Page 1

© 2006 Mantis, Div. of Schiller-Pfeiffer Inc. All Rights Reserved.

© 2006 Mantis, Division de Schiller Pfeiffer Inc. Tous droits réservés.

© 2006 Mantis, Division von Schiller Pfeiffer Inc. Alle Rechte vorbehalten.

Owners manual and safety instructions

Manuel d’utilisation et consignes de sécurité

Benutzerhandbuch und Sicherheitshinweise

Pruner E System

Élagueur E System

E-System-Astsäge

Page 2

1

Table of contents

Important information

A. Introduction

This attachment is designed for trimming light to medium size

branches.

B. Pruner attachment specification.

C. Contents of the package

1. Pruner attachment assembly with plastic gear case cover

2. Chain guide

3. Saw chain

4. Chain Guide cover

D. Service information contact

If you have questions about any topic in this manual,contact

your local authorised Mantis dealer.

WARNING DANGER

ATTENTION: THIS SYMBOL POINTS OUT

IMPORTANT SAFETY INSTRUCTIONS

WHEN YOU SEE THIS SYMBOL

HEED ITS WARNING! STAY ALERT!

WARNING DANGER

READ & UNDERSTAND THIS MANUAL BEFORE

ATTEMPTING TO OPERATE THIS MACHINE.

TO REDUCE THE POTENTIAL FOR ACCIDENTS,

COMPLY WITH THE SAFETY INSTRUCTIONS IN

THIS MANUAL. FAILURE TO COMPLY MAY RESULT

IN SERIOUS PERSONAL INJURY AND OR

EQUIPMENT AND PROPERTY DAMAGE.

Important information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Special safety information . . . . . . . . . . . . . . . .1

Safety and warnings

Safety labels . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General safety rules . . . . . . . . . . . . . . . . . . . . .3

Assembly instructions . . . . . . . . . . . . . . . .5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . .7

Maintenance . . . . . . . . . . . . . . . . . . . . . . .8

Sharpening the blade . . . . . . . . . . . . . . .10

Warranties policy . . . . . . . . . . .Back cover

E. Special safety information

MODEL SHAFT TOTAL OIL TANK

LENGTH WEIGHT VOLUME

330106 75 cm 1.8 kg

(4.1 oz)

