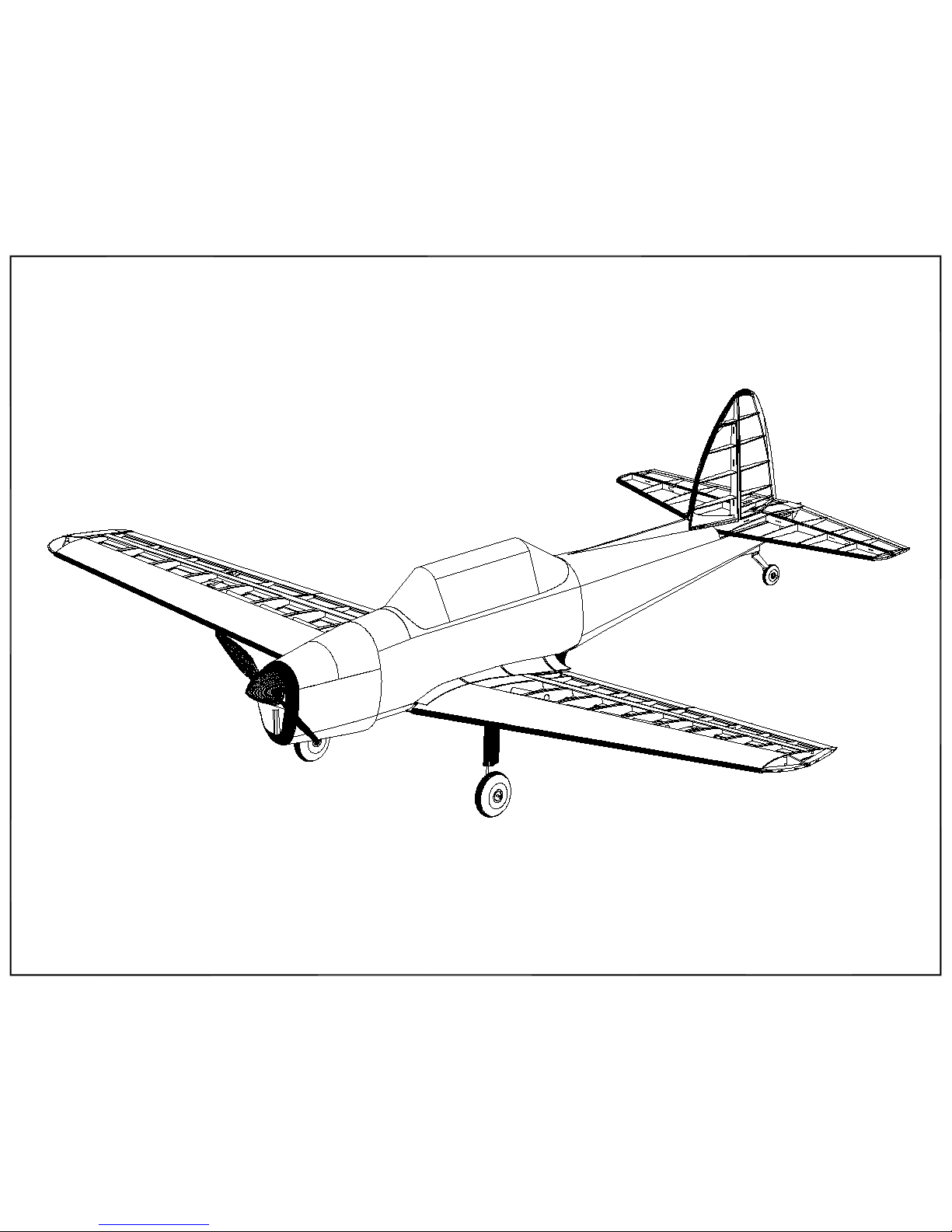

deHavilland DHC-1 Chipmunk

Assembly Guide

Manzano Laser Works

The Manzano de Havilland DHC-1 Chipmunk is based on a design developed by Ivan

Pettigrew.The structural design has been updated to take advantage of laser cut parts and to

help reduce the build time.

Construction of this model can be in any order preferred, but this assembly guide has been

organized to follow a suggested build sequence. That sequence begins with the tail surfaces

followed by the wing then the fuselage. This sequence is not critical but does facilitate

construction of the fuselage. Completion of the fuselage depends on having the wing and tail

surfaces available for shaping of some of the parts.

