Page 1

DCell

DSC

DCell & DSC

Strain Gauge or Load Cell Embedded Digitiser

Module – 2

nd

Generation

Software Version 3 onwards

User Manual

Micron Meters

Web: www.micronmeters.com

Email: metersinfo@micronmeters.com

Page 2

Micron Meters DCell & DSC User Manual

1

Contents

Chapter 1 Introduction ................................................................................................................. 4

Overview ................................................................................................................................... 4

Key Features ............................................................................................................................... 4

Special Facilities .......................................................................................................................... 5

Version 3 Additions and Enhancements ............................................................................................... 5

Version 4 Additions and Enhancements ............................................................................................... 6

The Product Range ....................................................................................................................... 6

Which Device To Use ..................................................................................................................... 6

Additional DCell & DSC Variants Available ........................................................................................... 7

Some Application Examples ............................................................................................................. 8

Chapter 2 Getting Started with the Evaluation Kit ............................................................................... 9

The Evaluation Kit ........................................................................................................................ 9

Contents .................................................................................................................................... 9

Checking the Device Protocol Type and Station Number ......................................................................... 10

Connecting Up The Evaluation Kit For RS485 ....................................................................................... 10

Connecting Up The Evaluation Kit For RS232 ....................................................................................... 10

Initial Checks ............................................................................................................................. 11

Instrument Explorer ..................................................................................................................... 11

What Can Instrument Explorer Do? ................................................................................................... 11

Installing Instrument Explorer ......................................................................................................... 11

Running the Instrument Explorer Software .......................................................................................... 11

Instrument Explorer Icon ............................................................................................................... 12

Instrument Explorer Window .......................................................................................................... 12

Instrument Settings...................................................................................................................... 13

Viewing Device Data .................................................................................................................... 14

Instrument Explorer Parameter List .................................................................................................. 14

Connecting a Load Cell ................................................................................................................. 15

DSJ1 Evaluation Board Sensor Connections ......................................................................................... 16

Performing A System Calibration ..................................................................................................... 17

Sys Calibration, Table method ........................................................................................................ 18

Sys Calibration, Auto Method .......................................................................................................... 19

Chapter 3 Explanation of Category Items ......................................................................................... 22

Communications ......................................................................................................................... 22

Station Number, STN .................................................................................................................... 22

Baud rate Control, BAUD ............................................................................................................... 23

Reset: New For Version 4 (DSC Only) ................................................................................................. 23

DSC Issue 3 pcb or Higher .............................................................................................................. 23

Communications Failure Count, CFCT ............................................................................................... 24

Output Format Controls, DP and DPB (ASCII ONLY) ................................................................................ 24

Information ............................................................................................................................... 24

Software Version, VER .................................................................................................................. 24

Serial Number, SERL and SERH ........................................................................................................ 24

Strain Gauge .............................................................................................................................. 25

mV/V output, MVV....................................................................................................................... 25

Nominal mV/V level, NMVV ............................................................................................................ 25

mV/V Output In Percentage Terms, ELEC ........................................................................................... 25

Temperature Value, TEMP ............................................................................................................. 25

Output Rate Control, RATE ............................................................................................................ 25

Dynamic Filtering, FFST and FFLV .................................................................................................... 25

Cell ......................................................................................................................................... 27

Temperature Compensation In Brief ................................................................................................. 27

Cell Scaling, CGAI, COFS ............................................................................................................... 27

Cell Limits, CMIN, CMAX ................................................................................................................ 28

Linearisation In Brief .................................................................................................................... 29

System ..................................................................................................................................... 29

System Scaling, SGAI, SOFS ............................................................................................................ 29

Page 3

Micron Meters DCell & DSC User Manual

2

System Limits, SMIN, SMAX ............................................................................................................. 30

System Zero, SZ .......................................................................................................................... 30

System Outputs, SYS, SOUT ............................................................................................................ 30

Reading Snapshot, SNAP, SYSN ........................................................................................................ 30

Control ..................................................................................................................................... 31

Shunt Calibration Commands, SCON and SCOF ..................................................................................... 31

Digital Output, OPON and OPOF ...................................................................................................... 31

Flags ....................................................................................................................................... 31

Diagnostics Flags, FLAG and STAT .................................................................................................... 31

Latched Warning Flags (FLAG) ......................................................................................................... 31

Dynamic Status Flags (STAT) ........................................................................................................... 32

Output Update Tracking ................................................................................................................ 33

User Storage .............................................................................................................................. 33

USR1…USR9 ............................................................................................................................... 33

Reset ....................................................................................................................................... 33

The Reset command, RST .............................................................................................................. 33

WARNING: Finite Non-Volatile Memory Life ......................................................................................... 33

Chapter 4 The Readings Process .................................................................................................... 34

Flow diagram ............................................................................................................................. 34

Cell and System Scaling................................................................................................................. 35

Calibration Parameters Summary and Defaults .................................................................................... 36

Chapter 5 Temperature Compensation ............................................................................................ 37

Purpose and Method of Temperature Compensation .............................................................................. 37

Temperature Module Connections and Mounting (DTEMP) ....................................................................... 37

DCELL connections to DTEMP .......................................................................................................... 37

DSC connections to DTEMP ............................................................................................................. 37

Control Parameters ...................................................................................................................... 38

Internal Calculation ..................................................................................................................... 38

The Temperature Measurement ....................................................................................................... 39

How to Set Up a Temperature Compensation ...................................................................................... 39

Parameter Calculations ................................................................................................................. 40

Chapter 6 Linearity Compensation ................................................................................................. 41

Purpose and Method of Linearisation ................................................................................................ 41

Control Parameters ...................................................................................................................... 41

Internal Calculation ..................................................................................................................... 41

How to Set Up Linearity Compensation .............................................................................................. 42

Parameter Calculations and Example ................................................................................................ 42

Chapter 7 Self-Diagnostics ............................................................................................................ 44

Diagnostics Flags ......................................................................................................................... 44

Diagnostics LED .......................................................................................................................... 44

Chapter 8 Communication Protocols ............................................................................................... 45

Bus Standards............................................................................................................................. 45

Serial Data Format ...................................................................................................................... 45

Communications Flow Control ......................................................................................................... 45

Communications Errors ................................................................................................................. 45

Choice of Bus Formats .................................................................................................................. 45

The RS232 Bus Standard ................................................................................................................ 45

The RS485 Bus Standard ................................................................................................................ 46

Communications Protocols ............................................................................................................. 46

Choosing a Protocol ..................................................................................................................... 46

Communications Software for the Different Protocols ............................................................................ 46

Common Features of All Protocols .................................................................................................... 47

Data Type Conversions and Rounding ................................................................................................ 47

The ASCII Protocol ....................................................................................................................... 48

Continuous Output Stream (ASCII ONLY)............................................................................................. 50

New for Version 4 ........................................................................................................................ 50

The MODBUS-RTU Protocol ............................................................................................................. 50

The Mantrabus-II Protocol .............................................................................................................. 52

Page 4

Micron Meters DCell & DSC User Manual

3

Chapter 9 Software Command Reference ......................................................................................... 55

Commands in Access Order ............................................................................................................ 55

Chapter 10 Installation ................................................................................................................ 57

Before Installation ....................................................................................................................... 57

Physical Mounting ........................................................................................................................ 57

Electrical Protection .................................................................................................................... 57

Moisture Protection ..................................................................................................................... 57

Soldering Methods ....................................................................................................................... 58

Power Supply Requirements ........................................................................................................... 58

Cable Requirements ..................................................................................................................... 58

Strain Gauge Input (DSC) ............................................................................................................... 58

Power and Communication ............................................................................................................. 58

Temperature Sensor ..................................................................................................................... 59

Identifying Strain Gauge Connections ................................................................................................ 59

DCell Input Connections ................................................................................................................ 59

DSC Input Connections .................................................................................................................. 59

Identifying Bus-End Connections ...................................................................................................... 60

DCell Bus Connections .................................................................................................................. 60

DSC4-RS485 Versions-Bus Connections ............................................................................................... 60

DSC2-RS232-Bus Connections .......................................................................................................... 60

Strain Gauge Cabling and Grounding Requirements ............................................................................... 61

DCell Strain Gauge Wiring .............................................................................................................. 61

DCell Strain Gauge Wiring Arrangement ............................................................................................. 61

DSC Strain Gauge Cabling Arrangement ............................................................................................. 62

Communications Cabling and Grounding Requirements ........................................................................... 62

DCell Power and Communications Wiring ........................................................................................... 62

DSC4-RS485 Versions- Power and Communications Wiring ....................................................................... 63

DSC2-RS232 Versions Bus-End Arrangement ......................................................................................... 63

Suitable Cable Types .................................................................................................................... 64

DCell/DSC4-RS485 Versions-RS485 Bus Cable ....................................................................................... 64

Warning: Special Problems with Portable Computers ............................................................................. 64

To Avoid These Problems ............................................................................................................... 64

RS232 Bus Layout ........................................................................................................................ 64

RS485 Bus Layout ........................................................................................................................ 64

RS485 Bus Connections for Multiple DCells .......................................................................................... 65

RS485 Bus Connections for Multiple DSC RS485 Versions ......................................................................... 65

RS232 & RS485 Bus Converters ........................................................................................................ 66

Strain Gauge Sensitivity Adjustment (DSC ONLY) .................................................................................. 67

Identifying the DSC ‘Rg’ Resistor ..................................................................................................... 67

Chapter 11 Troubleshooting ......................................................................................................... 68

LED Indicator ............................................................................................................................. 68

No Communications ..................................................................................................................... 68

Bad Readings ............................................................................................................................. 69

Unexpected Warning Flags ............................................................................................................. 69

Problems With Bus Baud Rate ......................................................................................................... 70

Recovering a ”lost” DCell/DSC ........................................................................................................ 70

Chapter 12 Specifications ............................................................................................................. 71

Technical Specifications DSC/DCELL High Stability ................................................................................ 71

Technical Specifications DSC/DCELL Industrial Stability ......................................................................... 72

Mechanical Specification for DSC ..................................................................................................... 73

Mechanical Specification for DCell ................................................................................................... 73

CE Approvals .............................................................................................................................. 73

Warranty .................................................................................................................................. 74

Page 5

Micron Meters DCell & DSC User Manual

4

Chapter 1 Introduction

This chapter provides an introduction to DCell/DSC products, describing the product range, main features and

application possibilities.

Overview

The DCell and DSC products are miniature, high-precision Strain Gauge Converters; converting a strain gauge sensor

input to a digital serial output. They allow multiple high precision measurements to be made over a low-cost serial

link. Outputs can be accessed directly by PLCs or computers, or connected via various types of network, telephone

or radio modem, all without compromising accuracy.

Key Features

Ultra-miniature

The DCell ‘puck’ format can be fitted inside most load cell pockets, and similar restricted spaces. The DSC cards

are similarly very small, optimised for mounting as a component onto custom PCBs.

High-precision

Industrial Version.

25ppm basic accuracy (equates to 16 bit resolution)

High

Stability

5ppm basic accuracy (equates to 18 bit resolution) with comparable stability – far exceeds standard instrument

performance.

Low-power

Low-voltage DC supply (5.6V min), typically 40mA for RS485 &.52mA for RS232 (including 350R strain gauge).

Adjustable sensitivity

Configured for standard 2.5mV/V full-scale strain gauges as supplied.

