Page 1

OPERATION AND REFERENCE MANUAL

MODULAR TEST SYSTEM

First Edition

March 2001

MTS-3000 SERIES

Tel: +1(905) 828-6 469 Fax: +1(905) 828-6850

e-mail: support@mantatest. com Internet: http://www.mantatest.com

Manta Test Systems Incorporated

4060B Sladeview Crescent, Unit #1

Mississauga, Ontario, L5L 5Y5, Canada

Page 2

MTS-3000 Modular Test System

Operati on and R eference Manual

All rights reserved by Manta Test Systems Incorporated. No part of this publication may be reproduced or

distributed in any form or by any means without the permission of Manta Test Systems Incorporated.

The information and specifications contained within from Manta Test Systems are believed to be accurate

and reliable at the time of printing. However, because of the nature of this product, specifications shown in

this manual are subject to change without notice.

The features and capabil ities described herein reflect those available in the following firmware versions:

• MTS-3000: 2.0

• MTS-3010: 1.1

• MTS-3020: 1.1

• MTS-3030: 2.0

• MTS-3040: 2.0

• MTS-3060: 2.0

March 2001.

Document ID#: CU M004 01A

Powertest™ is a trademark of Manta Test Systems Inc.

Tel: +1(905) 828-6469 Fax: +1(905) 828-6850

e-mail: support@mantatest.com Internet: http://www.mantatest.com

Toll-free technical support (U.S.A & Canada): 1-800-233-8031

Manta Test Sys tems Incorporated

4060B Sladeview Crescent, Unit #1

Mississauga, Ontario, L5L 5Y5, Canada

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Section 1

Introduction

1.1 DISTINCTIVE CHARACTERISTICS .........................................................1-1

1.2 GENERAL DESCRIPTION..........................................................................1-1

1.3 APPLICATIONS...........................................................................................1-2

1.3.1 Standard Applications..............................................................................1-2

1.4 TERMINOLOGY ...... ...... .... ...... .... ...... .... ........... .... ...... .... ...... .... ...... .... ...... ..1-2

1.4.1 AC Current Module (ACI)........................................................... .......... ..1-2

1.4.2 AC Voltage Module (ACV).....................................................................1-2

1.4.3 Control Module (CM).............................................................................. 1-2

1.4.4 Device Under Test (DUT) .......................................................................1-2

1.4.5 Dynamic Fault Mode ...............................................................................1-2

1.4.6 Dynamic Relay Testing ...........................................................................1-3

1.4.7 MTS.........................................................................................................1-3

1.4.8 On Panel Testing......................................................................................1-3

1.4.9 Programming Mode.................................................................................1-3

1.4.10 Static Relay Testing.................................................................................1-3

1.4.11 Test Mode ................................................................................................1-3

1.4.12 V/I Module (VI).......................................................................................1-3

1.4.13 WFG Module...........................................................................................1-3

1.5 SAFETY CONSIDERATIONS.....................................................................1-3

1.6 TECHNICAL CONSIDERATIONS.............................................................1-4

1.7 TECHNICAL SUPPORT ..............................................................................1-4

Section 2

Specifications

2.1 INPUTS .........................................................................................................2-1

2.2 OUTPUTS .....................................................................................................2-1

2.2.1 MTS-3010 Digital I/O Module (Optional)..............................................2-1

2.2.2 AC Currents: MTS-3060 AC Current Module........................................2-1

2.2.3 AC Voltage and Current: MTS-3030 AC Voltage/Current Module........2-2

2.2.4 Output frequency .....................................................................................2-2

2.2.5 Harmonics................................................................................................2-1

2.2.6 Phase control............................................................................................2-2

2.2.7 DC Voltage: MTS-3020 DC Voltage Module.........................................2-2

2.2.8 DC Current: Current Source option.........................................................2-2

2.2.9 MTS-3010 Digital I/O Module (Optional)..............................................2-2

2.3 METERING...................................................................................................2-3

2.3.1 Time measurement...................................................................................2-3

2.3.2 Frequency measurement ..........................................................................2-3

2.4 STATIC/DYNAMIC TESTING CAPABILITIES........................ .... ...... .... ..2-3

2.5 OPTIONS.......................................................................................................2-3

2.5.1 System Options ........................................................................................2-3

2.5.2 AC Voltage Module Options ...................................................................2-3

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL iii

0$17$#7(67#6<67(06

Page 4

TABLE OF CONTENTS

2.5.3 AC Current Module Options....................................................................2-4

2.5.4 AC Voltage/Current Module Options......................................................2-4

2.6 PHYSICAL CHARACTERISTICS ..............................................................2-4

2.6.1 Minimum Configuration..........................................................................2-4

2.6.2 Control Module........................................................................................2-4

2.6.3 AC Voltage Module.................................................................................2-4

2.6.4 AC Current Module .................................................................................2-4

2.6.5 AC Voltage/Current Module ...................................................................2-4

2.6.6 Three Phase System: Control Module, AC Voltage and AC Current

Modules ...................................................................................................2-4

