Manusa VECTOR Installation Manual

Installation Manual

VECTOR Operator

1

D00619EN - v0 VECTOR OPERATOR - INSTALLATION MANUAL

TRANSLATED DOCUMENT

0 CONTENTS

Read thoroughly all of these instructions before installing

the operator

Keep this manual in a safe place for future reference

This manual is meant exclusively for professional installers.

Installation Manual

VECTOR

1. PRODUCT IDENTIFICATION

1.1 Product Description

1.2 Symbol Description

1.3 Versions

1.4 Product EC Marking

1.5 Noise Statement

1.6 Radiation, Gas, Fumes and Dust Produced

by the Machine

1.7 Use in Flammable and/or Explosive Environments

1.8 Accessories

2. TRANSPORTATION, STORAGE AND MAINTENANCE

2.1 Machine Delivery Conditions

2.2 Transport Conditions

2.3 Storage Conditions

3. TECHNICAL DATA

3.1 General Dimensions

3.2 Technical Specifications

3.3 Low Energy

3.4 Operation

3.4.1 ON-OFF Switch

3.4.2 Mode Selection Switch

3.5 Installer Instructions

3.6 Decommissioning, Dismantling and Removal

3.7 Intended Use and Uses that Should be Avoided

3.8 Application Limitations

4. PRE-INSTALLATION

4.1 Training Requirements for Installation Technicians

4.2 Physical and Environmental Requirements

4.3 Electrical Pre-installation Requirements

5. INSTALLATION

5.1 Type of Arm that Can Be Installed

5.2 Installing the Operator

5.3 Positioning Levels for the Fixing Holes

5.4 Extendable Rigid Arm Installation

5.4.1 Rigid Arm and Guide Installation

5.5 Installing the Pushing Articulated Arm

5.5.1 Attaching the Arm to the Leaf

5.6 Spring Adjustment

5.7 Selecting Breaking Level without Power

5.8 Testing Operations

5.9 Connecting to the Power Supply

5.10 VECTOR Electronic Card

5.11 Electronic Connections

5.12 Arm-Type Selection

5.13 Connecting the Controls/Inputs

5.14 Connector to Auxiliary Outputs

5.15 Installing and Acquiring the Sensors

5.16 Dip-Switch Management

5.17 Display Management

6. COMMISSIONING

6.1 Start-up

6.2 Management and Use

6.2.1 Operational Logic Settings

6.2.2 Management of Electronic Locks

6.2.3 Program Switch Connector

6.2.4 External Peripherals Connectors (15 VDC)

6.2.5 Double Vector Connection and Use

6.2.6 Interlocking Connection and Use

6.2.7 Connection to a PC

6.2.8 Normal Stop and Emergency Stop

7. SAFETY

7.1 General Safety Instructions

7.2 Required Personal Protection Equipment

7.3 Identifying Dangerous Areas in the Machine

7.4 Risk Evaluation

7.5 Safety Regulations

8. MAINTENANCE AND INSPECTION

8.1 General Maintenance to be Performed by the User

8.2 Maintenance Tasks Exclusively Reserved for

the Manufacturer

9. TROUBLESHOOTING

10. APPENDIXES

10.1 EC Declaration of Conformity

10.2 Installation Check-list

10.3 Maintenance Book

10.3.1 Frequency of Interventions

10.3.2 Actions Log

10.4 Notes

2

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

CARACTERÍSTICAS MECÁNICAS

1 PRODUCT IDENTIFICATION

The manusa VECTOR swing operator has been especially designed to make fast, safe and controlled access of persons to

all types of facilities possible.

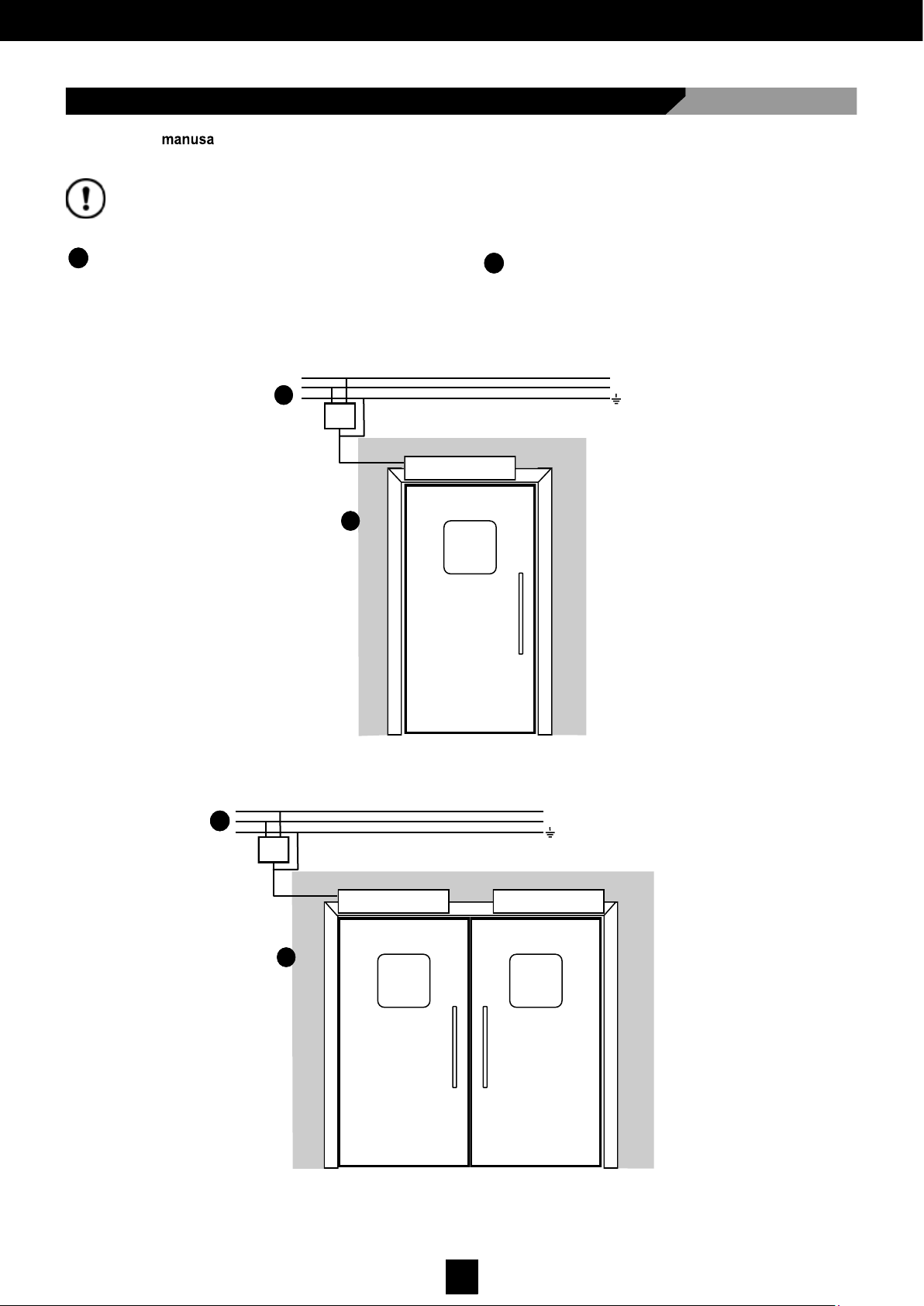

It is an operator for automatic swing doors with high traffic flow, available with dragg or push arms for single-slide and biparting door versions.