122 ml

Page 3

2

Safety and warnings

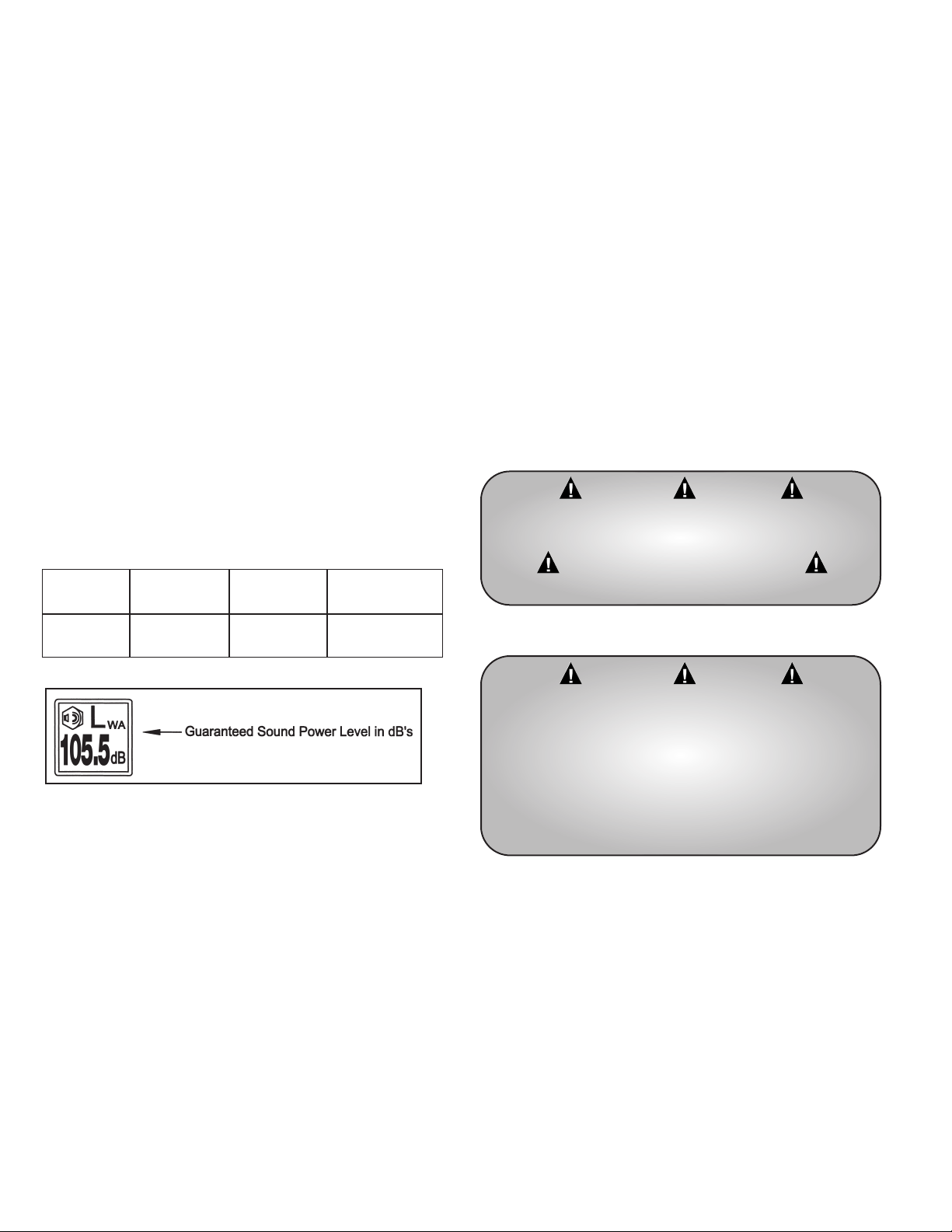

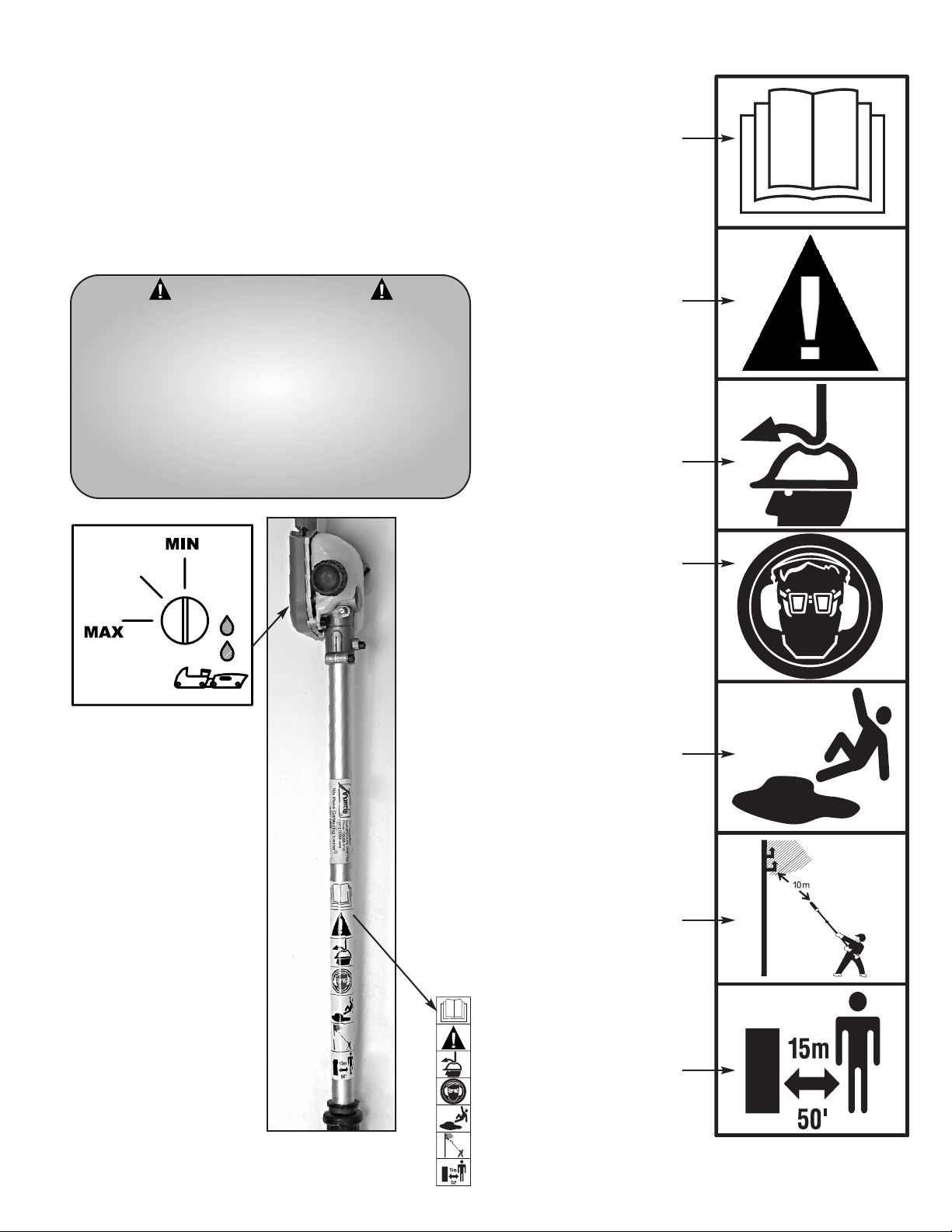

A. Safety labels

Please pay particular attention to the warning and information

labels found on various parts of this pruner attachment unit.

They are an important part of the safety system. These labels

must be replaced in time due to abrasion, etc. It is your

responsibility to replace the labels when they become hard to

read. The location of these labels and their part numbers for

ordering are shown below.

WARNING – DANGER

IMPROPER USE OR CARE OF THIS PRUNER,

OR FAILURE TO WEAR PROPER PROTECTION

CAN RESULT IN SERIOUS INJURY.

READ AND UNDERSTAND THE RULES FOR

SAFE OPERATION AND ALL INSTRUCTIONS

IN THIS MANUAL.

WEAR EYE AND HEARING PROTECTION,

HELMET AND PROPER CLOTHING.

READ AND

UNDERSTAND

OPERATOR’S MANUAL

BEFORE USING!

WARNING! WEAR

HELMET. DANGER OF

FALLING BRANCHES

WARNING! WEAR SLIP-

RESISTANT FOOTWEAR.

MAINTAIN FOOTING

AND BALANCE AT ALL

TIMES.

DO NOT STAND

ON SLIPPERY, UNEVEN

OR UNSTABLE

SURFACES. DO NOT

WORK IN ODD

POSITIONS OR ON A

LADDER. DO NOT

OVER REACH.

WARNING! DANGER

FROM OVERHEAD

ELECTRIC POWER

LINES. KEEP SAFE

DISTANCE!

KEEP BYSTANDERS AT

A SAFE DISTANCE

WARNING! WEAR EYE

AND EAR PROTECTION

WARNING!

Oilier control label

P/N 331178

P/N 331177

Page 4

3

General safety rules

1. Remove branches in sections. Maintain safe operating

positions, to avoid risk of being struck by falling branches

or by those that rebound after hitting the ground

2. Cover saw chain with guard during transport and storage.

3. Do not hit rocks, stones, tree stumps, and other foreign

objects with the working unit. If saw chain strikes an

obstruction, stop engine immediately, unplug unit and

inspect saw chain for damage.

4. Do not operate with a dull, fractured or damaged saw

chain.

WARNING

WHEN USING ELECTRIC TOOLS, BASIC SAFETY

PRECAUTIONS, INCLUDING THE FOLLOWING,

SHOULD ALWAYS BE FOLLOWED TO REDUCE

THE RISK OF FIRE, ELECTRIC SHOCK AND

PERSONAL INJURY.

Pay particular attention to all sections regarding safety.

Read and understand all these instructions before operating this

product and save these instructions. Be familiar with the

controls and the proper use of equipment.

For safe operations:

1. Keep work area clean.

Cluttered areas and benches invite injuries.

2. Consider work area environment.

Do not expose power tools to rain. Do not use power tools

in damp or wet locations. Keep work area well lit. Do not

use power tools where there is risk of fire or explosion.

3. Guar

d against electric shock.

Avoid body contact with earthed or grounded surfaces,

e.g. pipes, radiators, stoves, ovens, refrigerators.

4. K

eep children away.

Do not let visitors touch the tool or extension cord. All

visitors should be kept away from area. Local regulations

may restrict the age of the operator.

5. Store idle tools.

When not in use, tools should be stored in a dry, high or

locked up place, out of reach of children.

6. Do not force the tool.

It will do the job better and safer at the rate for which it

was intended. Walk, never run.

7. Use the right tool.

Do not force small tools or attachments to do the job of a

heavy duty tool. Do not use tools for purposes not

intended; for example, do not use chain saw attachment to

cut tree limbs or logs.

8. Dr

ess properly.

Do not wear loose clothing or jewellery that can be caught

in moving parts. Long trousers, non-slip gloves and sturdy

work shoes with non-skid soles are recommended when

working outdoors. Wear protective hair covering to contain

long hair.

9. Use protective equipment.

To avoid injury, wear ear, eye protection, face or dust mask

if the operation is dusty. To avoid injury from falling

branches, wear helmet. Eye protection must meet

applicable CE requirements.

10. Do not abuse the cord.

Never carry the tool by the cord or yank it to disconnect it

from the socket. Keep the cord away from heat, oil and

sharp edges.

11. Maintain tool with car

e.

Keep cutting tools sharp and clean for better and safer

performance. Follow instructions for lubrication and

changing accessories. Inspect tool cord periodically and if

damaged, have it repaired by an authorised service facility.

Inspect extension cords periodically and replace, if

damaged. Keep handles dry, clean and free from oil and

grease.

12. Disconnect tools.

When not in use, before servicing and when changing

accessories such as blades, bits and cutters.

13. Remove adjusting keys and spanners.

Form the habit of checking to see that keys and adjusting

spanners are removed from the tool before turning it on.

14. A

void unintentional starting

.

Do not carry a plugged in tool with a finger on the switch

trigger. Ensure switch is off when plugging in.

15. Use outdoor e

xtension leads.

When tool is used outdoors, use only extension cords

intended for outdoor use.

