Page 1

Page 2

WELCOME TO THE V¢O D

OF NTIS GA ENING!

Here's your new MANTIS Tiller...

the lightweight wonder that "Makes

Gardening Easier."

Unlike big tillers, your MANTIS Tiller

weighs only 20 pounds. So it lifts easil>>;

handles smoothly, tilIs and_ weeds precisely

And, unlike other small tillers, it features

serpentine tines that churn soil up to ten

inches deep. It creates a soft, smooth seed

bed, even in problern soil.

Once you know hovv to use your tiller

correctly, we guarantee you'll love it. So

first, please read this manual. It shows, step

by step, how to use your tiller safely Plus,

it shows how the MANTIS Border Edger

can make light work of your edging needs.

If you have questions about any topic in

this Manual, or if you wish to order

MANTIS Attachments, contact your local

authorized MANTIS dealer.

TABLE OF CONTENTS

Salety Rules & Warnings ............... 3-4

Safety Decals ........................... 3

Engine & Fuel Warnings .................. 4

Assembly and Mixing Fuel ............... 5-7

Starting .............................. 7-8

Additional Information ................... 8

What to Do Just in Case ................... 8

Getting to Your Garden ................... 9

Tilling & Cultivating ................... %10

Tine Positioning ........................ 10

Cultivating ............................ 10

iiiiiiiii

Maintenance ........................ 11-12

Storage ................................ 13

"Double Shooting & Specifications ....... I4-1.5

Service Maintenance Guide ................ 15

Using The Border/Edger Attachment ........ 16

MANTIS Tiller Assembly Layout ........... 17

Engine Parts Assemblies ............... 1.7-18

EPA Phase 2/California Tier III Emission

Control Warranty Statement .............. 19

Limited Warranty Information ............ 20

2

Page 3

SAFETY RULES & WARNINGS

You will notice throughout this Owners Manual Safety Rules and Important Notes. Make sure you

understand and obey these warnings for your own protection.

I. Special Safety Information

II. Safety & "Warnings

WARNING

The Engine Exhaust from this

product contains ch,._micals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

PRODUCT EMISSION DURABILITY

The 300 hour emission durability compliance period is the time span selected by the manufacturer ce_if_iing the

engine emissions output meets applicable emissions regulations, provided that approved maintenance procedures are

followed as listed in file Maintenance Section of this manual

III.

Safety Decal Information

P/N 400620

become hard 1o read. 'Ihe location and part tmmbers (PIN) of these decals are illustrated on Page 27.

An imporianl part of the safe b system incorporated in this tilier are the warrd:ng

and informa[ioi_ decals tbund on various parts of the tiller+ These decaIs must be replaced

in time due _oabrasion, etc. It is your responsibility to replace these decals when they

CUTRNG HAZARD; KEEP DO [',JOTCARRY THE READ OWNERS MANUAL DON'T FUEL REFUEL,

FEET AND HANDS NN'AY TILLER iN THS BEFORE USING TILLER, OR ORCH_CK FUEL WHILE

FROM ROTAT NG TINES, POSITION PERFORMING ANY REPAIR SMOKING, OR NEAR AN

OR MNNTENANCE KEEP OPEN ELAME OR

OWNERS MANUAL _NA OTHER _GNmON

SAFE PLACE SOURCE,

@

CAUTION: WHEN ASSEMBUNG

THE HANDLES, MAKE SURE

FUEL TANK EACESOPERATOR,

THiS ISTHE REAR OF THE

TILLER, REFERTO ASSEMBW

INSTRUCTION ON PAGE7_

iNCORRECT ASSEMBLY,

WEAR EAR AND EYE

PROTECT_ON_

50:1

.[_1)+_

MIX UNLEADED GAS

WITH 2 CYCLE 50:10_L

3

Page 4

IV. Warnings - Do's

Read and understand the owner's

manual. Pay particnlar attention to aIl

sections regarding safety'.

1. Always keep a firm grip o13both

handles while the tines are moving and/or

the engine is running. BE AWARE!! The

tines may coast after throttle trigger is

released. Make sure tines have come to a

complete stop and engine is oil betore

letong go of the tiller.

2. Always maintain a firm tboting and

good balance Do not overreach while

operating the tille> Betbre you start to use

the tiller check the work area for obstacles

that might cause you to lose your tboting_

balance or control of the machine.

3, Thormaghly inspect the area where

equipment is m be used and remove all

objects, which can be thrown by the

machine.

4. Mways keep area clear of children,

pets, and bystanders.

5. Always stay alert. Watch what yon

are doing and use CO/T_moHsense. Do not

operate unit when faOgued.

6° Always dress properly. Do not wear

loose clothing or jewelry, they might get

caught in moving parts. Use sturdy gloves.

Gloves reduce the transmission of vibration

to your hands. Prolonged exposure to

•dbration can cause numbness and other

ailments.

7. "_qafleworkhug, always wear

substantial tbotwear and lomg trousers. Do

not operate the equipmem when bareloot

or wearing open sandaIs

8, Always wear ear and eye protection.

Eye protection nmst meet ANSI Z 87.1. _o

avoid hearing damage, we recommend

hearing protec0on be worn whenever using

the equipment.

9. To reduce life hazard, keep the

engine, and petrob_gasstorage area t)'ee of

vegetative material and excessive grease.

1O, Start d-mengine carefull> according

to the manulacmrer's instructions and with

leer well away trom tool(s),

11, Keep all nuts, bolts and screws tght

to be sure the equipment is in sate working

condioon.

12. Use *_\me caution when reversing

or pulling the machil_e towards you,

13, W'brk only in daylight or good

artificial light.

14. Always be sum of your footing on

slopes

15. Exercise exuvme cannon when

changing direction on slopes.

16, Always keep a safe distmqce

between two or more people when

working together.

17, Always inspect your unit before

each use and ensure that N1 handles,

guards and fasteners are secunL operating,

and in place.

18, Always maintain and examine your

Tiller with care. Fotlow maintenance

instructions given in manua!.

19. Always store tiller in a shehered

area (a dry, place), not accessible m

children, The tiller as well as tSaelshould

not be stored in a house

V. Warnings - Don'ts

Don't use tiIler with one hand. Keep

both hands on handles with fingers and

thumbs encircling the handles, while tines

are moving, and engine is running.

Don't overreach. Keep a good _boting at

all times,

En#ne/Fuel Warnings - Do's

Always use flesh gasoline in the fuel

mixture. Stale gasoline can cause damage.

Always store fuel in containers

specifically designed tk_rthis purpose.

Always D_ll starter cord slowly until

resistance is felt, Then pull cord rapidly to

avoid kickback and prevent arm or hand

injm7¢

Engine/Fuel Warnings - Don'ts

Don't fi_el, refud or check fuel while

smoking, or near an open flame or other

ignition source Stop engine and be sure it is

cool bd0re refueling.

Don't leave the engine running while the

tiller is unattended. Stop engine betore

putting the tiller down or while transporting

from one place to anothe>

Don't refi,el, start or run this Oiler

indoors or in an improperly ventilated area.

Don't run engine when electrical system

Don't run with the machine, walk.

Don't work on excessively steep slopes.

Don't attempt to clear tines while they

are moving. Never try to remove jammed

material betbre switching the engine off

and making sure the Ones have stopped

completd>

Always operate engine with spark

arrestor installed and operating properly:

The use of spark arrestor mufflers is

required by law in the state of California

(Section 4442 o[ the Calitomia Public

Resources Code), as well as in other states

or municipalities_ Federal laws apply on

[kdeml lands.

causes spark outside the cylinder, During

periodical checks of the spark plug, keep

plug a safe distance from cylinder to avoid

burning of evaporated fuel t?om cylinder:

Don't check lor spark with spark plug or

ping wire removed, Use an approved tester.

Don't crm3kengine with spark plug

removed unless spark plug wire is

disconnected, Sparks can ignite fumes.

Don'trun enginewhen the {_.torofgasoline

kspre:-_ntor odmr explosivecondition,se>_t.

Don'l allow children or incapable

people to operate this tiller_

Dofft operate while under

the influence of alcohol or drugs.

Don't attempt m repair this tiller. Have

repairs made by a qualified dealer or

repairman. See that only original MANTIS

parts are used.

Stop the engine whenever you leave the

machine.

Allow the engine to cool before storing

in any enclosure,

If the fuel tank nee& to be &ained, this

should be done outdoors°

Don't operate the unit if gasoline is

spilled. Clean up spill completely before

starting engine.

