Page 1

maplePrint

GUIDE

1

BUILD GUIDE

mapleMaker

ADDITIVE ENGINEERING

Page 2

SECTION

A

1.1 Introduction 2

1.2 Table of Contents 3

1.3 Required Tools 4

1.4 Reseller Information 5

1.5 Components 6

Page 3

Page 4

A

1.1

Introduction

Welcome, and Thank you!

Thank you for your interest in the mapleMaker Mini V2 3D Printer.

The mapleMaker Mini introduces you to the world of additive

manufacturing and 3D printing. With your own 3D printer, your

concepts and design ideas can be translated from computer

drawings to physical objects in short period of time.

The goal of this guide is to introduce you to the parts and pieces

that will be required before you can assemble your printer kit. Most

of these items can be sourced both locally and from any number of

online retailers.

The aim of this kit was to reduce costs and create an accessible,

hackable, upgradeable, and ultimately, user customizable

3D Printer. We believe that a 3D printer should evolve with it’s

users needs and knowledge, and become a platform for any

number of future upgrades and additions without the need for costly

re-works or additional components.

Ultimately though, we want to empower the next generation of

designers, developers, and engineers by giving them the platform

and tools to suite their needs for today, tomorrow, and well into

the future.

We are Open Source. Collaboration fuels Innovation.

Create, Innovate, and Share.

4

Page 5

Table of Contents

This guide is broken into several sections which encompasses the build process of the

maplePrint Mini 3D printer. The process begins with the basic frame assembly and nishes

with the nal wiring and installation.

While we try to maintain the most up to date diagrams and illustrations, there may be

slight dierences between the illustrations contained within this guide, and the printed

parts in your kit. If there are major changes or dierences between the instructions

contained within and the printed parts, you should have received an updated insert in

your kit containing the revised instructions.

A

1.2

Section A:

1.1 Introduction 2

1.2 Table of Contents 3

1.3 Required Tools 4

1.4 Reseller Information 5

1.5 Components 6

Section B:

2.1 Z Motor Assembly 16

2.2 Lower Frame Assembly 18

2.3 Upper Frame Assembly 24

2.4 Lower/Upper Frame Union 26

Section C:

3.1 Extruder Assembly 34

Section D:

4.1 X-Carriage Assembly 48

4.2 Y Carriage Assembly 62

4.3 Print Bed Assembly 76

4.4 Z Carriage Assembly 82

Section E:

5.1 GT2 Belt Installation 98

5.2 LCD Installation 102

5.3 RAMPS Installation 106

5.4 Upper Bed Installation 116

5 .5 Wiring & Final Configuration 118

Section F:

6.1 Appendix 136

5

Page 6

A

A

1.1

Required Tools

1.3

Before we begin the assembly process, it is vital that we have the proper tools to complete the build.

Thankfully though, there are only a few tools required for the build. These tools were either included

with your kit, or available at any local hardware or tool store.

You will need the following:

#2.5 Allen Key (for use with M3 screws)

#3 Allen Key (for use with M4 screws)

#4 Allen Key (for use with M5 screws)

Ceramic screw driver (for adjusting RAMPS drivers)

Spatula (to remove printed parts from the print bed)

Exacto Knife (for trimming and cleaning parts)

Needle nose or similar pliars

Solder iron and solder

Nylon wire ties or zip ties (for securing wiring looms)

3M Blue painters tape (for printing with PLA)

Hot glue gun (to secure endstops)

Additional information regarding this build guide:

We’ve attempted to keep this build guide simple and easy to understand. We’ve broken the

assembly into several sections, and each step into individual illustrations to simplify the build

process further. Each illustrated step in this guide is also accompanied by a list of parts and

hardware required to complete the step. The illustrations of fasteners in these lists are printed to

scale and may be used to size the hardware included in your kit. Simply place a fastener on top

of or next to the illustration to determine if its the correct one for the job!

6

Page 7

A

Reseller Information

Below is a list of resellers and manufacturers of the components used in the mapleMaker

Mini 3D Printer.

Some components may be sourced from your local home improvement retailers or

specialist hobby stores.

Electronics, motors & extruders

Folger Technologies, LLC: www.folgertech.com

Active Surplus: www.active123.com

EckerTech Inc: www.eckertech.com

Misumi www.us.misumi-ec.com/

Mixshop www.mixshop.com

Filastruder www.lastruder.com

A

1.4

1.1

SDP/SI CA www.sdp-si.com/

Skyhunt www.skyhunt.net

ROBOTDIGG www.robotdigg.com

Voxel Factory www.voxelfactory.com

Linear rods & movement

Folger Technologies, LLC: www.folgertech.com

ROBOTDIGG www.robotdigg.com

EckerTech Inc: www.eckertech.com

Mixshop www.mixshop.com

Fasteners

HD Supply Canada: www.brafasco.com (minimums may apply)

Fastenal www.fastenal.com (minimums may apply)

Misc. electronics

Digikey: www.digikey.ca

McMaster-Carr www.mcmaster.com (minimums may apply)

7

Page 8

A

Components

1.5

The following list comprises the components required to build your printer. For the purposes of this build,

we have used ROBOTDIGG (www.robotdigg.com) to source the majority of the components. ROBOTDIGG

oers almost every component required, minus fasteners and threaded rod. The hot end has been sourced

through e3D’s authorized distributor, Filastruder (www.lastruder.com)

NEMA 17 48oz Stepper Motor

Quantity: 3

URL: http://www.robotdigg.com/product/206/Nema17-48mm-Stepper-Motor

Unit Cost: $9.50

NEMA 17 34oz Stepper Motor

Quantity: 2

URL: http://www.robotdigg.com/product/28/NEMA14-34mm-0.8A-or-1.25A-stepper-motor

Unit Cost: $6.80

Flexible Coupling - 5mm to 5mm

Quantity: 2

URL: http://www.robotdigg.com/product/83/Flexible-Coupling-5mm-Shaft-to-5mm-Screw

Unit Cost: $1.80

20 Tooth GT2 Pulley

Quantity: 2

URL: http://www.robotdigg.com/product/166/2GT-20-Tooth-6.35mm-Bore-Pulley

Unit Cost: $1.85

Open Ended 6mm GT2 Belt (2 meters

Quantity: 1

URL: http://www.robotdigg.com/product/10/Open-Ended-6mm-Width-GT2-Belt

Unit Cost: $1.80

LMS8UU (Short) 8mm Linear Bearing

Quantity: 12

URL: http://www.robotdigg.com/product/13/LM8UU-Linear-Bearing

Unit Cost: $0.60

8

Page 9

623ZZ Ball Bearing

Quantity: 4

URL: http://www.robotdigg.com/product/62/623ZZ-Ball-Bearing

Unit Cost: $3.60

Poloululu 4988 Stepper Drivers

Quantity: 4

URL: http://www.robotdigg.com/product/120/A4988-stepper-driver

Unit Cost: $3.80

Endstop

Quantity: 3

URL: http://www.robotdigg.com/product/141/Endstop,-Snap-Action-Limit-Switch-SS-5GL

Unit Cost: $0.60

RAMPS 1.4 Controller

Quantity: 1

URL: http://www.robotdigg.com/product/121/Ramps-1.4-Board

Unit Cost: $12.80

Arduino Mega 2560

Quantity: 1

URL: http://www.robotdigg.com/product/123/Arduino-Mega-2560-R3

Unit Cost: $15.80

RAMPS LCD Display

Quantity: 1

URL: http://www.robotdigg.com/product/122/RAMPS-LCD2004-with-SD-Socket

Unit Cost: $12.80

30mm Cooling Fan

Quantity: 4

URL: http://www.robotdigg.com/product/197/12V-3CMHotend-Cooling-Fan

Unit Cost: $1.50

9

Page 10

A

Components

1.5

12V 5A Power Supply

Quantity: 1

URL: http://www.robotdigg.com/product/350/12V-5AAC/DC-Adapter-Power-Supply

Unit Cost: $5.00

NEMA 17 34oz Stepper Motor

Quantity: 2

URL: http://www.robotdigg.com/product/28/NEMA14-34mm-0.8A-or-1.25A-stepper-motor

Unit Cost: $6.80

Thermistor Cable (1m)

Quantity: 1

URL: http://www.robotdigg.com/product/188/2pin-1MLong-Thermistor-Cables-w/-Dupont-Connector

Unit Cost: $0.40

Endstop Cables (1m)

Quantity: 3

URL: http://www.robotdigg.com/product/189/3pin-1MLong-Endstop-Cables-w/-Dupont-Connector

Unit Cost: $0.60

e3D Lite6 All Metal Hot End

Quantity: 1

URL: http://www.lastruder.com/products/lite6

Unit Cost: $35.00

MK8 Extruder Drive Gear

Quantity: 1

URL: http://www.robotdigg.com/product/242/MK8-Filament-Drive-Gear

Unit Cost: $3.00

Compression Spring (for Extruder & bed)

Quantity: 5

URL: http://www.robotdigg.com/product/71/Compression-Spring-for-Heatbed-and-Extruder

Unit Cost: $2.00

10

Page 11

762mm length Linear Rods (Pack of 6)

Quantity: 1

URL: http://www.robotdigg.com/product/113/Rostock-Mini-492mm-Long-8mm-Diameter-Smooth-Rod-Pack

Unit Cost: $24.00

Allen Key Set

Quantity: 1

URL: http://www.robotdigg.com/product/128/1.5,-2,-2.5,-3,-4-size-allen-key-with-ball-head-in-pack

Unit Cost: $2.00

Nylon Cable Ties (100 pack)

Quantity: 1

URL: http://www.www.robotdigg.com/product/127/Nylon-Cable-Ties-2.5*100mm-100pcs-n-3.6*200mm-

100pcs-Pack

Unit Cost: $1.80

Ceramic Screwdriver

Quantity: 1

URL: http://www.robotdigg.com/product/181/Ceramicscrewdriver-for-A4988-stepper-driver

Unit Cost: $1.20

4GB SD Card

Quantity: 1

URL: http://www.robotdigg.com/product/345/4GB-SDCard-for-3D-Printing

Unit Cost: $4.50

Fasteners & Threaded Rod:

You will also require the following fasteners and threaded rod to complete the build.

These items can be purchased from your local hardware retailer or online.

