Page 1

LVDT/A & LVDT/D

Amplifier / Signal Conditioner

User Manual

MICRON METERS

www.micronmeters.com

metersinfo@micronmeters.com

Page 2

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

1

LVDT/A & LVDT/D Manual

Contents

Chapter 1 The LVDT Conditioner ..................................................................................................... 1

Chapter 2 Installing the LVDT/A & LVDT/D ......................................................................................... 2

Terminal Connection ..................................................................................................................... 3

Dimensions of the Enclosure and Mounting Holes ................................................................................... 3

Output Connections ...................................................................................................................... 4

Output Current Mode Settings – Jumpers JP1 & JP2 ................................................................................ 5

Chapter 4 Input Calibration ........................................................................................................... 6

Span (gain) - SW1 (0 = OFF 1 = ON) .................................................................................................. 6

Zero (offset) - SW2 ....................................................................................................................... 7

Excitation Amplitude - SW2/8 .......................................................................................................... 7

The LVDT/A & LVDT/D Filter ........................................................................................................... 7

Filter Cut off - SW3 (0 = OFF 1 = ON) ............................................................................................... 7

Chapter 5 Specification for LVDT/A & LVDT/D .................................................................................... 8

W A R R A N T Y .......................................................................................................................... 10

Chapter 1 The LVDT Conditioner

The LVDT provides a wide range of signal conditioning for LVDT transducers.

Offered in two versions, the LVDT/A for 110/240 V AC or 18-24 V DC operation and the LVDT/D which is DC powered

only.

Transducer sensitivities between 20 mV and 10 V are accommodated by a combination of DIL switch settings and a

fine trim potentiometer.

Similar arrangements are provided for any ‘zero’ errors in the transducers and can be used to offset the readings by

up to ±35% of full scale.

A wide frequency response is offered, of typically DC to 200 Hz. There is an on-board low pass filter, which can be

switched in to reduce high frequency fluctuations or induced electrical noise, to give stable readings under adverse

conditions.

A wide range of output options for current, and uni-polar or bi-polar voltage can be configured by DIL switch

settings.

Both the AC and DC versions are based on a common board and are mounted in a light grey ABS case sealed to IP65

standard.

Page 3

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

2

Chapter 2 Installing the LVDT/A & LVDT/D

In order to maintain compliance with the EMC Directive 2004/108/EC the following installation recommendations

should be followed.

Inputs:

Analogue

Output:

Use individually screened twisted multipair cable. (e.g. FE 585 - 646)

The pairs should be :

pins 1 & 6

pins 2 & 5

pins 3 & 4

Terminate all screens at pin 1 of the input. The screens should not be

connected at the transducer end of the cables.

Use screened twisted pair cable. (e.g. RS 626-4761)

Terminate screen at pin 1 of the input.

The screen should not be connected at the host port.

Pin 1 of the input should be connected to a good Earth. The Earth connection

should have a cross-sectional area sufficient enough to ensure a low

impedance, in order to attenuate RF interference.

Country

Supplier

Part No

Description

UK

Farnell

148-539

Individually shielded twisted multipair cable (7/0.25mm)- 2 pair

Tinned copper drain. Individually shielded in polyester tape.

Diameter: 4.19 mm

Impedance: 54 Ohms: Capacitance/m: core to core 115 pF & core to

shield 203 pF

UK

Farnell

585-646

Individually shielded twisted multipair cable (7/0.25mm)- 3 pair

Tinned copper drain. Individually shielded in polyester tape.

Diameter: 6.86 mm

Impedance: 62 Ohms: Capacitance/m: core to core 98 pF & core to

shield 180 pF

UK

RS

367-533

Braided shielded twisted multipair cable (7/0.2mm)- 1 pair

Miniature- twin -round Diameter: 4.8 mm

Impedance: 62 Ohms: Capacitance/m: core to core 120 pF & core to

shield 210 pF

Page 4

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

3

UNPACKING

Carefully remove the LVDT unit from its packing. Check that the unit is complete and undamaged.

The LVDT/A & LVDT/D units can operated in any industrial environment providing the following limits are not

exceeded

Operating

temperature

-10ºC to +50ºC

Humidity

95% non condensing

Storage temperature

-20ºC to +70ºC

Two power supply options are available

LVDT/A:

220/230 VAC, 50/60 Hz

110/120 VAC, 50/60 Hz

5 W Max.

LVDT/A & LVDT/D:

18-24 V DC, 5 W (approx. 150 mA fully loaded)