Don't operate your _ilier if there is art

accmnulation of debris anmnd the muffler

and cooling fins.

Don't touch hot runners, cylinders

or cooling fins as contact may cause

serious bums_

Don't change the engine governor

setting or over speed the engine.

4

Page 5

ASSEMBLY

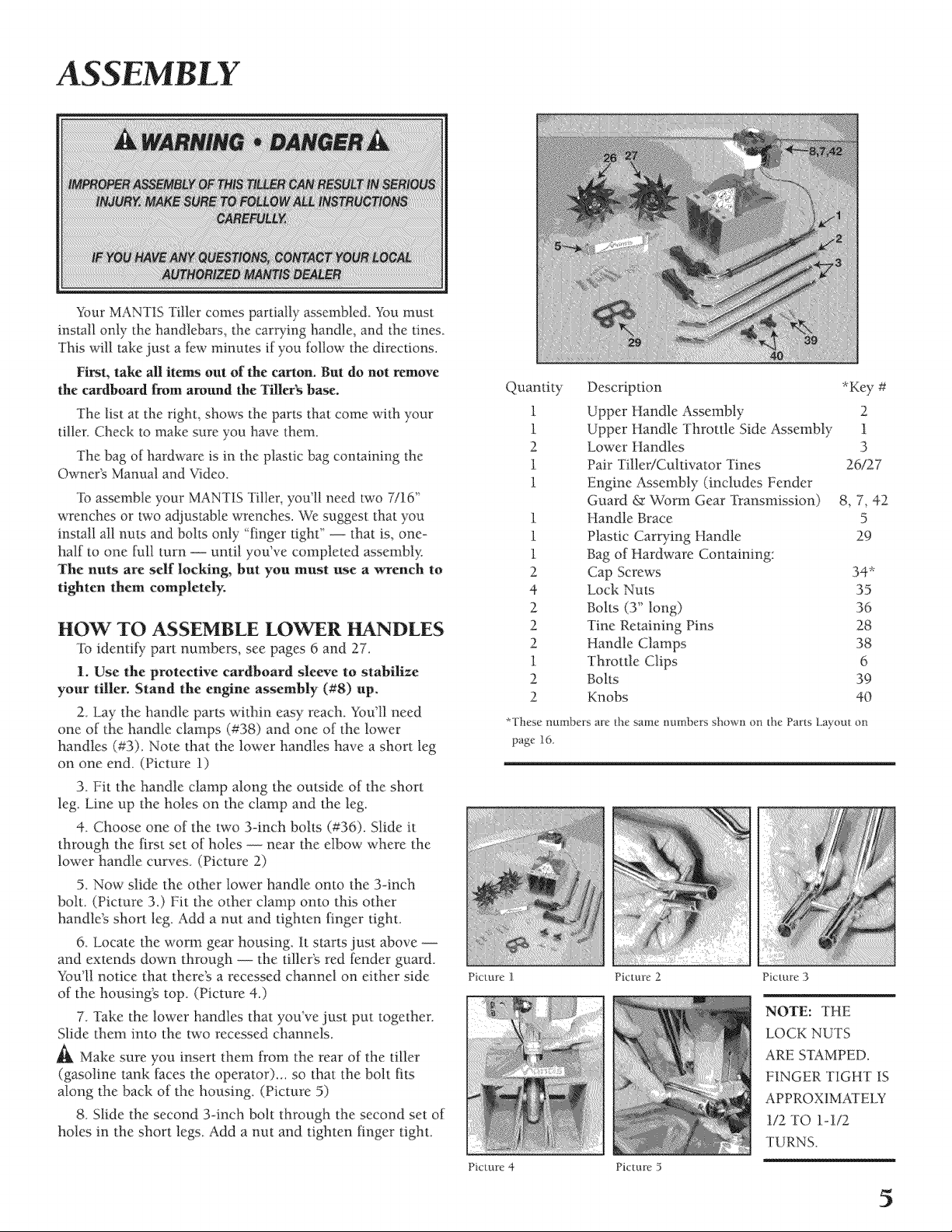

Your MANTIS filler comes partially assembled. You must

insmI1 only the handlebars, the carrying handle, and the tines.

This will take just a few minutes if you follow the directions.

First, take all Reins out of the ca_on. But do not remove

tile cardboard t¥om around the Tiller's base.

The list at the right, shows the parts that come with your

tiller. Check to make sure you have them.

The bag of hardware is in the plastic bag containing the

Ownerg Manual and Video.

To assernble your MANTIS Tiller, you'll need two 7/16"

wrenches or two adjustable wrenches, We suggest that you

install all nuts and bolts only 'finger tight" -- that is, one-

half to one lull turn -- until you've completed assembly.

The nuts are sdf locking, but you must use a wrench to

tighten them completely.

HOW TO ASSEMBLE LOWER HANDLES

To identify part numbers, see pages 6 and 27.

1. Use the protective cardboard sleeve to stabilize

your tiller. Stand the engine assembly (#8) up.

2. Lay the handle parts within easy reach. '_;ou'llneed

one of the handle clamps (#38) and one of the lower

handles (#3). Note that the lower handles have a short leg

on one end. (Picture I)

3. Fit the handle clamp along the outside of the short

leg. Line up the holes on the clamp and the leg.

4. Choose one of the two 3-inch bolts (#36). Slide it

through the first, set of holes -- near the elbow where the

lower handle curves. (Picture 2)

5. Now slide the other lower handle onto the 3-inch

bolt. (Picture 3.) Fit the other clamp onto this other

handle?s short leg. Add a nut and tighten finger tight.

6. Locate d'_eworm gear housing. It starts just above --

and extends down through -- the tiller); red fender guard.

You'll notice that there_ a recessed channel on either side

of the housing's top. (Picture 4.)

7. Take the lower handles that you've just put together.

Slide them into the two recessed channels,

Make sure you insert them from the rear of the tiller

(gasoline tank faces the operator)., so that the holt fits

along the back of the housing. (Picture 5)

& Slide the second 3-inch bolt through the second set of

holes in the short legs. Add a nut and tighten finger tight.

Quantity

1

1

2

i

1

1

1

1

2

4

2

2

2

1

2

2

*These numbers are the same nm,/bers shown on the Parts Layout on

page !6.

Picture 4 Picture 5

Description "_Key#

Upper Handle Assembly 2

Upper Handle Throttle Side Assembly I

Lower Handles 3

Pair Tiller/Cultivator Tines 26127

Engine Assembly (includes Fender

Guard & Worm Gear Transmission) 8, 7, 42

Handle Brace 5

Plastic Carrying Handle 29

Bag of Hardware Containing:

Cap Screws 34*

Lock Nuts 35

Bolts (3" long) 36

Tine Retaining Pins 28

Handle Clamps 38

Throttle Clips 6

Bobs 39

Knobs 40

Pictm_e 2 Pictt_re 3Picture I

NOTE: THE

LOCK NUTS

ARE STAMPED.

FINGER TIGHT IS

APPROXIMNfELY

112TO 1-1/2

TURNS

5

Page 6

ASSEMBLY (continued)

HOW TO ASSEMBLE

UPPER HANDLES &

PIASTIC CARR_ING

HANDLE.

i, Lightly squeeze the lower handles

(#3) toward one another so that they

line up with the two smaller holes on

the carrying handle (#29). Then slide

the carrying handle over and down the

lower handles. It will rest about four to

six inches above the engine (Picture 1)

2. Gently pull the lower handles out

to their original position

3. Attach the upper handle assembly

(#I) - the handle with the throttle

cable and ground wire - onto the right

handle, and secure with the handle

knob (#40) and 1 J_und head bolt

(#39) (Picture 2). Be sure you have

proper throttle movements and that

the throttle cable is not wrapped or

twisted around the handle bar.

Squeeze trigger and let go. The triangle

must click in both directions. If there

is any doubt, remove air :filter and

visually check that the throttle triangle

hits both the idle screw and the full

open swp, THIS MUST BE DONE

BEFORE S'IT*_RTINGTHE ENGINE.

4. Follow the same steps to install

the left upper handle onto the other

lower handle. (Picture 3)

5. Use the clip (#6) to secure the

throttle cable and wire in place on the

lower handle. (Picture 4)

6. Now install the Handle Brace.

Line it up with the holes on the upper

handles. Then insert a Cap Screw

(#34) and a Lock Nut (#35) on either

side (Picture 5)

7, Use a w_mch to tighten Cap

Screws and Lock Nuts.

8, Now use wrench to tighten all

nuts and bolts firmly and securely.