Section 3

Operation Summary

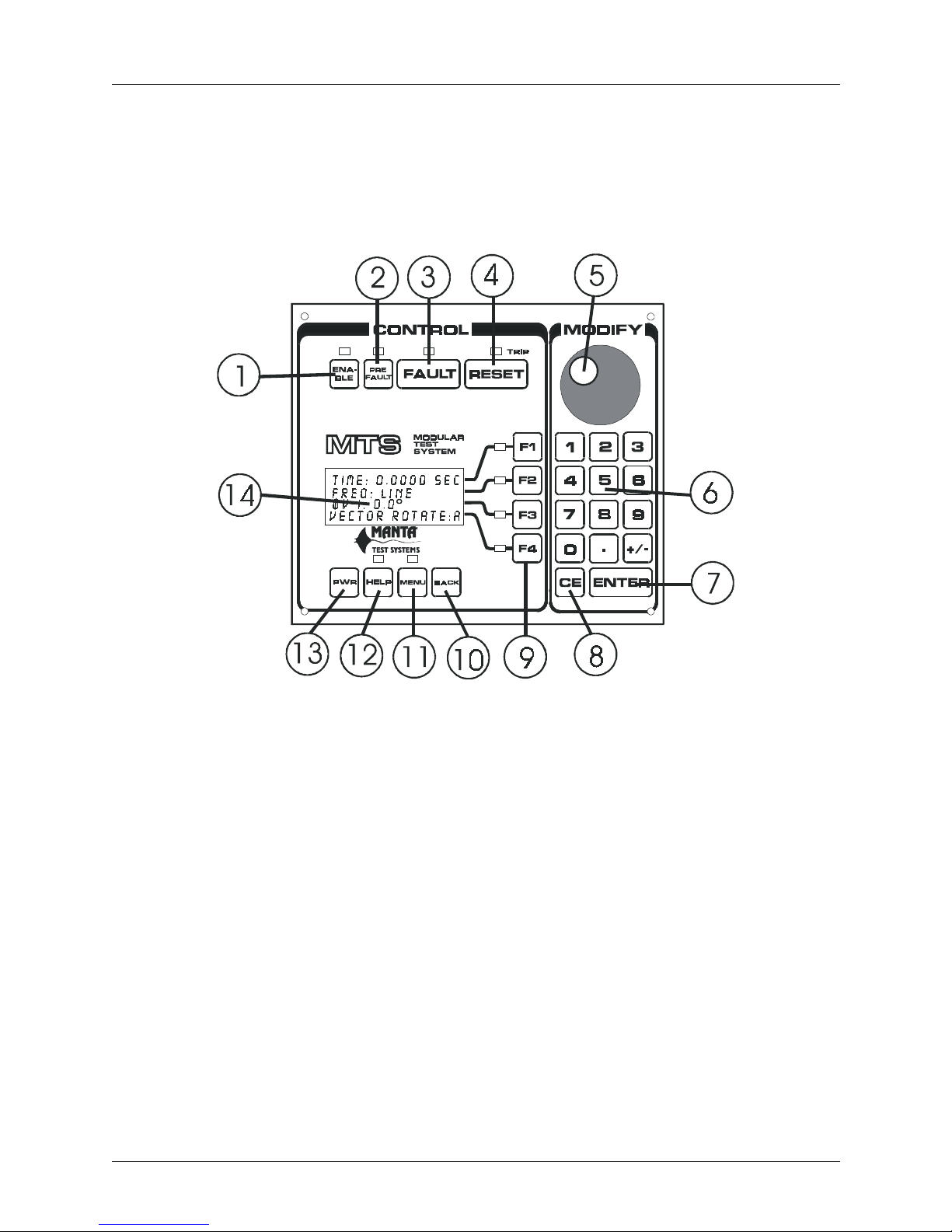

3.1 FRONT PANEL LAYOUT...........................................................................3-1

3.1.1 MTS-3000 Control Module, CM.............................................................3-1

3.1.2 MTS-3010 Digital I/O Module................................................................3-4

3.1.3 MTS-3010 DC Voltage Source................................................................3-5

3.1.4 MTS-3040 AC Voltage Module ..............................................................3-5

3.2 REAR PANEL LAYOUT .. ...... .... ...... .... ........... .... ...... .... ...... .... ...... .... ...... ....3-7

3.2.1 MTS-3000 Control Module Rear Panel...................................................3-7

3.3 BASIC APPLICATIONS ..............................................................................3-9

3.3.1 Getting Started.........................................................................................3-9

3.3.2 Basic AC Voltage, Current and Phase Angle Output ..............................3-12

3.3.3 Frequency Output ....................................................................................3-14

3.3.3.1 BASIC FREQUENCY OUTPUT. ...................................................3-14

3.3.3.2 ADVANCED FREQUENCY OUTPUT. ....................... ...... .... ...... ..3-15

3.3.4 DC Voltage ..............................................................................................3-15

3.3.4.1 BASIC DC VOLTAGE OUTPUT. .................................................3-15

3.3.4.2 ADVANCED DC VOLTAGE OUTPUT. . .... .... ...... .... ...... .... ...... .... 3-16

3.3.5 DC Current Output...................................................................................3-16

3.3.6 High AC Voltage Output.........................................................................3-17

3.3.7 High AC Current Output..........................................................................3-18

3.3.8 Overcurrent Relay Test............................................................................3-18

3.3.8.1 SETUP. ............................................................................................3-19

3.3.8.2 MINIMUM PICKUP TEST. ............................................................3-19

3.3.8.3 INVERSE-TIME CHARACTERISTIC TEST. ...............................3-19

3.3.8.4 INSTANTANEOUS ELEMENT TEST. .........................................3-20

3.3.8.5 TARG ET/SEAL-I N TEST. .. ........ ......... ................ ........ ................ ..3-21

3.3.9 Differential Relay - Three Terminal Type ..............................................3-22

3.3.9.1 PICKUP TEST. ................................................................................3-22

3.3.9.2 OPERATE TIME TEST. .................................................................3-23

3.3.9.3 HARMONIC RESTRAINT TEST. ................................................3-23

3.3.9.4 INSTANTANEOUS TEST. ............................................................3-24

3.3.9.5 TARGET TEST. .............................................................................3-24

3.3.10 Differential Relay - Independent Coil Type ............................................3-25

3.3.10.1 SLOPE TEST. ..................................................................................3-25

iv MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

0$17$#7(6 7#6<67(06

CU M004 01A

Page 5

TABLE OF CONTENTS

3.3.10.2 OPERATE TIME TEST. .................................................................3-26

3.3.10.3 HARMONIC RESTRAINT TEST. .................................................3-27

3.3.10.4 INSTANTANEOUS TEST. .............................................................3-27

3.3.10.5 TARGET TEST. ..............................................................................3-28

3.3.11 Voltage Relay Test...................................................................................3-28

3.3.11.1 SETUP. ...........................................................................................3-28

3.3.11.2 MINIMUM PICKUP TEST. ...........................................................3-29

3.3.11.3 TIMING TEST. ..............................................................................3-29

3.3.11.4 TARGET/SEAL-IN TEST. .............................................................3-30

3.3.12 Frequency Relay Test ..............................................................................3-30

3.3.12.1 SETUP. ............................................................................................3-30

3.3.12.2 PICKUP TEST. ................................................................................3-30

3.3.12.3 TIMING TEST. ...............................................................................3-31

3.3.12.4 TARGET/SEAL-IN TEST. .............................................................3-31

3.3.12.5 UNDERVOLTAGE INHIBIT TEST. .............................................3-32

3.3.13 Synchronizing/Reclosing or Synchrocheck Relay...................................3-33

3.3.13.1 PHASE ANGLE LIMIT TEST. ....................................................... 3-33

3.3.13.2 VOLTAGE LIMIT TEST. ...............................................................3-33

3.3.13.3 SLIP FREQUENCY LIMIT TEST. .................................................3-34

3.3.14 Single Phase Impedance Relay or Directional Overcurrent Relay Test..3-35

3.3.14.1 SETUP. ............................................................................................3-35

3.3.14.2 REACH/MINIMUM PICKUP TEST. ..............................................3-35

3.3.14.3 MTA TEST. .....................................................................................3-36

3.3.14.4 OPERATE TIME TEST. .................................................................3-36

3.3.15 Three Phase Impedance Relay Test .........................................................3-37

3.3.15.1 PREPARATION. ............................................................................3-38

3.3.15.2 REACH TEST. ...............................................................................3-39

3.3.15.3 MTA TEST. .....................................................................................3-40

3.3.15.4 OPERATE TIME TEST. .................................................................3-40

3.3.16 Ground Fault Overvoltage Relay.............................................................3-41

3.3.16.1 SETUP. ...........................................................................................3-41

3.3.16.2 OVERVOLTAGE PICKUP TEST. ................................................3-42

3.3.16.3 OVERVOLTAGE TIMING TEST. ................................................3-42

3.3.16.4 UNDERVOLTAGE INHIBIT TEST. ............................................3-42

3.3.17 DC Auxilliary/Time-Delay Relay Test....................................................3-42

3.3.17.1 PICKUP TEST. ...............................................................................3-42

3.3.17.2 TIMING TEST. ..............................................................................3-43

4.1 FAULT STATES...........................................................................................4-1

4.1.1 Prefault State............................................................................................4-1

4.1.2 Fault State ................................................................................................4-1

4.1.3 Postfa u l t S t a t e ... ........ ........ ........ ................. ........ ................ ........ .............. 4 -1

4.2 CHARACTERISTICS OF FAULT STATES ...............................................4-1

4.3 OPERATION MODE - STATIC VS. DYNAMIC .......................................4-2

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL v

Section 4

Detailed Operation

0$17$#7(67#6<67(06

Page 6

TABLE OF CONTENTS

4.3.1 Static Fault Mode.....................................................................................4-2

4.3.2 Dynamic Fault Mode ...............................................................................4-3

4.4 TRIGGER/TIMER OPERATION.................................................................4-4

4.4.1 External Trigger Inputs............................................................................4-4

4.4.2 Trigger Threshold Levels.........................................................................4-4

4.4.3 Start Trigger (FLT) ..................................................................................4-4

4.4.4 Stop Trigger (TRIP).................................................................................4-5

4.4.5 Reset.........................................................................................................4-5

4.4.6 Timer Start ...............................................................................................4-5

4.4.7 Two-Wire Pulse Timing ..........................................................................4-5

4.4.8 Timing in Cycles......................................................................................4-5

4.4.9 Testing SCR Output Type Relays............................................................4-5

4.5 CURRENT MODES......................................................................................4-6

4.5.1 Curre n t Rang e ............. ................ ........ ......... ................ ........ ................ ....4-6

4.5.2 HARMONIC Current Mode ....................................................................4-7

4.5.2.1 DEFINITION OF PERCENTAGE HARMONIC. ..........................4-8

4.5.2.2 SPECIAL N O TES. ..... ................ ......... ........ ................ ........ ............4-8

Section 5

Advanced Operation

5.1 MENU OPERATION ....................................................................................5-1

5.1.1 Basic Usage..............................................................................................5-1

5.1.1.1 ACTIVATING THE MAIN MENU. ..............................................5-1

5.1.1.2 SELECTING MENU ITEMS. ........................................................5-1

5.1.1.3 MENU NAVIGATION. .................................................................5-1

5.2 SETTINGS.....................................................................................................5-5

5.2.1 Reset to Defaults......................................................................................5-5

5.2.2 Fault Type................................................................................................5-5

5.2.2.1 VECTOR MODE. ...........................................................................5-5

5.2.2.2

Φ−N,Φ−Φ, 3Φ

MODE. ............................................................................5-5

5.2.3 Harmonics................................................................................................5-6

5.2.3.1 HARMONICS OPTIONS. ..............................................................5-6

5.2.4 Parallel Current........................................................................................5-6

5.2.5 Ramps ......................................................................................................5-7

5.2.5.1 FREQUENCY RAMPING. ............................................................5-8

5.2.5.2 PHASE RAMPING. .......................................................................5-8

5.2.5.3 VOLTAGE RAMPING. .................................................................5-8

5.2.5.4 CURRENT RAMPING. .................................................................5-8

5.2.6 Frequency 2..............................................................................................5-8

5.2.7 Breaker Times (

5.2.8 AC Current Range

Bkr Times

(ACI Range)

)......................................................................5-9

..............................................................5-9

5.2.9 Reclose.....................................................................................................5-9

5.2.10 Fault Incidence Angle

5.2.11 Maximum Fault Duration

(FIA)

....................................................................5-10

(Max Flt Dur)

................................................5-10

5.2.12 Display Options .......................................................................................5-10

5.2.12.1 DEFAULT DISPLAY

(Hz &

Φ)

. ..................................................5-10

vi MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

0$17$#7(6 7#6<67(06

CU M004 01A

Page 7

TABLE OF CONTENTS

5.2.12.2 SLOPE. ...........................................................................................5-11

5.2.12.3 IMPEDANCE. ................................................................................5-11

5.2.12.4 FREQUENCY & V/Hz. ..................................................................5-13

5.2.12.5 FREQUENCY & SLIP. ..................................................................5-13

5.3 QUICK TEST ................................................................................................5-13

5.4 PREFERENCES............................................................................................5-15

5.4.1 Button Tone .............................................................................................5-15

5.4.2 VI Module #1...........................................................................................5-15

5.4.3 VI Module #2...........................................................................................5-15

5.4.4 COM 1 RS-232 ........................................................................................5-15

5.4.5 COM 2 RS-232 ........................................................................................5-15

5.4.6 Assign Ports .............................................................................................5-15

5.4.7 LCD Contrast...........................................................................................5-16

5.5 INDEX...........................................................................................................5-18

5.6 OTHER ..........................................................................................................5-18

5.6.1 Version.....................................................................................................5-18

5.6.2 Calibration ...............................................................................................5-18

5.6.3 Printer Test...............................................................................................5-18

5.6.4 Diagnostics...............................................................................................5-18

5.7 DIGITAL I/O.................................................................................................5-20

5.7.1 Input Channel 1 (

5.7.1.1

TRIP (ie STOP)

5.7.1.2 EXTERNAL START

5.7.1.3

5.7.1.4

5.7.1.5

5.7.1.6

5.7.1.7

Pulse Timing.

Reset.

...............................................................................................5-20

Reclose.

Foot Switch.

Off.

..................................................................................................5-21

5.7.2 Input Channel 2 (

5.7.3 Input Debounce (

5.7.4 DC Current (

5.7.5 Output Channel 1 (

5.7.5.1

5.7.5.2 /

FAULT (NO)

FAULT (NC)

5.7.5.3 Breaker Open

5.7.5.4

5.7.5.5

5.7.5.6

PERMISSIVE

UNBLOCK

Off.

..................................................................................................5-22

5.7.6 Output Delay (

5.7.7

Version

.....................................................................................................5-22

I/P Chan 1

) ..................................................................5-20

. ..............................................................................5-20

(FLT (i e ST O P))

. .........................................5-20

..................................................................................5-20

...........................................................................................5-20

....................................................................................5-20

I/P Chan 2

I/P Debounce

IDC

) ...................................................................................5-21

O/P Chan 1

) ................................................................5-21

) .............................................................5-21

) .............................................................5-21

. ..................................................................................5-21

. .................................................................................5-21

(BKR OPEN : 52 B)

. ..................................................5-21

. .................................................................................5-22

. .....................................................................................5-22