A single additional resistor configures the input between 0.5 and 100 mV/V full-scale.

Temperature sensing and compensation (optional)

An optional temperature sensor module is available and advanced 5-point temperature-compensation of

measurement.

Linearity compensation

Advanced 7-point linearity compensation.

Serial output

Lower-cost cabling, improved noise immunity, and longer cable runs with no accuracy penalty.

Device addressing allows up to 253 devices on a single bus, drastically reducing cabling cost and complexity.

Two-way communications allow in-situ re-calibration, multiple outputs and diagnostics.

No separate measuring instruments needed.

Digital calibration

Completely drift-free, adjustable in-system and/or in-situ via standard communications link.

Two independent calibration stages for load cell-and-system-specific adjustments.

Programmable compensation for non-linearity and temperature corrections.

Calibration data is also transferable between devices for in-service replacement.

Self-diagnostics

Continuous monitoring for faults such as strain overload, over/under-temperature, broken sensors or unexpected

power failure.

All fault warnings are retained on power-fail.

Multiple output options

Choice of two communications standards: RS232 (DSC only) or RS485.

Choice of three different protocols: ASCII, MODBUS or MANTRABUS, for ease of integration.

All variants provide identical features and performance.

Page 6

Micron Meters DCell & DSC User Manual

5

Special Facilities

Output Capture Synchronisation

A single command instructs all devices on a bus to sample their inputs simultaneously, for synchronised data

capture.

Output Tare Value

An internal control allows removal of an arbitrary output offset, enabling independent readings of net and gross

measurement values.

Dynamic Filtering

Gives higher accuracy on stable inputs, without increased settling time.

Programmable Output Modes

Output rate control enables speed/accuracy trade-off.

ASCII output version provides decimal format control and continuous output mode for ‘dumb terminal’ output.

Unique Device Identifier

Every unit carries a unique serial-number tag, readable over the communications link.

Communications Error Detection

An interruption of normal communications due to drop-outs or noise is detected as badly formatted receive data,

which triggers a communications failure counter to be incremented.

External Temperature Sensing (optional)

An external temperature module for improved accuracy (especially tracking changing temperature conditions).

Software Reset

A special communications command forces a device reboot, as a failsafe to ensure correct operation.

Version 3 Additions and Enhancement s

The following are an outline only more detail will be found further on in this manual

DCell

• Easy mounting via a 2mm screw

• Connection via solder holes to either side of PCB

• Lower profile, single PCB construction

DSC

• Addi

tional I/O

• Easier shielding connection at load cell connector end

DCell & DSC

• Baud Rates to 230400. Higher baud rate allow faster polling of groups of devices on a single bus, also faster

measurement sampling requires faster communications for individual devices allowing the higher sampling

to be realised over the communications link.

• Higher sampling rates. Sampling to 500Hz can now be achieved. Also more sampling rates are available as

follows 1, 2, 5, 10, 20, 50, 60, 100, 200, 300 & 500Hz.

• Lower cost. With new technology and further use of miniaturisation the cost is now lower.

• ESD protection to +/-15KV (RS485 version). Higher ESD voltage rating reduces the possibility of damage by

static.

• Real mV/V calibration. Instead of % full scale the base measurement is in mV/V and is factory calibrated to

within 0.1%. the % of FS output “ELEC” is still available.

• Extreme Noise Immunity, 5 x heavy industrial level.

• Diagnostics LED. An LED is used to indicate that the device is powered and working correctly. The LED is also

used to indicate which protocol the device is.

• Remote shunt cal. A 100K 1% 50ppm/Deg C resistor can be switched across the bridge to allow load cell

integrity to be established.

• Peak & Trough Measurements. Added to allow the faster rates to hold a peak or trough readings. These are

stored in volatile memory & are therefore reset on power up.

Page 7

Micron Meters DCell & DSC User Manual

6

• Programmable dynamic filtering. The filtering is the same as used on Version 2 but with the advantage of

being able to set the characteristics using the communications.

• Wide Operating Voltage. The operating voltage is now 5.6 to 18V allowing the device to be powered from a

wider range of available system supplies.

• DC Excitation. DC excitation has now been employed allowing longer cable lengths for the load cells which is

particularly useful for DSC. This is a 4 wire measurement.

• Defaults have been changed so that the device is shipped with a baud rate of 115200 and station number of

1.

• Scaling implementation has been changed for both “CELL” and “SYS”. The gain is applied before the offset

thus following the more standard approach. This allows for an offset change to be made easily as the offset

is not a component of gain.

Version 4 Additions and Enhancement s

DSC

• Reset to default communication parameters. A pair of pads on the underside of the DSC, when shorted

together at power up will reset Station no. to 1 and baudrate to 115200

Note: This is only for issue 3 pcb and higher. Please refer to underside for issue marking.

DCell & DSC

• For ASCII versions. Setting Station No. to 998 gives continuous output streaming as version 3, except that,

on powering on streaming starts without requiring an XON character

The Product Range

Devices are available in two physical formats.

Wh

ich Device To Use

It is important to select the correct product for your application.

• First choose DCell or DSC based on your physical installation needs

• Choose the communications protocol depending on performance/integration requirements

• the RS232 output option may be simpler if your system only uses a single DSC card

Common Features

Both physical formats offer identical control and near-identical measurement performance

Both are available in all three output protocols: MODBUS, ASCII or MANTRABUS

The DCell (puck) products consist of a Digital Strain

Gauge Signal Conditioner with RS485 bus output in

double sided component population format.

This is suitable for installation in very small spaces,

including load cell pockets.

External connections are made by wiring to through

hole pads. Mounting is via a 2mm mounting hole to

accept M2 screw or American equivalent #0-80.

Important Note: DO NOT USE #2 screw size.

The

DSC

(card) products are very similar to the DCell

but in a different physical form for mounting standalone or on a board.

The DSC is also available with an RS232 output.

External connections are via header pins which can

plug into connectors, or be soldered to wires or into a

host PCB. DSC has an open collector output and volt

free digital input.

Page 8

Micron Meters DCell & DSC User Manual

7

D

ifferences

Only the DSC (card) is available with the RS232 output option and has the digital Input & output.

Special Aspects To Consider

The DCell fits neatly into a strain gauge pocket

The DSC lends itself to PCB mounting

The RS485 output version must be used for multiple devices on the same bus

Additional DCell & DSC Variants Available

A separate variant is available with CANbus output. Refer to DCell & DSC CAN - 2nd Generation - Manual.

(These variants are sufficiently different to require their own manuals).

The following order codes are supported by an earlier version manual ‘DCell & DSC Version 2’

DLCPKASC, DLCPKMAN, DLCPKMOD, DSC2AS, DSC2MA, DSC2MB, DSC4AS, DSC4MA, DSC4MB

Page 9

Micron Meters DCell & DSC User Manual

8

Some Application Examples

Simple Distributed Measurement

Pressure loads are taken at a number of keys points in a manufacturing process, distributed over a large area.

Each pressure sensor contains a DCell unit, and all the sensors are connected by a single cable carrying power and

RS485 communications. A central PC allows continuous display, monitoring and logging of all values from a central

control room. This displays a control-panel and current display window, and logs information to an Excel

spreadsheet for future analysis.

Further monitoring checks and displayed information can easily be added when required to the system where up to

253 ‘nodes’ can be installed.

Low Cost Dedicated Weighing Station

A basic load cell weighing-pad device has a cable leading to a wall mounted weight display.

Digital Load Cell

Load cell products are offered with a high-precision digital communications option.

A DCell is fitted into the gauge pocket of each load cell in manufacture. During product testing, each unit undergoes

a combined load test and temperature cycle. Each unit is then programmed with individually calculated gain, offset,

linearity and temperature compensation tables. All units perform to a very tight specification without the use of any

trimming components.

High Reliability Load sensing

A road bridge has a dedicated load monitoring and active control computer system. System calibration adjustments

are only established during construction, so sensors must be replaceable without recalibration.

Each load monitoring point has a digital load cell fitted, with calibration values set during construction. Selfdiagnostics aid detection of failures.

When a failed load cell is replaced it will produce identical force measurements. The old load cell set-up data

values are programmed into the separate user-level calibration store in the unit, to produce an identically

performing replacement.

Remote Radio Weigher

A variety of lifting machines in a loading yard can be used with a weighing link to display weight in tonnes on a

remote hand-held readout.

A heavy duty strain gauge load-link is fitted with a battery-powered radio modem and DCell. The independent

handheld display unit communicates with the DCell over a transparent radio link, providing a simple LCD readout

and tare button operation.

Load Balance Monitor

A lorry loading weighpoint monitors left/right load balance and sounds a warning if loading is too uneven for safety.

A drive-on weighing platform is provided with load cells at each of four corners. Each cell is wired to a DSC unit, and

these are cabled to a 3

rd

party LCD display and control unit, producing a complete turnkey system. A digital I/O card

is wired to the same bus to control the warning alarm. Application software running on the control unit provides a %

left/right balance readout with a graphical tipping display, and a total weight indication.

The balance indication is calculated by comparing the different corner readings. If it exceeds a programmed limit, a

command to the I/O card turns the relay on.

Total weight is calculated by summing the individual results mathematically.

Automatic re-zeroing occurs when the total is near zero for more than a few seconds.

A control button enables a set-up mode for recalibration (protected by operator password), which displays individual

readings and total. Corner compensation can be checked by observing the changing total as a weight is moved

around. Simple button presses control two point recalibration for any cell.

Weighing Subsystem For Process Control

Several strain gauge loads are monitored as part of a larger data acquisition/monitoring system, based around a

high-speed Profibus network. The load measurements occur in groups of physically related signals which relate to

specific ‘area modules’ along with a number of other measurements and control outputs. The strain gauges are

wired to DSC cards, controlled and interrogated via MODBUS protocol commands on an RS485 bus. The DSCs and

other 3

rd

party MODBUS-compliant devices which govern the area module are all connected to a single RS485 ‘spur’.

The devices in each area-module spur are controlled from the main Profibus backbone, using an off-the-shelf bus

gateway unit.

Page 10

Micron Meters DCell & DSC User Manual

9

Chapter 2 Getting Started with the Evaluation Kit

This chapter explains how to connect up a DCell/DSC for the first time and how to get it working. For simplicity,

this chapter is based on the standard DCell/DSC Evaluation Kit, which contains everything needed to communicate

with a puck or card from your PC.

It is advised that first time users wishing to familiarise themselves with the product use the Mantracourt Evaluation

Kit. This provides a low cost, easy way to get started.

If you do not have an Evaluation Kit, the instructions in this chapter mostly still apply, but you will need to wire up

the device (and possible bus-converter) and have some means of communicating with it. See Communications

Protocols in chapter 10 as appropriate to the protocol type.

