Page 1

UAB

Universal Amplifier/Digitiser

User Manual

MICRON METERS

www.micronmeters.com

metersinfo@micronmeters.com

Page 2

Mantracourt Electronics Limited UAB User Manual

1

Chapter 1 Introduction To The Universal Process Amplifier System ......................................................... 4

Chapter 2 Installation ................................................................................................................... 5

Environmental Requirements ........................................................................................................... 5

Terminal Connections .................................................................................................................... 6

Section 1 -The Rack (RUA) Variant .................................................................................................... 7

Figure 2.1 - Rear view of Rack (RUA2) ................................................................................................ 7

Figure 2.2 UAB Rear Connection Terminals ......................................................................................... 7

Figure 2.3 The 32 Way A & C (DIN41612) Connections ............................................................................. 7

Figure 2.4 Rack Module Layout ......................................................................................................... 8

Figure 2.5 LP2 Hand Held Programming Unit ........................................................................................ 8

Figure 2.6 RUA1 for External Programmer (LP2) .................................................................................. 8

Figure 2.7 RUA2 On-Board Programmer .............................................................................................. 8

Section 2 - The Surface Mount (SMP) Variant ........................................................................................ 8

Figure 2.8 The IP65-ABS Case (LAB) Dimensions & Mounting Points ............................................................. 9

Figure 2.9 The DIN Rail Mounting (D2) Dimensions ................................................................................. 9

Figure 2.10 Stainless Steel Panel Mount & Programming Display Module, Dimensions & Mounting Points ................ 9

Figure 2.11 LCS Stainless Steel Panel Cut Out ...................................................................................... 10

Figure 2.12 Connection & Fitting Details for the Surface Mounted Amplifier (UAB) ......................................... 10

Programmers for Surface Mount Variants ........................................................................................... 11

Figure 2.13 LP1 On-Board Programmer Unit ........................................................................................ 11

Figure 2.14 LP2 Remote hand Held Programmer Unit (UAB) ..................................................................... 11

Chapter 3 Power Supplies ............................................................................................................ 12

Section 1 - The Rack Version (RS1) ................................................................................................... 12

Table 3.1 .................................................................................................................................. 12

Table 3.2 .................................................................................................................................. 12

Section 2 - The Surface Mount Versions (LS1 and LS3) ............................................................................ 12

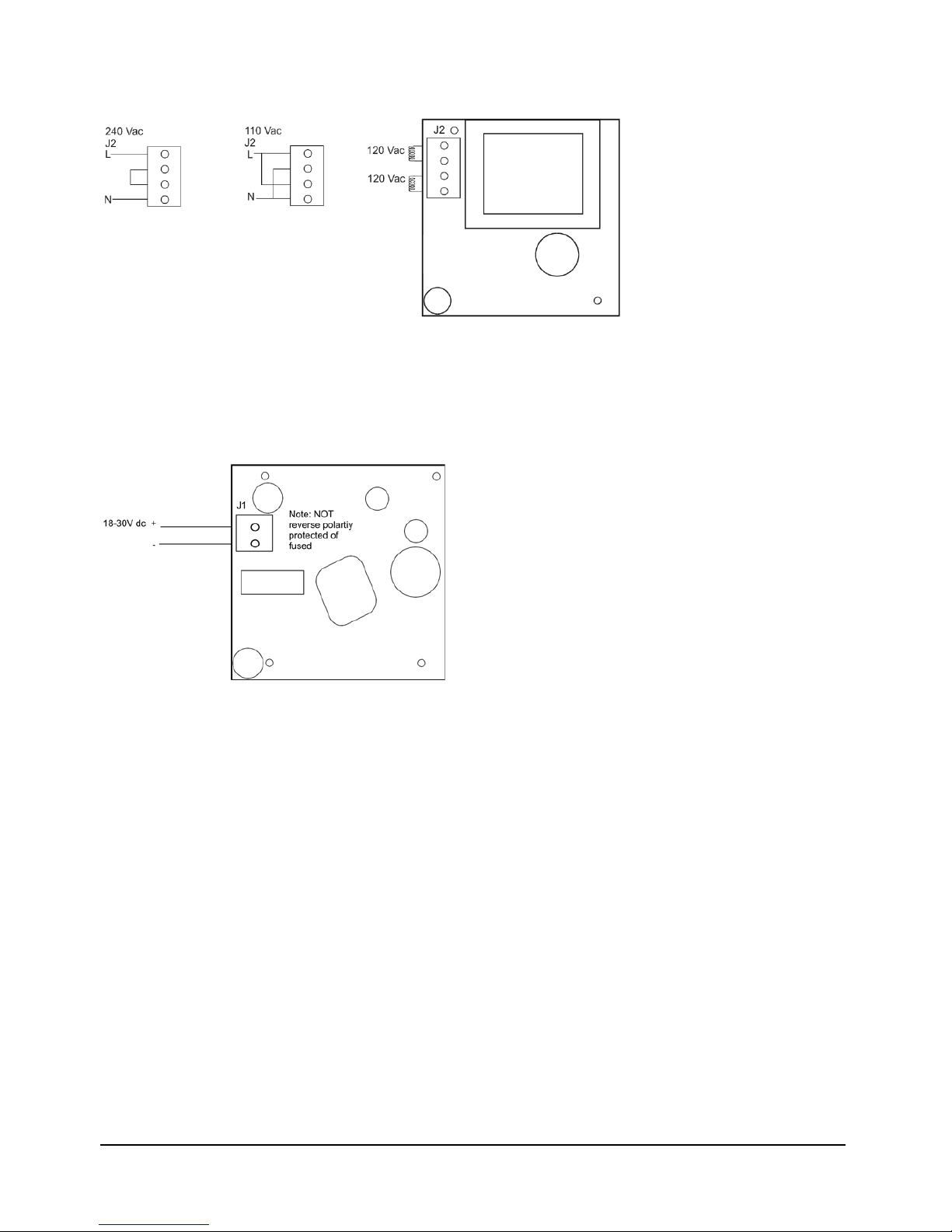

Figure 3.1 Power Supply LS1 Connections ........................................................................................... 13

Figure 3.2 LS3 Connections ............................................................................................................ 13

Chapter 4 Input Modules .............................................................................................................. 14

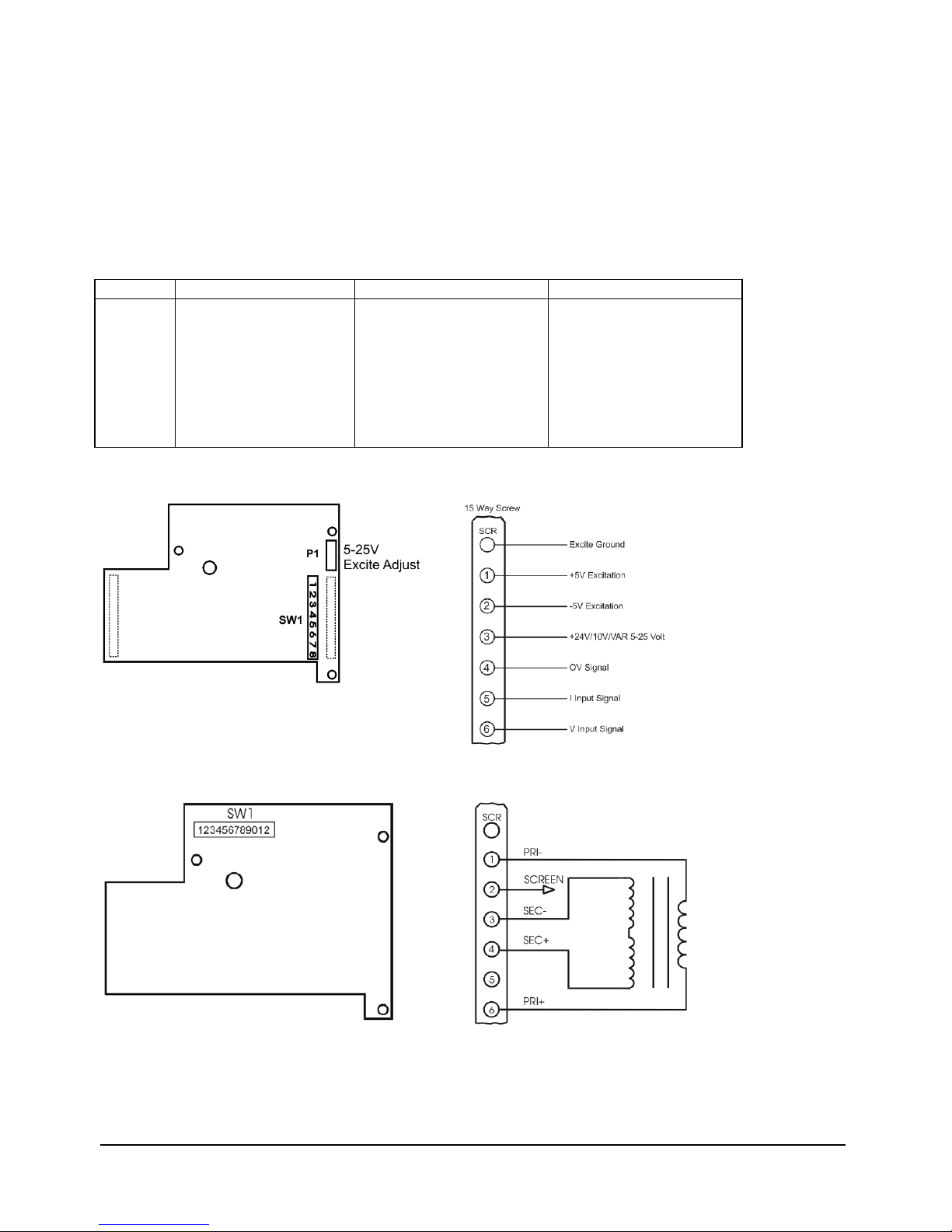

Table 4.1 UADCV1 and UADCA1 Switch Configuration ............................................................................. 14

Figure 4.1 The UADC1 & UADCA1 Modules .......................................................................................... 14

Figure 4.2 The UALV1 - LVDT Module Rear Panel Connections .................................................................. 14

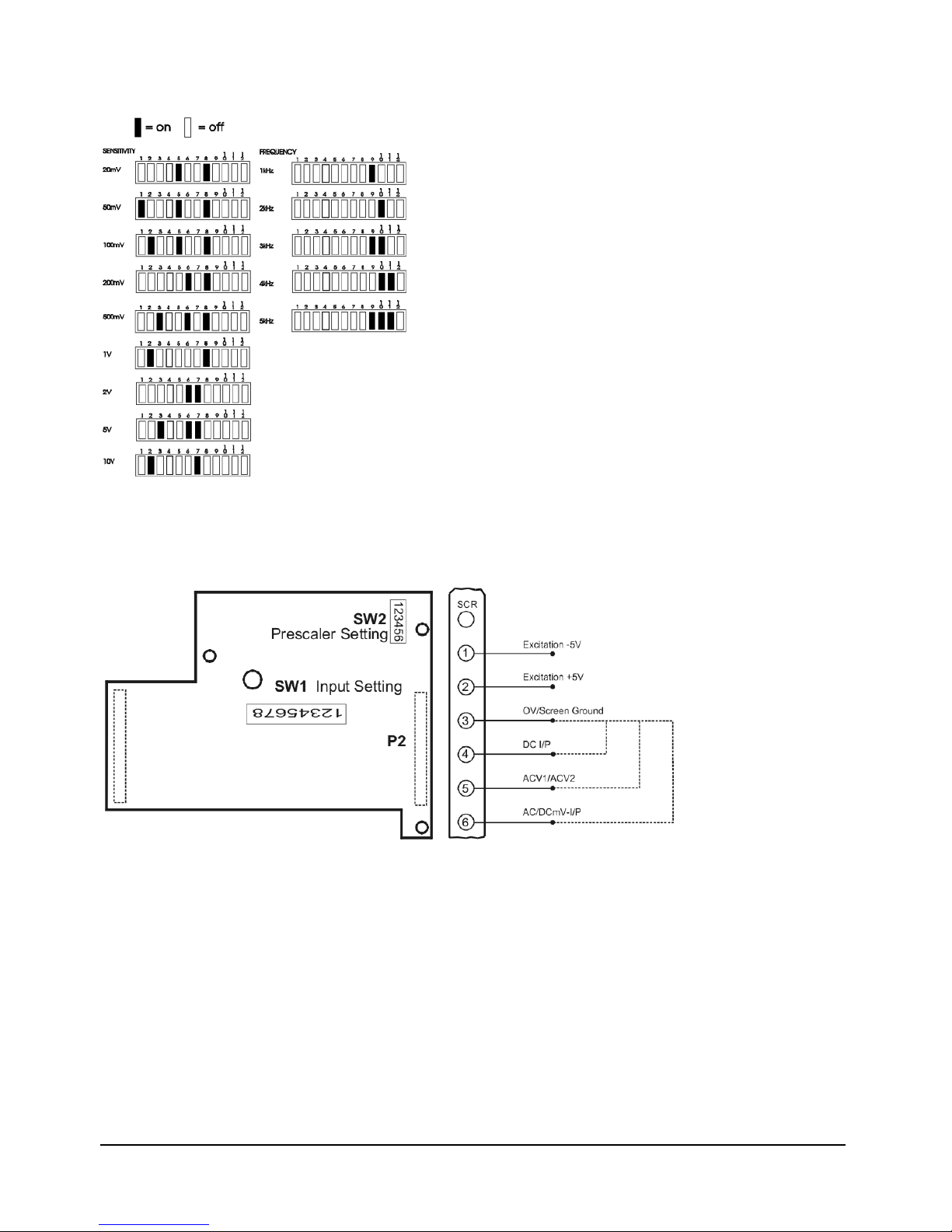

Figure 4.3 LVDT Switch Settings ...................................................................................................... 15

