Page 1

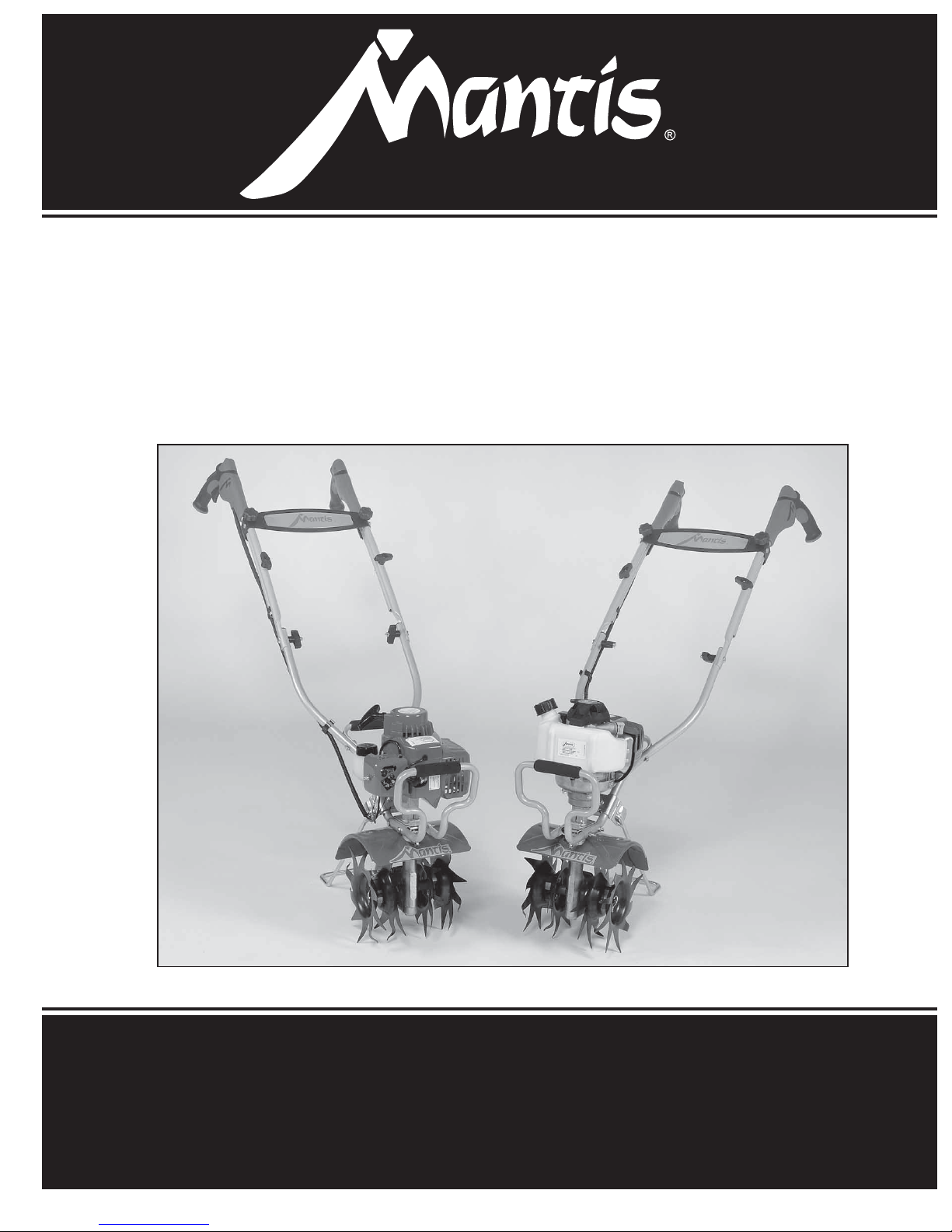

OPERATOR / PARTS MANUAL

DELUXE 2-CYCLE TILLER

7234

DELUXE 4-CYCLE TILLER

7264

2-Cycle– 7234 4-Cycle– 7264

Assembly Instructions Start on Page 7!

Please review the Warning & Safety Information on Pages 4-6

and the Assembly Instructions before unpacking the box.

IMPORTANT!

Page 2

Welcome to the World of Mantis Gardening

Here’s your new MANTIS Tiller . . . the lightweight wonder that’s

Changing the Way Americans Garden.®

Unlike big tillers, your MANTIS Tiller weighs only 26 pounds. So it lifts

easily, handles smoothly, tills and weeds precisely. And, unlike other

small tillers, it features serpentine tines that churn soil to ten inches

deep. It creates a soft, smooth seed bed, even in problem soil.

Once you know how to use your tiller correctly, we guarantee you’ll

love it. So fi rst, please read this manual. It shows, step by step, how

to use your tiller safely.

ATTENTION MANTIS PRODUCT OWNERS!

Get maintenance tips for your Mantis

product on our web site

at www.mantis.com

2-Cycle– 7234

4-Cycle– 7264

2 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

Page 3

IMPORTANT MESSAGE

Thank you for purchasing this Schiller Grounds Care, Inc. product. Y ou have purchased a world class product, one of the best designed

and built anywhere.

This machine comes with Operation and Safety instructions, Parts and Service instructions and Engine instructions. The useful life

and good service you receive from this machine depends to a large extent on how well you read and understand these manuals. Treat

your machine properly, lubricate and adjust it as instructed, and it will give you many years of reliable service.

Your safe use of this Schiller Grounds Care, Inc. product is one of our prime design objectives. Many safety features are built in, but

we also rely on your good sense and care to achieve accident-free operation. For best protection, study the manuals thoroughly. Learn

the proper operation of all controls. Observe all safety precautions. Follow all instructions and warnings completely. Do not remove or

defeat any safety features. Make sure those who operate this machine are as well informed and careful in its use as you are.

See a Schiller Grounds Care, Inc. dealer for any service or parts needed. Schiller Grounds Care, Inc. service ensures that you continue

to receive the best results possible from Schiller Grounds Care, Inc. products. You can trust Schiller Grounds Care, Inc. replacement

parts because they are manufactured with the same high precision and quality as the original parts.

Schiller Grounds Care, Inc. designs and builds its equipment to serve many years in a safe and productive manner. For longest life,

use this machine only as directed in the manuals, keep it in good repair and follow safety warnings and instructions. You’ll always be

glad you did.

Schiller Grounds Care, Inc.

1028 Street Road

Southampton, PA 18966-4217

PHONE (800) 366-6268 • FAX (215) 956-3855

TABLE OF CONTENTS

PAGE

SAFETY RULES & WARNINGS

Special Safety Information .....................................4

Safety & Warnings .................................................4

Safety Decal Information ....................................4-5

Warning Do’s .........................................................5

Warning Don’ts ......................................................6

Engine/Fuel Warning Do’s .....................................6

Engine/Fuel Warning Don’ts ..................................6

ASSEMBL Y ................................................................7

Lower Handle .....................................................8-9

Kickstand ...............................................................9

Tines ....................................................................10

Upper Handle Assembly .................................10-12

Upper Handle Positioning ....................................12

FUELING & STARTING

2-Cycle Fueling & Starting ...................................13

4-Cycle Fueling/Oil & Starting .............................14

4-Cycle Corrective Action ....................................14

OPERATION ........................................................15-16

TRANSPORT ...........................................................17

STORAGE ................................................................17

MAINTENANCE

2-Cycle ................................................................18

4-Cycle ................................................................18

2-Cycle & 4-Cycle Basic Maintenance ................19

MANTIS TILLER ASSEMBLIES

2-Cycle Tiller Assembly .......................................20

4-Cycle Tiller Assembly .......................................21

TROUBLESHOOTING .............................................22

CONTROL ................................................................23

EPA ...........................................................................24

LIMITED WARRANTY INFORMATION ... BACK PAGE

This Operator / Parts Manual is part of the machine. Suppliers of both new and

second-hand machines must make sure that this manual is provided with the

machine.

3Contact us at www.mantis.com

Page 4

Safety Rules & Warnings

You will notice throughout this Owners Manual Safety Rules and Important Notes. Make sure you understand and obey these

warnings for your own protection.

I. SPECIAL SAFETY INFORMATION

Attention: This symbol points out our

important safety instructions.

When you see this symbol,

heed it’s warning!! Stay alert!!

To reduce the potential for accidents, comply

with the safety instructions in this manual.

Failure to comply may result in serious

personal injury, and/or equipment

and property damage.

II. SAFETY & WARNINGS

Improper use or care of this tiller or failure to wear

proper protection can result in serious injury.

Read and understand the rules for safe

operation and all instructions in this manual.

