric keypad.

Creates a multi-state graphics object, which changes state (picture) and position on the screen

according to a value in a PLC register.

Creates a multi-state graphics object, which changes state (picture) on the screen according to a

value in a PLC register. The positions on the screen are predefined.

Configures the OIT to monitor PLC data registers to display for a specific window popup by a

PLC word address

Data Transfer

(triggered)

Data Transferred

(time-based)

Event Displays Displays messages detected in the Alarm/Event Log and can acknowledge the message(s).

Data Sampling

(Data Logging)

Alarm/Event Log Contains the data for detecting alarm conditions.

Trend Displays

Bar Graph

Displays

Meter Displays Creates a scale meter.

Recipe Transfer Transfers data to the specified PLC registers.

System

Message

Transfers data to the specified PLC registers based on a touch or PLC bit status.

Transfers data to the specified PLC registers on a timed basis.

Stores data for trending and archiving.

Creates a trend graph. Samples data in a single or multiple 16-bit PLC register and plots the

data on a time graph.

Creates a bar graph with alarm monitoring.

Customizes the content of system-generated messages.

PLC Control Configures the OIT to monitor PLC data registers to display full window screens.

History Data

Display

Displays historical data in a tabular format.

1010-1007W, Rev 06

Page 11

6 Sil ver Se ries In stal la tion & Operation Man ual

Backup Copies recipe, event or historical data to one of the USB memory devices.

Data Block

Display

XP Plot Creates an XY Plot.

Media Player Displays a video file.

Option List Creates a drop-down list blox

Scheduler Peforms an action based upon a time schedule.

Displays the data in a series of registers as a line graph.

1010-1007W, Rev 06

Page 12

In stal la tion of OITs 7

Chapter 1 - Installation of OITs

Be fore You Be gin

Please read the following for proper handling of your new OIT.

Un packing the Unit

Carefully unpack the OIT. Please read any instructions or cautions that appear on the shipping container. Check all

material in the container against the enclosed packing list. Maple Systems, Inc. will not accept responsibility for

shortages against the packing list unless notified within 30 days. The equipment and its accessories were inspected

and tested by Maple Systems before shipment; all of the equipment should be in good working order. Examine the

equipment carefully; if any shipping damage is evident, notify the carrier immediately. You are responsible for

claim negotiations with the carrier. Save the shipping container and packing material in case the equipment needs to

be stored, returned to Maple Systems, or transported for any reason.

Man aging Elec tro static Dis charge

It is best NOT to remove the rear enclosure of the OIT. When the rear part of the enclosure is removed, the circuitry

inside is exposed to possible damage by electrostatic discharge during handling. Minimize the possibility of

electrostatic discharge by:

• Discharging personal static by grounding yourself prior to handling the OIT

• Handling the OIT at a static-free grounded workstation

• Connecting the frame ground (FG) connector of the OIT to a clean earth ground

• Placing the OIT in an anti-static bag during transport

CE Com pli ance

The Silver Series OITs have been tested to conform to European CE requirements per Council Directive

89/336/EEC. The European Union created these requirements to ensure conformity among products traded in those

countries. Specifically, the Silver Series OITs meet or exceed the noise emissions and immunity requirements as set

forth in the EN50081 (Emissions) and EN50082 (Immunity) standards. These products are designed to withstand

electrical noise in harsh ind ustrial environments. They also conform to requirements that limit electrical emissions.

However, this does not guarantee that the products will be totally immune from possible malfunction in cases where

severe electrical noise occurs. Therefore, we strongly recommend that you follow the guidelines outlined in this

chapter for proper wire routing and grounding to insure the proper operation of the Silver Series OIT.

NEMA Rat ing

The Silver Series OITs are rated for NEMA 4X/12 (indoor only) or IP65 installations. This means that when the

OIT is properly mounted to a panel or other enclosure, the front enclosure of the OIT will provide protection to the

inside of the panel from splashing water, wind blown dust, rain, or hose-directed water. The OIT must be installed

according to the instructions in this chapter to be properly sealed.

En vi ron men tal Con sid er ations

The Silver Series is designed to operate in temperatures from 0-45° C. It is intended for indoor installations and not

designed for outdoor applications. Avoid installing the Silver Series in environments with severe mechanical

vibration or shocks. Do not install the OIT in enclosures with rapid temperature variations or high humidity. Either

will cause condensation of water inside the device and eventual damage to the OIT.