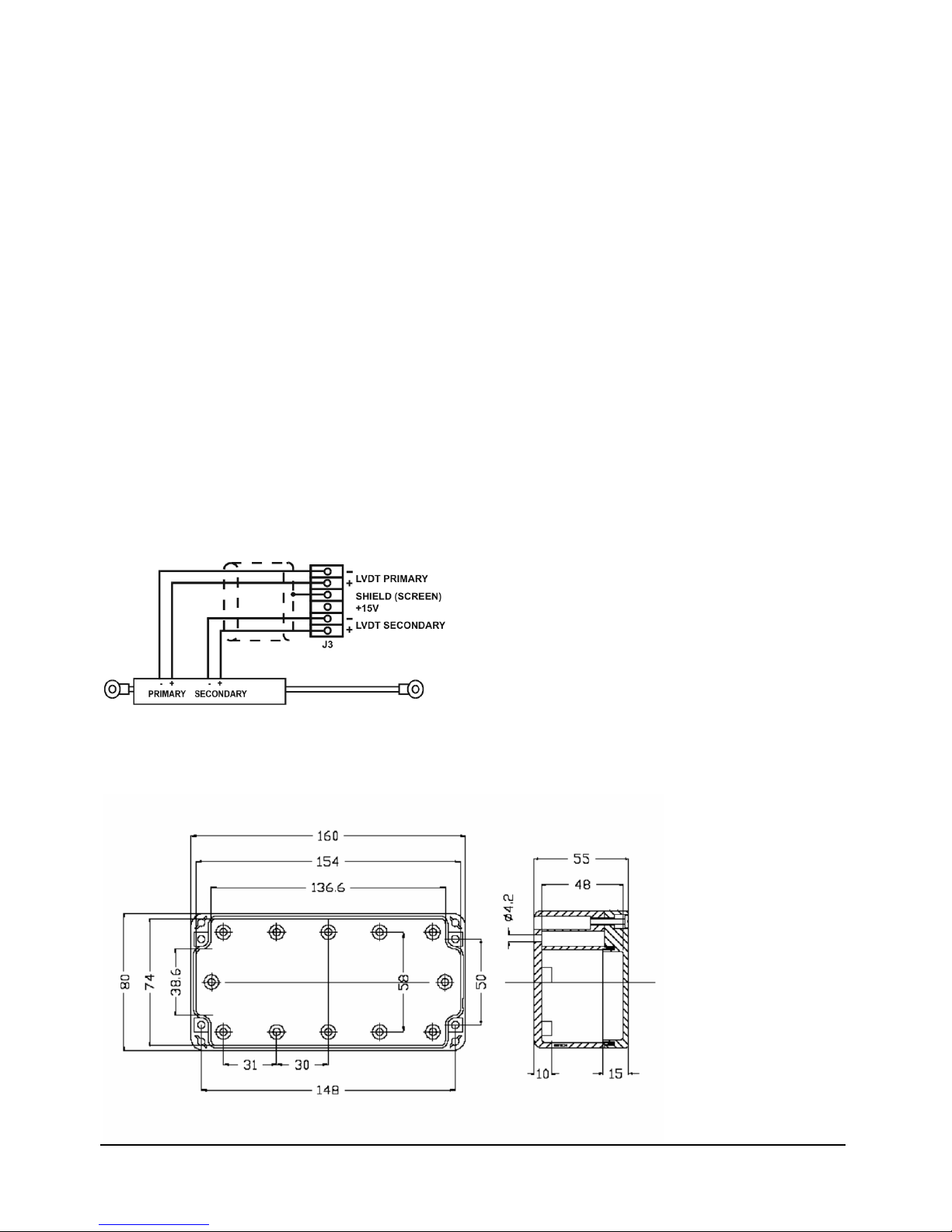

Terminal Connection

On the surface mounted versions, connections to the LVDT/A & LVDT/D input/output signal and the power supply

are made via 2.5mm² field terminal blocks.

Cable entry in the cased versions is via glands in the side of the case.

Dimensions of the Enclosure and Mounting Holes

Page 5

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

4

Chapter 3 Analogue Outputs

Two analogue outputs are available from the LVDT, DC current and DC voltage. The ranges offered are as follows:-

Output

Range

DC voltage

±10 V

±5 V

NB:

Maximum Load on voltage ranges is 2 mA. Bi-polar input, -F.S.

to +F.S.

0 – 10 V

0 - 5 V

DC current

0 – 20 mA

NB:

Maximum impedance 500 R. Uni-polar input, zero to +F.S.

4 – 20 m

The analogue output options are summarised below,

NB. Full scale output for the voltage ranges is achieved with a bi-polar ( ± ) input.

Output Connections

In ‘Sink’ mode the +ve end of the load is connected to the internal +15V supply on the LVDT and the -ve end is

connected to the LVDT output. The current through the load is ‘sunk’ by the LVDT towards ground (0V).

N.B. In this mode neither connection to the output load is electrically common to the load cell.

Select this option by fitting the two jumpers in the positions next to the span trimmer (See Output Current Mode

Settings – Jumpers JP1 & JP2)

In ‘Source’ mode the +ve end of the load is connected to the LVDT output and the current is ‘sourced’ by the LVDT

output through the load towards ground (0V).