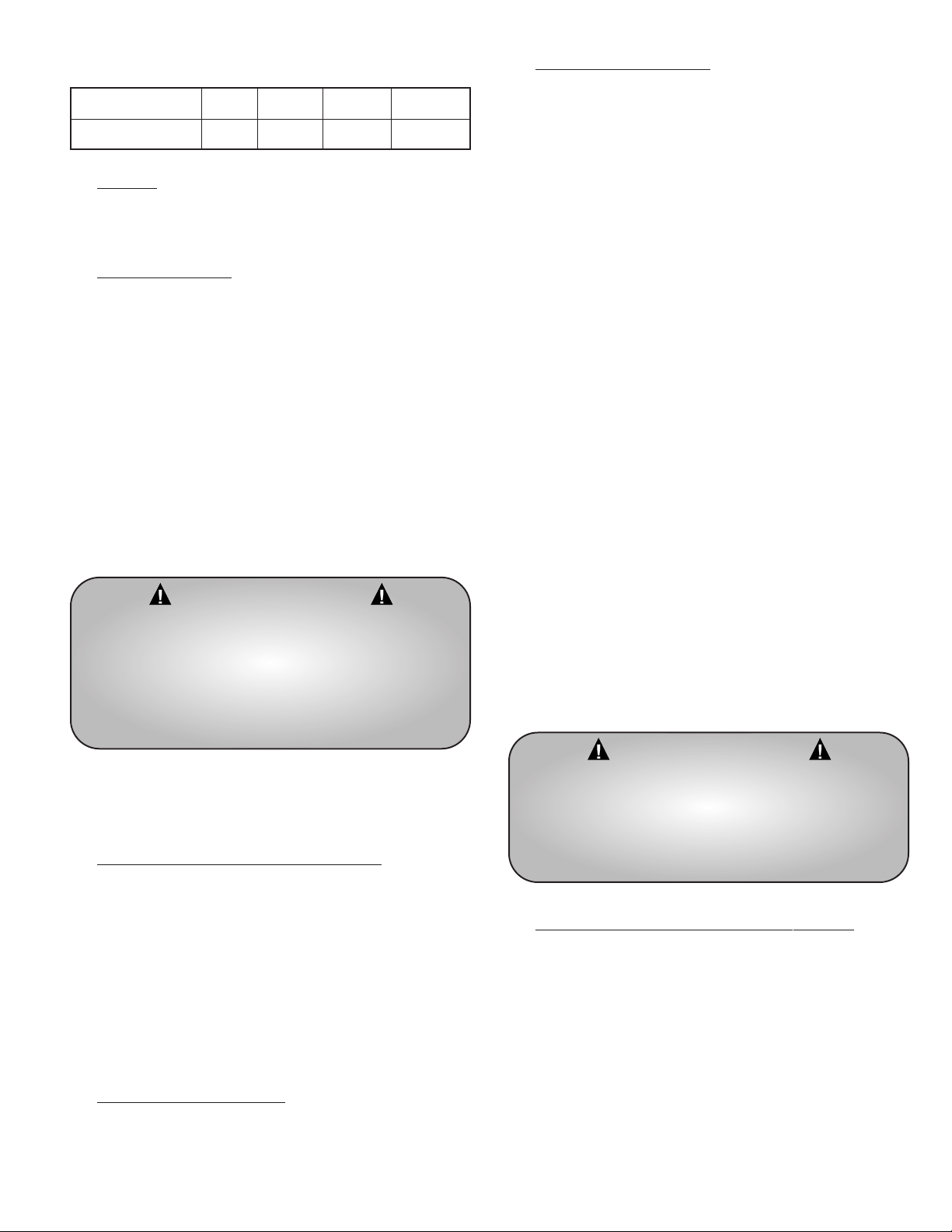

16. Important extension cord information:

a. Make sure the extension cords are in good condition

before use.

b. Based on the total length of cord that you are going

to use, check the chart to make sure the cord meets the

correct minimum cord gauge (AWG) requirements.

IMPORTANT NOTE:

Using an undersized cord or a larger number cord gauge

(AWG) than recommended in the chart, will cause a loss in

power and overheating of the unit. Using a smaller number

cord gauge (AWG) than recommended in the chart, is

acceptable.

Page 5

4

Extension cord chart (minimum cord gauge (AWG)

17. Stay aler

t

.

Watch what you are doing. Use common sense. Do not

operate tool when you are tired, ill or under the influence

of alcohol or other drugs.

18. Chec

k damaged par

ts.

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it

will operate properly and perform its intended function.

Check for alignment of moving parts, free running of

moving parts, breakage of parts, mounting and any other

conditions that may affect its operation. A guard or other

part that is damaged should be properly repaired or

replaced by an authorised service centre unless otherwise

indicated in this instruction manual. Have defective

switches replaced by an authorised service facility. Do not

use the tool if the switch does not turn it on and off.

Don’t operate the machine with a damaged or excessively

worn cutting device.

Length (metres)

.3 to 7.8 7.9 to 15.5 15.6 to 30.6 30.7 to 45.7

Cord gauge (AWG) 18 16 14 12

WARNING – DANGER

LITTLE WONDER WILL NOT BE RESPONSIBLE

FOR THE FAILURE OF CUTTING DEVICES OR

ACCESSORIES THAT HAVE NOT BEEN TESTED

AND APPROVED FOR USE WITH THIS UNIT.

USE ONLY MANUFACTURER-RECOMMENDED

REPLACEMENT PARTS.

19. The use of any accessory or attachment, other than those

recommended in this instruction manual, may present a

risk of personal injury.

20. Have your tool repaired by a qualified person.

This electric tool conforms to relevant safety requirements.

Repairs should only be carried out by qualified persons

using original spare parts, otherwise this may result in

considerable danger to the user.

21. Keep in mind that the operator or user is responsible for

accidents or hazards occurring to other people or their

property.

22. Work only in daylight or in good artificial light.

23. Keep all guards attached at all times when unit is operated.

24. Always use the shoulder strap.

Adjust the strap for comfort before starting the engine.

25. Secur

e unit dur

ing tr

ansport to prevent damage or injury.

26. Machine should not be used in any position that causes

any part to come within 3 metres of overhead electrical

lines. Always be aware of overhead power lines.

27. Always keep a firm grip on both handles when motor is

running: one hand grasps the front “loop” handle while the

other hand grasps the rear handle. Severe injuries can

result if you try to use this machine with only one hand or

with an insecure grip.

28. Thoroughly inspect the area where equipment is to be

used and removed all objects, which can be thrown by the

machine.

29. Always keep area clear of children, pets, and bystanders.

30. Always inspect your unit before each use and ensure that

all handles, guards and fasteners are secure, operating, and

in place. Be sure that all electrical cords are not damaged

or broken.

31. Always maintain and examine your attachments with care.

Follow maintenance instructions given in manual.

32. Don’t attempt to repair any part of the extended reach

“E” system. Have repairs made by a qualified repairman.

See that only original “Mantis” parts are used.

33. Maintain a firm footing and good balance, do not

overreach while trimming. Before you start to trim, check

the work area for obstacles that might cause you to lose

your footing, balance or control of the machine. While

operating the machine always be sure of a safe and secure

operating position especially when using steps or a ladder.

Always be sure of your footing on slopes.

WARNING – DANGER

IMPROPER ASSEMBLY OF THIS EQUIPMENT

CAN RESULT IN SERIOUS INJURY. MAKE SURE

TO FOLLOW ALL INSTRUCTIONS CAREFULLY.

IF YOU HAVE ANY QUESTIONS, CONTACT YOUR

LOCAL AUTHORISED MANTIS DEALER.

34. Always disconnect power cord from power source:

a. Before cleaning blockages.

b. Before checking, cleaning or working on the

cutting portion of the unit.

c. After striking a foreign object: inspect the cutting

part for damage and make repairs before restarting

and operating the unit.

d. If machine starts to vibrate abnormally (check

immediately).

e. Whenever you leave the unit.