1010-1007W, Rev 06

Page 13

8 Sil ver Se ries In stal la tion & Op er a tion Man ual

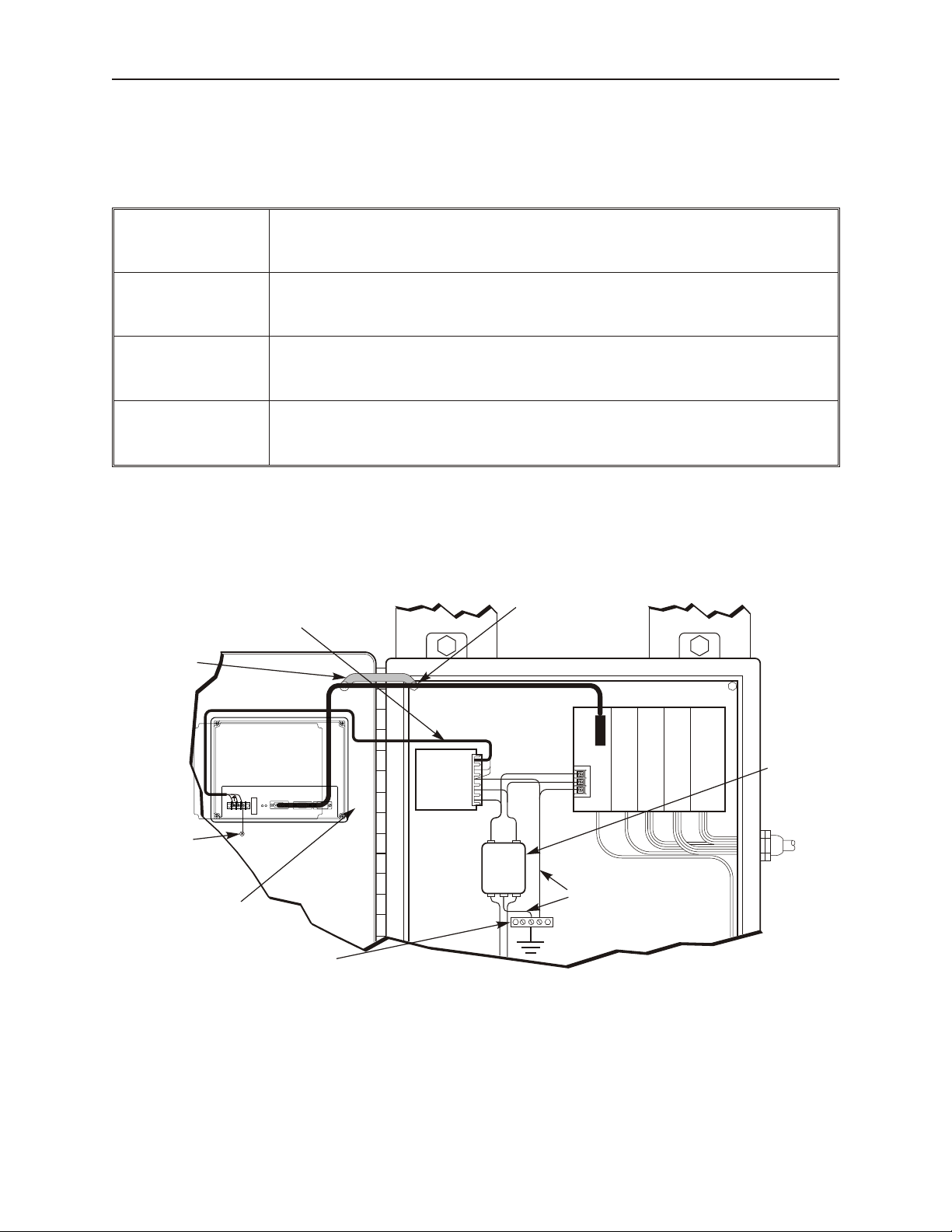

I / O control lines

PLC/Host

Ground wires

(rear side)

OIT is

grounded to

control panel

Ground

strap

Power

line

filter

Quiet ground

(isolated)

Quiet ground

Line

Filter

OIT

Power

Supply

Shielded power cable

Shielded

communication

cable

Control panel is

tied to a reliable

earth ground

Silver Series

OIT

24V

GND

COM1 [RS-485 2/4W]

PLC [RS-232]

COM3 [RS-485]

COM3 [RS-232]

COM1 [RS-232]

COM2 [RS-232]

Safety Pre cau tions

Please observe the following precautions when installing the Silver Series OIT. Failure to comply with these

restrictions could result in loss of life, serious personal injury, or equipment damage.

Warning: Do not operate the OIT in areas subject to explosion due to flammable gases,

vapors, or dusts.

Warning: Do not connect the OIT to an AC power source. You will cause permanent damage

to the OIT.

Warning: Do not attempt to use a DC power supply that does not meet OIT power

requirements. You may cause malfunction or permanent damage to the OIT.

Warning: Do not power the OIT with a DC power supply used for inductive loads or for input

circuitry to the programmable logic controller. Severe voltage spikes caused by these devices may

damage the OIT.

Con trol Panel De sign Guide lines

Pay careful attention to the placement of system components and associated cable routing. These items can

significantly enhance the performance and integrity of your control application.

Con trol Panel Ex am ple

1010-1007W, Rev 06

Page 14

In stal la tion of OITs 9

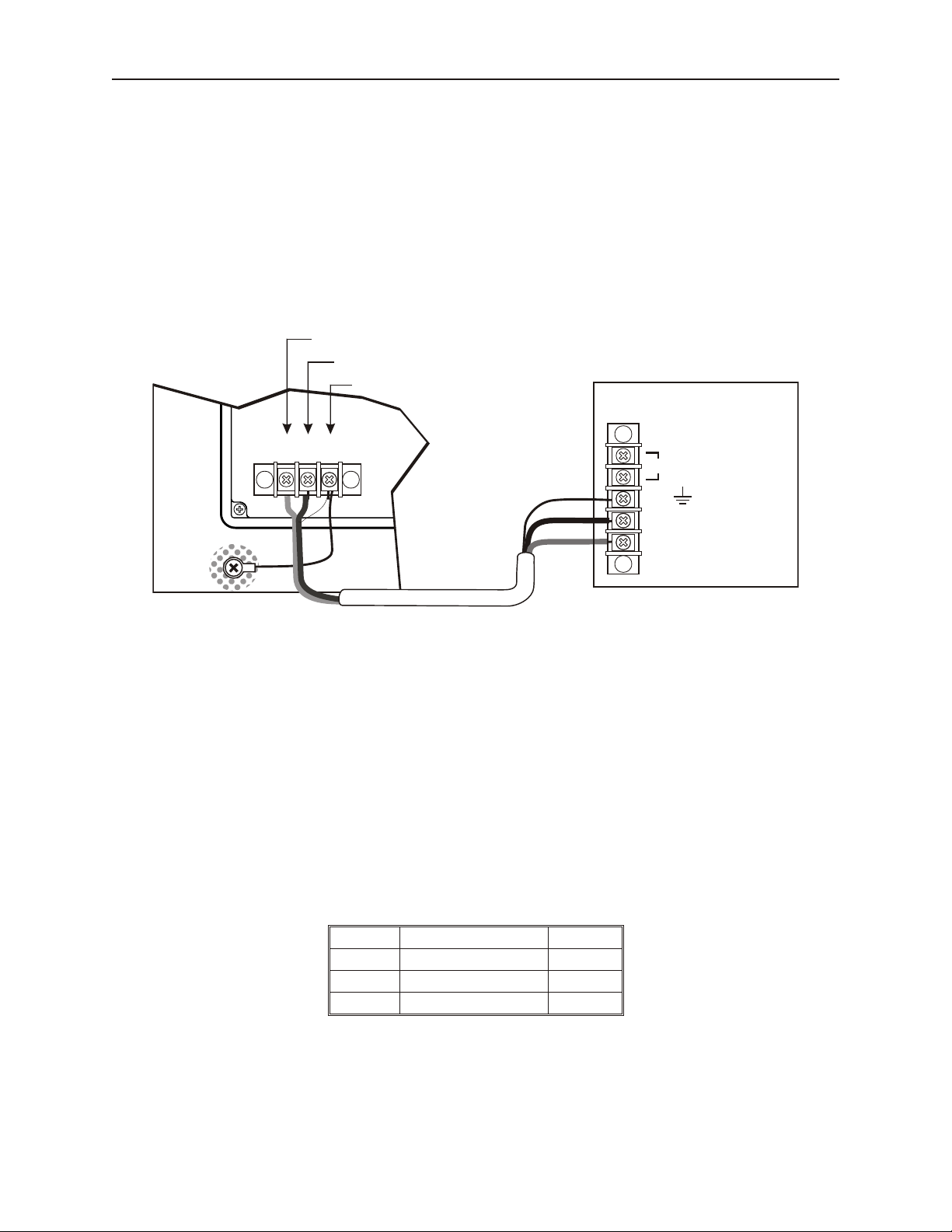

Frame ground (marked FG)

Stud or screw

Area on panel free of paint

Control panel

(connected to earth ground)

Con trol Panel Grounding

The control panel should be connected to a good, high-integrity earth ground both for safety considerations and

shielding purposes. Maple Systems cannot overemphasize the importance of good grounding. If you fail to use

good grounding procedures during installation, sporadic malfunction of the OIT may occur:

· Connect the OIT’s chassis ground terminal to a reliable earth ground with a low-resistance path.

