Manzano Laser Works Junkers Ju 88 Assembly Manual

Copyright 2007 Thomas A. Jacoby and WarbirdKits.com

Junkers Ju 88

Junkers Ju 88Junkers Ju 88

Junkers Ju 88

Manual Version 1.2 – 13 March 2008

Specifications

Wingspan: 49.75 inches

Area: 339 square inches

Length: 36.12 inches

Power: 2x BP21 Brushless

2x Speed-400

Assembly Manual for Junkers Ju 88

Copyright 2007 Thomas A. Jacoby and WarbirdKits.com 2

Materials

This kit contains the following materials:

This construction manual

Plan sheet

Decal sheet

Laser-cut wood pack

Vacuum-formed plastic canopy

Vacuum-formed plastic nose glazing

Vacuum-formed plastic spinners (2)

To complete this kit, you will need the following additional

materials:

1/4” x 3/8” x 48” Balsa for wing leading edge

3/32” x 3” x 36” Balsa for fuselage sheeting

1/16” x 4” x 24” Balsa sheet for wing skin, 6 each

1/16” x 1/4” Balsa planks for nacelles

3/8” x 36” Balsa triangle stock for fuselage, 2 each

1/4” square Hardwood motor mounts (for Speed-400)

3/16” x 12” Hardwood dowel for elevator joiner

Wing mounting bolt

Hinges (ailerons, elevator)

Miscellaneous servo mounting materials and pushrods

Covering materials and paint

Glue

NOTE: We recommend that you read this entire

manual before beginning construction.