Wear hearing and eye protection.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

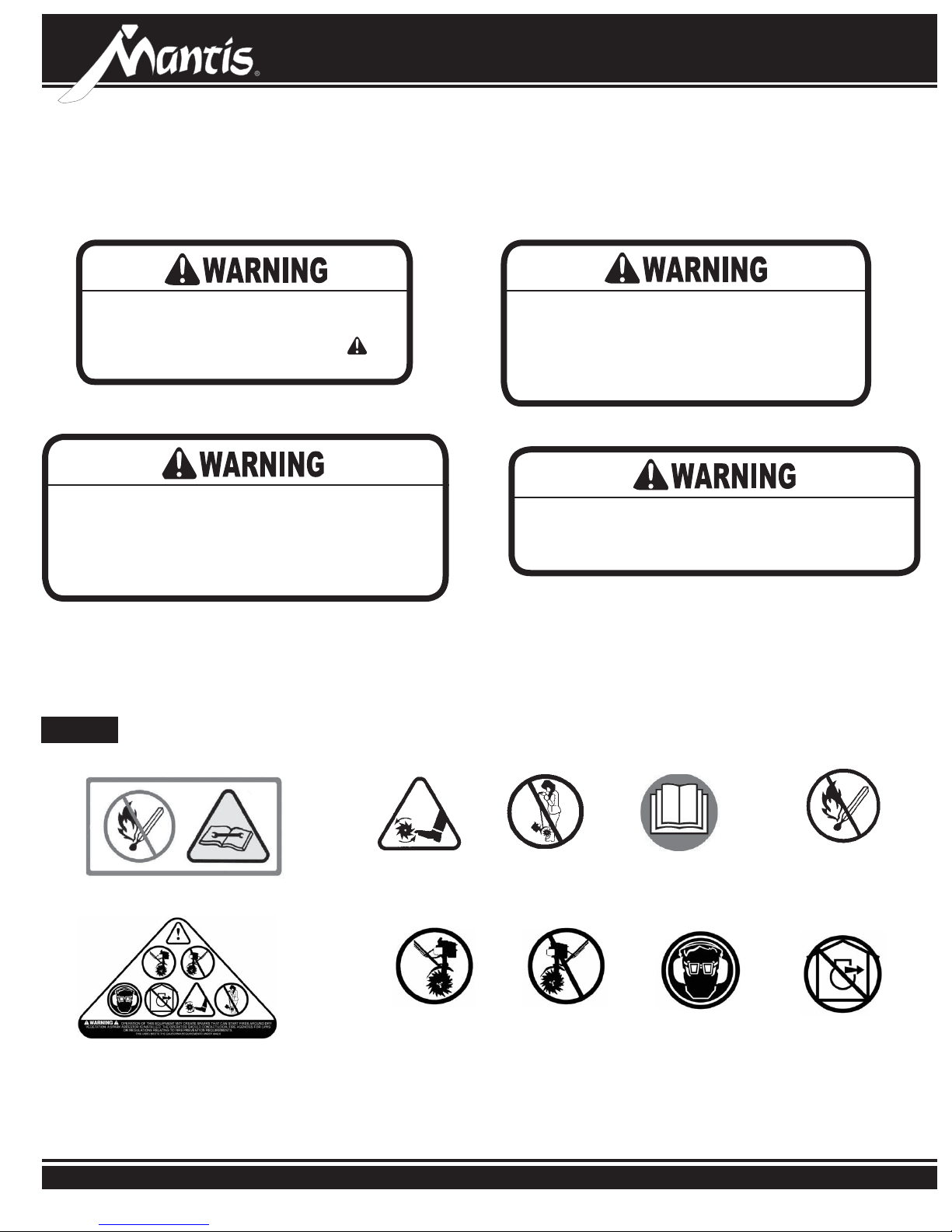

III. SAFETY DECAL INFORMATION

An important part of the safety system incorporated in this tiller are the warning and information decals found on various parts of

the tiller. These decals must be replaced in time due to abrasion, etc. It is your responsibility to replace these decals when they

become hard to read.

2-Cycle

Read owner’s manual before

using tiller, or performing any

repair or maintenance. Keep

owners manual in a safe place.

Wear ear and

eye Protection.

P/N 430057

P/N 400630

Cutting hazard;

keep feet and

hands away from

rotating tines.

Caution: when assembling

the handles, make sure fuel

tank faces operator. This

is the rear of the tiller, refer

to assembly instruction on

page 8-9.

Do not carry

the tiller in this

position.

Incorrect assembly.

4 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

Don’t fuel, refuel, or

check fuel while smoking,

or near an open fl ame or

other ignition source.

Don’t operate

indoors

Page 5

4-Cycle

Safety Rules & Warnings

Cutting hazard; keep

feet and hands away

P/N 430057

P/N 400631

from rotating tines.

If the tiller is used improperly or safety precautions

are not followed, the users risk serious injury

to themselves and others.

Read and understand this manual before

attempting to operate this tiller.

IV. WARNINGS - DO’S

Read and understand the owner’s manual.

Pay particular attention to all sections

regarding safety.

1. Always keep a fi rm grip on both handles

while the tines are moving and/or the

engine is running. BE AWARE!! The

tines may coast after throttle trigger is

released. Make sure tines have come to

a complete stop and engine is off before

letting go of the tiller.

2. Always maintain a fi rm footing and

good balance. Do not overreach while

operating the tiller. Before you start to

use the tiller check the work area for

obstacles that might cause you to lose

your footing, balance or control of the

machine.

3. Thoroughly inspect the area where

equipment is to be used and remove

all objects, which can be thrown by the

machine.

4. Always keep area clear of children,

pets, and bystanders.

5. Always stay alert. Watch what you are

doing and use common sense. Do not

operate unit when fatigued.

6. Always dress properly. Do not wear

loose clothing or jewelry, they might

get caught in moving parts. Use sturdy

gloves. Gloves reduce the transmission

of vibration to your hands. Prolonged

exposure to vibration can cause

numbness and other ailments.

7. While working, always wear substantial

footwear and long trousers. Do not

operate the equipment when barefoot or

wearing open sandals.

8.

Always wear ear and eye protection.

Eye protection must meet applicable CE

requirements. To avoid hearing damage,

we recommend hearing protection be

worn whenever using the equipment.

9. To reduce fi re hazard, keep the

engine, and petrol/gas storage area free

of vegetative material and excessive

grease.

10. Start the engine carefully, according to

the manufacturer’s instructions and with

feet well away from tool(s).

11.

Keep all nuts, bolts and screws tight

to be sure the equipment is in safe

working condition.

12.

Use extreme caution when reversing

or pulling the machine towards you.

13. Work only in daylight or good

artifi cial light.

14. Always be sure of your footing on

Wear ear

and eye

Protection.

Do not carry

the tiller in this

position.

Read owner’s manual before

using tiller, or performing any

repair or maintenance. Keep

owners manual in a safe place.

Caution: when assembling

the handles, make sure

fuel tank faces away from

operator. This is the rear of

the tiller, refer to assembly

instruction on page 8-9.

Don’t operate

indoors

Operation of this equipment may create sparks

that can start fi res around dry vegetation. A spark

arrestor is installed. The operator should contact

local fi re agencies for laws or regulations relating

to fi re prevention requirements.

slopes.

15. Exercise extreme caution when

changing direction on slopes.

16. Always keep a safe distance between

two or more people when working

together.

17. Always inspect your unit before each

use. Keep all knobs, nuts, bolts and

screws tight to be sure the equipment

is in safe working condition.

18. Before using your tiller, always visually

inspect to see that the tools are not

worn or damaged. Replace worn or

damaged elements and bolts in sets to

preserve balance.

19. Always maintain and examine your

Tiller with care. Follow maintenance

instructions given in manual.

20. Always store tiller in a sheltered area

(a dry place), not accessible to children.

The tiller as well as fuel should not be

stored in a house.

21. Always keep in mind that the operator

or user is responsible for accidents or

hazards occurring to other people or

their property.

Don’t fuel, refuel,

or check fuel while

smoking, or near an

open fl ame or other

ignition source.

Incorrect assembly.

5Contact us at www.mantis.com

Page 6

Safety Rules & Warnings

V. WARNINGS - DONT’S

Don’t use tiller with one hand. Keep

both hands on handles with fi ngers and

thumbs encircling the handles, while

tines are moving, and engine

is running.

Don’t run with the machine, walk.

Don’t work on excessively steep slopes.

Don’t attempt to clear tines while they

Handle fuel with care, it is highly fl ammable. Fueling a hot engine or near an ignition source can

cause a fi re and result in serious personal injury and/or property damage.

VI. ENGINE/FUEL WARNINGS - DO’S

2-Cycle Always

the fuel mixture. Stale gasoline can cause

damage.

4-Cycle Always use fresh gasoline.

Always store fuel in containers

specifi cally designed for this purpose.

Always add fuel before starting

the engine.

use fresh gasoline in

are moving. Never try to remove jammed

material before switching the engine off

and making sure the tines have stopped

completely.

Don’t allow children or people unfamiliar

with these instructions to use the

machine. Local regulations can restrict

the age of operator.

Always replace all fuel tank and

container caps securely.

Always pull starter cord slowly until

resistance is felt to avoid kickback and

prevent arm or hand injury.

Always operate engine with spark

arrestor installed and operating properly.

Don’t operate while under the infl uence

of alcohol or drugs.

Don’t attempt to repair this tiller. Have

repairs made by a qualifi ed dealer or

repairman. See that only original Mantis

parts are used.

Stop the engine whenever you leave

the machine and before refueling. Allow

the engine to cool before storing in any

enclosure. Replace worn or damaged

parts for safety.

If the fuel tank needs to be drained, this

should be done outdoors.

VII. ENGINE/FUEL WARNINGS - DON’TS

Never pick up or carry a machine while

the engine is running.

Don’t fuel, refuel or check fuel while

smoking, or near an open fl ame or other

ignition source. Stop engine and be sure

it is cool before refueling.

Don’t leave the engine running while the

tiller is unattended. Stop the engine when

carrying out maintenance and cleaning

operations, when changing tools and

when being transported by means other

than under its own power.

Never remove the cap of the fuel tank or

add petrol while the engine is running or

when the engine is hot.

Don’t refuel, start or run this tiller indoors

or in an improperly ventilated area.

Don’t run engine when electrical system

causes spark outside the cylinder. During

periodical checks of the spark plug, keep

plug a safe distance from cylinder to

avoid burning of evaporated fuel from

cylinder.

Don’t check for spark with spark plug

or plug wire removed. Use an approved

tester.

Don’t crank engine with spark plug

removed unless spark plug wire is

disconnected. Sparks can ignite fumes.

Don’t run engine when the odor of gasoline

is present or other explosive conditions exist.

Do not attempt to start the engine if

petrol is spilled, but move the machine

away from the area of spillage and avoid

creating any source of ignition until petrol

vapors have dissipated.

Don’t operate your tiller if there is an

accumulation of debris around the

muffl er, and cooling fi ns. To reduce the

fi re hazard, keep the engine and petrol

storage area free of vegetative material

and excessive grease.

Don’t touch hot muffl ers, cylinders

or cooling fi ns as contact may cause

serious burns.

Don’t change the engine governor

setting or over speed the engine.