Figure 4.4 Rear Panel Connections ................................................................................................... 15

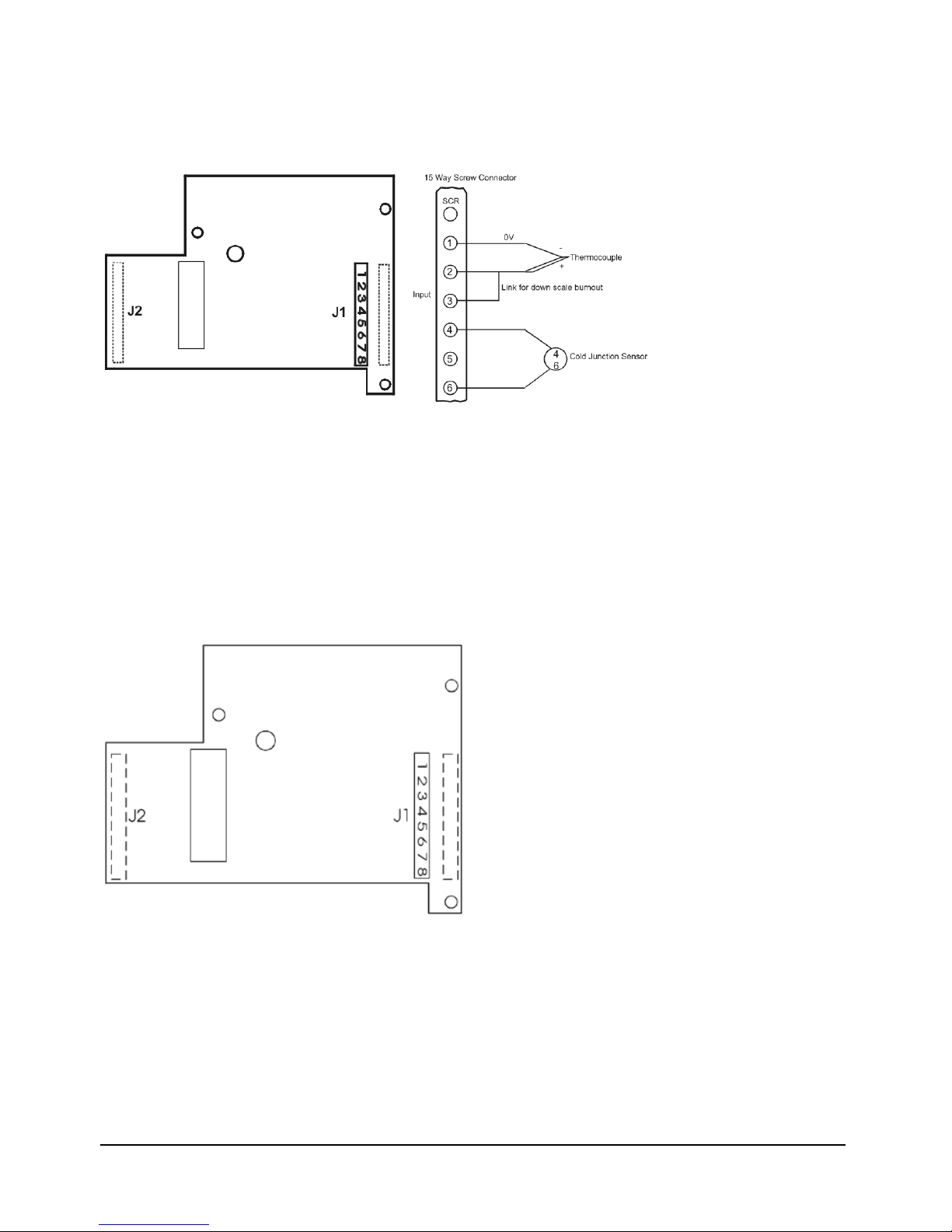

Figure 4.5 UAT1 & 2 ..................................................................................................................... 16

Figure 4.6 Thermocouple Connectors ................................................................................................ 16

Figure 4.7 RTD Module UAPT .......................................................................................................... 16

Figure 4.8 RTD Connections ............................................................................................................ 17

Fast Strain Gauge The (UAFLC) Module .............................................................................................. 18

Figure 4.9 UAFLC Module ............................................................................................................... 18

Figure 4.10 UAFLC Connections ....................................................................................................... 18

Figure 4.11 the UADIA Modules ........................................................................................................ 18

Figure 4.12 UADIA Connections ....................................................................................................... 18

Chapter 5 Output Modules ............................................................................................................ 19

Section 1 - General Description ....................................................................................................... 19

Figure 5.1 Showing the Potentiometer for Gain & Offset Adjustment ......................................................... 19

Figure 5.2 UAFAO Connections ........................................................................................................ 19

Section 2 - Digital Output Modules ................................................................................................... 20

Figure 5.3 RR1 Module .................................................................................................................. 21

Figure 5.4 LR1 Module .................................................................................................................. 21

Figure 5.5 Installation of LR1 .......................................................................................................... 22

Figure 5.6 Connection to the Surface Mount/DIN Rail Version UAI²C (S) ...................................................... 22

Section 3 - The Communications Port Modules ..................................................................................... 22

Figure 5.7 LC1 Current Loop ........................................................................................................... 23

Figure 5.8 IF25 Connecting Multiple Process Amplifiers .......................................................................... 23

LC3 Isolated RS232/485 Communications Module .................................................................................. 23

Figure 5.9 LC3 Isolated RS232/485~Mode Connections ........................................................................... 23

Page 3

Mantracourt Electronics Limited UAB User Manual

2

Figure 5.10 Connecting Multiple Units on RS485 ................................................................................... 24

Figure 5.11 LC3 RS232 Mode Connection to PC ..................................................................................... 24

Figure 5.12 LC3 RS232 Mode Connection to Printer ............................................................................... 24

RC1 Communications Current Loop Module Connections ......................................................................... 25

Figure 5.13 RC1 Communication Connections ...................................................................................... 25

Figure 5.14 RC1 Baud Rate Selection................................................................................................. 25

Figure 5.15 Connecting Multiple Process Amplifiers ............................................................................... 26

RC3 RS232/485 Communication Connectors ........................................................................................ 26

Figure 5.16 RC3 RS232/485 Communication Connections ........................................................................ 26

Figure 5.17 - RC3 Baud Rate Selection ............................................................................................... 27

Section 4 Serial Communication Protocol ........................................................................................... 27

Fast MANTRABUS - selected when CP is 128 ........................................................................................ 27

Communications Commands ........................................................................................................... 28

Data Transmitted To Process Amplifier For Command 1 ......................................................................... 28

Table 5.1 .................................................................................................................................. 33

Process Amplifier Printer Format ..................................................................................................... 33

Chapter 6 The Amplifier Displays ................................................................................................... 35

Figure 6.1 Programmer Unit Panel Layout (RUA2) ................................................................................ 35

Figure 6.2 LP2 Remote Hand Held Programmer Unit ............................................................................. 35

Figure 6.3 Programmer Unit Panel Layout (LP1) ................................................................................... 35

Control Panel Guide ..................................................................................................................... 36

Figure 6.4 Programmer Unit Panel Layout .......................................................................................... 36

Figure 6.5 Display Module Connections and Switch Settings ..................................................................... 37

Table 6.1 .................................................................................................................................. 37

Chapter 7 Programming The Amplifiers ........................................................................................... 38

Section 1 - Display & Programming Mnemonics .................................................................................... 38

Table 7.1 Configurable Parameters for Process Input ............................................................................. 38

Table 7.2 Configurable Parameters for Dual Input Modules ...................................................................... 41

Configurable Parameters for UAFLC - Fast Strain Gauge Input Module ........................................................ 41

Table 7.3 Configurable Parameters .................................................................................................. 42

Section 2 - Setting the Conditions for Linear Inputs ............................................................................... 42

Figure 7.1 Linear Input Scaling ........................................................................................................ 42

Method of Calculating IPL and IPH from any known input values ............................................................... 42

Input Calibration Routine .............................................................................................................. 43

Section 3 - The Temperature Input Modules (UAT1 & UAT2) ..................................................................... 43

Table 7.4 - Thermocouple Input Codes ............................................................................................. 44

Table 7.5 .................................................................................................................................. 44

Section 4 - The Rate/Totaliser Input Module (UARTL)............................................................................ 45

Setting up the Input ..................................................................................................................... 45

Table 7.6 .................................................................................................................................. 45

Table 7.7 Input Configuration ......................................................................................................... 45

Setting the Prescaler .................................................................................................................... 45

Table 7.8 .................................................................................................................................. 46

Rate Measurement ....................................................................................................................... 46

Period (Time measurement between pulses) ...................................................................................... 46

Input Code ................................................................................................................................ 46

Table 7.9 .................................................................................................................................. 46

(i) Period in mSeconds ................................................................................................................. 46

Table 7.10 Period mS Fixed Scale .................................................................................................... 46

(ii) Period in µSeconds .................................................................................................................. 46

Table 7.11 Period µS Unity Scale (IPSF 1.0000) .................................................................................... 46

Frequency ................................................................................................................................. 46

Table 7.12 ................................................................................................................................. 47

Figure 7.2 Frequency Unity Scale Inputs ............................................................................................ 47

RPM ......................................................................................................................................... 47

Table 7.13 RPM Unity Scale ............................................................................................................ 47

Figure 7.3 RPM Unity Scale Range .................................................................................................... 48

Count/Rate Scaling & Scaling/Rate .................................................................................................. 48

Page 4

Mantracourt Electronics Limited UAB User Manual

3

Scaling Example: - ....................................................................................................................... 48

RTL Module Inputs ....................................................................................................................... 49

Figure 7.4 RTL Module Inputs .......................................................................................................... 49

Section 5 - Programming the Output Functions .................................................................................... 49

Hysteresis (HYS) .......................................................................................................................... 49

Latching Outputs (OL) .................................................................................................................. 50

Table 7.14 Output Latch Codes (OL) ................................................................................................. 50

Output Action (OA) ...................................................................................................................... 50

Table 7.15 Output Action Codes (OA) ................................................................................................ 50

Delay Timers .............................................................................................................................. 50

Delay On Timer ........................................................................................................................... 50

Delay Off Timer .......................................................................................................................... 50

PID Functions ............................................................................................................................. 50

PID Empirical Tuning .................................................................................................................... 51

Section 6 - Scaling the Analogue Outputs ........................................................................................... 51

Output Scaling ............................................................................................................................ 51

Figure 7.5 Analogue Output ............................................................................................................ 51

Method of Calculating OPL & OPH from any known Output & Display Values ................................................. 52

Calibration ................................................................................................................................ 52

Figure 7.6 Showing the Potentiometers for Gain and Offset Adjustment ..................................................... 52

Figure 7.7 Showing the Potentiometers for Gain & Offset Adjustment ........................................................ 53

Chapter 8 Order Codes ................................................................................................................ 54

RUA Rack Mounted Universal Input Process Amplifier ............................................................................. 54

UAB Universal Amplifier ................................................................................................................ 54

SMP Surface Mount Process Indicator & Controller ................................................................................ 55

CE Approvals .............................................................................................................................. 56

Instrument Setup Record Sheet ....................................................................................................... 57

W A R R A N T Y .......................................................................................................................... 57