· Route all earth ground wires that lead from the OIT, the PLC, the power supply, and the line filter to a

central earth ground point such as a barrier strip. This will ensure that no ground current from one device

influences the operation of the other devices.

· Connect the OIT chassis ground terminal to the control panel door using a heavy-gauge short braided cable

or ground wire to minimize resistance.

· Connect the power cable’s shield wire to the OIT’s chassis ground terminal.

· Connect the control panel to earth ground using a copper grounding rod close to the OIT and control panel.

Hinged doors on control panels do not provide a long-term electrical connection to the rest of the enclosure.

Corrosion develops over time and prevents good electrical contract. For this reason, a separate wire braid should be

installed from the hinged control panel to the rest of the enclosure.

For a more in-depth overview of ground wiring techniques, refer to technical note #1027, “OIT Ground Wiring and

Electrical Noise Reduction,” which you can find on our web site.

Con nect OIT Chas sis Ground to Con trol Panel

To reduce the possibility of electrical interference, con nect the chassis ground terminal of the OIT to a clean earth

ground. If the control panel is metal, make sure it is properly grounded. Then connect a short heavy-gauge wire

(#18 AWG) from the chassis ground terminal of the OIT to a mounting bolt on the control panel door. The

mounting bolt must have good electrical contact to the control panel; scrape away any paint that may be covering

the panel to provide a good connection.

If the control panel is made of a non-conductive material, it is essential that you connect the chassis ground terminal

of the OIT to a clean earth ground point located close to the panel.

Typ i cal Chas sis Con nec tion

1010-1007W, Rev 06

Page 15

10 Sil ver Se ries In stal la tion & Op er a tion Man ual

Power Sup ply Se lec tion

The power supply used to power the OIT should provide an output of +24 VDC 5% measured at the OIT power

terminal block. A 24VDC regulated power supply dedicated to the OIT is required. Consult the datasheet of your

particular OIT for current requirements.

The power cable for the OIT should be 18AWG, 2-conductor wire with a shield drain wire and protective shield

(foil or braid). The shield drain wire must be connected to earth ground at both ends of the cable. Please refer to the

“Connect the OIT to Power” section for more information.

A power line filter installed at the AC input to the OIT power supply is highly recommended as a safeguard against

conducted RF noise, which is often present on factory power lines. The wires connecting the output of the power

line filter to the power supply should be kept as short as possible to minimize any additional noise pickup. The case

of the power line filter should be connected to a quiet earth ground. The power line filter should have a current

rating of at least 3 Amps with common mode and differential mode attenuation.

Do not use the power supply used to provide power to the OIT to power switching relays, solenoids, or other active

devices.

Power Line Fil ter Connection

Ca ble Routing and Noise Im mu nity

Follow these guidelines when routing cable to the OIT:

· Always route the OIT communication cable and the power cable away from any AC voltage or rapidly

switching DC control lines.

· Never bundle the OIT cables together with 120VAC power wires or with relay wiring.

· Try to keep at least 8 inches (20 cm) of separation between the OIT cables and other power wiring. If

voltages greater than 120VAC are used in the system, greater separation is required.

· If the OIT cables must come near AC wiring, make sure they cross at 90 degrees.

· Run AC power wires in a separate grounded conduit to reduce electrical noise interference.

· Keep the cable lengths for the OIT as short as possible. Do not coil excess cable and place it next to AC

powered equipment.

· Cover any equipment used in the enclosure that operates at high frequency or high current levels with a

grounded metal shield.

In stal la tion

It is necessary to follow all installation procedures described in this chapter for electrical noise immunity and CE

compliance.

Your Maple Systems OIT is designed to connect easily to your PLC. External rear connectors provide quick

connections for power, communications and programming wiring.

1010-1007W, Rev 06

Page 16

In stal la tion of OITs 11

OIT

(rear side)

24Vdc

power supply

Control

panel

Shield wire (bare)

Black wire (-)

Red wire (+)

24V

120Vac

Black

Shield drain

Red

FG

DC Output -V (Gnd)

DC Output +V (+24V)

(+)

GND

(-)

FG

There are two connectors for serial communications on the rear of the OIT. Both of these are D-subminiature 9-pin

connectors.

Use the supplied separate 3-position terminal block to provide power to the OIT.

Con nect the OIT to Power

The power cable for the OIT should be 18AWG, 2-conductor wire with a shield drain wire and protective shield

foil. You may buy cable P/N 6030-0009 by the foot from Maple Systems to make these.

Always run the DC ground wire directly back to the signal return of the power supply. Do not use the chassis

ground wire as your signal return.

4To connect the OIT to power:

1. Connect the power cable to the OIT

a. Strip the power cable shield to expose 2” of the black and red wires.

b. Strip about ¼” of insulation from the black and red wires.

c. Thread the black and red wires through the ferrite core. The shield wire must be outside.

d. Connect the red wire to the DC positive (+) input of the OIT power terminal.

e. Connect the black wire to the DC negative (-) input of the OIT power terminal.

f. Connect the power cable shield wire to the OIT power terminal’s chassis ground input.

2. Route the power cable to the OIT power supply. The power cable should not be any longer

than necessary.

3. Install the power supply wires as follows (with colors shown for Maple Systems cable P/N

6030-0009):

OIT Power Inputs

Color Power Supply OIT

Red +Output/+24 Vdc +24V

Black -Output/+24 Vdc return GND

Shield Case ground FG

1010-1007W, Rev 06

Page 17

12 Sil ver Se ries In stal la tion & Op er a tion Man ual

The power connector on the Silver Series is a terminal block with wire clamps. Lugs

are not required.

Typ i cal Power Wir ing

Panel Prep a ra tion

A metal panel or mounting surface with a minimum thickness of 15 gauge (0.059 inch/3.3mm) if cold-rolled steel or

hardened steel, or 10 gauge (0.101 inch/2.6mm) if aluminum alloy (6061-T6 preferred) is required. Thinner panels

or surfaces may bow between the mounting clamps and not form a seal with the gasket.

The area of the panel or mounting surface where the gasket comes into contact must be flat and free of scratches,

pits, and other features that prevent the gasket from sealing properly. If the panel or mounting surface is not

uniform, thick, flat, stiff, or smooth enough, then a sealant such as silicone may be required.