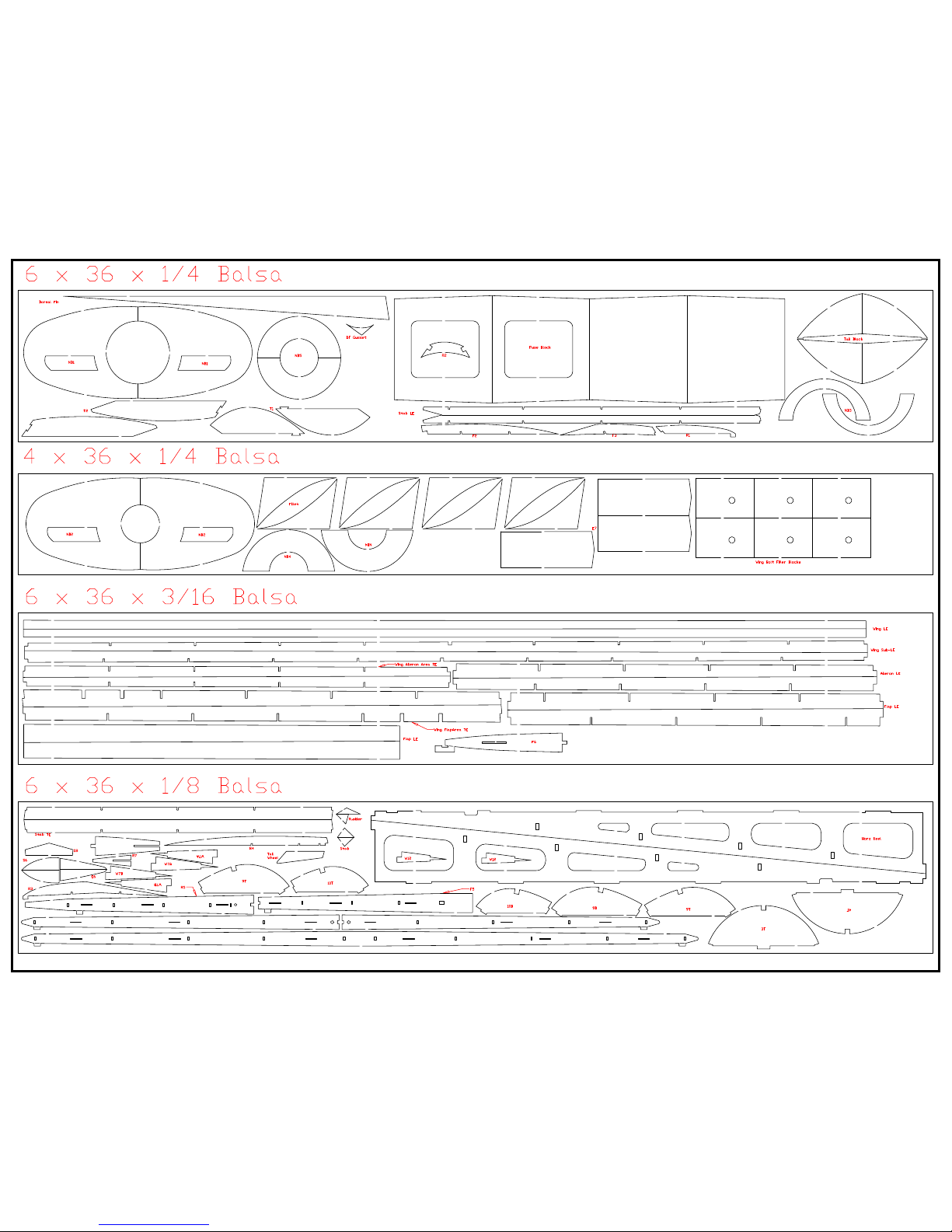

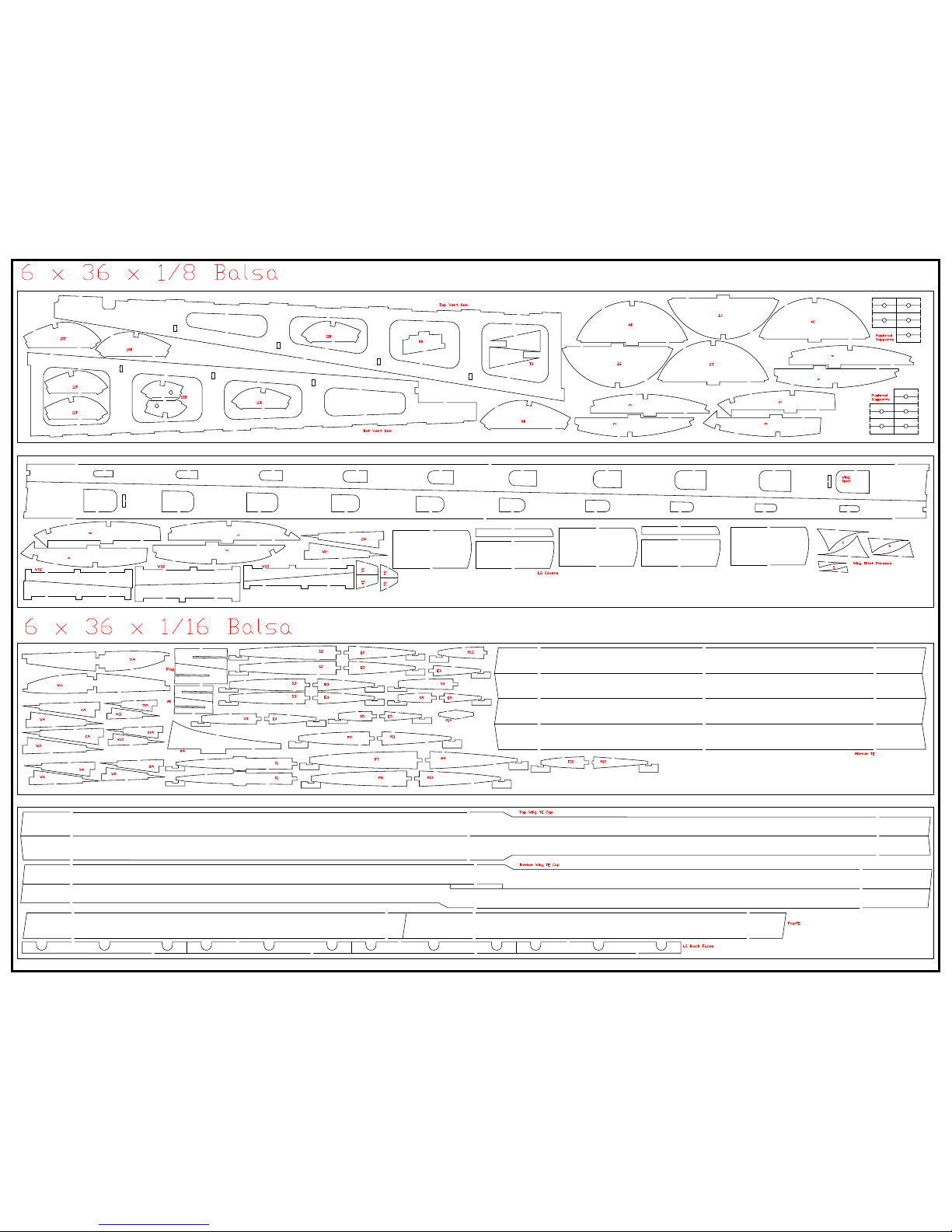

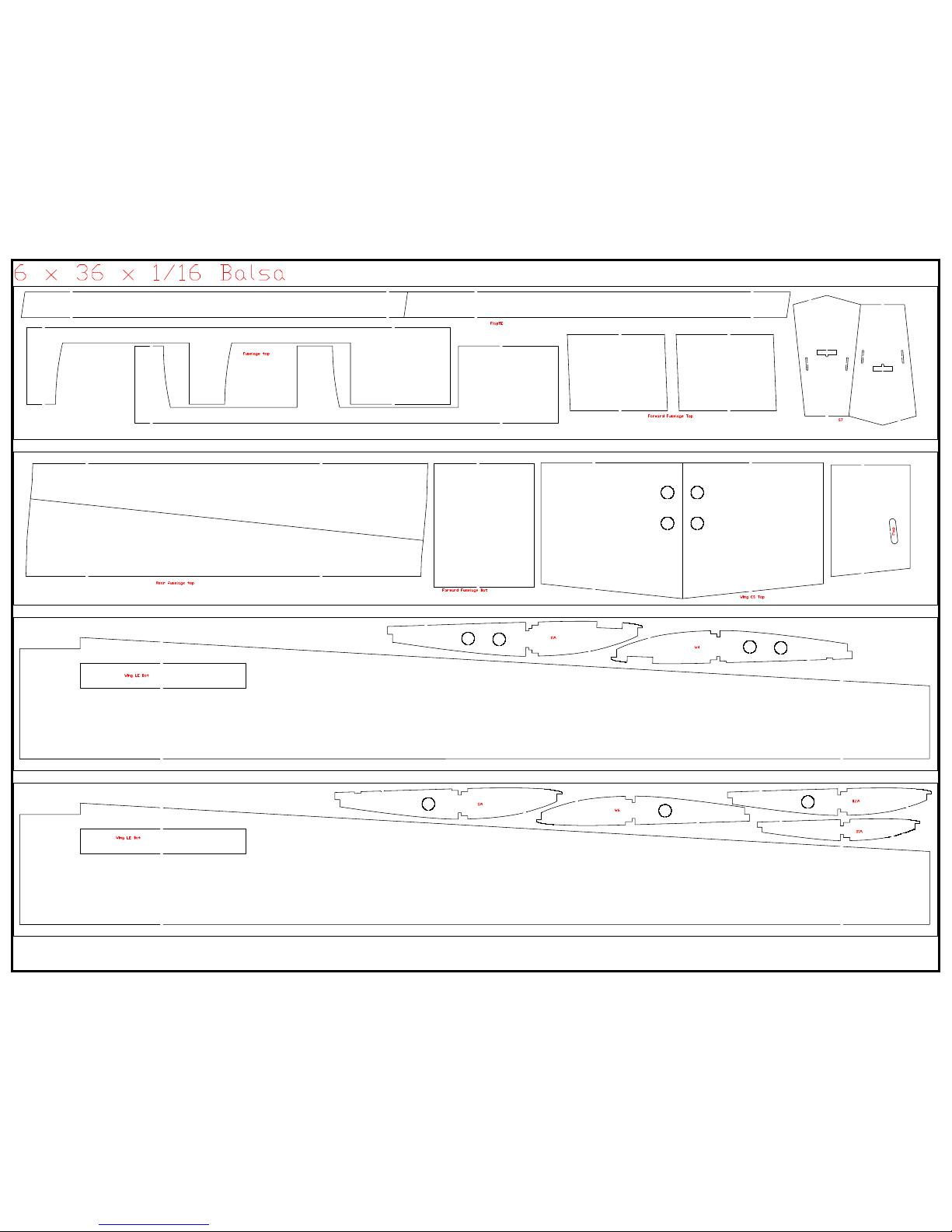

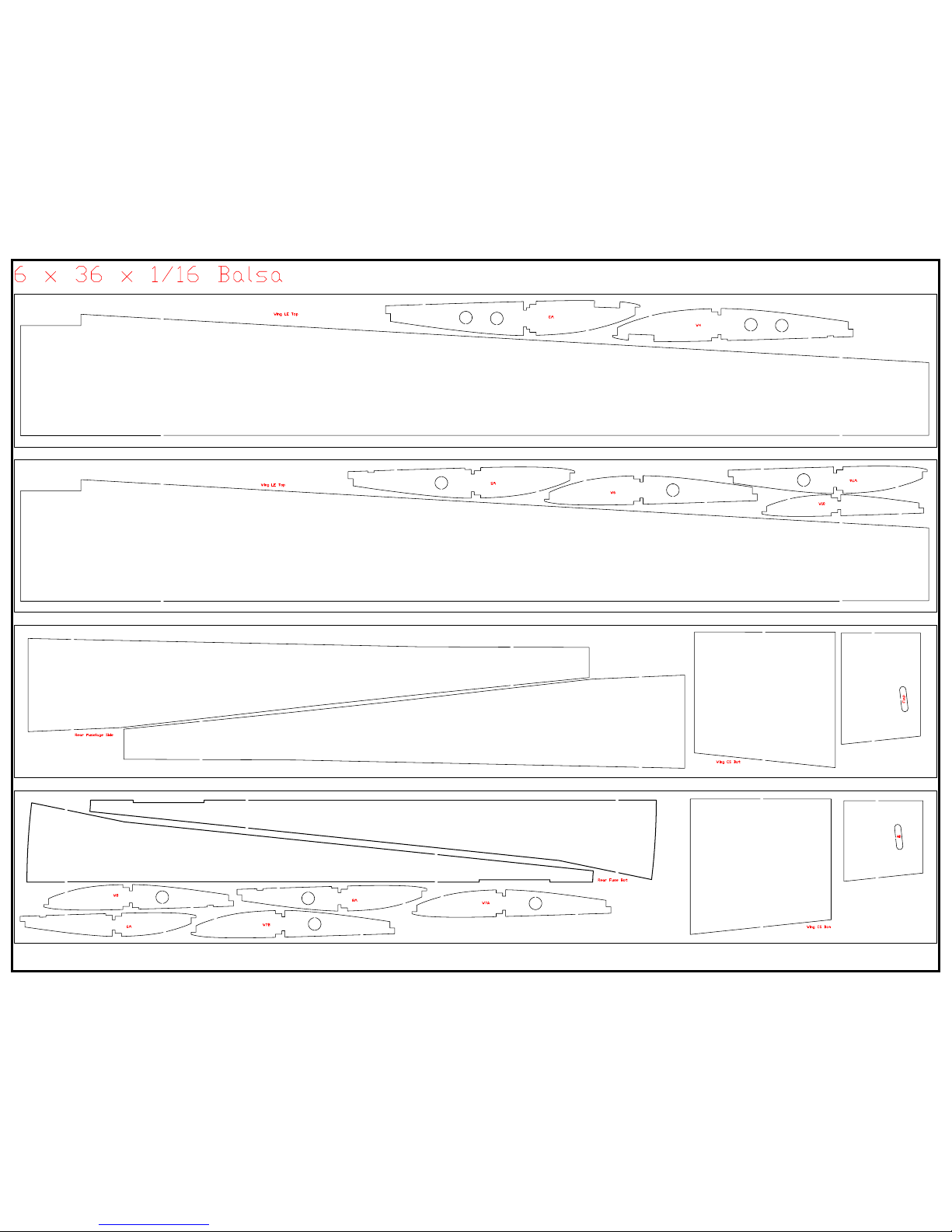

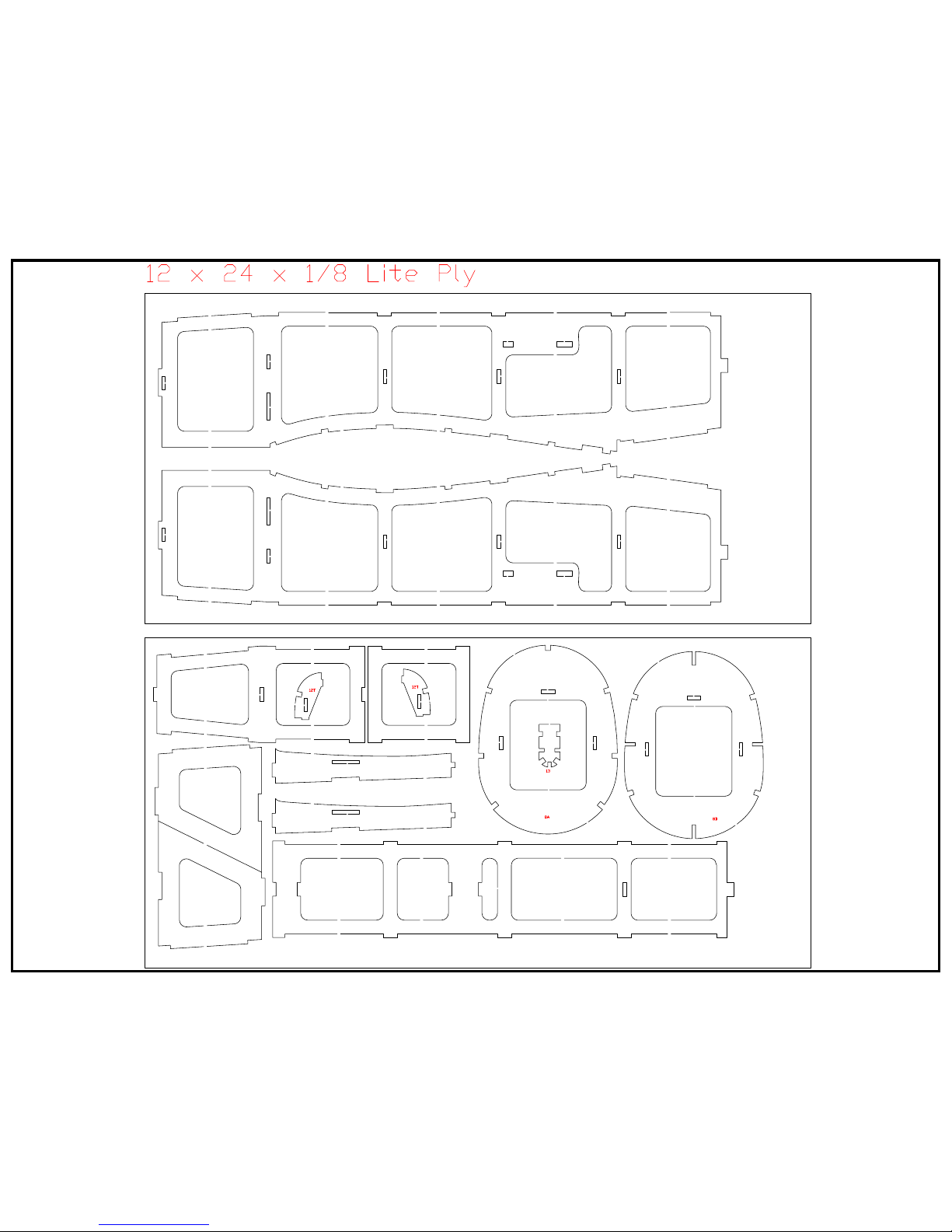

There are three 36” x 80” plan sheets for this model as follows:

Sheet 1 - Fuselage

Sheet 2 - Wing, Stab, Fin/Rudder

Sheet 3 - Sheeting and part layouts not included on the other plan sheets

Materials used in this model include balsa, liteply,plywood, brass tubing, and piano wire. A

formed plastic canopy is also used. Most of the wood and the formed canopy is supplied with

the kit. The builder supplies 3/16” and 1/8” square balsa strip stock, piano wire, brass tubing,

and the hardware needed to complete the model.

The completed model should have a flying weight in the 5 to 6 pound range. To provide a

reasonable power level for handling wind and take offs from rough terrain, a power loading of

at least 70 watts per pound is suggested. That translates to a motor/prop/battery selection that

can deliver at least 420 watts. The battery area of the model can accommodate up to four cell

lipo packs in the size range suitable for this model.

TAIL SURFACES ASSEMBLY

1.