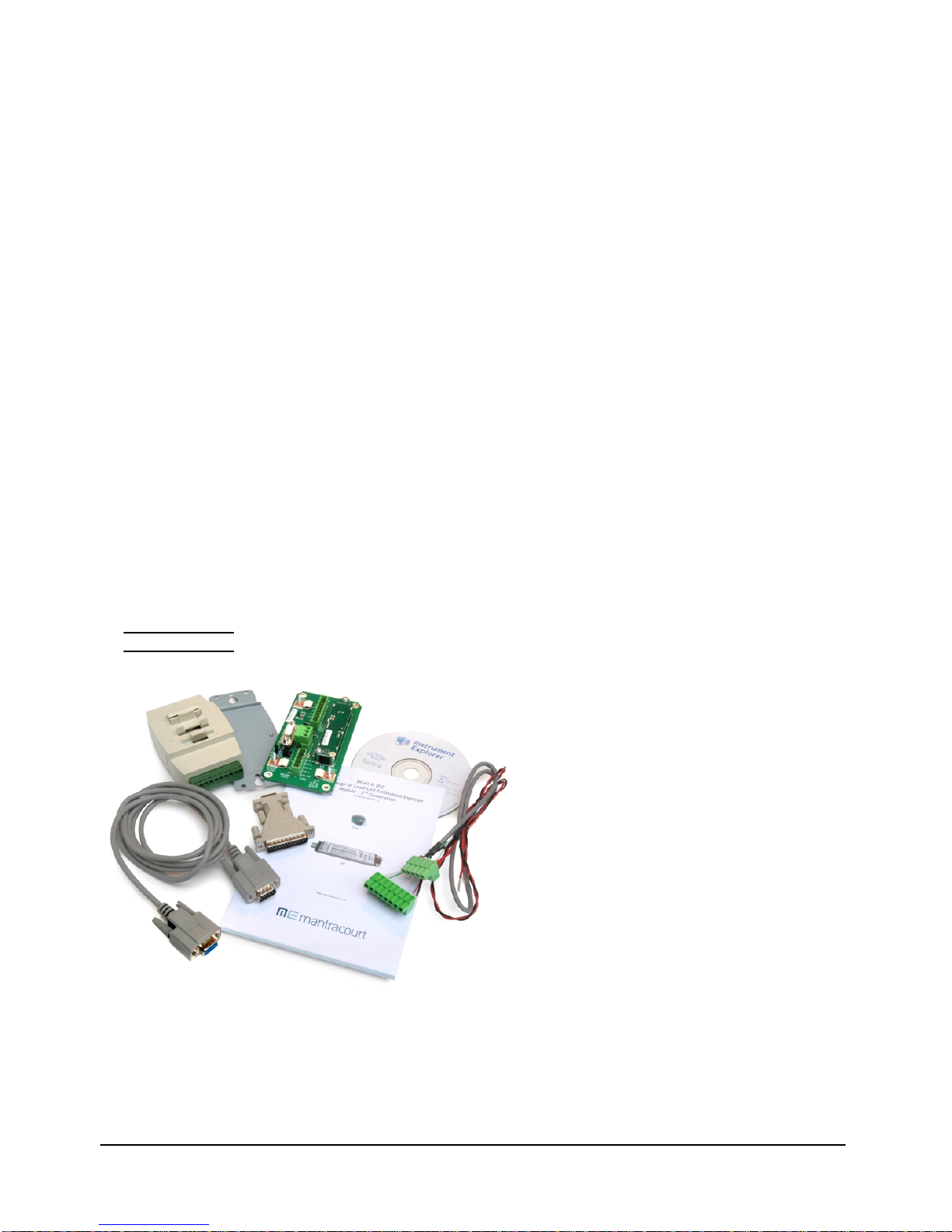

The Evaluation Kit

Contents

DSJ1 mount board

A 8 way screw connector for the strain gauge & Temperature sensor

A 5 way screw connector for power & RS485 comms

A 9 way ‘D’Type for direct RS232 connection to PC, CAN & RS485

Link headers for RS232 or RS485 comms selection

Terminating resistor for CAN & RS485

ON board Temperature Sensor for easy evaluation of Temperature compensation

LED for power indication

LED for digital output (DSC only)

Push Switch for digital input (DSC only)

• A

n Evaluation DCell or DSC of your choice

• A CD ROM containing Instrument Explorer software

• A 9 to 25 way ‘D’Type adaptor for the PC comms port

• A 9 way ‘D’Type extension lead

• For RS485 ONLY an RS232 to RS485 converter and connecting cable

• For RS232 ONLY a power connection cable

O

ther Things you will need

• A regulated power supply, capable of providing 10 –18V at 100mA (10V is minimum requirement for RS485

converter)

• A PC running Windows 98 or above, with a spare RS232 communications port and 45Mb free disk space

and, ideally

• A strain gauge, load cell or simulator typically 350-5000 ohms impedance. (Refer to specifications Chapter 12)

Page 11

Micron Meters DCell & DSC User Manual

10

Checking the Device Protocol Type and Station Number

Before running the communications application, you will need to know both the protocol to use and the station

number of the device.

For DSC the product label shows the product code which determines the protocol and its serial number.

For the DCell the serial number is it’s only means of identification. The serial number must be used to cross

reference the dispatch note to identify the protocol of the device.

For a DCell, the Product Code is one of the following 6 types

DLCSASC

DLCSMAN

DLCSMOD

DLCHASC

DLCHMAN

DLCHMOD

Industrial Stability ASCII output

Industrial Stability MANTRABUS output

Industrial Stability MODBUS output

High Stability ASCII output

High Stability MANTRABUS output

High Stability MODBUS output

For a DSC card, the Product Code is one of the following 12 types

DSCS4ASC

DSCS4MAN

DSCS4MOD

DSCS2ASC

DSCS2MAN

DSCS2MOD

DSCH4ASC

DSCH4MAN

DSCH4MOD

DSCH2ASC

DSCH2MAN

DSCH2MOD

Industrial Stability RS485 output card with ASCII protocol

Industrial Stability RS485 output card with MANTRABUS protocol

Industrial Stability RS485 output card with MODBUS protocol

Industrial Stability RS232 output card with ASCII protocol

Industrial Stability RS232 output card with MANTRABUS protocol

Industrial Stability RS232 output card with MODBUS protocol

High Stability RS485 output card with ASCII protocol

High Stability RS485 output card with MANTRABUS protocol

High Stability RS485 output card with MODBUS protocol

High Stability RS232 output card with ASCII protocol

High Stability RS232 output card with MANTRABUS protocol

High Stability RS232 output card with MODBUS protocol

NOTE: For evaluation purposes, the electrical output standard RS485 or RS232 is not important: Your kit should

contain the correct equipment to connect the device to a PC.

The product code should match your original order.

The serial number of the device is also shown.

The station number of a New DCell/DSC device is factory set to 1

This can be changed if required but for ease of evaluating it is suggested that you use this default value.

Connecting Up The Evaluation Kit For RS485

Connect the PC using the 9 way ‘D’Type to the RS232/RS485 converter. Plug the cable provided into the converter

and connect the other end to the 5 way connector marked J1 on the DSJ1 PCB.

Ensure LK1 & LK5 are set to “CAN/RS485”. Fit LK2 which terminates the RS485 comms. Connect the power cable

(Red & Black twisted) to your power supply, which has been set to deliver between 10 & 18 volts. Switch on, the

Green Power LED should be on.

Connecting Up The Evaluation Kit For RS232

Connect the supplied power cable (Red & Black twisted) to the 5 way connector marked J1. Connect the 9 way

‘D’Type extension lead to the 9 way ‘D’Type socket marked J3 of the DSJ1 and the other end to the comms port of

the PC.

Ensure LK1 & LK5 are set to “RS232” see PCB ident for the markings of these links.

Now connect power cable to your power supply, which has been set to deliver between 10 & 18 volts. Switch on, the

Green Power LED should be on.

Note that if your PC serial port has a 25 way serial port connector, you should use the 9 to 25 way ‘D’ type adaptor

provided to connect to the evaluation hardware.

Page 12

Micron Meters DCell & DSC User Manual

11

Initial Checks

With no load cell connected The LED of the DCell or DSC should flash OFF for 100ms every 0.5, 1 or 2 seconds

depending on protocol. See following table.

Protocol

LED Flash Period

ASCII

0.5 seconds

MODBUS

1 second

MANTRABUS II

2 seconds

Note: If a Load cell is connected and there are no errors then the LED will Flash ON for 100mS then Off for the

above period. This being the normal healthy state

Another check that the device is working okay is by noting the current drawn from the supply. For RS232 variants

this should be about 33mA for RS485 Variant about 30mA.

Instrument Explorer

Instrument Explorer is Mantracourts own communication interface for our range of standard products. It provides

communications drivers for the DCell/DSC products. A complimentary copy is provided on CD-ROM with the

DCell/DSC Evaluation Kit. Instrument Explorer can also be downloaded from Mantracourts website

www.mantracourt.co.uk/products_software.html

Instrument Explorer is a software application that enables communication with Mantracourt Electronics

instrumentation for configuration, calibration, acquisition and testing purposes.

The clean, contemporary interface allows full customisation to enable your Instrument Explorer to be moulded to

your individual requirements.

What Can Instrument Expl orer Do?

• Save and restore customisable user workspace

• Read and Write individual instrument parameters

• Save and restore parameter configurations

• Log data to a window or file

• Perform calibration and compensation

Installing Instrument Explorer

Install the Instrument Explorer software by inserting the CD in the CD ROM drive. This should start the ‘AutoRun’

process, unless this is disabled on your computer.

(If the install program does not start of its own accord, run SETUP.EXE on the CD by selecting ‘Run’ from the ‘Start

Menu’ and then entering D:\SETUP, where D is the drive letter of your CD-ROM drive).

The install program provides step-by-step instructions. The software will install into a folder called

InstrumentExplorer inside the Program Files folder. You may change this destination if required.

Shortcut icons can be created on your desktop and shortcut bar. After installation you may be asked to restart the

computer. This should be done before proceeding with communications.

Note about CAN drivers

It is not necessary to install the optional CAN drivers which are selected by default.

Running the Instrument Explorer Software

Having installed Instrument Explorer you can now run the application, which the rest of this chapter is based

around.

From the Windows ‘Start’ button, select Programs, then Instrument Explorer or click on the shortcut on your

desktop.