This mode has the advantage that the negative output connection is common to the load cell

‘- Excitation’ terminal.

Select this option by fitting the two jumpers in the positions furthest from the span trimmer (See Output Current

Mode Settings – Jumpers JP1 & JP2)

Page 6

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

5

Output Current Mode Settings – Jumpers JP1 & JP2

Switch Settings (0 = Off 1 = On x = Don't care) :-

Analogue Output Options - SW4

SW4

1 2 3 4 5

± 10 V

0 0 0 x x

± 5 V

0 1 0 x x

0-10 V

0 1 1 x x

0-5 V

1 1 1 x x

0-20 mA

x x x 0 0

4-20 mA

x x x 1 1

LVDT Excitation Frequency - SW4 (0 = OFF 1 = ON)

6 7 8 1 0 0

1 kHz

0 1 0

2 kHz

1 1 0

3 kHz

1 0 1

4 kHz

0 1 1

5 kHz

Page 7

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

6

Chapter 4 Input Calibration

The LVDT/A & LVDT/D provides the excitation and signal conditioning to cater for a wide range of LVDT

transducers.

Select the analogue output range as detailed in 'Chapter 3' by means of SW4.

Span (gain) - SW1 (0 = OFF 1 = ON)

1 2 3 4 5 6 7 8 0 0 0 0 1 0 0 1

20 mV

1 0 0 0 1 0 0 1 50 mV

0 1 0 0 1 0 0 1 100 mV

0 0 0 0 0 1 0 1 200 mV

0 0 1 0 0 1 0 1 500 mV

0 1 0 0 0 0 0 1 1 V

0 0 0 0 0 1 1 0 2 V

0 0 1 0 0 1 1 0 5 V 0 1 0 0 0 0 1 0

10 V

Potentiometer P1, provides fine trimming and range overlap to enable the LVDT/A & LVDT/D to be calibrated

precisely to any given value within its ranges.

SW1 sensitivity settings shown in the table are for a Full Scale Output e.g. 0-10volts.

The LVDT/A & LVDT/D can be calibrated with the transducer connected, provided that two calibration points can be

implemented. e.g. by applying known displacements.

Actual calibration is carried out in the following way:-

1. Set the correct switch settings on SW1 using the transducer's calibration sheet supplied by the manufacturer ( see

table Chapter 4 Page 1) . This is normally specified as sensitivity or full range output, and should be in mV or

Volts.

2. Apply the known low calibration displacement (this may be zero if required), and note the analogue output,

having ensured that the SW1 settings are correct for the transducer sensitivity as 1.

3. Apply the known high calibration displacement and note the analogue output. (For optimum accuracy this should

be at least 80% of full scale)

4. Use the fine trim control, P1, to obtain the required change in volts or mA, between the two calibration points.

e.g.

Required output at low calibration point = 0V

Required output at high calibration point = 7.5 V

i.e.

A difference of 7.5 volts is required between the calibration points. If the actual reading at the low calibration

point is say, 0.5 Volts, then trim the high point to 8.0 volts, to achieve a difference of 7.5 volts.

Note: It may be necessary to repeat these steps, until the required change in output is

achieved.

5. Use the fine offset control, P2 in conjunction with the coarse switches SW2/3 -5 to set the output to the

required absolute values. Each switch within SW2, offsets the output by a particular amount, shown as a % of full

scale in the following table.

Page 8

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

7

Zero (offset) - SW2

SW2

1 2 3 4 5 6 7 8 Offset

+ve

-ve

20%

10%

5% x x

x

Note: SW2/1 & /2 Should not both be on.

Use switches 3 - 5 in conjunction with the polarity switches 1 and 2, to get as close as possible to the required

offset value.

Use the fine control P2 to achieve the final setting.

If more than one switch is on at a time, then the output of each is summed to give an overall offset to the output,

which can be up to ±35% of full value.

This offset adjustment can be used either to compensate for the transducer offset error or to introduce a shift into

the output's working range.

Excitation Amplitude - SW2/8

Normally off.

Switching SW2/8 on reduces the excitation by a factor of two. This allows lower impedance transducers to be used

without overloading the electronics.

Please note that it may be necessary to alter the setting of the Span switch, SW1 to compensate for the resulting

lower input signal.

The LVDT/A & LVDT/D Filter

The LVDT/A & LVDT/D incorporates a second order low pass filter which can be switched in to improve performance

in electrically noisy environments. It can also be used to reduce the effects of high frequency fluctuations in the

displacement.

