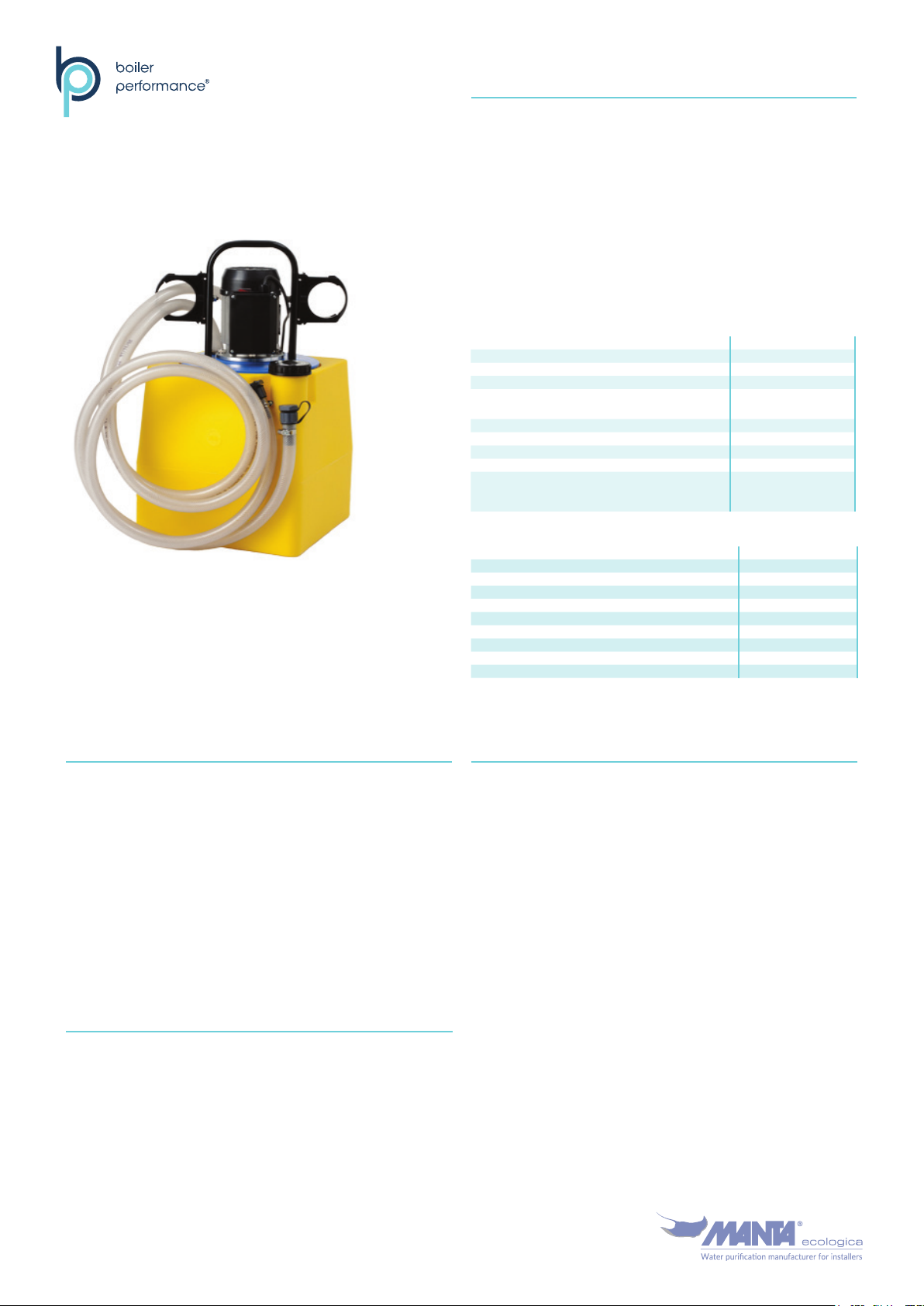

BOSS 36 - BOSS 36 FI

Descaling pump for boilers, heat

exchangers, cooling systems, plastic press moulding machines, evaporative towers, wall-mounted and

floor-standing boilers.