VECTOR is an advanced electromechanical operator used for the automation of any type of new or existing swing door.

It is a highly-efficient, high-performance operator, especially designed for intensive use, as it can automate both light and

very heavy doors.

manusa VECTOR is also recommended for hermetic doors for clean rooms, and for environments with strong winds,

thanks to its specific operating modes.

Other main features:

- Compact design, with minimum aesthetic impact

- Formal and attractive design with pleasant lines

- Door closing by means of an motor-assisted spring in normal operation

- Door closing by means of a spring in case of power supply failure

- Available modes for Low Energy and Push&Go activation

- Easy installation and monitoring thanks to its built-in double display

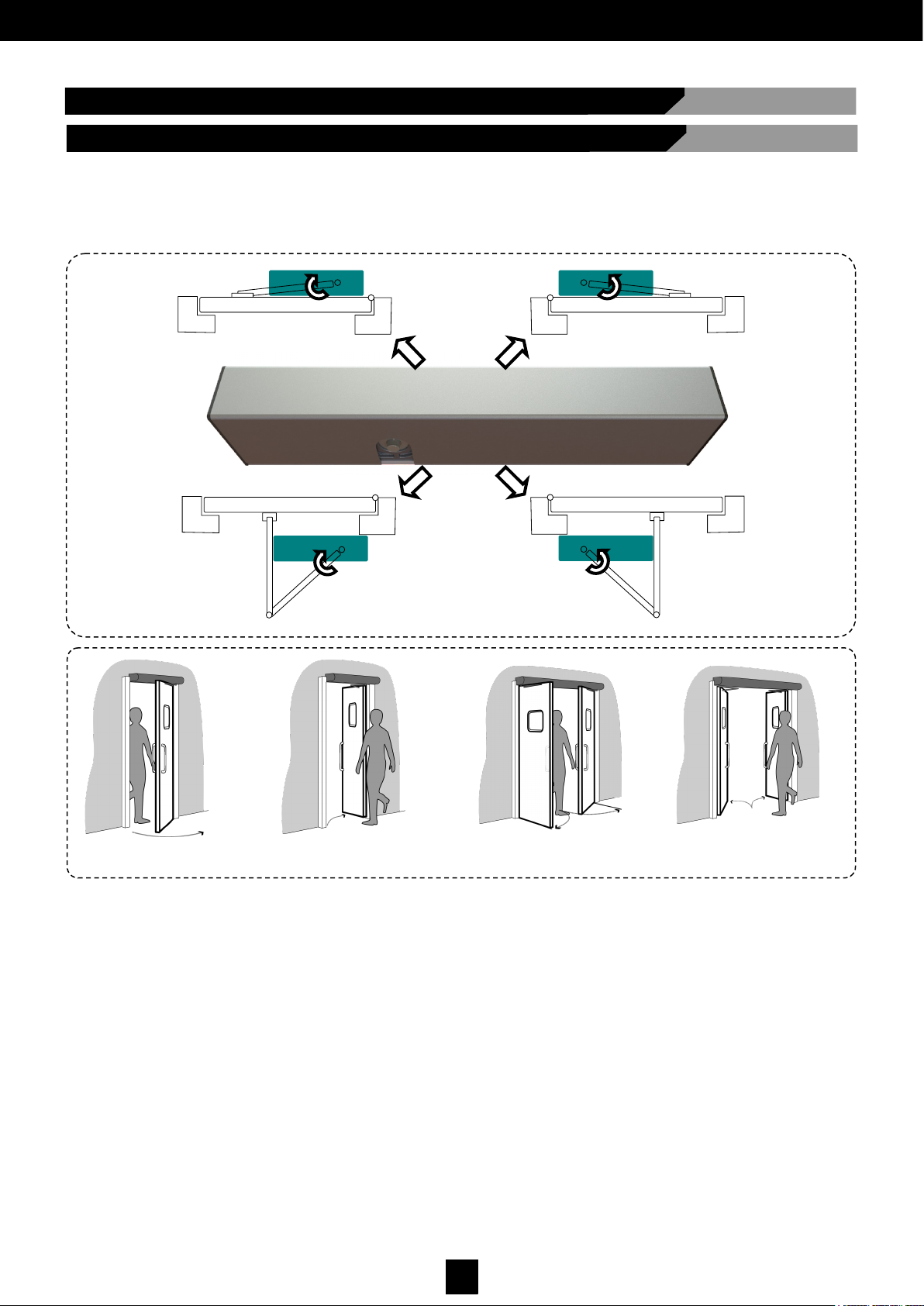

Single + Pull arm Single + Push arm Bi-parting + Push arm Bi-parting + Pul arm

1.1 Product Description

3

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

This manual details all the basic instructions for assembling the automatic door. Read it thoroughly and, when in doubt,

contact the Technical Support Department (see back of the manual).

For your own safety, adhere at all times to all the technical instructions detailed in this manual. manusa accepts no

responsibility for damages and faults derived from not complying with these instructions.

Finally, we would like to thank you for your trust in acquiring a product from the manusa range, a company with more than

50 years experience designing, manufacturing and installing automatic access systems.