Page 6

5

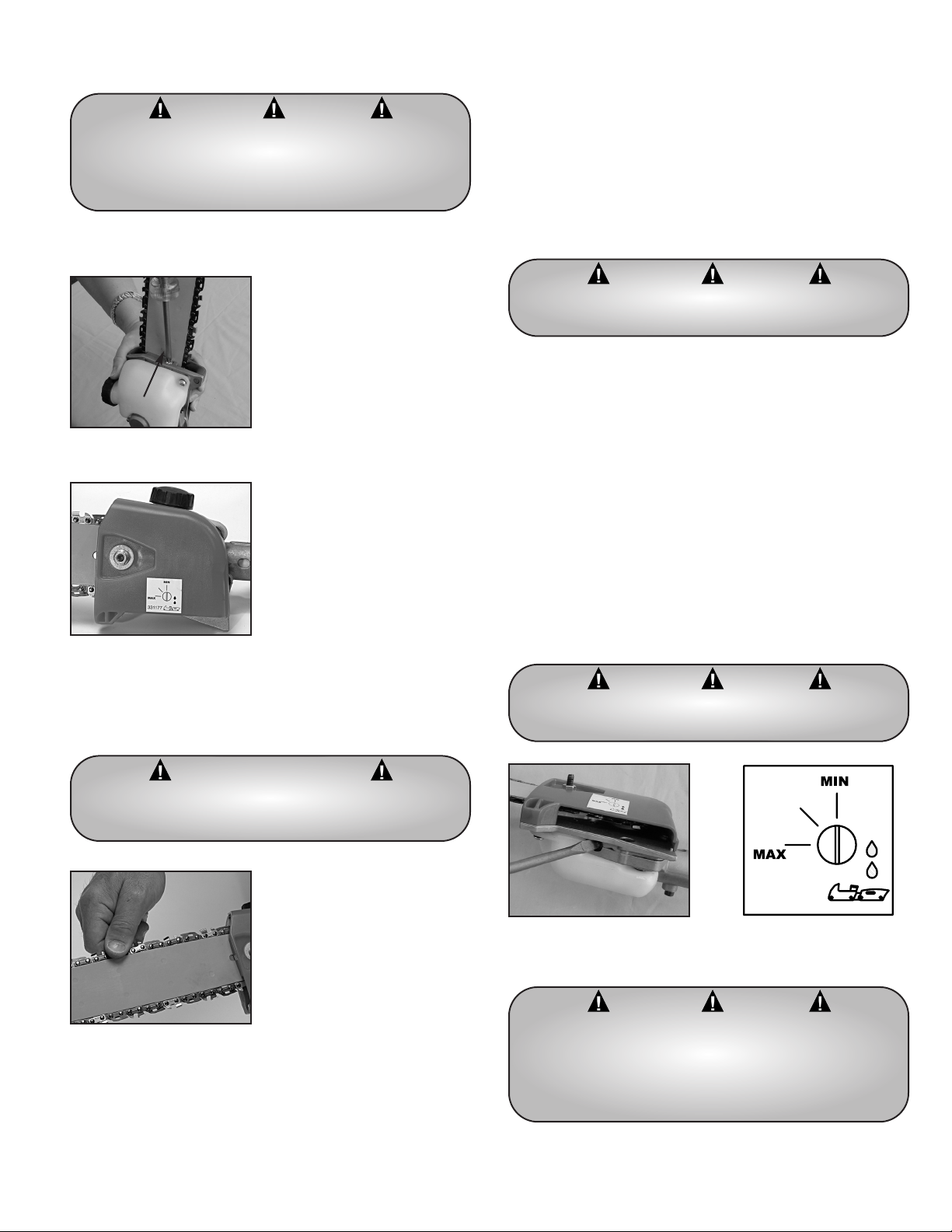

1. Unscrew the mounting nut from the gear case cover. Open

the cover. (Picture 3)

2. Mount the chain guide. Be sure that threaded pin fits into

the opening in the guide bar. (Picture 4)

3. Fit the saw chain into the groove in the chain guide bar,

and around the sprocket.

4. Be sure that pin of the chain tensioner fits into the lower

hole of the guide bar. (Picture 4)

5. Be sure the orientation of the chain is correct.

(Pictures 5 and 6)

6. Hold it in place, and put gear case cover over the threaded

pin. Attach mounting nut. Do not tighten. (Picture 7)

7. Adjust the tension of the chain and tighten the nut.

(Picture 8)

Assembling the Pruner (installing the saw chain)

With a basic understanding of kickback, you will reduce or

eliminate the element of surprise that may contribute to an

accident.

Kickback may occur when the moving saw chain at the nose of

the guide bar touches an object, or when the wood closes in

and pinches the saw chain in the cut. In some cases, this may

cause fast reverse action, kicking the unit up and back or down

and back towards the operator. The operator can lose control of

the device, and that could result in serous personal injury.

Kickback

WARNING DANGER

CHAIN HAS A VERY SHARP EDGE, HANDLE WITH

CARE. ALWAYS WEAR GLOVES; OTHERWISE

SERIOUS PERSONAL INJURY MAY RESULT!

Picture 3

Picture 7 Picture 8

WARNING DANGER

PAY ATTENTION TO THE CORRECT DIRECTION

OF THE CHAIN SAW TEETH

Keep a firm grip on the pruner handles at all time!

Picture 6

Direction of the chain movement

35. Securing the e

xtension cor

d.

Bend the extension cord about 40 cm from the plug end.

Push that bend through the oblong opening, then loop the

bend under the

cord retaining clips as

shown. This will prevent

the extension cord from

detaching from the hedge

trimmer plug.

Picture 4

Threaded pin

Opening in guide bar

Pin of

the chain

tensioner

Picture 5

Correct direction

of chain links

Page 7

6

1. Loosen mounting nut and adjust the chain tension by

turning the tensioner screw

2. Hold unit vertically, and tighten mounting nut

3. Move saw chain backwards on guide bar by hand. Saw

chain should move freely on guide bar if it is in proper

mesh with the sprocket. If saw chain is difficult to rotate or

binds on guide bar, it is too tight. Re-adjust if necessary.