IM[PORTANT NOTE:

Make sure you have installed the

handles properly: When yon stand

behind your tiller, holding the

handles, you should face the

gasoline tank.

Picture 1 Picture 2

Picture 3 Picture 4

A

WARNING:

Improper thro_ie

installation can

cause tines to

rotate unexpectedly.

Pictm_e5

Assembling the Tines for

Tilling

1. Remove the cardboard from around

your "riller's base.

2. Slide the tines onto the axle shafts.

The "D" hole goes on the outside.

3 Make sure you've installed the trees

properly for tilling. Liken the tines to

your fingers. When your pahn. t_ces the

ground, your fingers curl down. Stand

behind the Tiller and hold your hand

next to the tines. Do the tine blades curl

down, as your fingers do? If so, thW are

in tire tilling position. ('Ib switch to the

cuhivaOng position, see pagy_10.)

4. _lb secure each tine to the axle,

insert a tine retaining pin.

IMPORTANT NOTE:

Belore you use your MANTIS Tiller,

read the Safe D, Rules & Warnings on

pages 3-4.

Your MANTIS Tiller comes with a

Dee pre_measured bottle of two<ycle

engine oil. Here's how to mix the oil

with the gas:

I.Pour 1/2 of the gasoline into a sate,

container. Do not mix the fuel and oil in

the engine fuel tank.

2. Add 2.6 ounces of two-cycle

engine oil to the gasoline and mix.

Then add the rest of the gasoline.

3. Screw the cap onto the gasoline

can. Then swirl the can to blend the

oil and gas.

4 Carehtlly pour the fuel mix into

the tiller_s fuel tank. After putting the

fuel tank_ cap back on, wipe up any

spilled fuel from tank and gasoline

cal2.

IMPORTANT:

Fwo stroke tiael separates and ages. Do

not mix more than you wit/use in a

month. Using old fuel can cause

difficult starting or engine damage°

Shake fuel container to thoroughly mix

fuel before each use. Do not attempt to

run your engine on gasoline only, use

proper t;ael mixture.

Need more pre-nreasured engine oil?

You can order it from your local

authorized MANTIS dealer.

Remember .,,

*Always :nix two-cycle oil with

gasoline betore fueling your tiller.

Neveg ever run your tiller on gasoline

alone. This will ruin your engine and

void all warranties.

•Always use a clean gas can and always

use unleaded gas.

• Never try to mix the oil and gasoline

in the engine fuel tank_

•Always mix oil and gas in the proper

proportions: 26 ounces of two<ycle

engine oil to one gallon of unleaded

gasoline.

IMPORTANT NOTE:

Do Not use old or stale oil/gasoline

mixture. Always use the proper

oil/gasoline m_ture. If you do not,

your en#ne will suffer rapid,

permanent damage. And you _1l

void the engine warramy.

6

Page 7

ASSEMBLY

STARTING

(continued)

M ng Fuel

Your MANTIS Tiller is powered by a

commercial two stroke, air cooled engine

which requires a luel mixture of gasoline

and lubricating oil.

Use a mixture of 50 par_s unleaded

regular gasoline and I part two-stroke

MANTIS oil (50:1.) Use branded 89 octanc

(R÷M+2) unleaded gasoline or gasobol

(maxmmm 10% ethyl alcohol, or 15% MTBE, no methyl alcohol.)

To Start Your Tiller for the

First Time:

1_ Fill the luel tank with the proper

oib"g/asoline mixture°

(See previous section.)

2. Hand tighten the gasoline cap just

until it_ snug_

3. Place the O/I switch into the

"start!on" position (Picture 1)

4. Pull the choke button all the way

out, to completely close the choke

(Picmre 2)

5. Locate the purge bulb on the

upper right of the engine, in front of

the fuel tank. (See Picture 3) It sends

fuel into the carburetoL for easy

starting. Press the purge bulb until

you see fuel flow through the clear fuei

return line. Since you're starting

"cold," you may need to press six to

eight times. As soon as fuel starts

flowing through the clear fuel line, stop

pressing! (Picture 3)

6. Don't press the throttle trigger

during the starting of the engi_e.

7. Pull the starter cord (Picture 4)

until resistance is t)tlt. Then give the

recoil starter coMa few brisk pulls until

the engine fires, Note: Pull the starter

cord about 12'' to 18". During cold start-

ing, you may need to pull at least three or

four times belbre the engine fires.

NOTE: When the choke is closed,

never pull the cord more than four or

Never use starting fluids as they will cause permanent engine

damage. Using them will void the warranty. Before you use the

tiller, read the Safety& Warning rules on pages 3_4.

five times. Ovewulling may cause

flooding. Also, bear in mind that, when

the engine fires, it only coughs or

sputter, and will not run on choke.

8. Push the choke button in, all the

wag to open the choke. (Picture 5)

9. Then pull the starmr cord again°

The engine should start and run. Let the

engine warm up two to three minutes

before using.

Follow these stqos whenever you are

starting the engine "cold", or when the

engine has run dry and you have .just

added fiM, Remember, always _se short,

b_isk pulls, DoM give the co_d a tong,

jbr_efuI yank, ArM, do not let the cord

snap bach into the start_ housing,

Picture i

Picture 3 Picture 4

Picture 2

Picmre 5

7

Page 8

STARTING (co.ti.ued)

Additional Information

How to Stop

the Engine

Simply push the oh

' stop/start" switch to

'O" (Picture 3). This

will stop the engine

instantly. If it should Picture 3

ever fail to do so, just

pull out the choke button. The engine

will stop at once.

About the Choke

The choke controls the amount of

air drawn into the engine. Your tiller

will run only if the choke is open --

that is, if the choke is pushed in.

¥HAT TO

DO JUST IN CASE

If you follow the normal

starting procedure, you should

have no problem starting your

tiller. But, just in case you do

have problems, here's what to do.

Make sure the oh switch is on I

%tart." You'd be surprised how

many people forget to push the

switch into the 'T' position.

If the switch was on 'o" when

you pulled the cord, you may have

flooded the engine.

•First, examine the spark plug. Use the

special wrench that comes with our

optional MANTIS Handy Item Kit

(item #8444) or a 3/4 inch spark plug

wrench. (Picture 1)

•Remove the cap over the spark plug.

•Unscrew the spark plug. (Picture 2)

IMPORTANT NOTE:

To avoid possible damage to the

threads, do not try" to remove the plug

from a hot alminum Wlinder head.

Starting a Flooded Engine

1. if the end of the spark plug is wet,

the engine may be flooded. Make sure

the switch is in the "0" position,

8

A Special Feature

(with the idle set properly

and the en_ne running)

Even when the engine is running,

the tines won't turn unless you press

the throttle lock out button and

squeeze the throttle lever on the

handlebars. And, when you release the

throttle lever, the tines will stop.

A Tip for Extending

Your Engine's Life

After you start the engine, let your

tiller warm up for two to three minutes

betore you use it. Then, before you put

Picture 1 Picture 2 Picture 3

disconnect spark plug wire and

remove plug. Use a paper towd or a

dean rag to dry, the spark plug, then,

with the spark plug out of the engine,

pull the starter cord several times.

Next, replace the spark plug.

Use the wrench to tighten it and replace

the cap. Next, put the switch in the "|"

position and pull the choke button out.

Pull the starter cord three or four times

until the engine coughs or sputters.

Open the choke (push the choke button

in) and pull the cord a few times, the

engine should start and run.

2, If the end of the spark plug is dry;

check to see if the fuel liine is blocke&

First loosen the fuel cap to relieve the

pressure in the tank. The fuel line runs

from the fuel tank to the carburetor,

Pull it off at the carburetor end. Fuel

should drip slowly from the line Wipe

off any excess or spilled fuel.

If fiaeI does not drip from t/he line,

flow of fuel to the engine. Just

If fuel drips too freely, the line may be

disconnected from the fuel filter. >au'll

find the t;aelfilter inside the fuel tank.

Just re-attach the line to the filter, and put

your tiller away; let it idle for a minute to

give the engine a chance to cool down.

the filter back in the rank. Then follow

the normal starting procedure.

Here's Another Way to

Start your MA_NTIS Tiller

if you follow the steps above and

your engine still won't start, try this:

I Push the switch to 'l".

2. Push in the choke button to open

the choke,

3. Press the plastic bubble a few times.

4_ Give the starter cord a few short,

quick pulls_ The engine should start

and run_

5. If the engine does not start, then

pull out the choke button to cIose the

choke. Pull the starter cord four to five

times. The engine should sputter or

cough.