Page 5

Mantracourt Electronics Limited UAB User Manual

4

Chapter 1 Introduction To The Universal Process Amplifier System

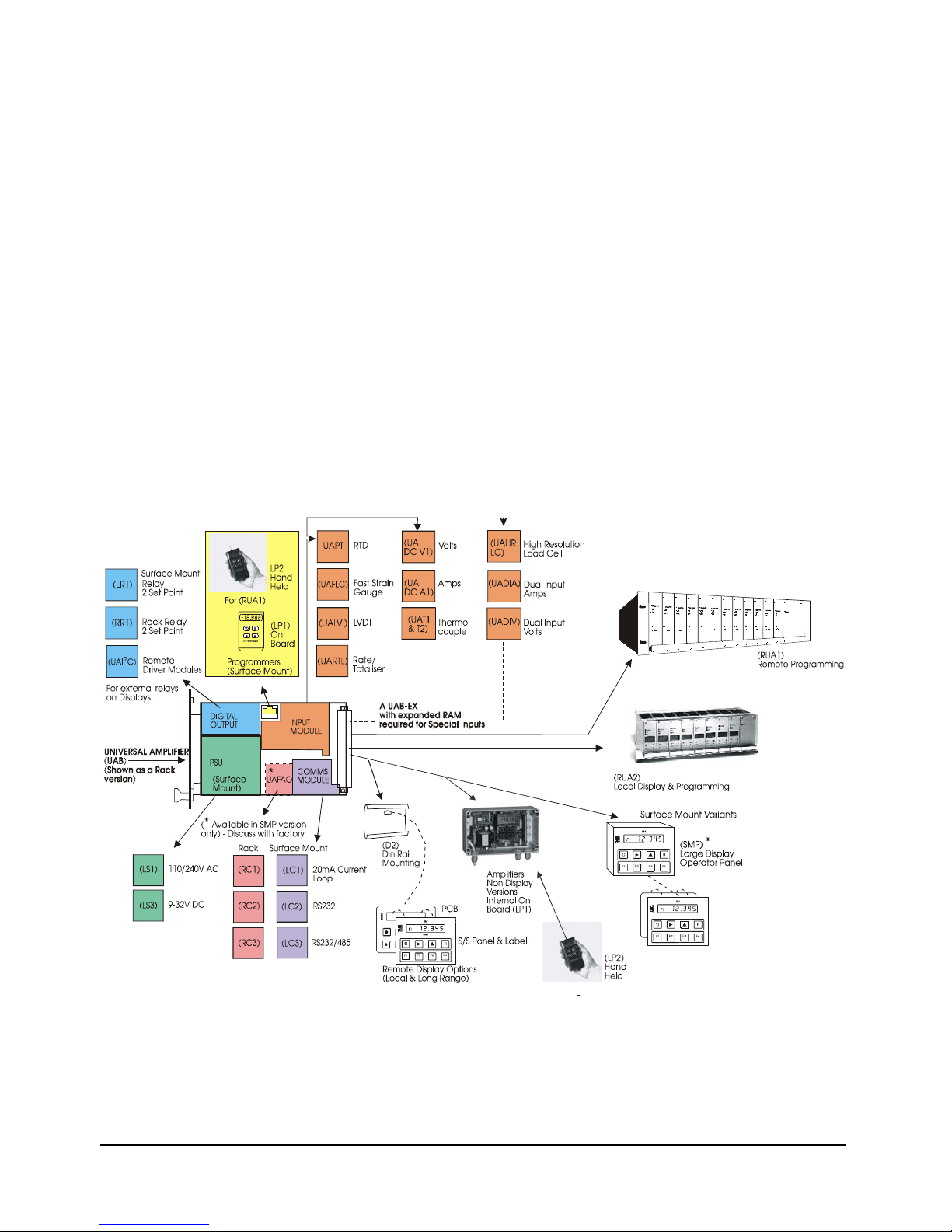

The Mantracourt Electronics Universal Process Amplifier System is based upon a concept of modular construction. By

adopting such a concept, it is possible to offer a great deal of flexibility of construction, to meet the wide and

varying needs of system building.

The system is centred on a Eurocard sized amplifier PCB, which consists in its standard form of, Central Processing,

and voltage and current Analogue output ports. Facilities are provided to connect a series of ‘plug in ’ option boards

for inputs, relay and communications outputs together with mains and low voltage DC power supply options.

A special Fast Analogue output module is also available to complement a Fast Strain Gauge input option.

The modular concept offers the opportunity for assembly in Surface Mount, DIN Rail and 19-inch Rack variants.

The system concept is described in diagrammatic form with the range of options listed. The options will be

described under the various Chapters as follows:

1. Introduction

2. Installation requirements

3. Power Supplies

4. Input Modules

5. Output Modules & Communications Information

6. The Amplifier Displays

7. Programming the Amplifier including essential INPUT CALIBRATION ROUTINES, which must be actioned. See

Chapter 7

8. Order Codes

9. Specifications

Page 6

Mantracourt Electronics Limited UAB User Manual

5

Chapter 2 Installation

In order to maintain compliance with the EMC Directive 2004/108/EC the following installation recommendations

should be followed.

Inputs:

Comms Port:

Analogue

Output:

Use individually screened twisted multipair cable. (e.g. FE 585 - 646)

The pairs should be :

pins 1 & 6

pins 2 & 5

pins 3 & 4

Terminate all screens at pin 1 of the input. The screens should not be

connected at the transducer end of the cables.

Use individually screened twisted multipair cable. (e.g. FE 118-2117)

The pairs should be:

-Tx & +Tx

-Rx & +Rx

Terminate screens at pin 1 of the input .

The screens should not be connected at the host port.

Use screened twisted pair cable. (e.g. RS 626-4761)

Terminate screen at pin 1 of the input.

The screen should not be connected at the host port.

Pin 1 of the input should be connected to a good Earth. The Earth connection

should have a cross-sectional area sufficient enough to ensure a low

impedance, in order to attenuate RF interference.

Country

Supplier

Part No

Description

UK

Farnell

118-2117

Individually shielded twisted multipair cable (7/0.25mm)- 2 pair

Tinned copper drain. Individually shielded in polyester tape.

Diameter: 4.1mm

Capacitance/m: core to core 115 pF & core to shield 203 pF

UK

Farnell

585-646

Individually shielded twisted multipair cable (7/0.25mm)- 3 pair

Tinned copper drain. Individually shielded in polyester tape.

Diameter: 8.1mm

Capacitance/m: core to core 98 pF & core to shield 180 pF

UK RS 626-4761 Braided shielded twisted multipair cable (7/0.2mm)- 1 pair

Miniature- twin -round Diameter: 5.2 mm

Capacitance/m: core to core 230 pF & core to shield 215 pF

Environmental Requirements

UAB units can operate in any industrial environment provided the following limits are not exceeded at the point of

installation:

Operating

Temperature:

-10 ºC to 50 ºC

Humidity:

95 % non condensing

Storage Temperature:

-20ºC to +70ºC

Page 7

Mantracourt Electronics Limited UAB User Manual

6

Units can operate from any one of the following:

or

or

220/240V AC, 50/60Hz

110V AC, 50/60Hz

9-30V DC, 50/60Hz (Not RUA)

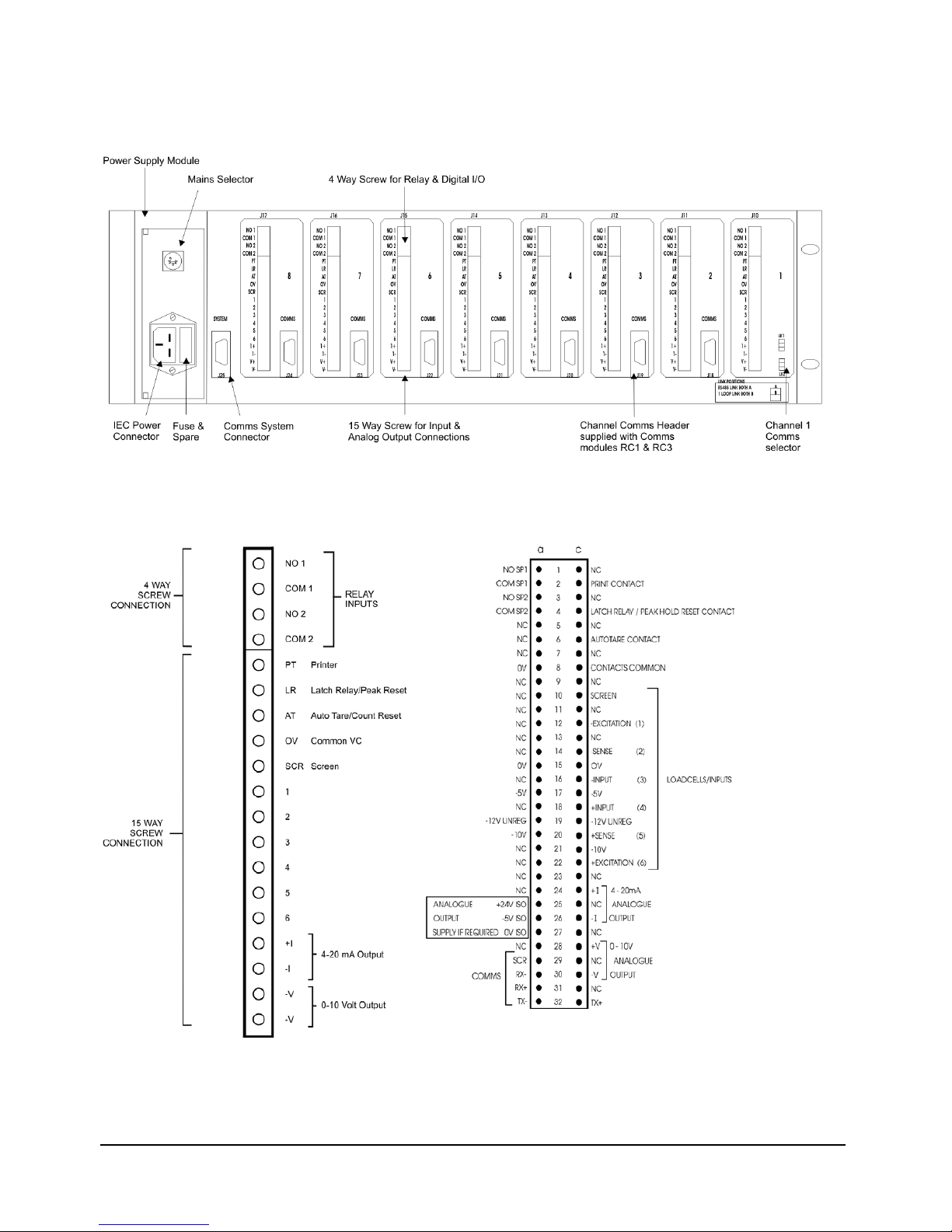

Terminal Connections

Connection between the UAB modules and input/output signals, are made via screw connections to the rear of the

rack, or edge of the UAB in Surface Mount Versions.

(See Figure 2.1)

Page 8

Mantracourt Electronics Limited UAB User Manual

7

Section 1 -The Rack (RUA) Variant

Figure 2.1 - Rear view of Rack (RUA2)