WARNING: The OIT requires a stiff, flat, smooth mounting surface free of blemishes

to seal properly to NEMA 4.

Clean and deburr the panel cutout before the OIT is installed.

1010-1007W, Rev 06

Page 18

In stal la tion of OITs 13

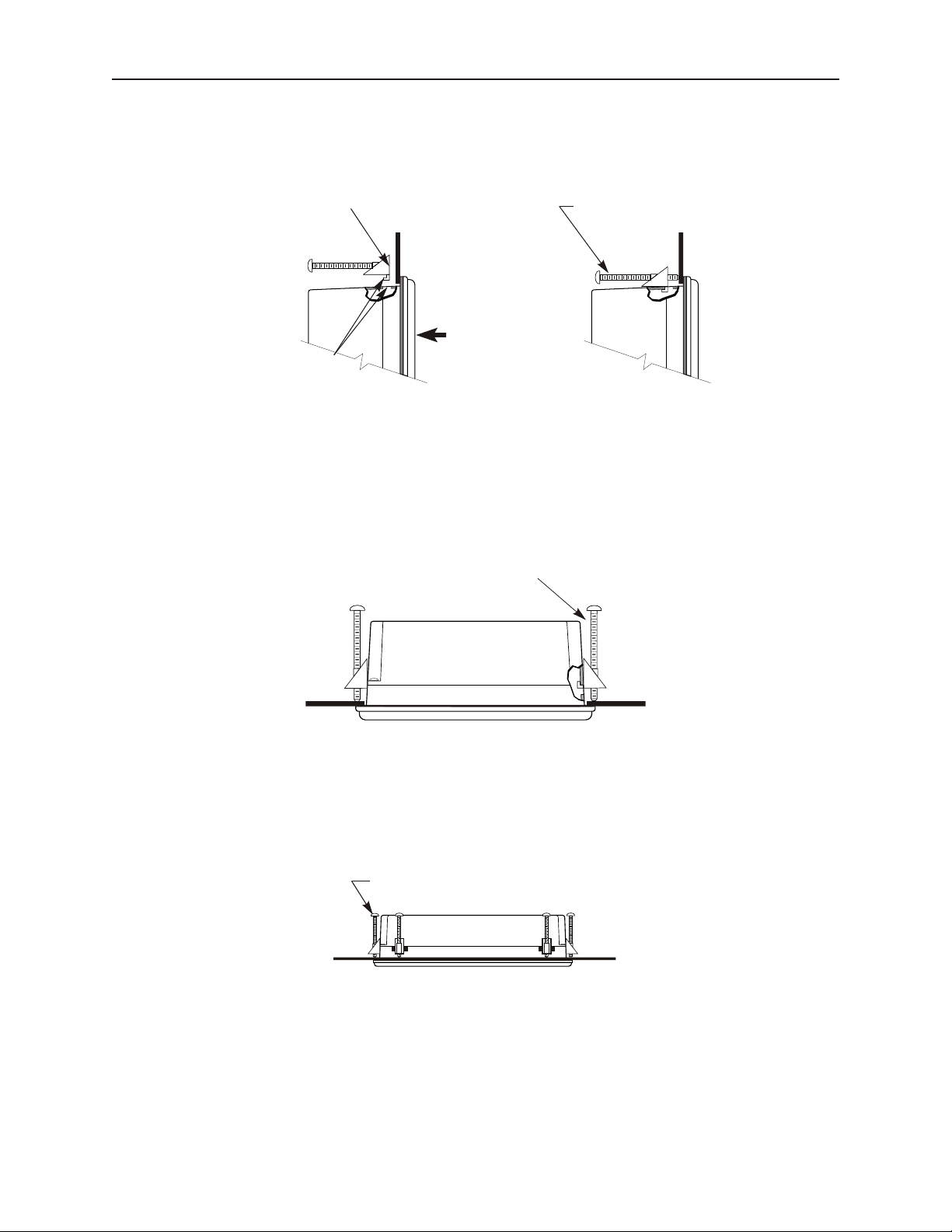

Position 4 screw clamps

(2 each side)

Panel

Position screw clamps 6 places in slots provided:

2 screw clamps each side and one top and bottom

Panel

Side View

Screw clamp locking

tabs go through the

slots

Tighten all screw clamps until

they are uniformly snug

Ends of screws must not

protrude from the clamp

Screw Clamp Placement Clamps Tightened

Hold the OIT against

the panel until all screw

clamps are in position

PanelPanel

Mount the OIT to the Panel

In stall ing Screws on the OIT

STEPS:

1. Prepare the screw clamps for the OIT by positioning the metal brackets at the midpoints of the screws.

Position the screws so that the ends don’t protrude from the plastic portions.

1010-1007W, Rev 06

Page 19

14 Sil ver Se ries In stal la tion & Op er a tion Man ual

2. Set the OIT in the panel cutout and hold it in place until all clamps are in position.

3. Tighten the screw clamps until all are uniformly snug.

CAUTION: Do not over-tighten the screws beyond snugness, or you may damage the housing, or cause the

touchscreen to malfunction.

REINSTALLATION: Because the gasket will take a “set” to the panel, be sure to reinstall the OIT to the same

panel cutout when a NEMA 4 seal is required. For best results, also replace the gasket itself.

1010-1007W, Rev 06

Page 20

15 Sil ver Se ries In stal la tion & Op er a tion Man ual

Con fig u ra tion Wir ing

The OIT must be configured for a particular protocol before use. The EZware software is used for configuring the

OIT. For detailed instructions on installing and using the software, please refer to the software documentation

section of this manual.

Con nect the OIT to the PC for Con fig u ra tion

To configure the OIT using Maple System’s configuration software, you will need either an Ethernet crossover

cable, Maple P/N 7431-0104 or a USB download cable, Maple P/N 7431-0115 depending upon the OIT model used.

If using a switch or router between the PC and the OIT, use a straight-through or crossover cable as required by the

switch or router.

If an Ethernet port is not available on the PC, you may be able to install a USB

Ethernet adapter. You can also transfer the project to the OIT with a Compact Flash or

USB memory device. Refer to Chapter 2, OIT Local Setup.

1010-1007W, Rev 06

Page 21

16 Sil ver Se ries In stal la tion & Op er a tion Man ual

Please Use This Page For Your Notes:

1010-1007W, Rev 06

Page 22

OIT Lo cal Setup 17

Chapter 2 - OIT Local Setup

Factory Configuration

Each OIT arrives from the factory with a demo project file that illustrates some of the most popular features of the

OIT. Please follow the directions enclosed in Chapter 4, Creating Your First Project, to configure your OIT for the

PLC that you are using.