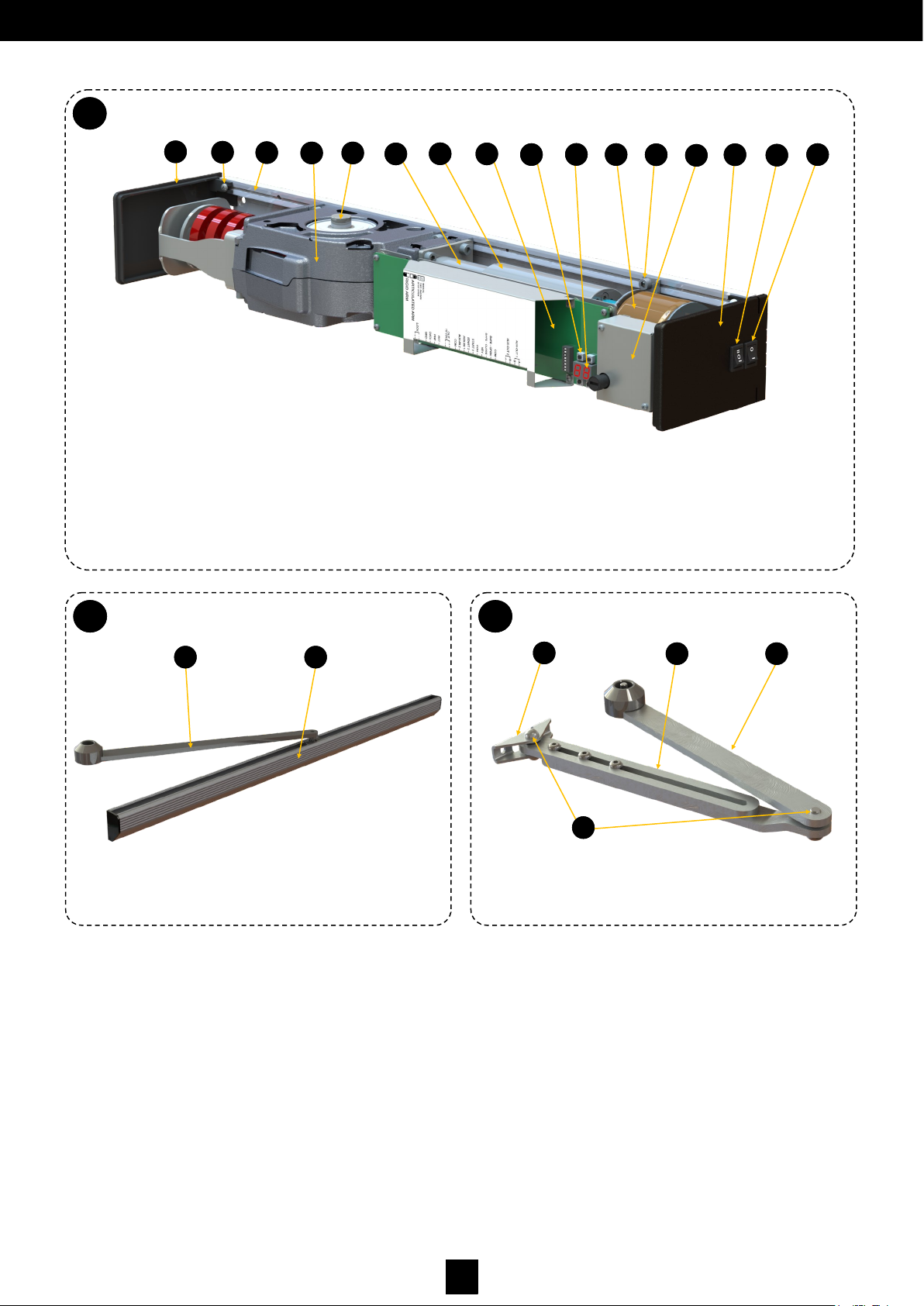

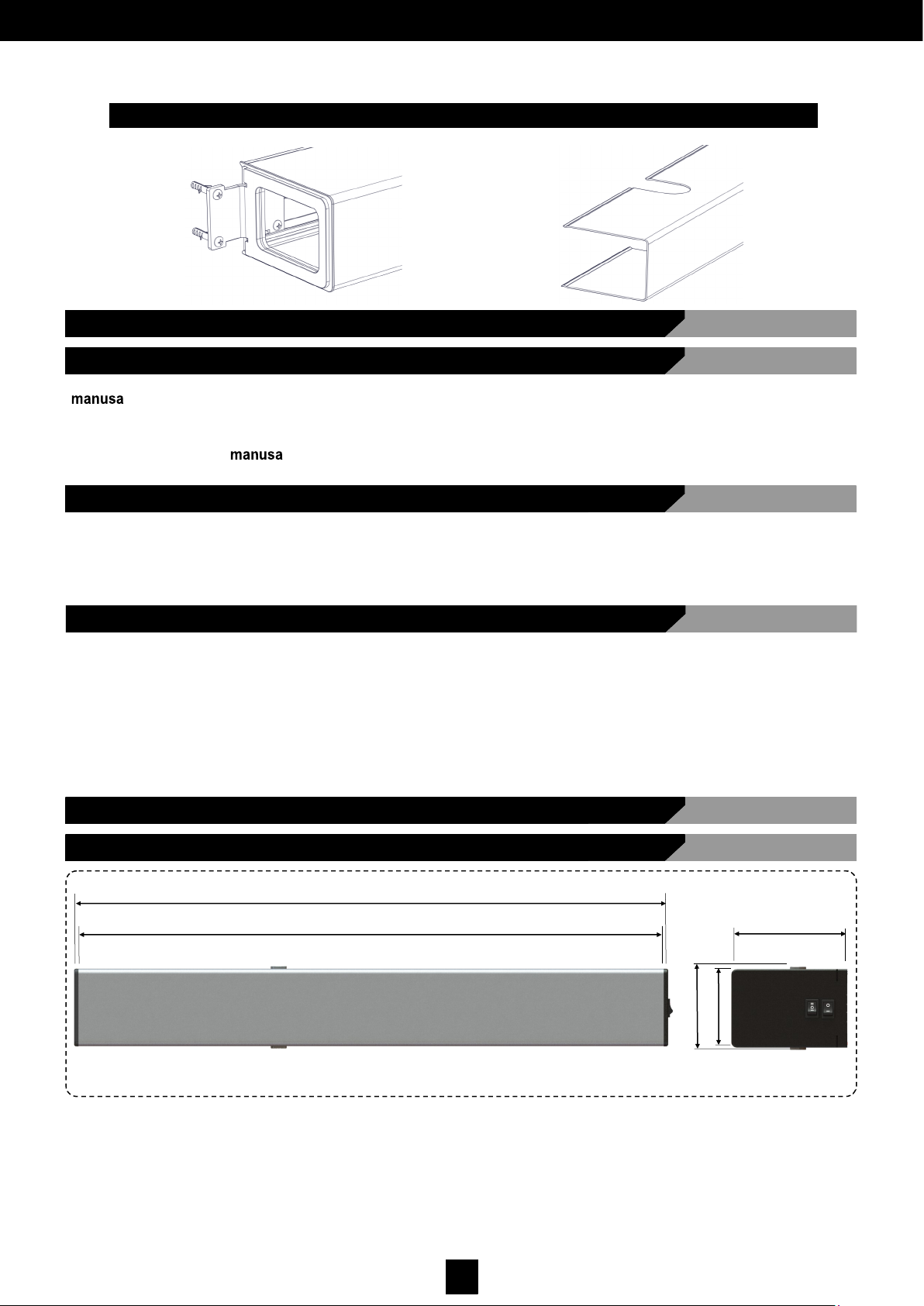

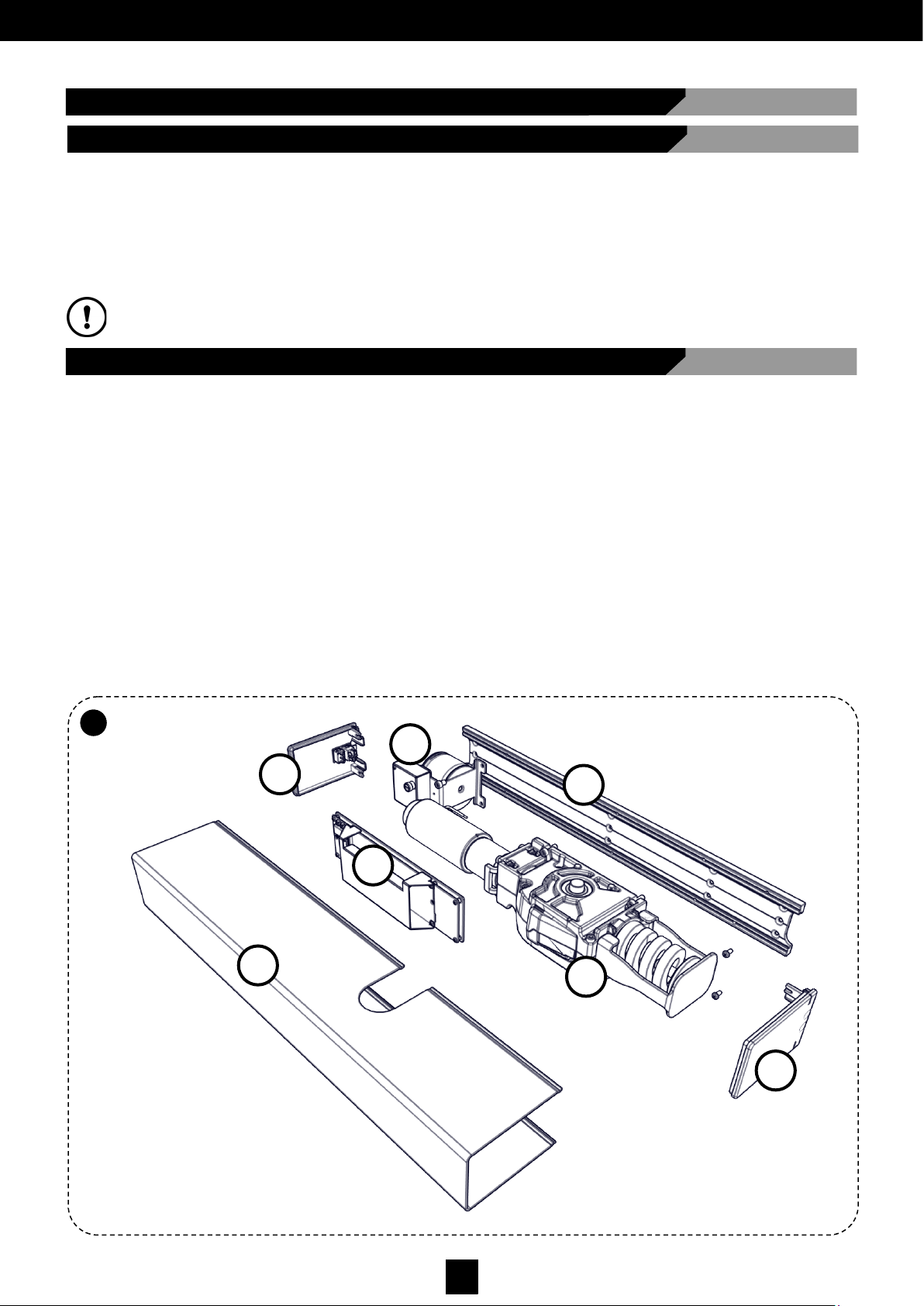

Drag arm

B

1.1

VECTOR Swing Operator

A

1.1

Push arm

C

1.1

17. Drag arm

18. Drag guide profile

19. Arm-to-leaf anchor

20. Joints

21. Adjustable-depth plate

22. Push arm

17 18

19

21 22

20

2

3

1

4 5

6

7

8

9

10

11

13

14 12

15

16

1. Blind side cover

2. Cover screws

3. Main chassis profile

4. Re-send mechanism

5. Axis with upper and lower outputs

6. Gear

7. Motor

8. Electronics

9. Navigation buttons

10. Operator control display

11. Transformer

12. Installation screws

13. Filter

14. Side cover

15. Mode selection program switch/ Mode switch

16. ON-OFF button

4

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

The symbols that appear in this manual and/or in the machine are listed below:

1.2 Symbol Description

ELECTRICAL HAZARD. The inside of the machine must

not be manipulated unless it has been previously

disconnected from the power supply.

DANGER. Improper use may cause injuries to people

and damage the machine.

IMPORTANT WARNING. Strictly adhere to the