M3X10mm Socket Cap Screw x135

M3X20mm Socket Cap Screw x8

M3X16mm Socket Cap Screw x8

M4X10mm Socket Cap Screw x1

M4X16mm Socket Cap Screw x2

M5X12mm Socket Cap Screw x60

M4X40mm Socket Cap Screw x1

4mm - 0.7 Stainless Steel Threaded rod

4mm - 0.7 Flat nut x3

11

Page 12

A

1.5

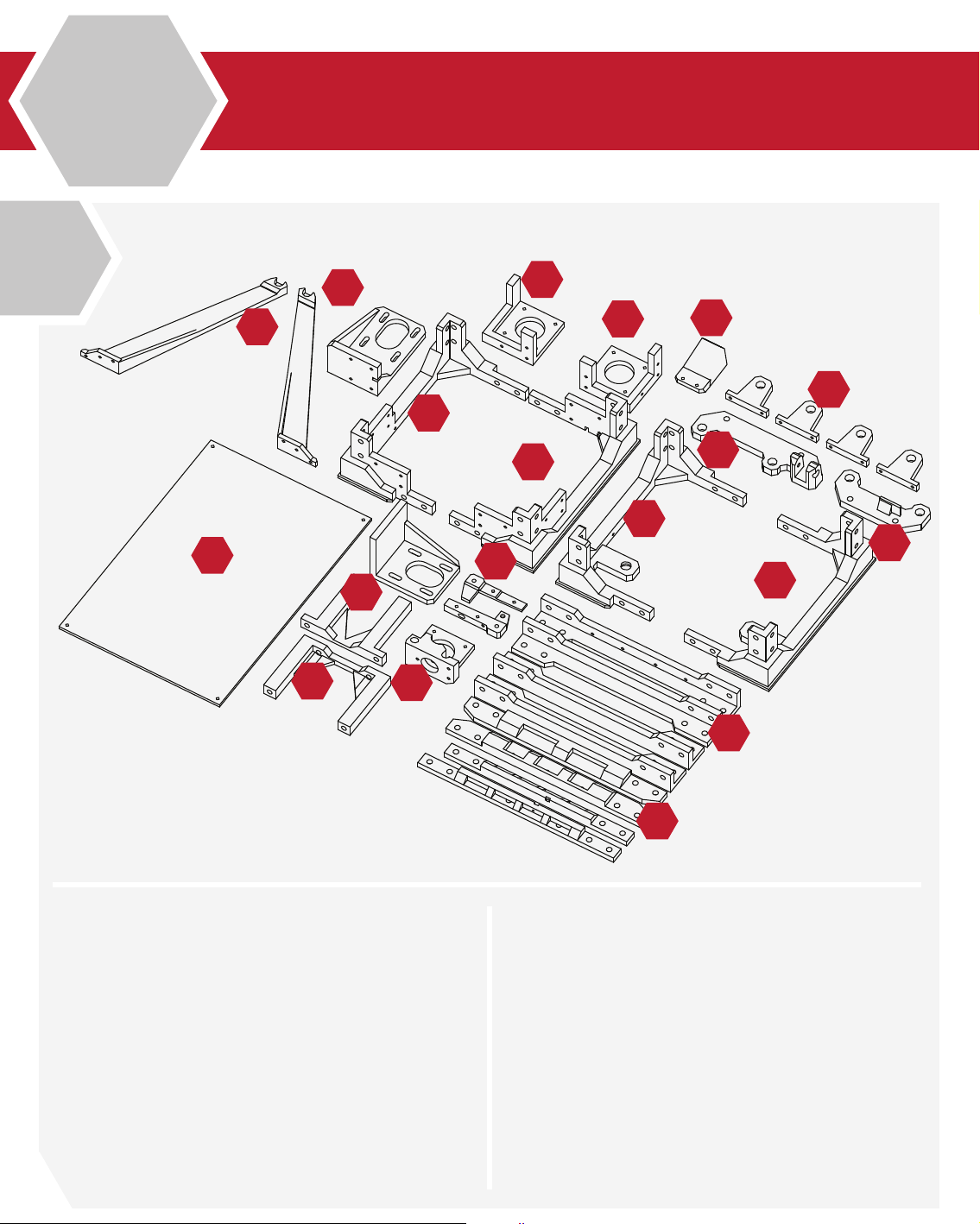

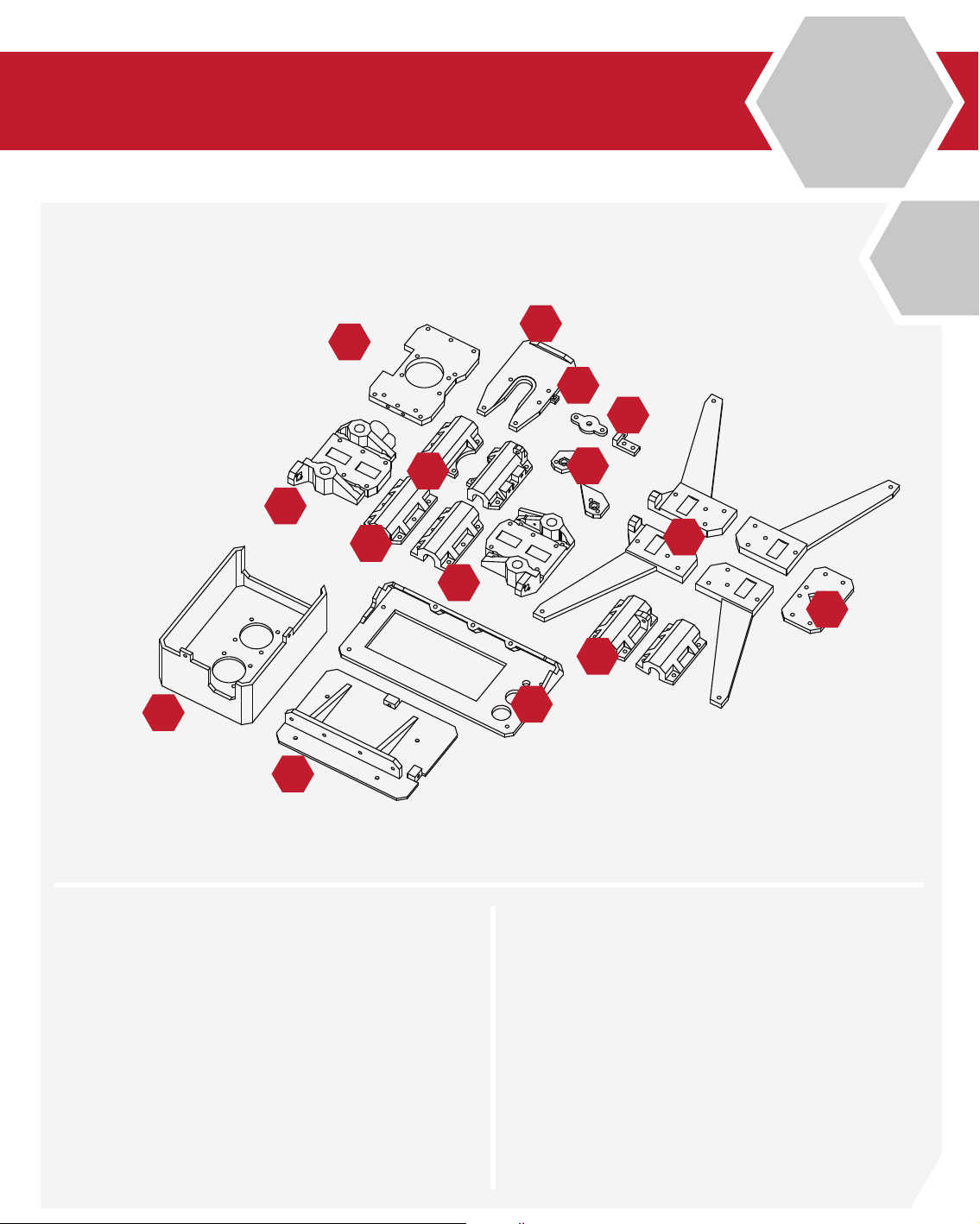

Printed Components

1

14

13

10

12

11

17

5

6

1

2

3

18

19

7

8

9

4

16

12

1. Left Lower Frame

2. Right Lower Frame

3. Right Upper Frame

4. Left Upper Frame

5. Left Z Motor Mount

6. Right Z Motor Mount

7. Z Axis Linear rod Mounts

8. Y Axis Carrier (Front)

9. Y Axis Carrier (Rear)

10. Y Axis Mount (Front)

15

11. Y Axis Mount (Rear)

12. Y Axis Motor Mount

13. Spool Holder Mounts (2)

14. Upper Bed (Printed)

15. Lower/Upper Frame rails (4)

16. Frame Upright Rails (4)

17. Extruder Mount

18. Extruder Idler Arm

19. Print Cooler Duct

Page 13

20

A

1.5

2

21

22

23

33

20. Extruder Base Mount

21. Hot-End Mount

25

32

28

27

24

30

26

31

29

34

28. Z Axis Bearing Carriers (2)

29. Y Axis Bearing Carriers (2)

22. X Axis Idler Cover

23. Z Axis Adjustment Mount

24. Z Axis Nut Covers

25. X Axis Assembly (Left)

26. X Axis Assembly (Right)

27. X (Extruder) Bearing Carriers (2)

30. Lower Bed Frame (4)

31. Lower Bed Union

32. Electronics Backplate

33. Electronics Enclosure