Don’t attempt to remove spark plug while

engine is hot. Removing a spark plug

from a hot engine can cause irreparable

damage to the engine and will void your

warranty.

Don’t use starter fl uids as they will cause

permanent engine damage.

6 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

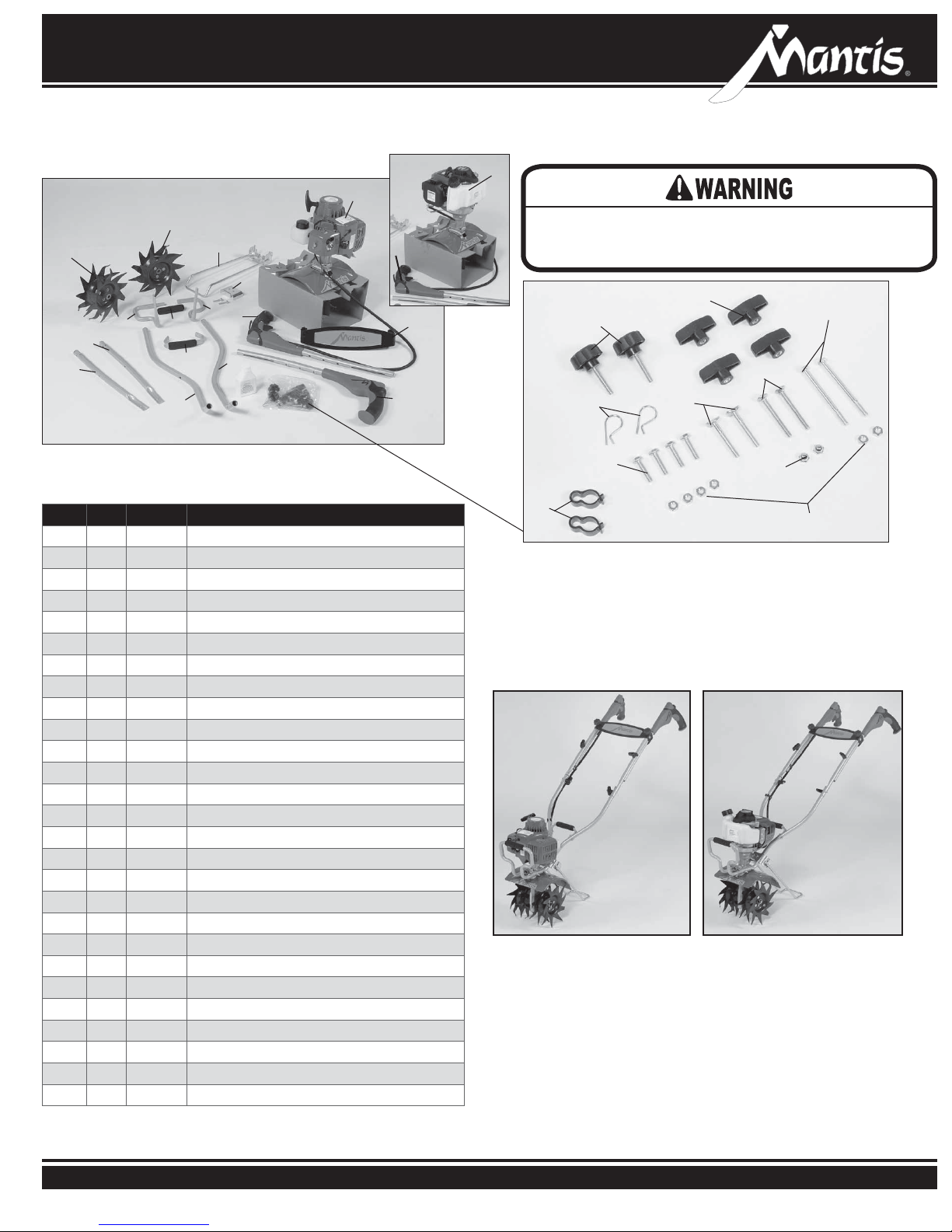

Page 7

W

M

N

Assembly

A

A

V

Y

K-1

Z

B

C

D

K-2

O

I

F

Improper assembly of this tiller can result in serious injury. Make

sure to follow all instructions carefully. If you have any questions,

contact our factory at 1-800-366-6268 or an authorized Mantis dealer.

Bag Contents

P

Q

G

R

E

L

G,H, J, P, Q,

R, S, T, X, U

WHAT COMES IN THE BOX

Key Qty. Part No. Description

A 1 N/A Transmission And Engine Assembly

B 1 430023 Loop Handle Right Half

C 1 430022 Loop Handle Left Half

D 1 430025 Foam Grip

E 1 430051 Lower Handle W/Plug, Right

F 1 430050 Lower Handle W/Plug, Left

G 2 4049 Bolt 1/4-20 X 3.25”

H 6 972 1/4-20 Two-Way Lock Nut

I 1 430049 Carry Handle With Grip

J 4 144-2 1/4-20 X 1.125” Hex Head Cap Screws

K-2 1 430003 Trigger Handle Assembly, 2-Cycle Engine, Right

K-1 1 430004 Trigger Handle Assembly, 4-Cycle Engine, Right

L 1 430006 Handle Assembly , Left

M 1 430053 Middle Handle W/Plug, Right

N 1 430052 Middle Handle W/Plug, Left

O 1 430021 Handle Brace

P 2 430038 Knob, 1/4-20 X 1.5 Male

Q 4 400523 Knob, Two Prongs, Female

R 2 430039 Carriage Bolt 1/4-20 X 2.25”

S 2 430048 Curved Head Bolt, 1/4-20 X 2”

T 2 395 Acorn Nut

U 2 478 Throttle Clip

V 1 438RA Tine Assembly, Right

W 1 438LA Tine Assembly , Left

X 2 418-1 Tine Retaining Pins

Y 1 410158 Kickstand, Stand Assembly

Z 1 430037 Kickstand, Bracket and Hardware

X

J

U

S

T

H

Congratulations! You have just purchased a super high-quality

product, the Mantis Deluxe Tiller/Cultivator.

Whether you have purchased the 2-Stroke or 4-Stroke model,

this manual will show you how to Assemble, Start, Operate,

Transport, Store and Maintain your Tiller. The Mantis Deluxe

Tiller/Cultivator is designed to bring you years of solid, reliable

performance.

2-Cycle Tiller 4-Cycle Tiller

WHAT YOU WILL NEED

TO ASSEMBLE THE TILLER

Prior to removing the contents and assembling, it is important to:

• Have a clean work area.

• Make sure all necessary

tools are handy.

• You will need a 7/16”

crescent wrench

• A ratchet with an extension

• A 7/16” socket

• A 3/8” socket or

crescent wrench.

7Contact us at www.mantis.com

Page 8

Assembly

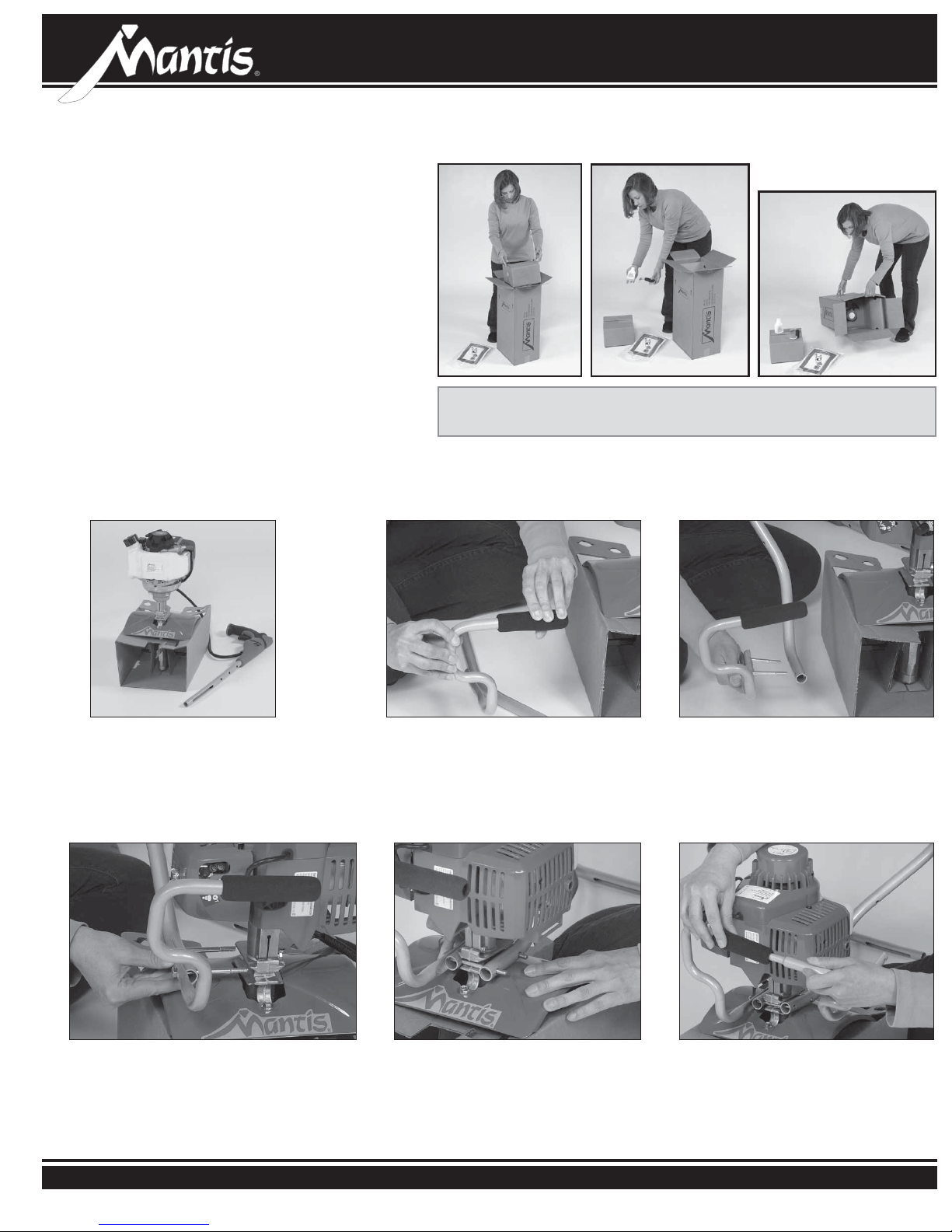

LET’S BEGIN

The following instructions are for the 2-Stroke and

4-Stroke Tiller.