Figure 2.2 UAB Rear Connection

Terminals

Figure 2.3 The 32 Way A & C

(DIN41612) Connection s

Page 9

Mantracourt Electronics Limited UAB User Manual

8

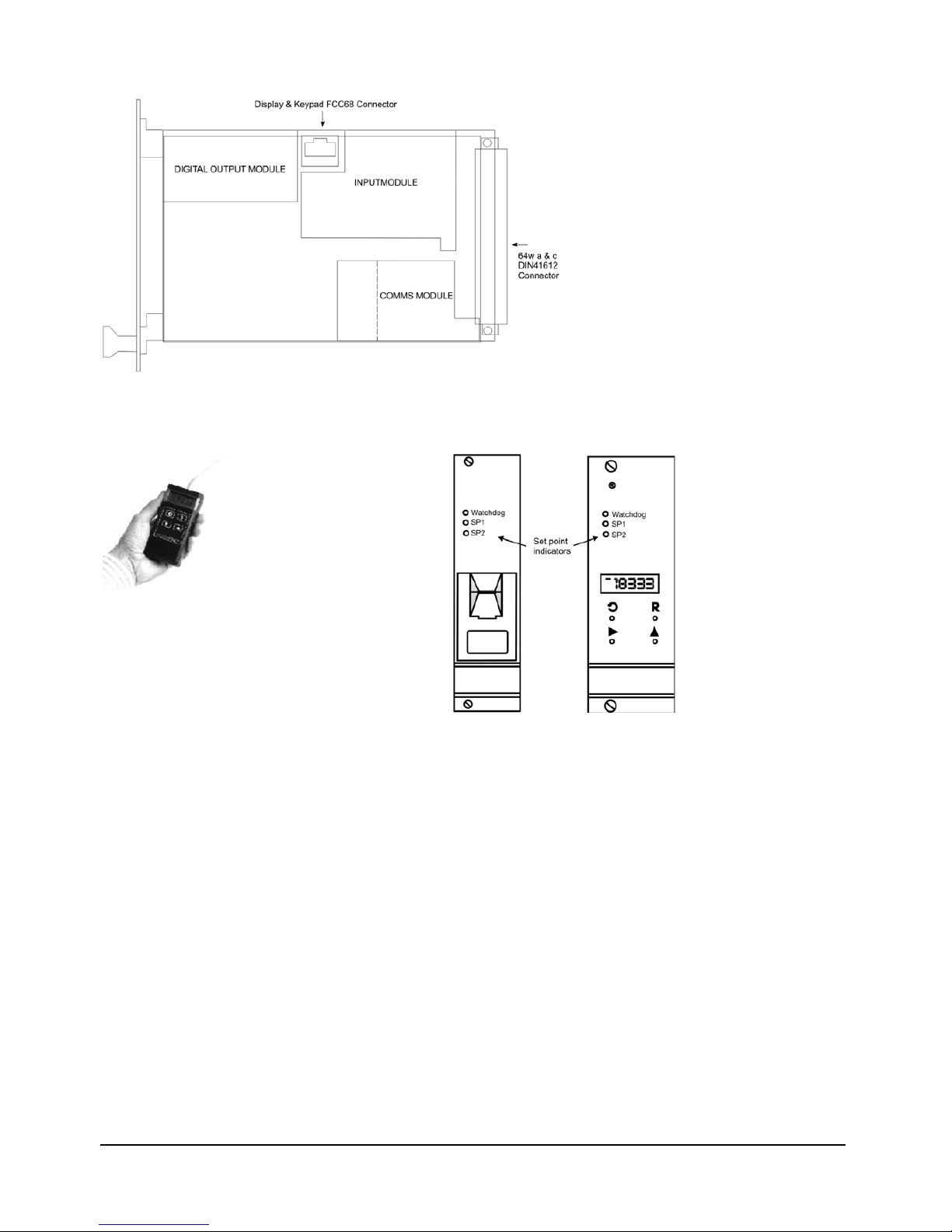

Figure 2.4 Rack Module Layout

Figure 2.5 LP2 Hand

Held Programming Unit

Figure 2.6 RUA1 for

External Programmer

(LP2)

Figure 2.7 RUA2 On-Board

Programmer

Section 2 - The Surface M o unt (SMP) Variant

The surface mount variant of the Universal Amplifier is offered in a number of different configurations dependant

upon the system installation requirements, to which any of the input, output and communications modules can be

fitted as described in the diagram in Section 1. Each description is followed by the order coding for ease of

identification.

1.The surface mount IP65 ABS cased version with a large LCD display and programming module mounted in the lid,

where local programming and control is required. - (SMP/C).

2.The DIN rail mounted version with a remotely connected large LCD display and programming module fitted with a

stainless steel panel mounting fixture which will operate up to 2 metres from the amplifier. (SMP/D) A version of

the (SMP/D) above is offered with a driver package (LCDR) where there is a requirement for the remote display

and programming module to operate over distances greater than 2 metres, and up to 100 metres from the

amplifier. Where order codes are required for individual items, please refer to the order code list in the rear of

the manual at Chapter 8.

3.ABS Cased Versions are available without a display and programming module mounted on the lid. Programmed

through the internal FCC socket on the UAB, (using an LP2 Hand Held Programmer see Figure 2.13) or the remote

LP1 On Board Programmer see Figure 2.14

Page 10

Mantracourt Electronics Limited UAB User Manual

9

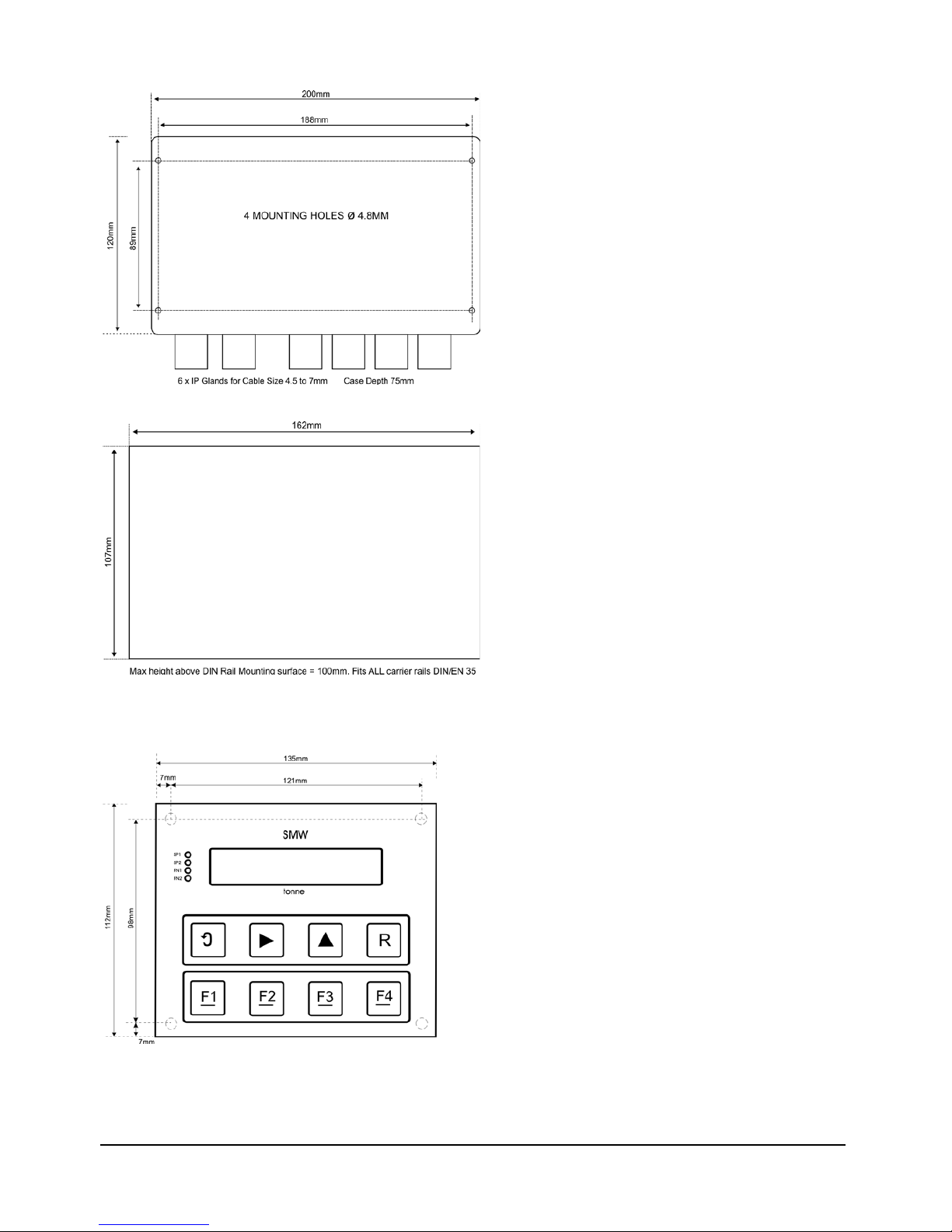

Figure 2.8 The IP65-ABS Case (LAB) Dimensions & Mounting Points

Case Depth = 75mm

Figure 2.9 The DIN Rail M o u n ting (D2) Dimensio ns

Max height above

DIN Rail Mounting

surface = 100mm.

Fits ALL carrier rails

DIN/EN 35

Figure 2.10 Stainless Steel Panel Mount & Programming Display

Module, Dimensions & Mounting Points

4mm M4 studs x 12mm for mounting. Sealing is provided by a Neoprene gasket

For LCD max cable length = 2 meters. For LCDR max cable length = 100 meters

Page 11

Mantracourt Electronics Limited UAB User Manual

10

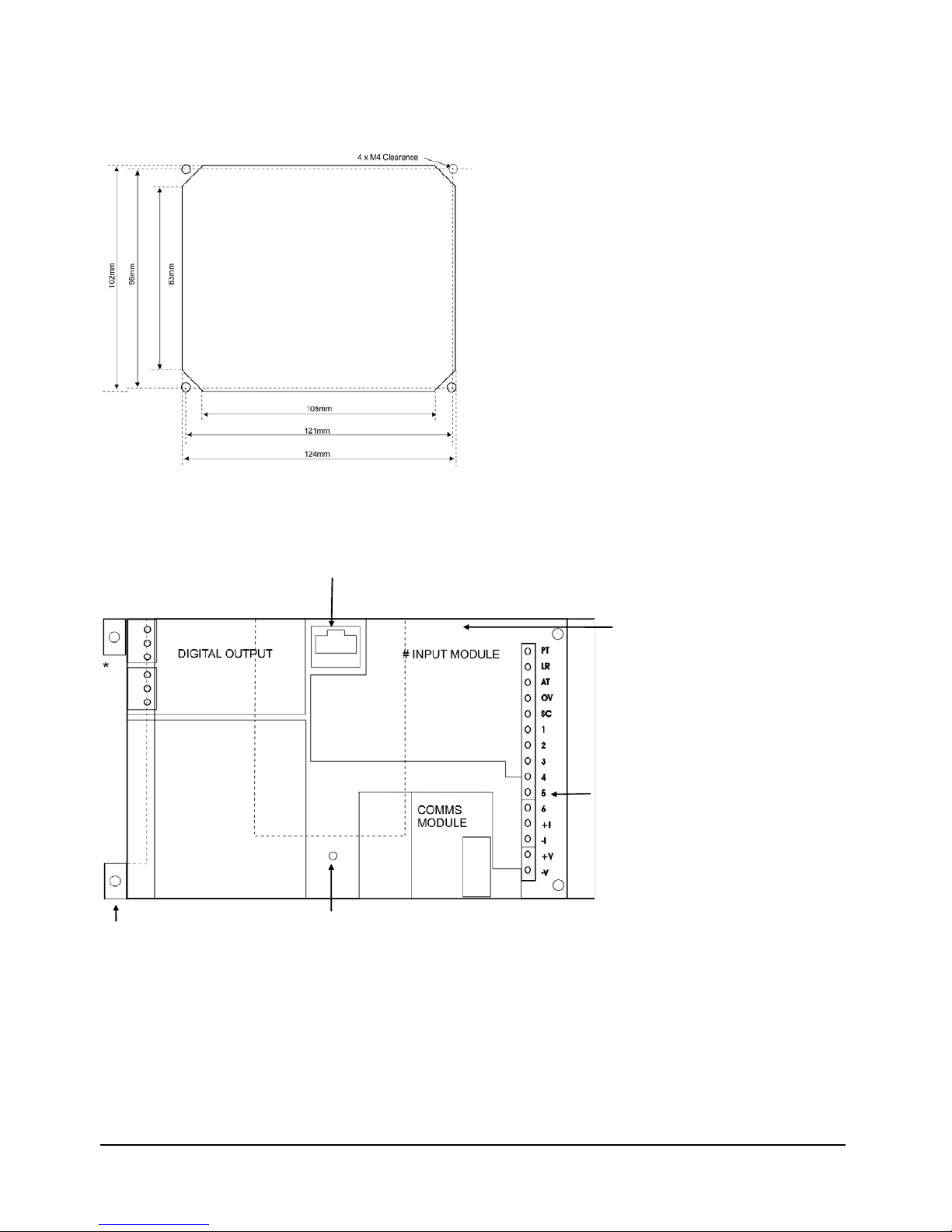

Figure 2.11 LCS Stainless Steel Panel Cut Out

Where there is a requirement for the stainless steel fixture to be mounted in a panel please note the details of the

‘Cut Out’ are as described in the following drawing.

Figure 2.12 Connection & Fitting Details for th e Surface Mounted

Amplifier (UAB)

Display & Keypad FCC68 Connector (For Surface Mounted Display or Hand

Held Programmer LP2 for Non Display Versions.)