Construction

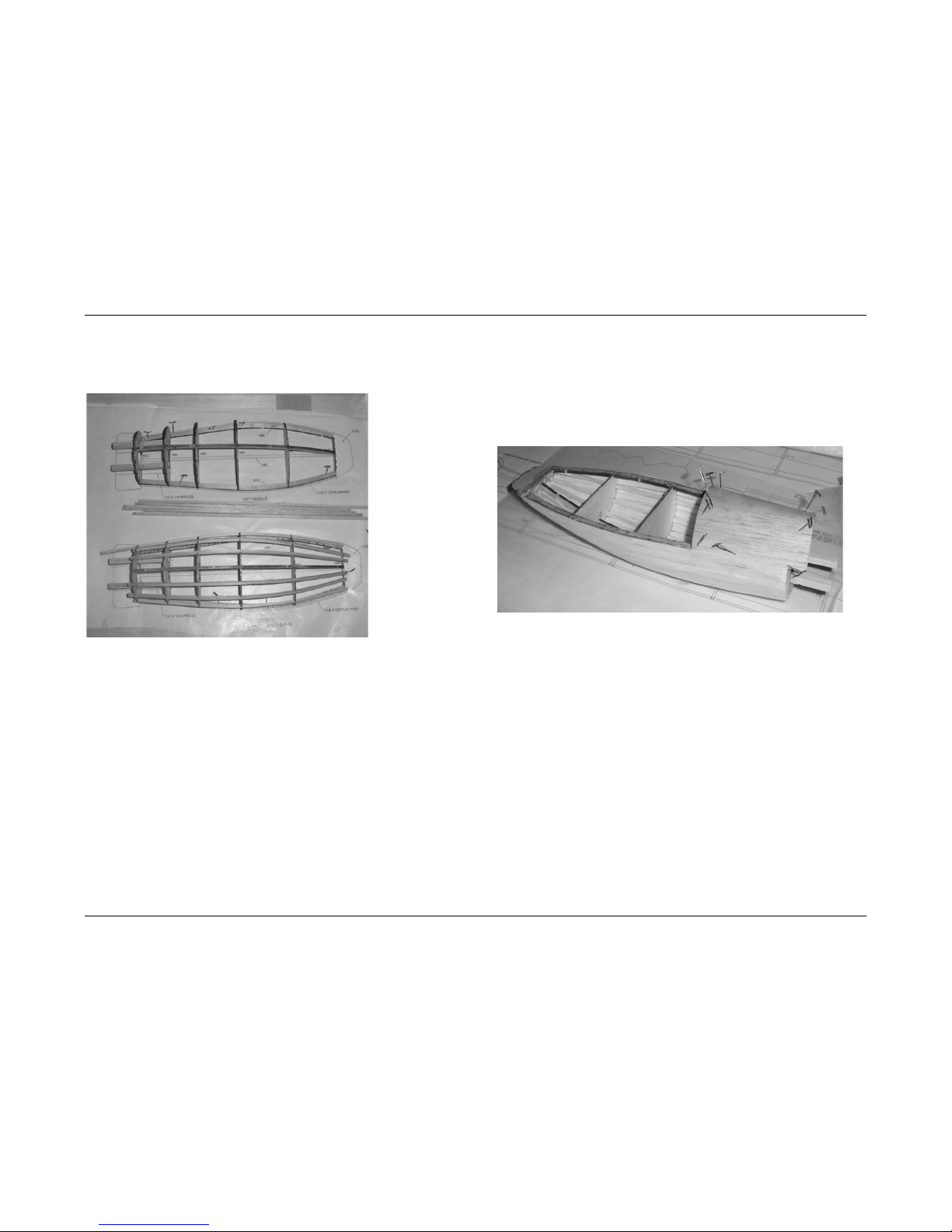

Wings

Assemble the wing skins. The easy way to do this is

tape them together on the “good” side. Use low-tack painter’s

tape so that it releases easily later on. Then bend the joints

open, apply a thread of aliphatic resin in the groove, then close

the joints. Lay a sheet of wax paper on a flat surface, lay the

glued skin on it, cover with another sheet of wax paper, and

weight with heavy books. As you glue each skin, add it to the

stack, making sure you put a sheet of wax paper between

each skin. Let the glue dry overnight.

Using the same procedure as in step 1, assemble two

wing top skins, using the bottom skins as templates. Make the

top skin about 1/4” wider (chord-wise) than the bottom skin.

Block sand the good side of the wing skins. Make them

nice and smooth, as this will be the outer surface of the wing,

and it’s hard to sand later on.

Begin with the left wing. Cover your building board with

a sheet of wax paper. Remove the balsa from the aileron

hatch location, and pin the bottom left skin to the building

board. Keep your plan separate for reference.

Cut, fit and glue the 1/4" x 3/8” leading edge to the

wing skin.

Remove one set of ribs W1 thru W11 from the laser-cut

sheets. Leave the aileron ribs (the rear sections of ribs W7

Assembly Manual for Junkers Ju 88

Copyright 2007 Thomas A. Jacoby and WarbirdKits.com 3

thru W11) attached to the sheet for now. Also remove spars

W12 thru W14 from the sheets.

Trial-fit the wing ribs to the spars. Place the assembled

ribs and spars on the skin and align with the etched lines. Glue

the ribs to the bottom skin. Make sure that W1 fully engages

the notches in the spars so that the correct dihedral angle is

established. Then glue the three main spars to the skin and

ribs. Glue braces G1 and G2 in place where rib W7 meets the

leading edge.

Glue spar W15 in place. Now find the rear section of rib

W7 and glue it in place.

Find a scrap piece of 1/8” balsa sheet to use as a

spacer between W15 and W16. Carefully glue the aileron spar

W16 to the bottom skin, and remove the spacer.

Now glue the aileron ribs (from W7 thru W11) in place,

butting to the aileron spar.

Fit and glue leading edge brace W17 in place.

Glue the 1/16” plywood aileron hatch base in place.

Sand a taper into the trailing edge of the wing skin, so

that the skin is 1/32” thick at the trailing edge.

Repeat steps 3 thru 13 for the right wing.

NOTE: You may wish to apply the top skins to the wing before

joining the panels. If you do, remember to pull the motor and

servo wiring through!

Trial-fit the wing halves together. Pin down one side

and block up the other side so that there is 3-1/2” total dihedral

at the wingtip. Make sure that the two W1 ribs butt closely

together.

When satisfied with the fit, glue the wing halves

together with 15-minute epoxy between the W1 ribs. Let the

epoxy fully cure before moving the wing.

Install the servo leads and motor wiring in the two wing

halves.

Cut a hole in the top left wing skin for the motor wiring

to exit the wing. The hole should be about halfway between

ribs W1 and W2, ahead of the forward spar W13.

Cut a similar hole in the top right wing skin for the

aileron servo cables.

Assembly Manual for Junkers Ju 88

Copyright 2007 Thomas A. Jacoby and WarbirdKits.com 4

Fit and install the top wing skins. The easy way to do

this is a) apply aliphatic resin to the tops of the ribs and spars;

b) CA the skin to the leading edge; c) smooth the skin down

onto the ribs; and d) use thick CA to join the skins at the

trailing edge.