Adjusting saw chain tension

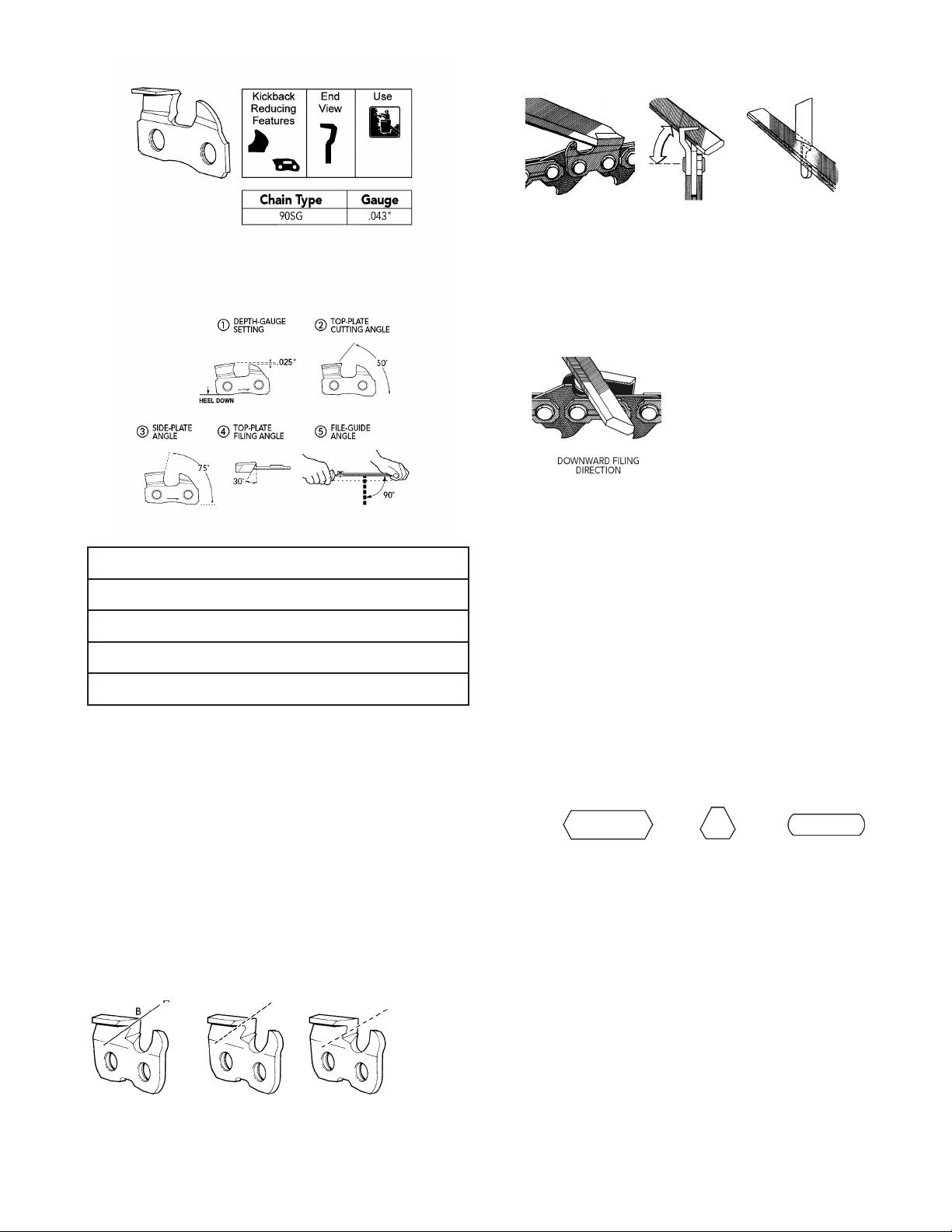

1. Power pruning mechanism is equipped with the automatic

oiling system that can be adjusted in the field. The saw

chain bar, and chain are lubricated when chain rotates. The

pump is set at the factory to a minimum flow rate.

2. Remove oil fill cap and fill reservoir with a quality, low

viscosity guide bar and saw chain oil. Tighten the cap

securely.

3. After starting the motor, run the chain at medium speed

and check the saw chain. Very little visible oil on the saw

chain will provide sufficient lubrication.

4. The oil tank will provide about 40 min. of cutting time

(when set to a minimum flow rate). Refill the oil tank as

needed.

5. A temporary increase in oil flow is recommended when

cutting hardwood or wood showing a large amount of sap.

This will speed oil consumption, and require more frequent

oil tank refills.

6. To adjust oil pump to max, the control screw must be

pressed in slightly prior to turning. Failure to do so

could damage the pump or screw.

7. Wipe debris from around the oil fill cap prior to re-filling

the oil reservoir.

Lubricating the guide bar and chain

WARNING DANGER

IT IS VERY IMPORTANT TO MAINTAIN THE

PROPER CHAIN TENSION. RAPID WEAR OF THE

GUIDE BAR OR THE CHAIN COMING OFF EASILY

CAN BE CAUSED BY IMPROPER TENSION.

WARNING DANGER

NEVER FILL THE OIL TANK OR ADJUST THE OIL

FLOW WHILE MOTOR IS RUNNING.

DISCONNECT POWER CORD FROM THE

POWER SOURCE FIRST.

WARNING DANGER

THE OIL FLOW RATE ADJUSTING SCREW HAS 3

INCREMENTAL SETTINGS.

WARNING DANGER

TO PREVENT PLASTIC DETERIORATION, DO NOT

USE SYNTHETIC OR SILICONE BASED OIL.

WARNING – DANGER

BE SURE UNIT IS UNPLUGGED BEFORE

MAKING ANY ADJUSTMENTS.

Page 8

7

Check the balance of the assembled unit. The handles and

shoulder harness have been assembled at the factory and set

according to the average size person. This can be adjusted to

the operator’s preference by simple loosening the screws and

sliding handles up or down the shaft. Re-tighten the screws.

Balancing the unit

If you need to cut 7-10 cm diametre branches use the

following technique:

1. Start cutting from the bottom of the branch moving pruner

up. (Fig 1)

2. Finish the cut by starting from the top of the branch and

moving down. (Fig. 2)

How to cut thicker branches

No tools are required to attach the pruner to the power head.

1. Pull the spring pin up on the adapter of the power head

shaft assembly. (Picture 7)

2. Carefully fit pruner drive shaft into adapter, making sure

that male spline of the inner drive shaft engages into the

female spline socket of the power head shaft.

3. When the drive shaft is properly aligned, the spring pin

will drop into the hole on the shaft of the pruner

attachment. A click should be heard when completed.

4. Insure two shaft parts are fully engaged by twisting them.

Full engagement will prevent shaft rotation.

5. Secure assembly by tightening the knob. (Picture 8)

6. Unit handles can be re-adjusted to the operator’s

preference by simple loosening the screws and sliding

handles up or down the shaft.

Attaching the Pruner to the Power

Head Assembly

1. Check direction branch will fall.

2. If branch is long, remove it in several pieces.

3. Do not stand directly under the branch being cut.

4. With both hands on the handles, push lockout trigger

button with your thumb and squeeze trigger. Start cutting

when chain rotates at full RPM.

5. Proper cutting position of the pruner:

Hold the pruner against the branch as shown above. This

position will reduce branch movement.

Pruning techniques

Picture 6

Picture 7

Picture 8

branch

Lockout trigger button

Trigger

Page 9

8

Service maintenance guide

Area Maintenance procedure Frequency

Spline male/female connection of the

inner drive shaft

Lubricate 20-25 hrs

Gear case

Use a grease gun to insert lubricant

into the grease nipple of the gear case.

Use EP2 lithium grease

20-25 hrs

Guide bar

Inspect/clean/replace

The guide bar opening should be always

a square. When it’s worn, the chain tilts.

Check for wear of the guide bar opening.

Worn bar needs to be repaired or replaced.

Keep lubrication opening of the

guide bar clean from sawdust

Before each use

Remove

Lubricate

Grease nipple

Remove sawdust

from the groove

Guide bar lubrication opening

GOOD

WORN

GUIDE BAR SECTION

Page 10

9

Area Maintenance procedure Frequency

Oiling port

Inspect/clean

Before each use

Nose sprocket

Clean/lubricate Before each use

Saw chain Inspect/clean/sharpen/lubricate/replace Before each use

Screws/nuts/bolts Inspect/tighten/replace Before each use

Service maintenance guide

Oiling port

Grease port of the nose

sprocket

Area Maintenance Before Every 25 Every 50 Every 100 Note

use hours hours hours

Cutting Parts Replace if

something is wrong

Screws, nuts Tighten, replace Not adjusting

bolts screws

IMPORTANT: Time intervals shown are maximum. Actual use and your experience will determine the frequency of

required maintenance.