Page 13

Micron Meters DCell & DSC User Manual

12

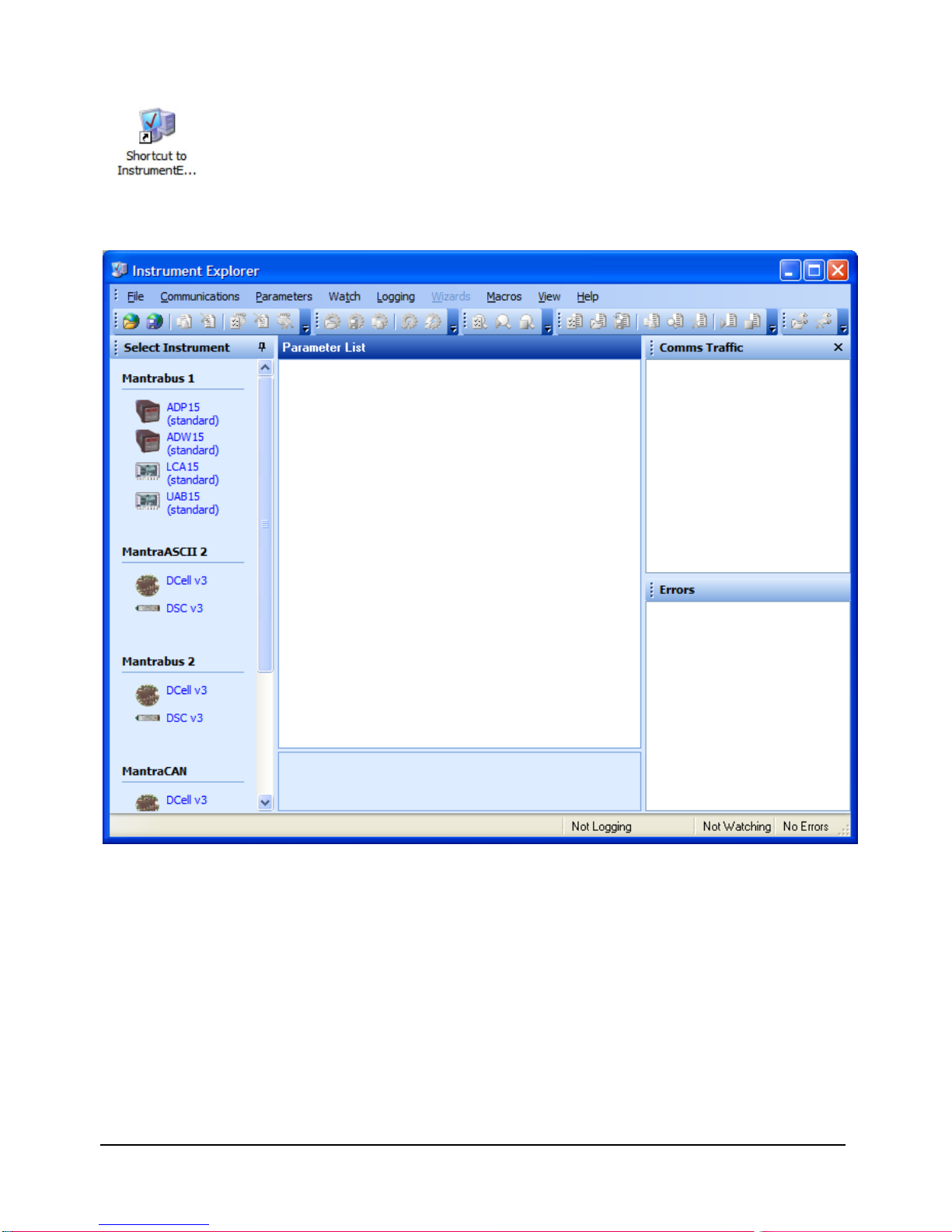

Instrument Explorer Ico n

The a

pplication should open and look like the following screen shot.

Instrument Explorer Window

The l

ayout of Instrument Explorers Window and child windows allows the user full customisation to their

requirements. If the application show a different arrangement of child windows than the above screen shot, then

load one of the default workspaces as follows:

Clic

k File on the menu and select Open Workspace. From the file dialogue window select Layout – Standard.iew.

This will ensure your application layout matches this document.

A l

ist of available instruments is displayed in the Select Instrument pane of Instrument Explorer. Select the relevant

device and protocol, to match the device you are working with, by clicking on the required device icon.

Page 14

Micron Meters DCell & DSC User Manual

13

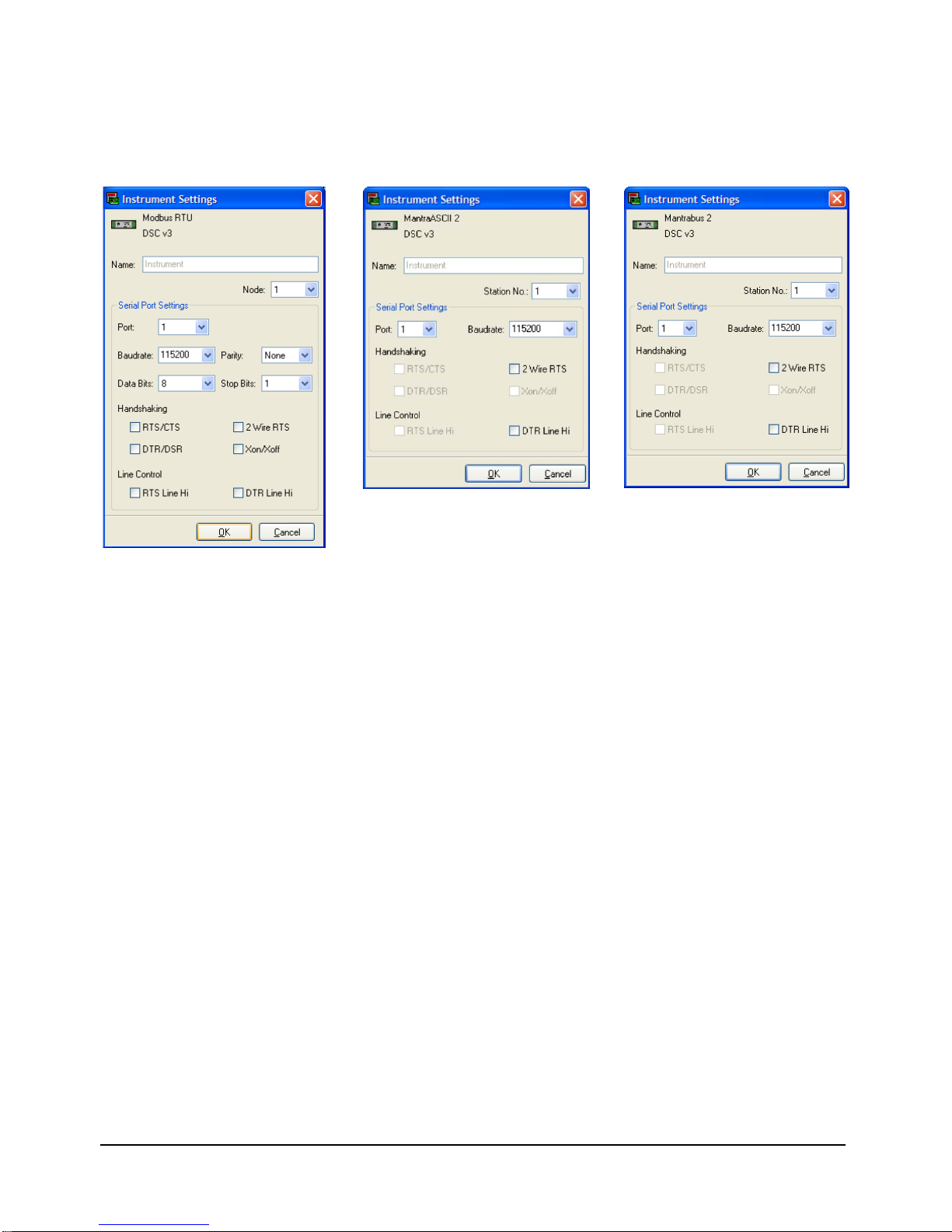

Instrument Setting s

One of the following dialogue windows will be displayed:

Modbus

MantraASCII

MantraBus

• S

elect the serial port to which the device is connected.

• Select the baud rate to which the device is set. The factory default is 115200.

• Select the Station No. / Node. The factory default is 1.

• Now click the ‘OK’ button…

The above assumes factory defaults. If your device is known to have different settings use these instead of the ones

stated above.

Page 15

Micron Meters DCell & DSC User Manual

14

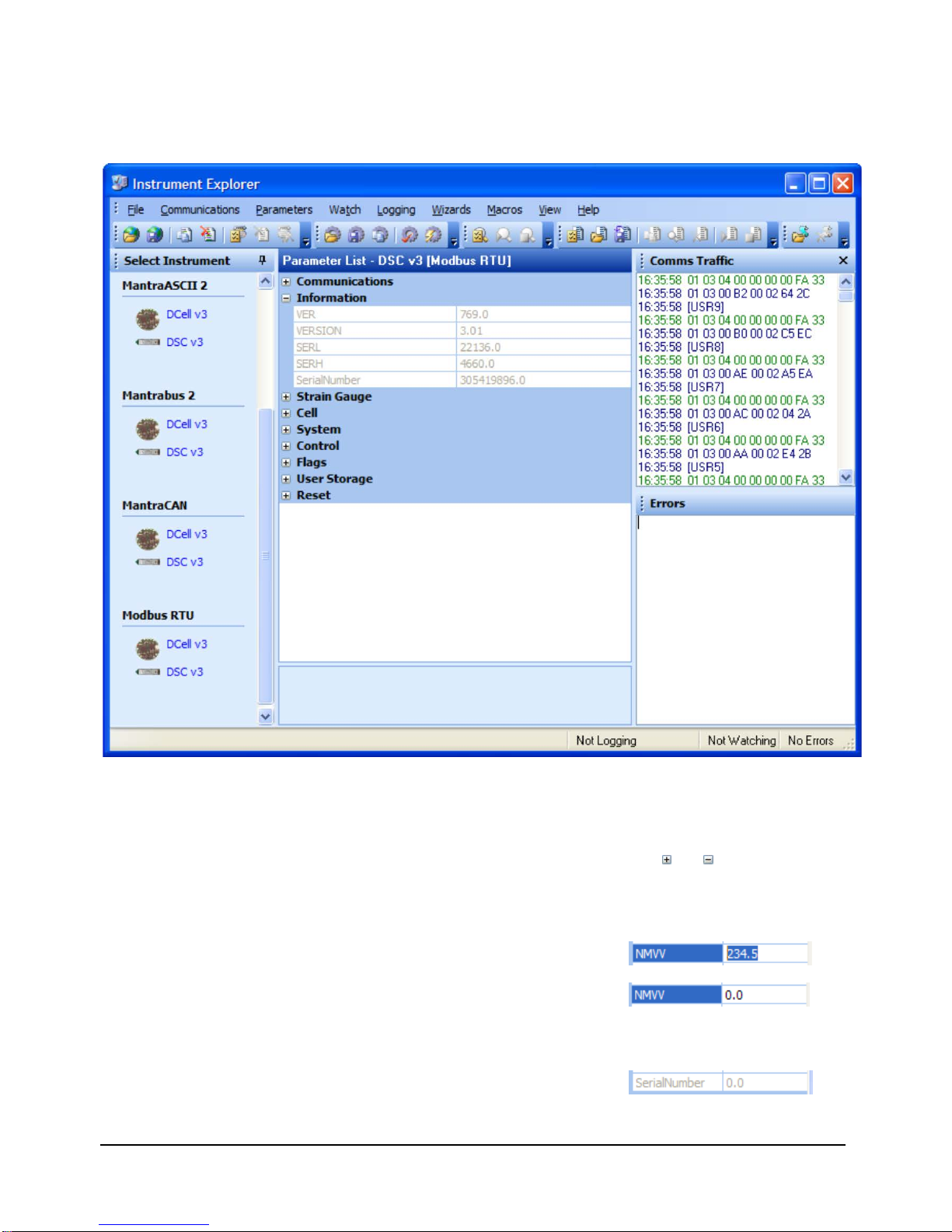

Viewing Device Da ta

The following main parameter list should now appear in the central pane.

Instrument Explorer Parameter List

W

hen an instrument has been selected from the Select Instrument Window this parameter list window will become

populated.

Th

e parameters and commands which are available for the selected device will appear in this list in a structured

hierarchic manner enabling the user to expand or contract categories by clicking the

and buttons on the left of

the list.

There are four types of parameters and commands:

Read/write Numeric

– These parameter values are displayed in the right

hand column and can be edited by clicking the value.

The value can then be changed and pressing the Enter key or moving away

from the edited value will cause the new value to be written to the

device. There are no checks on the data entered and it is up to the user

to enter the correct data.