• With the box upright, open the box and remove the

tine box and the loose parts that are at the top of the

tiller box. Do not remove any other parts in the box.

• Lay the box on one side and open the bottom fl aps.

• Return the box to an upright position (as shown) and

pull the box straight up.

• The right handle, additional parts and tiller engine will

be in the box cradle. Leave the engine and throttle in

the cradle to assist in the assembly.

• Lay everything out so you can easily identify the

parts (see parts image and list on page 7).

LOWER HANDLE ASSEMBLY

NOTE: Some of the photos in this manual do not represent your

4-Stroke tiller engine. They are for assembly purposes only.

1

• For ease of assembly and stability it

is important that you keep the engine

assembly in its cardboard cradle.

23

• Slide the foam grip onto the right

loop handle.

• Line up the holes of the Right Loop

Handle with the holes of the Lower

Right Handle.

• Slide the two 3.25” bolts through

the hole

456

• Position this assembly onto the

recessed channels below the engine.

• Slide the lower left handle onto

the bolts

• Slide the left loop handle into the

8 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

foam grip and right loop handle

Page 9

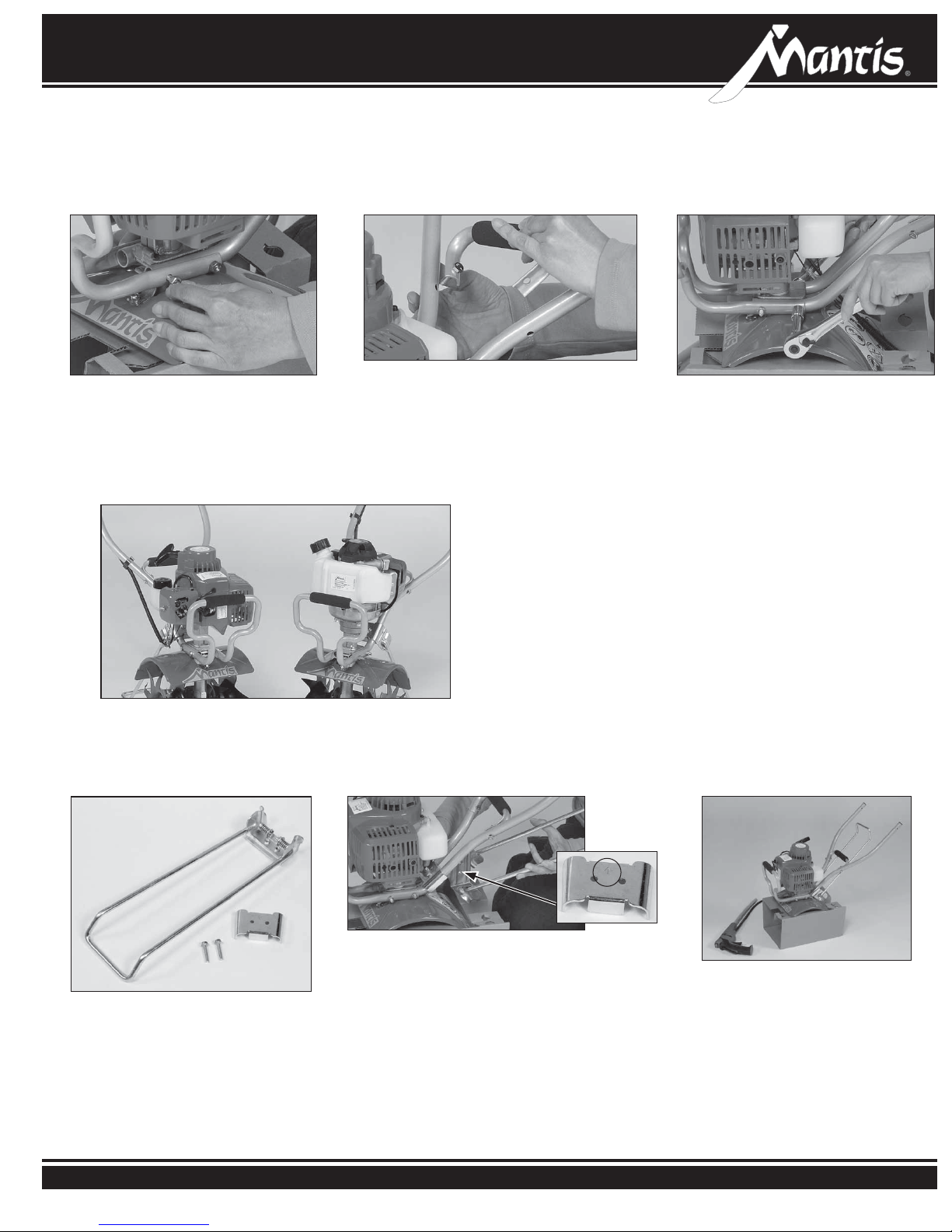

LOWER HANDLE ASSEMBLY (CONTINUED)

Assembly

7

• Slide loop handle through bolts

and over top lower left handle,

then take two lock nuts and

fasten them fi nger tight

10

2-Cycle Tiller 4-Cycle Tiller

8

• Place the Carry Handle between the

lower handles and line up the holes

• Place two of the 1.125” bolts through

holes with hex head on inside of carry

handle and with two lock nuts fasten

them tight with wrench and socket.

• At this point, your Mantis tiller should look like

this when lower handle assembly is complete.

9

• Use the 7 /16” wrenches and socket

to tighten the rest of the handle bolts.

KICKST AND ASSEMBLY

1

2

• Position the kickstand brace

just above the bend of the lower

handles. The stamped arrow

should be pointing up

• Position the kickstand under the

lower handles, line up the holes

and thread the kickstand brace

bolts into the kickstand

•Tighten with the 3/8” wrench

3

• Your Mantis tiller will look

like this when lower handle

assembly and kickstand is

complete.

9Contact us at www.mantis.com

Page 10

Assembly

TINE ASSEMBL Y

123

• You’ll need the 2 Tines and the

2 Retaining pins

• Remove the unit from the

cardboard cradle and turn the

unit slightly on its side

• You will notice that one side of the

Tine has a circular hole while the

other has a “D” shaped hole.

456

• Attach the Tine so that the circular hole

slides onto the axle fi rst.

*NOTE: The Tiller is laying down for assembly purposes only.

See page 14 for important information.

• When the axle protrudes from the

other side it will line up perfectly

with the “D” shaped hole.

• Slide a Retaining Pin through the

hole in the axle to secure the Tine.

• Repeat steps for the other side.

UPPER HANDLE ASSEMBLY

1

• To assemble the Upper Handles,

fi rst put the Kickstand down

2

• Layout the Middle and Upper Handles

and the Handle Brace as shown above

3

• Take the Right Middle Handle and

attach the brace using a hex head

cap screw and a 2-way lock nut.

Finger tighten.

• Repeat for left side.

10 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

Page 11

Assembly

UPPER HANDLE ASSEMBLY (CONTINUED)

456

• Thread a 2-pronged knob onto

• Take the Right Upper Handle, the

one with the throttle, and slide it

between the Middle Handle and the

lower fl ange of the Brace.

• Insert a curved head bolt into the

slot at the bottom of the Upper

Handle so that it comes out the

top of the Middle Handle.

the bolt two full turns while leaving

it loose.

• Repeat for left side.

789

• Line up the top holes of the Upper

Handles with the holes on the top of

the Brace so the handles are in the

lowest position.

• Insert the round knob into the

Brace and tighten.

10 11 12

• With a 7/16 in. wrench and socket,

tighten the nuts and bolts that hold

the Brace onto the handles

• Insert the carriage bolts into the

bottom holes of the Upper Handles

then through the top holes of the

Lower Handles.

• Now fully tighten the lower

2-prong knobs

• Loosely thread the other 2-pronged

knobs onto the carriage bolts

11Contact us at www.mantis.com

Page 12

Assembly

UPPER HANDLE ASSEMBLY (CONTINUED)

13 14 15

• Lift the Upper Handles until they line

up with the Lower Handles and fully

tighten the knobs at the pivot point.

UPPER HANDLE POSITIONING

• Cap the exposed bolts with the acorn

nuts and tighten with your 7/16”

wrench until snug. Do not over tighten.

• Attach the throttle cable clips to

the Upper and Lower Handles.

Make sure the cable is not

wrapped or twisted and you have

the proper throttle movement.

* See important notes listed below.

12

• Adjust your handle height by loosening the

upper 2-prong knobs and removing the

round knobs then sliding the Upper Handles

to the desired position.

• Then re-insert the round knobs and

re-tighten the 2-prong knobs

IMPORTANT NOTE:

Make sure you have installed the handles properly. When you stand behind your tiller, holding the

handles, the fender warning label should face you.

IMPORTANT NOTE:

Before you use your MANTIS Tiller, read the

Safety Rules & Warnings on pages 4-6

IMPORTANT NOTE:

Be sure you have proper throttle movements and

that the throttle cable is not wrapped or twisted

2-Cycle Tiller 4-Cycle Tiller

Improper Throttle installation can cause tines to rotate unexpectedly.

around the handle bar. Hold down the lockout

lever, fully squeeze the throttle trigger and let go.

The throttle triangle must click in both directions.

If there is any doubt, remove air fi lter and visu-

ally check that the throttle triangle hits both the

idle screw and the full open stop. THIS MUST BE

DONE BEFORE STARTING THE ENGINE.