O/P Delay

) ......................................................................5-22

6.1 ADVANTAGES OF QUICKTEST................... ...... .... ...... .... ...... .... ...... .... ....6-1

6.2 QUICKTEST ALGORITHMS......................................................................6-1

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL vii

Section 6

QuickTest

0$17$#7(67#6<67(06

Page 8

TABLE OF CONTENTS

6.3 QUICKTEST TERMINOLOGY AND ABBREVIA TIONS ........................6-2

6.4 SUMMARY OF OPERATION.....................................................................6-2

OVERCURRENT TEST

6.5 TIMED 1

Φ

..............................................................6-4

6.5.1 Test Description.......................................................................................6-4

6.5.2 Example 1Φ Test Descriptions ................................................................6-4

6.6 INSTANTANEOUS 1Φ OVERCURRENT TEST ......................................6-6

6.6.1 Test Description.......................................................................................6-6

6.6.2 Example 1Φ Instantaneous Over Current (50).........................................6-6

6.7 TIMED 1Φ UNDER VOLTAGE TEST . .. ......... ...... .... ...... .... ...... .... ...... .... ....6-8

6.7.1 Test Description.......................................................................................6-8

6.7.2 Example 1Φ Timed Under Voltage (27)..................................................6-8

6.8 INSTANTANEOUS 1Φ UNDER VOLTAGE .............................................6-10

6.8.1 Test Description.......................................................................................6-10

6.8.2 Example 1Φ Instantaneous Under Voltage (27) ......................................6-10

6.9 TIMED 1Φ OVER VOLTAGE TEST ..........................................................6-12

6.9.1 Test Description.......................................................................................6-12

6.9.2 Example 1Φ Timed Over Voltage (59)....................................................6-12

6.10 INSTANTANEOUS 1Φ OVER VOLTAGE TEST .....................................6-14

6.10.1 Test Description.......................................................................................6-14

6.10.2 Example 1Φ Instantaneous Over Voltage (59)........................................6-14

6.11 TR A N S FORMER DIFF ERENTIAL TEST. .. ................ ........ ........ .............. 6 -1 6

6.11.1 Test Description.......................................................................................6-16

6.11.2 Example Transformer Differential...........................................................6-17

Section 7

RS-232C Interface

7.1 RS-232C CONNECTION..............................................................................7-1

7.1.1 Interface Specifications............................................................................7-1

7.1.2 COM 1 RS232C Port...............................................................................7-1

7.1.2.1 COM 1 RS-232C CONNECTOR PIN ASSIGNMENTS. ..............7-1

7.1.3 COM 2 RS232C Port...............................................................................7-2

7.1.3.1 COM 1 RS-232C CONNECTOR PIN ASSIGNMENTS. ..............7-2

7.1.4 Baud Rate Selection.................................................................................7-2

7.1.4.1 COM 1 BAUD RATE. .................................... .... ...... .... ...... .... ...... ..7-2

7.1.4.2 COM 2 BAUD RATE. .................................... .... ...... .... ...... .... ...... ..7-2

7.1.5 XON/XOFF Handshaking .......................................................................7-3

7.2 COMMAND DESCRIPTIONS............................. ...... .... ...... .... ...... .... ...... ....7-3

7.2.1 Control Mode Programming......................................... .... ...... .... ...... .... ...7-3

7.2.2 Fault State Control...................................................................................7-3

7.2.3 External Data Mode.................................................................................7-5

7.2.4 Voltage Programming..............................................................................7-5

7.2.4.1 COMMANDS. ................................................................................7-5

7.2.4.2 EXAMPLES. ..................................................................................7-6

7.2.5 Current Control........................................................................................7-6

7.2.6 Phase Control...........................................................................................7-7

7.2.6.1 COMMANDS. ................................................................................7-7

viii MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

0$17$#7(6 7#6<67(06

CU M004 01A

Page 9

TABLE OF CONTENTS

7.2.6.2 EXAMPLES. ..................................................................................7-8

7.2.7 Frequency Control/Programming............................................................7-8

7.2.7.1 COMMANDS. ................................................................................7-8

7.2.7.2 EXAMPLES. ..................................................................................7-9

7.2.8 RS-232 Control........................................................................................7-10

7.2.9 Print Commands ......................................................................................7-12

7.2.10 Other Commands .....................................................................................7-14

7.2.11 DC Voltage Control .................................................................................7-15

7.2.12 Digital Input/Output and DC Current Control.........................................7-16

7.3 PROGRAMMING HINTS ............................................................................7-17

ALPHABETICAL RS-232 COMMAND SET

APPENDIX A

....................................................................................... ...................... ..........A-1

APPENDIX B

POWERSCOPE PROGRAM

B.1 INTRODUCTION .........................................................................................B-1

B.1.1 Features....................................................................................................B-1

B.1.2 Operation Instructions..............................................................................B-2

B.1.3 Button Bar ...............................................................................................B-2

B.1.4 Configuring the Comm Port ....................................................................B-2

B.1.5 System Configuration ..............................................................................B-3

B.1.6 Operating Modes......................................................................................B-3

B.1.6.1 REAL TIME MODE. .....................................................................B-3

D.1.6.2 DEMO MODE. ...............................................................................B-3

B.1.7 Displaying Phasor & Impedance Diagrams.............................................B-4

B.2 PHASORS WINDOW...................................................................................B-5

B.3 SYMMETRICAL COMPONENTS ..............................................................B-5

B.3.1 Current Components Window.................................................................B-5

B.3.2 Voltage Components Window.................................................................B-6

B.3.3 Interpretation of Symmetrical Components Displays..............................B-7

B.4 IMPEDANCE WINDOW... .... .. .... .... .. .... .... ..... .... .... .. .... .... .. .... .... .. .... .... .. .... ..B-8

B.4.1 Using the Impedance Window................................................. .......... ......B-8

B.4.2 Defining & Displaying Theoretical Relay Characteristics ......................B-9

B.5 POWER WINDOW.......................................................................................B-10

B.6 SPECIAL NOTES .........................................................................................B-10

ALPHABETICAL RS-232 COMMAND SUMMARY

C.1 USER ERRORS - INAPPROPRIATE BUTTON PRESSING.....................C-1

C.2 HARDWARE ALARMS...............................................................................C-2

C.3 SOFTWARE ALARMS................................................................................C-4

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL ix

APPENDIX C

0$17$#7(67#6<67(06

Page 10

TABLE OF CONTENTS

............................................................................................................... D-1

.................................................................................................................E-1

GLOSSARY

INDEX

x MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

0$17$#7(6 7#6<67(06

CU M004 01A

Page 11

TABLE OF CONTENTS

LIST OF ILLUSTRATIO NS

Figure Title Page

Number Number

3.1 CONTROL MODULE PANEL.....................................................................3-1

3.2 D IGITAL I/O PA N EL ...... ........ ................ ......... ................ ........ ................ ....3-4

3.3 DC VOLTAGE PANEL................................................................................3-5

3.4 AC VOLTAGE PANEL................................................................................3-6

3.5 CONTROL MODULE REAR PANEL.........................................................3-7

3.6 TYPICAL THREE PHASE SYSTEM ..........................................................3-9

3.7 DISPLAY MESSAGES.................................................................................3-10

3.8 TEST CONNECTIONS.................................................................................3-10

3.9 BASIC AC ADJUSTMENTS........................................................................3-12

3.10 FREQUENCY ADJUST................................................................................3-14

3.11 DC VOLTAGE ADJUST..............................................................................3-15

3.12 DC CURRENT ADJUST ..............................................................................3-16

3.13 AC VOLTAGE VECTOR.............................................................................3-17

3.14 AC CURRENT VECTORS...........................................................................3-18

3.15 OVERCURRENT RELAY TEST .................................................................3-18

3.16 THREE TERMINAL DIFFERENTIAL RELAY TEST...............................3-22

3.17 INDEPENDENT COIL DIFFERENTIAL RELAY TEST ...........................3-25

3.18 VOLTAGE RELAY TEST............................................................................3-28

3.19 SYNCHRONIZING RELAY TEST..............................................................3-33

3.20 IMPEDANC E RELAY TEST .............. ...... ......... ...... .... ...... .... ...... .... ...... .... ..3-35

3.21 THREE PHASE IMPEDANCE RELAY TEST............................................3-37

3.22 IMPEDANC E RELAY TEST DISPLAY ................................................... ..3-38

3.23 GROUND OVERVOLTAGE RELAY TEST...............................................3-41

3.24 DC RELAY PICKUP TEST..........................................................................3-42

3.25 DC RELAY TIMING TEST..........................................................................3-43

4.1 EXAMPLE OUTPUT SEQUENCE (PREFAULT OFF)..............................4-2

4.2 EXAMPLE OUTPUT SEQUENCE (PREFAULT ON) ...............................4-2

4.3 FAULT STATE DIAGRAM FOR STATIC MODE ....................................4-3

4.4 FAULT STATE DIAGRAM FOR DYNAMIC MODE ...............................4-3

4.5 TEST CONNECTIONS FOR SC R OUTPUT TYPE RELAY . .... .... .... .... .... 4-6

4.6 DIFFERENTIAL RELAY HARMONIC RESTRAINT TESTING .............4-7

5.1 ROOT MENU................................................................................................5-1

5.2 MENU TREE SETTINGS.............................................................................5-4

5.3 PARALLEL MENU ......................................................................................5-7

5.4 PARALLEL CONNECTION........................................................................5-7

5.5 MENU TREE: PREFERENCES...................................................................5-14

5.6 MENU TREE: INDEX/OTHER....................................................................5-17

5.7 MENU TREE: DIGITAL I/O ........................................................................5-19

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL xi

0$17$#7(67#6<67(06

Page 12

TABLE OF CONTENTS

xii MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

0$17$#7(6 7#6<67(06

CU M004 01A

Page 13

INTRODUCTION - Section 1

INTRODUCTION

1.1 DISTINCTIVE CHARACTERISTICS

• Unique expandable modular design.

• Economical.

• Individual display and control of all voltages,

currents and phase angles.

• Built in “Quick-Test” functions for most

common relay elements.

• Output test reports directly to a printer.

• On- or Off-line programming via keypad and/or

rotary knob.

• Many productivity enhancing features.

• Static and dynamic testing.

• Compact and rugged.

1.2 GENERAL DESCRIPTION

The Manta MTS-3000 is a flexible modular test system, geared particularly towards protective relay

testing, but configurable for numerous other applications requiring AC and/or DC voltage and/or current

sources.

Systems can be as simple as a single phase AC current source, or as complex as a full three phase AC

voltage and current source with DC voltage and current, multi-channel digital input operation sensing and

digital output control, and accurate timing measurement capability. Multi-system control, with one system

functioning as the master to one or more slave units, is also possible. An economically priced system may

be configured with only the minimum number of features required for today’s applications, with the

flexibility to expand as tomorrow’s requirements and budgets dictate.

The MTS-3000 is specifically engineered for a short learning curve. A ‘Vector Control’ mode provides

for individual amplitude and phase adjustment of all AC voltage and current outputs, with the added

convenience of numeric keypad input for quick absolute control settings, or rotary knob control of

incremental changes to settings. Additional ‘intelligent control’ modes automate much of the setup

required for three phase test applications, and provide single-input control of multiple parameters as

found, for example, during phase-to-phase or three phase fault simulations.

A unique feature of the equipment is its ability to automatically test many protective relays using built-in

automated test routines. This permits fast, consistent testing for routine work that may not justify the

expense and learning curve necessary for full computer based testing. Field reports can be generated on

the spot using a portable printer.

CU M004 01A

0$17$#7(67#6<67(06

MTS-3000 OPERATION AND REFERENCE MANUAL 1-1

Page 14

INTRODUCTION - Section 1

An MTS-3000 System consists of a Control Module (CM), and one or more AC output modules. These

modules connect together to form a stack, with the control module at the top.

An AC Current Module (ACI), an AC Voltage Module (ACV), or an AC Voltage/Current Module (ACV/

I) may be easily added or removed from a stack to configure the system to your needs. All the required

electrical connections are made when a module is added to the stack. The CM recognizes and configures

the system for all the modules in a stack on power up. This "plug and play" capability allows modules to

be added or removed at any time.

1.3 APPLICATIONS

1.3.1 Standard Applications

•

Static and dynamic testing of virtually all protective relays.

•

Calibration and verification of V, I, W, Z, and Frequency transducers.

•

T esting of fault recorders, fault locators, and automatic voltage regulators.