34. LCD Frame Assembly

13

Page 14

SECTION

2.1 Z Motor Assembly 16

2.2 Lower Frame Assembly 18

2.3 Upper Frame Assembly 24

B

2.4 Lower/Upper Frame Union 26

Page 15

Page 16

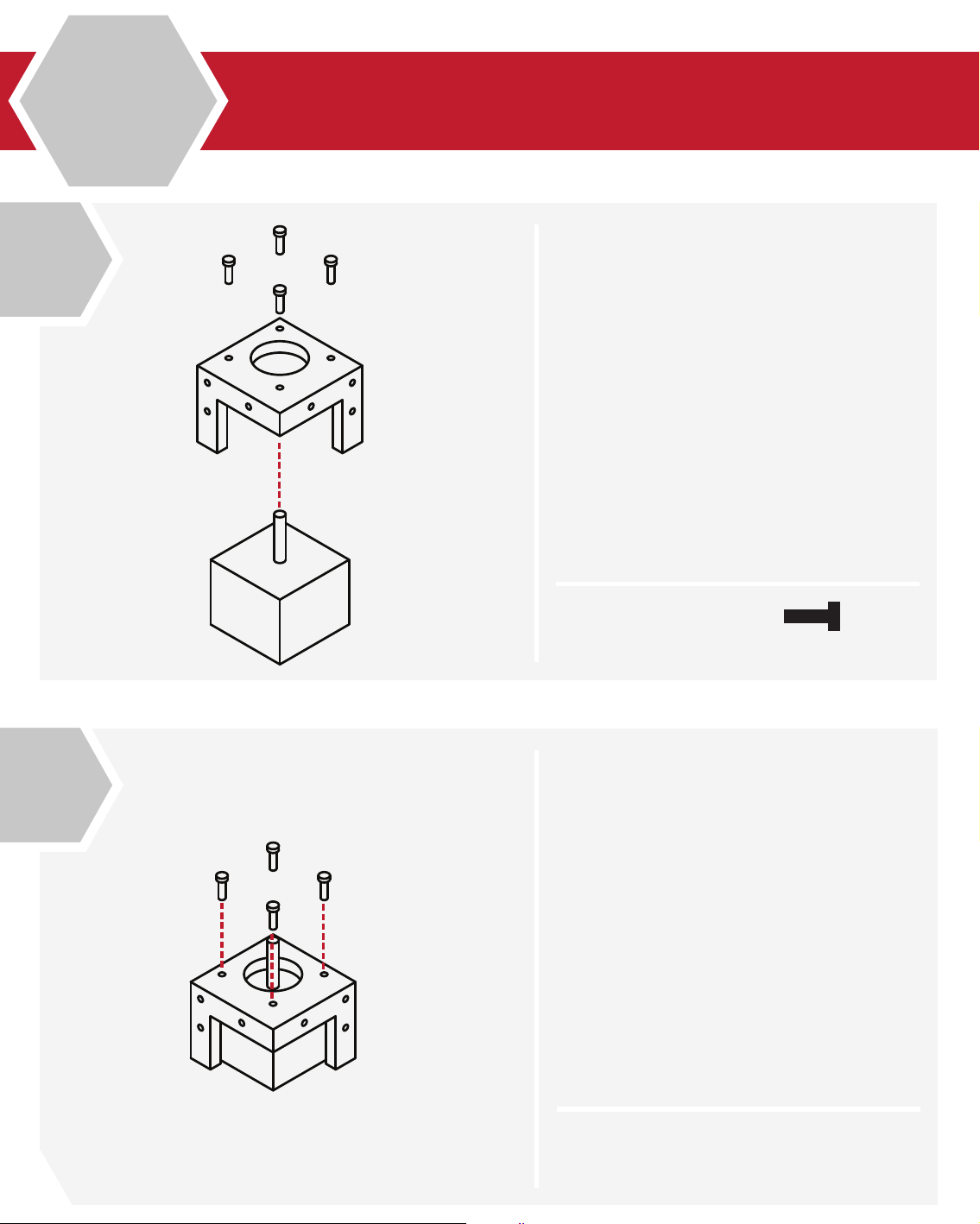

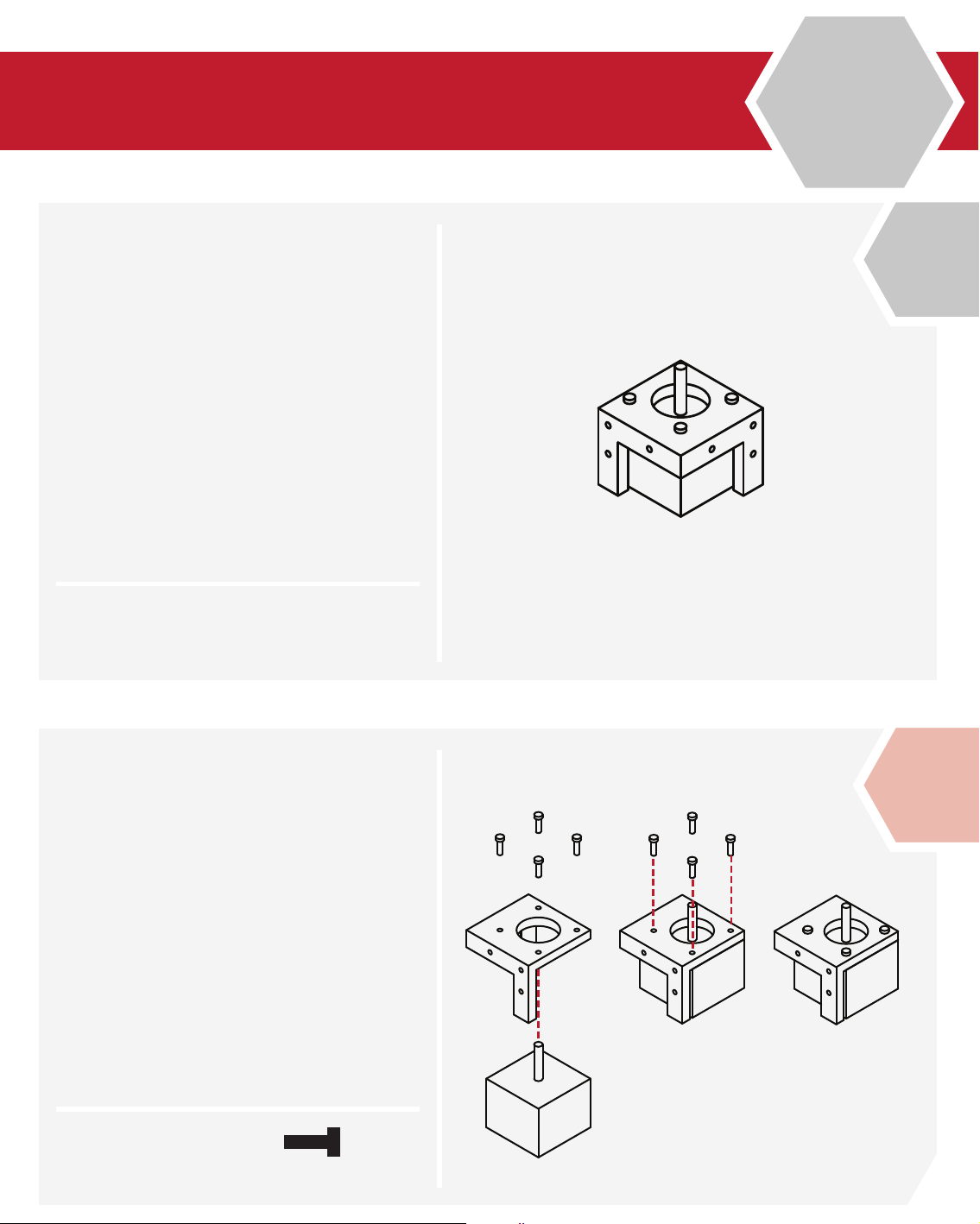

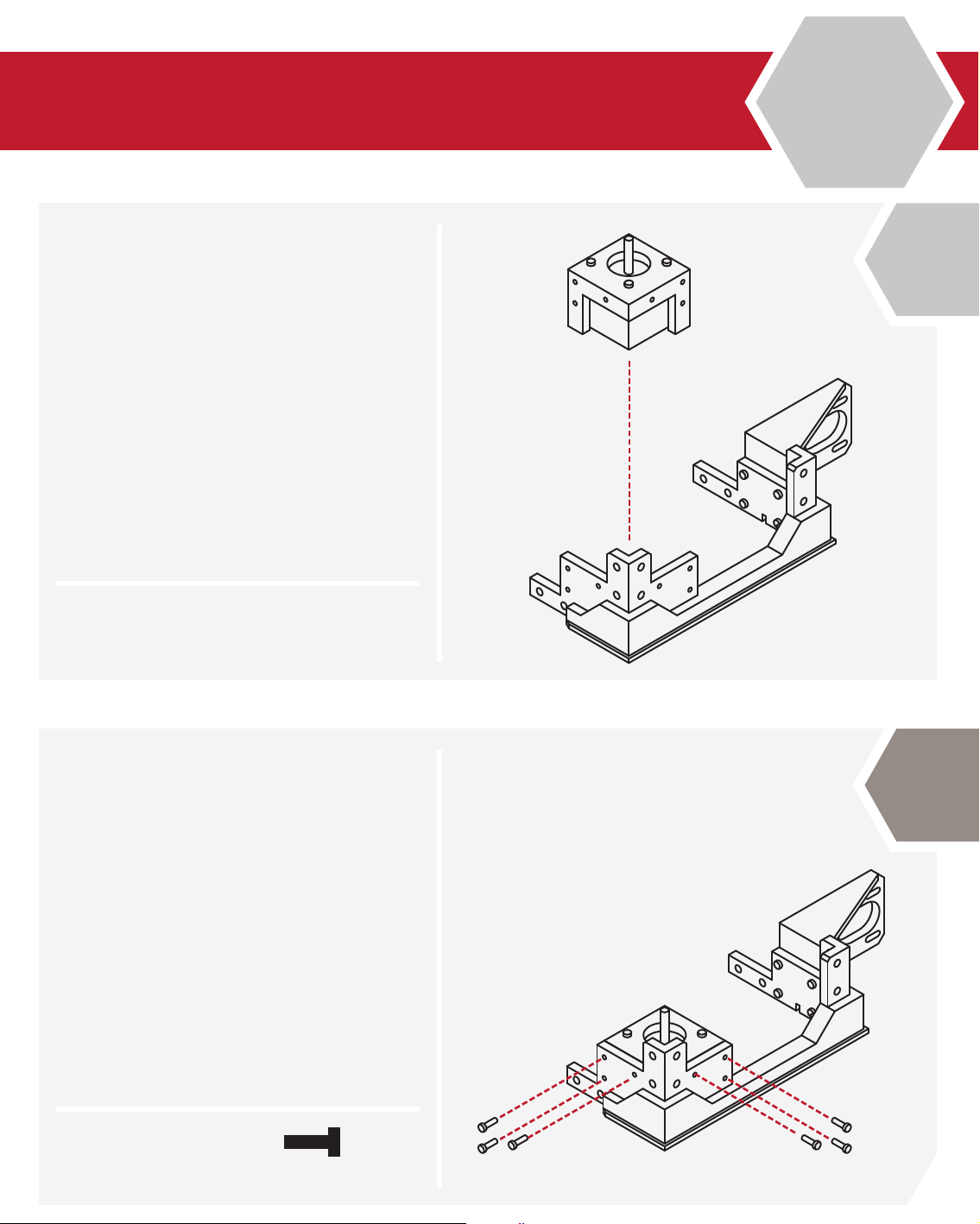

1

B

2.1

Z Motor Assembly (Right Front)

Locate the Hardware bag marked:

Z-Motor Mounts

Locate the Right Front Motor mount, the

upright mounts should face the outside of

the frame.

From the Stepper Motor package, select 1 of

the 34mm (short) stepper motors.

From the Fastener package, select:

4 M3x10 cap screws

2

X 4

Insert the Stepper Motor into the base of the

Right Front Motor Mount

The threads on the face of the Stepper Motor

should align with the 4 holes of the Right

Front Motor Mount.

M3 x 10

16

N/A

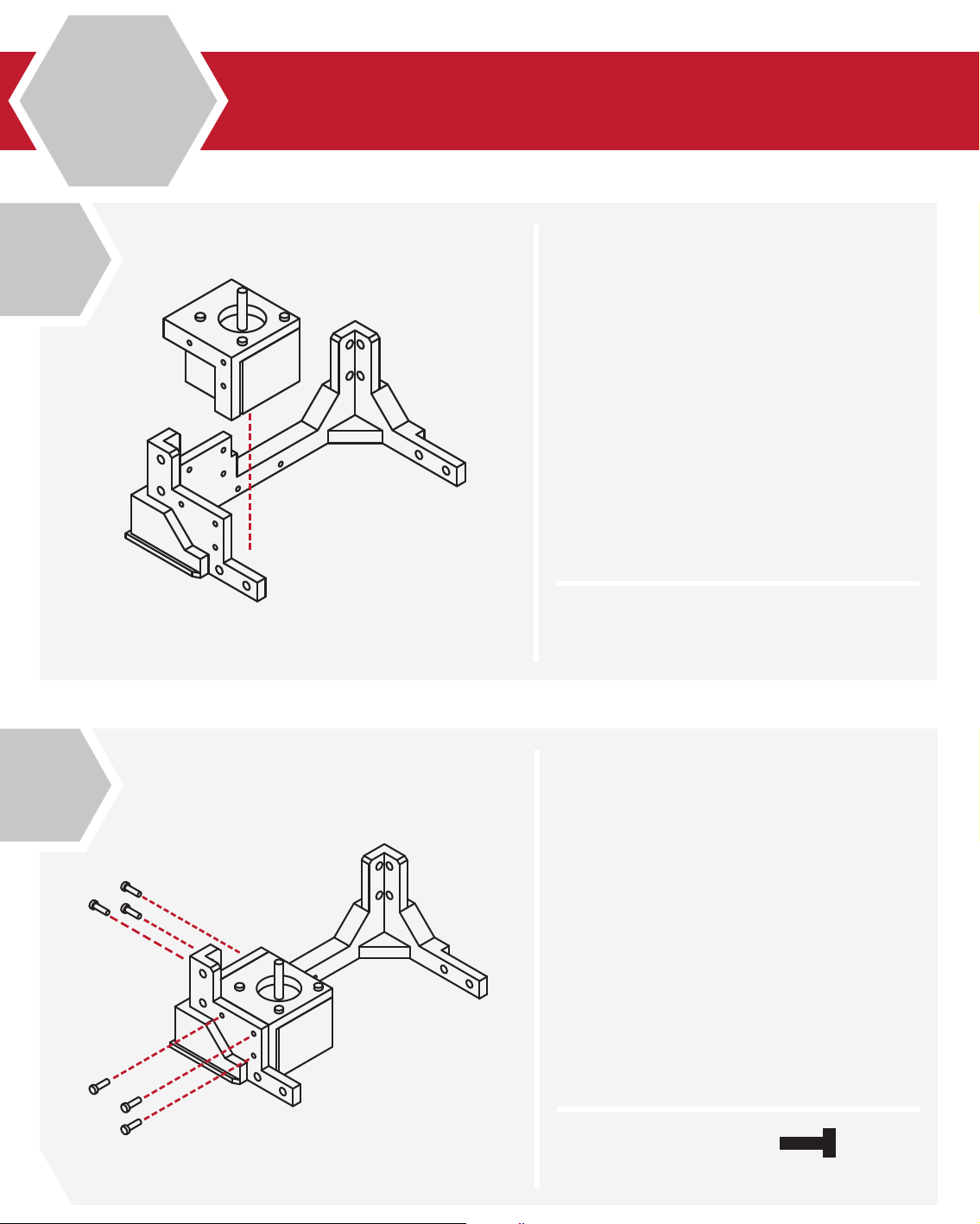

Page 17

Z Motor Assembly (Right/Left Front)

Using the M3 Hex wrench, screw the

4 M3 x 10 cap screws through the Right

Front Motor mount into the stepper motor.

Note: Take care not to over-tighten the

screws, or you may break the motor mount.

Congratulations, the Right Front Z Motor

Assembly is complete!

B

2.1

3

N/A

Alert: Left Front Z Motor Assembly

Collect the Left Front Motor Mount, the

second 34mm (short) stepper motor and

4 M3x10 cap screws.

Repeat Steps 1-3 to complete the Left Front

Z Motor Assembly

!