Read-Only

– These parameter values are displayed ‘greyed out’ and

cannot be changed.

Page 16

Micron Meters DCell & DSC User Manual

15

Read/write Enumerated

– These parameters can only be changed by

selecting the new value from a drop down list.

Clicking in the right hand column will display a down arrow button which

when clicked will display the parameter value options in a list.

Note that all enumerated data (apart from on/off) will be displayed with

a numeric value, hyphen then the description of the value.

The numeric value is the value of the parameter and the description is

just there to help.

Commands – These commands have ‘Click to execute…’ displayed in the

right hand column. Clicking here will display a button. Click this to

issue the command to the device.

A

s parameters are changed the communications traffic is displayed in the Traffic Pane.

If any errors occur these will be shown in red in the Error Pane. Once an error occurs it will need to be reset before

any more communications can take place. Reset errors by either right-clicking the Error Pane and selecting Reset

Errors from the pop-up menu or select the Communications menu and click the Reset Errors item.

To

manually refresh the parameter list click the

button on the toolbar or select Sync Now from the Parameters

menu.

Now you have successfully established communications with your evaluation device the next step is to perform a

simple calibration.

Connecting a Load Cell

You can now connect a strain gauge bridge, load cell or simulator to the DCell/DSC.

A suitable strain gauge should have an impedance of 350-5000ohms and (at least for now) a nominal output of

around 2.5mV/V.

Page 17

Micron Meters DCell & DSC User Manual

16

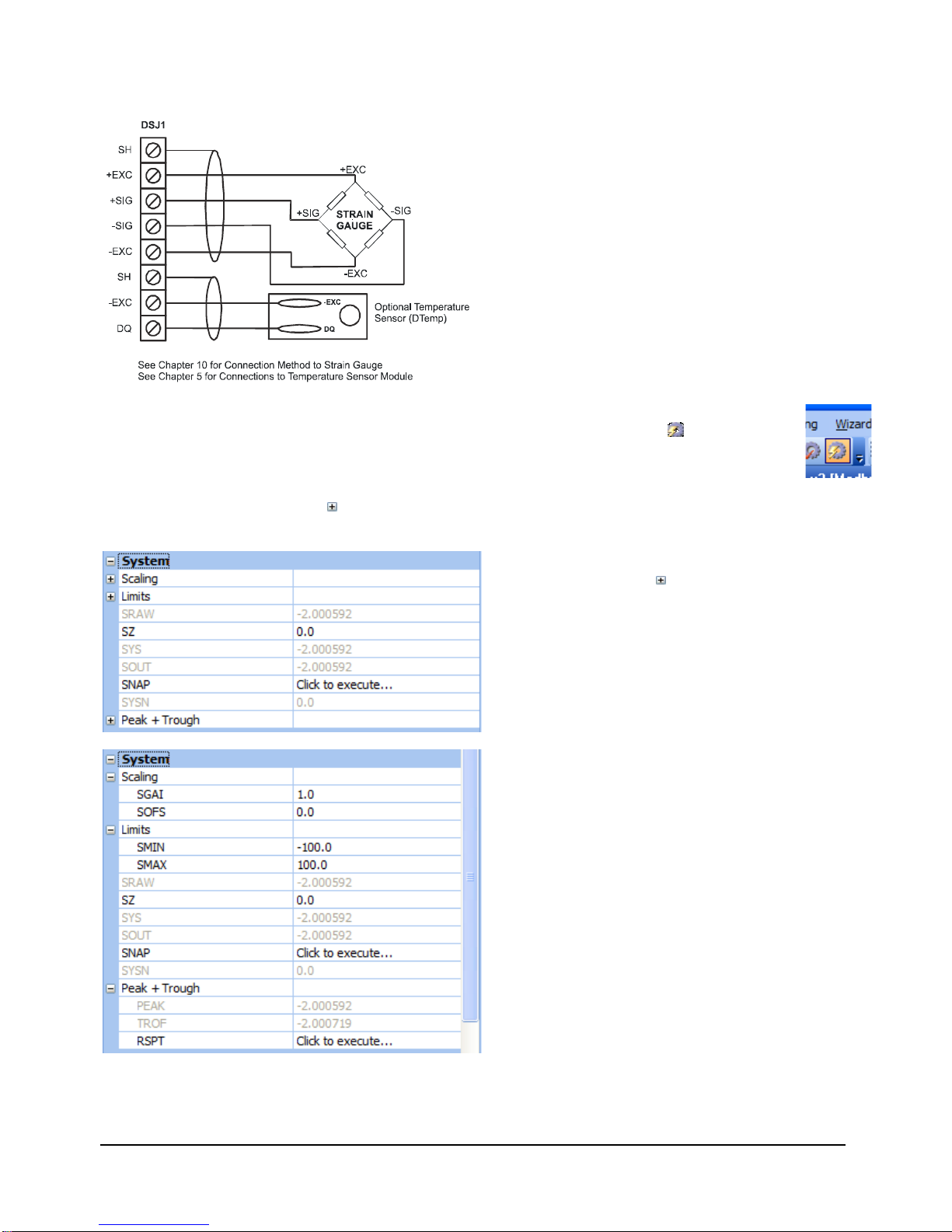

DSJ1 Evaluation Board Sensor Connections

Next, we will set Instrument Explorer to automatically update dynamic parameters from the device so

that we can see values such as SYS changing on the screen. To do this either click the button on the

toolbar or click on the Parameters menu and select the Auto Sync item. Note that these options toggle

so be sure to leave your selection in the active state.

From the Parameter List click the

next to the System heading to expand this level. The Parameter List should look

as follows:

This now exposes more levels that can be expanded as

required by clicking the

next to the heading name.

D

ynamic values (such as SYS and SRAW) will now be updating in real-time from the device.

Page 18

Micron Meters DCell & DSC User Manual

17

Once you have connected the load cell, you should see ‘believable’ output values, in the “SYS” parameter displayed

in the parameter list pane. These values should correspond to mV/V assuming the device is in it’s factory default

state.

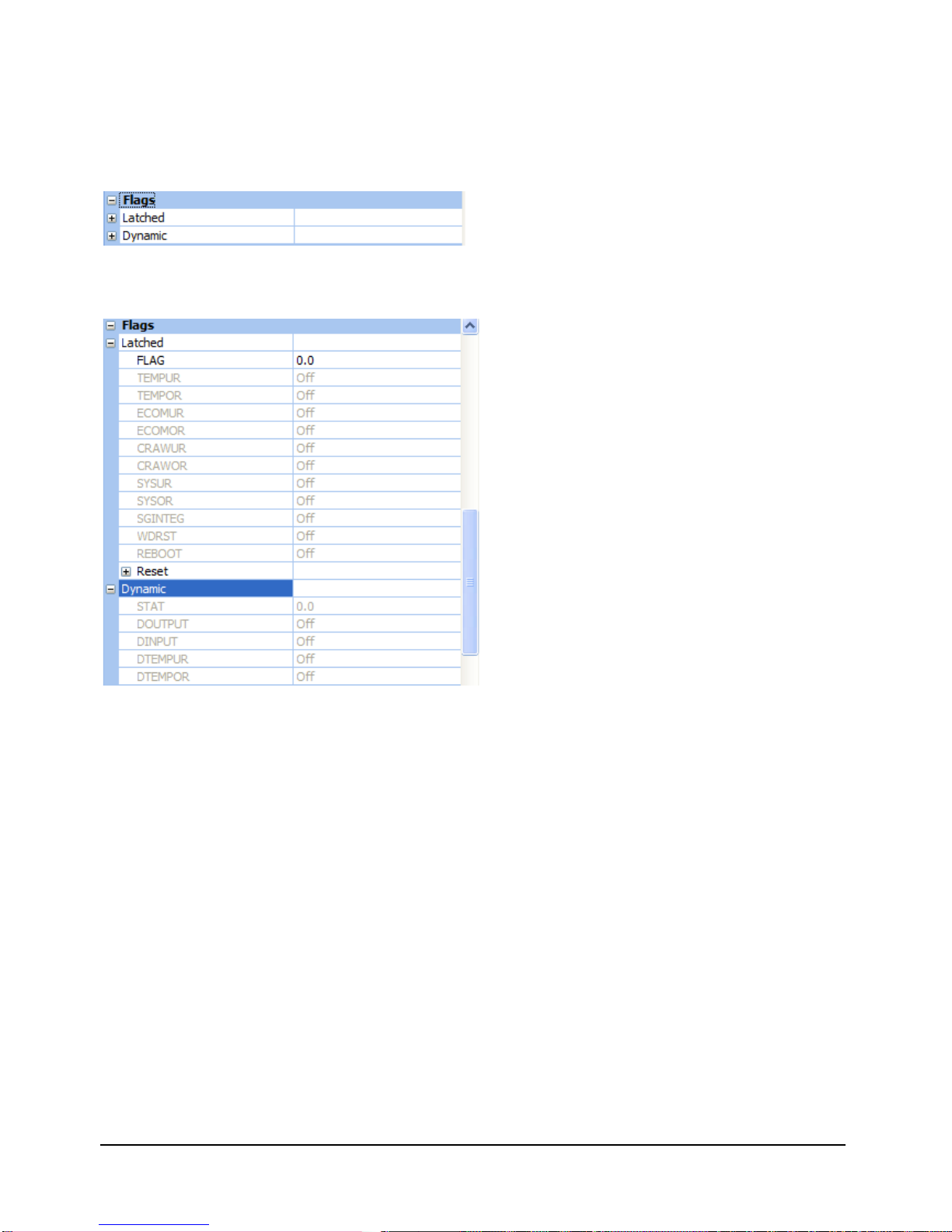

For diagnostics the device has two sets of flags. One being latched and held within the devices non volatile memory

(FLAG parameter), the other being dynamic and volatile (STAT parameter).

I

nstrument Explorer provides a simple method of displaying and resetting of individual flags although these are held

within the device in FLAG and STAT parameters.

To

quickly clear all the flags simply write zero to the FLAG parameter. Now if no problems exist all flags should in

their off state.

If any flags remain on then refer to Chapter 8 for flag definitions.

Performing A System Calibration

The values obtained so far are in mV/V units, these are factory calibrated and fixed to within 0.1% accuracy.

The device also contains two separate user-adjustable calibration parameter groups, these are termed “Cell” and

“System”. Cell being used to convert from mV/V to a calibration value and System to convert this calibration value

to the required engineering units. The use of “CELL” is optional. We shall be using “System” for the following

exercise where we rescale the output value to read in units of your choice, and to calibrate precisely to your load

cell / system hardware.

Instrument Explorer provides Wizards to allow quick and simple calibration operations to be undertaken without the

use of a calculator. Wizards can be activated by simply selecting the required item from the Wizard menu.

Since we are now calibrating at system level we have a choice of two calibration methods:

Sys Calibration Table – This technique is used when a manufacturers calibration document is available for the

connected strain gauge. This normally gives mV/V to engineering unit values.

Page 19

Micron Meters DCell & DSC User Manual

18

Sys Calibration Auto – This technique is used when the input can be stimulated with real input values. For example

you have access to test weight / forces.

We will now describe each of these techniques with an example.