Begin with the stab and elevators. Assembly begins by

laminating the spars. They are made up from a lamination of 1/8"

balsa and a lamination of 1/16" plywood.

Dry fit the stab ribs to the stab spar. Make sure the tabs on the

spar tips face down.The plywood laminations faces the r bs.

Place the assembly over the plan.

With the stab assembly lined up over the plan, dry fit the leading

edges to the r bs. They will lie flat on the rib tabs. The nose of

each rib fits in the leading edge notches. When everything is

properly aligned apply glue to all joints. Also glue the 1/8" balsa

joined to the center joint of the leading edge pieces.

2. 3.

4. 5. 6.

7. 8. 9.

Remove the stab assembly from the plan. The r b and spar tabs

can be removed at this time. The 1/16" balsa center section

sheeting will be installed during the final assembly steps.

Glue the stab tips to the assembly. The leading edge, tips, and the

back side of the spar can now be sanded to shape. Refer to the

plan cross section drawings for the shape of the spar back face.

The elevators are assembled using the same procedure as the

stab. Dry fit the r bs to the spars and then place on the plan. The

plywood side of the spars face the ribs. Add the trailing edge

pieces so the rear of each rib engages the notches. When

everything is lined up glue all of the joints.

Plywood boxes made from laminations of 1/32" plywood are used

to transfer the elevator control horn inputs to the elevator halves.

Glue the parts for each horn box and then install them in the

elevator halves. The tabs fit in elevator rib E1.

Remove the r b and spar tabs. Glue the elevator tips to the

assemblies. Sand the forward edge of each elevator half to the

profile shown on the plan cross section drawing. Sand the trailing

edge to a taper following the the rib top and bottom profile. Also

sand the elevator tips.

The fin and rudder assembly is very similar to the stab and

elevator halves. Begin by making up the fin and rudder spars.

They are laminated from 1/8" balsa and 1/16" plywood.

10.

Dry fit the fin ribs to the fin spar. Place the assembly over the

plan.

Glue the fin leading edge pieces F2 and F3 together. Place the fin

leading edge on the ribs making sure the nose of each rib is fully

seated in the notches. The leading edge will rest on the tabs. When

everything is lined up, glue all the joints.

Glue the fin gusset to the assembly.

11. 12.

13. 14. 15.

16.

17. 18.

Remove the rib and spar tabs from the fin assembly. Shape the

leading edge and the rear spar face to the profile shown on the

plan cross section drawing.

Dry fit rudder r bs R9 through R12 to the rudder spar. Place over

the plan. Glue the rudder trailing edge parts R3 and R4 together.

Place the rudder trailing edge on the assembly. When every thing

is lined up glue the joints.

Dry fit rudder rib R8 to the assembly. Confirm the fit and alignment

and then apply glue to the joints. Make up rib R7 from the two

halves and the key. Sand a bevel on the forward face of the rear

half of R7 to match the plan profile. Glue the halves together using

the balsa key to align and strengthen the joint. Sand the forward

half of R7 to match the joint angle. Install R7.

Dry fit the rudder tip parts R1 and R2. When satisfied with the fit

glue the joint. Place the rudder tip on the assembly. R2 should be

centered on R3. When satisfied with the fit apply glue to the joints.

Also glue the gusset to the assembly.

The rudder horn box is made from 1/32" plywood laminations. The

core is three laminations. Build the rudder horn box and glue it to

rib R8 and the back face of the rudder spar.

Remove the r b and spar tabs. Sand the trailing edge to a taper

following the rib profiles. Shape the tip and sand the front face of

the spar to the profile shown on the plan cross section drawing.

This completes the assembly of the stab, elevator halves, fin, and

rudder. After they are covered CA hinges are use to mate the

surfaces. The balsa dorsal fin is shaped and installed on the model

during final assembly.

WING ASSEMBLY

1.

The wing assembly begins by laying a 36" strip of 1/8" square

balsa over one side of the wing plan in the location shown on the

plan. This strip generates the tip washout as the wing is built on

top.

Glue the 1/16" plywood doublers to ribs W3 and W4.

Layout one set of ribs W2 through W11 and one of the 1/8" balsa

sheet wing spars. Slide the ribs through their corresponding

openings in the spar and then twist them to be vertical. DO NOT

GLUE.

2. 3.

4. 5. 6.

7. 8. 9.

Fit the sub leading edge over the steps on the nose of each wing

rib. Make sure the sub LE is fully seated on each rib step. DO

NOT APPLY ANY GLUE YET.

Lay the UNGLUED assembly over the plan. Place r bs W2A and

W12. Slide the aileron and flap area trailing edge pieces on to the

rib steps making sure they are fully seated on each step. Again, DO

NOT glue anything yet.

Check the alignment of all the wing half parts relative to the plan.

Also make sure all of the ribs are touching the building surface and

the 1/8" square strip. A few straight pins can help make sure

everything stays in the proper place. Apply thin CA to all of the

joints.

Make up four paper tubes that are 1/2" in diameter. Allow for a bit

of overlap when rolling the tubes. Two of the tubes need to be 20"

long and the other two 7" long. Slide one of the long tubes into the

forward set of holes in the ribs. Slide a shorter tube into the other

set of wing r b holes. Apply a small amount of glue to each rib tube

interface.

Place rib W1 and parts W13 and W14. When satisfied with the fit

glue them in place. When the glue is set remove the assembly

from the building surface for the next step.

The 1/4" x 1/8" spar caps are now installed. It is recommended

that an air dry glue such as Elmer's Carpenter Glue or Titebond be

used. Apply some glue to the forward face of the spar where the

cap will go and to each rib notch. A.after the spar caps are in

place, lay the assembly on the plan over the washout strip to dry

W4

W3

Note that W7A and W7B are

together in the same spar slot

W13

W14

10.

Remove the structure from the building board. Sand the top and

bottom edges of the sub leading edge and trailing edges so they

match the contour of the ribs. Be careful not to sand the ribs.