Page 11

10

• A Low-kickback

Chain

• Low-vibration Chain

• Narrow-kerf Chain

FILING

TOOLS FOR FILING

Saw chain sharpening procedure

Square-ground Filing

WHO SHOULD PERFORM SQUARE-GROUND FILING?

Most chain saw users will probably never need to use square

ground chain, nor learn to perform square ground filing. But in

areas where the timber is larger and the guide bars used are

longer, the performance advantages of square-ground chain can

outweigh the fact that square-ground filing is more difficult

and much less forgiving of filing errors.

FILE POSITIONING

The file will sharpen the top plate, and the side plate,

simultaneously. This creates a line, (A), where the top plate

cutting angle meets the side-plate angle. For best results, file so

that the line joins the cutting corner (B).

CORRECTLY INCORRECT INCORRECT

FILED CORNER TOO HIGH TOO LOW

To properly sharpen the cutter, use the correct filing position,

as shown here from three different points of view:

FILE DIRECTION

The chain manufacturer

recommends that square-ground

chain be filed from the outside in

(in a downward direction). This

leaves a better edge on the

chromed cutting surfaces and

makes it easier to keep the file’s

position, and the resulting cutting

edges, in correct alignment as

shown in the preceding “File positioning” section. Filing from

the outside in will wear out your file faster, however. Some

square-ground chain users may prefer to file from the inside

out (in an upward direction). You should be aware that insideout filing is much more difficult. But whichever direction you

choose, be sure your file and your cutting edges stay

positioned as shown in the preceding “File positioning”

section. File all cutters on one side of the chain, then reverse

the chain and repeat the process. Use the same file positions

for cutters on the opposite side of the chain.

TOOLS

Only use files specially designed for square-ground chisel

cutters, available from your chain saw dealer.

DOUBLE BEVEL HEXAGON “GOOFY”

SIDE VIEW END VIEW TOP VIEW

Description

4.5 mm Round file

4.5 mm Assembled file guide

.025 inch Drop-centre depth-gauge tool

Depth-gauge file (flat)

Page 12

11

GULLET FILING

Approximately every 5th sharpening, clean out gullets

with a 7/32" round file. File gullets from the inside out (the

side opposite from sharpening). Leave a 1/8 inch (3.175 mm)

shelf behind the gullet.

The depth-gauge setting for all square-ground chisel chain is

.025 inch (0.64 mm).