The OIT also has a black reset push button and a four position DIP switch located through an access hole on the

back of the enclosure. The reset switch can be used to r einitialize the OIT if the OIT malfunctions. Only Dip

switch 1 has functionality. Dip switch 1 puts the OIT into Touch Calibration mode. For normal operation, all of

the DIP switches should be set to the OFF position.

This chapter describes how to use the Silver Series’ local setup options. The local setup allows touchscreen

calibration, transferring projects to and from the OIT, configuring the OIT’s IP settings, passwords, time and date,

screen contrast, as well as managing the storage of recipe and history files. Additionally, memory and other system

information can be viewed.

Calibrating the Touchscreen

The touchscreen of the OIT is fully calibrated before it leaves the factory so you shouldn’t need to adjust it.

However, with time the touchscreen may need to be recalibrated.

4To calibrate the touchscreen:

1. Turn Dip Switch 1 ON.

2. Cycle power to the OIT.

3. After the OIT displays a crosshair cursor, you are prompted to touch the cursor for:

a. Top left position

b. Top right position

c. Bottom right position

d. Bottom left position

e. Center position.

4. The OIT will then resume initializing.

Getting into Local Setup

Accessing the local setup menus requires a USB-mouse be connected to the OIT. Using the mouse, point to the

lower right-hand corner of the OIT. The open bar icon will appear.

Click on the icon to call up the setup toolbar: (note this tool bar is on HMI screen)

System settings

icon

System info icon

Small keyboard

icon

Virtual keyboard

icon

Open/close bar

icon

Large keyboard

icon

Please Note: the above tool bar is located on the HMI.

1010-1007W, Rev 06

Page 23

18 Sil ver Se ries In stal la tion & Op er a tion Man ual

Changing the System Settings

4 To change the system settings on the OIT:

1. Open the Setup Toolbar as described above, and click the System Settings icon.

2. A dialog will be displayed requesting the Local password. The default password is 111111.

You may have to move windows around a bit to gain access to the virtual keyboard.

You may also have to click inside the password field again.

3. Once the correct password has been entered, the System Settings dialog is displayed. For all

tabs, the Cancel, Apply, and OK buttons are available.

Cancel Close the System Settings dialog without saving any changes.

Apply Save the current settings without closing the System Settings dialog.

OK Save the current settings and close the System Settings dialog.

4. Click on the Network tab to configure network settings. The Network dialog is displayed.

5. The Network tab allows configuration of the IP settings. The default setting is Auto Get IP

Address. Use this setting if the OIT will provide an IP address by a DHCP server. If

connected to a DHCP server, this dialog will display the IP settings obtained by the OIT. The

IP fields are disabled, and are not editable.

6. If using a static IP address, use the IP Address Get From Below option. The IP fields are

enabled. Enter the appropriate settings for your network.

1010-1007W, Rev 06

Page 24

OIT Lo cal Setup 19

7. Click the Time/Date tab to configure time/date settings. The time/date dialog is displayed.

8. Configure appropriate time and date settings.

9. Click on the Security tab to display the security settings dialog. Here, you can select your

system passwords.

1010-1007W, Rev 06

Page 25

20 Sil ver Se ries In stal la tion & Op er a tion Man ual

10. Configure your password settings.

Local Password The password required to enter local setup.

Upload Password The password required to upload data from the OIT to a PC or memory module.

Download Password The password required to download data to the OIT from a PC or memory module.

Upload (History)

Password

The password required to upload history from the OIT to a PC or memory module.

11. The new password must be entered, and then entered again to confirm. As the password is

entered into the confirm field, an indicator will show if the two passwords match.

12. Click on the History tab to display the History dialog. This is where data stored in the OIT

can be cleared.

1010-1007W, Rev 06

Page 26

OIT Lo cal Setup 21

This will not clear data stored on a Compact Flash or USB device.

Clear Recipe The OIT’s stored recipe data will be cleared when the Clear button is clicked.

Clear Eventlog The OIT’s stored event log data will be cleared when the Clear button is clicked.

Clear Datalog The OIT’s stored data log data will be cleared when the Clear button is clicked.

13. Click on the Backlight tab to disp lay the Backlight dialog. The Backlight tab adjusts the

brightness of the OIT’s backlight. Use the mouse or touchscreen to roll the wheel. Rolling to

the left decreases the brightness, rolling to the right increases the brightness.

System tags Backlight Up, Backlight Down, and Backlight Index can be used to adjust

the brightness at runtime.

14. Click on the CF Card tab to display the CF card dialog. The CF Card tab displays

1010-1007W, Rev 06

Page 27

22 Sil ver Se ries In stal la tion & Op er a tion Man ual

information about the Compact Flash module. If no CF card is present, the dialog will show

None. Otherwise, volume data about the CF card is displayed.

The Eject button will cause the OIT to ignore the CF device. It will not actually eject the card

from the OIT. If the Eject button is pressed, the CF card must be removed and re-inserted

before the OIT will recognize. Note that USB devices will not be displayed.

Viewing System Information

4 To view system information:

1. Open the Setup Toolbar as described above, and click the System Information icon. A dialog

will be displayed with two tabs.

2. Click on the Network tab to display the current IP settings.

1010-1007W, Rev 06

Page 28

OIT Lo cal Setup 23

3. Click on the Version tab to display the current firmware information.

Transferring Projects and Data from USB/CompactFlash

When a USB or Compact Flash device is inserted into the Silver Series OIT, a dialog is displayed. The same dialog

is displayed for transferring projects or data.

Data is placed on the USB or CF device by EasyBuilder or Project Manager.

Download Project Transfer data from the USB/CF to the OIT

Upload Project Transfer data from the OIT to the USB/CF

Restart Project and exit Close the dialog and restart the OIT

Cancel Close the dialog without transferring

Restart after download/upload When checked, the OIT will restart after the transfer

Time Remaining

The dialog will automatically close after 10 seconds if no selection is

made; shows the time remaining

1010-1007W, Rev 06

Page 29

24 Sil ver Se ries In stal la tion & Op er a tion Man ual

When Download is selected, a dialog will appear requesting the Download password and what data to download.

Password Enter the Download password.

Download Project Files When checked, the OIT will check the specified folder for project data, and transfer it if it exists.

Download History Files

When checked, the OIT will check the specified folder for history data, and transfer it if it exists.

History data includes Recipe , Event Log, and Data Log data.

1010-1007W, Rev 06

Page 30

Con nect the OIT to the PLC or Controller 25

Chapter 3 - Con nect the OIT to the PLC or Controller

The Silver Series family of OITs can connect to one, two or more PLC/controllers. This is accomplished via two

9-pin D-sub serial communications connectors (Port A and Port B) and one Ethernet port. Each PLC/Controller has

its own wiring requirements. Maple Systems offers OIT-to-PLC/Controller communication cables that connect

directly to software controlled COM1, which is available on either Port A or Port B for most PLC/Controllers that

are built to any length and tested for high reliability. The Silver Series family has three software controlled

communications ports located on two physical connectors, designated as Port A and Port B (see Figures 1 & 2,

below).