Applying a strip of masking tape along the top and bottom of the

ribs just behind the sanding area is a good way to protect them.

Glue the trailing edge cap pieces to the wing. Make sure you use

the top piece on top.

Make up the two landing gear mounting blocks. They are made

from two laminations of 1/8" plywood with a 1/16" balsa face.

The balsa face can be sanded to match the bottom leading edge

sheeting.

Glue one of the landing gear mount blocks to the wing half. Use

the notches in r bs W2, W3, and W4. The hole goes toward the

wing root. Epoxy is recommended as the adhesive.

11. 12.

13. 14. 15.

16.

17. 18.

Cut and fit the top leading edge sheeting. Use an air dry glue l ke

Titebond for this step. Place the wing panel on the building board

over the plan when gluing the top leading edge sheeting in

place. This will help lock in the tip washout.

Remove the wing panel from the building surface. Cut and fit the

bottom leading edge sheeting. Glue it in place. Check to be sure

the tip washout has not been altered before the glue dries.

Glue the wing bolt reinforcement 1/4" balsa laminations together.

Fit and glue the filler block to the wing panel. Shape the filler

block to match the top and bottom r b contour.

Using 1/16" x 1/4" balsa strip stock, cut and glue a cap strip to the

top and bottom of wing ribs W4 through W12.

Install the 1/16" plywood servo tray rails in the flap servo rib bay

formed by W4 and W5, and the aileron servo bay formed by ribs

W8 and W9.

Install the leading edge piece. Next install the wing tip pieces.

Sand the leading edge and tip to their final shape.

Place a piece of 1/8" diameter piano wire next to

the first lamination before gluing the second

lamination. Remove the piano wire when both top

lamination pieces are in place.

Fit the bottom center section sheeting. Using the wing bolt holes

as a guide, from the top drill the bolt holes in the bottom sheeting.

19.

20.

21.

22. 23.

24.

25.

Make up each aileron and flap control horn assembly. Glue them

to the plywood rib in each aileron and flap. Also glue the balsa

pieces that provide a covering platform around the control horns to

the bottom of each assembly.

Build the ailerons and flaps over the plan. Dry fit the ribs to the

notched leading edge parts. Place the assemblies over the bottom

trailing edge pieces. Glue when aligned. Be sure to taper the rear

edge of the bottom trailing edge pieces. Note that the flap leading

edge is two pieces. Glue the forward piece to the assembly after

the other parts have been glued together.

Sand the leading edge of each aileron and flap assembly to the

profile shown on the cross sections provided on the wing sheet of

the plan set.

Also sand the wing trailing edge in the aileron area to the profile

shown by the plan wing cross sections.

Build the second wing panel following steps 1 through 18 of this assembly guide section. The two wing panels are joined using two 1/8"

plywood doublers. Use epoxy to join the wing panels. Glue the center wing dowel to one wing panel before joining both panels. With one

wing panel laying flat on the building surface, the opposite tip should be 6" above the surface.

6" at the base of W12

Fit the top center section sheeting. Sand a taper at the rear of the

rearward piece to mate with the bottom sheeting. Using the wing

bolt holes as a guide, from the bottom drill the bolt holes in the top

sheeting.

Taper

Taper

Aileron

Flap

Add pieces of 3/16 balsa to the back face of the flap leading edge and wing trailing edge where the flap hinges will be installed. Refer to

the plan for this step. Robart hinge points are used for the flap hinges. Refer to the wing plan cross section drawings to see the proper

orientation of the hinge points. Drill the flaps and wing trailing edge for the hinge points. Dry fit the flaps to the wing. Make sure they will

rotate down freely and then remove them and the hinge points from the wing.

26. 27.

This completes the wing structural assembly. The ailerons and flaps are installed after they and the wing are covered. Make sure the flaps still rotate down freely after the hinge points have been

glued. CA hinges are used for the ailerons.

After the ailerons and flaps have been installed, mount servos to the servo trays. Servo extenson leads will be necessary for the servos.

Route the servo leads through the servo lead tubes starting from the servo bays. Pull the connectors through the appropriate holes in the center section top sheeting.

Mount the servo trays using four wood screws in the corners of the trays.

28.

29.

Bend the landing gear legs using 1/8" diamater piano wire.

Place the landing gear legs into the slots of the landing gear

mounting blocks. Place a plywood retaining lug in the pockets of

the mount block. Mark the location of the retaining screws. After all

of the screw locations have been marked, dirll pilot holes for the

screws. Run screws into each hole.

Make up the four servo trays using the 1/32" plywood and 1/16"

balsa tray laminations. The flap and aileorn trays are different in

size so be sure to match the appropriate part pairs. Set the

laminations so there will be a right and left tray. The balsa

lamination faces the outside of the wing. The servo mounting lugs

are the same for all four trays.

FUSELAGE ASSEMBLY

1.

Fuselage assembly begins with the internal liteply box.

Assemble the sides, top pieces, and formers 3B, 4B, and 7B.

Dry fit all the parts before adding any glue.

Add the bottom internal box piece that fits behind 7B.

Install the top, side, forward, and rear formers. These are a

combination of balsa, plywood, and liteply parts.

2. 3.

4. 5. 6.

7. 8. 9.

Install the battery pack tray. Place one tabbed end in the notch

of 4B and then rotate the other end down so the tab fits in the

the notch in the bottom of the forward bulkhead.

Install 3/16" square balsa stringers in the slots of the formers. The

outer edges of top formers 3T,4T, 4C, 5T, and 6T are glued to the

stringers that run parallel to the top of the internal liteply box.

Install parts 4S and 7S on each side of the fuselage in the

locations shown. The bottom edge of each part is flush with the

top of the notches in the wing saddle area next to side formers 4

and 7. The parts should be on the wing saddle side of each side

former.

4S

7S

Assemble the two sets of wing saddle parts WS1 through WS3.

The wing saddles are then glued to the fuselage internal box and

the bottom of the side formers. The tabs on the wing saddles fit in

the notches of the liteply box sides. The bottom of formers 5 and 6

along with pieces 4S and 7S match the dihedral angle.