1. Drain the oil tank.

2. Remove sawdust.

3. Lubricate for rust prevention

4. Use chain cover.

5. Store indoor.

Storage

Page 13

12

48

2

4

3

6

5

8

7

9

5

12

13

1

1

14

15

16

17

16

18

19

20

21

22

23

25

24

26

27

28

29

30

31

32

33

34

36

37

35

39

38

44

40

43

41

42

47

47

46

45

46

50

49

51

Pruner “E” System exploded view

13

51

24

25

39

38

7

12

8

48

5

9

2

26

14

20

49

21

23

22

6

3

4

19

18

15

16

17

16

1

5

1

50

27

28

29

30

31

35

44

32

37

36

34

33

43

47

46

41

45

46

40

42

47

Page 14

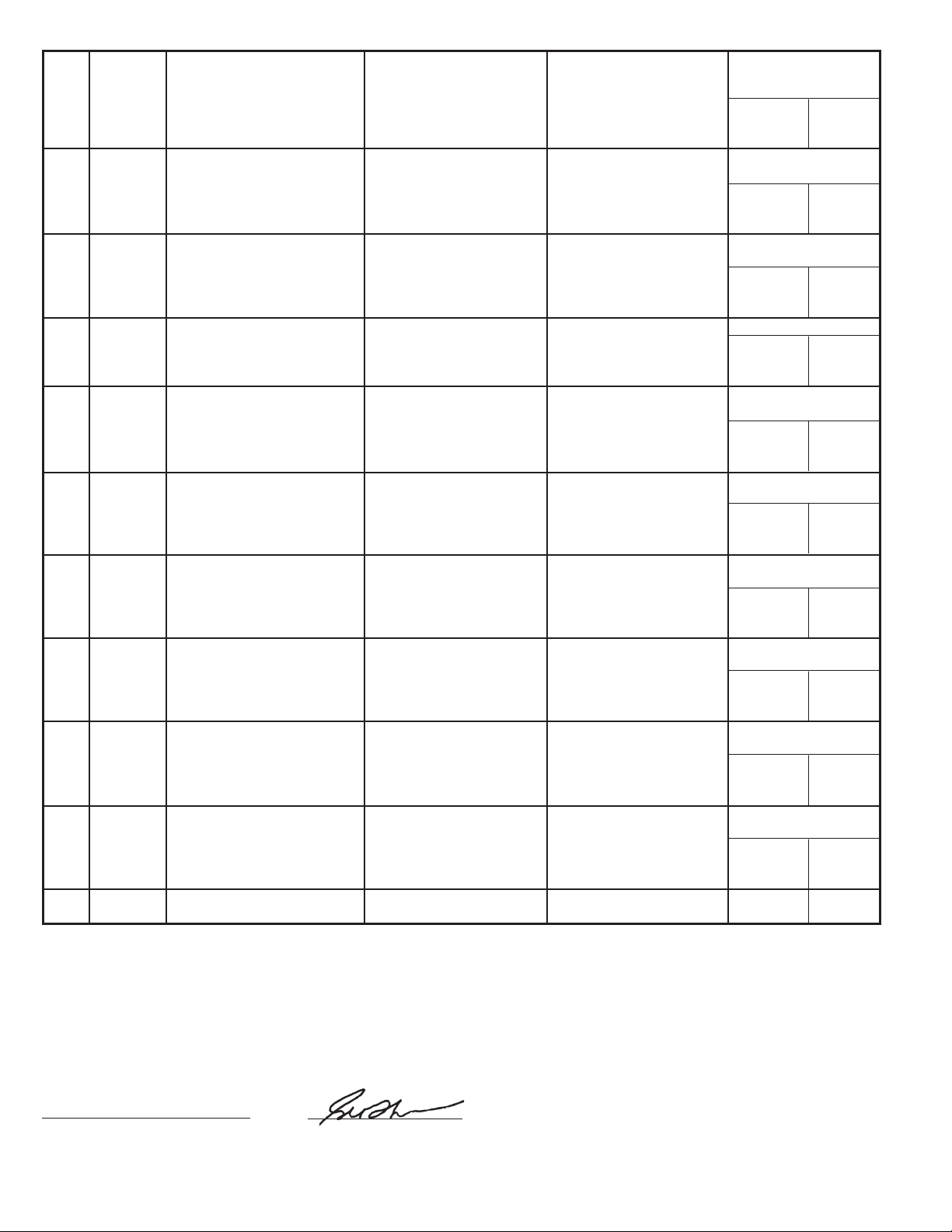

KEY # DESCRIPTION PART # QTY

1 GEAR CASE COVER 3331100 1

2 BEARING 6001-2Z 331101 1

3 GEAR CASE 331102 1

4 BEARING 627 331103 1

5 BOLT M5X12 331500 5

6 GREASE FITTING 331104 1

7 SCREW, TENSIONER 331501 1

8 CHAIN TENSIONER 331105 1

9 BOLT M6X30 331502 1

10 SHIM 331106 1

11 BOLT M5X25 331503 1

12 PLASTIC CHAIN COVER 331107 1

13 FLANGE LOCK NUT M6 331504 1

14 WORM GEAR 331108 1

15 OIL PUMP ASS’Y 331109 1

16 BOLT M4X10 331505 2

17 GASKET 331110 1

18 OIL PIPE ASS’Y 331111 1

19 OIL PIPE 331112 1

20 FILTER 331113 1

21 OIL TANK ASS’Y 331114 1

22 VALVE 331115 1

23 SCREW W/WASHER M5X12 331506 2

24 OIL CAP ASS’Y 331116 1

25 GASKET OIL CAP 331117 1

26 GEAR SHAFT 331118 1

KEY # DESCRIPTION PART # QTY

27 BEVEL, PINION 331119 1

28 BEARING 609 331120 1

29 BEARING 609-2Z 331121 1

30 SNAP RING 331122 1

31 SNAP RING 331123 1

32 CULLER 331124 1

33 SPROCKET 331125 1

34 COVER 331126 1

35 OILIER CONTROL LABEL 331177 1

36 WASHER 06 331507 1

37 BOLT M6X14 331508 1

38 GUIDE BAR 12” 331127 1

39 CHAIN 3/8”X0,042” 331128 1

40 OUTER SHAFT O24X750MM 331129 1

41 INTERNAL SHAFT 755X7MM 331130 1

42 INTERNAL SHAFT ADAPTER 331131 1

43 SPACER 331132 1

44 WARNING LABEL 331178 1

45 GRIP 331133 1

46 SCREW M3X12 331509 2

47 CLAMP 331134 2

48 GEAR CASE SUB-ASSEMBLY 331135 1

49 GEAR 331136 1

50 LOCK WASHER 331561 1

51 CHAIN SAFETY COVER 331270 1

13

Pruner “E” System parts list

Page 15

Specifications, descriptions, and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without notice.

MANTIS

1028 Street Road

Southampton , PA 18966

+ (215) 355-9700

2 YEAR LIMITED SERVICE & WARRANTY POLICY

FOR PRUNER ATTACHMENT

MANTIS extends this limited warranty against defects in material and workmanship for a period of

two years from the date of purchase, to the first retail purchaser and each subsequent owner during

the warranty period. This warranty covers all portions of the Mantis Pruner Attachment.

MANTIS will repair or replace, at its option, any part or parts of the product proven to be

defective in material or workmanship under normal usage during the warranty period. Warranty

repairs and replacements will be made without charge for parts or labor. All parts replaced under

warranty will be considered as part of the original product, and any warranty on the replaced

parts will expire coincident with the original product warranty. In the event of a defect or

malfunction, the purchaser must send the product, postage paid to:

Mantis

2800 Turnpike Dr.

Suite #1

2800 Commerce Centre

Hatboro, PA 19040

MANTIS assumes no responsibility in the event that the product was assembled or used in

noncompliance with any assembly, care, safety, or operating instructions contained in the Owner’s

Manual; was not used with reasonable care; or was misused, used for other than normal or

intended purposes. This warranty does not extend to parts affected or damaged by normal wear

and tear.

MANTIS MAKES NO EXPRESS OR IMPLIED WARRANTIES OR REPRESENTATIONS

EXCEPT THOSE CONTAINED HEREIN. THE DURATION OF ANY IMPLIED WARRANTY,

INCLUDING MERCHANTABILTY AND FITNESS FOR A PARTICULAR PURPOSE, IS

LIMITED TO THE DURATION OF THIS WRITTEN LIMITED WARRANTY. MANTIS

DISCLAIMS ALL LIABILITY FOR INDIRECT AND/OR CONSEQUENTIAL DAMAGES.

SOME

STATES DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY

LASTS AND/OR DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THAT ABOVE LIMITATIONS AND EXCLUSIONS MAY

NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU

MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

Page 16

DE Wir erklären in alleiniger Verantwortung, dass die elektrische 230-V-, 50-Hz-E-System-Astsäge mit einer installierten Nettoleistung von 0,95 kW:

FR Nous, déclarons sous notre seule responsabilité que l’élagueur électrique « E System » 230 V, 50 Hz d'une puissance installée nette de 0,95 kW :

GB We, declare on our sole responsibility that the 230V, 50Hz “E System” Electric Pruner with net installed power of 0.95kW:

NL Wij,

verklaren als enige verantwoordelijke dat de "E System" elektrische snoeikettingzaag van 230 V, 50 Hz met netto geïnstalleerd vermogen van 0,95 kW:

ES Nosotros,

declaramos por responsabilidad exclusiva que la motosierra podadora eléctrica “E System” de 230 voltios, 50 Hz con una potencia neta instalada de 0,95 kW:

IT Noi,

dichiariamo sotto la nostra unica responsabilità che la potatrice a sega elettrica “E System” da 230 V, 50 Hz con potenza netta all'installazione di 0,95 kW:

SE Vi, förklarar på eget ansvar att elektriska grenskärare “E System”, 230 V, 50 Hz, med installerad nettoeffekt på 0,95 kW:

DK Vi, erklærer under eneansvar, at den elektriske 230V, 50 HZ “E System” beskærer med nettoinstalleret effekt på 0,95 kW:

NO Vi, erklærer på eget ansvar at den elektriske 230-volts, 50 Hz “E System” besskjæreren med netto installeret effekt på 0,95 kW:

FI Me, ilmoitamme omalla yksinomaisella vastuullamme, että “E-Systemin” puutarhaleikkuri, 230 V, 50 Hz, jonka asennettu nettoteho on 0,95 kW:

DE Modell: Seriennummer(n): siehe auf dem Gerät Konstruktionsjahr: siehe auf dem Gerät

FR Modèle: Numéro(s) de série: voir sur l'appareil Année de construction: voir sur l'appareil

GB Model: 330112/ Serial number(s): see tool Year of manufacture: see tool

NL model: 330106 serienummer(s): zie op het apparaat constructiejaar: zie op het apparaat

ES Modelo: Número(s) de serie: véase en la máquina Año de fabricación: véase en la máquina

IT Modello: Numero(i) di serie: vedi la targhetta sull'apparecchio Anno di costruzione: verdi la targhetta sull'apparecchio

SE modell: serienummer: se apparat konstruktionsår: se apparat

DK model: serienummer: se apparatet konstruktionsår: se apparatet

NO model: seriennummer: se apparatet konstruksjonsår: se apparatet

FI Malli: Sarjanumero/-numerot: ks. työkalua Valmistusvuosi: ks. työkalua

DE …beschrieben in der beigelegten Dokumentation, mit den grundlegenden Gesundheits- und Sicherheitsanforderungen der Maschinenrichtlinie 98/37/EG, der Richtlinie zur

elektromagnetischen Kompatibilität 89/336/EWG und ihrer derzeit geltenden Nachträge und der Lärmschutzrichtlinie 2000/14/EG (das Konformitätsbewertungsverfahren ist

in Anhang V beschrieben) übereinstimmt.

FR ... décrite dans les documents ci-joints est conforme aux exigences essentielles de santé et de sécurité de la directive sur les machines 98/37/CE, à la directive de

compatibilité électromagnétique 89/336/CEE et amendements en vigueur et à la directive sur les niveaux sonores 2000/14/CE (La procédure d’évaluation de conformité est

incluse à l’annexe V).

GB described in the accompanying documentation conforms to the Essential Health and Safety Requirements of the Machinery Directive 98/37/EC, Electromagnetic

Compatibility Directive 89/336/EEC and current amendments, Sound Directive 2000/14/EC (conformity assessment procedure is Annex V).