Fig ure 1 - Com Ports - Rear View

Fig ure 2 - Com Ports - Bot tom View

The three software controlled ports are COM1, COM2, and COM3. Each software controlled communications port

can only be selected for one communication type. Once a communication type is selected for one of these software

controlled ports, that port cannot be used for another communication type. Each of these communication ports has

between one and three communication types. COM1 can be RS232, RS485 4-Wire, or RS485 2-Wire. COM2 is

strictly RS232. COM3 is either RS232 or RS485 2-Wire. COM1 cables are readily available for purchase from

Maple Systems. COM2 and COM3 cables are custom-made according to wiring diagrams that can be found on

Maple Systems' web site. Connecting multiple PLCs and controllers may require a s plitter.

1010-1007W, Rev 06

Page 31

26 Sil ver Se ries In stal la tion & Op er a tion Man ual

COM Ports for the HMI5080/HMI5100/HMI5104/HMI5121/HMI5150

1010-1007W, Rev 06

Page 32

Con nect the OIT to the PLC or Con trol ler 27

COM Ports for the HMI5043/5056/5070

1010-1007W, Rev 06

Page 33

28 Sil ver Se ries In stal la tion & Op er a tion Man ual

5

TX/RX- 1

TX/RX+ 1

GND

1

2

9P

OIT

COM1

RS485

GND5

TX/RX- 1

1

TX/RX+ 12

9S

NOTES:

Shield wire must be terminated to connector metal shell.

1

1

1

WHT/BRN

WHT/GRN

BLU

9

6

COM3

RS485

GND5

TX/RX+ 3

9

TX/RX- 36

9S

1

GRN

BRN

BLU

TX/RX- 3

TX/RX+ 3

Standoff, Hex Extender,

F/F,4-40X0.236,ZP

COM1 RS485 Label

DE9S Connector

& Backshell

1.00”

COM3 RS485 Label

2.00”

DE9P Connector

& Backshell

4-40 x 1/2 Retainer

Screw, 2 places

P/N Label

Approx. 12.00”

Connecting to COM1 and COM3 on Port A

Maple Systems Silver Series family of OITs is capable of connecting to multiple PLC/controllers. If you choose to

take advantage of this feature, and one of your PLC/controllers uses either RS485-4 Wire or RS485-2 Wire

communication, one of four splitters P/N 7431-0111, 7431-0112, 7431-0113, or 7431-0114 will be needed.

Sce nario 1 – One RS232 PLC/Con trol ler, COM1 con fig ured for RS232

When using two RS485-2 Wire PLC/Controllers, with COM1 configured for RS485-2 Wire and COM3 configured

for RS485-2 Wire, splitter P/N 7431-0111 is needed.

1010-1007W, Rev 06

Page 34

Con nect the OIT to the PLC or Con trol ler 29

Standoff, Hex Extender,

F/F,4-40X0.236,ZP

COM1 RS485-4W Label

DE9S Connector

& Backshell

1.00”

COM3 RS485 Label

2.00”

DE9P Connector

& Backshell

4-40 x 1/2 Retainer

Screw, 2 places

P/N Label

Approx. 12.00”

3

RX- 1

RX+ 1

GND

1

2

9P

OIT

COM1

RS485-4W

TX- 13

RX- 1

1

RX+ 1

2

9S

NOTES:

Shield wire must be terminated to connector metal shell.

1

1

1

WHT/BRN

BRN

WHT/GRN

5

4

COM3

RS485

GND5

TX/RX- 3

6

TX/RX+ 39

9S

1

WHT/ORN

ORN

BLU

TX- 1

TX+ 1

9

6

TX/RX- 3

TX/RX+ 3

GRN

BLU

GND

TX+ 1

5

4

Sce nario 2

When using one RS485-4 Wire and one RS485-2 Wire PLC/Controller, with COM1 configured for RS485-4 Wire

and COM3 configured for RS485-2 Wire, splitter P/N 7431-0112 is needed.

1010-1007W, Rev 06

Page 35

30 Sil ver Se ries In stal la tion & Op er a tion Man ual

3

RX- 1

RX+ 1

GND

1

2

9P

OIT

COM1

RS485-4W

TX- 13

RX- 1

1

RX+ 1

2

9S

NOTES:

Shield wire must be terminated to connector metal shell.

1

1

1

WHT/BRN

BRN

WHT/GRN

5

4

COM3

RS232

GND5

TXD 3

7

RXD 38

9S

1

WHT/ORN

ORN

BLU

TX- 1

TX+ 1

8

7

TXD 3

RXD 3

GRN

BLU

GND

TX+ 1

5

4

Standoff, Hex Extender,

F/F,4-40X0.236,ZP

COM1 RS485-4W Label

DE9S Connector

& Backshell

1.00”

COM3 RS232 Label

2.00”

DE9P Connector

& Backshell

4-40 x 1/2 Retainer

Screw, 2 places

P/N Label

Approx. 12.00”

Sce nario 3

When using one RS485-4 Wire and one RS232 PLC/Controller, with COM1 configured for RS485-4 Wire and

COM3 configured for RS232, splitter P/N 7431-0113 is needed.

1010-1007W, Rev 06

Page 36

Con nect the OIT to the PLC or Con trol ler 31

5

TX/RX- 1

TX/RX+ 1

GND

1

2

9P

OIT

COM1

RS485

GND5

TX/RX- 1

1

TX/RX+ 12

9S

NOTES:

Shield wire must be terminated to connector metal shell.

1

1

1

WHT/BRN

WHT/GRN

BLU

8

7

COM3

RS232

GND5

RXD 3

8

TXD 37

9S

1

GRN

BRN

BLU

TXD 3

RXD 3

Standoff, Hex Extender,

F/F,4-40X0.236,ZP

COM1 RS485 Label

DE9S Connector

& Backshell

1.00”

COM3 RS232 Label

2.00”

DE9P Connector

& Backshell

4-40 x 1/2 Retainer

Screw, 2 places

P/N Label

Approx. 12.00”

Sce nario 4

When using one RS485-2 Wire and one RS232 PLC/Controller, with COM1 configured for RS485-2 Wire and

COM3 configured for RS232, splitter P/N 7431-0114 is needed.

1010-1007W, Rev 06

Page 37

32 Sil ver Se ries In stal la tion & Op er a tion Man ual

5

RXD1

TXD1

GND

2

3

9S

OIT

COM1

RS232

GND5

RXD1

2

TXD13

9P

NOTES:

Shield wire must be terminated to connector metal shell.