12 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

Page 13

2-CYCLE TILLER FUELING ONLY

Before you start your Mantis Deluxe 2-Cycle Tiller/Cultivator for

the fi rst time you will need to mix the fuel and oil.

Pour the pre-measured bottle of Mantis approved, 2-Cycle oil

into one gallon of 89 octane gasoline and mix well.

Put the kickstand down to position the tiller upright.

Remove the fuel cell cap.

Carefully add the fuel mixture to the tank until it is about 4/5

full. And remember, always drain the gas when transporting the

unit from one location to another.

Replace the cap.

2-CYCLE TILLER STARTING ONLY

The FastStart feature works by winding up the starter coil to

store energy in the starting mechanism. The following process

will allow you to easily start your Mantis tiller.

Cold Starting

• First make sure the stop/start switch located on the throttle

handle, is in the start position, which is indicated by the

“I” symbol.

• Close the choke by pulling the choke button out.

• Press the primer bulb approximately 6 times until the bulb

is fi lled with gas. Once it is fi lled, press it two more times.

• Pull the starter cord out a few clicks (8 to 12 inches)

to store energy in the starting mechanism. Return the

starter cord to the original position. Briskly pull the

starter cord. The stored energy is released and the

engine will start.

IMPORTANT NOTE:

If the engine does not start on the fi rst attempt, repeat

the above starting process a maximum of 5 times. If

you are still experiencing diffi culties, push the choke

button in and repeat the above starting process again.

2-Cycle Tiller Fueling & Starting

Switch

• Once it is running, open the choke by pushing the button

back in, if you have not already done so.

• To stop the engine, simply push the start / stop switch to the

stop position “O”.

• Before using the tiller, let the engine idle for one minute to

warm up. Before shutting it down, let the engine idle for two

to three minutes to cool down.

Warm Starting

• To start a warm engine, follow the same procedure. The only

exception is that you can leave the choke button in and you

don’t have to pump the primer bulb.

• Before using the tiller, let the engine idle for a minute to warm

up. Before shutting it down, let the engine idle for two to three

minutes to cool down.

Choke

If engine does not stop when switch is put in the stop

position, release the throttle, allow engine to idle, put

the tiller down and pull the choke button out to shut

engine down. Have product serviced before using.

Do not operate the engine in a confi ned

space where dangerous carbon monoxide

fumes can collect.

Fuel is extremely fl ammable. Handle it with

care. Keep away from ignition sources. Do not

smoke while fueling your equipment

Avoid accidental blade engagement.

Do not squeeze the throttle trigger when starting. Main-

tain proper idle speed adjustment (2500-3100 rpm)

13Contact us at www.mantis.com

Page 14

4-Cycle Tiller Fueling & Starting

4-CYCLE TILLER FUELING AND OIL ONLY

IMPORTANT!

It is normal for your 4 stroke engine to smoke for the fi rst

minute or two of operation, however it is not necessary

for this to occur every time. This is a result of the oil being

pulled through the engine for lubrication.

• Rock the tiller forward so

that it rests on its front loop

handle.

• It is important to position

the Mantis Deluxe 4-Cycle

Tiller as shown in Figure 1

so the oil will properly fi ll the

crankcase. Failure to do so

will cause engine damage.

• Remove the oil plug.

• Pour in the bottle of pre-measured, Mantis approved, 4-cycle

engine oil.

• Always check the oil level before each use. The oil level

should reach the inner fi rst thread of the reservoir. Do not

overfi ll.

• Replace the oil plug.

• Then return the unit to the upright position and put the

kickstand down.

Fueling your Mantis 4 Cycle Deluxe Tiller/Cultivator is easy.

Unscrew the gas cap and fi ll the tank about four-fi fths of the

way up with 89 octane unleaded gasoline. And remember,

always drain the gas when transporting the unit from one

location to another.

Figure 1

4-CYCLE TILLER STARTING ONLY

Starting the engine for the fi rst time, or “cold

starting”, is easy.

• First, make sure the start/stop switch, located

on the throttle handle, is in the start position,

which is indicated by the “I” symbol.

• Close the choke by moving the choke lever to

the up position.

• Press the primer bulb approximately 6 times until he bulb is

fi lled with gas. Once it is fi lled, press it two more times.

• Pull the starter cord lightly until you feel resistance and then

give it a short, brisk pull. Your tiller should start immediately.

Do not pull the cord all the way out and do not let it snap back

into the starter housing.

•

Once it is running, open the choke. Ensure the lever is fully down

• To stop the engine, simply push the start/stop switch to the

stop position “O.”

• To start a warm engine, follow the same procedure. Except

now you can leave the choke lever in the down position and

there is no need to pump the primer bulb.

• Before using the tiller, let the engine run for a minute to warm

up. And before shutting it down, let the engine run briefl y to

cool down.

IMPORTANT NOTE:

Check the oil level in the engine before each use. If

oil is low see your 4 Stroke Tiller Engine Manual and

information above for details.

Never use starting fl uids as they will cause permanent

engine damage. Using them will void the warranty.

Before you use the tiller, read the Safety & Warning

rules on pages 4-6.

Switch on

4-CYCLE CORRECTIVE ACTION

If you suspect the engine is

overfi lled the following procedure

should remove the excess oil from

the crankcase and valve cover.

If the engine is overfi lled, oil will

enter the crankcase and it does

not simply pour out of the oil fi ll

opening. The excessive oil has

to be pumped out as the engine

runs. Checking the oil level and

draining any excess between

multiple 30 second running

intervals will bring the oil back to

the proper level.

1. Place the engine on a level

surface resting fl at on the front

loop handle and remove the

oil fi ll cap/dipstick. Use a catch

basin for any oil that overfl ows

from the oil fi ll opening.

2. Replace the oil fi ll cap/

dipstick and run the engine

for approximately 30 seconds

then repeat step one. Continue

steps 1 & 2 until oil no longer

overfl ows when the oil fi ll cap/

dipstick is removed.

3. Once the oil level is corrected

the engine may continue

to smoke while running for

several minutes while the

residual oil burns off.

4-CYCLE PROPER OIL FILL/

LEVEL CHECK POSITION

Engine must be resting on a fl at surface on

the fuel tank

14 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

This position does

not allow for a

proper oil level

reading and may

cause overfi lling.

Page 15

2-Cycle & 4-Cycle Tiller Operation

If engine does not stop when switch is put in the stop position, release the throttle, allow engine to idle.

Put the tiller down, and slide the choke lever to the cold start (closed) position. Have product serviced.

Figure 1

Read the instructions carefully. Be

familiar with the controls and the

proper use of the equipment.

NOW YOU’RE READY TO USE

YOUR MANTIS TILLER.

If you’ve seen other tillers, your MANTIS

Tiller may surprise you. It tills best when

you pull it backward! You see, when you

pull your MANTIS Tiller backward, you

give extra resistance to the tines, so they

dig deeper. (Figure 2)

In addition, when you go backward,

you erase your footprints. So your soil

stays light and fl uffy. With other tillers,

by contrast, you walk right over the soil

you’ve just tilled, packing it down, so it’s

less plantable.

RUN YOUR MANTIS TILLER

LIKE A VACUUM CLEANER

Place your Tiller at the head of the row

or area you want to till. Start it up. Then

use an easy rocking motion. First, pull

your Tiller backward. Then use an easy

A SPECIAL FEATURE

(With the idle set properly and the

engine running)

Even when the engine is running, the

tines won’t turn unless you squeeze

the throttle trigger on the handlebars.

And, when

you release the throttle trigger, the

tines will stop

.

A TIP FOR EXTENDING

YOUR ENGINE’S LIFE

After you start the engine, let your

tiller warm up for two to three

Figure 2 Figure 3 Figure 4

rocking motion. Again, pull your Tiller

backward. Then, let it move forward just

a little bit. Then pull it backward again.

This will help you till deeper.

Keep repeating these steps until you’ve

tilled an entire row. Start again on the

next row. It’s much like running a vacuum

cleaner! (Figure 3)

You Can Even Control Depth.

For Deeper Tilling:

Move your Tiller slowly back and forth, as

you would a vacuum cleaner. Work the

same area over and over until you’ve dug

to your desired depth. (Figure 4)

For Shallow Tilling:

Switch the tines to the cultivating

position. (See page 16 to learn how.)

minutes before you use it. Then,

before you put your tiller away, let it

idle for a minute to give the engine a

chance to cool down.

OPERATION

With engine running, and both

hands on the handles, hold down

the throttle lock out lever (Figure

1), then squeeze the throttle trigger

gradually to increase the engine

speed and engage the tines.

NOTE: This step must be repeated

each time your tiller trigger is

released.

Then move your Tiller quickly over your

soil surface.

For Big Weeds or Tough Roots:

Let your Tiller rock back and forth over

the tough spot, until the tines slice

through the weed or root.

Your MANTIS Tiller Handles Special

Tilling Projects:

Want to turn part of your lawn into a

colorful fl ower border? Your MANTIS

Tiller makes it easy! Just run your Tiller

back and forth until the sod begins to

break up. Then continue tilling. Your Tiller

will chop the clumps of sod until they’re

fi ne. Then, it will work them into the soil.

Pretty soon, you’ll have a soft, fresh

planting bed.

15Contact us at www.mantis.com

Page 16

2-Cycle & 4-Cycle Tiller Operation

If your tines get jammed or entangled, shut off the

engine at once. Remove the obstruction while the

engine is off. Never try to remove an obstruction while

the engine is running. Serious injury can result.

Figure 1

YOUR MANTIS TILLER MAKES

WEEDING A PLEASURE!

As a tiller, your MANTIS Tiller works the soil

down to 10” (25.4 cm) deep. But, as a cultivator,

it gently cultivates the surface, only 2” to 3” (5.09

cm to 7.62 cm) deep.

First, you must switch the tines to the weeding,

cultivating position. This takes less than a

minute.

Then, your MANTIS Tiller’s sharp “tine teeth” will

slice up those pesky weeds, burying them as you

go along. And, since the tines in this position

won’t dig too deep, they won’t hurt your plants’

precious root systems.