6. Alter the engine sputters, push the

choke button in. Then pull the starter

cord The engine should start and run.

7_ If the engine still does not start,

repeat steps 2 through 6.

8. If the engine still does not start,

call your local authorized I_NTIS

dealer.

IMPORTANT NOTE:

Never u_ starting tluids° Starting fluids

will eau_ permanent en_e damage.

Using them will void the warranty.

IMPORTANT NOTE:

Before yon use your MANTIS Tiller,

read the Safety Rules & Warnings on

pages 3-4.

Page 9

GETTING YOUR TILLER TO YOUR GAP EN

Walk it.

Once your tiller is running, you can

"walk" i/to your garden. Just press the

throttle lock out button and squeeze

the throttle lever gently and let the

tiller "tipotoe" across your yard on its

tines. It won't hurt your lawn or

Car_ It.

Make sure the engine is off. Then

use one hand to grasp the convenient

carrying handle. Use the other hand to

hold the handlebars. (Picture 1) Then

lift your tiller and car D , it to your

garden. Since it weighs only 20

pounds, it won't strain your muscles or

tire you out!

TILLING

Now You're Rea@ to Use Your

MANTIS Tiller.

if you've seen other tillers, your MANTIS

Tiller may surprise you. It tills best when

you pull it backward! You see, when you

pull your MANTIS Tiller backward, you

give extra resistance to the tines, so they dig

deeper. (Picture 1)

Whatg more when you go backward, you

erase your footprints. So your soil stays

Picture 1

Picture 2

light and f/uf[}_.With other tillers, by

contrast, you walk right over the soil you've

just tilled, packing it down, so it's less

plantable,

Run Your MANTIS Tiller like

a Vacuum Cleaner.

Place your Tiller at the head of the row

or area you want to till. Start it up. Then

use an easy rocMng motion. First, pull your

Tiller backward Then use an easy rocking

motion. Again, pull your J?ller backward.

Then, let it move forward just a little bit.

Then pull it backward again. This witl help

you till deeper_

Keep repeating these steps until you've

tilled an entire row. Start again on the next

row. It_ much like running a vacuum

cleaner! (Picture 2)

Take It for a _de.

You can easily transport your

MANTIS Tiller to a [fiend's or relative's

house Just empty the f_ael tank_ (This

is crucial.) Then stow your Tiller in

the trunk of your car or truck. It fits

easily. And you can put it in and take it

out without straining your back.

You Can Even Control Depth.

For Deeper Tilling:

Move your Tiller slowly back and k)rth,

as you would a vacuum cleaner. Work the

same area over and over until you've dug to

your desired depth. (Picture 3)

For Shallow Tilling:

Switch the tines to the cultivating

position. (See page 10 to learn how.) Then

move your Tiller quickly over your soil

surface.

For Big Weeds or Tough Roots:

Let your Tiller rock back and torth over

the tough spot, until the tines slice

through the weed or root.

Your NL&NTIS Tiller Handles

Special T_ng Projects.

Want to mrn part of your lawn into a

colorful flower border? "four MANTIS Tiller

makes it easy! Just run your Tiller back and

forth until the sod begins to break up Then

continue tilling. Your Tiller will chop the

clumps of sod until they're line. Then, it

,#ill work them into fbe soil. Pretty soon,

you'll have a soft, fresh planting bed.

Picture I

Picture 2

Picture 3

9

Page 10

How about a family-size

vegetable garden?

Nowadays many gardeners prefer

small gardens -- especially in the

suburbs, where space is at a

premium. But, if you're t0rtunate

enough to own a large lot, you can

create a bigger garden -- a half acre

or more. Here's how:

1. First,. hire someone with a

tractor or big tiller to break ground

for you. This is a one-time-only

investment that's well worth the

small cost.

2. Then, use your _filler to break

up any remaining clumps of soil or

sod. Unlike a tractor or big tiller,

your MANTIS Tiller is a precision

tool. It will pulverize your soil into a

smooth seed bed.

"Your MANTIS Tiller Makes

Weeding a Pleasure!

As a tiller, your MANTIS Tiller

works the soil down to 10" (25.4 ca)

deep. But, as a cultivator, it gently

cultivates the sur[ace, only 2" to 3"

(509 cm to 7.62 cm) deep.

First, you must change the tines to

the weeding position. This takes less

than a minute.

Then, your MANTIS Tillerg sharp

"tine teeth" will slice up those pesky,

weeds, burying them as you go along.

And, since the tines in this position

won't dig too deep, they won't hurt

your plants' precious root systems.

CULTIVATING

Tilling Position

Tine teeth point in the

same direction as the

rotation of the tin< or

toward the [ront of the

Tiller, away from the

operator,

Cultivating

Position

Tine teeth point in the

opposite direction as the

rotation of the tine. Tines

point toward the back of

the tiller, or toward the

operator.

The result? Your Tiller will cut your

weeding time in half, and turn a

tiresome chore into a pleasure

How to Switch From Tilling to

Cultivating Position

1. Make sure your Tiller is off.

2. Ren-tove the retaining pins from

the tines.

3 Remove the tines [rom the axle

4. Place the right-side tine onto the

left-side axle. Place the left side tine

onto the right-side axle. The "D" hole

should be to the outside.

5. Here is how to make sure you've

installed the tines properb: Sand behind

Now You're Ready to

Cultivate or Weed.

Guide your Tiller where you

want to weed and start it up.

Pull your Tiller backward

slowly_then let i_ move [orward

a biL in a gentle rocking

motion. "Watch it slice, shred,

and bury those weeds!

Got tough weeds? Lighten

yore" pressure on the throttle to

slow your Tiller down. Then

work back and forth until your

Tiller chops up the weeds, it's

easy and eltective!

Remember, any tiller will

tangle in tall grass_ stringy

vines, or supe>bg weeds, So, ff

you have a "backyard jungle,"

first use a knife, pruner, or

brush cutter to chop up the

ove>growth, If the tines become

tangled anywa> push the

switch to the "o" position to

turn the engine off complele|y

be[ore trying to clear them.

Picture 1 Picture 2

the Tiller and hold your hand, pahn up,

next to the tines. Do the tine points

curl up, as your fingers do? if so, they

are in the correct cultivating position.

6. Reinsert the pins.

The optional Tine Detangler

(Item #1322) will clear tines in

a jifl_. Call your local authorized

MANTIS dealer,

Your M&NTIS Tiller

"Will Weed Between

Narrow Rows!

Your MANTIS Tiller is a

precision weeder that easily fitsm

tiOxtplaces. So don't be afraid to

weed awwhere: between plan_

and shrubs; in corners; against

[ences; on raised beds; in wide

rows; even in very narrow rows.

_AmrMANTIS Tiller weeds six*

to nme inches wide. So you can

run it in a tightly planted garden

without damaging your delicate

plants. That's good news for

suburban gardeners, who often

have to plant rows dose together!

*V,/ith optional Planter

Furrower attachment

(Item #6222.)

10

Page 11

MAINTENANCE

Check the Air Filter Often

A wet or dirty air fiher can affect the

way your engine starts, performs, and

wears, So, it's a good idea to check }*our

air filter once a month.

If you work in dust}, soil, or if you

want to be on the saff_ side -- then

check your filter more often (for

instance, betore each use). But be sure

to replace it at least once a year, in the

spring or/all. Clean or change it as

needed. It is recommended to change

the air filter yearly

How to Check, Clean and

Change the Air Filter

1. Loosen the wing nut on _he side

Picture [ Picture 2 Picture 3

of the ai>cleaner cover, (See Picture 1,

or took up Key #1 in Air Cleaner Parts

Assembly on page 17,)

2. Take off the cover. Make sure to

clear the choke button. (Picture 2)

3, The air filter is the pad on the

inside of the ai>cleaner cover. Check

whether it is soiled or moist

4. If the air filter needs cleaning or

no longer fits properly; remove it. Just

lift an edge careRdly and 'peel" it out

(Picture 3)

5. Use a brush to remove debris

fl'om the pa&

6. If the air filter is so dirty"that it

won't come clean, you m.ust replace it

or severe eng:ine damage will occur.

Order a new one directly fi'om our

Customer Service Dept. CalI 1-800-

366_6268o

7 Insert your clean filter inside the

ai>cleaner cover.

IMPORTANT! blake sure filter

is "seated" properly in the

cover. The filter must fit

snugly inside the rim that

holi[s the filter in place.

installing the filter incorrectly will

cause engine damage and void the

warrant): Fit the cover back over the air

cleaner. (Again, make sure to clear the

choke buttom)

8. Tighten the wing nut to secure the

cover.