X 4

M3 x 10

17

Page 18

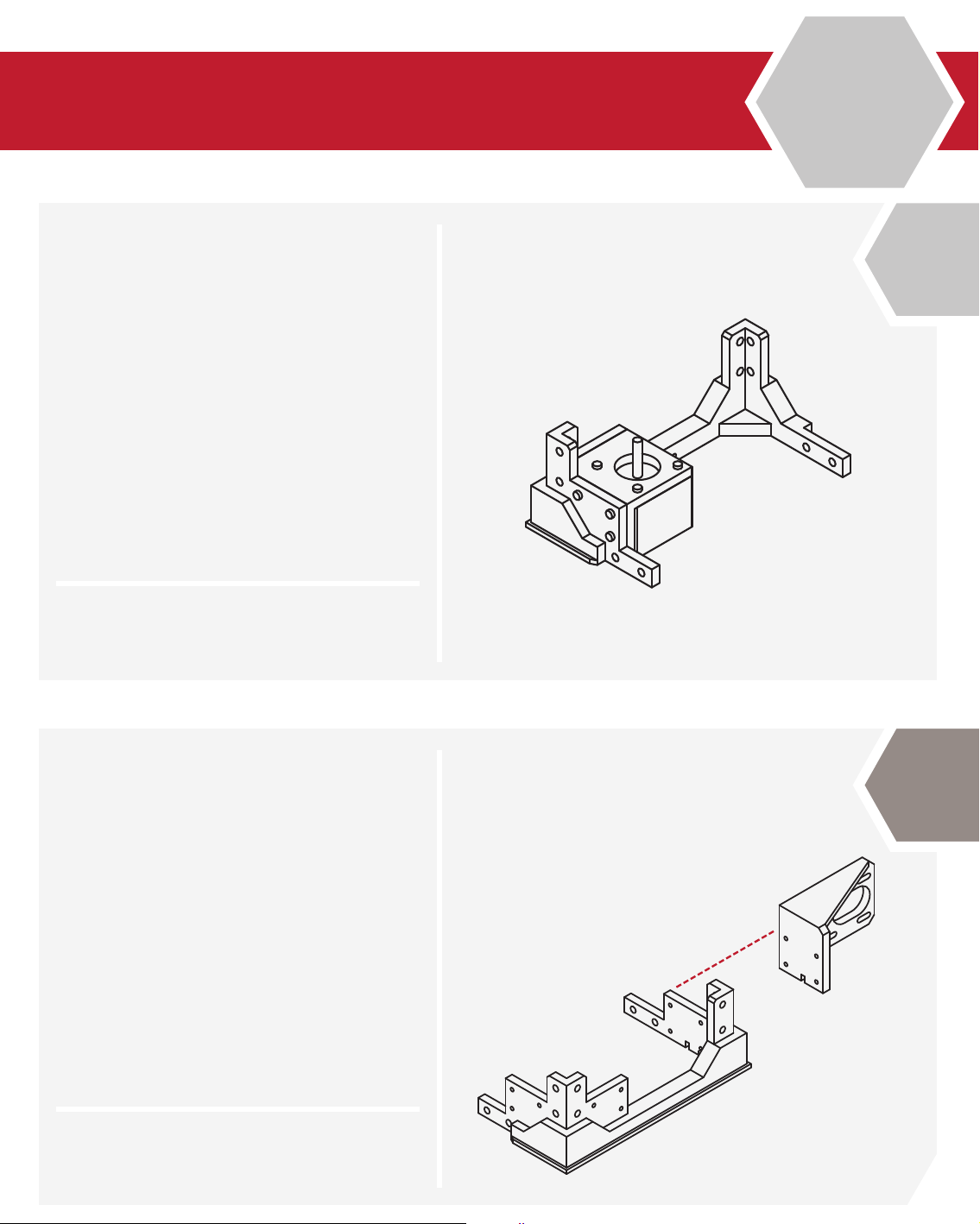

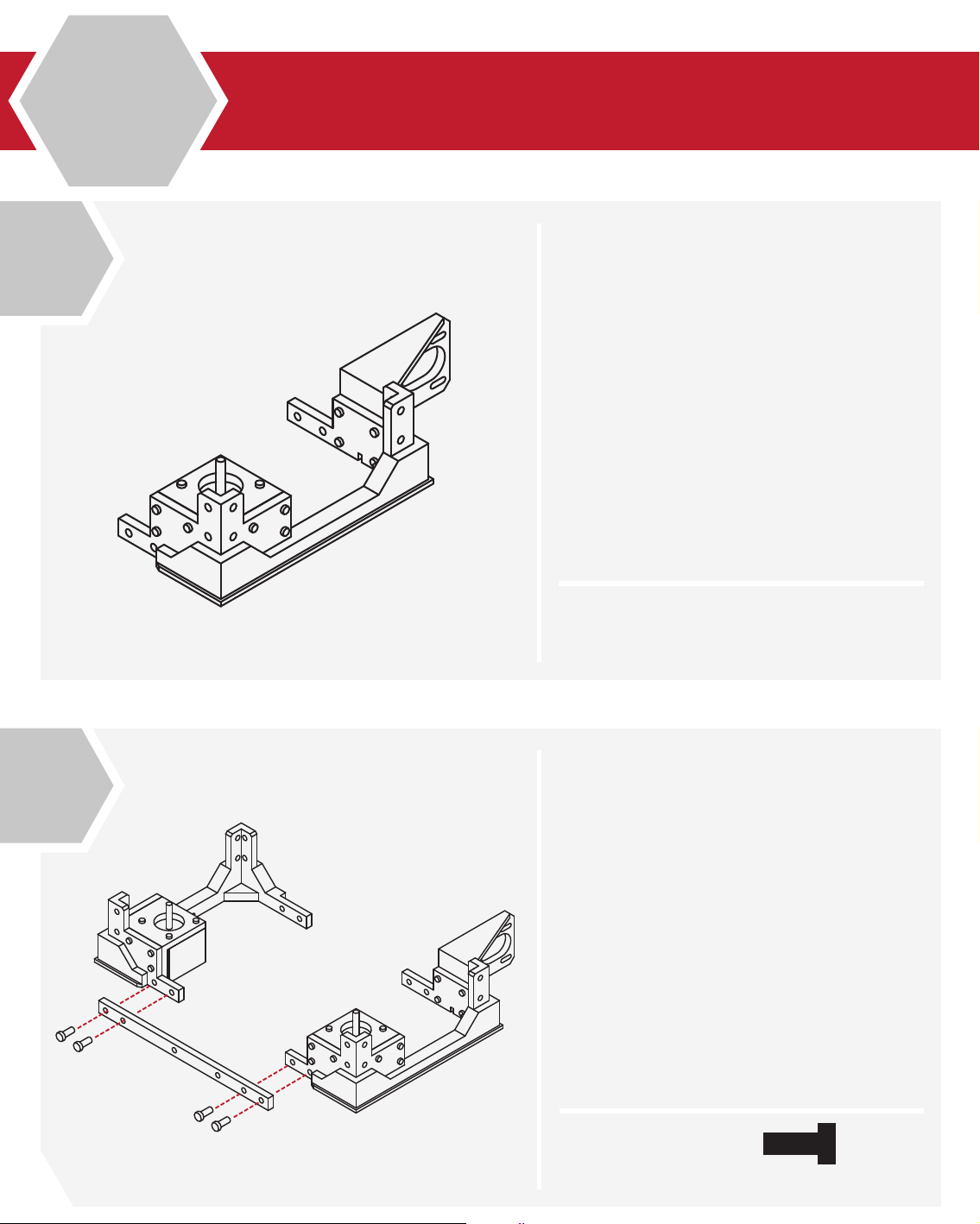

1

B

2.2

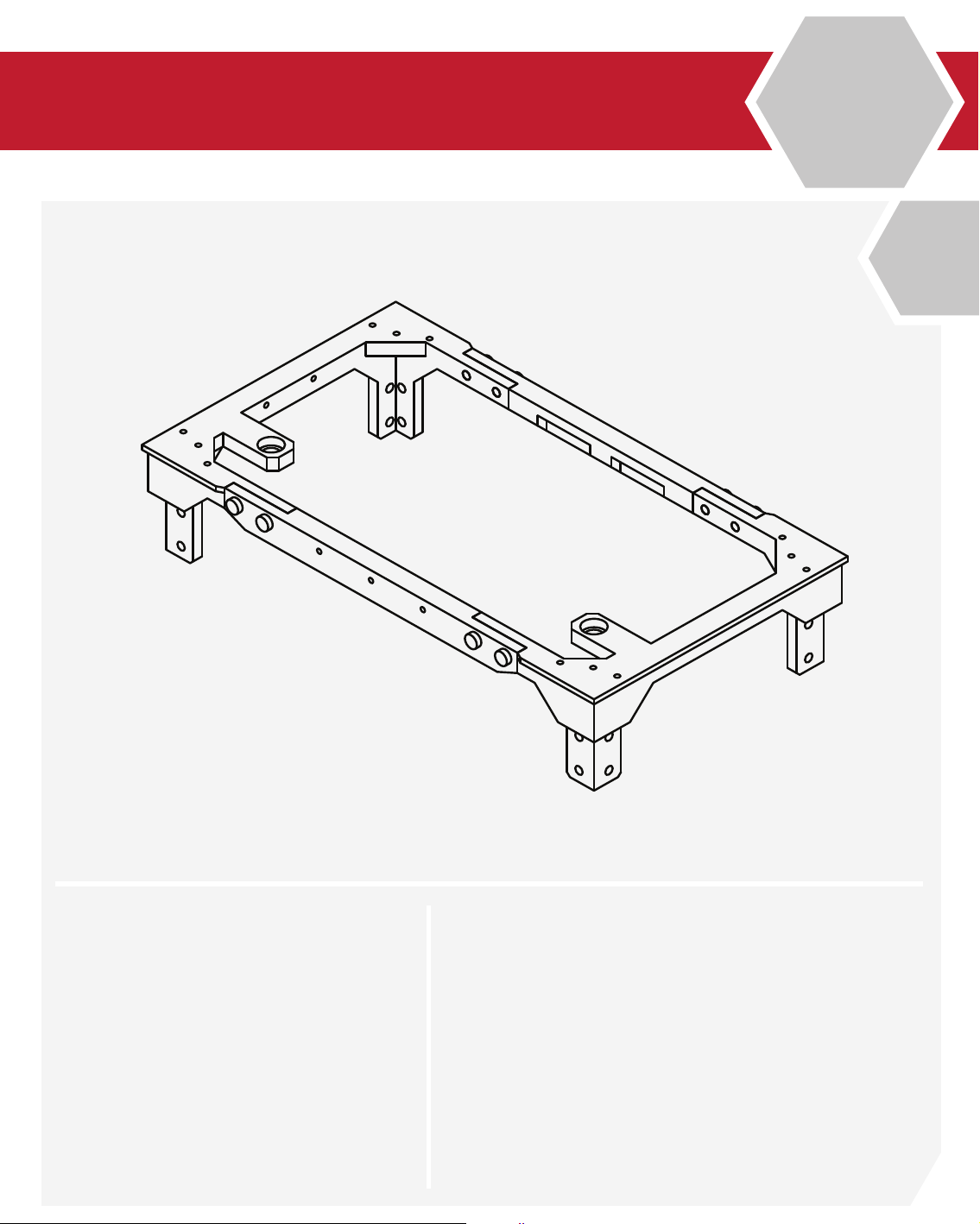

Lower Frame Assembly

Locate the lower left side frame, and collect the left Z motor assembly completed

in the previous steps.

Place the motor assembly into the lower

left frame.

The screw holes on the motor assembly

should match the screw holes in the lower

left frame assembly.

2

N/A

From the hardware bag, collect 6 M3 X 10

screws.

Using your M3 Hex wrench, attach the

motor assembly to the lower frame assembly.

18

X 6

M3 x 10

Page 19

Congratulations, you’ve completed the

left lower frame assembly.

Check the t and ensure that all screws are

tight.

Don’t over tighten the screws, as this may

strip the parts.

B

2.2

3

N/A

Locate the Y axis motor mount from your

printed parts kit. This mount is longer than

the similar X axis motor mount.

Also from your printed parts, locate the

lower right side frame.

Check the tment of both pieces before

proceeding to the next step.

4

N/A

19

Page 20

5

B

2.2

Lower Frame Assembly

From the hardware bag, select 4 M3 X 10

screws.

Using the screws, attach the Y axis motor

mount to the lower right side frame.

6

X 4

The Y axis motor mount is now complete.

Check the tment of the mount to the

lower frame.

Ensure that the mount is tight to the

frame and secure.

Do not over-tighten the screws holding

the mount in place.

M3 x 10

20

N/A

Page 21

Locate the right Z motor assembly that

was assembled in the previous steps.

Place the motor assembly into the lower

right frame.

The screw holes on the motor assembly

should match the screw holes in the lower

right frame assembly.

B

2.2

7

N/A

From the hardware bag, collect 6 M3 X 10

screws.

Using your M3 Hex wrench, attach the

motor assembly to the lower frame assembly.

8

X 6

M3 x 10

21

Page 22

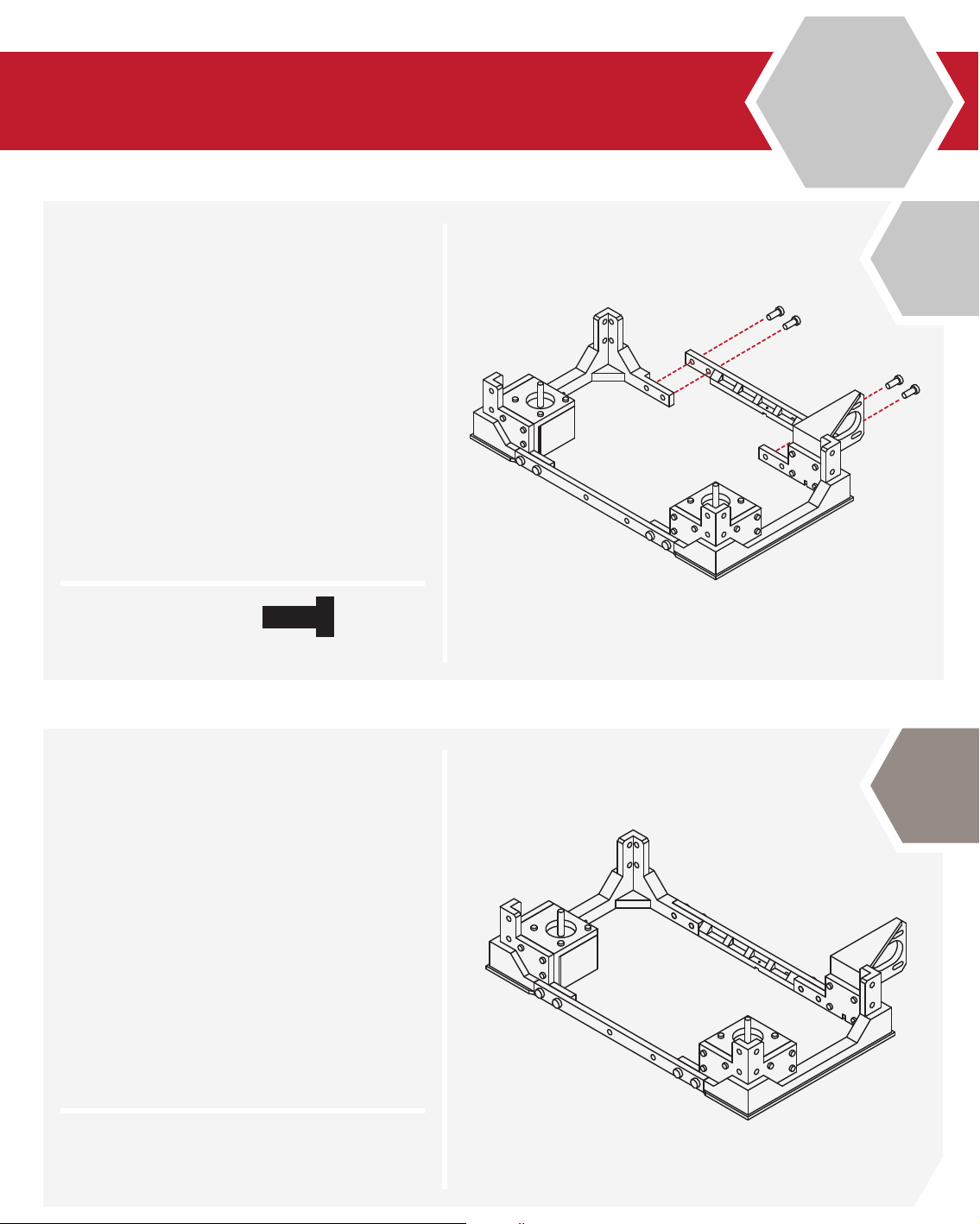

1

B

2.2

Lower Frame Assembly

Congratulations, you’ve completed the right

lower frame assembly.