The standard

(100mS) strain

gauge input is

contained within

the LCB module &

therefore has no

separate input

module

15 Way field screw

connection for

input, contacts &

AN-OP

For DIN mounting cut off

PCB on white line

WATCHDOG LED

Page 12

Mantracourt Electronics Limited UAB User Manual

11

Programmers for Surface Mou n t V arian ts

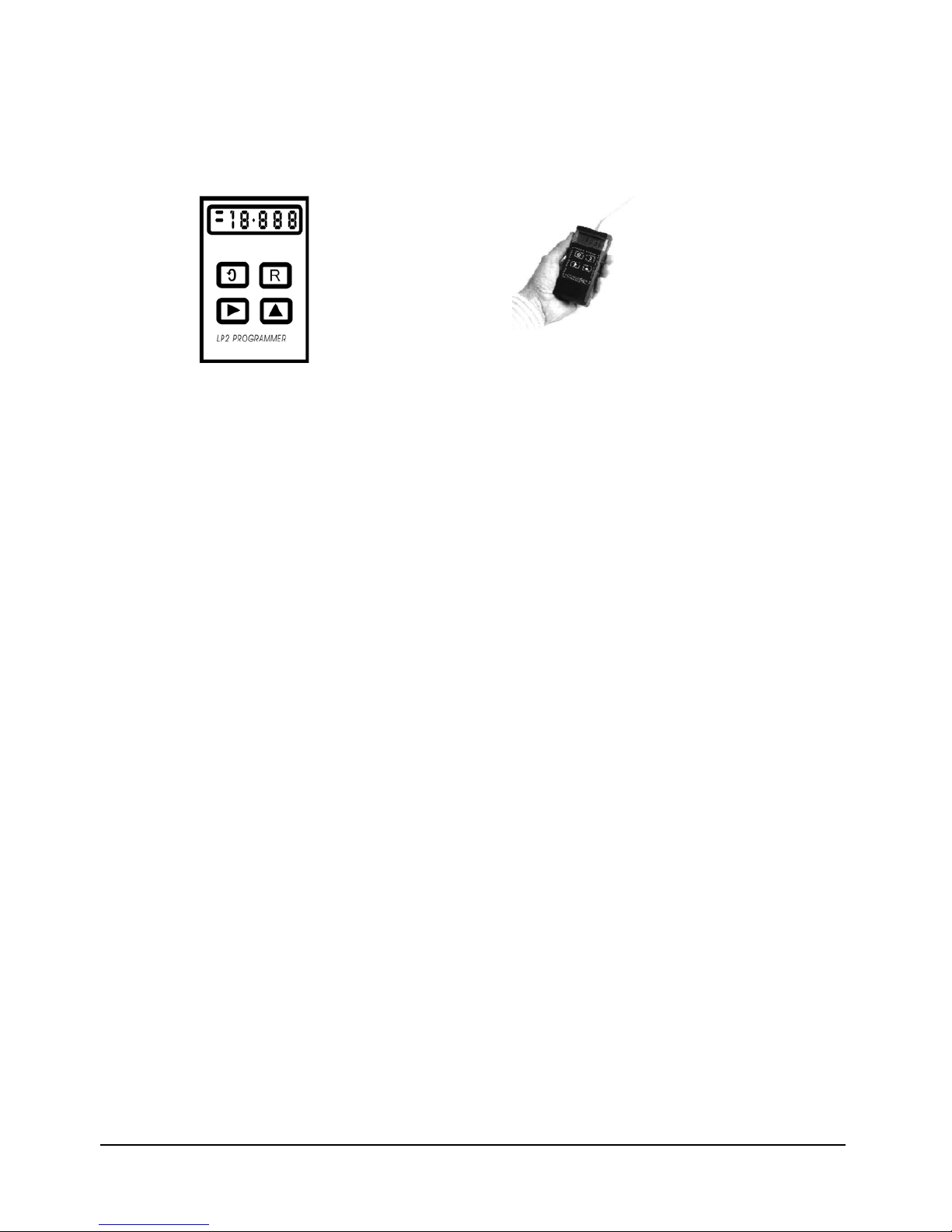

Figure 2.13 LP1 On-Board

Programmer Unit

Figure 2.14 LP2 Remote hand Held

Programmer Unit (UAB)

Page 13

Mantracourt Electronics Limited UAB User Manual

12

Chapter 3 Power Supplies

There are three types of power supply available within the UAB system. The rack versions RUA1 and RUA2 are served

by a common power supply, which offers power to the 12 channels in the case of the RUA1 and 8 channels for the

RUA2. The Surface Mount versions are offered with mains an AC version or a low voltage DC version.

Section 1 - The Rack V ersion (RS1)

The RS1 supplies power to the channels within the rack via the common back plane, offering 220/240VAC at 50/60

Hz or 110VAC at 50/60 Hz. The 110/240 is selected by a switch on the rear of the power supply module. A green LED

on the front panel indicates when power is applied

A 5-Ampere protection fuse is fitted within the power input socket.

The maximum power rating for a full rack is 100 Watts.

Connection to the rack is made via a flying lead with a shrouded and earthed IEC mains connector

Note: Inputs are not intended to be connected to voltages above 50 VAC or 120Vdc

Tables 3.1 and 3.2 show details of the connections and voltages for the various supply rails.

Table 3.1

SUPPLY CONNECTION

TO DIN 41612

MIN V MAX V MAX ac V CURRENT

per channel

COMMENTS

0V 15a, 15c - - - - Common for

processor supplies

-5V 17a, 17c -4.80 -5.2 1mV 110Ma Power supply

-14V

UNREG

19a, 19c

-11

-18V

150mV

2mA

Used to detect power

fail

-9V8 20a, 20c -9.1 -10.2 1mA 200mA Provides excitation

for stain gauges and

relays

Table 3.2

SUPPLY

CONNECTION

TO DIN 41612

MIN V

MAX V

MAX ac V

CURRENT

per channel

COMMENTS

+24V ISO

25a

+20

+32

240mV

32mA

Only required if ANOP to be used

-5V ISO

26a

-4.75

-5.25

1mV

5mA

Only required if ANOP to be used

0V ISO

27a - - - -

Only required if ANOP to be used

Section 2 - The Surface Mount Versions (LS1 and LS3)

The LS1 power supply is a ‘plug in’ module supplying 110 Volts AC at 50/60 Hz or 220/240 Volts AC at 50/60 Hz.

A maximum power rating of 10 Watts is available, with this module.

The running current for each amplifier is between 250 and 480 milliamps dependant upon module configuration,

with a start up current of 3 Amps for 20 milliseconds. Earthing (or shield)- If the amplifier is not earthed elsewhere,

an earth should be made to the screen (SC) of the 15 way connector.

PROC-

ESSOR

SUPPLIES

ANALOGUE

OUTPUT

ISOLATED

SUPPLY

Page 14

Mantracourt Electronics Limited UAB User Manual

13

Figure 3.1 Power Supply LS1 Connections

Figure 3.2 LS3 Connections

The LS3 module should be protected on installation by an in line fuse.

The LS3 power supply is a 'plug in' module supplying 9 to 30 Volts DC. Similar in characteristics to the LS1 with

regard to power and current ratings.

The module is not reverse polarity protected and will require similar protection at installation.

Page 15

Mantracourt Electronics Limited UAB User Manual

14

Chapter 4 Input Modules

The following DC Voltage & Current input modules are available:

-

UADCV1 -

UADCA1 UADCV2 UADIA -

UADIV -

0 to 10 Volts

0 to 20mA

± 200mV

Dual Input - 4 to 20mA

Dual Input - 0 to 10 Volts

Table 4.1 UADCV1 and UADCA1 Sw itc h Configuration

SW1

±200mV

0-10V

0-20mA

1

2

3

4

5

6

7

8

10V Excite

24V Excite

5-25V VAR Excite

ON

OFF

OFF

OFF

OFF

10V Excite

24V Excite

5-25V VAR Excite

OFF

ON

ON

OFF

ON

10V Excite

24V Excite

5-25V VAR Excite

OFF

ON

ON

ON

OFF

Figure 4.1 The UADC1 & UADCA1 Modu l es

Figure 4.2 The UALV1 - LVDT Module Rear Panel Connections

Page 16

Mantracourt Electronics Limited UAB User Manual

15

Figure 4.3 LVDT Switch Settings

The UARTL - Rate/Totaliser Module

Figure 4.4 Rear Panel Connections

Note: See Chapter 7 Section 4 for details of input and pre scaler settings.

UAT1 UAT2 -

Thermocouple Type K Modules

Thermocouple Type J Modules

Connecting the Thermocouple

WARNING:

ENSURE POWER IS SWITCHED OFF BEFORE MAKING CONNECTION TO THE UAB

1. Connect the thermocouple to the UAB terminal as shown in Figure 4.6

Note: If the thermocouple has a floating input, connect terminal 1 to ground.

2. The external cold junction sensor is always connected between input terminals 4 and 6. If no external sensor is

used, link terminals 4 & 6.

Page 17

Mantracourt Electronics Limited UAB User Manual

16

3. Normally, thermocouple burnout is indicated by upscale over range. If downscale indication is required, link

terminals 2 & 3.

Figure 4.5 UAT1 & 2

Figure 4.6 Thermocouple Connectors

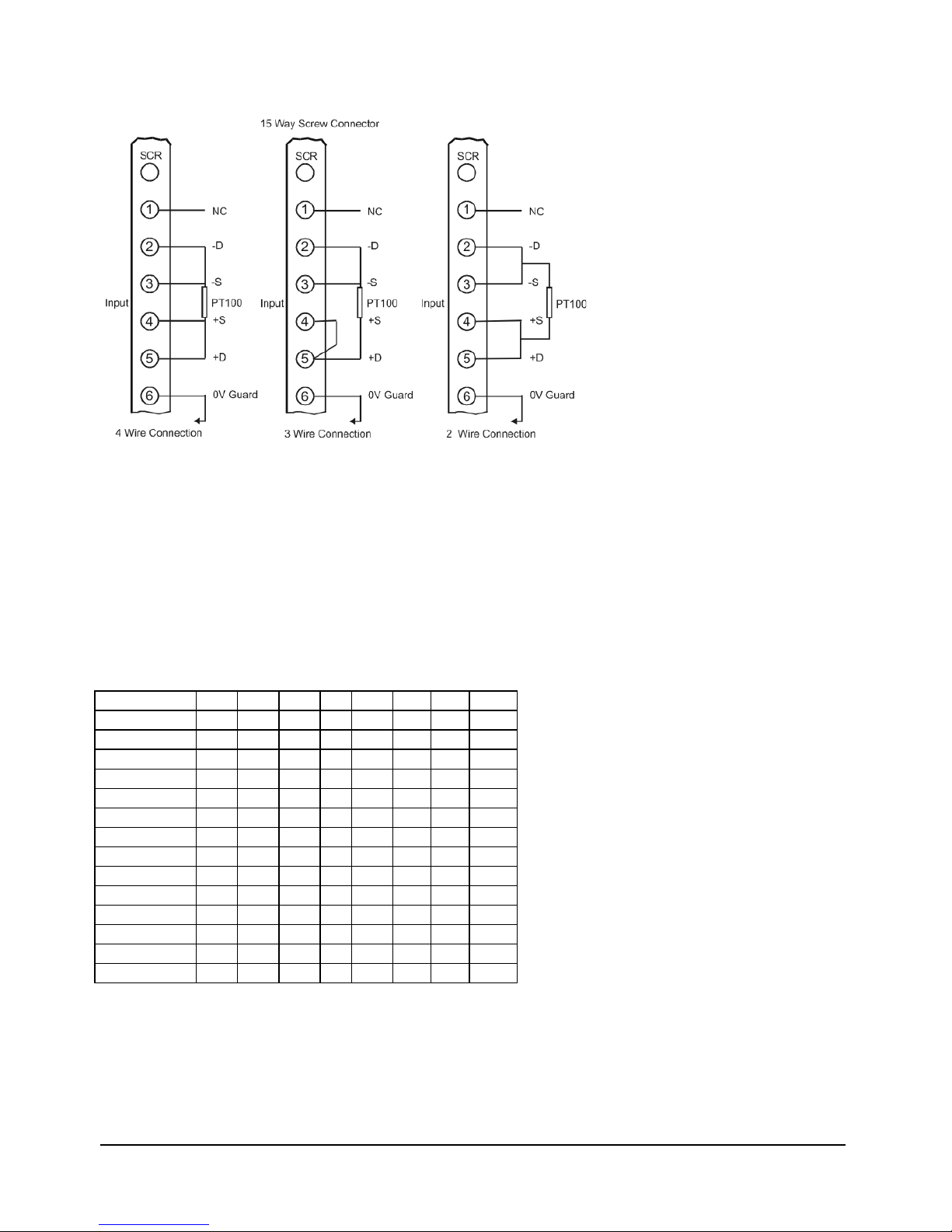

The UAPT Connecting the Resistance Thermometer Module

Connect the resistance thermometer to the UAB terminals as shown in Figure 4.8 using the terminals appropriate to

2, 3 and 4 wire connections.

Note: It is recommended that 4 core-screened cable be used for this connection with terminal 6 used for screen and

ground.

If however, this is not practical, terminal 2 may be used for guard and ground.

Figure 4.7 RTD Module UAP T

Page 18

Mantracourt Electronics Limited UAB User Manual

17

Figure 4.8 RTD Connections

UAFLC Fast Strain Gauge

The UAFLC offers a direct connection to most low level (foil) strain gauge sensors.

A 10-volt excitation is provided and it is monitored to compensate for any variation due to supply drift, load

regulation or voltage drop in the cable between the sensor and the UAFLC.