Note:

Please check the lip on the Air Cleaner

Cover. If the lip is chipped or cracked,

it should be replaced. This Mll prevent

dirt from being ingested through the

carburetor into the inside of the engine.

How to Check the Grease

Level Inside the

Worm Gear Housing

When we buih your MANI1S Tiller

we lubricated the worm gear housing

thoroughly

It is imperative that you inspect the

grease level once a year: Simply remove

the cover plate on the worm gear

housing. (Picture I) Then check to

make sure the grease comes almost to

Picture: 1

the top of the housing_ If it doesn't, add

lithium #0 grease (Item 9985.) This is

the only- way to add grease to the worm

gear housin& (Picture 2) 'lb purchase

MANTIS grease, call your local

authorized MANTIS dealer.

Please do not overfill. Too much

grease can create pressure, which could

cause seals to fail or the clutch to slip.

Fuel Filter Replacement:

Fuel filter to be changed at the end of

every season,

Picture 2

Clear Blockages From

the Fuel Line & Filter:

After you've used your Tiller [br a few

seasons_ check [or blockages in the fuel

tank and fuel filter. Such blockages can

keep your ?filler from stardngo

Clear any blockages you see in the

tank, fuel filter, or fuel line. Remember:

The fuel filter is located inside the tank.

(See Picture 3) Then use the normal

starting procedure to start your Tiller.

Picture 3

11

Page 12

MAINTENANCE

What to Do ff Your

Engine Idles Too High

What it your engine runs too last

.. or if the tines turn the instant you

start the Tiller? "x_9umay need to

adjust the idle screw (Key #19 under

Carburetor on page 17) by itself right

below the H and L screws. Gently turn

it counter-clockwise. _bu'll know

you've adjusted it correctly when the

axles do not turn at low idle.

V_rhat to Do ff Your

Engine Runs "Rough"

If your engine runs "rough" or

stalls, you may need to adjust the

carburetor and idle screws.

(continued)

Picture I

If you remove the air-cleaner coveL

you'll see the two carburetor,

adjustment screws next to the choke

button. (Picture 1)

The "RED" screw is the HIGH-

speed adjustment..The "WHITE"

screw is the low speed adjustment.

First, remove the tines from the

axle_ Then start engine. Let it run for

two to three minutes. "F:LASH" the

choke several times during the warm-

up to clear any air from the Fuel

system.

Then stop the engine after it

reaches operating ternperamre.

Now, turn the RED, high-speed

screw counter-clockwise all the way to

stop. °Then turn the WHITE, low

speed screw hali\vay between the

counter-clockwise and clockwise stop

positions.

Now restart the engine to finish the

carburetor adjustment.

Run the engine at full speed two or

three seconds to clear out any excess

fiael. Then return to idle.

Now, accelerate the engine to flail

throttle several times to check for a

smooth transition from idle to high

speed.

If the engine hesitates turn the

WI!ITE, low-speed screw counte>

clockwise one<ighth of a turn. Then

accelerate the engine.

Repeat the adjustrnent until you get

a smooth transition to high speed.

Picture I ,., Note how the engine

doesn't sit all the way down on the

transmissions.

Ho'w tO Reseai

the Flange

At some point, you may find

that the tines won't turn when

you press the throttle. This may

mean the engine isn't sitting all

the way dov,m on the worm gear

housing.

Perhaps you've been using

your Tiller for several years. Or

perhaps you've removed the

engine for use with our hedge

trimmer attachment, then

replaced it. In either case, the

flange bolt (Key #38, page 18)

may have come loose and lifted

the engine up.

If this happened you'll

notice a gap between the

bottom of the engine clutch

case (Key #37, page 18) and

Picture 2 ,.. Note how the engine sits all

the way down on the transmission.

the top of the worm gear

housing. (Picture 1)

To fix t_his,loosen the flange

bolt. Take the engine off the

worm gear housing. Notice tl:le

hex head on top of the drive

shaft (Key #9, Page 16). Inside

the clutch case, you'H find the

clutch drum (Key #31, Page

29). Make sure the hex head

lines up with the clutch drurn

inside the clutch case.

Then put the engine back on

the worm gear housing. Make

sure the plastic carrying handle

is not under the fuel tank.

If you've [bHowed these steps

properly, there will be no gap

between the clutch case and the

worm gear housing. (Picture 2)

Make sure you tighten the flange

bolt!

Cleaning the

Muffler Screen

1. Take out the spark

plug

2. Remove the red

cylinder covet (Key #32)

which is held on by 2

phillips-head screws,

(Key #33) and 1 hex-

head screw, (Key #34)

which you will need an

allen wrench to remove.

3. _fbuwilt see the

metal exhaust guide, held

on by 3 more phflfips-head

screws. (Key #26) Remove

the exhaust guide.

4. Behind the exhaust

guide (Key #25) will be

the muffler gasket (Key

#24) and muffler screen

(Key #23), The screen

sits under the gasket.

5. If the screen (Key

#23) is clogged with

deposits, it needs to be

cleaned. Use carburetor

cleaner, and any brush

that is not metal Brush

the screen until you are

able to see through it.

6. if the screen

remains plugged after

attempts at cleaning, it

must be replaced.

12

Page 13

Each/illl-- orbeforeyoustoreyour

MANTISTillertbranylongperiod-- be

suretotakethese measures:

1. Do not store your l?ller with fuel

still in it. Even under ideal conditions,

stored fuel containing ethanol or MEBE

can start to go stale in 30 days. And,

since stale fuel has a hNh gum content,

it can clog the carburetor, this, in turn,

will restrict fuel flow. So, when yon're

read}, to store your Tiller, or NIl not

be using it for more than 2 weeks,

drain the furl tank completely (Picture 2)

2. Next, restart the engine to make

sure no fuel is left in the carburetor:

Then run the engine until it stops. This

will prevent gum deposits, forming

inside of the carburetor and possible

engine damage.

3. Disconnect spark plug wire and

remove the spark plug. (Use the wrench

that comes in our optional Handy item

Kit, Item #8444. Or use a 19ram or 3/4"

spark-plug wrench.) Pour about a

teaspoon of clean, at>cooled, two-cycle

oil through the spark-plug hole into the

combustion chamber. (Picture 3) Leaving

the spark plug out slowly pull the starter

cord two or three times to coat the inside

of the cylinder +wall+

4. Replace the spark plug with a NGK-

BPMSY. A repIacement spark plug is

included in the optional Handy Item Kit

item # 8444.

5 Install the spark plug, but leave the

spark plug wire disconnected.

6. Clean the air fiher as described on

Page 11.

7. Clean dirt, grass, and other

materials t?om the entire machine.

8. Wipe the tines with oil or spray

them with WD-40, to prevent rusting,

9. Oil the throttle cable and all -,qsible

moving parts (Do not remove the

engine cover.)

10. Replace the fuel filter.

1I. Check the grease level in the worm

gear housing, as described on page 11,

12. Order new parts to replace any

that are badly worn or broken, Just coil

your local authorized MANTIS dealer.

13. Store your Tiller, in an upright

position, in a clean, dry place, "_bucan

store with the handles in an extended

position or folded down. (Picture 1)

14. "Ib fold the handles, tbllow these

easy steps: Loosen the handle knobs

(#40), fold the handles forward (see

picture 1, inset). Tighten knob securel>

Your handles are now folded and ready

to store in a smaller area,

15. Do you have fuel left over from

last season? Dispose of it properly_ Buy

fresh oil and gasoline next season.

How to Prepare Your

MANTIS Tiller for

Restarting

Unfold _he handles into an upright or

extended position. Tighten the two

handle knobs (#40)

In the Spring, when you take your Tiller

out of storage, remove the spark plug.

Pull the star_er cord three or four times

to clean oil from the combustion

chamber

(Picture 4) Wipe oil from the spark

plug. Place the spark plug back into the

cylinder, Re-connect the spark plug wire

back on the spark plug. Then lollow the

steps on pages 9 & 10 to ret:uel and

restart your Tiller.

Again, Check the

Carburetor.

if your Tiller won't restart in the

Spring -- or if it lacks its usual power

-- the carburetor may need attention.

Follow the steps on page 19 for adjusting

the H and L screws. (Picture 5)

Check the Spark PLug Too.