•

Testing and calibration of metering systems.

1.4 TERMINOLOGY

The following terminology is use d throughout this user’s guide:

1.4.1 AC Current Module (ACI)

The AC current module or ACI refers to the MTS-3060 module. This module can have from one to three

AC current chan nels.

1.4.2 AC Volt age Module (ACV)

The AC voltage module or ACV refers to the MT S- 3040 module. This module can have from one to three

AC voltage channels.

1.4.3 Control Mo du l e (CM )

Control module or CM refers to the upper most module that makes up the MTS stack.

1.4.4 Device Under Test (DUT)

DUT refers to the protective relay or similar device being tested.

1.4.5 Dynamic Fault Mode

This mod e re fers to t he fault mode that’s used w he n p erforming operate time t est s. See Section 4. 3 .2 fo r a

detailed explanat ion.

1-2 MT S-3000 OP ERA TIO N AND REFERE NCE MANUAL

0$17$#7(67#6<67(06

CU M004 01A

Page 15

INTRODUCTION - Section 1

1.4.6

Dynamic Relay Testing

Dynamic relay testing refers to testing of relays using instantaneous steps and/or ramping of voltage and

current inputs. To closely simulate the conditions the device sees in service, the voltages and currents are

typically stepped from a nominal, prefault level, to a predetermined fault level.

1.4.7 MTS

The "modular test system" MTS-3000 and its various optional modules.

1.4.8

On Panel Testing

This refers to testing of relays and relay systems while they’re installed on panels or equipment racks.

This involves injecting voltages or currents directly into the panel to test the complete system response,

and to verify the correct input/output wiring and phasing of the panel.

1.4.9 Programming Mode

Programming mode is used to preset AC output parameters for either prefault or fault state. The AC

outputs are disabled while the system is in programming mode.

1.4.10 Static Relay Testing

This refers to relay testing by slowly varying inputs to accurately locate pickup points and to perform

repeatable measurements.

1.4.11 Test Mode

The AC outputs are enabled while in test mode.

1.4.12 V/I Module (VI)

The V/I module or VI refers to the MTS-3030 module. This module can be ordered with either one or two

convertable AC output channels. Each channel can operate in either voltage mode (0-150 V), or current

mode (0-25 A).

1.4.13 WFG Module

WFG refers to waveform generation modules such as the MTS-3030, MTS-3040, and MTS-3060.

1.5 SAFETY CONSIDERATIONS

The MTS-3000 can generate high levels of current and voltage. Incorrect usage may cause personal injury

and/or damage to the instrument. The user must be qualified to work safely in the intended application

environment of this instrument. Non-adherence to the following minimum requirements constitutes

misuse of the Modular Test System, MTS, and the manufacturer accepts no liability for damages arising

from such misuse.

CU M004 01A

0$17$#7(67#6<67(06

MTS-3000 OPERATION AND REFERENCE MANUAL 1-3

Page 16

INTRODUCTION - Section 1

The instrument case must always be effectively grounded. The rear panel grounding stud of the Control

Module, CM, must be connected by a minimum 12-gauge wire to a known secure ground. This ground is

in addition to the power cord ground.

All leads and connectors must be in good condition and rated for the voltage and current carrying

requirements. Current outputs must be securely connected with a minimum 12 gauge leads with C-hook

term ina ls.

MTS outputs must not be connected to live outputs or to live equipment. All outputs must be turned off

before making any changes to the connec tions. Never exceed the following maximum ratings:

(a) 300V rms to ground on any input, power or control.

(b) 300VDC differential to the contact (external trigger) inputs.

(c) 5Arms or 5A DC through any contact output.

All rear panel fuses must contain properly rated fuses.

1.6 TECHNICAL CONSIDERATIONS

The optional DC current source, when enabled, will source up to 2.5A of DC current out of the two left

terminals of Input 1 of the DIGITAL I/O module. The low impedance nature of this source could provide

the necessary trip path to inadvertently trip an auxillary relay or circuit breaker. The DC current output

only should be used when the protective relays trip output circuit is properly isola te d.

1.7 TECHNICAL SUPPORT

The design of the MTS reflects decades of experience in the electric power industry. However, we

recognize that situations may be encountered that were not considered during its design. We encourage

you to forward any questions, problems or suggestions to us either through the representative from whom

you purchased your system, or directly to us via the phone, fax or e-mail numbers found on the front

cover.

1-4 MT S-3000 OP ERA TIO N AND REFERE NCE MANUAL

0$17$#7(67#6<67(06

CU M004 01A

Page 17

SPECIFICATIONS

NOTE: All specifications are subject to change. All AC quantities are RMS values, except as

otherwise noted.

Power outputs are specified for nominal 120VAC/60Hz or 240VAC/50Hz power input,

and 25°C ambient operating temperature.

For some configurations, the 15A / 7.5A rating may be exceeded if all outputs are at

full power. Derating applies for lower input power voltages and higher ambient

temperatures. For all current outputs, maximum obtainable current will vary inversely

with load impedance. For extended operation at high power output levels, ensure

adequate cooling (i.e. don’t obstruct cooling intakes or exhaust outlets).

2.1 INPUTS

110-130 VAC @ 15A, Single phase, 47-63 Hz, or

210-250 VAC @ 7.5A, Single phase, 47-63 Hz (Future)

SPECIFICATIONS - Section 2

2.1.1 MTS-3010 Digital I/O Module (Optional)

NC or NO wet/dry contact inputs, Start/Stop trigger inputs for fault initiation/termination

Programmable contact de-bounce delay, 0.1 - 999.9 msec, 0.1 msec resolution

300VDC/AC maximum, fully isolated (12V threshold level, 52K ohms impedance minimum)

2.2 OUTPUTS

2.2.1 AC Voltages: MTS-3040 AC Voltage Module

One to three direct coupled outputs depending on configuration, connected wye (common neutral)

0-150V rms phase to neutral, direct coupled

100 VA per phase maximum @ 70V Φ-N output, P.F.=1.0

125 VA per phase maximum @ 150V Φ-N output, P.F.=1.0

Setting resolution 0.01V:Accuracy greater of 0.25% of setting or 0.1% of full scale

Fully short circuit proof and thermal overload protected

2.2.2 AC Currents: MTS-3060 AC Current Module

0-25A rms, 250 VA maximum per channel, direct coupled

12A rms continuous

Three-phase wye current: 12A rms continuous per channel

25A rms per channel into 0.25 ohm load

Single phase current, three channels in parallel, high current range: 0-75A rms, 300 VA, 30% duty cycle

Single phase current, three channels in parallel, high voltage range: 0-35A rms, 600 VA, 30% duty cycle

Fully open and short circuit proof and thermal overload-protected

Setting resolution 0.001 Amps: Accuracy greater of 0.25% of setting, or 0.1% of full scale

CU M004 01A

MTS-3000 OPERATION AND REFERENCE MANUAL 2-1

0$17$#7(67#6<67(06

Page 18

SPECIFICATIONS - Section 2

2.2.3 AC Voltage and Current: MTS-3030 AC Voltage/Current Module

One or two outputs, depending on configuration, connected common neutral

0-150V rms phase to neutral, direct coupled, specifications as for MTS-3040 module above

0-25A rms, 120 VA maximum per channel, specifications as for MTS-3060 module above

Can be configured for any voltage and/or current combination of two output channels

Fully open and short circuit proof and thermal overload-protected

2.2.4 Output frequency

Power Line, frequency and phase locked

Variable: 8.000 - 99.999 Hz (0.001 Hz resolution, 0.01% accuracy)

100 - 499.99 Hz (0.01 Hz resolution, 0.02% accuracy)

500 - 1000 Hz (0.1 Hz resolution, 0.02% accuracy)

Two independently variable frequencies are available.

2.2.5 Harmonics

Harmonic mode for harmonic restraint testing

Single harmonic, 2nd through 10th, maximum harmonic frequency = 1000 Hz

Harmonic amplitude 0 - 50% of fundamental

2.2.6 Phase control

Phase angle of all AC outputs adjustable from 0 to 360°

Setting resolution: 0.1° (Accuracy: 0.5°)

2.2.7 DC Voltage: MTS-3020 DC Voltage Module

This optional module installs in the Control Module case.

DC voltage output 0-300 VDC @ 100W maximum

Setting resolution 0.1V: Accuracy greater of 1% of setting or 0.75V

Current Limit: 2A, fully short circuit proof

2.2.8 DC Current: Current Source option

0-2.5A DC @ 20VA maximum

Maximum compliance voltage: 12V

Setting resolution: 0.001 AmpsAccuracy: greater of 1% of setting, or 10mA

Current Limit 2.5A, fully open and short circuit proof

2.2.9 MTS-3010 Digital I/O Module (Optional)

Programmable auxiliary contact output, fully isolated

5A @ 300VAC, 1A @ 125VDC, 0.5A @ 250VDC, 0.35A @ 300VDC resistive load

Breaker signal (52A/52B) simulation

Permissive/unblock signal simulation with programmable delay, 0 - 9999.0 msec, 0.1 msec resolution.

2-2 MTS-3000 OPERATION AND REFERENCE MANUAL

0$17$#7(67#6<67(06

########################################################

CU M004 01A

Page 19

SPECIFICATIONS - Section 2

2.3 METERING

2.3.1 Time measurem en t

Measures interval from eithe r fault initiation or an external start trigger signal

0 - 99999 sec, auto-ranging scale

0 - 99999 cycles, auto-ranging scale

Resolution: 0.1 ms/ 0.1 cyclesAccuracy: ± 0.5ms, ± 1 digit

Two wire pulse timing mode

2.3.2 Frequency measurement

Resolution, 8Hz - 99.999Hz: ± 0.001 HzAccuracy: ± 0.01 Hz

Resolution, 100Hz - 499.99Hz: ± 0.01 Hz Accuracy: ± 0.05 Hz

Resolution, 500Hz - 1000.0Hz: ± 0.1 Hz Accuracy: ± 0.1 Hz

2.4 STATIC/DYN AMIC TES TING CAPABILITI ES

Phase to ground, phase to phase and three phas e faul ts (when equipped with sufficient modules)

Phase, frequency, volta ge and current ramping with adjustable ramp rates

Programm abl e au to -rec los e t ime d el ay an d rec lose-into-fault ev ent s

Programmable breaker opening and closing times

Fault incidence angle control (point-on-wave)

2.5 OPTIONS

Control Module Options:

Option 01 MTS-3010 Programmable Digital I/O Module with trigger channels.

Option 02 DC Current Source. Option 01 must be present.

Maximum configuration: one per Contro l Module, two if there’s no DC Voltage Module.

Option 03 Digital I/O Expansion. Option 01 must be present (Future).

Option 04 MTS-3020 DC Voltage Module.

Maximum configuration: one per Contro l Module.

Option 05 240V, 50/60 Hz line input Control Module.