Tilling Cultivating

IMPORTANT:

To change the tines on your Mantis

Tiller, push the tiller forward and

allow it to rest on the loop handle.

The operator of this tiller is responsible for

accidents or hazards occurring to himself,

other people or their property.

The result? Your Tiller will cut your weeding time

in half, and turn a tiresome chore into a pleasure.

HOW TO SWITCH FROM TILLING TO

CULTIVATING POSITION

1. Make sure your Tiller is off.

2. Remove the retaining pins from the tines.

(Figure 1)

3. Remove the tines from the axle.

4. Place the right-side tine onto the left-side axle.

Place the left side tine onto the right-side axle.

The “D” hole should be to the outside.

5. Reinsert the pins.

To set them for tilling, attach the tines

so the points of the blades face forward

- away from the operator. The tines’

points will contact the ground fi rst.

For cultivating, reverse the tines

so that the points of the tines face

backward - toward the operator. Now

the long fl at part of the tine’s blade

will contact the ground fi rst.

16 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

Page 17

2-Cycle & 4-Cycle Tiller Transportation & Storage

Figure 1 Figure 2

2-CYCLE & 4-CYCLE TILLER STORAGE

5. Install the spark plug, but leave the

spark plug wire disconnected.

6. Wipe the tines with oil or spray them

Do not store in an area where

fuel fumes may accumulate

and reach a fl ame or spark.

Each fall, or before you store your Mantis

Tiller for any long period, be sure to take

these measures:

1. Do not store your Tiller with fuel still in

it. Even under ideal conditions, stored

fuel containing ethanol or MTBE can

start to go stale in 30 days. And, since

stale fuel has a high gum content, it

can clog the carburetor, this, in turn,

will restrict fuel fl ow . Therefore, when

you’re ready to store your Tiller, or will

not be using it for more than 2 weeks,

drain the fuel tank completely.

2. Next, restart the engine to make

sure no fuel is left in the carburetor.

Then, run the engine until it stops.

This will prevent gum deposits,

forming inside of the carburetor

and possible engine damage.

3. Disconnect spark plug wire and

remove the spark plug. Slowly

pull the starter cord once.

4. Inspect the spark plug, and if

necessary, clean it. If you need to

replace it, buy a NGK-CMR5H.

with WD-40, to prevent rusting.

7. Oil the throttle cable and all visible

moving parts. (Do not remove the

engine cover.)

8. Store your Tiller in an upright position

in a clean, dry place. You can store

with the handles in an extended

position or folded down.

To fold the handles down, simply

loosen the lower 2-pronged knobs

until you can pivot the upper handles

down. (Figure 3)

Or it can be hung using the handle

brace. (Figure 4)

9. To fold the handles, follow these

easy steps: Loosen the handle knobs

(#40) then fold the handles forward.

Tighten knob securely. Your handles

are now folded and ready to store in

a smaller area.

10. Do you have fuel left over from last

season? Dispose of it properly. Buy

fresh oil and gasoline next season.

11. Remove Tilling Tines or attachments

and lightly oil tine shaft at least once

a year.

2-CYCLE & 4-CYCLE

TILLER TRANSPORTATION

Transporting your Tiller is easy.

It’s light enough and easy to carry

using the carrying handle as seen

in Figure 1.

Or, with it running, you can walk

it by gently squeezing the throttle

until it moves at a comfortable pace

seen in Figure 2.

Your tiller is easily transported in

the back of a car or truck. Be sure

to empty the fuel tank (This is

crucial)! Then stow your tiller in the

trunk of your car or truck.

Figure 3 Figure 4

IMPORTANT:

It is important to store your Mantis

Tiller in an upright position. Laying the Tiller on its side will cause

the oil to leak out of the engine

through the air cleaner case.

IMPORTANT:

Avoid any orientation that places

the top cover (engine head) down

-this may allow oil from the crankcase to enter the combustion

chamber and cause hard starting

or a locked piston.

Never store the equipment

with Fuel in the tank or inside

a building where fumes can

accumulate and breach an

open fl ame or spark

17Contact us at www.mantis.com

Page 18

2-Cycle Tiller Maintenance

2-CYCLE TILLER BASIC MAINTENANCE ONLY

Your Deluxe 2 Cycle Tiller will require some basic maintenance

to keep it performing year after year.

Of course, your Mantis is designed to be used in the soil, but

dirt is the enemy of any engine. You should check the air fi lter

regularly

To replace the fi lter, remove the fi lter cover by fi rst unscrewing

the wing nut. Carefully remove the fi lter cover, then simply pull

out the fi lter and replace It with a clean fi lter.

If a new fi lter is not immediately available, you can clean the

old fi lter with a brush to remove debris.

If you are storing your tiller for the season or longer than 30

days it is very important to empty the fuel tank to prevent

engine damage from foul fuel.

The fuel fi lter should be replaced every year. Open the fuel cap

and using the cap retainer you can remove the fuel intake line.

The fi lter is at the end.

Air Filter

Hold the fuel line and work the fi lter out. Then just push the

new one back into the tube making sure the clamping wire is up

high enough to engage with the stem of the fi lter .

Fuel Filter

4-Cycle Tiller Maintenance

4-CYCLE TILLER BASIC MAINTENANCE ONLY

Your Deluxe 4 Cycle Tiller will require some basic

maintenance to keep it performing year after year.

If you are storing your tiller for the season or longer than

30 days it is very important to empty the fuel tank to

prevent engine damage.

Undoubtedly, you will be putting your tiller through

rigorous use.

Check engine oil level, air fi lter and fuel fi lter.

®

Refer to your Honda

engine manual for more details.

Air Filter

Dipstick

Fuel Filter

18 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

Page 19

HOW TO RESEAT THE FLANGE

2-Cycle & 4-Cycle Tiller Basic Maintenance

At some point, you may fi nd that the

tines won’t turn when you press the

throttle. This may mean the engine isn’t

sitting all the way down on the worm

gear housing.

Perhaps you’ve been using your Tiller

for several years. Or perhaps you’ve

removed the engine for use with our

hedge trimmer attachment, then replaced

it. In either case, the fl ange bolt may

have come loose and lifted the

engine up.

If this happened you’ll notice a gap

between the bottom of the engine clutch

case and the top of the worm gear

housing. (Figure 1)

To fi x this, loosen the fl ange bolt. Take

the engine off the worm gear housing.

Notice the hex head on top of the drive

shaft . Inside the clutch case, you’ll fi nd

the clutch drum. Make sure the hex head

lines up with the clutch drum inside the

clutch case.

Figure 1

Note how the engine doesn’t sit all

the way down on the transmission.

Then put the engine back on the

worm gear housing. Make sure the

plastic carrying handle is not under the

fuel tank.

If you’ve followed these steps properly,

there will be no gap between the clutch

Note how the engine sits all the

way down on the transmission.

Figure 2

case and the worm gear housing.

(Figure 2) Make sure you tighten the

fl ange bolt!

All other engine maintenance issues can

be found in the Honda

included in your tiller package.

®

Engine Manual

TRANSMISSION CARE

Check the transmission grease level after the fi rst

10 hours of use, then check yearly.

With the tines off, remove the transmission plate

(Figure 3) and gasket to see if the grease level is up

to the plate fl ange (Figure 4). If it is not, you will need

to add lithium zero grease.

Wipe off any excess grease, replace the transmission

gasket and plate.

Figure 4

Figure 3

19Contact us at www.mantis.com

Page 20

2-Cycle Tiller Assembly

1

53

49

48

8

17

9

3

17

13

48

51

49

4

19

13

6

42

53

47

53

42

15

55

12

41

18

49

48

44

20

49

50

54

39

52

35

33

23

35

29

26

25

24

31

22

43

21

2

46

48

10

19

14

7

16

11

53

38

37

36

34

38

36

20 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

45

30

28

27

37

41

32

40

Page 21

Key Qty. Part No. Description

29 1 424 Worm Thrust Bearing

30 1 422 Worm Shaft

31 1 426 Worm Disk

32 1 428 Retaining Ring

33 1 429 Worm Gear

34 1 431 Tine Shaft

35 2 430 Worm Gear Thrust Washer

36 2 432 Worm Gear Bearing

37 2 434 Bearing Seal

38 2 435 Bearing Seal Retainer

39 1 438RA Tine Assembly, Right

1 430020 Brace with Labels, Includes Key #’s 8,9,51

40 1 438LA Tine Assembly, Left

41 2 418-1 Tine Retaining Pin

42 2 430039 Carriage Bolt 1/4-20 X 2.25"

43 1 430042 Ground Wire Jumper, 2 Cycle Engine

44 1 400630 Triangle Warning Label (2 Cycle Engine)

45 1 458 Roller Bearing (closed end)

46 1 430058 Mantis Logo Label

47 2 395 Acorn Nut

48 6 972 1/4-20 Two-way Lock Nut

49 4 144-2 1/4-20 X 1.125 Hex Head Cap Screw

50 2 140 Bolt 1/4-20x3/8" Long

51 1 430057 Warning Label

52 1 400010 Transmission Assembly*

53 4 400523 Knob, Two Prongs, Female

54 1 410158 Kickstand, Stand Assembly

55 1 430037 Kickstand, Bracket And Hardware

Key Qty. Part No. Description

1 1 430003 Trigger Handle Assembly, 2 Cycle Engine, Right

2 1 430006 Handle Assembly, Left

3 1 430053 Middle Handle W/plug, Right

4 1 430052 Middle Handle W/plug, Left

6 1 430051 Lower Handle W/plug, Right

7 1 430050 Lower Handle W/plug, Left

8 1 430021 Handle Brace

9 1 430056 Label, Handle Brace

10 1 430023 Loop Handle Right Half

11 1 430022 Loop Handle Left Half

12 2 4079 M6 Internal Lock Washer

13 2 478 Throttle Clip

14 1 430025 Foam Grip

15 1 430049 Carry Handle With Grip

16 2 4049 Bolt 1/4-20 X 3.25"