Check the t and ensure that all screws are

tight.

Don’t over tighten the screws, as this may

strip the parts.

2

N/A

From the printed parts kit, locate the front

lower frame rail. The front lower frame rail

should be longer in length than the rear.

Take the left and right lower frame

assemblies and match it to the lower front

frame rail.

From the hardware bag select 4 M5 X 12

screws and using your hex wrench screw

them through the lower front rail and into the

left and right lower frame assemblies.

Check to make sure the pieces align and there

are no gaps.

22

X 4

M5 x 12

Page 23

Similar to the previous step, select the

rear lower frame rail from the parts kit. This

rail is longer than the front lower rail.

Select 4 M5 X 12 screws from the hardware

bag.

Like the previous step, take the screws and

using your hex wrench attach the rear frame

rail to the lower frame assemblies.

Ensure that the screws are tight and that

there are no gaps or alignment issues with

the pieces.

B

2.2

3

X 4

Congratulations! You’ve completed the

lower frame assembly!

Take a break and marvel at your

accomplishment.

M5 x 12

4

N/A

23

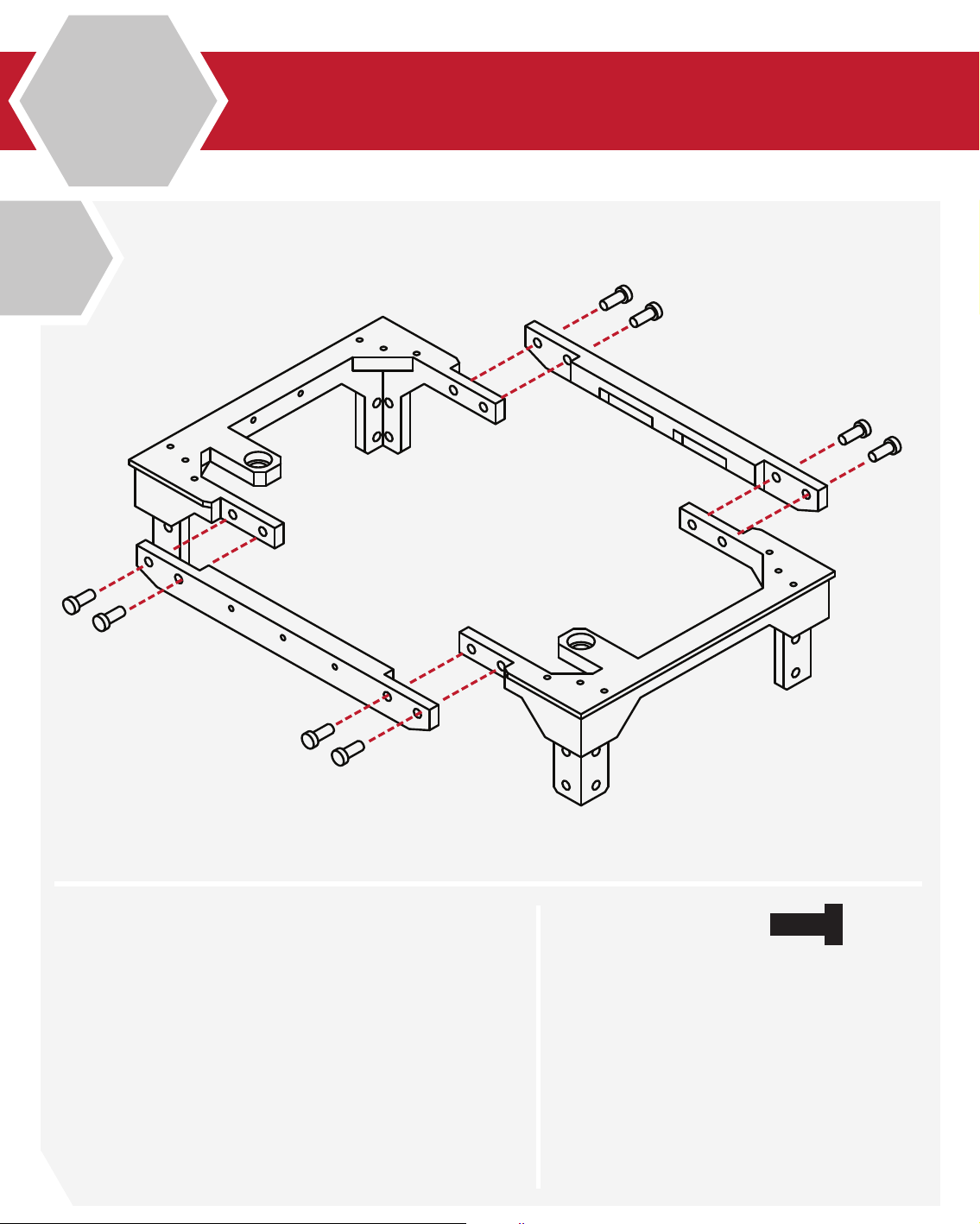

Page 24

1

B

2.3

Upper Frame Assembly

The upper frame assembly is similar to the lower frame

assembly. You will need to locate the left and right upper

frame assemblies, as well as the front and rear upper

frame rails.

The front frame rail is easily identied by the 3 screw

holes for the LCD panel. You will also need to collect

8 M5 X 12 screws from the hardware bag.

Like the lower assembly, use your hex wrench to secure

the upper frame rails to the upper frame assemblies.

24

X 8

M5 x 12

Page 25

B

2.3

2

N/A

Congratulations! You’ve assembled the upper frame

assembly! Wasn’t that easy?

Take a moment to check that the frame appears square

and that the frame rails are tight to the frame assemblies.

Ensure that the screws are not over-tightened as well.

25

Page 26

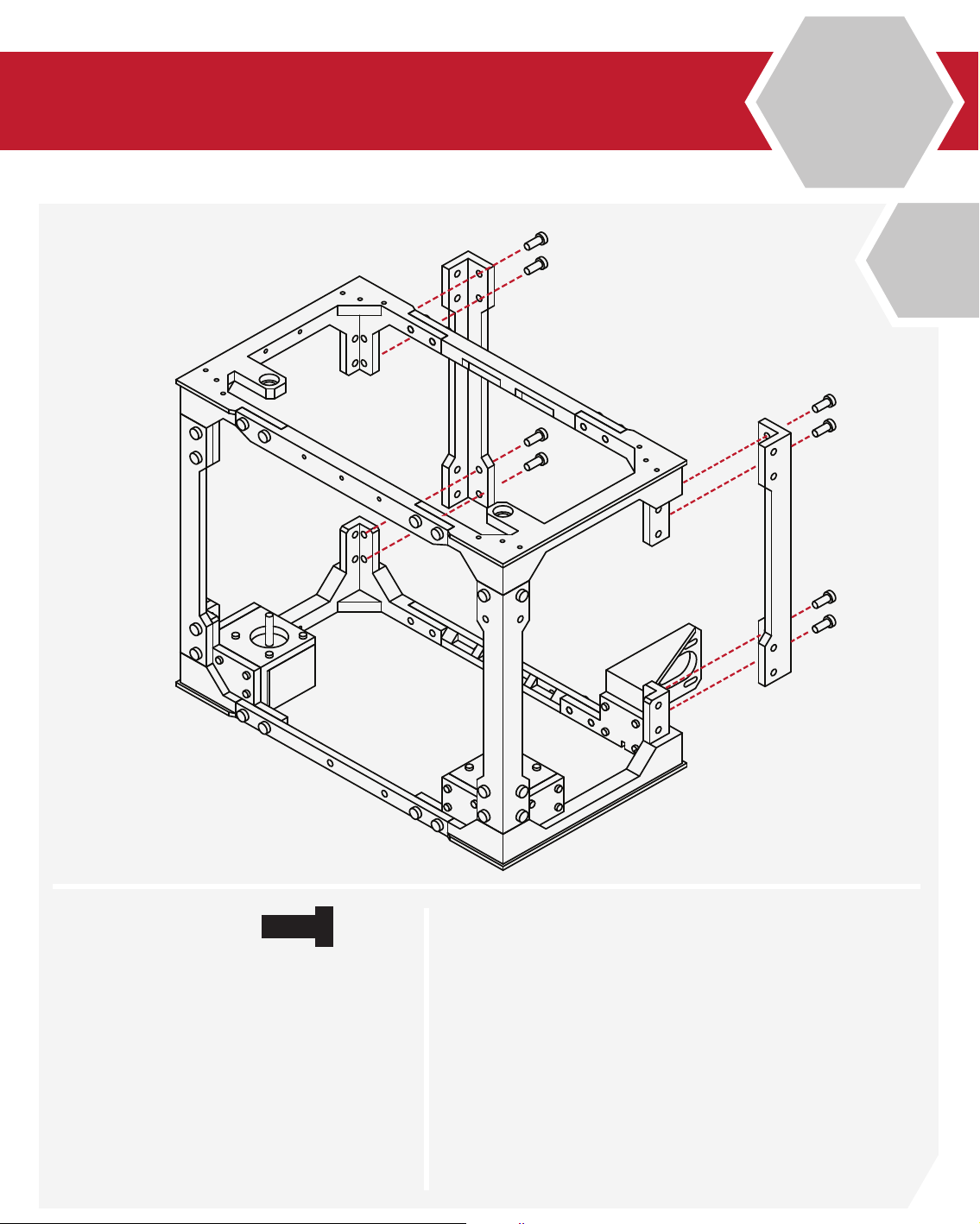

1

B

2.4

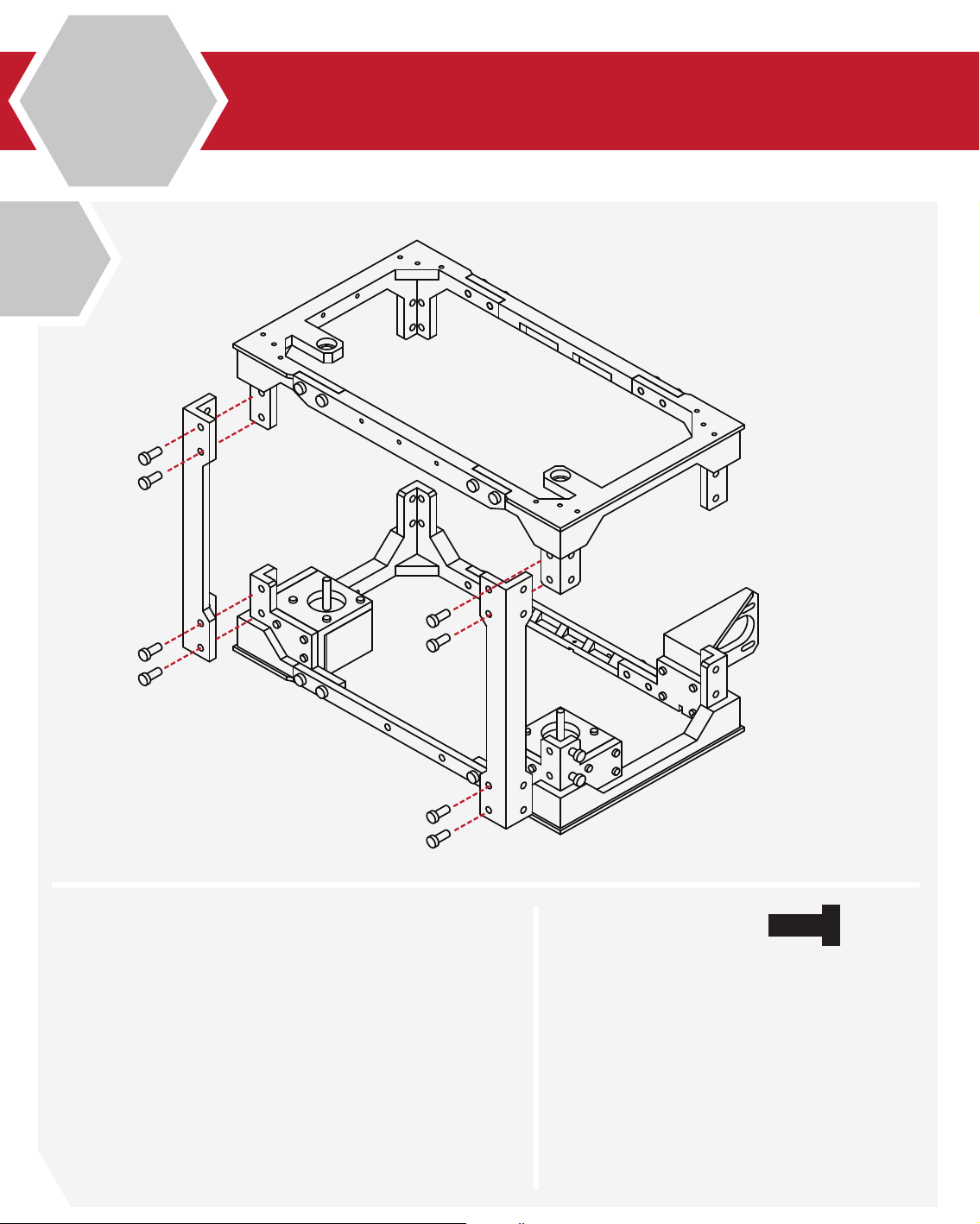

Lower & Upper Frame Union

From the parts kit, select 2 of the main frame uprights.