COD. 300601008

FI - COD. 300601007

TECHNICAL FEATURES

TANK 36 l 36 l

MAX FLOW RATE 48 l/min 68 l/min

CONNECTIONS 3/4" 3/4"

MOTO R 230 V/50 Hz/0,29 kW 230 V/50 Hz/0,29 kW

PRESSURE 1,5 bar 1,6 bar

DEGREE OF PROTECTION IP 55 IP 55

WEIGHT 11 kg 11 kg

MAX TEMPERATURE 60° C 60° C

DIMENSIONS H: 630 mm

PACKAGING FEATURES

NUMBER OF PIECES PER BOX

N. OF PCS PER EPAL PALLET

BOX DIMENSIONS

EPAL PALLET DIMENSI ON S

PRODUCT WEIGHT

BOX WEIGHT

EPAL WEIGHT

CUSTOMS CODE *

BARCODE EAN 13

*Data updated in May 2016

Boss 36 FI Boss 36

L: 350 mm

P: 350 mm

Boss 36 FI Boss 36

1 pc 1 pc

18 18

H: 67 L: 37 P: 37,5 cm H: 67 L: 37 P: 37,5 cm

80x120x214 cm 80x120x214 cm

11 kg 11 kg

12,5 kg 12,5 kg

245 kg 245 kg

8413.82.00 8413.82.00

8054633849774 8054633849767

H: 630 mm

L: 350 mm

P: 350 mm

ADVANTAGES

• Acid resistant material

• Operates up to 60 °C and up to 70 °C on

request

• Self-protection against damage caused by

dry running

• Hose clips/handles

• Suitable for small and medium heat

exchangers

• Wheels are optional if required

• Easy removable tank

BENEFITS

• Restores the optimal heat exchange

• Reduces energy consumption and lower bills

• Extends the heating sustem’s life

MAIN FEATURES

Descaling pu

the most suitable device for the descale of wallhung boilers, boilers, water heaters and coils

obstructed by limestone. It is characterized by

an excellent manageability, high prevalence and

flow rate, safety of use and easy maintenance to

guarantee the highest results and speed of intervention. It is completely made with anti-acid

material, except for the motor with vertical axis,

properly protected with an anti-acid shrinkable

membrane. The motor is assembled on a strong

lid on the tank closure, completely unscrewing

and removable, to guarantee an extremely easy

maintenance. Equipped with Flow Inverter (FI)

that guarantees to the descaling liquid to alternatively act at both side of the circuit. The use

of descaling products with inhibitors, created by

Manta Ecologica S.r.l. assure a fast intervention

and the maximum safety for heating systems

and workers.

mps BO

SS 36 and BOSS 36 FI

are

For the correct functioning of the pump use exclusively chemical products of BP descaling line.

is suggested for a long duration of the device to not leave any acid products inside the tank, once

the cleaning process is over, and to let circulate for few minutes the neutralizing solution Neutral

Liquid or Neutral Powder, in order to eliminate acid debris present inside the system.