NL …beschreven in de bijgevoegde documentatie voldoet aan de Essentiële gezondheids- en veiligheidsvereisten van de EG-machinerichtlijn, 98/37/EG, de EG-

elektromagnetische compatibiliteitsrichtlijn 89/336/EEG, en huidige wijzigingen daarvan, EG-geluidsrichtlijn, 2000/14/EG (conformiteitsbeoordelingsprocedure is Bijlage V).

ES …según se describe en la documentación anexa cumple con los requisitos esenciales de la Directriz 98/37/EC de Salubridad y Seguridad de la Maquinaria, Directriz

89/336/EEC de Compatibilidad Electromagnética, y sus enmiendas actualizadas, Directriz 2000/14/EC de Nivel de Ruido, (en el proceso de evaluación de su conformidad

es el anexo V).

IT ...descritta nella documentazione in dotazione, è conforme a quanto prescritto in materia di Sicurezza e Sanità dalla Direttiva sui macchinari 98/37/EC, dalla Direttiva sulla

compatibilità elettromagnetica 89/336/EEC e relativi emendamenti e dalla Direttiva sulle emissioni acustiche 2000/14/EC (la procedura di accertamento della conformità

è indicata nell’Allegato V).

SE ... som beskrivs i bifogade dokumentation överensstämmer med väsentliga hälso- och säkerhetskrav i maskindirektivet 98/37/EG, direktivet för elektromagnetisk

kompatibilitet 89/336/EEG och aktuella ändringar, ljuddirektivet 2000/14/EG (och bedömning av överensstämmelse görs enligt Bilaga V).

DK …beskrevet i den medfølgende dokumentation overholder betinget sundheds- og sikkerhedskrav i maskineridirektivet 98/37/EU, direktivet for elektromagnetisk

kompatibilitet 89/336/EEU og aktuelle ændringer, lyddirektivet 2000/14/EU (procedure for overensstemmelsesvurdering er Tillæg V).

NO ...beskrevet i vedlagte dokumentasjon, samsvarer med viktige krav til helse og sikkerhet i maskindirektiv 98/37/EU, direktiv for elektromagnetisk kompatibilitet 89/336/EEC

og gjeldende endringer, støydirektiv 2000/14/EU (vurderingsprosedyre for overensstemmelse er vedlegg V).

FI …joka on kuvattu oheisissa asiakirjoissa, täyttää koneita koskevan direktiivin 98/37/EY ja sähkömagneettista yhteensopivuutta koskevan direktiivin 89/336/ETY olennaiset

terveys- ja turvallisuusvaatimukset, mukaan lukien nykyiset muutokset, ja ulkona käytettävien laitteiden melupäästöjä koskevan direktiivin 2000/14/EY vaatimukset

(vaatimustenmukaisuuden arviointimenetelmä on liite V).

DE EG-KONFORMITÄTS-ERKLÄRUNG ES DECLARACION DE CONFORMIDAD CEE

FR DÉCLARATION DE CONFORMITÉ CE IT DICHIARAZIONE DI CONFORMITÀ CEE

GB EC DECLARATION OF CONFORMITY SE EG FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

NL EG CONFORMITEITSVERKLARING DK EU OVERENSSTEMMELSESERKLÆRING

NO EU OVERENSSTEMMELSESERKLÆRING FI EY-VAATIMUSTENMUKAISUUSVAKUUTUS

MANTIS

®

Mantis

1028 Street Rd.

Southampton,

PA 18966

USA

Page 17

DE

FR

GB

NL

ES

IT

SE

DK

NO

FI

Modell

Modèle

Model

Model

Modelo

Modello

Modell

Model

Modell

Malli

330112/

330106

Schalldruckpegel

an Bedienerposition

dB (A)

Pression sonore au poste de

l’opérateur dB (A)

Sound Pressure at the

operator position dB (A)

Geluidsdruk bij de plaats van

de operator dB (A)

Presión del ruido en la

posición del operario dB (A)

Pressione acustica presso

l’operatore dB (A)

Ljudtryck vid

användarposition dB (A)

Lydtryk ved

førerposition dB (A)

Lydtrykk ved brukerposisjon dB (A)

Äänenpaine

käyttäjän asemassa dB (A)

N/A

Schalleistungspegel

(gemessen) dB (A)

Niveau sonore (mesuré)

en dB (A)

Sound Power Level

(measured) dB (A)

Geluidsvermogenniveau

(gemeten) dB (A)

Nivel de potencia del ruido

(medido) dB (A)

Livello di potenza acustica

(misurato) dB (A)

Ljudeffektnivå (mätvärde)

dB (A)

Lydeffektniveau (målt)

dB (A)

Støy fra strøm

Nivå (målt)

dB (A)

Äänitehotaso

(mitattu)

dB (A)

102.5

Schalleistungspegel

(garantiert) dB (A)

Niveau sonore (garanti)

en dB (A)

Sound Power Level

(guaranteed) dB (A)

Geluidsvermogenniveau

(gegarandeerd) dB (A)

Nivel de potencia del ruido

(garantizado) dB (A)

Livello di potenza acustica

(garantito) dB (A)

Ljudeffektnivå (garanterad)

dB (A)

Lydeffektniveau (garanteret)

dB (A)

Støy fra strøm

Nivå (garantert)

dB (A)

Äänitehotaso

(taattu)

dB (A)

105.5

Schwingungsmessungen

m/s

2

Bügelgriff Hinterer

Griff

Mesure des vibrations

en m/s

2

Poignée Poignée

annulaire arrière

Vibration measurements

m/s

2

Loop Rear

Handle Handle

Trillingmetingen m/s

2

Lus-hendel Achter-

hendel

Medición de la

vibración m/s

2

Mango Mango

semicular trasero

Misura delle

vibrazioni m/s

2

Impugnatura Impugnatura

circolare posteriore

Vibrationsmätningar

m/s

2

Öglehandtag Bakre handtag

Vibrationsmål

m/s

2

Bøjlehåndtag Bageste

håndtag

Vibrasjonsmåling

m/s

2

Håndtak Håndtak

foran bak

Tärinän mittaukset

m/s

2

Silmukkakahva

Takakahva

3.37 3.47

DE Name, Vorname: Onraet, Bob DE Stellung: Prasident

FR Nom, Prénom: Onraet, Bob FR Position: President

GB Surname, First Name: Onraet, Bob GB Position: President

NL Naam, Voornaam: Onraet, Bob NL Positie: President

ES Apellido, Nombre: Onraet, Bob ES Posición: Presidente

IT Cognome, Nome: Onraet, Bob IT Posizione: Presidente

SE Namn, Fornamn: Onraet, Bob SE Position: President

DK Navn, Fornavn: Onraet, Bob DK Stilling: Direktor

NO Navn, Fornavn: Onraet, Bob NO Stilling: President

FI Sukunimi, etunumi: Onraet, Bob FI Asema: Toimitusjohtaja

Doc REV B 7/26/06 Declaration of Conformity-331706

DE Ort. Dautm, Unterschrift GB Place, Date, Signature ES Lugar y fecha, Firma SE Ort, datum, Underskrift

FR Lieu, Date, Signature NL Plaats, Datum, Handtekening IT Luogo e date, Firma DK Sted, dato, Underskrift

NO Sted, og, Underskrift FI Paikka, Päivämäärä, Allekirjoitus

SOUTHAMPTON,

PA. USA July 26, 2006 Onraet, Bob

Page 18

P/N 331706

7/06 REV B

MANTIS

1028 Street Road

Southampton , PA 18966

+ (215) 355-9700

Loading...

Loading...