2.5.1 System Options

Option 18 Digital I/O and DC Voltage Test Lead Kit

Option 19 Additional Operati on and Reference Manual

Option 20 Additional One Year extended warranty

2.5.2 AC Voltage Module Options

Option 41 240V, 50/60 Hz line input

Option 42 2nd AC Voltage Channel

Option 43 3rd AC Voltage Channel

Option 44 AC Voltage Test Lead Kit

Maximum configuration: three Channels per ACV Module, two Modules per stack

CU M004 01A

MTS-3000 OPERATION AND REFERENCE MANUAL 2-3

0$17$#7(67#6<67(06

Page 20

SPECIFICATIONS - Section 2

2.5.3 AC Current Module Options

Option 61 240V, 50/60 Hz line input

Option 62 2nd AC Current Channel

Option 63 3rd AC Current Channel

Option 64 AC Current Test Lead Kit

Maximum configuration: three Channels per ACI Module, two Modules per stack.

2.5.4 AC Voltage/Current Module Options

Option 31 240V, 50/60 Hz line input

Option 32 2nd AC Current Channel

Option 33 3rd AC Current Channel

Option 34 AC Current Test Lead Kit

Maximum configuration: two Channels per ACV/I Module, two Modules per stack.

2.6 PHYSICAL CHARACTERISTICS

2.6.1 Minimum Configuration

Control Module and one AC Voltage module, one AC Current module, or one AC Voltage/Current

module. Modules connect together in a stack, with the Control Module on the top, shipped in a hard shell

shipping case with a removable protective front cover.

2.6.2 Control Module

14 3/4" W x 6 3/4" H x 11 3/8" D (37.5cm W x 17.2cm H x 29.0cm D)

Weight: 17.8 lbs. (8.1 kg). Includes MTS-3010, MTS-3020, top and bottom covers.

Built-in side carry handles.

2.6.3 AC Voltage Module

14 3/4" W x 6 3/4" H x 11 3/8" D (37.5cm W x 17.2cm H x 29.0cm D)

Weight with three Channels: 23.2 lbs (10.5 kg)

2.6.4 AC Current Module

14 3/4" W x 6 3/4" H x 11 3/8" D (37.5cm W x 17.2cm H x 29.0cm D)

Weight with three Channels: 28.8 lbs (13.1 kg)

2.6.5 AC Voltage/Current Module

14 3/4" W x 6 3/4" H x 11 3/8" D (37.5cm W x 17.2cm H x 29.0cm D)

Weight with two Channels: 27 lbs (12.2 kg)

2.6.6 Three Phase System: Control Module, AC Voltage and AC Current Modules

Weight with three voltage and three current channels, top and bottom covers and the protective front

cover 69.8 lbs (31.7 kg)

2-4 MTS-3000 OPERATION AND REFERENCE MANUAL

0$17$#7(67#6<67(06

########################################################

CU M004 01A

Page 21

OPERA TION SUMMARY

3.1 FRONT PANEL LAYOUT

3.1.1 MTS-3 000 C o ntrol Mo du l e, CM

OPERATION SUMMARY - Section 3

FIGURE 3.1 CONTROL MODULE PANEL

1. ENABLE PUSHBUTTON

This pushbutton enables the AC outputs. If the enable status LED isn’t lit, the outputs are disabled

and there will be no AC current or voltage available from the output terminals of the AC output

modules. This is defined as Programming mode.

When the outputs are e nabled by pressing this pushbutton, the enable status LED will light, as will

the output channel warning LEDs of all AC output module channe ls that are equipp ed with voltage

or current sources. This is define d as Test mode.

2. PREFAULT PUSHBUTTON

This pushbutton selects the Prefault state for off-line programming (ENABLE off) or toggles the

Prefault mode on or off (ENABLE on, Test mode). Current status is indicated by the PREFAULT

LED.

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL 3-1

###################################0$1 7$#7( 67#6<67(06

Page 22

OPERATION SUMMARY - Section 3

•ON - System is in Programming mode, prefault state is selected.

•BLINKING - System is in Test mode, prefault state is selected and active.

•OFF - Either the system isn’t in PREFAULT state or Prefault mode isn’t selected.

3. FAULT PUSHBUTTON

This pushbutton selects Fault state for off-line programming (ENABLE off), or causes the MTS to

enter Fault state (ENABLE ON, Test mode).

Momentary operation (<250 msec.) of the pushbutton latches the MTS into Dynamic Fault state

until RESET is pressed or the Device Under Test (DUT) operates, as detected by an Input channel

on the DIGITAL I/O module. Sustained pressing of the pushbutton maintains the equipment in

Fault state only as long as it’s held depressed, and trip operations of a DUT will be annunciated,

but won’t trip off the outputs.

Current status is indicated by the FAULT LED

• ON - System is in Programming mode, FAULT is selected for programming

• BLINKING - System is in Test mode, FAULT is selected and active

• OFF - System is in either PREFAULT or POSTFAULT state

4. RESET PUSHBUTTON

This pushbutton is pressed to restore the system to Prefault state either following an operation of a

DUT (i.e. the system is in Postfault mode), or during a Fault sequence. It clears the timer reading

to zero while restoring any frozen AC output readings to normal.

When the TRIP LED above the RESET button is on, it indicates the system is in POSTFAULT

state as a result of a trip (DUT operation) during FAULT state.

5. MODIFY KNOB

This rotary knob can be used to make incremental changes to any currently selected parameter,

such as amplitude, phase, or frequency. Clockwise increases the value; counterclockwise decreases

it. Turning it faster makes larger coarser adjustments; slower makes smaller finer adjustments.

When performing data entry with the keypad, the knob is disabled until ENTER is pressed. The

knob is also used to scroll through menu items.

6. NUMERIC KEYPAD

These keys are used to enter numeric data, and to modify the currently selected parameter, such as

amplitude, phase, or frequency.

7. ENTER KEY

This key is used to signal the end of a numerical entry sequence, and to restore operation of the

MODIFY knob.

3-2 MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

#0$17$#7(67#6<67(06###########################################

CU M004 01A

Page 23

OPERATION SUMMARY - Section 3

8. CANCEL ENTRY KEY

This key is pressed to clear all numbers just entered on the keypad. The BACK pushbutton (10)

will clear a single numeric entry. A second press of CE will restore the previously entered value.

9. FUNCTION KEYS

These keys are press ed to select or enable modification of a reading or parameter on the respec tive

line of the adjacent four-line liquid crystal display (LCD).

10. BACK PUSHBUTTON

This pushbutton is pressed to back up one level through the menu which appears on the display

above it, as well as to back up one key entry on the numeric keypad (6). Pressing it during normal

operation will force the display to menu mode and directly restore the user to the last menu option

accessed.

11. MENU PUSHBUTTON

Pressing this pushbutton toggles on or off an extensive menu which appears on the display above

it.

12. HELP PUSHBUTTON

Context sensitive help regarding operati on of many of the MTS system’s controls may be called up

by pressing this pushbutt on.

13. POWER PUSHBUTTON

This pushbutton turns on or off the mains power to the Control Module and to any AC output

modules connected to the Control Modul e.

14. ALPHANUMERIC DISPLAY

This Liquid Crystal Displa y (LCD) provides infor mation on current equ ipment status , and displa ys

numerous menu options.

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL 3-3

###################################0$1 7$#7( 67#6<67(06

Page 24

OPERATION SUMMARY - Section 3

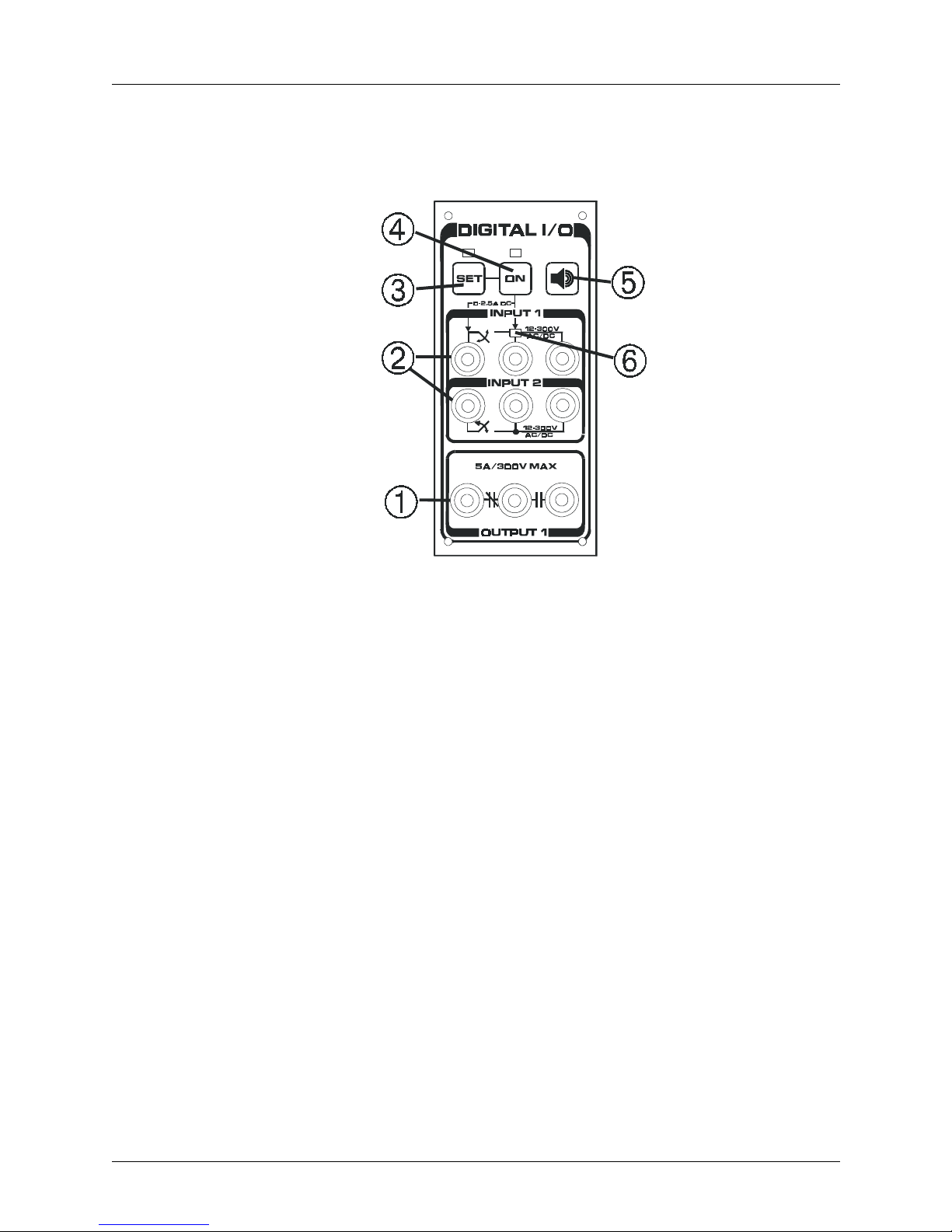

3.1.2 MTS-3010 Digital I/O Module

FIGURE 3.2 DIGITAL I/O PANEL

1. OUTPUT CONTACT TERMINALS

By default these contacts are configured, as indicated by the NC/NO symbols shown on the panel,

and contact changeover follows Fault mode status. Other modes are programmable via the menu.