17 2 430038 Knob, 1/4-20 X1.5 Male

18 2 4078 M6 Jam Nut

19 2 430048 Curved Head Bolt, 1/4-20 X2"

20 1 465 Fender Guard

21 1 400904 Engine Assembly Sv-5ci/2

22 1 468 Drive Shaft

23 1 466 Worm Gear Housing

24 1 436 Gasket

25 1 437A Gear Housing Cover

26 4 651 #8 Self Tapping Screw

27 1 423 Roller Bearing

28 2 425 Worm Bearing Race

* Includes Key #22

21Contact us at www.mantis.com

Page 22

4-Cycle Tiller Assembly

17

51

48

49

13

4

42

42

19

13

18

6

53

47

53

54

49

48

15

50

1

53

49

48

8

9

17

3

49

20

44

55

60

41

23

59

33

35

39

35

29

52*

26

25

24

31

27

28

37

41

14

10

57

56

43

21

48

16

11

58

2

22

12

46

19

7

53

38

37

36

34

36

38

22 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

30

45

32

40

Page 23

Key Qty. Part No. Description

31 1 426 Worm Disk

32 1 428 Retaining Ring

33 1 429 Worm Gear

34 1 431 Tine Shaft

35 2 430 Worm Gear Thrust Washer

36 2 432 Worm Gear Bearing

37 2 434 Bearing

38 2 435 Bearing Seal Retainer

39 1 438RA Tine Assembly , Right

40 1 438LA Tine Assembly, Left

41 2 418-1 Tine Retaining Pin

42 2 430039 Carriage Bolt 1/4-20 X 2.25”

1 430020 Brace with Labels, Includes Key #’s 8,9,51

43 1 400130 Engine Flange

44 1 400631 Triangle Warning Label (4 Cycle Engine)

45 1 458 Roller Bearing

46 1 430058 Mantis Logo Label

47 2 395 Acorn Nut

48 6 972 1/4-20 Two-Way Lock Nut

49 4 144-2 1/4-20 X 1.125 Hex Head Cap Screw

50 2 140 Bolt 1/4-20x3/8” Long

51 1 430057 Warning Label

52 1 400010 Transmission Assembly*

53 4 400523 Knob, Two Prongs, Female

54 1 430043 Ground Wire Jumper, 4 Cycle Engine

55 2 4079 M6 Internal Lock Washer

56 1 400132 Bearing

57 1 400131 Clutch Drum

58 4 400511 M6x12 Flange Bolt

59 1 410158 Kickstand, Stand Assembly

60 1 430037 Kickstand, Bracket And Hardware

Key Qty. Part No. Description

1 1 430004 Trigger Handle Assembly, 4 Cycle Engine, Right

2 1 430006 Handle Assembly, Left

3 3 430053 Middle Handle W/Plug, Right

4 1 430052 Middle Handle W/Plug, Left

6 1 430051 Lower Handle W/Plug, Right

7 1 430050 Lower Handle W/Plug, Left

8 1 430021 Handle Brace

9 1 430056 Label, Handle Brace

10 1 430023 Loop Handle Right Half

11 1 430022 Loop Handle Left Half

12 1 910502 10-32 X 3/4” Flange Bolt

13 2 478 Throttle Clip

14 1 430025 Foam Grip

15 1 430049 Carry Handle W/Grip

16 2 4049 Bolt 1/4-20 X 3.25”

17 2 430038 Knob, 1/4-20 X1.5 Male

18 2 4078 M6 Jam Nut

19 2 430048 Curved Head Bolt, 1/4-20 X2”

20 1 465 Fender Guard

21 1 400911 Engine Assembly-25cc Honda

22 1 468 Drive Shaft

23 1 466 Worm Gear Housing

24 1 436 Gasket

25 1 437A Gear Housing Cover

26 4 651 #8 Self Tapping Screw

27 1 423 Roller Bearing

28 2 425 Worm Bearing Race

29 1 424 Worm Thrust Bearing

* Includes Key #22

30 1 422 Worm Shaft

23Contact us at www.mantis.com

Page 24

Troubleshooting

Problem Cause Remedy

1. Tines don’t turn when throttle

is depressed.

2. Engine fails to start.

3. Engine hard to start.

4. Engine continuously fl oods.

5. There is black smoke coming

from exhaust.

6. Engine misses.

7. Engine lacks power.

8. Engine overheats.

9. Engine noisy or knocking.

10. Engine stalls under load.

• Engine is not seated properly on the gear housing.

• O/I switch is in “O” position.

• No fuel in tank.

• Fuel strainer clogged.

• Fuel line clogged.

• Spark plug shorted or fouled.

• Spark plug is broken (cracked porcelain or

electrodes broken).

• Ignition lead wire shorted, broken or

disconnected from spark plug.

• Ignition inoperative.

• Water in gasoline or stale fuel mixture.

• Too Much oil in fuel mixture. (2-Cycle only)

• Engine under or over choked.

• Carburetor out of adjustment. (2-Cycle only)

• Gasket leaks (carburetor or cylinder base gasket).

• Weak spark at spark plug.

• Fuel tank vent line is not in an upright position.

(2-Cycle only)

• The muffl er screen may be clogged.

• The exhaust port may be restricted.

• Dirt in fuel line or carburetor.

• Carburetor improperly adjusted.

• Spark plug fouled, broken or incorrect gap setting.

• Weak or intermittent spark at spark plug.

•Air fi lter clogged.

•Carburetor out of adjustment.

•Muffl er clogged.

•Clogged exhaust ports.

•Spark Arrestor Clogged.

•Poor compression.

• Insuffi cient oil in fuel mixture. (2-Cycle only)

• Air fl ow obstructed.

•Spark plug in incorrect heat range.

•Bearings, piston ring or cylinder walls are worn.

• Engine overheats.

• Carburetor adjustment too “lean.”

• Re-install engine following the instructions on

page 18 (How to reseat the fl ange).

• Move switch to “I.”

• Fill Tank.

• Replace Strainer.

• Clean fuel line.

• Install new spark plug.

• Replace spark plug.

• Replace lead wire or attach to spark plug.

• Contact your local authorized dealer.

• Drain entire system and refi ll with fresh fuel.

• Drain and refi ll with correct mixture.

• If fl ooded by over choking, proceed according to

instructions in operation section. If under choked,

move choke lever to closed position and crank two

or three times.

• Replace gaskets.

• Contact your local authorized dealer.

• Return the fuel tank vent line to the upright

position and place it under the cylinder cover in

the small “pocket” in the cylinder cover.

• Clean carbon from muffl er screen.

• Clean exhaust port.

• Remove and clean.

• Clean or replace spark plug - set gap to .024-.028

in. (0.6-0.7 mm).

• Contact your local authorized dealer.

• Clean or replace air fi lter.

• Clean carbon from muffl er.

• Clean Spark Arrestor.

• Contact your local authorized dealer.

• Mix fuel as described in starting instructions.

(2-Cycle only)

• Clean fl ywheel cylinder fi ns and screen.

• Replace with plugs specifi ed for engine.

• Contact your local authorized dealer.

• Remove dust and dirt from between fi ns.

• Contact your local authorized dealer.

24 Deluxe 2-Cycle & 4-Cycle Tiller Operator’s Manual

Page 25

ECHO INCORPORATED EMISSION CONTROL WARRANTY STATEMENT

FOR ECHO AND SHINDAIWA BRANDS

The Environmental Protection Agency (EPA) and the California Air Resources Board (C.A.R.B.) and ECHO Incorporated (ECHO Inc.)

are pleased to explain the emission control system warranty on your 2010 and later equipment/small off-road engine (SORE). New

equipment/SORE must be designed, built and equipped to meet stringent EPA and C.A.R.B. anti-smog standards. ECHO Inc. must

warrant the emission control system on your equipment/SORE for the periods of time listed below, provided there has been no abuse,

neglect or improper maintenance of your equipment/SORE. Your emission control system may include parts such as: carburetor, fuelinjection system, ignition system, catalytic converter/muffl er, fuel tank, fuel feed lines, fuel cap assembly, spark plug, air fi lters, and

other associated components. Where a warrantable condition exists, ECHO Inc will repair your equipment/SORE at no cost to you

including diagnosis, parts and labor. The Emission Control System warranty is extended to the original owner including all subsequent

owners.

MANUFACTURER’S WARRANTY COVERAGE:

The emission control system is warranted for 2 years or the length of the ECHO Inc. warranty, whichever is longer. If any emissionrelated part on your equipment is defective, the part will be repaired or replaced by ECHO Inc. or its Authorized Service Representative.

OWNER’S WARRANTY RESPONSIBILITIES:

As the equipment/SORE owner, you are responsible for the performance of the required maintenance listed in your Operator’s Manual.

ECHO Inc. recommends that you retain all receipts covering maintenance on your equipment/SORE however, ECHO Inc. cannot deny

warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance. As the equipment/

SORE owner, you should be aware that ECHO Inc. may deny you warranty coverage if your equipment/SORE or a part has failed due to

abuse, neglect, improper maintenance or unapproved modifi cations.

You are responsible for presenting your equipment/SORE to an ECHO Inc. authorized service representative as soon as a problem

exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If a warrantable condition

exists and there is no Authorized Dealer within 100 miles, ECHO Inc. will pay to ship the unit to the nearest authorized dealer. If you

have questions regarding your warranty coverage, you should contact ECHO Inc. at 1-800-673-1558, web site WWW.ECHO-USA.COM

or contact Shindaiwa at 1-877-986-7783, web site WWW.SHINDAIWA.COM.

WHAT DOES THIS WARRANTY COVER?

ECHO Inc. warrants that your equipment/SORE was designed, built and equipped to conform with applicable EPA and C.A.R.B.

emissions standards and that your equipment/SORE is free from defects in material and workmanship that would cause it to fail to

conform with applicable requirements for 2 years or the length of the ECHO Inc. warranty, whichever is longer. The warranty period

begins on the date the product is purchased by an end user..