1

1

1

WHT/BRN

WHT/GRN

BLU

6

4

COM2

RS232

GND5

RXD2

6

TXD24

9P

1

GRN

BRN

BLU

TXD2

RXD2

Standoff, Hex Extender,

F/F,4-40X0.236,ZP

COM1 RS232 Label

DE9P Connector

& Backshell

1.00”

COM2 RS232 Label

2.00”

DE9S Connector

& Backshell

4-40 x 1/2 Retainer

Screw, 2 places

P/N Label

Approx. 12.00”

Connecting to COM1 and COM2 on Port B

If both controllers use RS232 communication then only one splitter, P/N 7431-0110 is needed.

1010-1007W, Rev 06

Page 38

Con nect the OIT to the PLC or Con trol ler 33

RS-485

Silver Plus Series OIT

PLC

PLC

PLC

PLC

Connecting multiple PLC/controllers serially using daisy chaini ng

The RS485 4-wire and RS485 2-wire communications ports of the Silver Series family supports multi-drop

connections. A daisy-chain connection is made from the OIT to the first PLC/controller, and then from the first

PLC/controller to the second and so on (see below). The network may need biasing resistors – refer to the

PLC/controller documentation for more information.

Refer to the Help Section of EasyBuilder-5000, under the How do I Section… for more

information.

Connecting one or more PLC/controllers via Ethernet

The Silver Series OITs have a single RJ45 Ethernet connector, configured for 10BaseT and 100BaseT operation.

This port is for both communicating with a PC for configuration purposes, as well as for communicating with

supported Ethernet PLCs and protocols.

The connector is wired just like the RJ45 Ethernet connector on a PC. The Ethernet connection to a PLC/controller

will vary with each PLC/controller. Some will require a straight-through connection, while others require a

crossover connection. See Maple Systems' website for cable drawings of Ethernet cables.

4To connect a single PLC/controller to an OIT:

1. Attach one end of the Ethernet cable to the RJ45 connector on the OIT

2. Attach the other end to the RJ45 connector on the PLC/controller

A router or switch is required to connect multiple PLCs/controllers to a single OIT. In general, standard

straight-through type cables can be used when connecting to a PLC/controller through a router or switch. Some

routers and switches may be auto-sensing. In this case, either type of cable may be used.

1010-1007W, Rev 06

Page 39

34 Sil ver Se ries In stal la tion & Op er a tion Man ual

Please Use This Page For Your Notes

1010-1007W, Rev 06

Page 40

Cre ating Your First Project 35

Chapter 4 - Creating Your First Project

Often the best way to learn about new software is to jump right in. This chapter will step you through the process of

installing the EZware-5000 configuration software and then using the software to create a sample project that can be

downloaded to your OIT. We won’t go into much detail about how each feature works. The purpose of this

chapter is only to provide you with an overview of the process of creating a functional OIT that can communicate to

a PLC. For our sample project, we will configure the OIT using the local OIT Memory, but you may feel free to

select whichever protocol driver you intend to use.

By the end of this chapter, you should be able to:

• Install EZware-5000 configuration software.

• Create a sample project with two windows and several graphics objects.

• Save a project, compile a project and download the project to the OIT.

• Verify that the OIT is functioning properly.

Be fore You Be gin

Before you install EZware-5000, make sure your computer meets the following minimum system requirements:

• Pentium-based 1.7 GHz or higher processor

• 512 MB of RAM (more memory improves performance)

• 200 MB available hard disk space

• VGA or higher-resolution monitor set for 16 Bit color 1024 x 768 pixel mode

• Microsoft mouse or compatible pointing device

• One available Ethernet port

• Microsoft Windows XP, 2000 or Vista

Con nect ing OIT to Com puter

Before you start your first project, the OIT should be connected to the computer so that the project can be

downloaded after creating it. You should also connect the PLC that you are using to the OIT so that you can test the

operation of the OIT after you have finished creating this sample project.

4To connect your OIT to the computer

1. Connect a +24VDC power supply to the OIT.

2. Connect a crossover Ethernet cable between the OIT and PC.

3. Apply power to the OIT.

Starting EZware-5000

Before you can create a sample project, you must start the configuration software. The EZware-5000 software has

two main applications:

• EasyBuilder – used to create the project downloaded to the OIT.

• Project Manager - used to place the OIT into different operating modes.

4To start the EZware-5000

1. From the Windows Task Bar, click the Start button, point to Programs, and then click the

Maple Systems-EZware-5000-Project Manager.

2. On the Project Manager dialog box, click EasyBuilder5000.

3. The Welcome to EasyBuilder dialog box appears. Select the correct OIT model.

4. Click OK to display the System Parameters screen of EasyBuilder.

1010-1007W, Rev 06

Page 41

36 Sil ver Se ries In stal la tion & Op er a tion Man ual

The following illustration shows the various sections of EasyBuilder.

Manager toolbar

Part1toolbar

Work area

Part2 toolbar

Draw Toolbar

Cre at ing a Sam ple Pro ject

This section walks you through the creation of an EasyBuilder project named MTPrj1. Once downloaded to the

OIT, this basic configuration allows the OIT to connect to the PLC, display a startup screen, and display a screen

containing one PLC register monitor when a switch on the startup screen is pressed.

Although we strongly recommend that you perform the following steps to create this sample project, the project is

already included in your EasyBuilder software with the following filenames:

HMI5056.MTP-sample project for the HMI5056

HMI5070.MTP-sample project for the HMI5070

HMI5080.MTP-sample project for the HMI5080

HMI5104.MTP-sample project for the HMI5104

HMI5121.MTP-sample project for the HMI5121

HMI5150.MTP-sample project for the HMI5150

Set ting the Sys tem Pa ram e ters

Whenever you begin a new project, you should always set the system parameters before you create any windows.

System parameters determine the basic operating conditions of the OIT such as what type of PLC it is connecting to.

4To edit the System Parameters

1. Click the Edit menu on the main screen of EasyBuilder.

1010-1007W, Rev 06

Page 42

Cre ating Your First Project 37

2. At the bottom of the menu, click System Parameters. The System Parameters dialog box

appears.

3. The dialog box has six tabs: Device, Model, General, Security, Font and Extend Memory.

Select the Device tab.

4. Click New… The Printer Server Dialog appears.

1010-1007W, Rev 06

Page 43

38 Sil ver Se ries In stal la tion & Op er a tion Man ual

5. Select your controller from the drop down menu next to PLC Type: Click Settings... The

Com Port Settings dialog appears.