If your 'Filler won't restart, or if it

lacks full power, the spark plug may be

at fault. Check to see if the plug is

fkmled with oil.,/black deposits. Clean or

replace it if it is. (Picture 6)

Also, check whether the center

electrode is rounded at the end,

or if the ground electrode is worn. If

either is the case, you should replace it

with a NGK_BPM8Y spark plug. Use a

19rmn or a 3/4" spark-plug wrench to

install it. Adjust the plug gap to .024

,028 in. (0.6 to 0.7 ram)

Caution: Do not over ti_titen

the plug. The correct torque is 18 to

22 ft.-lbs. (24-30 n.m)

IMPORTANT NOTE:

To avoid possible damage to the

threads, do not try to remove

the plug from a hot aluminum

cylinder head.

Picture i

Picture 2

P_cture 5

Picture 3

Picture 4

Picture 6

13

Page 14

TROUBLE SHOOTING

Problem Cause Remedy-

1° Tines don't turn when throttle + Engine is not seated properly on the gear + Re+instaI1 engine following the instructions

is depressed on page I2 (How to reseat the _Tange).

2. Engine fails to start O11switch is in +o" position, Move switch to _+12+

* No fuel in tank.

+ Fuel strainer clogged.

* Fuel line clogged.

, Spark plug shorted or fouled+

* Spark plug is broken (cracked

porcelain or electrodes broken)

, ignition lead wire shorted, broken or

disconnected from spark plug.

* Ignition inoperative

o

Fill Tank.

Replace Strainer.

Q

Clean fuel line

Install new spark plug.

o

Replace spark plug.

o

Replace lead wire or attach to spark plug

Contact your local authorized dealer+

3_ Engine hard to start.

* '&'ater in gasoline or stale fiael mixture.

+ lbo much oil i_ iuel mixture+

* Engine under or over choked

Drain entire system and refill with

fresh fuel.

Drair_ and refill with correct mixture.

If flooded by over choking, proceed

according to instructions iu operation+

section, If under choked, move choke

lever to dosed position m_d crank two or

three times.

4. Engine continuously floods.

* Carbm,:tor out of adjustmenL

- Gasket leaks (carburetor or cylinder

base gaske0+

Weak spark at spark plug.

+ Fuel tank vent line is not in an

upright position.

See "Carbtxretor Adjustment'

Replace gaskets.

Contact your local authorized dealer+

Return the t:uel tank vent line to the

upright: position and place it under the

cyiinder cover in the small pocket" in

the cylinder cover

5+ There is black smoke coming from * The muffler screen is clogged * Clean carbon frorn mufIler screen (page 12)

exhaust

6. Engine misses.

7+ Engine lacks power

* Dirt in tuel line or carburetor.

+ Carburetor improperly adjusted+

* Spark plug fouled, broken or incorrect

gap setting_

* Weak or intermittent spark at spark plug.

* Air filter clogged

, Carburetor out of adjusnrmnt+

+ Muffler clogged

+ Clogged exhaust ports.

+ Remove and clean.

* See '_Carburetor Adjustment2

* Clean or replace spark plug - set gap to

024-.028 in. (06-0.7 mm)

- Comact your local authorized dealer.

Clean or replace air filter.

o

See "Carburetor A_ustment"

Clean carbon from muNer+

Remove muff lee rotate engine until the

piston is at top of cylinder. With a

wooden scraper or blunt tool. remove all

carbon from exhaust ports. Be carefu! not

to scratch or damage piston or cylinder

wails+ Blow out all loose ca_on with

compressed air+Install muffler and gasket.

+ Spark Arrestor Clogged. +

* Poor compression.

Clean Spark Arrestor

Contact your local authorized dealer.

8+ Engine overheats. + Insut_icient oiI in fuel mixture + Mix fueI as described iu slarting

instructions.

+ Air flow obstructed + Clean flywheel cylinder fins and screen.

91 Engine noisy or knocking. + Spark plug in incorrect heat range. + Replace x_ith plugs specified for engine.

* Beatings, piston ring or cylinder walls + Contact your local authorized dealer

are worn.

i0. Engine stalls under load. + Carburetor adjustment mo 'leanY+ + See 'Carburetor AdjustmentY

+ * Remove dust and dirt from between fi_s+

14

Page 15

ENGINE SPECIFICATIONS

Dry Weight ....... 2.8kg -- 6 lbs., 3 ounces

I)pe of Engine .... Air Cooled, Two stroke, Single-Cylinder,

Gasoline Engine

Rotation ....... Clockwise, viewed from TOP

Bore ............ 32.2 mnr (1,268 in.)

Stroke .......... 26.0 mm (1.04 in)

Spark Plug ........ NGK BPMSY

Fuel ........... Premixed two stroke fuel

Fuel Oil Ratio ..... 50:1 ratio with MANTIS oil

Gasoline ......... Unleaded (see page 7)

Displacement ..... 21.2 cc (1.294 cu. in,)

Exhaust System .... Spark arrester muffler

Carburetor ......... ZAMA diaphragm model C1U type

Ignition System .... Flywheel magneto, capacitor discharge

ignition type

Starter ........... Automatic rewind type

Oil ............ Designated, two-stroke, ai>cooled

engine oil

FueI Tank Capacity .0.5 lit. (17.0 oz)

SER CE MAINTENANCE GUIDE

Area Maintenance Frequency

Air Filter Clean Daily or every 4 hrs use

Replace Every 3 mths. or 90 hrs. use

Fuel Filter Inspect Mor_th|y

Replace

Spark Plug Clean Every 3 mtbs. or 90 hrs_ use

Replace 6 months or 270 hrs. use

Carburetor Check / Rebuild 6 months or 300 hrs. use

Replace Yearly or 600 brs. use*

Cylinder Exhaust Port Every 3 mths. or 90 hrs. use

luspect / Clean Betore Use

Inspect / Clean Monthly

Gear }lousing Check Grease Yearly

Trees Inspect / Clean / Lubricate After Use

Fuel Leaks Inspect / Repair Betore Use

Fasteners Inspect / Tighten / Replace Bet}:_reUse

Labels Befure Use

Handles Behare Use

Guards / Safety Devices Inspect / Replace Before Use

Fuel Line Inspect / Replace Monthly

Starter Rope Monthly

Fuel Strainer Replace EveW 3 mths. or t00 hrs. use

Choke Check With each reo_t_aeling

Ignition .System Clean No maintenance

Replace For coil and flywheel

Replacement w_tlbe required for commerdal use aher 600 hours. For CoT_sumeruse, cleaning every 6 months is required. Cleaning i_c[udes Rebuild Kils.

IMPORTANT: Time Intervals shown are rnaxinmm. Actual use and your experience will determine the frequency of required maintenance.

Notes:

15

Page 16

USING THE BORDER EDGER ATTACHMENT

Your MANTIS Tiller has been

designed and built to accept a -,vide

range of MANTIS Tiller Attachments to

increase its usehalness in your lawn and

garden. And, all MANTIS Tiller Attach-

rrtents have been designed/br quick and

easy attachment to the Tiller or Engine.

The Border Edger

(Item #3222)

The most popular attachment, the

Border Edger can be used to create

clean, neat edges along walkways, or

around trees, shrubs, and garden beds.

The Border Edger has two parts: a

Wheel and a hardened steel blade, with

pointed tines.

How to Install the

Border Edger

The foliowing instructions refer to

'right" and ' left" axles. Assume that

you're standing behind your Tillec as

you would for tilling and cultivating.

Some areas of your yard may harbor

roots and other underground

obstructions. In places like this you'll

want to edge your borders shallowly

(1" to 2" deep). Here's how to install

the Border Edger tor shallow edging:

I. First remove your tilling,,'

cultivating tines.

Picture 1 Picture 2

2. Then slide the Edgerg wheel onto

the right axle,

3. Now slide the Edger blade onto

the left axle. The blade's angled face

should bit the ground when you spin

the blade forward; do not operate tiller

without tine pins in place

4. Insert retaining pins on both le[t

and right axles.

Around walkways and garden beds,

you'll want to edge more deeply (3" to

4" deep). Here_ how to install the

Border Edger for that purpose:

1. Remove the tilling/cultivating

tines.

2 Slide the Edger_ blade onto the

right axle The bladeE pointed face

should hit the ground when you spin

the blade forward; do not operate tiller

without tine pins in place

3 Slide the wheel onto the left axle.

4. Insert retaining pins on both sides.

How to Use the

Border E@r

i. Position your MANTIS Tiller so

that the Edger blade is right along (he

garden edge and the wheel is outside

(on the lawn, on the sidewalk,

wherever). (Picture I)

2. Start your Tiller and pull your

MANTIS backward along the garden

edge. (Picture 2)

The Border Edger Can

Handle Special Projects!