It

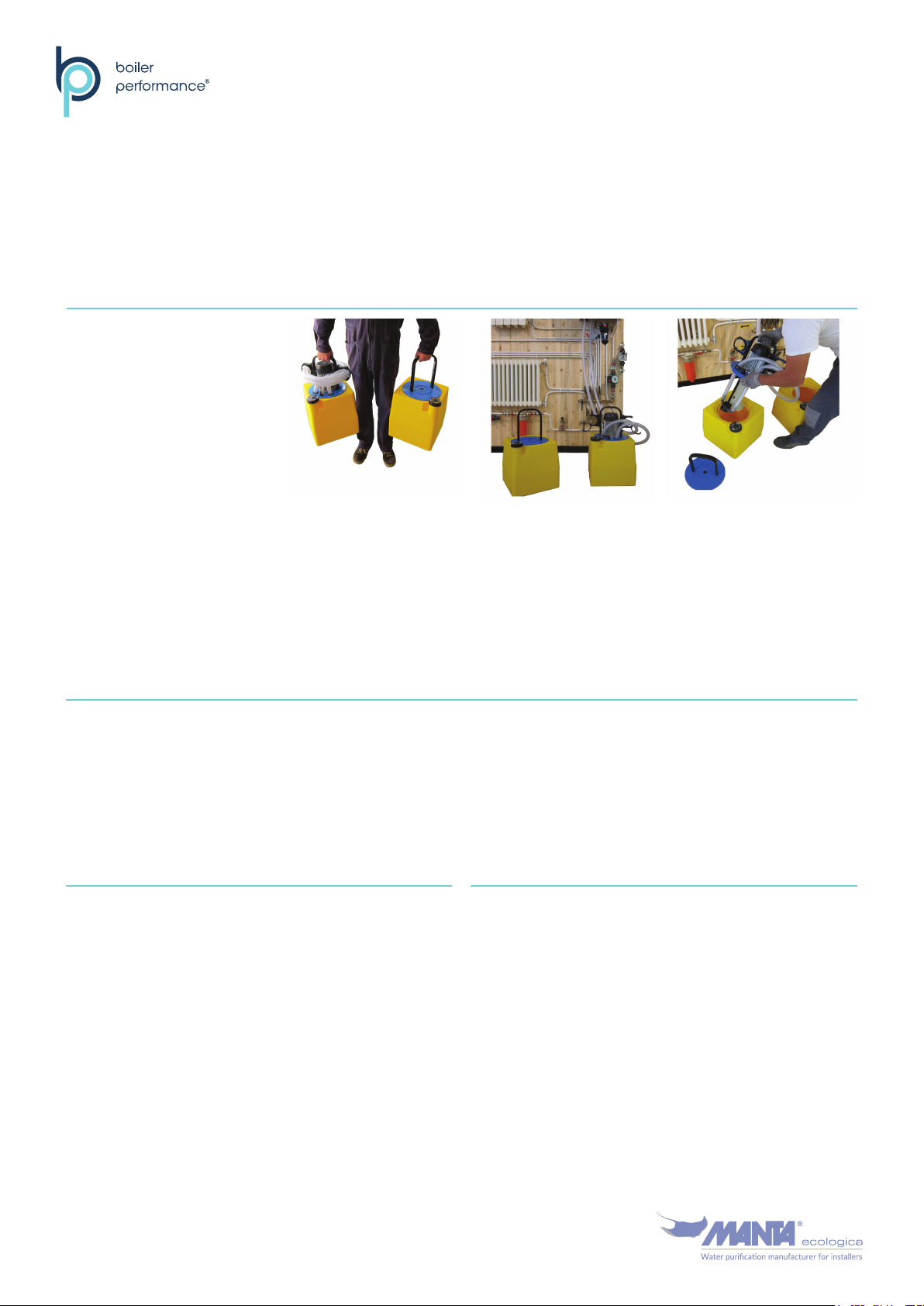

APPLICATION AND USE

Descaling pump for boilers, heat exchangers,

plastic press moulding

machines, wall-mounted

and floor standing boilers. Boss 36 and Boss

36 FI, have as accessory

a gasket and a screwing

cap ACID TANK 36 code

300610008 where the ready-to-use acid solution, could be prepared. This guarantees to have always available the pump for the neutralizing solution, so maximum safety and protection of the

pump and of the system that has to be descaled. Thanks to the possibility of unscrewing and screwing the pump in 10” and without any tools, Manta is the only manufacturing company, that guarantees to be in the working place with both acid solution and neutralizing solution ready for the rapid use.

WHAT DO I NEED TO INSTALL IT

• Flexible pipes for an easier connection

• Nipples

• Connections

• Typical plumber ‘tool for connections of different type.

INSTALLAZIONE

CORRECT INSTALLATION

1. Control, as first thing (if it is possible)

if inside the device that has to be descaled, there is enough space to guarantee the passage for the acid solution on

the contrary, the operation is not possible.

2. Disconnect the outlet and inlet of the de-

vice to descale, if it is possible, drain it from

the internal water and then connect it to the

pump, through the use of equipped pipes.