indicaons provided with this symbol.

OPTIONAL. These elements are oponal; they will be

included in the box depending on the order placed.

LEFT

Side Opening

BI-PARTING RIGHT

Side Opening

):

1.3 Versions

Both the operator and the two arm versions (dragging and pushing) are universal for any leaf typology: bi-parting, left

and right opening.

It is available in the following transmission arm configurations, in single or bi-parting variants:

Drag arm: attached to the wall on the same side as the hinges (see picture).

Push arm: attached to the wall on the opposite side as the hinges (see picture).

5

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

CARACTERÍSTICAS MECÁNICAS

1.8 Accessories

machines are compatible with the range of accessories. Technical Department shall perform an

evaluation for any integration with machines from other manufacturers.

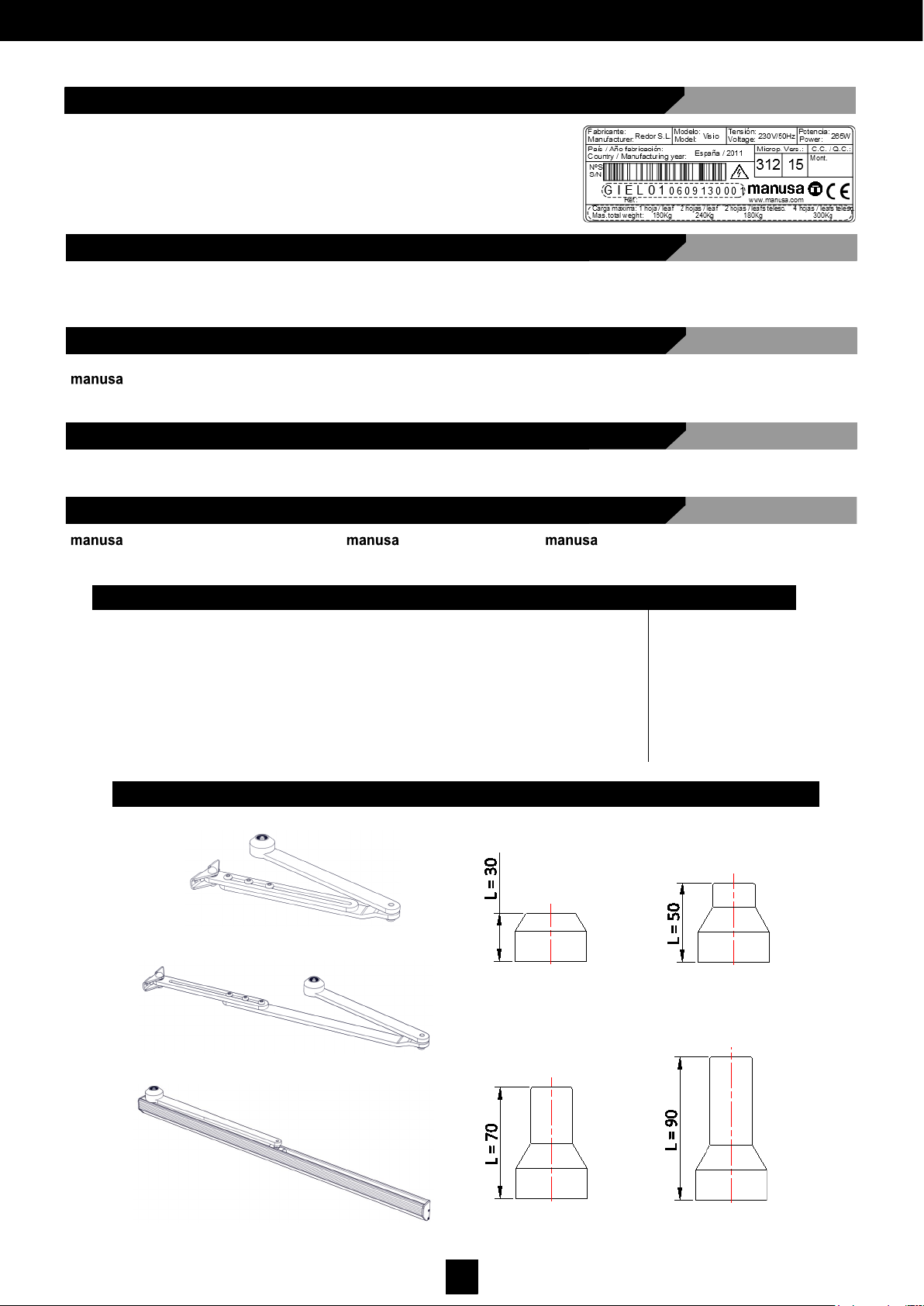

1.4 Product EC Marking

La máquina debe disponer de una etiqueta de marcado similar a la de la

imagen. De no ser así, informar de la incidencia al Servicio Asistencia

Técnica (ver dorso del manual).