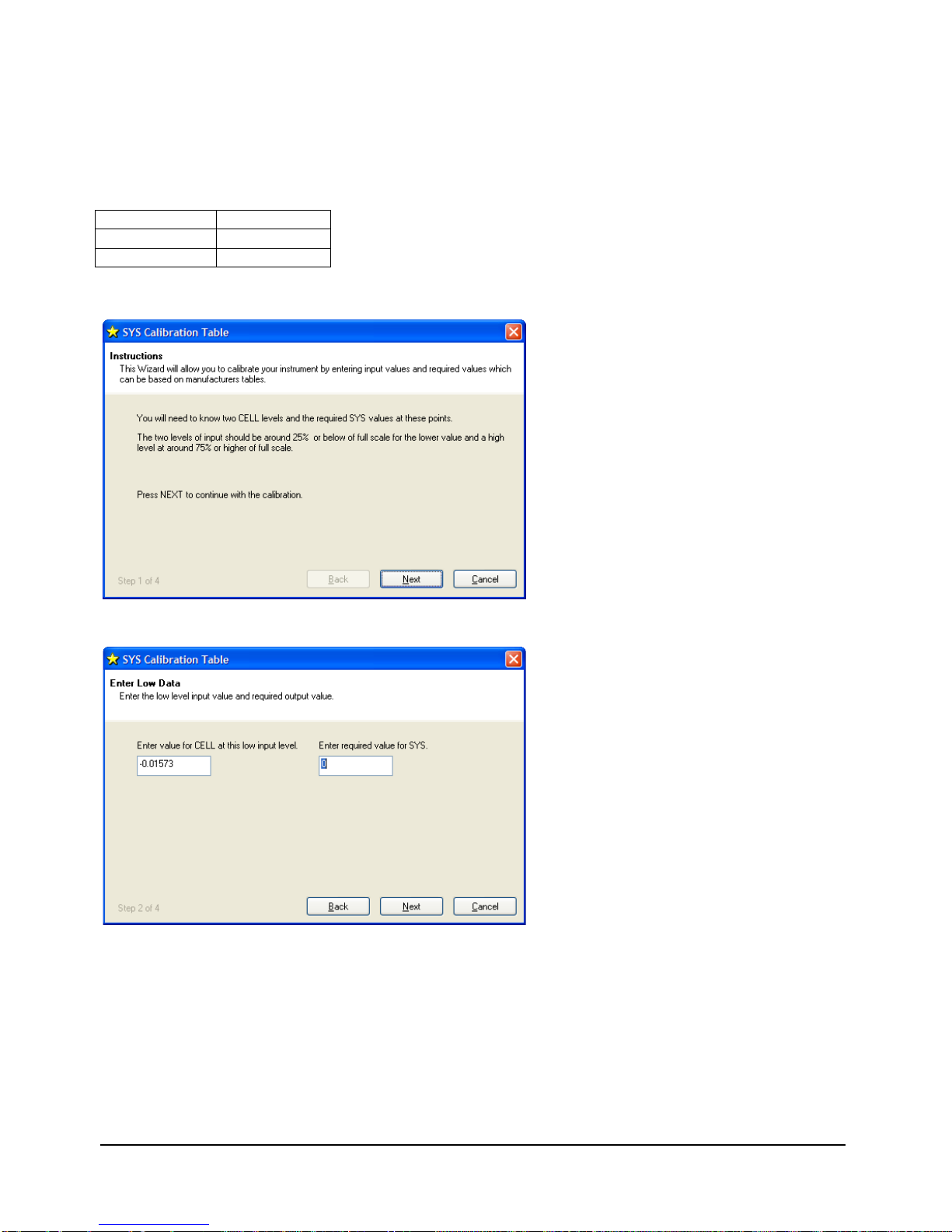

Sys Calibration, Table method

A 10 tonne load cell manufacturer gives the following data:

mV/V output

Force

2.19053

10 tonne

-0.01573

0 tonne

Start the wizard by selecting Sys Calibration Table from the Wizard menu

Click the Next button and enter the low values as shown below.

Page 20

Micron Meters DCell & DSC User Manual

19

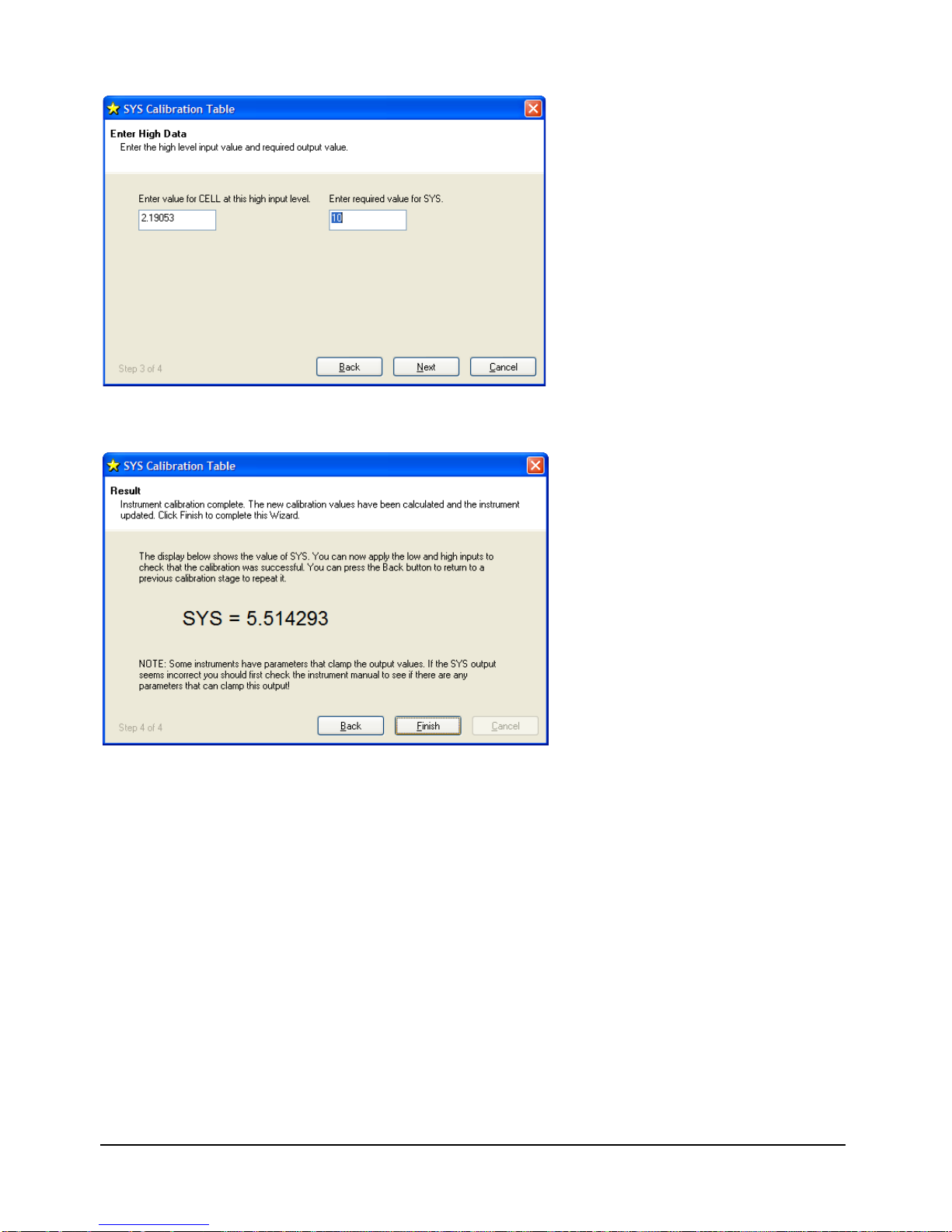

Click the Next button and enter the high values as shown below.

Click Next the following window will be displayed showing the calibrated SYS value which is dependent on the

current input values.

The device is now calibrated. However you may find SYS has been ‘clamped’ if the resultant SYS is greater than

SMAX or less than SMIN. If this is the case then change these values to suitable limits. In this example we may set

SMIN to –0.5 (tonne) and SMAX to 12.0 (tonne). This would then provide clamping of SYS to these values and also a

flags being set in FLAG and STAT.

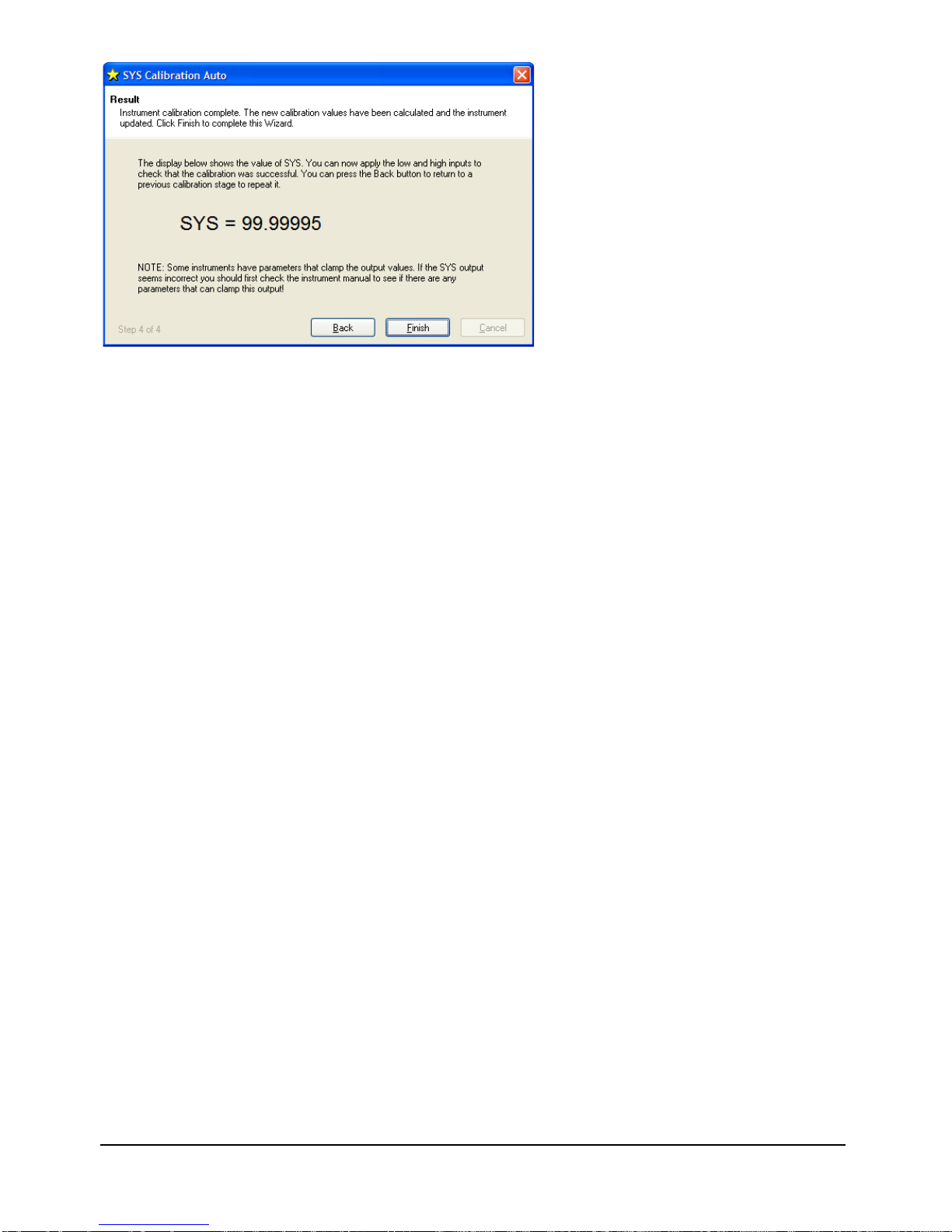

Sys Calibration, Auto Method

Assume we require to calibrate for Kg output and we have available a known accurate 10 Kg and 100 Kg test

weights.