3. Remove the tank cap and add cold wa-

ter up to half tank (please notice that

operational temperature during descaling must never exceed 60 °C).

CORRETTA

4. Turn the pump on with the switch and start

adding slowly the descaling chemical, un-

til required concentration is obtained.

This operation guarantees the correct acid

product blending. Please carefully follow use

and safety information reported on the label of product. Anyway, maximum operational time (continuously) of the motor, should

not exceed 2 hours. Please after 2 hours,

let the system rest for at least half an hour.

ATTENTION: on all version equipped with

Flow Inverter (FI) the acid solution flow can

be inverted acting on the external control

(directional valve) to obtain a better result.

In case of excessive foam production, dilute the

acid solution and switch off for a short time the

pump. At the end of the descaling operation,

replace the acid solution inside the pump, with

clean water and rinse the descaled element.

1.

3.

LEFT

INVERSION

RIGHT

INVERSION

2.

1. Connection in/out pipes to the boiler

2. Pipes connection details

3. General view of the pump correctly installed

EXPLODED VIEW AND SPARE PARTS

1 - TANK

2 - RING NUT

3 - IMPELLER COVER

4 - IMPELLER

5 - O-RING 117,07x3,53 mm

6 - PLASTIC SCREW M6 x 20 mm

7 - PUMP BODY

8 - PLASTIC NUTS

9 - FLOW INVERTER

10 - DEVIATOR

11 - KIT DIRECTIONAL VALVE LEVER

12 - THREADED PIPE 19x26

13 - HOSE CONNECTOR 8120 3/4”x19

14 - MALE NUT 8200 3/4”

15 - PIPE HOLDER D. 75 mm

16 - FAIRLEAD FG 216

17 - FAIRLEAD FG 028

18 - MOTOR

19 - ANTI OIL GASKET

PACKAGING CONTENT

• 1 connections bag

• 1 User’s guide

• Connection pipes: 2 threaded pipes from 2,5 m each

• Pump

MAINTENANCE

At the end of descaling operation:

1. Do not leave pump unattended during the operations.

2. Control the pH is included between 6,5 and 9,5. For the liquid neutralization, both the ones pre-

sent inside the pump, and also the ones present inside the descaled elements, we recommend to

use neutralizing products (ex. Neutral Liquid or Neutral Powder).

3. Switch off the pump and disconnect as first thing the powder cord.

4. Wait till when the solution circulating inside the descaled device returns inside the tank.

DO NOT LEAVE ANY ACIDIC SOLUTION INSIDE THE TANK: fumes may seriously damage pump

components.

OFFER DESCRIPTION

Descaling pump, ¾” F connections, 36 litres tank. FI version, equipped with FLOW INVERTER valve.

To be used for the cleaning of wall-mounted boilers, oor standing boilers, heat exchangers, plastic

press moulding machines, kettles, small and medium systems. 230 VAC alimentation.

COMPLIANCE

This products mod. BOSS 36 and BOSS FI has been designed and constructed in accordance with

the following European directives (including all applicable amendments):

Directive 2006/42/EC: Machine

Directive 2014/35/UE: Low Voltage

Directive 2014/30/UE: Electromagnetic Compatibility

Directive 2011/65/EC: RoHS

It also declares that the product complies with the following standards:

EN 60335-2-41:2003, A1:2004, A2:2010 in conjunction with

EN 60335-1:2012, A11:2014, A13:2017, EN 55014-1:2017, EN 55014-2:2015, EN 61000-32:2014, EN 61000-3-3 :2013, IEC 62321:2008, IEC 62321-3-1:2013, IEC 62321-5:2013, IEC

62321-4:2013, IEC 62321-6:2015, IEC 62321-7-1:2015, IEC 62321-7-2:2017, EN 50564:2011.

ORIGIN OF THE PRODUCT

Made in Italy

P.S.345_Boss 36_20191018

Boiler Performance by Manta Ecologica s.r.l.

Viale Archimede, 45 – 37059 Zevio (VR) Italy

www.mantaecologica.com – Tel.: +39 045 8731511

Loading...

Loading...