The cut-off frequency of the filter is set by the 8 way DIL switch SW3 as shown in the following table:-

Filter Cut off - SW3 (0 = OFF 1 = ON)

SW3

1 2 3 4 5 6 7 8 5Hz 0 0 0 0 1 1 x x

10Hz

1 0 0 1 1 1 x x 15Hz

0 1 1 0 1 1 x

x

20Hz

1 1 1 1 1 1 x x 50Hz

0 0 0 0 0 0 x x 100Hz

1 0 0 1 0 0 x x 150Hz

0 1 1 0 0 0 x x 200Hz

1 1 1 1 0 0 x

x

Page 9

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

8

Chapter 5 Specification for LVDT/A & LVDT/D

Parameter

Min

Typical

Max

Unit

Power supply ac LVDT-A only (110/230 Vac) 50-60Hz

Power supply dc: LVDT-A and -D

Power supply current dc: (depends on loading)

Excitation

LVDT Frequency (Selected by Switch 1,2,3,4,5 kHz)

LVDT Impedance

LVDT Sensitivity (switchable)

Gain adjustment (Pot - fine adj)

Offset adjustment (Pot - fine adj)

Offset adjustment (Switchable - coarse adj)

Output load (voltage output)

Output load (current output)

Bandwidth (No filter) 3 dB point

Filter cut-off (switchable ranges)

Output ripple 200Hz filter (1kHz excitation)

Output ripple 50Hz filter (1kHz excitation)

Zero temperature coefficient

Span temperature coefficient

Linearity

99/198

18

138

1

50

0.02

-

-

0

0

DC

5

-

-

-

-

-

110/230

24

145

4.5

200

-

-

-

-

-

-

-

-

0.3

0.05

2

0.01

0.05

126/253

28

150

5

10

25

10

30

2

500

200

200

-

4

0.015

0.1

V AC

V DC

mA (200 R)

V rms

kHz ±20%

Ohms

V

% FSD

% FSD

% FSD

mA

Ohms

Hz

Hz

% FSD

% FSD

µV/ºC

% FSD/ºC

% FSD

Gain stability - 1st 1000 hours

Gain stability - 2nd 1000 hours

90 day offset stability

Output load stability gain (0 - 100%)

Output load stability offset (0 - 100%)

Power supply rejection gain (0 - 100%)

Power supply rejection offset (0 - 100%)

Operating temperature range

Storage temperature range

Humidity

Noise (1kHz / 20Hz filter / dc powered)

-

-

-

-

-

-

0

-20

-

-

0.2

0.1

6

-

-

-

-

-

-

3

0.4

0.2

10

0.01

0.01

0.05

0.05

50

70

95

7

% FSD

% FSD

µV

% FSD

% FSD

% FSD

% FSD

ºC

ºC

%

mV p-p

Output options: ±10 V, ±5 V, 0-10 V, 0-5 V, 0-20 mA, 4-20 mA

Connections: Field screw terminals - 2.5mm² rising clamp.

Enclosure: ABS case 160 x 80 x 55 mm sealed to IP65 fitted with 3 off cable glands

Controls: Gain pot

Offset pot

Coarse gain switches

Coarse offset switches

Filter cut-off switches

Output mode switch

CE Approvals

European EMC Directive

Low Voltage Directive

2004/108/EC

BS EN 61326-1:2006

BS EN 61326-2-3:2006

2006/95/EC

BS EN 61010-1:2001

Rated for Basic Insulation

Normal Condition

Pollution Degree 2

Permanently Connected

Insulation Category lll

Page 10

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

9

Page 11

Mantracourt Electronics Limited LVDT/A & LVDT/D User Manual

10

W A R R A N T Y

All LVDT products from Mantracourt Electronics Ltd., ('Mantracourt') are warranted against defective material and workmanship for a period of

(3) three years from the date of dispatch.

If the 'Mantracourt' product you purchase appears to have a defect in material or workmanship or fails during normal use with in the period,

please contact your Distributor, who will assist you in resolving the problem. If it is necessary to return the product to 'Mantracourt' please

include a note stating name, company, address, phone number and a detailed description of the proble m. Also, please indicate if it is a

warranty repair.

The sender is responsible for shipping charges, freight insurance and proper packaging to prevent breakage in transit.

'Mantracourt' warranty does not apply to defects resulting from action of the buyer such as mishandling, improper interfacing, operation outside

of design limits, improper repair or unauthorised modification.

No other warranties are expressed or implied. 'Mantracourt' specifically disclaims any implied warranties of merchantability or fitness for a

specific purpose. The remedies outlined above are the buyer’s only remedies. 'Mantracourt' will not be liable for direct, indirect, special,

incidental or consequential damages whether based on the contract, tort or other legal theory.

Any corrective maintenance required after the warranty period should be performed by 'Mantracourt' approved personnel only.

In the interests of continued product development, Mantracourt Electronics Limited reserves the right to alter product specifications without

prior notice.

Code No. 517-152 Issue 1.9 26.08.14

Loading...

Loading...