Page 21

Micron Meters DCell & DSC User Manual

20

Start the wizard by selecting Sys Calibration Auto from the Wizard menu

Click Next.

Apply the low known test weight and enter the required SYS value for this weight. In this case it will be 10 as we

want the units of SYS to be Kg. Click Next to continue

Apply the high known test weight and enter the required SYS value for this weight. In this case it will be 100. Click

Next to continue.

Page 22

Micron Meters DCell & DSC User Manual

21

The device is now calibrated. However you may find SYS has been ‘clamped’ if the resultant SYS is greater than

SMAX or less than SMIN. If this is the case then change these values to suitable limits. In this example we may set

SMIN to –0.5 (Kg) and SMAX to 110.0 (Kg). This would then provide clamping of SYS to these values and also a flags

being set in FLAG and STAT.

For detailed information about calibration calculations please refer to chapter 3.

Page 23

Micron Meters DCell & DSC User Manual

22

Chapter 3 Explanation of Category Items

Instrument Explorer shows the categories to which parameters and generated variables belong. This provides a

convenient method for describing the functionality and purpose of each. The categories can be seen from

Instrument Explorers Parameter List pane and are as follows.

Communications

This allows the devices station number / node and baud rate to be changed and also to monitor and reset the

communications failure counter CFCT. For the ASCII protocol there are DP and DPB controls which set the format of

the ASCII string returned by the device. See Chapter 12

Care should be taken when changing the station number or baud rate as communications can be lost with the host.

Also note that some commands require the reset (RST) command to be sent or a power cycle before the new values

take effect. STN, BAUD, DP and DPB are such commands.

When using Instrument Explorer to change either the STN or BAUD parameter, communications with the device will

be lost after the RST command has been issued as the software will be using the previous settings. In this case you

need to change the device settings in Instrument Explorer by selecting Change Settings from the Communications

menu.

Station Number, STN

The STN parameter controls the ‘station number’, which specifies the device address for bus communications.

As supplied, devices have the station-number factory set to 1, as described previously in Version 3 Additions and

Enhancements, Chapter 1.

Page 24

Micron Meters DCell & DSC User Manual

23

Checking the Device Protocol Type and Station Number.

To connect multiple devices on the same bus, it is first vital to set all the station numbers to different values.

This is because if two devices with the same station number are connected to the same bus, it is not possible to talk

to them individually: So in particular, you cannot correct the problem by changing the station number of one of

them!

If a bus connects to two devices with the same station number, the only solution is to remove one of them and

connect it to a one-to-one link to change its station number.

The new value of STN does not take effect until the RST command is issued or the device is power cycled.

To Change the Station Number of your Device

1. First set STN to a suitable new value (making sure that no other device of the same number is also connected!)

2. Send a RST command or power cycle the device.

3. Change the device settings in Instrument Explorer by selecting Change Settings from the Communications menu.

N

OTES:

• The valid range of STN depends on the protocol, but it is always at least 1-253

• All the protocol types have a ‘bus address’ type device identifier, which is known as the ‘station number’ for

MANTRABUS, ‘address’ for ASCII and ‘node id’ for MODBUS.

• The valid ranges for different protocols are: 1-253 for MANTRABUS, 1-999 for ASCII and 1-255 for MODBUS.

• In all cases, if STN is set outside the valid range, it behaves as if set to a default of 1.

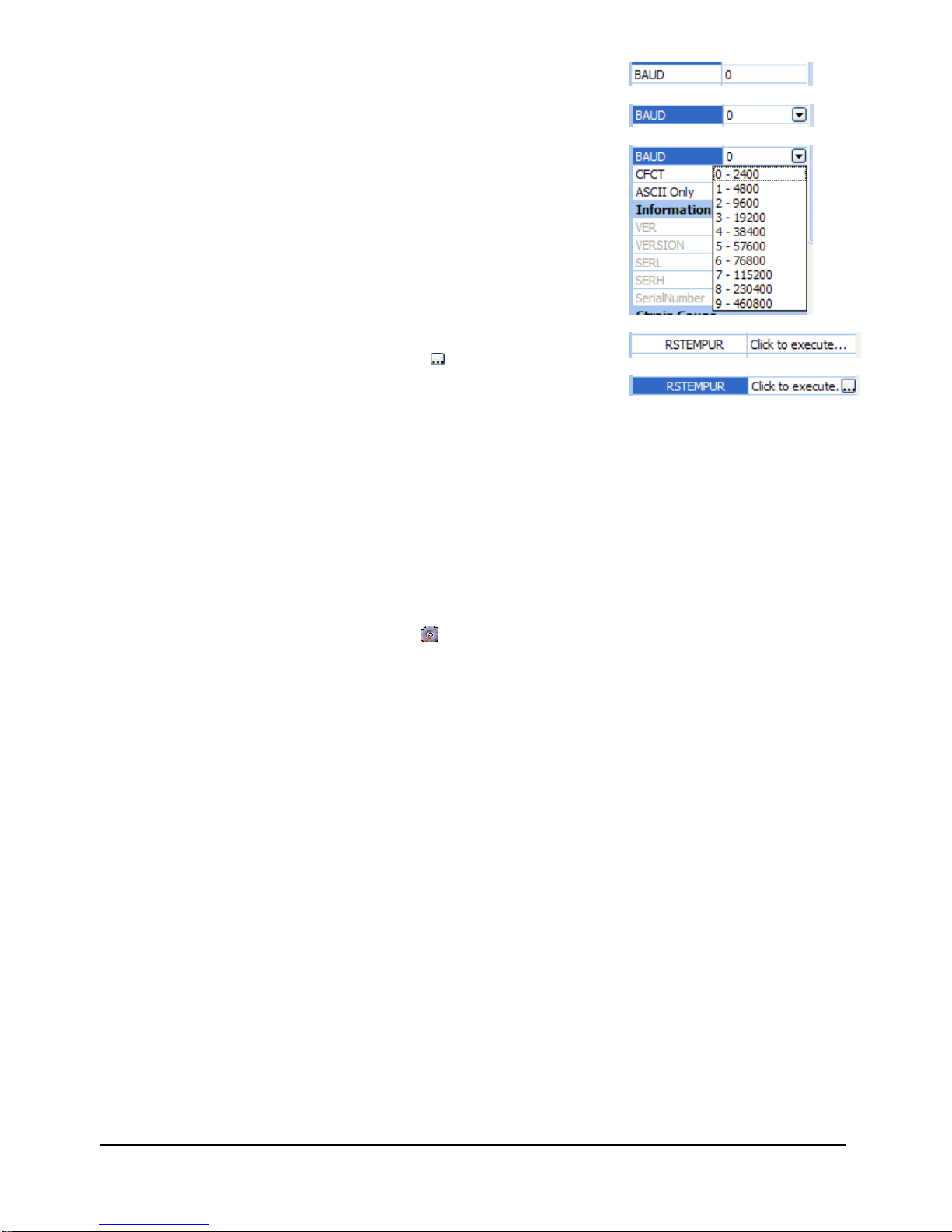

Baud rate Control, BAUD

The BAUD parameter is a read/write byte value specifying a standard communications baud rate according to the

following table –

BAUD

value

0 1 2 3 4 5 6 7 8 9

baud rate

(bps)

2400 4800 9600 19K2 38K4 57K6 76K8 115K2 230K4 460K8

BAUD can only take the values shown above. If set <0 or >9, the baud rate defaults to 9600

Warning: When changing this setting it is possible to lose communication with the device. As well as keeping

track of the correct baud rate, it is also essential in this case to be sure that your hardware supports the rate

you are changing to.

The evaluation kit supports all possible DCell/DSC baud rate settings UPTO 115200

ReSet: (New For Version 4 (DSC Only))

• With version 3 pcb and higher. A reset to comms defaults is available. This will return Station No. to 1 and

baudrate to 115200. This is achieved by powering off the DSC shorting the 2 pads together whilst powering

on.

DSC Issue 3 pcb or Higher

T

he new value of BAUD does not take effect until the RST command is issued or the device is power cycled.

To Change The Baud Rate, follow a similar sequence to changing the STN value

1. First set BAUD to the new value

Ensure issue 3 or Higher 2 unmasked pads

Page 25

Micron Meters DCell & DSC User Manual

24

2. Send a RST command or power cycle the device.

3. Change the device settings in Instrument Explorer by selecting Change Settings from the Communications menu.

Select new baud rate.

Communications Failure Co u n t, CFCT

The Communications Failure Count, CFCT, can be used to indicate the quality off the communications bus. Each

time there is a UART framing error or a data overrun error the count is incremented. This is a read/ Write

parameter so resetting is by writing the value 0. This value is not saved on power fail and is reset to zero on power

up.

Output Format Controls, DP and DPB (ASCI I O NL Y )

The parameters DP and DPB are used to control the formatting of floating-point values in the ASCII protocol.

DP controls the number of decimal places after the point and DPB controls the number of decimal places before the

point. Values of 1..8 are appropriate in both cases.

All output values are then transmitted in this same format. As values are limited to a normal 4-byte accuracy

(about 7 digits), it may sometimes be necessary to alter the formatting for best accuracy in reading/writing values.

eg. if DP=5 and DPB=2, the value 1.257 is output as “+01.25700”

The new value of DP and DPB does not take effect until the RST command is issued or the device is power

cycled.

It is important to ensure that when settings DpB the maximum number expected to be formatted does not

exceed the number of integer digits. i.e. DpB = 3 cannot display numbers greater than or equal to 1000. Failure

to observe this will lead to non-numeric ASDCII codes after the polarity character.

Information

Reports the current version of the devices software and the devices unique serial number. Note that VERSION is the

read able item derived from the devices internal value of VER and SerialNumber is derived from SERL and SERH.

Software Version, VER

The VER parameter (read-only byte) returns a value identifying the software release number, coded as 256*(major-

release)+(minor-release)

eg. current version 3.1 returns VER=769

Serial Number, SERL and SERH

SERL and SERH are read-only integer parameters returning the device serial-number.

This is decoded as = 65536*SERH + SERL.

Page 26

Micron Meters DCell & DSC User Manual

25

Strain Gauge

This is where the measurement process starts. If the optional temperature module is fitted then TEMP will display

actual temperature in Degree C. Otherwise TEMP will display 125 Degree C.

RATE is the parameter that selects measurement cycle update rate.

mV/V output, MVV

MVV is the factory calibrated mV/V output and it is this value that all other measurement output values are derived

from. Factory calibration is within 0.05%.

Nominal mV/V level, NMVV

This is used to represent the nominal mV/V value representing 100% of full scale. This value is used solely for the

generation of ELEC. It is factory set for 2.5mV/V. If the electronic gain is adjusted by changing the gain resistor

then if ELEC is used NMVV value must be changed to represent the new nominal mV/V.

mV/V Output In Percentage Terms, ELEC

This is mainly for backwards compatibility with Version 2. It is the mV/V value represented in percentage terms,

100% being the value set by NMVV.