HOW WILL A COVERED PART BE CORRECTED?

If there is a defect in a part covered by this warranty, any ECHO Inc. Authorized Service Dealer will correct the defect. You will not have

to pay anything to have the part adjusted, repaired or replaced. This includes any labor and diagnosis for warranted repairs performed

by the dealer. In addition, engine parts not expressly covered under this warranty but whose failure is a result of a failure of a covered

part will be warranted.

WHAT PARTS ARE COVERED?

• Any applicable emission related part not scheduled for “required maintenance” will be repaired or replaced within the warranty period.

The repaired or replaced part will be warranted for the remaining ECHO Inc. warranty period.

• Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the warranty

period stated above. Any such part repaired or replaced under warranty will be warranted for the remaining ECHO Inc. warranty

period.

• Any emission related part scheduled for replacement during “required maintenance” is warranted for the period of time prior to

the fi rst scheduled replacement point for that part. Any such part repaired or replaced under warranty shall be warranted for the

remainder of the period prior to the fi rst scheduled replacement point for that part.

• Any manufacturer-approved replacement part may be used in the performance of any warranty maintenance or repairs on emission

related parts, and must be provided without charge if the part is still under warranty.

• Any replacement part that is equivalent in performance and durability may be used in non-warranty maintenance or repairs, and shall

not reduce the warranty obligations of the manufacturer.

• Throughout the equipment/SORE warranty period, ECHO Inc. will maintain a supply of warranted parts suffi cient to meet the

expected demand for such parts.

SPECIFIC EMISSION RELATED WARRANTED PARTS:

• Electronic Ignition System • Spark Plug

• Catalytic Converter / Muffl er Assembly • Carburetor (complete assembly or replaceable components)

• Choke • Fuel-Injection Assembly (or replaceable components)

• Fuel Tank • Fuel Cap Assembly

• Air Filter • Fuel Feed Line (and associated clamps/connectors as applicable)

WHAT IS NOT COVERED?

Any failure caused by abuse, neglect, improper maintenance, unapproved modifi cations, use of unapproved add-on parts/modifi ed

parts or unapproved accessories.

This Emission Control Warranty is valid only for the U.S.A., it’s Territories, and Canada. 99922201033 01/2010

Page 26

EPA PHASE 2 / CALIFORNIA TIER III EMISSION CONTROL

WARRANTY STATEMENT YOUR RIGHTS AND OBLIGATIONS

The Environmental Protection Agency (EPA) and the California Air Resources Board (C.A.R.B.) and The Equipment Manufacturer are pleased to explain

the emission control system warranty on your EPA Phase 2 / C.A.R.B. Tier III model year 2005 and later small off road engine (SOREs). New small off

road engines must be designed, built and equipped to meet stringent EPA and C.A.R.B. anti-smog standards. Echo, Incorporated must warrant the

emission control system on your small off road engine for the periods of time listed below provided there has been no abuse, neglect or improper

maintenance of your small off road engine.

Your emission control system may include parts such as the carburetor or fuel injected system, and the ignition system and catalytic converter. Also

included may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, the Manufacturer will repair your small off road engine at no cost to you including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

The 1995 and later small off road engines are warranted for two years. If any emission-related part on your engine is defective, the part will be

repaired or replaced by the Manufacturer.

OWNER’S WARRANTY RESPONSIBILITIES:

- As the small off road engine owner, you are responsible for the performance of the required maintenance listed in your Operator’s Manual.

The Manufacturer recommends that you retain all receipts covering maintenance on your small off road engine, but the Manufacturer

cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

- As the small off road engine owner, you should however be aware that the Manufacturer may deny you warranty coverage if your small off

road engine or a part has failed due to abuse, neglect, improper maintenance or unapproved modifi cations.

You are responsible for presenting your small off road engine to the Manufacturer’s authorized service center as soon as a problem exists. The

warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact your Product Manufacturer.

EPA PHASE 2 / CALIFORNIA TIER III EMISSIONS DEFECT WARRANTY EXPLANATION

This is additional detailed information about the EPA PHASE 2/ CALIFORNIA TIER III EMISSIONS DEFECT WARRANTY for your small off road engine.

WHAT DOES THIS WARRANTY COVER?

The Manufacturer warrants that your unit was designed, built and equipped to conform with applicable California emissions standards and that your

unit is free from defects in material and workmanship that would cause it to fail to conform with applicable requirements within fi ve (5) years. The

warranty period begins on the date the product is delivered to a retail purchaser. This is your emission control system, DEFECTS WARRANTY.

HOW WILL A COVERED PART BE CORRECTED?

If there is a defect in a part covered by this warranty, a Manufacturer’s Authorized Service Dealer will correct the defect.

You will not have to pay anything to have the part adjusted, repaired or replaced. This includes any labor and diagnosis for warranted repairs

performed by the dealer. In addition, engine parts not expressly covered under this warranty but whose failure is a result of a failure of a covered part

will be warranted.

Emissions System repairs covered under this warranty should be completed in a reasonable time, not to exceed 30 days.

IMPORTANT

If the diagnosis reveals no defect, the emission defect warranty does not apply.

WHAT PARTS ARE COVERED BY THE EPA PHASE 2/ CALIFORNIA TIER III 2005

& LATER SMALL OFF ROAD ENGINE EMISSIONS DEFECT WARRANTY?

• Any emission related part not scheduled for, “required maintenance” (See Engine Operators Manual, “SERVICE MAINTENANCE SCHEDULE”) will be

repaired or replaced within the warranty period. The repaired or replaced part will be warranted for the remaining Emissions Defect warranty period.

• Any emission related part scheduled for replacement during “required maintenance” (See Engine Operators Manual, “SERVICE MAINTENANCE

SCHEDULE”) is warranted for the period of time prior to the fi rst scheduled replacement point for that part. Any such part repaired or replaced

under warranty shall be warranted for the remainder of the period prior to the fi rst scheduled replacement point for that part.

• Any manufacturer-approved replacement part may be used in the performance of any warranty maintenance or repairs on emission-related parts,

and must be provided without charge if the part is still under warranty.

• Any replacement part that is equivalent in performance and durability may be used in non-warranty maintenance or repairs, and shall not reduce the

warranty obligations of the manufacturer.

• The owner is responsible for the performance of the required maintenance described in the operators manual.

SPECIFIC EMISSION RELATED WARRANTED PARTS:

- Choke - Carburetor (complete assembly or replaceable components) - Fuel Injection Assembly or replaceable components

- Air Filter - Electronic Ignition System - Spark Plug - Catalytic Converter / Muffl er Assembly

WHAT IS NOT COVERED BY THE EPA PHASE 2/CALIFORNIA TIER III 2005 & LATER SMALL OFF ROAD

ENGINE EMISSIONS DEFECT WARRANTY?

• Any failure caused by abuse, neglect, improper maintenance.

• Any failure caused by unapproved modifi cations, use of unapproved add-on parts/modifi ed parts or unapproved accessories.

Page 27

LIMITED WARRANTY

MANTIS extends this limited warranty against defects in material and workmanship for a period of fi ve (5) years under normal

usage for residential purposes and two (2) years under normal usage for commercial purposes, from the date of purchase by

the original purchaser.

MANTIS will repair or replace, at its option, any part or parts of the product found to be defective in material or workmanship

during the warranty period. Warranty repairs and replacements will be made without charge for parts or labor. All parts replaced

under warranty will be considered as part of the original product, and any warranty on the replaced parts will expire coincident

with the original product warranty. If you think your MANTIS TILLER is defective in material or workmanship, you must send it,

along with your proof of purchase (sales receipt) to:

Mantis

1028 Street Road

Southampton, PA 18966

You are responsible for pickup and delivery charges; the product must be returned to us postage paid.

MANTIS assumes no responsibility in the event that the product was not assembled or used in compliance with any assembly,

care, safety , or operating instructions contained in the Owner’s Manual or accompanying the product. This limited warranty does

not cover damages or defects due to normal wear and tear, lack of reasonable and proper maintenance, failure to follow operating

instructions or owner’s manual, misuse, lack of proper storage or accidents [or routine maintenance parts and service].This limited

warranty shall not be effective if your Mantis tiller has been subjected to negligence or has been repaired or altered by anyone

other than an authorized dealer or authorized service center.

Y ou must maintain your MANTIS TILLER by following the maintenance procedures described in the owner’s manual. Such routine

maintenance, whether performed by you or a dealer, is at your expense.

MANTIS MAKES NO EXPRESS OR IMPLIED WARRANTIES, REPRESENTATIONS OR PROMISES EXCEPT THOSE

CONTAINED HEREIN. THERE ARE NO OTHER WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. ALL WARRANTIES OTHER THAN THE EXPRESS WARRANTY SET FORTH ABOVE

ARE SPECIFICALLY DISCLAIMED. THE DURATION OF ANY IMPLIED WARRANTY, INCLUDING MERCHANTABILITY AND

FITNESS FOR A P ARTICULAR PURPOSE, IS LIMITED TO THE DURA TION OF THIS WRITTEN LIMITED WARRANTY. MANTIS

DISCLAIMS ALL LIABILITY FOR INDIRECT, INCIDENTAL AND/OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH

THE USE OF THE MANTIS PRODUCTS COVERED BY THIS W ARRANTY. SOME STATES DO NOT ALLOW LIMIT A TIONS ON

HOW LONG AN IMPLIED W ARRANTY LASTS AND/OR DO NOT ALLOW THE EXCLUSION OR LIMIT ATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THAT ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU. THIS

WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

ST ATES TO STATE.

MANTIS

1028 Street Road

Southampton, PA 18966

(215) 355-9700

Specifi cations, descriptions, and illustrative material in this literature are as accurate as known at the time of publication, but are

subject to change without notice.

©2012 Schiller Grounds Care, Inc. All Rights Reserved. P/N 401775 rev 4/12

Loading...

Loading...