CARACTERÍSTICAS MECÁNICAS

1.7 Use in Flammable and/or Explosive Environments

The machine described in this manual has not been designed to operate in flammable and/or explosive environments.

1.5 Noise Statement

The weighted acoustic pressure level of emissions A is below 70 dB.

CARACTERÍSTICAS MECÁNICAS

1.6 Radiation, Gas, Fumes and Dust Produced by the Machine

machines do not produce any type of radiation, gas, fumes or dust.

ARMS

- Short push arm.

- Long push arm.

- Pull arm.

AXIS EXTENSIONS

- 30mm axis extension. - 50mm axis extension.

- 70mm axis extension. - 90mm axis extension.

WIRED RANGE WIRELESS RANGE DETECTION CONTROL / OTHER

- Push button

- Elbow push button

- Key switch

- Proximity reader

- Keypad

- Autonomous print

reader

- Push button

- Elbow push button

- Key switch

- Keypad

- Remote control

- Hands-free access

identifier

- Movement sensor

- Reopening photocell

- Standard presence sensor

- Recessed presence sensor

- Unsupervised movement and pres-

ence sensor

- Supervised movement and pres-

ence sensor

- Touchless switch

- Emergency stop

- Buzzer and/or

warning light

6

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

CARACTERÍSTICAS MECÁNICAS

2 TRANSPORT, STORAGE AND MAINTENANCE

2.1 Machine Delivery Conditions

is in charge of the initial delivery of the machine. Please make sure that all the parts and components arrive in good

condition: that they have not been tampered with, that there is no item missing from the list on the delivery note, that it did not

get wet or suffer from damage caused by the environment. If this is not the case, please log this in writing in the appropriate

delivery note and contact .

2.2 Transport Conditions

For subsequent transportation, the machine must always travel conveniently packaged and protected from the elements.

CARACTERÍSTICAS MECÁNICAS

2.3 Storage Conditions

If the machine is not going to be installed immediately, make sure it is stored in an area that meets the following criteria:

• A safe place, protected from impact and out of reach from people who are not to use the product.

• The machine needs to rest on a flat, smooth and resistant surface, maintaining the same distribution as in the transport

container or vehicle.

• A location protected from corrosive environments, from the elements, damp, oils, fumes, etc.

OTHER

- Intermediate cover kit - Cover to measure

3. TECHNICAL DATA

CARACTERÍSTICAS MECÁNICAS

3.1 General Dimensions

130

89

94

Lop = 665

Lop = 675

Fig. 1.

7

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

The manusa VECTOR swing operator offers high-end kinematic performance in the industry:

OPERATING LIMITS

10 years

ELECTRICAL FEATURES

Power supply

230 V 50Hz—110 V 60 Hz

Nominal power

85W

Max. output shaft torque

45Nm

Power supply to external devices

15VDC—12W Max.

Operating temperature

De -10°C a 50°C

Servicing

Continuous

APPLICABLE STANDARDS

Low Voltage

2014/35/CE

Electromagnetic Compatibility

2014/30/CE

Construction Products

2011/305/CE

Machine Safety

2006/42/CE

Automatic Door Use Safety:

EN 16005

MECHANICAL FEATURES

Dimensions (Height x Width x Length) (Fig.1)

89x130x675mm (1 leaf) 89x130x2800mm

(max. 2 leaves)

Maximum leaf weight

250 Kg (See fig.2)

Opening time

3s (70°/s) ÷ 6s (20°/s)

Closing time

4s (40°/s) ÷ 15s (10°/s)

Closing force (second in 1154)

EN4 ÷ EN6 (See fig.18)

Maximum opening angle

110º

Width of the door leaf

700 ÷ 1400mm

Anti-crushing protection

Automatically limits force when obstacles are present

Weight

Approx. 11kg.