Reinforce the wing panel joint with a 1-1/2” fiberglass

bandage and 15-minute epoxy.

Assemble the wing tip blocks, and glue them to the

wing. Shape the wing tips.

Shape the leading edge per the plan.

Cut out the ailerons. Glue a 1/8 x 3/8 balsa strip to the

leading edge of each aileron, then shape the leading edge.

Cover the wing as desired.

Install the ailerons using your choice of hinges.

Nacelles

Tape the nacelle plans to your building board and

cover with wax paper. NOTE that the nacelle plans show the

nacelles from the bottom looking up! Also NOTE that the

nacelle parts are lettered with an “R” or an “L” to designate

their use on either the right or left nacelle.

Decide now whether you will use a Speed-400 motor or

an outrunner motor to power your Ju 88 model. If you decide

to use a Speed-400 (or brushless inrunner) motor, you will use

the 1/16” balsa firewalls N1 and two 1/4” square hardwood

motor mounts.

If using an outrunner brushless motor, laminate the 1/16” ply

firewalls N1 to the front of the balsa firewalls using a

carpenter’s wood glue (NOT CA).

If you are using a Speed-400 motor, you can use either

screws or magnets to hold the cowl to the nacelle. If you are

using an outrunner motor, use magnets to mount the cowl. If

using magnets, glue scrap 1/16” balsa in place to cover the

rear of the magnet mounting holes on firewalls N1. Then use

epoxy to mount two small super-magnets in each firewall. (The

magnet mounting holes are the two horizontally-opposed

holes.)

Pin nacelle stringers N7 and N8 over the plan. Note

that these stringers are cut to fit the inside line shown on the

plan.

Use the 1/8” balsa N-JIG to set firewall N1 at the

correct angle and glue the firewall in place.

Fit and glue nacelle formers N2 thru N6 to the stringers

N7 and N8. Glue stringer N9 in place.

Assembly Manual for Junkers Ju 88

Copyright 2007 Thomas A. Jacoby and WarbirdKits.com 5

Glue 1/8” square balsa stringers in place between N1

and N6.

Plank the nacelle with 1/4" x 1/16” balsa strips. Begin

with the strip nearest the building board. Note that the strip

must tip inward to meet the formers – see the plan for a detail

sketch. This helps the plank correctly fit the shape of the

nacelle.

Laminate three N10 pieces together and glue them to

the rear of the nacelle.

Glue 1/4” long 1/8” diameter dowels in the vertically-

opposed holes in the firewalls N1.

If using Speed-400 motors, glue the two 1/4” square

hardwood motor mounts in place. Note – you can also use

these motor mounts to strengthen the firewalls for brushless

motors.

Glue the upper portions of N1, N2 and N3 to the

nacelle bottom. Add a 1/8 square balsa stringer between N1

and N3.

Sheet the upper portion of the nacelle from N1 to N3

with 1/16 balsa.

Cover the nacelle as desired. We suggest using 1/2-

ounce fiberglass cloth and epoxy finishing resin for extra

strength, as this is the part of the model that contacts the

ground upon landing.

Pull the motor wires through the wing and nacelle, and

out through the firewall. Glue the right-side nacelle to the wing.

Cut the nacelle fairing from 1/16 balsa and glue it in

place.

Repeat for the left nacelle.