1. Install the Edger lor deep edging,

as directed above. Then use it to cut

sod strips.

2. Edge and weed at the same time!

Just attach the Edger blade on one axle

and a Tiller fine on the other axle, "Mix

and match" blades; don't be afraid to

experiment.

IMPORTANT NOTE:

If you do a lot of edging, you'll

appredate the Mk_NTIS Wheel Set

(Ire:m#9222.) It gives you added

stability, for even easier handling.

_lborder the Wheel Set or any

MANTIS Attachment, call your local

authorized MANTIS dealen

MANTIS TILLER ASSEMBLY

P/N 438LA

DIRECTION

Raised Hub

Teeth point in

a Clockwise

Direction

When _o_1look a a [me wiIh the aised tmb [amg

|TEI_NAME _q.TYNAT_81AL ITIENNAME QTY

1 400254 1 Trigger Handle !5 425 2

2 400255 I HandleAssm, LH

3 400224 2 Lower Handle -

4 400620 1 Label

5 148 1 Handle Brace

6 478 2 TbrotBe Ciip

7 465 1 Fender Guard

8 400908 ! EngineAssm, SVo

*9 468 1 Drive Shaft

10 466 ! Worm Gear

11 436 1

12 437A 1

13 651 4

14 423 1

16

Assm, RH

Foid Down

5C/2

Ho_sing

Gasket

Housing Cover

Rd Hd, Se#

Tapping Screw

Roller Bearing

16 424

17 422

18 426

19 428

20 429

2! 431

22 430

23 432

24 434

25 435

26 438RA

27 438LA

28 418-1

P/N 438RA

D_RECTION

Hub

.... a Counter C!ock_

When yo_ i_ok at "Ine ,vdl de raised hub facing you

a_d the _eeth are poi_Im_g in a (OUNIER Cn)CKW1S[:

_n_adm, ym_ a_ad a RIG[IT ;CIANI}MINE

MATernAL

WormBearing

Race

! Worm Thrust

Bearing

I Worm Shaft

I Worm Disk

1 Retaining Ring

! Worm Gear

1 Tine Shaft

2 Worm Gear

Thrust Washer

2 Worm Gear

Bearing

2 Beark/g Seal

2 BearingSea!

Retainer

I Ene Assm, (RT)

I Tine Assm (LT)

2 Fine Retaining

Hair Pin

ITeMNA_E Q_ NATEmA[

29 400218 1 Carrying Handle

30 487MA 1 Engine Label

31 4043 1 Tine Label

32 458 1 Relier Bearing

33 4058 1 Mantis LabeI

34 410 2 Cap Screw 1/4-

35 972 4 Lock Nut 1/4 - 20

36 470 2 1/4 - 20 x 3" Bolt

37 140 2 Bolt 1/4-20 x

38 377 2 HandIeCtamp

39 400509 2 Bolt

40 400510 2 Knob

41 400230 2 Plug

42 400010 1 Transmission

* Also in Key#42

point in

wee Direction

20 x 1" LG

3/8" kg.

Assm.

Page 17

SV-5C/2

ITEM PART# QTV, DESCRIPTION_S

ENGINE E4RTS

ASSEMBLIES

CA_URETOR

@

2 B _;t51_]€_20 _ Nl:']AINI_{, PURGE PUMP

4 I_X}51_;_NSI] 1 BASE PURGE

5 ----,,- - : /

6 12533942¢_30 1 SCREW METERING LEVER P_N

8 _2537242B30 1 SWWEL

111 NI:_;1_3107_1 I SItAFL TNR(YFrLE

@

2 125314139311 SCREW, THRUI_rLE VALVE

I4 1253_715_30 CLI_VrHROTrL_SIL'_

I6 _25 _2909a@ EAP, MIX'_URE LtMI EER- LOW SPE_iD

_25"{_)!a31g NEEDLE [tl!Gff S_EgD

8 /253293903# CAE M[XI URE L/MFIER - HIGH SPEED

22 125319i282t1 2 SCPd_W H)EL PUMP COVER

23 1253 _413 20 REIS\!R KIT / INCI,{ DES t_IEMS 24-3

25 I GASKE'E METt RING DIAPHRAGM

27 ................. 1 _VN{ ME_INNNG

2¢ I spin,o, MErVRNO1,Ev_a

3/I __._.ss____=..__ WELC_ Pi,_JG

3] ......................... STRAINER

3 ..................... 1 GASKEZ F/[:L PUMP

3g /2._30313 2B I GASKEZ;DIAPHRAGMKI_l{INCL1"DESI*ITiMS353g

;;; ; ; _ ;;;;;; DDNNRA(_M; MEJER!N()

36 ........................... I GASKEZ METERING DIAPHraGM

,;;,;,.22;.2:,;;2;2

38 GASKET, fUEL PUMP

v_a::vE,lal,_'_NBDEE

AxR CL NER, MVFFLER,& TnRorr E

GASKET KIT

ITEM PART # QTY DESCRIPTION / REMARKS

2 13032611522 i COVEK A_R CLEANER

4 lsos_c_4s(_t_ _rEa, A_

g 17851B00830 1 SEACER

::9

10 17881005230 I GROMMET

i ..........................

12 AO211DIl_N 1 EARB/;RETOR -- Ell-KS2

I_M PART # QTY. DESCRIPTION / REMARKS

19 Aaiu_IIlI0S2t 1 NKFFLER

23 14586240630 l S(REEN,MLEFLER

BOLD Indicates New Pa_

14 _._;_123805020 2 SCRE'@ 5X20

17

Page 18

SV-5C/2 ENGINE PARTS

FUELTANK

l_ _,_r _ {,FY_DEscmmoNREmRKS

2 _3R_528230 _ SPACER

4 V4711_i23{} _ PIPE, FI_EI 3X5X2 0MM/BtlKOgI']ON:9(}{}i4

7 ._z05ov_:o _ PILre_<FU_L

9 130H I00530 l CLIR PIPE

11 13201t}49030 _ NPE, RIJlUR)-a _3X_XS(P_IM/ BULK ON?ION: 9{_11

i

U_ 13101655830 _ GASKE'L 115EL'IANK ( AP

STARTER, PAWL CATCHER & CLUTCH

BLOCK

2 A ER_)/_550 1 CYLINDER

vio_:_l_-a_i ......... ............

4 P02_007712 t PIS_ON, KIT / INCLUDES ITEMS 5o8

i_i_:_x._)N _ _i _N ...... ................

6 10{R)1311520 t PIN, PISTON

8 10{5_314i152(} 2 SPACER, P_S'ION PIS;

AOlil_m_a

tO V55300(_)10 t BEi'_RING ,NEED_ E

12 1002_242031 2 OIL SEAL

i_v_50b_o

* I4 I(_F2_242031} t GASKET, CRANKCASE

/6 90016205028 3 BOI_ 5X28

Also i_chld_t iI_ GASKET KIT

i7 PI}2it}091 iI) l GASKE!i KIT

l_ A4iiiu_:i_aii COIL;iiiSi;ri0r;

20 i56! I_14920 1 BUSHING

v4v_c_ ...................

22 15901N)1620 t CAP, SI_RK PIUG

24 I59¢_I019830 t SPARK PlUG - BPM_Y

26 6t032502730 1 WOODRU/P KEY

®-@

ITEM PART # QTY. DESCRII:_rION / REMARKS

18 17722605530 1 ROPE STARI'ER 3MM(1/8' X t0(_gMM 39q/2 {

RULK O}ff1ON: 999444400%

20 177228tlt20 I S_ARTERGRIPK1T

22 11723644330 1 SCREW

a

25 17501(_)5020 ] bIU[_ CLUATH

N

2v i75oo_)5t3_2 SHOECLUTCH

{

29 9t)0_d._000010 1 WAS}tER/11

3_ :9_)0gf,)83@fX)

29 1772021222{} 1 S'_ARIER RAWLAS_x / INCLUDES [TfMS 3031

3] 177234t2220 2 SPRIN& PAWL R]2"IURN

32 A16(_1()0611} t COVER_ CYLINDER

2_4 9I_/l?o_/o_ 2 SCREW4X8

GASKET KIT

18

33 1750t4t1520 _ _aASI_ER, CLUTCH

35 900238{_0f4 4 SCRIW4X]4

37 90060500(K)5 i SPRING WASHER 5

g

38 5:N

39 6t022311520 1 CASE CLUTCH

BOLD k_dicatesNew Pmt

Page 19

EPA PHASE 2 / CALIFORNIA TIER III EMISSION CONTROL WARRANTY STATEMENT

YOUR RIGHTS AND OBLIGATIONS

The Elwironmental Protection Agency (EFLA)and the Cali[ornia Air Resources Board (C.A.R B_) and "rbe Equipment ManMi_cturer are pleased to explain the

emission control system warranty on your EPA Phase 2 / C.A.R B. "TierIII model year 2005 a_ul later small off road engine (SOREs). New small off road engines

must be designed, b_ilt and equipped to meet stringent EPA and C.A.R.B. anti--smog standards. Echo, incorporated must warrant the emission control system on

your small off road engine for the periods of time listed below provided there has been no abuse, neglect or improper maintenance o_ your small off r<)ad engi_le.