The maximum supply current is 150mA, which allows for the connection of 4 x 350 Ohm strain gauges.

Strain gauge sensitivity is preset via DIL switches to 0.5, 0.8, 1.0, 1.25, 1.5, 2.0, 2.5, 3.5, 5, 10, 20, 50, 100 and 200

mV/V. Select the next value higher than the strain gauge output maximum.

Note: It is important that the UAFLC is powered up with the strain gauge connected to the input as the A/D

performs an Autocal of its own on power up.

SW1 mV/V

1 2 3 4 5 6 7 8 0.5 x - - x - x x x

0.8

- x x - - x x x 1.0 - x - x - - x -

1.25

- x - - - - - x 1.5 - - x x x - - -

2.0 - - x - x - - x

2.5 - - x - - - - -

3.5 - - - x x - - -

5.0

- - - x - - - x 10.0

- - - - x - - x 20.0

- - - - - x - x 50.0

- - - - - - x x 100.0

- - - - - - - x 200.0

- - - - - - -

-

x = ON - = OFF

mV/V = ±mV/V nominal full range gain within ±3%

Page 19

Mantracourt Electronics Limited UAB User Manual

18

Fast Strain Gauge The (UAFLC) Mo d ul e

Figure 4.9 UAFLC Module Figure 4.10 UAFLC Connections

Dual Input Modules

Provide two non-isolated inputs either 4 to 20mA or 0 to 10 volts (This should be specified at time of order) as:

• UADIA = 4/20mA

• UADIV = 0/10 volts

These inputs have independent scaling factors IPLA and IPHA for input 'A' and IPLB and IPHB for input 'B'.

The display can be selected from the list of 'A' and 'B' functions as follows, and can be selected under the mnemonic

'Ab'

0 =

1 =

2 =

3 =

4 =

A + B

A - B

A x B

A/B

A = process input, B = setpoint (SP1)

Scale factors can be applied to this function using a scale factor 'SF', a division factor 'DF' and a display offset 'OFFS'.

The analogue output, relays and printer take their value from the function selected at 'Ab’.

Figure 4.11 the UADIA Modules Figure 4.12 UADIA Connectio ns

Page 20

Mantracourt Electronics Limited UAB User Manual

19

Chapter 5 Output Modules

Section 1 - General Description

Analogue outputs of 4 to 20mAmps and 0 to 10 volts are standard features and an integral part of the Universal

Amplifier pcb.

Further output modules are available offering alarm/control, printer and communications facilities. Analogue

outputs are fully scaleable, opto-isolated and digitally generated.

The analogue output signals are generated by the CPU from the displayed input variable, so that output signals are

normally related to displayed input values except where the PID function is selected. The 4 to 20 mA output is pre

calibrated to an accuracy of within 0.15% of the range. The 0-10V outputs are accurate to within 2% of the 4 to

20mA output.

Notes:

1. Maximum current load on voltage modules is 2mA

2. Maximum drive voltage available in current modules is 20V

The PID function is an option selectable within the standard software program and provides, where required an

analogue output so that outputs are related to the PID power levels and not the displayed input signal.

Note: In this mode the analogue output cannot be scaled.

A fast analogue output module (UAFAO) is available for use with the fast strain gauge (10msec) input (UAFLC),

where a fast capture facility is a requirement.

The digital output modules consist of two single pole change over relays with ON/OFF or PID control. If required,

latching outputs may be selected via the keypad, reset action being achieved by a contact closure or via the

communications module, where a program has been written via an appropriate protocol.

Set points and hysterisis are also set via the keypad or from a communications input.

Relay outputs may also be inverted via the keypad.

Relay operations are controlled by set point and hysterisis values, output inversion, time delays or by the PID time

proportioning output on set point 1.

Figure 5.1 Showing th e Potentiometer

for Gain & Offset Adjus tment

Figure 5.2 UAFAO Connections

Fast Analogue The (UAFAO) Module

Important Note 1: The output action mnemonic OA must be set to 32 when operating with this module.

Important Note 2: When changing the value of OA to, or from ’32; it is necessary to power the unit off and back on

again as a restart.

See Note with regard to calibrations on Chapter 7 ‘Method of Calculating OPL & OPH from any known output and

Display’

Page 21

Mantracourt Electronics Limited UAB User Manual

20

Section 2 - Digital Output Modules

Module Functions

The Universal Amplifier can be programmed so that the relay output module reacts to all or any of the following

functions:

• Set points

• In Flight compensation

• Hysteresis

• Relay inversion

• Latching

Set Points (SP)

Set points are used to produce output signals at any required value so that the operation of the monitored process

can be maintained to preset levels. Any excursion beyond set points will activate the relay or relays, to provide

alarm or initiate control as required.

Two set points (SP1) and (SP2) can be programmed to suit different applications. The actions of either or both set

points can inverted if required.

For normal operation the set point output is active until the input reaches the set point level. In this condition when

the input value is less than the set point, the SP indicator is on and the output relay is energised producing a closed

circuit on a normally open contact. When the set point value is reached, the SP indicator is off and the relay is deenergised producing an open circuit output.

For an inverted operation the reverse conditions apply.

Normal and inverted action is determined by the direction of the input value as it changes.

For example: In alarm applications.

A High-High operation allows for a rising input value to operate on two set points to define an acceptable quantity,

weight or band of operation.

A Low-Low operation operates on a falling value.

A High-Low operation will operate on a rising or falling value, setting a 'band' by one set point operating normally

and the other being an inverted action.

Hysteresis (HYS)

Once a Hysteresis value has been set, it will be applied to both set points entered. It is effective for both normal

and inverted action.

When Hysteresis is applied to set points with normal output action, the input is allowed to rise to the set point

value and the output is then turned off. The output is held off until the input value has dropped to the set point

minus the Hysteresis value.

For inverted action the input drops to the set point and the output goes off and comes on again when the input rises

to the set point plus the Hysteresis value.

Output Action (OA)

The Output Action facility allows the user to determine whether set points produce normal or inverted and latched

or unlatched output operation. If an analogue output module is also fitted, the Output Action function determines

whether the module's output is inverted or not.

For programming details refer to Chapter 7 Table 7.15

Latching Output (OL)

The latching facility allows the relay module output to held until the reset externally Latching is applied to the

status of the relay SP1 or SP2.

For programming details refer to Chapter 7 Table 7.14

Page 22

Mantracourt Electronics Limited UAB User Manual

21

Digital Output Modules -

(LR1) Surface Mount and (RR1) Rack Mount There are two relay modules available, which function in a similar way.

The ‘plug in’ module LR1 used with the surface mount version is fitted with relay status LEDs, connections being

made directly on to the module terminal block

The RR1, which is used with the rack version, is not fitted with relay status LEDs, these being brought out for

observation, to the front of the rack channel. Connections to the module are made to a 4 way field terminal at the

rear of the rack channel.

RR1 - 2 SPCO relays, SP1 and SP2

Relay contact rating - 50V @ 500mA

LR1 - 2 SPCO relays, SP1 and SP2,

Relay contact rating - 240V @ 5A AC

Figure 5.3 RR1 Module Figure 5.4 LR1 Module

The Remote Driver Modules - UAI ²C

The module offers a general I/O facility for connection to Relays, Real Time Clock and Remote Displays, and is a

direct 'plug in' replacement for the RR1 or LR1 Relay Module.

Two versions of the module are available one for the Rack and the other for the Surface Mount versions of the

Universal Amplifier Board.

Connection to the Rack version - UA1²C (R)

The Channel 4 Way Screw

NO 1

Com 1

NO 2

Com 2

Wire Colour from REMC1

Violet & Yellow

Red

Black

Blue

Signal

GND

+5V

CLK

DATA

Connection to the Surface Mount/DIN Rail version - UAI ²C(S)

Page 23

Mantracourt Electronics Limited UAB User Manual

22

Figure 5.5 Installa tion of LR1

To meet the Specified EMC Fast transient requirements

it is important that the ferrite ring supplied is fitted as

per the following instructions.

Illustration showing ferrite ring FEC 323-4940 fitted to

the LR1 relay wiring.

Two turns of the wiring are passed through the ring

positioned 12cm from the LR1 end of the cable to

improve immunity to electrical fast transients and

bursts.

Figure 5.6 Connection to the Surface Mount/DIN Rail Version UAI²C (S)

Section 3 - The Communications Port Modules

A series of communications modules in both surface mount and rack versions, provide for two way data links to an

intelligent host such as a Personal Computer, Main frame or PLC, which are able to acquire displayed values and

read or modify the user configurable parameters, using any of the following: -

A 20mA current loop usually connected through an IF25 current loop to RS232 interface unit for multiple amplifier

connection. - (LC1) for the surface mount and (RC1) for the rack version.

An RS232 for a one to one communication, usually where a printer connection is required. (RC2) for the rack

version.

A RS232/485 (link selectable) for one to one or multi-drop applications - (LC3) for the surface mount and (RC3) for

the rack version.

Three communication formats, FAST MANTRABUS, ASC11 and PRINTER are selected from the mnemonic CP via the

keypad of the display/programmer.

Integrity is ensured by pre-programmed default parameters, should a loss of communications with the host unit

occur.

Connection and Baud rate setting details are shown in the following module diagrams: -

Page 24

Mantracourt Electronics Limited UAB User Manual

23

Figure 5.7 LC1 Current Loop

Figure 5.8 IF25 Connecting Multiple Process Amplifiers

Connecting Multiple Process Amplifiers to the IF25 Interface

Notes

1. Maximum loop voltage is 50V dc.

2. Loop is isolated from host and Process Amplifiers. Loop should be earthed via Rx - on IF25/254

3. IF25 used for up to 25 Process Amplifiers.

4. At 19,200 Baud, max. cable length is 100m metres, using cable type BICC H8085.

LC3 Isolated RS232/485 Co m munications Modul e

Figure 5.9 LC3 Isolate d RS232/ 485~M ode Connection s

Note: When multi dropping in RS485 mode, the last device should be fitted with LK2, which acts as a 120Rterminating resistor.

Page 25

Mantracourt Electronics Limited UAB User Manual

24

Figure 5.10 Connec tin g M u l tiple Units on RS485

Figure 5.11 LC3 RS232 Mode Connection to PC

Note: LK1 must be fitted for RS232 operation

Figure 5.12 LC3 RS232 Mode Connection to Printer

Note 1: LK1 must be fitted for RS232 operation

Note 2: If no RTS is available from the printer, fit LK2

NOTE:

When using an RS232 to RS485 converter, which has a non-biased receiver, the following actions are recommended:

-

To bias the device:

1. Terminate the receiver with 140R in place of the usual 120R

2. Fit a 1.5K from the receive negative to the receiver +5V supply, or a 3K3 to the +12V supply.

3. Fit a 1.5K from the receive positive to the receiver supply Ground.

Page 26

Mantracourt Electronics Limited UAB User Manual

25

RC1 Communications Current Loop Module Connections

RC1 used in connection with an IF25 to provide a high noise immunity 20mA current loop. RC1 modules are supplied

with a BLUE 9 way bus-terminating header. One of these headers must be connected to each channel fitted with an

RC1 module, apart from Channel 1, which is terminated by links, LK1 & LK2 on back plane.

Figure 5.13 RC1 Commun ica tio n Connections

9 way ‘D’ type socket with

(RED) identifier

9 way ‘D’ type socket

(BLUE) for channels 2-12

supplied with RC1

Figure 5.14 RC1 Baud Rate Selection

Baud rate is selected by a link header

(SW1)

Page 27

Mantracourt Electronics Limited UAB User Manual

26

Figure 5.15 Connecting Multiple Process Amplifiers

IF25 To Multi Rack System

Notes:

1. Maximum loop voltage is 50V dc.

2. Loop is isolated from host and RCA15s. Loop should be earthed via Rx - on IF25/254

3. IF25 used for up to 25 RCA15s.

4. At 19,200 Baud, max. cable length is 100m meters, using cable type BICC H8085.

RC3 RS232/485 Communication Connectors

Providing isolated multi-drop RS485 for up to 25 RCA15 Channels.

For each RC3 module a GREEN 9 way bus terminating header is supplied. One of these must be connected to each

channel fitted with an RC3 module. Channel 1 is terminated by links LK1 & LK2 on back plane.

Figure 5.16 RC3 RS232/485 Communication Connections

Note: The last device may be terminated by 120R resistor by fitting LK2 on RC3 module.

LK1 on RC3 must not be fitted for multi-drop applications.