These pieces are universal and can be tted in any posi-

tion.

Select 8 M5 X 12 screws from your hardware bag as well.

Using your hex wrench, install the screws into the frame

uprights, and then into the lower and upper frame as-

sembly.

It is best to assemble the lower frame before the upper

frame assembly.

26

X 8

M5 x 12

Page 27

B

2.4

2

X 8

M5 x 12

With the rst uprights installed, from your hardware

bag, select 8 additional M5 X 12 screws.

Using your hex wrench, install the screws into the

uprights.

Ensure that the uprights are tight and aligned to the

upper and lower frame assemblies.

27

Page 28

3

B

2.4

Lower & Upper Frame Union

Congratulations! You’ve installed half of the frame!

We’re almost done!

28

N/A

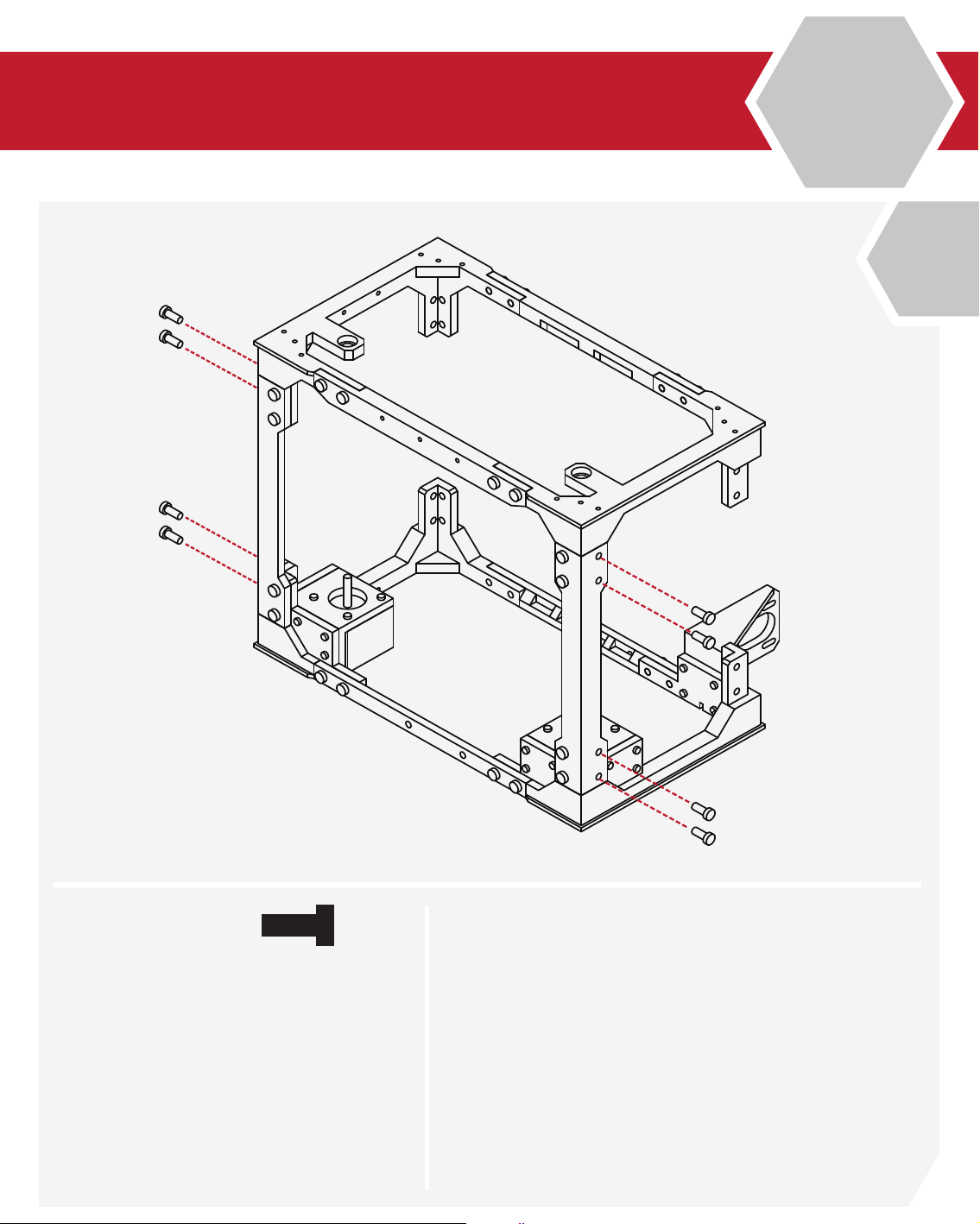

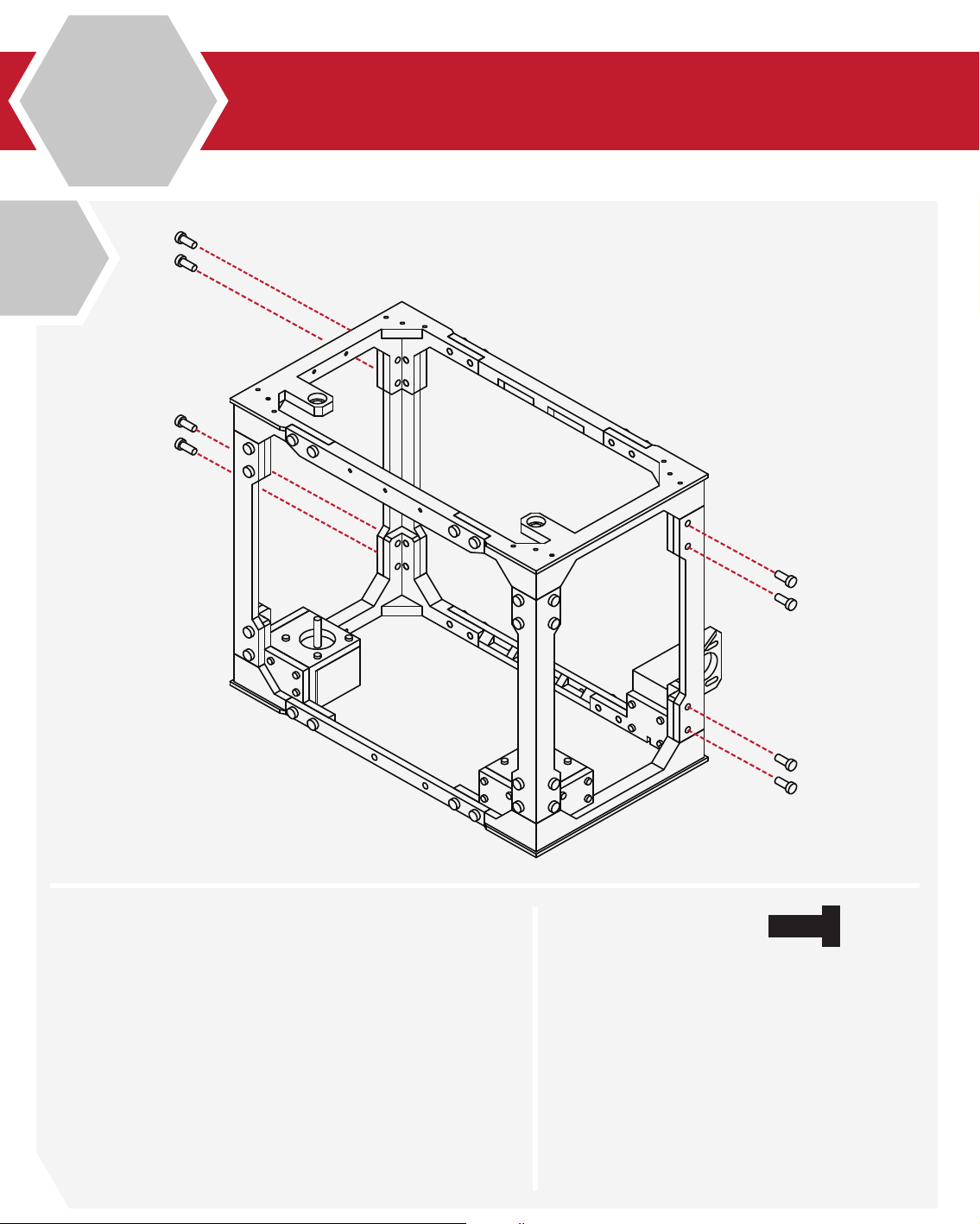

Page 29

B

2.4

4

X 8

M5 x 12

Like our previous step, select the two remaining frame

uprights and check their tment to the rest of the frame

assembly.

Select 8 M5 X 12 screws from the hardware bag.

Using your hex wrench, attach the two uprights to the

rear of the frame.

29

Page 30

5

B

2.4

Lower & Upper Frame Union

Select 8 additional M5 X12 screws from your

hardware bag.

Using your hex wrench, install the remaining screws into

the uprights and frame assemblies.