Degree of protection

IP40

3.2 Technical Specifications

Up to +35Pa

Up to +30Pa

X

Up to –100Pa

It does not open from –10Pa

WORKING PRESSURES

NEGATIVE PRESSURE -

POSITIVE PRESSURE +

Dragging

Pushing

Dragging

Pushing

8

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

3.5 Installer Instructions

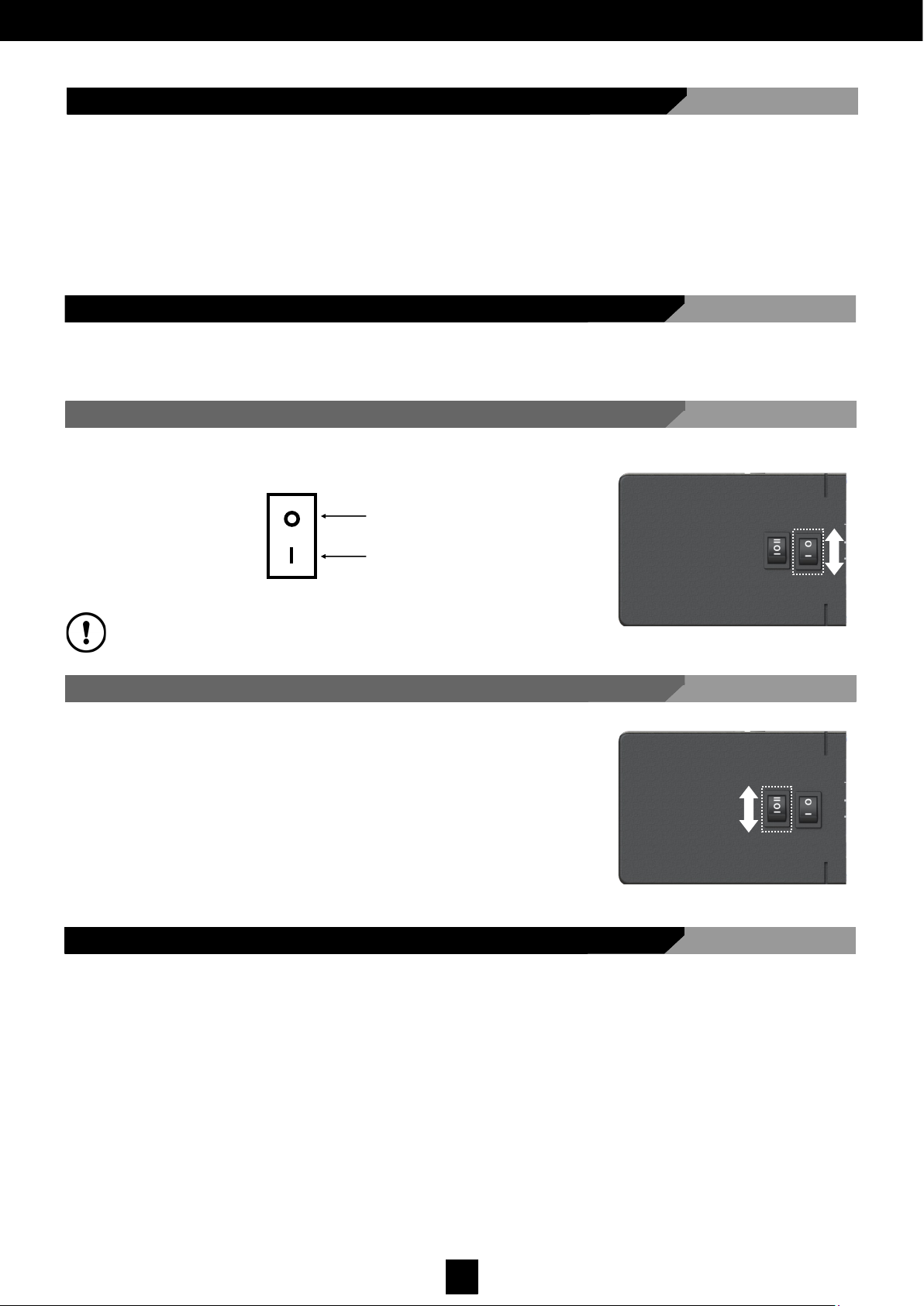

3.4 Operation

manusa doors are designed to operate automatically. Manual operation is only intended in the case of an emergency and to

carry out cleaning, maintenance and adjustment tasks.

3.4.2 Mode Selection Switch

This switch is located on the head of the operator, next to the ON-OFF switch. It

enables mode selections:

I Manual

0 Automatic (two radars)

II Stop open

The installation of external switches voids the operation of this mode selection switch.

3.4.1 ON-OFF Switch

A switch that turns the operator on and off:

Off

On

3.3 Low Energy

The operator can be regulated in Low-Energy mode in accordance with standard EN16005, thanks to the following

features:

- Reduced dynamic force on the door threshold

- Restricted operator force and limited speed

The installer should check the Low-Energy installation conformity with applicable standards. Protection of the closing

edge should be evaluated individually.

• Follow the instructions carefully when installing the operator.

• This product has been designed and manufactured to be used exclusively for the purposes indicated in this manual.

Any other use not expressly indicated may damage the product and/or be hazardous. manusa accepts no

responsibility for improper use of the operator.

• manusa will not be held liable for non-compliance with good installation practices when installing locks, nor for any

warping that may be caused by their use.

• Disconnect the electrical power supply before performing any type of intervention.

• Check that the electrical installation has an upstream circuit breaker and proper earthing.

• Safety devices should comply with standard EN 12978, and be installed in accordance with EN 16005.

See section 6 Commissioning in this manual

9

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

3.6 DECOMMISSIONING, DISMANTLING AND REMOVAL

This machine can be easily dismantled, and decommissioning does not have any special complications.

Proceed to dismantle the unit removing the different elements, and discard and recycle waste accordingly.

3.7 Intended Use and Uses that Should be Avoided

The intended use for the VECTOR operator is to automate swing doors designed for pedestrian access. Prohibited uses that

should be avoided are listed below:

• Do not modify the machine or any of its components.

• Do not disconnect, manipulate or decommission any of the machine’s safety components.

• Do not allow technicians not authorised by to perform work on the machine.

• Do not use spare parts other than original ones supplied by

• Do not use any part of the machine as support for objects and people.

• Do not allow children to play with the machine.

This list includes inappropriate uses of the door that are reasonably foreseeable. Despite this, shall not be held

responsible for possible accidents or damage caused by inappropriate uses not included in the list above.

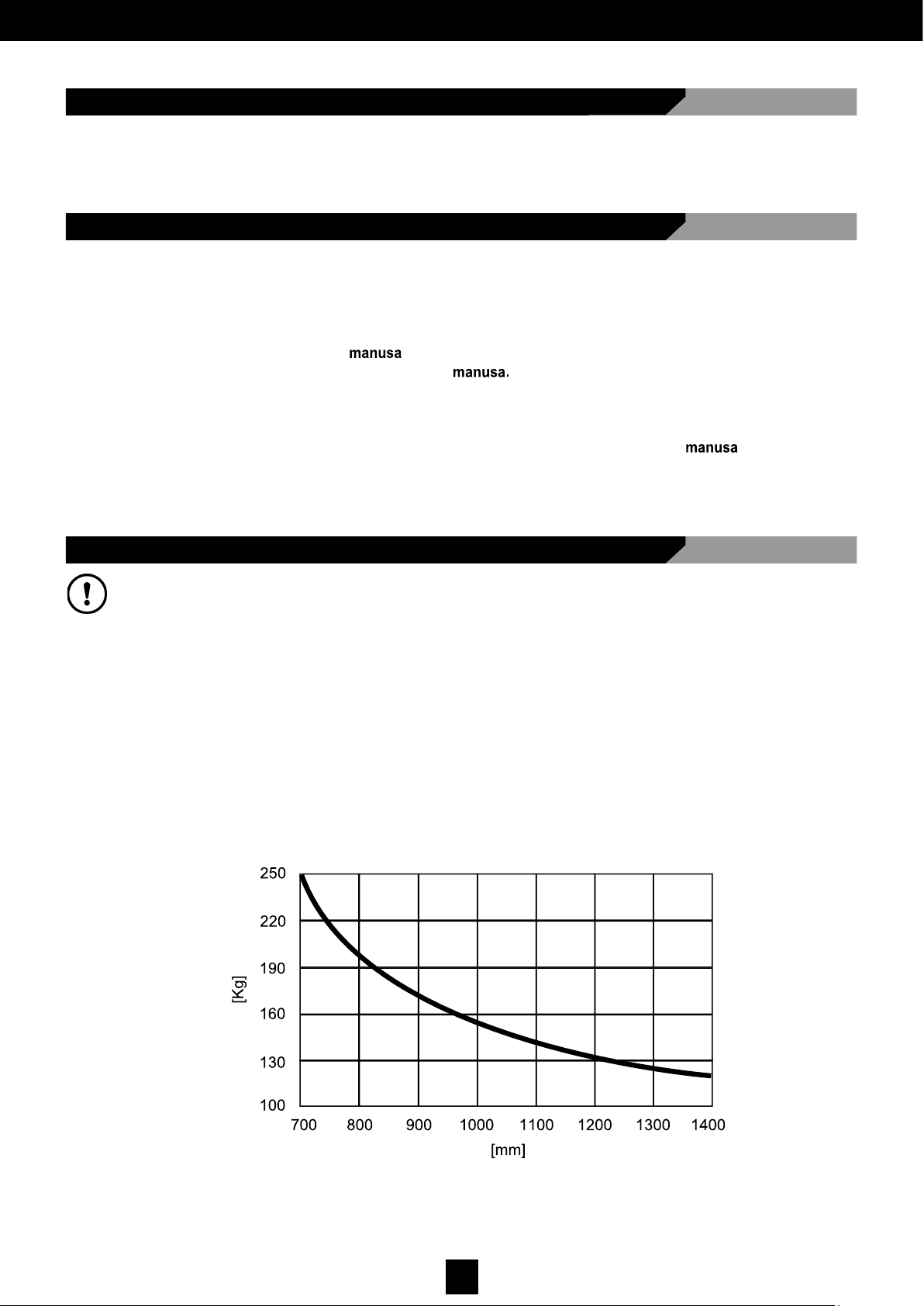

3.8 Application Limits

IMPORTANT: For the correct operation of the operator, the door must not exceed the weight or width indicated in

diagram Fig. 2.