Temperature Value, TEMP

If the optional temperature module is fitted, DTEMP then TEMP will display actual temperature in Degree C.

Otherwise TEMP will display 125 Degree C. TEMP is used by the temperature compensation. See chapter 5

Output Rate Control, RATE

The RATE parameter is used to select the output update rate, according to the following table of values –

RATE value

0 1 2 3 4 5 6 7 8 9 10

update rate (readings per

second)

1 2 5

10

20

50

60

100

200

300

500

The default rate is 10Hz (RATE=3): The other settings give a different speed/accuracy trade-off.

Invalid RATE values are treated as if it was set to 3.

The underlying analogue to digital conversion rate is 4.8Khz. These results are block averaged to produce the

required output rate.

To Change The Output Rate

1. Set RATE to the new value

2. Click on the ‘RST’ button to reboot the device

3. Wait for one second for the reset procedure to complete and measure cycle to start

W

ith RATE set to 0, you should be able to see the SYS update rate slow to once a second, and the noise level should

also noticeably decrease.

A

ll the main-reading output values are updated at this rate. Rate does not change the rate at which temperature

output TEMP is updated.

Dynamic Filtering, FFST and FFLV

The Dynamic filter is basically a recursive filter and therefore behaves like an “RC” circuit. It has two user settings,

a level set in mV/V by FFLV and a maximum number of steps set by FFST, maximum value FFST can be is 255. If a

difference between a new input value (RMVV) and the current filtered value (MVV) is greater than FFLV then the

fractional amount of the new reading added to the current reading is reset to 1, that is to say that output of the

filter will be equal to the new input reading. If the difference is less than FFLV then the fractional amount added is

Page 27

Micron Meters DCell & DSC User Manual

26

incremented until it reaches the maximum level set by FFST.IE if FFST = 10 then after a step change the fractional

part of a new reading is incremented as follows

1/1, 1/2, 1/3, 1/4, 1/5, 1/6…. 1/10, 1/10, 1/10

This allows the Filter to respond rapidly to a fast moving input signal.

With a step change, which does not exceed FFLV, the calculated new filtered value can be calculated as follows

N

ew Filter Output value = Current Filter Output Value + ((Input Value - Current Filter Output Value) / FFST)

The time taken to reach 63% of a step change input (which is less than FFLV) is the frequency at which values are

passed to the dynamic filter, set in RATE, multiplied by FFST.

The table below gives an indication of the response to a step input less than FFLV.

Update Rate is 1/table value of RATE see Chapter 3 Output Rate Control.

% Of Final Value

Time To settle

63%

Update Rate * FFST

99%

Update Rate * FFST * 5

99.9%

Update Rate * FFST * 7

For example, If RATE is set to 7 = 100Hz = 0.01s and FFST is set to 30 then the time taken to reach a % of step

change value is as follows.

% Of Final Value

Time To settle

63%

0.01 x 30 = 0.3 seconds

1%

0.01 x 30 x 5 = 1.5 seconds

0.1%

0.01 x 30 x 7 = 2.1 seconds

The following table shows the number of updates x FFST and the error % New Filter Output value will differ from a

constant Input Value.

x FFST

% Error

1

36.78794412

2

13.53352832

3

4.97870684

4

1.83156389

5

0.67379470

6

0.24787522

7

0.09118820

8

0.03354626

9

0.01234098

10

0.00453999

11

0.00167017

12

0.00061442

13

0.00022603

14

0.00008315

15

0.00003059

16

0.00001125

17

0.00000414

18

0.00000152

19

0.00000056

20

0.00000021

Remember that if the step change in mV/V is greater than the value set in FFLV then

New Filter Output value = New Input Value.

Page 28

Micron Meters DCell & DSC User Manual

27

And the internal working value of FFST is reset to 1, being incremented each update set by RATE until it reaches

the user set value of FFST.

Cell

Provides the level where the integration between the DCell/DSC and the strain gauge bridge takes place. Features

include, when the optional temperature module is fitted, 5-point temperature compensation to produce a

temperature compensated value CMVV. Scaling using a gain and offset, CGAI and COFS respectively, producing a

value known as CRAW. Linearisation, using up to 7-points, producing the final output from this section known as

CELL. Over load and under load values can be set in CMIN & CMAX to alert the user of forces less or greater than

the integrator has intended the unit to be operated. These features allow the output CELL to be in force units which

can be used by ‘System’ to convert to units of weight.

Temperature compensation and Linearisation are covered in detail in their own chapters.

Temperature Compensation In Brief

When the optional temperature hardware module DTEMP is connected the temperature compensation is available.

The temperature compensation facility can remove the need for the fitting of compensation resistors to the strain

gauges. This compensation can apply for gain and offset with up to 5 temperature points.

The input for the temperature compensation is MVV and the output from the process is CMVV. If not temperature

compensation is invoked the CMVV is equal to MVV

A Detailed explanation is given in chapter 5

Cell Scaling, CGAI, COFS

The temperature compensated value CMVV is scaled with gain and offset using CGAI and COFS respectively. The

gain is applied first and the offset then subtracted. This would be used to give a force output in the chosen units,

this output being termed CRAW.

CRAW = (CMVV X CGAI) – COFS

Two Point Calibration Calculations and Examples

Examples are given here for two point calibration, as this is by far the most common method.

Cell Calibration

The scaling parameters are CGAI and COFS

CGAI is in cell-units per mV/V’

COFS is in cell units

Th

e cell output calculation is (in the absence of temperature and linearity corrections) –

CRAW = (CMVV × CGAI) – COFS

If we have two electrical-output (MVV) readings for two known force loads, we can convert the output to the

required range. So if –

test load = fA CMVV reading = cA

test load = fB CMVV reading = cB

–

then calculate the following gain value

CGAI = (fB – fA) / (cB – cA)

and the offset is

COFS = (cA x CGAI) – fA

T

he outputs should then be CELL = fA, fB true force values, as required.

Calibration Methods

There are a number of ways of establishing the correct control values.

Method 1 - Nominal (data sheet) Performance Values

Page 29

Micron Meters DCell & DSC User Manual

28

This is the simplest method, where the given nominal mV/V sensor output is used to calculate an approximate value

for CGAI.

Example.

A 50 kN load cell has nominal sensitivity of 2.2mV/V full-scale.

So to get 50.0 for an input of 2.2mV/V, we set CGAI to 50/2.2≈22.7273. This assumes the output for 0kN is

0mV/V.

Method 2 - Device Standard (Calibration) Values

With some load cells you may have a manufacturer’s calibration document. This gives precise cell-output gain and

offset specifications for the individual cell. These values can be used to set the SGAI and SOFS values to be used.

Example.

A 10 tonne load cell has a calibration sheet specifying 2.19053mV/V full-scale output, and -0.01573mV/V

output offset.

CGAI is set to 10 / (2.19053- -0.01573) ≈ 4.532557.

COFS is set to –0.01573 x 4.532557≈ -0.0071297

N

OTE:

Methods 1 and 2 require no load tests. This means that systematic installation errors cannot be removed, such as

cells not being mounted exactly vertical. The accuracy is also limited by the DCell/DSC electrical calibration

accuracy, which is about 0.1%.

The remaining methods require testing with known loads, but are therefore inherently more reliable in practice, as

they can remove unexpected complicating factors relating to installation.

Method 3 - Two-Point Calibration Method

This is a simple in-system calibration procedure, and probably the commonest method in practice (as in the previous

example).

Two known loads are applied to the system, and reading results noted, then calibration parameters are set to

provide exactly correct readings for these two conditions.

eg. a 10kN (1-tonne) load cell has a CELL reading of +0.120721mV/V with no load, and –2.21854mV/V with a

known 100Kg test-weight.

To calibrate this to read in a –1.0 to +1.0 tonne range,

Calculate CGAI as 0.1 / (2.21854 - +0.120721) = 0.047669.

Set COFS= 0.120721 x 0.047669 = 0.005755.

Method 4 - Multi-point Calibration Test

For ultimate accuracy to a whole series of point measurements may be taken to determine the best linear scaling of

input output: Effectively, a ‘best line’ through the data is then chosen, and the calibration is set up to follow the

line.

Testing of this sort is also used to establish linearity corrections, and similar tests at different temperatures are

used to set up temperature compensation (see Chapters on Temperature Compensation and Linearity

Compensation).

Note: Instrument Explorer provides “wizards” for easy calibration of the Cell stage. There are two wizards, ‘Cell

Calibration Auto’ and ‘Cell Calibration Table’ these can be found under the menu item “Wizards”.

Cell Limits, CMIN, CMAX

These are used to indicate that the desired maximum and minimum value of CRAW have been exceeded. They are

set in Force units. On CRAW being greater than the value set in CMAX the CRAWOR flag is set in both FLAG and

STAT. On CRAW being less than the value set in CMIN the CRAWUR flag is set in both FLAG and STAT.

Page 30

Micron Meters DCell & DSC User Manual

29

Linearisation In B rief

Linearisation allows for any non-linearity in the strain gauge measurement to be removed. Up to 7 points can be set

using CLN. The principle of operation is that the table holds a value at which an offset is added. The point in the

table that refer to CRAW are named CLX1..CLX7. The offsets added at these point are named CLK1.. CLK7 and are

set in thousandths of a cell unit. The output from the Linearisation function is CELL. If no Linearisation is used (CLN

< 2) the CELL is equal to CRAW.

A Detailed explanation is given in chapter 6

System

System is where the “Force” output, CELL, is converted to weight when installed into a system. Other features such

as SZ offers a means of zeroing the system output SYS. Peak and Trough values are also recorded against the value

of SYS, these are volatile and reset on power up. A command SNAP records the next SYS value and stores in SYSN,

this is useful where more than 1 device in a system and to prevent measurement skew across the system the SNAP

command can be broadcast to all devices ready for polling of their individual SYSN values.

System Scaling, SGAI, SOFS

The cell output value CELL is scaled with gain and offset using SGAI and SOFS respectively. The g ain is applied firs t and the offset the

subtracted. This would be used to give a force output in the chosen units, this output being termed SRAW.

SR

AW = (CELL X SGAI) – SOFS

If we have two cell-output (CELL) readings for two known test loads, we can convert the output to the required

range. So if –

Test load = xA CELL reading = cA

Test load = xB CELL reading = cB

Then we calculate the following gain value

SGAI = (xB – xA) / (cB – cA)

And then the offset

SOFS = (cA x SGAI) - xA

The outputs should now be SRAW = xA, xB true load values, as required.

Example of calculations for SGAI and SOFS

Example:

A 2500Kgf load cell installation is to be calibrated by means of test weights.

The cell calibration gives an output in Kgf ranging 0–2000.

A system calibration is required to give an output reading in the range 0–1.0 tonnes.

Calculations

Take readings with two known applied loads, such as –

For test load of xA = 99.88Kg : CELL reading cA = 100.0112

For test load of xB = 500.07Kg: CELL reading cB = 498.7735

Calculate gain value. In this case put SGAI = (xB – xA) / (cB – cA)

= (0.50007 – 0.09988) / (498.7735 – 100.0112)

≈

0.001003580 = 1.003580x10-3

Page 31

Micron Meters DCell & DSC User Manual

30

Calculate offset value. In this case SOFS = (cA x SGAI) – xA

= (100.0112 x 1.003580x10-3) – 0.09988

≈