30

X 8

M5 x 12

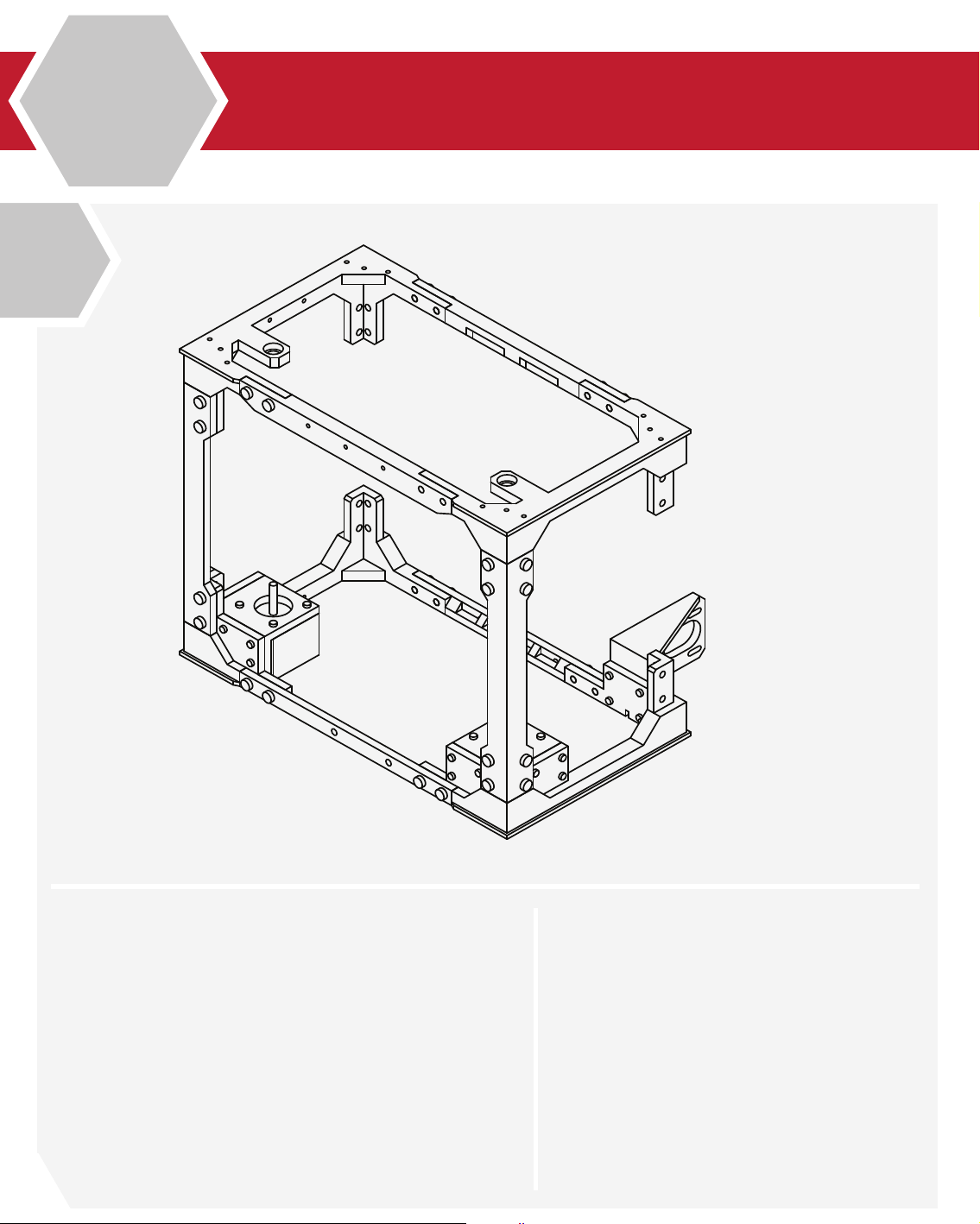

Page 31

B

2.4

6

N/A

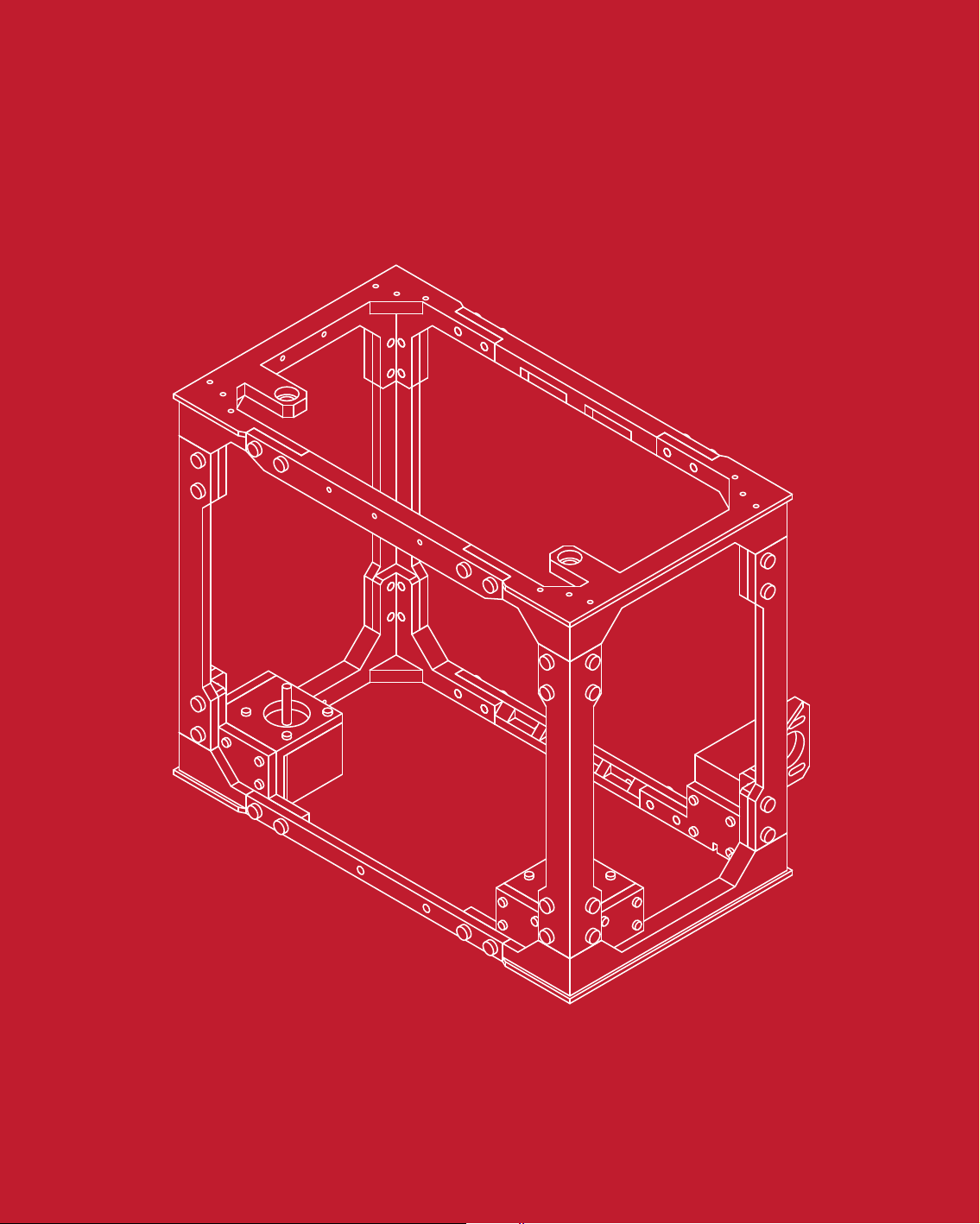

Congratulations! You’ve completed the outside frame!

This frame makes up the structural elements of

your printer, and is the building block for the remaining

elements!

You’ve done an awesome job, and I’m sure it looks

amazing!

Take a moment to relax and marvel at your feat of

engineering, we’re going to be kicking it up a notch

in the next chapter!

31

Page 32

SECTION

C

3.1 Extruder Assembly 34

Page 33

Page 34

1

C

3.1

Extruder Assembly

From the hardware kit, locate 4 LMS8UU

linear bearings, and the 2 lower extruder

bearing carriers. These can be identied by

their semi circle cut outs.

Insert the bearings into the bearing carriers.

Take care not to damage the bearings as they

are inserted.

2

N/A

When fully inserted, the bearings shoul

protrude slightly fom the carriers.

Ensure that the bearings are aligned, and fully

seated before proceeding to the next step.

34

N/A

Page 35

C

3.1

3

X 10

M3 x 10

Locate the lower extruder base from the hardware kits.

From the hardware bag, select 10 M3 X 10 screws.

Align the lower bearing carriers with the extruder base.

The semi circle cut-outs should align with the opening in

the extruder base.

Using your hex wrench, install 5 of the screws into each

of the bearing carriers, and into the extruder base.

35

Page 36

4

C

3.1

Extruder Assembly

With the carriers mounted to the extruder

base, check that the parts t well and that

there are no lose screws.

The bearings should be solidly captured and

should not rattle or move once the pieces are

assembled.

5

N/A

Locate your hot-end from the parts kit. We

will be wiring and installing the remainder of

its components later in this build.

Locate the hot-end mounting plate from

your hardware kit as well.

Insert the hot-end into the mount.

The ange on the hot-end should seat snuggly up against the lower mount.

36

N/A

Page 37

Check that there is not any excessive play in

the mount.

If there is any play in the mount, use a small

piece of tape on the mount to shim the

hot-end.

If the play is excessive, contact us for

a replacement or solution.

C

3.1

6

N/A

Select 2 M3 X 10 screws from your hardware

set.

Install the screws into the hot-end mount,

and into the extruder base.

Ensure that the mount is securely attached to

the lower frame assembly.

7

X 2

M3 x 10

37

Page 38

8

C

3.1

Extruder Assembly

From the hardware kit, select one of the

remaining 48mm stepper motors, as well

as the MK8 extruder gear and the included

grub screw.

9

N/A

Place the extruder drive gear onto the shaft of

the stepper motor.

Use the small hex wrench to slightly tighten

the grub screw to hold the gear in place.

We will need to ne-tune the gear’s location

later in this guide, so do not tighten the screw

completely.

38

N/A

Page 39

C

3.1

9

X 3

M3 x 10

Locate the upper extruder mount from the hardware kit,

and 3 M3 X 10 screws.

Insert the stepper motor into the extruder mount.

Take note to orientate the position of the motor such that

the wire connectors are facing upwards.

Insert the 3 M3 X 10 screws through the extruder mount

and into the stepper motor.

39

Page 40

10

C

3.1

Extruder Assembly

Locate 2 M3 X 10 screws and 1 M3 X 20 screws.

Take the lower extruder assembly and the upper

extruder assembly from the previous steps and mate

them together. The screw holes should align.

Insert the M3 X 20 screw into the right-rear hole, and

the 2 remaining screws into the other openings.

Check that the screws are tight, and that the mount is

secure. The hot-end should also be rmly in place with

no slop or play.

40

X 2

X 1

M3 x 10

M3 x 20

Page 41

Locate both the front and rear extruder

arm components, as well as 2 M3 X 10,

and 1 M3 X 20 screws.

Place the two arm components face to face.

The screw holes should align.

Insert the M3 X 10 screws into the arms to

secure them together. Place the M3 X 20

screw into the last opening.

C

3.1

11

X 2

X 1

The extruder arm is almost complete. Check

that all the screws are tight and that the parts

t correctly.

M3 x 10

M3 x 20

12

N/A

41

Page 42

13

C

3.1

Extruder Assembly

Locate 1 radial ball bearing and 1 M4 X 10

screw from the hardware kit.

Insert the bearing into the opening of the

extruder arm, and using your hex wrench

install the screw into the arm, and through

the bearing.

When tight, the bearing should still rotate

freely.

14

X 1

Locate 1 M4 X 40 screw, 1 compression

spring, 2 washers, and one M4 nut.

Place the screw through the extruder

arm, afterwards place one washer, the

compression spring, a second washer,

and nally the nut onto the screw.

Thread the nut partially compress the spring.

M4 x 10

42

X 1

M4 x 40

Page 43

C

3.1

15

N/A

Using the extruder assembly from the previous step,

take the completed extruder arm and place it onto the

extruder assembly.

The longer screw on the extruder arm should slot into

the base of the extruder. The at faces of the nut

should also match the side of the extruder base as well.

43

Page 44

16

C

3.1

Extruder Assembly

Insert a washer between the extruder arm

and extruder assembly.

Screw the last M3 X 20 screw from the

extruder arm into the extruder assembly

and stepper motor.

The arm should move freely. By tightining or

loosening the extruder spring screw, you can

adjust the tension between the extruder gear

and idler bearing. For now, set the tension so

that the idler bearing is pressing against the

extruder gear.

17

N/A

Select one of the 30mm cooling fans from

your parts kit, and 2 M3 X 16 screws.

Using your hex wrench, attach the cooling

fan to the side of the extruder assembly.

The cooling fan should sit ush with the

extruder assembly.

44

X 2

M3 x 16

Page 45

C

3.1

18

X 2

X 2

M3 x 16

M3 x 10

Select one of the 30mm cooling fans, and the fan duct

from your parts kit.

Select 2 M3 X 16 and 2 M3 X 10 screws from your

hardware kit as well.

Attach the cooling fan to the fan duct using the M3 X 16

screws, and attach the fan duct to the extruder assembly

using the M3 X 10 screws.

45

Page 46

SECTION

4.1 X Carriage Assembly 48

4.2 Y Carriage Assembly 62

4.3 Print Bed Installation 76

D

4.4 Z Carriage Assembly 82

Page 47

Page 48

1

D

4.1

X Carriage Assembly

Locate the Z Axis bearing holders from your

parts kit, and 2 linear bearings from the

hardware kits.

The Z axis bearing holders are identied by

their 6 screw holes and slight chamfer on the

leading edge.

Press the linear bearings into the bearing

carrier and ensure that they are fully seated

and aligned.

2

N/A

Fromy your parts kit, locate the left X axis

mount. The left X axis mount is identiable by

its semi-circle idler mounts on the rear.

Press the bearings and bearing holders into

the X axis mount.

Ensure that the bearings and bearing carrier

are ush with the mount and insert the

6 M3 X 10 screws to secure the bearing and

holder in place.

48

X 6

M3 x 10

Page 49

The left X axis mount is now complete.

D

4.1

Check that the bearing holder is tight to the

X axis mount.

N/A

Locate one of the M4 nuts from the hardware

kit along with 2 M3 X 10 screws, along with

the Z axis capture plate.

3

4

Insert the nut into the X axis carriage.

Using your hex wrench, insert the screws into

the capture plate, and then attach the plate

to the X axis assembly.

Take care not to damage the X axis mount or

over tighten the screws.

X 2

M3 x 10

49

Page 50

5

D

4.1

X Carriage Assembly

Take the completed X axis assembly and

locate the idler bearing cover plate, along

with 1 idler bearing, 1 M4 X 16 and 2 M3 X

20 screws.

Insert the screws through the cover plate, and

place the idler bearing onto the M4 screw.

Using your hex wrench, screw the assembly

into the X axis assembly.

6

X 2

X 1

The left X assembly is now complete. Check

that the idler bearing spins freely, and that all

screws are tight and secure.

M3 x 20

M4 x 16

50

N/A

Page 51

Locate the Z Axis bearing holders from your

parts kit, and 2 linear bearings from the

hardware kits.

The Z axis bearing holders are identied by

their 6 screw holes and slight chamfer on the

leading edge.

Press the linear bearings into the bearing

carrier and ensure that they are fully seated

and aligned.

D

4.1

7

N/A

Fromy your parts kit, locate the right X axis

mount. Ensure that the bearings and bearing

carrier are ush with the mount and insert the

6 M3 X 10 screws to secure the bearing and

holder in place.

Locate one of the M4 nuts from the hardware

kit along with 2 M3 X 10 screws, along with

the Z axis capture plate.

Insert the nut into the X axis carriage.

Using your hex wrench, insert the screws into

the capture plate, and then attach the plate

to the X axis assembly.

8

X 6

M3 x 10

51

Page 52

9

D

4.1

X Carriage Assembly

Locate the X axis motor mount, and right X axis mount.

From your hardware kit, select 4 M3 X 10 screws.

Align the X axis mount with the motor mount, and using

your hex wrench install the 4 screws.

Ensure that the motor mount is ush and tight with the X

axis mount.

52

X 4

M3 x 10

Page 53

From the hardware kit, select one of the

remaining 48mm stepper motors, as well as

the GT2 Pulley.