Closing the door is performed by:

- Motor assisted spring (normal operation)

- Only the spring (operating without power)

In addition, each transmission is assigned a different maximum depth value of the frame, above which a correct installation

cannot be carried out. The operator is designed to function exclusively on swing doors in dry environments, and should be

installed inside buildings.

manusa is not responsible for damages arising from any use or placement different from that for which it was designed,

not for unauthorised modifications.

Fig. 2.

Leaf weight (kg)

Leaf width (mm)

10

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

4 PRE-INSTALLATION

4.1 Training Requirements for Installation Technicians

Installing machines as well as any other intervention for maintenance, regulation adjustment, etc should be carried

out by qualified technical staff that meet the following requirements:

• Know how to use the maintenance and/or lifting equipment.

• Are able to correctly handle the loads.

• Know how to use the personal protective equipment.

• Know how to apply the Low Voltage Regulations instructions.

• Have technical knowledge of products.

• Know the reference and application standards for products and services.

4.2 Physical and Environmental Requirements

The VECTOR swing operator should be installed in places that meet the following requirements:

• Smooth, flat, level floor.

• Smooth, flat, level wall with sufficient load capacity. Capable of anchoring a suitable frame.

• An area free from shocks and vibrations.

Ambient temperature: -15 a +50ºC.

• Do not expose to direct sunlight.

• Do not expose to rain or excessive humidity.

Consideration of the location for the equipment should be carried out by technical personnel authorised by

During this process, the cable inlet location for the for the different units should be identified.

PRESSURE

In installations where the swing door is to be installed between two rooms with different pressure, it is recommended

that the door is planned for and installed such that the positive pressure always acts in the direction that the leaf

closes, thus helping to maintain the closed position.

11

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

4.3 Electrical Pre-Installation Requirements

Assembling a automatic door requires an electrical pre-installation with a 6A double-pole magneto-thermal switch,

and it must comply with the cable sections specified below:

Current Input:

- 16mm corrugated tube.

- 3 cables 1.5mm2 section: phase + neutral + earth.

1

2

The diagram shows the standard wiring for the elements that the operator includes as standard.

4A

F

N

Monofásico / Single-phase / Monophasé = 220V - 240V ±6%

2

1

Radars:

- Cables supplied with the accessory.

1

6A

F

N

Monofásico / Single-phase / Monophasé = 220V - 240V ±6%

2

MASTER SLAVE

1

12

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

5 INSTALLATION

5.1 Type of Arm that Can Be Installed

5.2 Installing the Operator

• RIGID ARM: (Used when the operator is installed on the same side that the door opens).

• STANDARD ARTICULATED ARM: The standard articulated arm can be mounted to PUSH. (It is used when the

operator is installed on the opposite side from where the door opens).

• LONG ARTICULATED ARM: The long articulated arm can be mounted to PUSH. (It is used when the operator is

installed on the opposite side from where the door opens, where the door jamb is particularly deep).

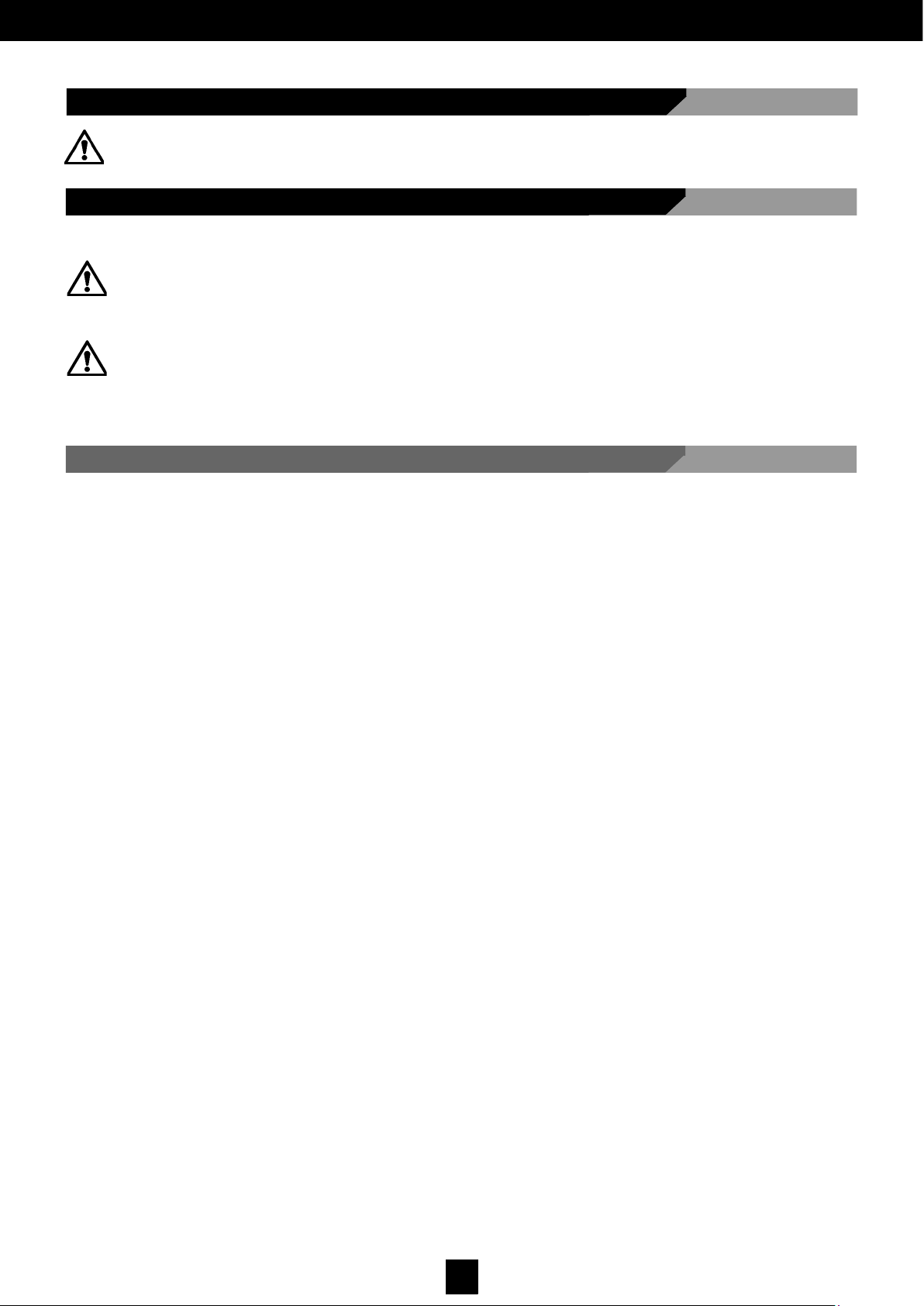

To attach the operator, follow the steps below (Fig. 3):

• Remove the main cover (B)

• Disconnect all connections (key-pad, switch, transformer, motor) on the electronic card ©, unscrew the 2 screws and

remove the card ©. The two screws remain in place between the circuit board and the lower base

• Unscrew and remove the 2 transformer fixing screws (G)

• Unscrew and remove the 4 gear motor group fixing screws (D)

• Remove the two end covers (E) and (F)

• Attach the main extruded profile (A) to the wall following the instructions in the following sections, depending on the type

of arm used

• Assemble all the components, with the exception of the end covers and the main cover, following the steps above in

reverse order.