Page 28

Mantracourt Electronics Limited UAB User Manual

27

Figure 5.17 - RC3 Baud Rate S election

Baud Rate is selected by a link header (J3)

Do not change baud setting with power on

NOTE:

When using an RS232 to RS485 converter, which has a non-biased receiver, the following actions are recommended:

- To bias the device:

1. Terminate the receiver with 140R in place of the usual 120R

2. Fit a 1.5K from the receive negative to the receiver +5V supply, or a 3K3 to the +12V supply.

3. Fit a 1.5K from the receive positive to the receiver supply Ground.

Section 4 Serial Communication Protocol

General

Incoming data is continually monitored by the Process Amplifier on its serial input line. Each byte of data is

formatted as an eight bit word without parity, proceded by one start bit and followed by one stop bit.

Transmission and reception of data up to 19.2K Baud is possible, the actual rate being selected by six position

header links on the communications module. The Baud rate depends upon the communications, hardware

specification, distance and cable type.

Fast MANTRABUS - selected when CP is 128

To signify commencement of a new 'block' of data, the HEX number FFH is used as a 'frame' character, followed by

the station number of the unit under interrogation. This is entered via the Process Amplifier keypad under

mnemonic SDSt and ranges from 0-254). The Process Amplifier acts upon incoming data only if its own station

number immediately follows the FFH character.

New data must be received as a string of four nibbles (bits 7-4 set to zero), which are assembled into two bytes, and

written into the variables store within the Process Amplifier. The most significant nibble must be received first and

the last nibble must have the most significant bit (bit 7) set to indicate the end of data. This is followed by the

checksum. The data transmitted from the Process Amplifier is always sent as complete bytes. The station number

precedes the data and the checksum follows the data. The data format used is signed 15 Bit. The most significant

Bit of the most significant Byte is set for negative numbers.

Operation

There are two modes of operation, namely data requests by the host controller and data changes. Data requests

from the Process Amplifier consist of either a complete dump of the data variables stores in RAM or the display

reading.

Data changes consist of writing new data to Process Amplifier variables, thus changing parameters such as Set

Points, in flights etc.

An acknowledgement message is returned to the Process Amplifier to indicate that the new data has been acted

upon.

Updating

The station number followed by the command byte determines the required mode or variable to be updated. An

EXOR checksum consisting of the station number command byte and any following data must be appended to the

received data. It is most important that the byte preceding the checksum must have its most significant bit set to

signify the end of data.

The Process Amplifier works out its own checksum and, if it disagrees with the received one, a not acknowledge

(NAK) message is returned.

Page 29

Mantracourt Electronics Limited UAB User Manual

28

Communications Commands

The following is a list of commands available for reading to or writing from the Process Amplifier.

Command No.

DEC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

HEX

1

2

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

15

16

Description

REQUEST ALL DATA INCLUDES PROCESS VARIABLE INPUT

REQUEST DISPLAY DATA

SET POINT 1

SET POINT 2

HYSTERESIS

OUTPUT LATCH

OUTPUT MODE SELECT

PROPORTIONAL BAND

INTEGRAL TIME

DIFFERENTIAL TIME

CYCLE TIME

INPUT LOW

INPUT HIGH

OUTPUT LOW

OUTPUT HIGH

INPUT RANGE SELECT

DECIMAL POINT POSITION

STATION NO.

EEPROM ENABLE/DISABLE FLAG

OUTPUT RELAY RESET

TOTALISER COUNT RESET

PEAK HOLD RESET

SP1

SP2

HYS

OL

OA

PB

IT (ont)

DT (oFFt)

CT(da)

IPL

IPH

OPL

OPH

IP

DP-r

SDSt

-

-

-

-

Command 1 Request for All Data:

Data Transmitted To Process Amplifier For Command 1

0FFH, Station Number, 081H, Chksum

Where Chksum = Station number EXOR with 081H. Example: To obtain a complete dump of the variables in the

Process Amplifier whose Station number is 47 send the following Data:-

0FFH, 02FH, 081H, 0AEH

Note MS Bit Set

Page 30

Mantracourt Electronics Limited UAB User Manual

29

Response to Command 1 From Process Amplifier

Byte

1

2,3

4,5

6,7

8,9

10,11

12,13

14,15

16,17

18,19

20,21

22,23

24,25

26,27

28,29

30,31

32,33

34,35

36

37

38

STATION NUMBER

DISPLAY

SET POINT 1

IN FLIGHT 1

SET POINT 2

IN FLIGHT 2

HYSTERESIS

OUTPUT ACTION

A/D COUNTS FOR LOW CALIBRATION POINT

A/D COUNTS FOR HIGH CALIBRATION POINT

DISPLAY LOW CALIBRATION VALUE

DISPLAY HIGH CALIBRATION VALUE

AUTO TARE

DISPLAY AVERAGING

OUTPUT LOW

OUTPUT HIGH

DECIMAL POINT POSITION

STATION NUMBER

EEPROM ENABLE/DISABLE FLAG

RELAY STATUS

EXOR CHECKSUM OF THE ABOVE DATA

NOTE: Most significant byte precedes least significant byte for data sent by Process Amplifier

Command 2 Request Display Data

DATA transmitted to Process Amplifier for Command 2.

0FFH, Station number, 082H, Chksum

Where Chksum = Station number EXOR with 082H Example: To obtain the display reading of an Process Amplifier

whose station number is 47 send the following Data:

0FFH, 02FH, 082H, 0ADH

Note MS Bit Set

Response to Command 2 from Process Amplifier

Byte

1. Station No.

2. Display reading M.S. Byte.

3. Display reading L.S. Byte.

4. EXOR checksum of above data and Station No.

If, when using commands 1 or 2, an error is detected by the Process Amplifier then the Not Acknowledgement string

is transmitted by the Process Amplifier.

Commands 3 To 18: Write data to Process Amplifier parameter

Commands 3 to 18 all have the same format. Format for data transmitted to Process Amplifier for Commands 3 to

18: 0FFH, Station No, Command No, MSN, NMSN, NLSN, LSN, CHKSUM

Where MSN

NMSN

NLSN

LSN

CHKSUM

= Most significant nibble of data

= Next most significant nibble of data

= Next least significant nibble of data

= Least significant nibble of data with MSBIT set

= The following EXOR’d with each other, Station number, command

number, MSN, NMSN, NLSN, LSN with MSBIT set

Example: To change SP1 to 200.0 on a Process Amplifier whose station number are 47. The following data is sent.

Page 31

Mantracourt Electronics Limited UAB User Manual

30

Please note the following points apply: -

1. The decimal point is ignored i.e. 200.0 equals 2000 digits

2. The data is sent in Hex nibbles so 2000 = 00H, 07H, 0DH, 00H

0FFH, 02FH, 03H, 00H, 07H, 0DH, 80H, 0A6H

Note MS BIT SET

Response to Command 3 to 22

If the data has been accepted by the Process Amplifier then the following acknowledgement string is transmitted by

the Process Amplifier.

Station number, 015H (NAK)

If there are any errors with the data received by the Process Amplifier then the following Not Acknowledgement

(NAK) string is transmitted by the Process Amplifier: -

Station number, 06H (ACK)

Command 19: EEPROM ENABLE / DISABLE

The EEPROM disable facility can be used for any of the following:

I. To limit the number of write cycles to EEPROM reducing degradations.

II. Change data in the Process Amplifier RAM only, allowing EEPROM to hold power up values.

III. Leave base constants in the EEPROM for later update to RAM, which allows manipulation of the RAM before

writing to the EEPROM.

Writing new data from the RAM to the EEPROM.

EEPROM disable is achieved by writing 0100H to the Process Amplifier via command 19. In this state all writing to, or

reading from the EEPROM is inhibited.

The EEPROM can be re-enabled in 2 ways:

By writing 0200H via command 19. This writes the current contents of the variables store in the Process Amplifier

into the EEPROM

By writing 0400H via command 19. This updates the variables store from the current contents of the EEPROM.

Examples

To disable the EEPROM on an Process Amplifier whose Station number is set to 47

0FFH 02FH 013H 00H 01H 00H 080H 0BDH

To re-enable the EEPROM and update the RAM with the old EEPROM constants:

0FFH 02FH 013H 00H 04H 00H 080H 0B8H

To re-enable the EEPROM and update it with the new RAM data:

0FFH 02FH 013H 00H 02H 00H 080H 0BEH

For response see 'Response to Command 3 to 22'.

Command 20: Output Relay Reset

DATA transmitted to Process Amplifier for Command 20

OFFH, Station number, 094H, CHKSUM

Where CHKSUM = Station Number EXOR with 094H Example: To output a relay reset to an Process Amplifier whose

Station Number is set to 47

0FFH, 02FH, 094H, 0BBH

Note MS BIT SET

For response by Process Amplifier see 'Response to Commands 3 to 22'

Page 32

Mantracourt Electronics Limited UAB User Manual

31

Command 21: Auto Tare

DATA transmitted to Process Amplifier for Command 21

OFFH, Station number, 095H, CHKSUM

Where CHKSUM = Station Number EXOR with 095H Example: To output an Auto Tare command to an Process

Amplifier whose Station Number is set to 47

0FFH, 02FH, 095H, 0BAH

Note MS BIT SET

For response by Process Amplifier see 'Response to Commands 3 to 22'

Command 22: Peak Hold Reset

DATA transmitted to Process Amplifier for Command 22

OFFH, Station number, 096H, CHKSUM

Where CHKSUM = Station Number EXOR with 096H Example: To output a Peak Hold reset to an Process Amplifier

whose Station Number is set to 47

0FFH, 02FH, 096H, 0B9H

Note MS BIT SET

For response by Process Amplifier see 'Response to Commands 3 to 22'

Example of a Basic C ode to Communicate wit h M ANTRABUS

open the serial port with no handshaking

OPEN"COM2:4800,N,8,1,RS,DS,BIN" FOR RANDOM AS#1

request display from device 1

Frame FF

Station No

1

Command 2

And add 80 hex

to this byte as it

is the last before

as the checksum

Checksum of

all bytes except frame

talk$=CHR$(&HFF)+CHR$(&H1)+CHR$(&H82)+CHR$(&H1 XOR&H82)

print the string to t h e port

PRINT#1,talk$;

(must add semicolon after string to stop transmitting a carriag e ret urn)

wait for a while (this depends on how many bytes you are expecting and the baud rate!)

input all the bytes in the serial buffer

input.from.uab$=INPUT$(LOC(1),#1)

ASCII Format - selected when CP is 129

The serial data to and from the Process Amplifier is formatted as eight bit words with no parity preceded by one

start bit and followed by one stop bit. The baud rate (up to 9.6k Baud) is selected on the COMMS module. All

communications are carried out using the standard ASCII character set. Incoming line feeds and spaces are ignored;

upper and lower case letters are permitted. The incoming data is continually monitored for Carriage Return

characters (Chr$13D). If one is received the next three characters (000 - 999) are compared with the Process

Amplifier station number (SDST) previously entered via the keypad. N.B. leading zeros must be included. If no match

is found the data that follows is ignored.

The next characters received (up to 4 max) are decoded as the 'label', i.e. which variable in the Process Amplifier is

to be acted upon. If the label is received incorrectly and cannot be decoded the Process Amplifier will return a '?'

followed by a C.R. character. If the received label is followed by a C.R. the Process Amplifier will return the current

value of the variable in question. Because there is no hardware handshaking, all transmission from the Process

Amplifier is performed one character at a time upon receiving a Null character (Chr$0) prompt from the Host

system. Thus for every character transmitted by the Process Amplifier a prompt character is required from

the host. The output from the Process Amplifier is an ASCII string of sixteen characters the last one being C.R. The

first four characters are the Station No. (with leading zeros if necessary) followed by a space. The label then follows

Page 33

Mantracourt Electronics Limited UAB User Manual

32

with spaces added if required to make a total of four characters. The next seven characters is the numerical value

of the required variable with polarity, spaces, d.p. and leading zeros added as required.If the received label is

followed by an '=' character the Process Amplifier accepts the following numerical data (which must be terminated

by a C.R.) and updates the variable in question and returns a C.R. character to the host when prompted. Data input

is reasonably flexible. If all five digits are entered, no decimal point need be included. If less than five digits are

entered with no decimal point then the last digit is assumed to be the units.

Under normal circumstances the EEPROM in the Process Amplifier continually refreshes the working RAM. However,

it can be disabled via the serial input, by sending the instruction 'DROM = 256' after the Station No. In this condition

all read/write operations to or from the EEPROM are inhibited. There are two instructions which will re-enable the

EEPROM:

1. 'ERRD' - this performs a read from the EEPROM and updates the working RAM with the contents of the EEPROM.

2. 'ERWR' - this instruction writes the new RAM values into the EEPROM.

In both cases the EEPROM continues to refresh the RAM.

Instruction Set for ASCII Serial Communications

Request for data:

DATA sent to Process Amplifier Data returned from Process Amplifier

CR xxx

Station No.

CR xxx

Station No.