D

4.1

10

N/A

Place the GT2 Pulley onto the shaft of the

stepper motor.

Use the small hex wrench to slightly tighten

the grub screw to hold the gear in place.

We will need to ne-tune the pulley’s location

later in this guide, so do not tighten the screw

completely.

11

N/A

53

Page 54

12

D

4.1

X Carriage Assembly

From your hardeare kit, locate 4 M3 X 10 screws, and

gather the stepper motor and X axis assembly from the

previous steps.

Insert the stepper motor into the motor mount. Ensure

that the cable connector on the motor is facing upwards.

Using your hex wrench, insert the 4 M3 X 10 screws into

the motor mount and into the stepper motor. We will be

adjusting the motor tension later in this guide, so there is

no need to completely tighten the screws.

54

X 4

M3 x 10

Page 55

D

4.1

13

N/A

Congratulations! You’ve completed the X motor

assembly.

Take a moment to ensure that all the scews and parts t

correctly and are tight.

55

Page 56

14

D

4.1

X Carriage Assembly

Locate the left X assembly from the previous steps as

well as 2 250mm linear rod.

These rods are the same length as the rods used for the

Z axis, but shorter than those used for the Y axis. Using a

soft mallet, gently drive the rods into the X assembly.

Take care to ensure the rods are inserted square to the

assembly and that you do not damage the X axis

assembly. When fully inserted, the rods should rest

against the small openings on the backside of the

X axis assembly.

56

N/A

Page 57

D

4.1

15

X 2

X 1

M3 x 10

M3 x 20

Locate the Z Axis screw mount from your parts kit, along

with 2 M3 X 10, and 1 M3 X 20 screws.

Using your hex wrench, attach the Z axis screw mount to

the outside of the X axis assembly.

Take the remaining M3 X 20 screw and screw it partially

through the mount. This will be used to level your initial

layer height later on.

57

Page 58

16

D

4.1

X Carriage Assembly

Locate the Extruder assembly that we assembled earlier

in this guide.

Orientate the extruder so that the hot-end cooling fan is

facing the X axis assembly.

Carefully slide the extruder assembly onto the linear rods.

Be careful when doing so, as it is easy to mis-align the

rods, and damage the bearings.

58

N/A

Page 59

D

4.1

17

N/A

With the extruder assembly in place, collect the right

X axis assembly that we assembled earlier.

Using a soft mallet, gently insert the X axis assembly onto

the linear rods.

Take care not to damage the X assembly or linear rods.

If you nd it particularily dicult, you can remove the 4

screws holding the motor assembly, and use the backside of X axis to hammer against directly. The linear rods

should be ush with the backside of the X axis assembly.

59

Page 60

18

D

4.1

X Carriage Assembly

From your hardware kit, select 2 M3 X 10 screws.

Using your hex wrench, insert the screws into the

backside of the extruder assembly.

The screws should sit roughly 6mm proud of the extruder

assembly. These will be used later in this guide to secure

the GT2 belts.

60

X 2

M3 x 10

Page 61

D

4.1

19

X 1

M3 x 20

Locate 1 M3 X 20 screw from your hardware kit.

Using your hex wrench, insert the screw partially

into the extruder assembly.

This screw will be used later to adjust your X axis

end-stop.

61

Page 62

1

D

4.2

Y Carriage Assembly

Locate the lower Y bearing carriers, and 4 linear

bearings from your parts kit.

Insert the bearings into the bearing carriers.

Ensure that the bearings are fully seated before

proceeding.

62

N/A

Page 63

D

4.2

2

N/A

Gather the 4 lower Y bed pieces from your parts kit and

arrange them like so.

63

Page 64

3

D

4.2

Y Carriage Assembly

Arrange the lower Y bed pieces such that the

indentations for the bearings align.

Ensure that the pieces t well.

You may use a sharp Exacto-knife or le to trim any parts

that do not t well.

64

N/A

Page 65

D

4.2

4

X 8

M3 x 10

From your hardware kit, locate 8 M3 X 10 screws. Gather

the bearing carriers that were assembled previously.

Using your hex wrench, install the 8 screws into the

bearing carriers, and then into the Y bed frame

components.

65

Page 66

5

D

4.2

Y Carriage Assembly

Ensure that all parts t correctly and that all screws

are tight.

The bearings should be rmly captured in their carriers

and should have little play in them.

66

N/A

Page 67

D

4.2

6

X 8

M3 x 10

Locate the Y bed cross member from your parts kit,

along with 8 M3 X 10 screws.

Using your hex wrench, install the screws into the cross

member, and then into the lower bed assembly.

67

Page 68

7

D

4.2

Y Carriage Assembly

With the cross member installed, ensure that all parts t

well and that all screws are tight.

68

N/A

Page 69

D

4.2

8

X 2

M3 x 10

Locate 2 M3 X 10 screws from your hardware kit.

Insert the screws into the 2 mounting points on the side

of the lower bed.

The screws should sit 6mm proud of the mount.

These screws will be used to secure the GT2 belt to later

in this guide.

69

Page 70

7

D

4.2

Y Carriage Assembly

Locate 1 M3 X 20 screw from your hardware kit and install it into the screw mount on the rear of the lower bed

assembly.

This screw will be used to home the bed later in your

conguration.

70

X 1

M3 x 20

Page 71

D

4.2

8

N/A

Congratulations! The lower bed assembly is complete!

Double check that all the fasteners are tight and that all

the parts are properly aligned.

71

Page 72

9

D

4.2

Y Carriage Assembly

From your parts kit, locate the front Y axis

carrier. Locate 1 bearing and 1 M4 X 16 screw

from your hardware kit.

Insert the bearing into the bearing holder,

and using youe hex wrench, insert the screw

into the bearing holder and bearing.

10

X 1

Ensure that the bearing can rotate freely in its

holder.

This bearing will act as the idler for the GT2

belt which will be installed later in this guide.

M4 x 16

72

N/A

Page 73

D

4.2

11

N/A

Locate the longest linear rods from your hardware kit.

Using a soft mallet, gently insert the linear rails into the

Y axis carrier.

Take care to ensure the rods are square and that the

carrier is not damaged.

When fully inserted, the face of the rods should be ush

with the face of the carrier.

73

Page 74

12

D

4.2

Y Carriage Assembly

Take the lower Y bed from the previous steps and

carefully insert the lower Y carriage assembly.

Take care when guiding the linear rods through

the bearings.

The bearings can easily be damaged if the rods are

mis-aligned or excessive force is used when inserting

them into the bearings.

74

N/A

Page 75

D

4.2

13

N/A

Locate the rear Y carrier from your parts kit.

Using a soft mallet, gently insert the carrier onto the

existing assembly.

Take care to not damage the rear carrier.

When fully inserted, the faces of the linear rods should

be ush with the face of the rear carrier.

75

Page 76

1

D

4.3

Print Bed Installation

Take the front Y axis mount from your parts kit, and

gather 2 M5 X 12 screws.

Using your hex wrench, attach the Y axis mount to the

front frame of the printer.

Ensure that the screws are tight and that the parts t

correctly.

76

X 2

M5 x 12

Page 77

D

4.3

2

X 2

M5 x 12

Repeat the same procedure for the rear, using the

rear Y axis mount and 2 M5 X 12 screws.

Ensure that the part is tight to the frame and that both

screws are tight.

77

Page 78

3

D

4.3

Print Bed Installation

Congratulations, the front and rear Y axis mounts are

installed.

Before proceeding, double check that all connections

are tight and that the parts t correctly.

78

N/A

Page 79

D

4.3

4

N/A

Locate the lower bed assembly that we completed

earlier in this guide.

Insert the lower bed assembly into the frame of the printer, and over top of the Y axis mounts.

If everything aligns, the lower bed assembly should drop

into place on the Y axis mounts.

If the lower bed does not t, or there is uneccessary force

needed to t it, use a soft mallet on the inside of the

Y axis carriers to lengthen them slightly and try again.

79

Page 80

5

D

4.3

Print Bed Installation

Locate 4 M5 X 12 screws from your hardware kit.

Using your hex wrench, install the screws through the

Y axis carriers and into the Y axis mounts.

80

X 4

M5 x 12

Page 81

D

4.3

6

N/A

Congratulations! The lower bed installation is complete.

Double check that the screws are secure and that

everything aligns properly.

Your printer should sit at with little or no ‘wobble’.

If there is any issues you may readjust the lower Y mount

until suitable.

81

Page 82

1

D

4.4

Z Carriage Assembly

With the lower bed installed, locate the

X axis assembly completed previously in this guide.

Insert the X axis assembly through the side of the frame.

The front of the extruder should face the front of the

frame as well.

82

N/A

Page 83

D

4.4

2

N/A

With the X axis assembly in the frame, it is advised that

you temorarily secure the X axis to the top of the frame

using cable ties or similar.

83

Page 84

3

D

4.4

Z Carriage Assembly

Locate the Z axis carriers from your parts kit, along with

the remaining 2 linear rods.

Using a soft mallet, insert the linear rods into the carriers.

When fully inserted, the face of the rod should be ush

with the face of the carrier.

84

N/A

Page 85

D

4.4

4

N/A

Take the Z axis rods and carriers assembled in the

previous step and insert them through the bottom of the

frame.

Insert the linear rods into the X axis assembly, taking care

to not damage the linear bearings.

85

Page 86

5

D

4.4

Z Carriage Assembly

With the Z rods in place, check that there is no binding

of the X axis and that everything is aligned before

proceeding to the next step.

86

N/A

Page 87

D

4.4

6

X 2

M3 x 10

Gather 2 M3 X 10 screws from your hardware kit.

Using your hex wrench, install both screws through the

ears of the Z axis mount and into the side of the frame.

Take care to ensure that the mount is tight against the

frame and that the fasteners are secure.

87

Page 88

7

D

4.4

Z Carriage Assembly

Repeat the same procedure in the last step, securing the

opposite Z mount using 2 M3 X 10 screws.

88

X 2

M3 x 10

Page 89

D

4.4

8

N/A

With the lower Z mounts secured to the frame, locate

the remaining 2 Z mounts from your parts kit.

Using a soft mallet, gently install the 2 mounts onto

the linear rods.

When properly installed, the face of the Z mounts

should be ush with the face of the linear rods.

89

Page 90

9

D

4.4

Z Carriage Assembly

Similar to the previous steps, locate 2 M3 X 10 screws

and secure the top Z mounts. Ensure that the mounts are

ush with the frame and that the fasteners are secure.

90

X 2

M3 x 10

Page 91

D

4.4

10

X 2

M3 x 10

Repeat the same procedure for the opposite Z mount.

Ensure that mount is ush with the frame, and that the

fasteners are secure.

91

Page 92

11

D

4.4

Z Carriage Assembly

From your parts kit, locate the Z couplers.

Slide these couplers onto the shaft of the Z axis stepper

motors.

Using your hex wrench, tighten the set screw on the

coupler to secure it to the shaft.

92

N/A

Page 93

D

4.4

12

N/A

Ensure that the coupler is positioned half way onto the

shaft.

The threaded rod will attach to these couplers in the

following steps.

93

Page 94

13

D

4.4

Z Carriage Assembly

Locate the threaded rods from your parts kit.

Insert the rods through the top of the frame and thread

the rods through the X axis mounts and into the couplers

installed previously.

Using your hex wrench, tighten the set screws on the

couplers to secure the threaded rod.

94

N/A

Page 95

D

4.4

14

N/A

With both rods secure, check that the X axis is level.

If the X axis is uneven, simply turn either one of the

threaded rods to raise or lower the axis until it appears

close to level.

95

Page 96

SECTION

E

5.1 GT2 Belt Installation 98

5.2 LCD Installation 102

5.3 RAMPS Installation 106

5.4 Upper Bed Installation 116

5.5 Wiring & Final Conguration 118

Page 97

Page 98

1

E

5.1

GT2 Belt Installation

From your hardware kit, locate the GT2 Belts.

If not already cut, cut the belt to length so that it is long

enough to loop around the motor, and opposite idler

bearing with some extra length.

The belt will be mounted with the teeth facing inwards.

Take one end of the belt and loop it around one of the

screws on the extruder assembly.

98

N/A

Page 99

E

5.1

2

Secure this using a cable tie so that the belt

teeth mesh together. Take the belt and loop it

around the idler bearing and back around the

pulley on the X axis motor.

Your belt should be long enough to reach the

remaining screw on the extruder assembly.

While holding the extruder assembly in place,

use a pair of pliers, or a second set of hands to

pull the belt as tight as possible to remove any

slack.

With the slack removed, secure the belt to the

screw using the same method as before.

When complete, the belt should be tensioned

and tight. If there is slack, you may loosen the

4 screws holding the motor in place and slide it

backwards, away from the frame to tension the

belt more.

Remember to tighten the motor mounts when

complete.

99

Page 100

3

E

5.1

GT2 Belt Installation

We will now complete the same procedure for the Y axis.

If not already cut, cut the belt to length so that it is long

enough to loop around the motor, and opposite idler

bearing with some extra length.

The belt will be mounted with the teeth facing inwards.

Take one end of the belt and loop it around one of the

screws on the lower bed assembly.

100

N/A

Loading...

Loading...