Your emission control ystem may include parts such as the carburetor or ItleI iqected system, and the ignition system and catalytic converter Also included

may be hoses, belts, connectors and other emissiomrelated assemblies.

Where a warrantable condition exists, the Manulacmrer wiiI repair your small off road engine at no cost to you including diagnosis, parts and labor

MANUFACTURER'S WARRANTY COVERAGE:

The 1995 and laier small off road engines are warranted lk_rtwo years If any emissionmelated part on your engine is del;ec{ive, the part will be

repaired or replaced by the Mannfacturer:

OWNER'S WARRANTY RESPONSIBILITIES:

-As the small off road engine owner; you a_: responsible for the performance of the required maintenance listed in your Operator's Mamla[. The

Manufacturer recommends thai you reiain al! receipts covering maintenance cm your small off road engine, but the Manufacturer cannot deny warranty

solely [or the lack of receipts or for your tailure to ensure the performance of a!l scheduled maintenance.

-As the small off road engine ow'ner; you should however be aware that the Manu_'acturer may deny you warranty coverage if your small off mad engine or

a part has lailed due to abuse, neglect, imp_a)per maintenance or unapproved modifications.

You are responsible for presenting your small off road engine to the Manu{k_cturer's authorized service center as soon as a problem exists. The warranty repairs

should be completed in a reasonable amount of time, not to exceed 30 days.

II you have any questions regarding your warrant}' rights and responsibilities, you should contact your Product Manufacturer.

EPA PHASE 2 / CALIFORNIA TIER III EMISSIONS DEFECT "WARRANTY EXPLANATION

This is additional detailed information about the ED\ PitAS_g..2L. ° _g.P_N.!o_[ [or your smali off road engine.

WHAT DOES THIS WARRANFY COVER?

The Manufacturer warrants tbat ym_r unit was designed, bnih and eq_ipped to coMbrm with applicable Calitornia emissions standards and that your unit is flee

from defecls in material and workmanship that would cause it to faiJ to cnMorm with applicable requirements within I_ve (5) years The wa_'ran_y period br@_s

on the date the product is delivered to a re_ail purchaser "this is your emission control system,

HOW WILL A COVERED PART BE CORRECTED?

If there is a de{_'et in a part covered by this walranty; a Mamdacmrer s Authorized Service Dealer will correct the deli, ct

You will _mt have to pay anything to have the part adjusted, repaired o_ replaced This includes any labor and diagnosis lot warrani:ed repairs performed by the

dealer, in addition, engine parts not expressly covered under this warranty but whose failure ix a _vsult qf a fhilut_: of acm, ered part will be warranted

Emissions System repairs covered under this warranty should be completed in a reasonaMe time, not to exceed 30 days

IMPORTANT

!f the dfagnosi reveals no delk_ct the emission defect warranty does not apply.

WHAT PARTS ARE COVERED BY TttE EPA PItASE 2/CALIFORNIA TIER III 2005 & LATER SMALL OFF ROAD ENGINE EMISSIONS

DEFECT _NARP_a_NTY?

,Any emission related part not scheduled to_; "required maintenance" (See Engine Operators Manual, %ERVICli MA1N'IENANCE SCHI!DULE ') wit! be

repaired or replaced witbin the warran V period. the repaired or reptaced part svill be warranted for the remaining Emissions Defect warramy period.

*Any emission related part scheduled for replacement during 'h_equired maintenance" (See Engine Opermors Mammal, _SERVICE MMNTENANCE

SCHEDULE) is warranted for the period of time prior to the first scheduled replacement point for that part Any such part repaired or replaced under

warranty shall be warranted tPr the remainder of the period prior to the first scheduled replacement point/)_r tbat part.

°Any manulacmrer-app_wed replacement part may be used in the perDarmance of any warranty maimenance or repairs on emission-related parts, and

must be provided without charge if the part is still under warranty:

,Any replacement part that is equivalem m pertk>rmance and dmabibty may be used m non-warranty maintenance or repai_'s, and shall not _:duce the

warramy obligations o_;the mamd;acturer.

-'['he owner is responsible for the pertormance of the required maintenance described in the operators manual.

SPECIFIC EMISSION RELATED WARRANTED PARTS:

- Choke

- Fuel injection Assembly or replaceable compo*_ents

Electronic Ignition System

* Catalytic Converter / Mtdtler Assembly

WHAT 1S NOT COVERED BY THE EPA PHASE 2/CALIFORNIA TIER III 2005 & LATER SMALL OFF ROAD ENGINE EMISSIONS

DEFECT \¥?kRRANTY?

,Any f!_iturc caused }_yabuse, nrglecL imprope_ maititenance.

,Any.fl_ilun, caused by unappr_wed modifications, _se _?funapp_nved aM-on parts/mod{fied parts or unapp_r>ved accessories.

- Carlmretor (complete assembly or replaceable components)

- Air Filter

- Spark Plug

19 ¸

Page 20

, NTIS LLER

LIMED

MANTIS extends this limited warranty against

defects in material and workmanship for a

period of five (5) years for nodal residential

purposes and two (2) years for commercial use

from the date of purchase, to the first retail

purchaser and each subsequent owner, during

the warranty period. This warranty covers ail

portiorm of the MANTIS TILLER

MANTIS will repair or replace, at its option, aW

part or parts of the product proven to be

defective in material or workmanship under

normal usage during the warranty period.

Warranty repairs and replacemenm will be made

without charge [or parts or labor. All parm

replaced under warranty will be considered as

part of the original product, and aW warranty on

the replaced parts ,s4it expire coincident ,xith the

original product warmnb: If you think your

MANTIS TILLER is defi:ctive in material or

workmanship, you must send it, along with your

proof of pumMse (sales receipt) to:

Mantis

1028 Street Road

Southarrq)ton, PA 18966

You are responsible for pickup and delivery

charges; the product must be returned to us

postage paid.

MANTIS assumes no responsibility in the e:%nt

that the product was not assembled or used in

compliance with aW assembly; care, safety, or

operating instructions contained in the Ownerg

Manual or accompanying the product; was not

used vdth reasonable care or requires replacement

or repair due to accidents or lack of proper

maintenance; or was misused, ahered, used for

other than normal or intended purposes. This

warranty does not cover damage due to nonnaI

wear and tear.

You must maintain your MANTIS TILLER by

following the mamtenance procedures

described in the owner's manual. Such routine

maintenance, whether performed by you or a

dealer, is at your expense.

MANTIS MAKES NO EXPRESS OR IMPLtED

WARRANTIES OR REPRESENTATIONS

EXCEPT THOSE CONTAINED HEREIN. THE

DURATION OF ANY IMPLIED WARILA_NTY,

INCLUDING MERCHAN'D_BILITY AND

FITNESS FOR A PARTICULAR PURPOSE, IS

LIMITED TO THE DURATION OF THIS

WRITTEN LIMITED \_v_A_RRANTY.MANTIS

DISCL4IMS ALL LIABIMTY FOR INDIRECT,

INCIDENTAL AND!OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE USE

OF THE MANTIS PRODUCTS COVERED BY

THIS VviARRANT'fl SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG AN

IMPMED \VARKANTY LASTS AND/OR DO

NOT ALLOW THE EXCLUSION OR

MMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO TI:LaS

ABOVE LIMITATIONS AND EXCLUSIONS MAY

NOT APPt2f TO YOU. THIS V_&RRANTY

GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY ALSO _ _'X/EOTHER RIGHTS

WHICH \_4F,Y FROM STATES TO STATE.

MANTIS

1028 Street Road

Southampton, PA 18966

(215) 3550700

Specifications, descriptions, and illustrative rnaterial in this literature am as accura:_e as known at the lime of publication, but are subject to change without notice

_) 2009 Mantis, Division d Schiiler Grounds Care, Ioc, Printed in USA

P/N 401710 1/09

Loading...

Loading...