Assembly Manual for Junkers Ju 88

Copyright 2007 Thomas A. Jacoby and WarbirdKits.com 6

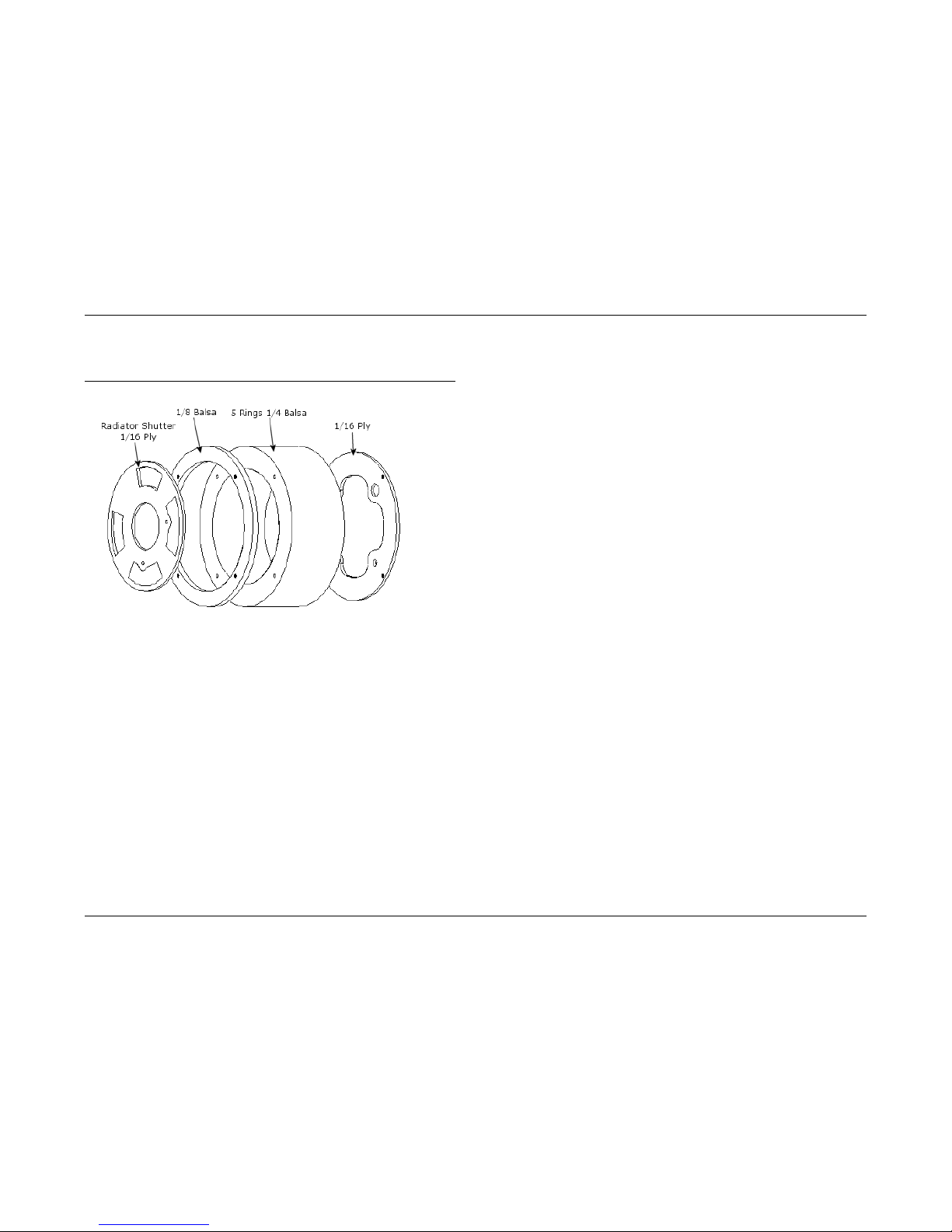

Cowlings

IMPORTANT:

* DO NOT CUT THE CENTERS OUT OF THE COWL RINGS

UNTIL YOU HAVE FINISHED SHAPING THE COWL.

* DO NOT GLUE THE CENTERS TOGETHER.

If using magnets to hold the cowl to the nacelle, install

two super-magnets in 1/16” plywood cowl mount C3 as

follows:

a. Glue scrap 1/16” balsa over the front side of C3

to cover the magnet holes.

b. Place a piece of wax paper over the nacelle

firewall.

c. Place a magnet over each of the two magnets

in the firewall.

d. Put one or two drops of epoxy in the magnet

holes on the cowl mount.

e. Place the cowl mount over the magnets so that

the magnets are in the magnet holes.

f. Pin, tape or weight the cowl mount in place until

the epoxy sets.

g. Remove the cowl mount from the firewall.

Glue the rear 1/16 ply mount C3, the five 1/4 balsa

rings C2, and the 1/8 balsa ring C1 together in the order

shown above. Use 1/16 wood dowels (cocktail skewer or

toothpick) to hold parts in alignment. The dowels should not

extend through the 1/8 balsa ring.

Sand the assembled cowl to shape. You can use a

long bolt and nut as a spindle to mount the assembled cowl in

a drill press.

Cut the centers out of the balsa and ply rings. This will

be easier to do if you temporarily remove the 1/16 ply mount

C3.

Glue the radiator shutter (forward 1/16 ply part) inside

the front 1/8 balsa ring.

If you are using outrunner motors, the cowl assembly is

complete. Skip forward to step 10.

Cut the two 1/4” square hardwood motor mount beams

to length, and slip them into their mounting holes on N1 and

N2.

Loading...

Loading...