6. Set Com Port Settings that match your PLC. Reserved settings are specific to each type of

PLC. Refer to the Controller I nformation Sheet for that PLC for more details. Click OK

twice to return to System Parameter Settings dialog

1010-1007W, Rev 06

Page 44

Cre ating Your First Project 39

7. Now click on the General tab.

8. In the Option section, for the Startup Window no: drop-down, select 10. WINDOW_010

9. Click OK to return to the EasyBuilder main screen.

For more information, consult your PLC operations manual or Maple Systems

Controller Information Sheets available on our website at www.maple-systems.com .

Creating a Popup Window

We will first configure Window #11 as a popup window. We will be using a function key in the startup window to

call this popup window; however, this window must first exist before we can map the function key to it, which is

why we are creating the popup prior to creating the startup window.

Multiple popup windows can be displayed on a full screen window. The windows may overlap each other or be

moved anywhere onscreen. This section will show how to create a scale and a numeric register that displays the

current value of the scale. You will also create an increment and decrement key to change the value in the scale

meter.

1010-1007W, Rev 06

Page 45

40 Sil ver Se ries In stal la tion & Op er a tion Man ual

4To create Window#11

1. From the Window menu, click Open Window. The Open Window dialog box appears.

2. Click New… The Select Window Style dialog box appears.

1010-1007W, Rev 06

Page 46

Cre ating Your First Project 41

3. Click Base Window. The Window Setting dialog box appears:

4. Type WINDOW_011 in the Name: field and 11 in the Window no: field.

5. In the Size section, enter 210 for the width. Enter 150 for the height.

6. Click the pull down box from the Background Color box. The Color dialog box appears.

7. Click on the white color box, then click OK. The color box will reflect the color that you

have chosen.

8. In the Popup window section, enter 60 for the X position. Enter 60 for the Y position.

9. Click OK. The Open Window dialog will reappear.

10. In the Open Window dialog , highlight Window 11, then click on the Open button. Window

11 now appears on your work area, configured to the size indicated above.

1010-1007W, Rev 06

Page 47

42 Sil ver Se ries In stal la tion & Op er a tion Man ual

4To create a meter display on Window#11

1. From the Objects menu, click Meter Display. The New Meter Display Object dialog box

appears.

2. Type Meter Display in the Description box.

3. Click the Outline tab to configure the meter style.

1010-1007W, Rev 06

Page 48

Cre ating Your First Project 43

4. In the Start Degree, type 270

5. In the End Degree box, type 90.

6. Uncheck "Full Circle".

7. Check Enable in the tick marks section.

8. Select black as the tick marks color.

9. Select main scale 6, sub. scale 1, length 6 for tick marks.

10. Select pointer arm style and length.

11. Click on the Limits tab.

12. Set value 0, Span 100.

13. Enable range limits and select low, mid and high colors. Width = 3.

14. Click OK.

15. Click the work area to place the meter.

16. On the main screen of EasyBuilder, you will see a white square outline that is attached to your

cursor in the work area. This represents the meter display just created. Click to place the

meter display in Window #11.

17. Now, resize the meter so that it is a better fit on the popup window. Double click on the

meter display to re-display the attribute dialog.

18. Click the Profile tab to display the profile form.

19. Enter the following values:

X: 45

Y: 13

Width: 120

Width: 120

20. Click OK.

4To create a numeric register on Window#11

1. From the Objects menu, click Numeric/ASCII - Numeric Display. The New Numeric

Display dialog box appears.

2. Type Numeric Data in the Description box.

3. Click OK.

4. On the main screen of EasyBuilder, you will see a white rectangle outline that is attached to

your cursor in the work area. This represents the numeric register just created. Click to place

1010-1007W, Rev 06

Page 49

44 Sil ver Se ries In stal la tion & Op er a tion Man ual

the numeric register on Window #11 somewhere underneath the scale meter. A numeric

register box will appear.

4To create an increment key on Window#11

1. From the Objects menu, click Button-Set Word. The New Set Word Object dialog box

appears.

1010-1007W, Rev 06

2. Type Increment Button in the Description box.

3. Click on the pull down box of the Mode: box and select Press and hold increment (JOG++)

4. Enter 1 in the Inc. value box.

5. Enter 100 in the Upper limit box.

6. Click on the pull down box of JOG Delay and select 0.5 second.

Page 50

Cre ating Your First Project 45

7. Click the Shape tab.

1010-1007W, Rev 06

Page 51

46 Sil ver Se ries In stal la tion & Op er a tion Man ual

8. Check Use shape, then click Shape library. The Shape Library dialog box appears.

9. Click Select Lib… The Open dialog box appears.

10. Select arrow1.plb from the list of shape libraries. Then click Open.

11. Click arrow1 in the Shape library box.

12. Scroll through the selections to selection 3. Click the shape, then click OK. The shape will

appear in the Shape tab.

13. Click OK.

14. On the main screen of EasyBuilder, you will see a white square outline that is attached to your

cursor in the work area. This represents the increment key just created. Click to place the

increment key on Window #11.

15. Use the blue handles surrounding the key to drag the increment key to the desired size and

then place to the left of and below the numeric object.

4To create a decrement key on Window#11

1. We are going to create the decrement key by copying the increment key and then making

changes to the attributes.

2. Click the increment key to highlight it.

3. From the Edit menu, click Copy.

1010-1007W, Rev 06

Page 52

Cre ating Your First Project 47

4. From the Edit menu, click Paste. A copy of the increment key appears in the upper left

corner of the work area. Deselect the increment key by clicking on any blank space in the

work area.

5. Double-click on the second increment key. The Set Word Object’s Attribute dialog box

appears.

6. In the General tab section, change the Description to Decrement Button.

7. Click on the pull down box of the Mode Attribute: and select Press and hold decrement

(JOG—).

8. Enter 0 in the Attribute Bottom limit box.

9. Click the Shape tab.

10. Click Shape library. The Shape Library dialog box appears.

11. Scroll through the selections to selection 4. Click the shape, then click OK. The shape

should appear in the Shape tab.

12. Click OK.

1010-1007W, Rev 06

Page 53

48 Sil ver Se ries In stal la tion & Op er a tion Man ual

13. Drag the decrement button to the bottom right area of your window.

4To create a close window button

1. Finally, we must create a button that will close the popup window. From the Objects menu,

click Function Key. The New Function Key Object dialog box appears.

2. Type Close Window in the Description box.

3. Click the Close Window radio button.

4. Click the Shape tab to display the shape dialog.

5. Unclick the Use shape checkbox and click the Use picture checkbox. Click the Picture

library button. The Picture Library dialog box appears.

6. Click the Select Lib. Button on the bottom of this dialog box. Select the computer.flb

library, then click Open.

7. Under the Library: list box, you will now see computer. Click on computer to display this

library.

8. Scroll through the selections to selection 21. Click the picture , then click OK. The color box

will reflect what you have chosen.