Assemble the motor mount. The mount is set up so the length can

be adjusted for the motor being used. The inner box can slide fore

and aft in the outer box. DO NOT GLUE the inner box in the outer

box until it is time to install the motor. Please note that the inner

box sets the right thrust. Make sure the top and bottom pieces

have the same orientation relative to the slanted faces.

Glue the motor mount outer box to the forward fuselage bu khead.

The tabs of the motor mount box fit in the corresponding slots in

the nose former.

WS1

WS2

WS3

10.

Assembly of the rear fuselage begins by gluing the 1/8" balsa

vertical keel parts together.

The horizontal 1/8" balsa keel pieces are glued in place after the

vertical pieces are glued together. The tabs fit in the vertical keel

slots.

Glue the rear fuselage formers to the keel parts. Use the slots in

the keel parts to locate each former segment. The rear former 13

is not installed at this time.

11. 12.

13. 14. 15.

16. 17. 18.

Bend the tail wheel leg using 3/32" piano wire. Be sure to place

the length of 1/8" brass tubing on the leg above the 90 degree

bend before bending the pushrod tiller arm. Make up the

pushrod link end from 1/8" brass tubing and solder it to the tiller

arm. Bind the brass tubing on the leg to the 1/8" plywood center

tail wheel support piece. Glue the 1/32" plywood face support

face pieces to the center support piece. Be careful not to get any

glue in the pivot tube.

Glue part KE to the bottom of the horizontal keel pieces at the rear.

Use the slot formed by the horizontal keel pieces to locate KE.

Glue the tail wheel assembly to the lower vertical keel. The brass

tube fits in the slot formed by the rear of the vertical keel and part

KE. The tail wheel leg should rotate freely without any interference

from the structure.

Bend the rudder control horn using 3/32" piano wire. Slide a 1 1/8"

length of 1/8" brass tubing on the wire after bending the push rod

link end and before bending the rudder tiller arm. Slide the 1/8"

plywood rudder horn support pieces on to the assembly as shown.

DO NOT APPLY ANY GLUE. These parts can slide freely for now.

Dry fit the rudder horn assembly and stab saddles to the rear

fuselage keel assembly. Also dry fit former 13 to help place the

stab saddles. DO NOT GLUE former 13. Adjust the vertical

position of the rudder horn brass tubing so the pushrod attachment

end is far enough below the horizontal keel pieces to clear a

clevis. When the stab saddles and rudder horn assembly are in

place glue those parts being careful not to glue former 13. Remove

former 13. Glue strips of 1/8" square balsa to the sides of the tail

wheel support assembly with the edge lined up with the bottom of

the vertical keel.

Make up and install the link between the rudder horn and tail

wheel. It is suggested that one threaded and one solder celvis be

used for the link ends.

Glue the rear fuselage structure to the forward section. The slots in

rear section former 8B fit over the tabs extending from forward

section former 8A.

8B

9

10

11

12

1/8" Brass tubing

KE

8A

8B

19.

Install the servo rails and then the servos. The servo rails are

three laminations of 1/16" plywood. They slide in to the slots

from the side. The rear slot is longer than the servo rail width to

allow for length adjustment.

Bend the elevator and rudder pushrods from 2-56 threaded

pushrod stock. Use the plan templates. Use solder clevises on

the rudder and elevator ends of the pushrods. Before making the

forward bend in the elevator pushrod slide a 16" length of

pushrod sleeve over the pushrod.

From the forward side of former 12, slide a 16" length of pushrod

sleeve under the horizontal keel piece through the hole in former

12. With the threaded clevis removed, slide the rudder pushrod

into the sleeve from the rear. Install the threaded clevis. Attach

the rudder horn clevis and then the servo clevis to their

respective control arms. The sleeve supports will be added

later.

20. 21.

22. 23. 24.

25. 26. 27.

Slide the elevator pushrod assembly into the fuselage from the

rear. It must pass to the right of the rudder control horn as

viewed from the rear. Connect the servo end clevis to the servo

output arm. The elevator pushrod assembly will get supports in

the next step. Length adjustments will be made later.

Install 3/16" square balsa stringers on the rear fuselage section

using the notches in the formers. The top stringer will need to be

tapered at the rear. The taper should start from about 5 1/2" from

the rear end of the top stringers.

The push rod supports are made from two pieces of 1/8" balsa. To

accommodate the variations in individual builds, the supports are

trimmed to fit each location. They are glued to the vertical and

horizontal keel pieces. Install a support at each fuselage former

location on both the rudder and elevator pushrods. Also glue

former 13 to the rear of the fuselage.

The bottom section of the fuselage right behind the wing saddle is

filled with a balsa block made from laminations of 1/4" balsa. That

block is installed after the fuselage sheeting has been added.

Make up the block at this time.

Also make up the laminated fuselage rear tail block. It is installed

and shaped after the fuselage 1/16" balsa sheeting has been

installed.

Elevator

Rudder

Solder

Clevis

Threaded

Clevis

Servo End

13

Taper this stringer

Install the 1/32" plywood cockpit floor pieces.

The wing bolt plate is three laminatons of 1/16" plywood. Glue the

laminations together and then glue the wing bolt plate to the

fuselage using epoxy. The tabs on the wing bolt plate fit in the

slots in the wing saddle. The bolt holes are drilled with the wing in

place on the wing saddle.

The fuselage is covered with 1/16" balsa sheet. Patterns have

been provided on the plan to help cut each sheet section to the

proper size and shape. Making up paper patterns before cutting

any balsa is a good idea to help make sure the pieces will fit the

target section properly.

After the fuselage sheeting has been installed, the filler block

behind the wing saddle is glued in place. It is shaped when the

fuselage sheeting is sanded. The edge of the filler block that

mates to the wing needs to be sanded to the wing bottom profile.

That is done by mounting the wing in the wing saddle and then

performing the final shaping of the filler block mating edge.

Balsa sheet is used under the stab to fill the area between the stab

saddle and the fuselage sheeting.