2. INPUT SENSING TERMINALS

Operation of a Device Under Test (DUT) may be sensed by these inputs, either a dry or wet

contact operation, or a change in status of an AC/DC voltage. Debounce times on input sensing are

programmable. These high impedance inputs are galvanicly isolated from one another and from

the MTS system.

3. SET PUSHBUTTON

Selection of this pushbutton opens menu options on the Control Module display to allow

programming of options for the inputs and outputs, plus adjustment of the DC Current, if this latter

option is fitted.

4. ON PUSHBUTTON

This pushbutton toggles on or off the optional DC Current output to the two left terminals of Input

1. When DCI is enabled by this switch, whenever an external relay contact (in series with a DC

current operated target) closes, the programmed DC current will flow through the external circuit.

3-4 MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

#0$17$#7(67#6<67(06###########################################

CU M004 01A

Page 25

5. TONE PUSHBUTTON

This pushbutton togg les on or off the audible indicator associated with the change of state det ector

circuits monitoring Input 1.

6. OPERATION SENSE LED

This LED illuminates if a change of contact state from NO to NC, or a change in voltage from off

to on, is sensed by Input 1. It’s particularly useful if the output contact of the relay being tested

cannot easily be observed, as is often the case with electronic relays.

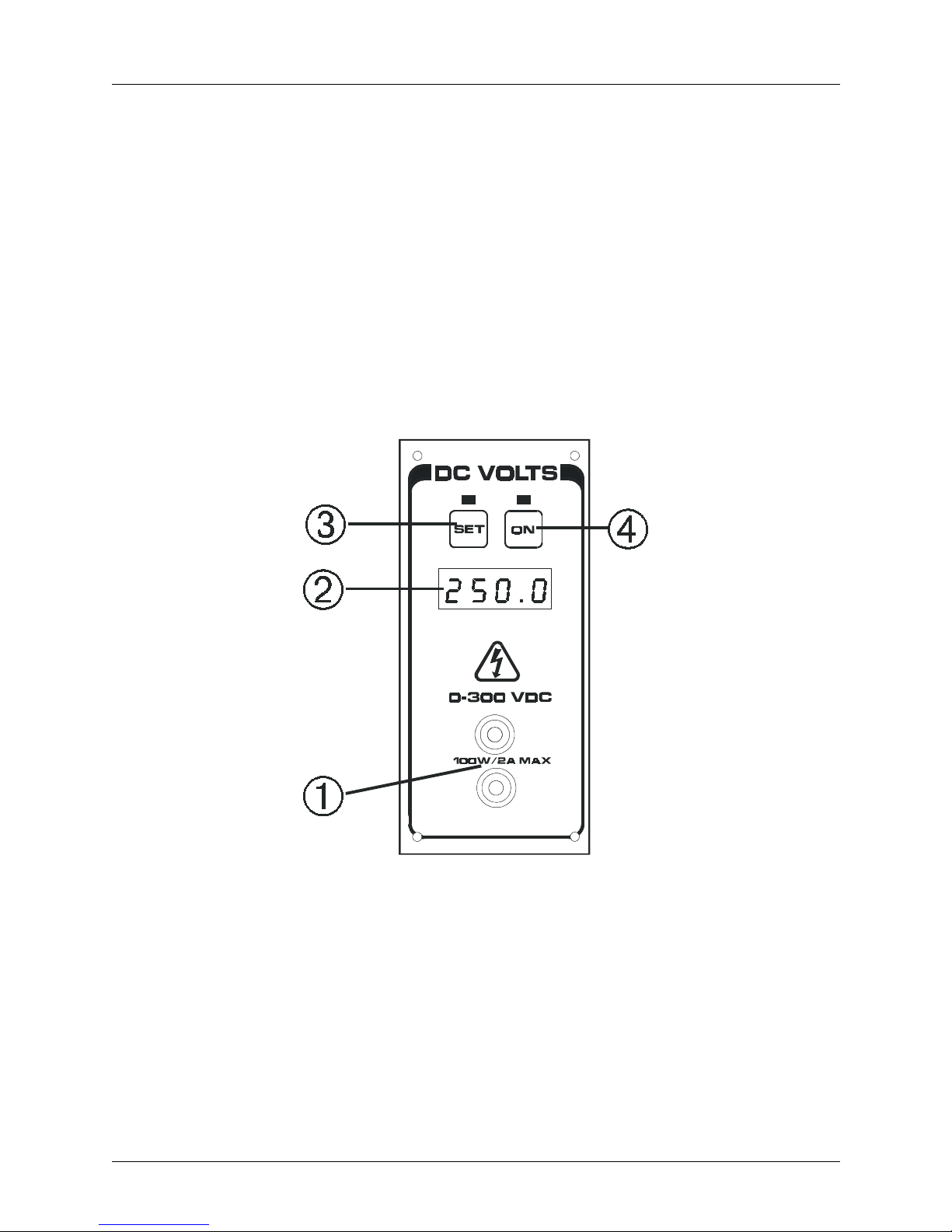

3.1.3 MTS-3010 DC Voltage Source

OPERATION SUMMARY - Section 3

1. OUTPUT TERMINALS

Up to 300VDC at 100 W is available here.

2. DC VOLTAGE DISPLAY

The present setting of the DC voltage module is displayed on this LED display.

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL 3-5

###################################0$1 7$#7( 67#6<67(06

FIGURE 3.3 DC VOLTAGE P ANEL

Page 26

OPERATION SUMMARY - Section 3

3. SET PUSHBUTTON

Pressing this pushbutton opens a menu on the main display of the Control Module to enable

adjustment of the DC voltage setting via the MODIFY keyboard and rotary knob.

4. ON PUSHBUTTON

This pushbutton toggles the output of the module on and off. Output On status is indicated by

illumination of the LED above the pushbutton.

3.1.4 MTS-3040 AC Voltage Module

Note: Features of the MTS-3060 AC Current and -3030 Voltage/Current modules are virtually

identical.

1. ALPHANUMERIC DISPLAY

This Liquid Crystal Display (LCD) provides information on current equipment status, including

amplitude and phase angle of each output source fitted to the unit.

2. FUNCTION KEYS

These keys are used to select a parameter prior to modifying it. The first press selects amplitude of

a given output, while the second selects its phase angle.

3. COOLING INTAKE/FILTER

The filter on this cooling intake may be removed for cleaning if necessary.

3-6 MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

#0$17$#7(67#6<67(06###########################################

FIGURE 3.4 AC VOLTAGE PANEL

CU M004 01A

Page 27

4. OUTPUT STATUS LEDS

Illumination of these LEDs indicates that the outputs are enabled and capable of delivering energy

to a connect ed load, even if the output settings are presently at zero. If a module doesn’ t have a full

complement of output sources, only those outputs equipped with an output source will illuminate.

5. OUTPUT TERMINALS

Connection is made here to the device(s) under test.

3.2 REAR PANEL LAYOUT

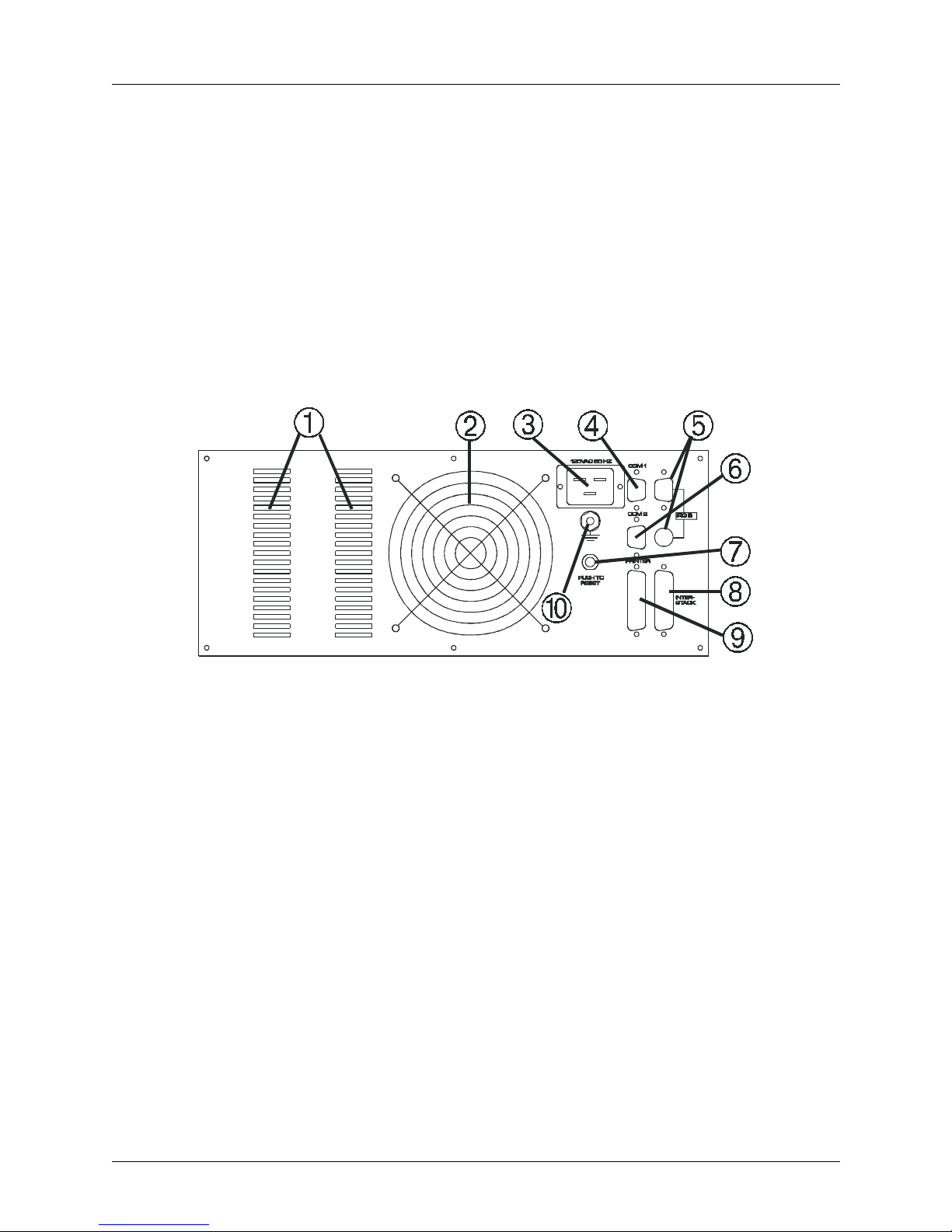

3.2.1 MTS-3 000 C o ntrol Mo du l e Re ar Panel

OPERATION SUMMARY - Section 3

FIGURE 3.5 CONTROL MODULE REAR PANEL

1. COOLING INTAKES

For adequate cooling, ensure that these are not obstructed.