When reassembling, to aid installation, tighten first the two lower gear motor group fixing screws, then support it on them,

tighten the other two, such that the gear motor shaft end is perpendicular to the upper profile of the leaf

5.2

A

WARNING: For a correct installation, consult the corresponding sections for ‘Installing the Arms’.

A

E

C

B

D

F

G

Fig. 3.

13

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

5.3 Positioning Levels for the Fixing Holes

5.4 Extendable Rigid Arm Installation

Make suitable holes for the type of fixing screw to be used, only after checking the ‘Positioning Levels’ indicated in the

sections corresponding to the type of arm used. In the case of a double operator, prepare the connections (cable

routes) between the two individual operators.

The rigid arm is used when the operator is installed on the same side as the door opens.

WARNING: To place the operator correctly, always use as the main reference the axis of the leaf hinges and the drive

shaft of the gear motor, as shown in Fig. 6 (LEFT-opening leaf) and Fig. 7 (RIGHT-opening leaf).

WARNING: The final tightening of the screws should be performed only after ensuring that the operator has been

placed vertically, guaranteeing that the hinges and the gear motor drive shaft are perfectly parallel. For this to happen,

after installing the rigid arm and the corresponding guide, ensure that the arm pin is not applying any force to the

cylindrical runner during the manoeuvre phase. An error in the positioning of the operator will cause the rigid arm pin to

oscillate with respect to the cylindrical runner, increasing the admissible tolerance and consequently causing a part of

the operator to deteriorate.

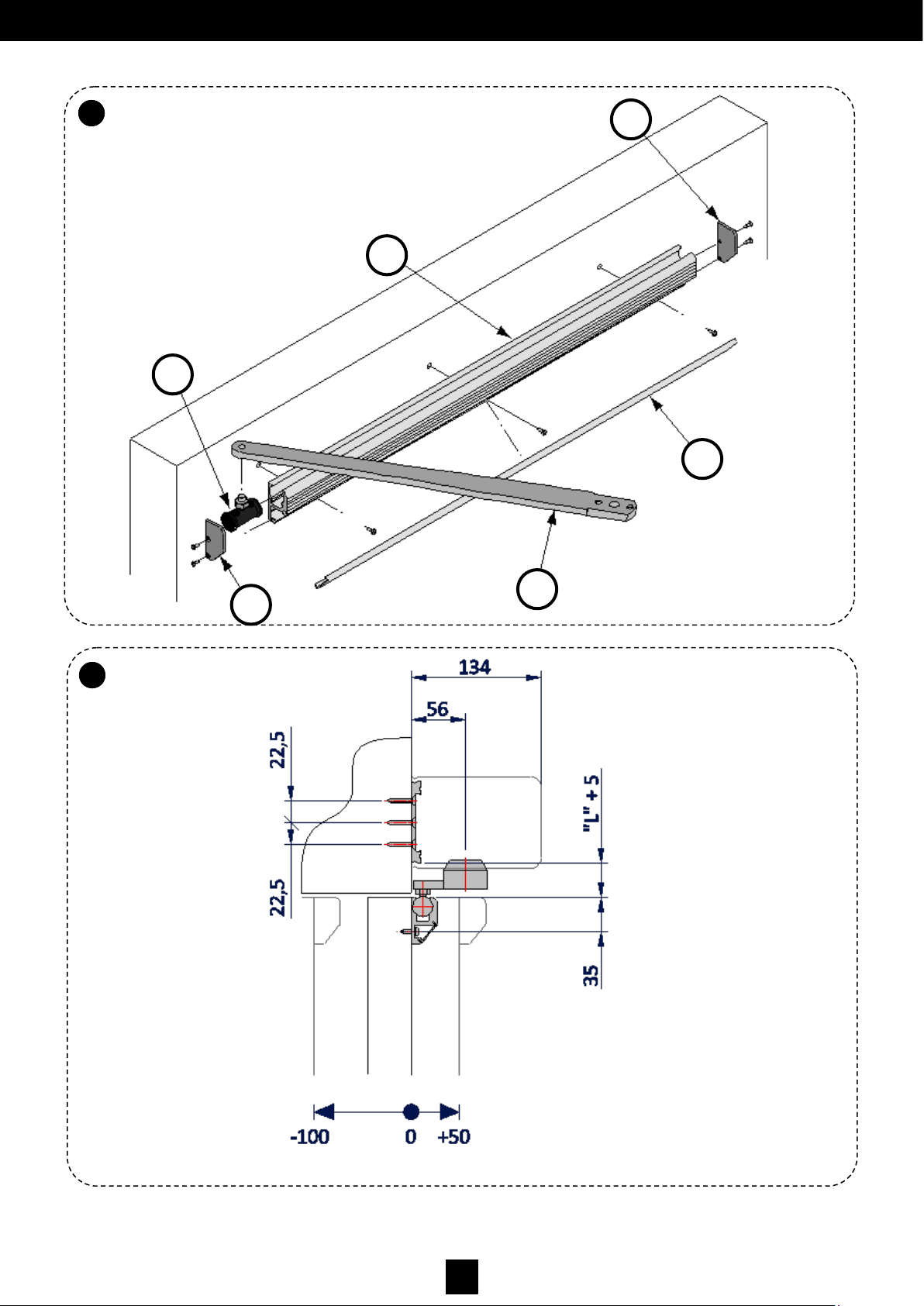

• Remove the cover (Fig. 4 Part A) from the main guide profile (Fig. 4 part B) to access the mounting compartment.

• Place the main guide profile (Fig. 4 part B) horizontally, following the fixing positioning levels indicated in

figures 5, 6 and 7.

• Make at least 4 holes coinciding with the ‘V’ mark on the guide profile, and attach it (Fig. 4 part B) to the frame using the

corresponding screws.

• Place the runner (Fig. 4 part C) in the guide (Fig. 4 part B).

• Tighten the nut (Fig. 8 part A) so that the spring is previously loaded until the plate ends (Fig. 8 part B) coincide with the

line that indicates the EN4 range start point (level L=0).

• With the door closed, find the position to introduce the arm (Fig. 9 part A) so that the ends of the arm (Fig. 4 part F)

coincide with the axis of the runner pin (Fig. 4 part C).

• Remove the arm, take out the arm connection and turn it (Fig. 9 part A) 1 or 2 teeth towards the closing part of the leaf

(Fig.10). Then re-insert the output axis.

• Insert the washer (Fig. 9 part B) and tighten the screw (Fig. 9 part C).

• Unscrew the spring tension screw slightly (Fig. 8 part A).

• Insert the arm (Fig. 9 part D) into the arm connection groove, and tighten the two screws (Fig. 9 part E).

• Open the door slightly and turn the rigid arm until the runner axis (Fig. 4 part. C) coincides with the end of the rigid arm

where the arm pin is attached.

• Screw the threaded end of the pin (Fig. 4 part C) to the rigid arm (Fig. 4 part F).

• Close the guide cover (Fig. 4 Part A) .

• Close the guide right (Fig. 4 part E) and left (Fig. 4 part D) end covers with the corresponding screws.

• Adjust the spring [see section ‘Spring Adjustment’].

5.4.1 Rigid Arm and Guide Installation

14

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

5.4

A

5.4

B

Fig. 4.

Fig. 5.

D

A

B

E

C

F

Loading...

Loading...