DISP CR

label

DOSP CR

incorrect label

xxx 'SPACE'

Station No.

xxx 'SPACE'

Station No.

DISP

label

DOSP

incorrect

label

YYYYYY CR

numerical value

'SPACE' ? CR

DATA sent to Process Amplifier Data returned from Process Amplifier

CR xxx

Station No..label

CR xxx

Station No.,

SP1 = 100.0

numerical value

SP3 = 100.0

incorrect label

numerical value

CR

?CR

Page 34

Mantracourt Electronics Limited UAB User Manual

33

Table 5.1

Labels

DISP

SP1

IF1

SP2

IF2

HYS

OA

At

DA

OPL

OPH

DP

SDST

DROM

ERRD

ERWR

RLYS

RES

TARE

PKR

Description

REQUEST DISPLAY READING

SET POINT 1 (SP1)

IN-FLIGHT 1 (IF1)

SET POINT 2 (SP2)

IN-FLIGHT 2 (IF2)

HYSTERESIS (HYS)

OUTPUT ACTION (OA)

AUTO TARE (At)

DISPLAY AVERAGES (dA)

OUTPUT LOW (OPL)

OUTPUT HIGH (OPH)

DECIMAL POINT (dP r)

CAN NOT BE WRITTEN TO (SDST/CP)

DISABLE EEPROM (DROM = 256)

ENABLE EEPROM AND READ FROM IT

ENABLE EEPROM AND WRITE TO IT

OUTPUT RELAY STATUS ( 0 = BOTH OFF, 1 = RELAY 1 ON, 2 = RELAY 2 ON, 3 = BOTH RELAYS ON)

OUTPUT RELAY RESET

AUTO TARE

PEAK HOLD RESET

Process Amplifier Printer Format

(CP must be set between 0 - 127)

Printer selection enables the Process Amplifier to print its current display value to a printer via its communications

port. This display value can either be assigned a date and time stamp and/or a log number depending on the user

set options entered under mnemonic 'CP'. The log number can be reset or preset using the mnemonic 'Ln'. This value

is not saved on power fail. A label can be suffixed to the printed display value using the mnemonic 'LAb'. A large

range of labels are available to the user.

The time and date are set in the TDP printer itself using its own menu. The printer allows the entry of an additional

custom text message.

Three connections are required between the Process Amplifier communications port and the printer with a

maximum cable length of 100 meters. (See Chapter 5 Figure 5.11 for Details)

All standard Process Amplifier options are available with the exception of the communications modules, which

cannot be connected when the printer option is used.

Additional Mnemonics for the Printer Operation:

When the printer option is fitted further mnemonics are included in the normal range. After the dP r mnemonic are

the following: -

Page 35

Mantracourt Electronics Limited UAB User Manual

34

CP

0

1

2

3

At this mnemonic the printer type and print format number is selected. This number

being

appropriate to the type of printer used. Details are advised with each type of printer

selected.

Present types available are: - For the ITT IPP-144-40E printer the following numbers apply

Prints a sequential log number with the current display and unit of measure

e.g. 00014 0011.3 tonne

Prints date and time with a sequential log number, current display and unit of measure

e.g. 00015 0001.7 tonne

05.03.2007 05:06

Prints a sequential log number, current display, unit of measure with customer text

message No 1

e.g. MANTRACOURT ELECTRONICS PROCESS AMPLIFIER PRINTER

00012 00023. tonne

Prints date and time with a sequential log number, current display, unit of measure and a

customer text message No.1

e.g. MANTRACOURT ELECTRONICS PROCESS AMPLIFIER PRINTER

00013 0023. tonne

05.03.2007 12:03:04

4-7

8,9

10

12

127

Digitec 6700 series

Amplicon AP24 and AP40

Eltron LP2142 - (The label file must be called 'MEL' and the label must contain a LOG

NUMBER, THE DISPLAY VARIABLE & a LABEL (not zero).

LOG NUMBER, THE DISPLAY VARIABLE & a LABEL (not zero)

ASCII string on print command

Continuous ASCII stream of the display data, transmitted on every display update

Note: 1

Note: 2

9 gives an inverted print out

It is anticipated that further types of printer will be added, and additional numbers

will be allocated as appropriate

Lab

Label Number

A number can be selected for the appropriate unit of measure. See table below:

Note: 0 = NO LABEL

0 BLANK

1 Deg R

2 Deg C

3 Deg F

4 Kelvin

5 Ib/in 2

6 bar

7 mbar

8 kPa

9 atm

10 mmHg

11 inHg

12 inH2O

13 cmHg

14 mm

15 Wh

16 Db

17 tonne

18 m

19 in

20 ft

21 degrees

22 L/s

23 L/min

24 L/h

25 gals/s

26 gal/min

27 gal/h

28 %RH

29 gram

30 kg

31 lb

32 kWh

33 mile/h

34 %

35 ton

36 %Dev

37 W

38 kW

39 MW

40 pH

41 ppm

42 uS

43 Ohms

44 m/s

45 ft/min

46 RPM

47 RPMx10

48 RPMx100

49 cos @

50 km/h

51 ms

52 RPM1000

53 Hz

54 kHz

55 V DC

56 mV DC

57 A DC

58 mA DC

59 V AC

60 mV AC

61 A AC

62 N

63 spare

64 spare

65 spare

66 spare

67 knots

68 s

Ln Log Number

A range of numbers 0 to 19,999 is available. Any sequential number logging

activity can be preset as desired, between these numbers. The number will

reset to zero after 19,999. The log number is not saved on power fail

and resets to zero on power up.

Page 36

Mantracourt Electronics Limited UAB User Manual

35

Chapter 6 The Amplifier Displays

A range of display /keypad variants are offered to accommodate both surface mount and rack versions of the

Process Amplifiers.

Rack Amplifiers

The two versions of the rack amplifier RUA1 and RUA2, have different display fixture requirements. The RUA1 is

provided with an FCC type shuttered socket on the front of each channel, into which a hand held programmer (LP2)

is inserted and latched and which can be removed, once programming is complete. In common with all amplifier

displays a 4.5 digit LCD display and keypad is provided to allow for common programming procedures.

The RUA2 is fitted with an On-Board front panel mounted display and programming facility of similar layout to the

(LP2). However in this case the programming is achieved by inserting a probe through the 2.2mm holes in the front

panel.

Figure 6.1 Programmer Unit Pane l

Layout (RUA2)

Figure 6.2 LP2 Remote Ha n d H e ld

Programmer Unit

When in the programming mode, a Flashing bar symbol ‘-’ is indicated in the top left hand corner of the display.

Surface Mount Amplifiers

A security link option on the rear of the display pcb, is available to prevent the change of data where required.

Where surface mount amplifiers are used, options are available to program with the (LP2), from the FCC socket

mounted on the main pcb, or by fitting an On-Board display module (LP1) with nylon stand off pillars, onto the main

pcb, using the same FCC socket. The layout of the keypad remains similar throughout.

Figure 6.3 Programmer Unit Panel Layout (LP1)

Page 37

Mantracourt Electronics Limited UAB User Manual

36

Control Panel Guide

d

Used to scroll through and change the set up data by displaying mnemonics for each

configurable parameter, followed by the appropriate data.

When in programming mode it should be noted that the first digit in the display

might not be visible, but the program indicator --- will be flashing to indicate that

the instrument is in programming mode, even though no digits can be seen to be

flashing.

b

Selects the display digit required. Selection value is indicated by a flashing digit

and flashing program indicator.

c

Increments each selected display digit 0-9.

Pressing the c key under programming conditions will display the leading digit as

either 1, -1, or a blank display for zero.

a

Resets the display to the input variable and enters new data in the LCA15 memory.

Returns the display to the current value after Hold.

If during the programming sequence, selection is not completed, the display will

revert to the input variable after 2 minutes.

The display and controls on the front panel mounted version (RL2) operate in a

similar way to the remote display/programmer described above, with program

buttons being accessed through 2.2mm holes in the panel.

A Large Keypad Panel Mount Display is also available which can be mounted to the lid of the ABS case of the

surface mount amplifier, or with the necessary driver hardware, can be fitted to a stainless steel panel and used

remotely.

Figure 6.4 Programmer Unit Pane l L ay o ut

Page 38

Mantracourt Electronics Limited UAB User Manual

37

Figure 6.5 Display Module Connections and Switch Settings

Table 6.1

Position ON

Function

Factory Settings

1

Enables Keys b and c

ON

2

Enables all Program Keys

d b c & a

ON

3

Enables e and f Function Keys

ON

4

Enables g and h Function Keys

ON

5

Forces display to always be GROSS

VALUE only

OFF 6 Forces display to always be NET VALUE

only

OFF

Page 39

Mantracourt Electronics Limited UAB User Manual

38

Chapter 7 Programming The Amplifiers

Section 1 - Display & Programming Mnemonics

As described in the previous chapter, there is common symbol and keypad layout for programming all the variants

whether it be rack or surface mounting units.

Table 7.1 Configurable Parameters for Process Input

The standard range of programming mnemonics is show in the following table: -

Display Function

(In order of Display)

Range

Function

PASS

SP1

SP2

HYS

OL

OA

1111

Set Point 1

Set Point 2

Hysteresis

Output Latch

Output Action

(Inversion)

of SP1 & SP2

±19999

2000

ADCL

ADCH

-19999 to +19999

-19999 to +19999

0 to +19999 in real

display units

Latch set by code in

range 0-3 as shown in

Table 5.1

Action set by code in

range 0-15 as shown in

Table 5.2

Security Password. Correct value required proceeding

further (special numbers on request).

Password for Analogue Input Calibration routine giving

access to:

A to D Calibration Low value

A to D Calibration High value

Sets first output trip or control

(Chapter 5 refers)

Sets second output trip or control (Chapter 5 refers)

Sets hysteresis applied to SP1 and SP2 when used for

ON/OFF control units (Chapter 5 refers)

Allows SP1 and/or SP2 to be latched

until reset externally, from the keypad or via

communications port.

Sets output relay action. Can be set

to ‘normal’ or ‘inverted’ operation for either or both set

points. Gives fail safe operation of any alarm

combination, High-High, High-Low, Low-High & LowLow. (Chapter 5 refers) Also selects whether analogue

outputs controlled by display module or PID element in

CPU Inversion of the analogue output.

Page 40

Mantracourt Electronics Limited UAB User Manual

39

Pb

Ont

(It)

OFFt

(dt)

dA

Proportional Band

Output on delay

Integral

Output off

delay

Derivative

Time

Display

Averaging &

Peak Hold

0 to 1024

0 to 255

0 to 6000

0 to 255

0 to 255

0 to 15

'O' Selects 'Ont'.'Offt' or 'da' function 1-1023 Selects PID

mode and value of proportional band, in displayed units.

1024 Selects Integral 'It' only control

When PID is not used, (PB=0) the mnemonic (Ont) sets a

delay on time for SP1 & SP2. Set in seconds. Or

Selects integral value for PID control in seconds/repeat.

0= Proportional only control.

When PID is not used, (PB=0) the mnemonic (Offt) sets a

delay off time for SP1 & SP2 set in seconds. Or

Selects derivative value for PID control. 0 = OFF (no

derivative)

When PID is not used, (PB=0) the mnemonic (dA) sets a

display averaging update rate.

Readings may be averaged over a number of updates and

can be set as follows:

Display update time

0 = 1 readings (standard) approx. 0.4S

1 = 2 readings approx. 0.8S

2 = 4 readings approx. 1.6S

3 = 8 readings approx. 3.2S

4 = 16 readings approx. 6.4S

5 = 32 readings approx. 12.8S

6 = 64 readings approx. 25.6S

7 = Fast update mode approx. 0.1S A peak hold

function, which will display the highest recorded value

of the measured input, can be set by adding 8 to any of

the above settings. To reset Peak Hold press the b key,

then within 1 second, press the c key. Can also be reset

externally or via comms.

Or

(ct)

IPL

(IpOf)

IPH

Cycle time

Input Low

Offset Factor

Input High

1 to 255

-19999 to 19999

-19999 to 19999

-19999 to +19999

Set time in seconds for one

complete power cycle output of PID

power (time proportioned through

SP1).

For linear analogue inputs, used to

set the required display reading

when an analogue input is at its

minimum value. Also provides an

OFFSET for value for non linear

analogue Inputs.Or

For rate/totaliser inputs, the value

provides an offset or for totaliser, a

count reset value.

For linear analogue inputs, used to

set the required display reading

when an analogue input is at its

maximum value.Or

Page 41

Mantracourt Electronics Limited UAB User Manual

40

(IpSf)

OPL

OPH

Scale Factor

Output Low

Output High

0 - 1.9999

-19999 to+19999

-19999 to+19999

Applies a variable gain to the rate