2. COOLING EXHAUST

Ensure that warm air exiting isn’t restricted nor reflected back towa rds intakes.

3. AC INLET

For 120V or 240V main supply, as indicated by panel label.

4. COM 1 RS232C PORT

Female DB-9 serial port wired as a DCE (Data Communications Equipment) for external PC or

DUT.

5. IRIG B CONNECTORS (OPTIONAL)

Connect to IRIG B datastream from GPS receiver.

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL 3-7

###################################0$1 7$#7( 67#6<67(06

Page 28

OPERATION SUMMARY - Section 3

6. COM 2 RS232C PORT

Male DB-9 serial port wired as a DTE (Data Terminal Equipment) for external PC.

7. MAINS CIRCUIT BREAKER

Press to reset if breaker trips.

8. EXTERNAL CONNECTOR

External I/O connector to run one or more systems in a master-slave configuration.

9. PRINTER PORT

Connects to external printer to print Quick-Test reports.

10. GROUNDING STUD

Connect to a secure external ground during testing.

3-8 MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

#0$17$#7(67#6<67(06###########################################

CU M004 01A

Page 29

OPERATION SUMMARY - Section 3

3.3 BASIC APPLICAT IONS

3.3.1 Getting Started

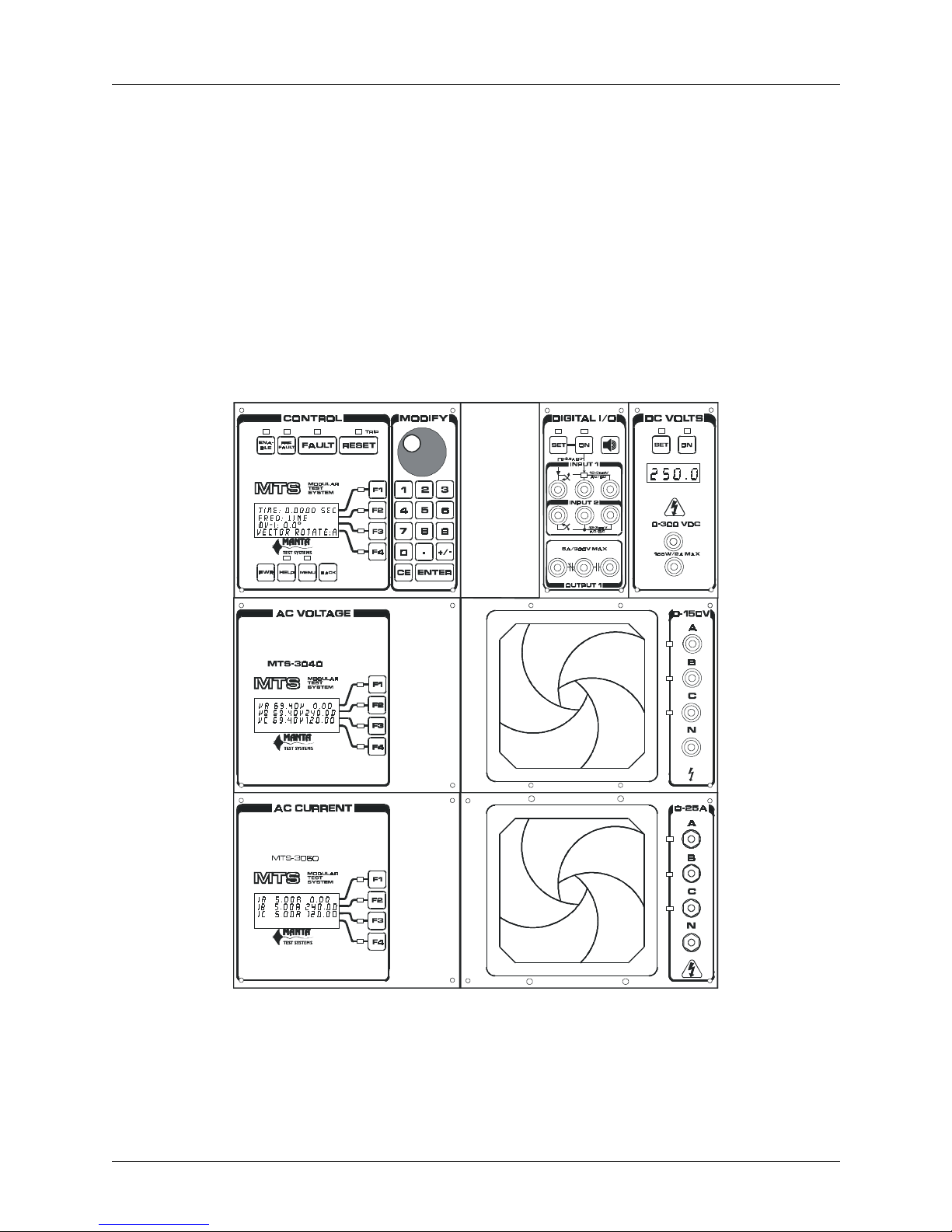

Because of its modularity, the MTS-3000 series system can be configured in many different ways. It’s not

feasible to provide a detailed operation description for every possible configuration. Except where noted,

the assumption is the equipment is configured as a three phase protective relay test system equipped with

three AC voltage sources, three AC current sources, a digital I/O module with DC current sourcing, and a

DC voltage module, as illustr ated below. Specific examples of less fully equipped syste ms will be provided

in the Detailed Operation section of this manual.

FIGURE 3.6 TYPICAL THREE PHASE SYSTEM

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL 3-9

###################################0$1 7$#7( 67#6<67(06

Page 30

OPERATION SUMMARY - Section 3

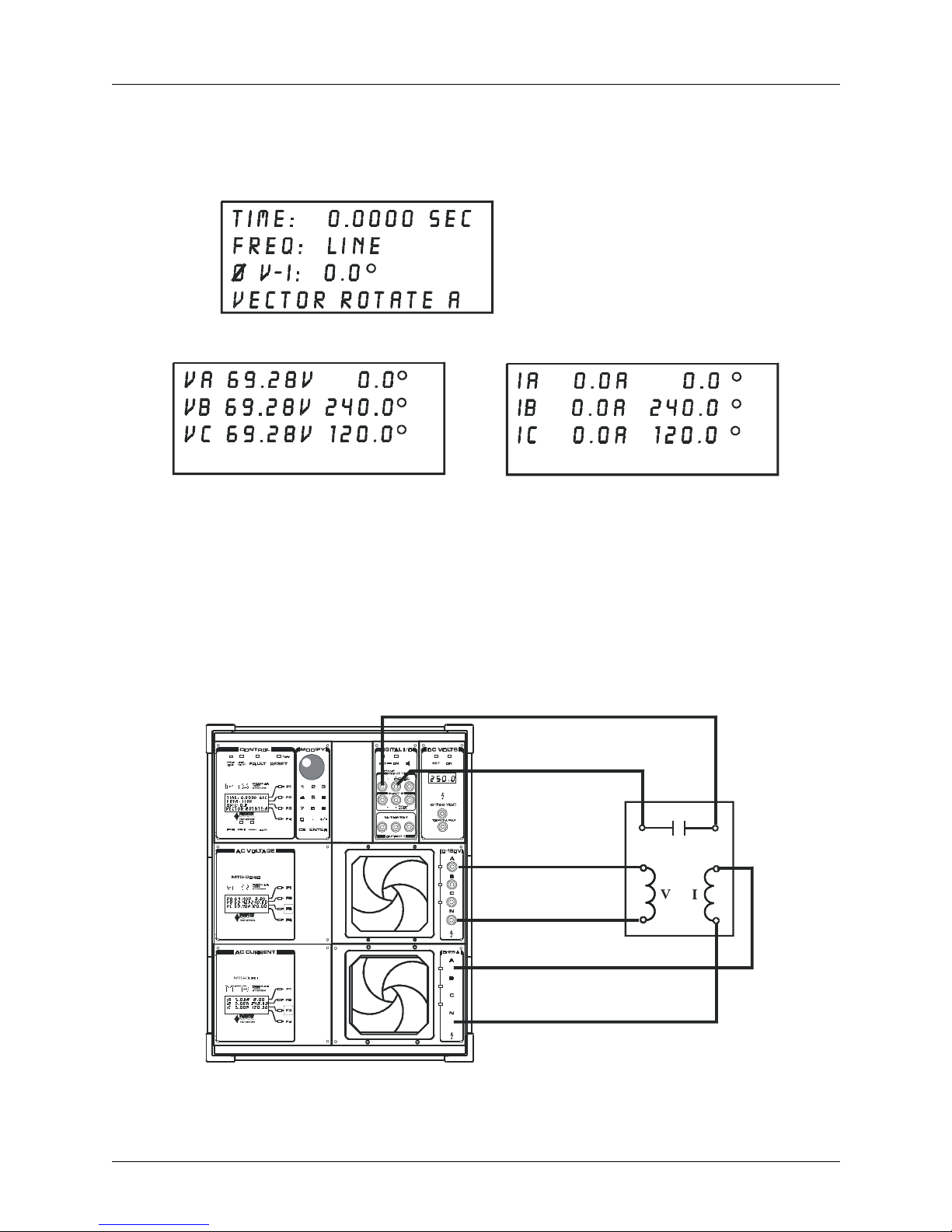

Connect mains power to the Control Module (CM), the rear panel chassis safety ground to a known good

ground, and press PWR. A momentary message, indicating software version number and other

information, appears briefly on the CM display. LEDs are turned on briefly, and then the default displays