Glue the rear tail block to former 13 and shape the block.

Use cowl parts C3T and C3B for this step. Place 3CT on top of the

forward internal fuselage box just forward of former 3. Mark the

location of the notch in C3T where it strikes the top of the internal

fuselage box. Remove C3T and glue the cowl retaining lug stand

off to the fuselage box and former 3T using the mark as the

location guide. Glue the lug face to the stand off. Repeat the

process with C3B on the bottom of the fuselage box.

28.

Using the templates provided on the plan, cut the 1/16" balsa

sheeting for the cowl halves.

After the sheeting has been applied to the cowl halves, glue the

nose block laminations together. A 1/16" plywood half ring is

glued to the front face of each nose block half. Glue the nose

block halves to their respective cowl halves. The nose blocks are

then shaped and the cowl halves are final sanded.

29. 30.

31. 32. 33.

34. 35.

There are four pairs of 1/4" x 1/8" magnets that are used to

retain the cowl. Install the magnets at this time. Glue a magnet in

each of the holes in the lower cowl half keel parts. Place a

magnet on the installed units. Mark the outer face of the second

set of magnets. One at a time, remove the second magnet and

glue it in the corresponding hole of the upper cowl half. The

marked face will go toward the inside of the cowl half.

The motor can now be installed. Mount the motor to the internal motor mount box. Make sure the orientation of the motor mount box is

set so the motor will have right thrust. Slide the motor mount box into the outer box that is attached to the fuselage. Place the cowl on

the model. Slide the motor back until you have the proper clearance between the spinner and forward edge of the cowl. Carefully

remove the cowl and mark the location of the motor mount on the motor mount box. Apply some epoxy to he outer faces of the motor

mount box and slide it back onto the outer box on the fuselage to the marks. Before the epoxy sets put the cowl back on to make sure

the spinner gap is still correct.

The finished cowl is installed on the fuselage by placing the back

face of each half against fuselage former 3. Each half is then slid

vertically until the bottom edge of the rear cowl formers engage

the retaining lugs on the fuselage. The magnet pairs keep the cowl

from separating in flight. To remove the cowl simply slide each half

up and down to disengage the retaining lugs.

C3B

C3T

Mark Here

Build the cowl halves by placing the cowl keel parts over the

plan. The upper cowl half keel parts have wider notches in the

middle. Glue the formers to the keel parts. Add 3/16" balsa

stringers. For the upper cowl half, the stringers need to be two

pieces. This will eliminate bending stress that can distort the

upper cowl half.

Note: There are 2

C2T formers

Mark this face

FINAL STRUCTURAL

ASSEMBLY

1.

Before covering the model there are a few final assembly steps

to perform. They begin with the installation of the wing fillets.

Glue the 1/32" plywood fillet base pieces to the bottom face of

the wing saddles.

To help define the shape of the fillets, balsa pieces are glue to

the fuselage and fillet bases at former locations 5, 6, and 7.

The area between the fillet shape formers is filled with balsa and

light weight spackle. When the spackle is fully dry sand it to

shape using the shape formers as a guide. A piece of 1 1/2"

dowel wrapped with sandpaper is a good tool to use for the

sanding.

2. 3.

4.

5.

The rear portion of the fillets from the wing trailing edge is

created using a balsa block made from 1/4" balsa laminations.

Shape the block to fit the fuselage. It can then be glued in place.

The curved surface can be created by sanding with the same

dowel and sandpaper tool used in the previous step.

Next the stab is installed. Before performing that operation connect the elevator control horn to the elevator pushrod clevis. Slip one of the balsa stab center section sheeting pieces over the rudder

horn. Place the stab over the rudder horn on top of the center section sheet. Glue the bottom center section sheeting to the stab. The tabs on stab ribs S1 align the sheeting. Mount the wing to the

fuselage and place the assembly on a flat surface like the floor. Block the wing tips so they are both the same height off the surface. Make sure the stab is centered on the saddle and check to see

that the distances from each tip to the surface are the same. Adjust if necessary by carefully sanding the stab support pieces. Check the distance from each stab tip to the corresponding wing tip.

When both distances are the same place reference marks on the stab. Use an air dry glue and glue the stab to the fuselage. Some masking tape can be used to hold the stab while the glue dries.

Before the glue dries double check the stab alignment.

Equal

Equal

6.

7.

8.

9.

Dry fit the stab top center section sheeting piece to the stab. Slide the fin spar base through the cutout in the top and bottom stab sheeting. With the fin resting on the stab check the alignment to be sure the fin

is vertical and the fin center line is aligned with the fuselage center line. When satisfied with the alinement glue the stab top sheeting to the stab. Remove the fin from the stab. Apply some air dry glue to the fin

spar base where it contacts the top rudder horn support and stab center section sheeting. Also apply glue to the bottom face of fin rib F6. Slide the fin into position and let the glue dry.

Sand the dorsal fin to the cross section shown on the plan. Dry fit

the dorsal fin to the fuselage and fin. When the fit is satisfactory

glue the dorsal fin to the fuselage and fin.

Glue the three 1/4" balsa elevator filler laminations together. Sand

the assembly to match the elevator root rib profile. Temporarily fit

the elevators to the elevator horn. They can be retained with

masking tape. Glue the elevator filler piece to the fuselage with it

centered between the elevators. Remove the elevator halves.

10.

The landing gear leg covers are made from three laminations of

1/8" balsa. Glue the center pieces to one side of the lamination

set. Use rubber cement to glue the other side of the lamination

set to the assembly. Sand the assembly to a streamlined cross

section. Separate the rubber cement joint and rub off any rubber

cement that remains. Place the covers on the landing gear legs

and then glue the lose outer piece to the assembly. Apply glue to

the landing gear leg as well.

This completes the structural assembly. The model is covered followed by installation of the control surfaces and radio equipment.

The CG location is shown on the plan. Be sure to check the balance with the battery pack that will be used in place.

Use rubber cement

for this lamination

Loading...

Loading...