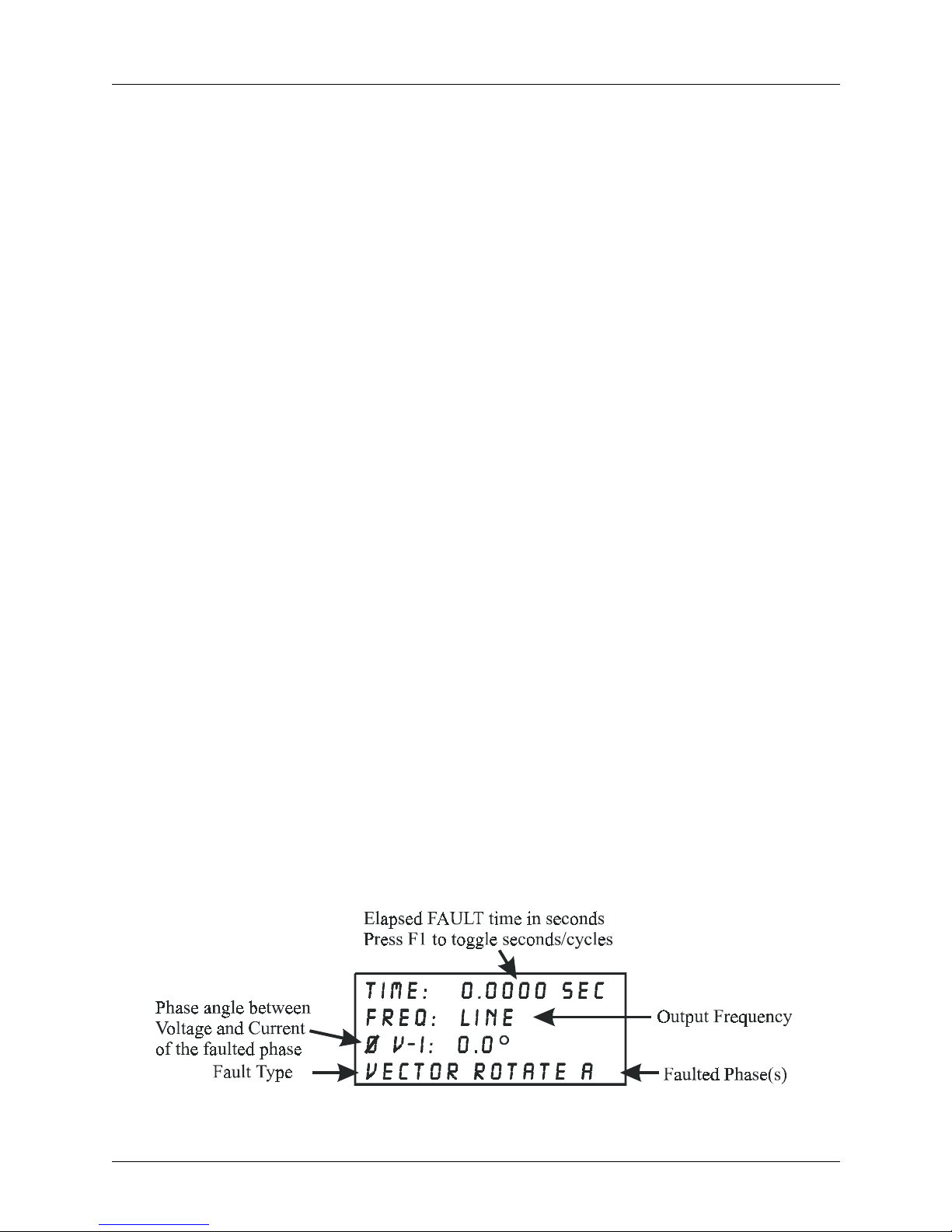

will appear as shown below:

The voltage and current modules will show default values as shown respectively below:

FIGURE 3.7

DISPLAY MESSAGES

These values correspond to a balanced three-phase voltage of 120V phase-to-phase, and current which will

be in phase with the voltage. If an output module isn’t fitted with a full complement of output sources,

there will be less data on the display(s). If the current output module, for example, has only two current

sources, only lines IA and IB will appear on the display.

The example that follows illustrates some of the important operating aspects of the system. It’s assumed

that a single phase impedance relay with a time delay response is connected to the MTS-3000 system,

operating at approximately 50 volts and seven amps, with a phase shift between voltage and current of 75°.

3-10 MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

#0$17$#7(67#6<67(06###########################################

FIGURE 3.8

TEST CONNECTIONS

CU M004 01A

Page 31

OPERATION SUMMARY - Section 3

The voltage coil is conne cted to AC voltage terminals A and N, the current coil to AC current terminals A

and N, and the relay output contact to INPUT 1 terminals of the DIGITAL I/O module. If it’s desired to

follow through the steps of the test process using your MTS system, a short jumper cord with male banana

terminals can be inserted into the two left terminals of INPUT 1 at the appropriate times to simulate relay

operation. It will be necessary to provide a current path by shorting terminals A and N of the current

module with a second jumper cord.

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL 3-11

###################################0$1 7$#7( 67#6<67(06

Page 32

OPERATION SUMMARY - Section 3

3.3.2 Basic AC Voltage, Current and Phase Angle Output

1.Ensure the system outputs are disabled. Press

ENABLE, if necessary, to extinguish its LED. Select

FAULT mode by pressing FAULT. The FAULT LED

lights to confirm the selection.

2. Press F1 of the voltage module. Its LED lights to

indicate selection of channel VA, and a flashing cursor

appears beneath the V on the first line of the adjacent

display.

3.Press 5, 0,., 0, and ENTER on the MODIFY keypad.

Channel VA amplitude reading follows the typed input

and changes to 50.00 V.

4.Press F1 on the current module. Its LED lights to

indicate selection of channel IA, and a flashing cursor

appears beneath the A on the first line of the adjacent

display. The LED on channel VA goes out.

5.Press 7,

Channel IA amplitude reading follows the typed input

and changes to 7.00A.

6.Press F1 again on the current module. Its LED remains

lit, and a flashing cursor appears beneath the degree

symbol (

7.Press 7, 5,

Channel IA phase angle reading follows the typed

input and changes to 75.0

FIGURE 3.9 BASIC AC ADJUSTMENTS phase angle reading on the CM display also changes to

75.0

8.Press ENABLE. The ENABLE LED lights.

9.Press and hold FAULT. The FAULT LED flashes to indicate fault state is active. The output warning

LEDS next to the output terminals of the current and voltage modules are also lit, indicating that the

outputs are enabled. The programmed (and other default) AC voltage and current values appear at the

outputs until the FAULT button is released.

, 0, 0, and ENTER on the MODIFY keypad.

.

°) on the ‘IA’ line of the display.

, 0, and ENTER on the MODIFY keypad.

.

°. The voltage-to-current

°.

If the programmed values in the example above were sufficient to operate the relay connected to the

outputs of the MTS system, then, upon operation of the relay the LED indicator associated with INPUT 1

will light, and the audible tone will sound. Once the FAULT button is released, the AC outputs return to

zero, the relay being tested drops out, and the indicator LED and tone turn off.

3-12 MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

#0$17$#7(67#6<67(06###########################################

CU M004 01A

Page 33

OPERATION SUMMARY - Section 3

If the chosen AC values were close to the relay operate point - but did not pick it up - the MODIFY knob

can be used to continuously vary one parameter until the pickup point is determined. Consider, for

example, that the voltage and phase angles were appropriate, but the current was too low.

10. Reselect IA current amplitude adjust mode by pressing F1 on the current module. Note that the initial

press selects amplitude adjust mode, the second press phase angle adjust mode, the third press

deselects that channe l (LED will go out), and the fourth press selects amplitude adjust mode again.

11. Press and hold the FAULT button, and rotate the MODIFY knob slowly cloc kwise until the relay being

tested operates, as ver ified by the DIGIT AL I/O visual (LED) and audible indicators.

12. If it’s desired to verify the operate point more precisely, the MODIFY knob is rotated

counterclockwise and clockwise, as required, to lower and raise respectively the output current

through the operate point.

Now consider that a timing check is to be done on the relay under test at a current well above the operate

point. For this example, it will be assumed that the relay minimum pickup occurred at 7.00 amp s a nd th e

timing check is to be performed at 10.00 amps.

13. Disable the outputs by pressing ENABLE. The ENABLE LED and the AC output warning LEDs will

go off. This permits the readjustment of current amplitude to be done ‘off line’.

14. Press FAULT. I ts status LED will light.

15. Reselect IA current amplitude adjust mode by pressing F1 on the current module. Press 1, 0,

., 0, and

ENTER on the MODIFY keypad. This new value appears in the IA channel display.

16. Press ENABLE to re-enable the AC outputs. The ENABLE LED lights.

17. Press the FAULT button briefly only. This automatically latches the system into Dynamic Fault mode,

the FAULT LED begins to flash slowly to indicat e the FAUL T mode is active, and the timer reading in

the first line of the Control Module display begins incrementing. The AC output warning LEDs light,

and the programmed AC values appear at the AC output terminals.

18. When the relay operates, it trips off the AC outputs of the MTS, freezes the timer a nd AC output

readings, and enters the ‘Post Fault’ state, as indicated by extinguishing of the FAULT LED and

illumination of the TRIP LED located above the RESET pushbutton.

19. Once the timing results have been observed and, if necessary, recorded, the system is returned to

normal by pressing RESET. This resets the timer and V/I readings, and extinguishes the TRIP LED.

Note the important difference in this ‘dynamic fault’ mode compared to the ‘static fault’ mode described in

steps 1-12.

CU M004 01A

MTS-3000 SERIES OPERATION AND REFERENCE MANUAL 3-13

###################################0$1 7$#7( 67#6<67(06

Page 34

OPERATION SUMMARY - Section 3

STATIC FAULT MODE

When the FAULT button is pressed and held, the system is in static fault mode. The AC outputs stay

energized as long as the FAULT button is held on, and the appearance of a trip signal at the DIGITAL I/O

module INPUT 1 will annunciate, but won’t trip off the AC outputs.

DYNAMIC FAULT MODE

A brief (<250 msec.) press on the FAULT button latches the system into dynamic fault mode. In this mode,

the AC outputs latch on until terminated by either pressing RESET or by appearance of a trip signal from

the relay under test, as monitored by INPUT 1 of the DIGITAL I/O module.

Typically, static test mode is used for accurate determination of pickup points, where it’s desired to swing

AC outputs repeatedly through the operate point without interrupting the outputs. Dynamic test mode is

usually used for timing checks, especially at higher current levels where it’s desirable to minimize the time

the current is applied to the device under test.

3.3.3 Frequency Output

By default, all AC outputs are synchronized to the input line frequency. Variable frequency mode can

generate one or two different frequencies for each fault state in the range of 8 to 1000Hz. Any output or

combination of outputs can be assigned to either of the frequency sources.

3.3.3.1 BASIC FREQUENCY OUTPUT.

Basic frequency mode allows one or more channels to be selected to output a frequency (Frq1) in the range

of 8 - 1000Hz. All other output channels will remain at the default "LINE" frequency. Frequency 1 (Frq1)

can be set to different frequencies for prefault and fault state, if desired.

1.Select the desired fault state - either prefault or

fault.

2.Press F2 in the MODIFY section of the CM. This

enables frequency adjust mode, the LED lights,

and the second and third lines of the display

change, as shown.

3.Enter the desired new frequency via the MODIFY

numeric keypad followed by ENTER, or by turning the rotary knob until the desired frequency is

shown on the second line of the display.

4. Individual output channels now may be assigned

this frequency by pressing their Fn keys. The

associated channel LEDs will flash to indicate

they’ve been set to the new frequency. A second

press of any Fn key will restore that channel to the

default line frequency. Deselecting F2 on the CM

by pressing it again locks all previously assigned

(flashing) channels to Frequency 1, disables the

MODIFY input, turns off the F2 LED, and returns

the display to normal.

FIGURE 3.10 FREQUENCY ADJUST

3-14 MTS-3000 SERIES OPERATION AND REFERENCE MANUAL

#0$17$#7(67#6<67(06###########################################

CU M004 01A

Page 35

OPERATION SUMMARY - Section 3

5. To return to the default (all output channels synchronized to LINE), press F2, followed by F3 on the

CM. F3 selects the SEL[ect] LINE SYNC mode, and disables the frequenc y adjust mode.