Manostar MS99 Instruction Manual

READ THE INSTRUCTION MANUAL BEFORE USING

INSTRUCTION MANUAL

RoHS

MANOSTAR SWITCH

MS99

No. TR-MS99-E02

1-2-3,Nishi-shiriike-cho,Nagata-ku,Kobe,Hyogo 653-0031 JAPAN

TEL. +81-78-631-6000 FAX. +81-78-631-6020

TABLE OF CONTENTS

INTRODUCTION

Ⅰ.PRECAUTIONS

Ⅱ.THE NAME OF EACH PART

.............................................................................................................................. 1

....................................................................................................................... 1

........................................................................................... 2

Ⅲ.INSTALLATION

1. Caution of service condition

2. Installation of MS99

3. Installation position

4. Wiring material

5. Accessory for MS99

6. Accessory for type C

7

. About an exchange of type C piping connector.

8

. Pressure of measurement and connection of piping

Ⅳ.

SETTING OF PRESSURE

1

. Switch contact configuration

....................................................................................................... 2

........................................................................................................ 3

................................................................................................................... 3

...................................................................................................... 3

................................................................................................... 4

.................................................................................... 2

................................................................................... 6

PAGE

......................................... 5

................................. 5

2

. Setting of upper limit/ lower limit

3

. Setting the dial

4

. Reset time

Ⅴ.

ABOUT BUILT-IN SWITCH

1

. Material of contact

2

. About measured gas and contact failure

3

. Protection of contact of switch

Ⅵ.

GENERAL PRECAUTIONS

1

. Prohibition of common piping

2

. Prevention of clogged piping due to drain

3

. Measurement of high temperature gases

4

. Errors caused by long distance piping

Ⅶ.

PERIODIC INSPECTION

Ⅷ.

PRODUCT WARRANTY

.................................................................................................................. 7

........................................................................................................................... 7

......................................................................................................... 8

............................................................................................ 11

............................................................................................. 11

........................................................................ 6

.......................................................... 8

............................................................................. 9

.............................................................................. 10

.................................................... 10

..................................................... 10

........................................................... 10

INTRODUCTION

Thank you very much for purchasing of "MANOSTAR SWITCH MS99".

To ensure your safety in using this instrument :

!

△

Caution

・Be sure to read the instruction manual carefully before using the instrument so that you

can use it properly.

Wrong use may result in failure of the instrument and lead to its damage and accident. This

manual should be kept in a proper place so that you can refer to it any time you need.

Ⅰ.PRECAUTIONS

! Warning

△

・Do not use the instrument where flammable gas is present.

The instrument is not explosion-proof. Do not use instruments in the circumstance where flammable gas is present. It

may cause explosion.

・Do not use the instrument at the place where corrosive gas is present.

The instrument is not corrosion resistance construction. Measuring corrosive gas may corrode the receiving element

and housing material of the instrument. It is expected that corrosive gas leaked out of the instrument will harm a

person.

・Do not apply the pressure to the instrument more than it can withstand.

The diaphragm and the retainer are broken and cause of injury or accident, etc. disaster if the pressure exceeding

withstanding pressure of the pressure receiving element is applied to the instrument. The case body and the

transparent cover of the instrument are broken and cause of injury or accident, etc. disaster if the pressure exceeding

withstanding pressure of the instrument body is applied to the instrument.

・The instrument is measurable for air and non-corrosive gas only.

The machine is exclusive use of dry air (90%RH or less). Using measuring the water or oil it may be damaged and

causes the accident.

・Avoid using where the instrument is subject to many vibration and impact.

Using the instrument where intensified vibration and impact may be damaged the instrument. It is expected that gas

leaks of the instrument which harms a parson.

・Do not exceed rated surrounding temperature, humidity and altitude in use.

Using the instrument by exceeding rated surrounding temperature and humidity and altitude it may be damaged and

cause the accident.

・Do not disassemble or reconstruct the instrument.

It may void the warranty.

・Do

・Wire

・As to where to install and how to install this instrument, be sure to follow the instruction manual provided

・Use the instrument indoors.

・In case of not being installed in dry and well-kept clean locations, the instrument must be enclosed in box.

・Do not use organic solvent for cleaning.

・Dropping the product.

・Removal of the piping

・MS99 acquires UL-approved as an open type enclosure.

exceed rated voltage in using

not

Using the instrument by exceeding rated voltage may cause fire or electric shock.

correctly

Incorrect wiring may cause fire.

.

! Caution

△

so as to ensure a proper method.

Use a cloth soaked with water-diluted neutral detergent to wipe the surface of a product. Using of organic solvent

causes damage on the surface.

Product is a precision instrument. If you drop the product, there is a possibility that the exterior, also the interior

mechanism damage.

Please do not pull the pipe with a strong force. There is a possibility that the pipe cap is broken.

For UL listing application, install MS99 in the system, and configure so that the entire system will be UL-approved.

1

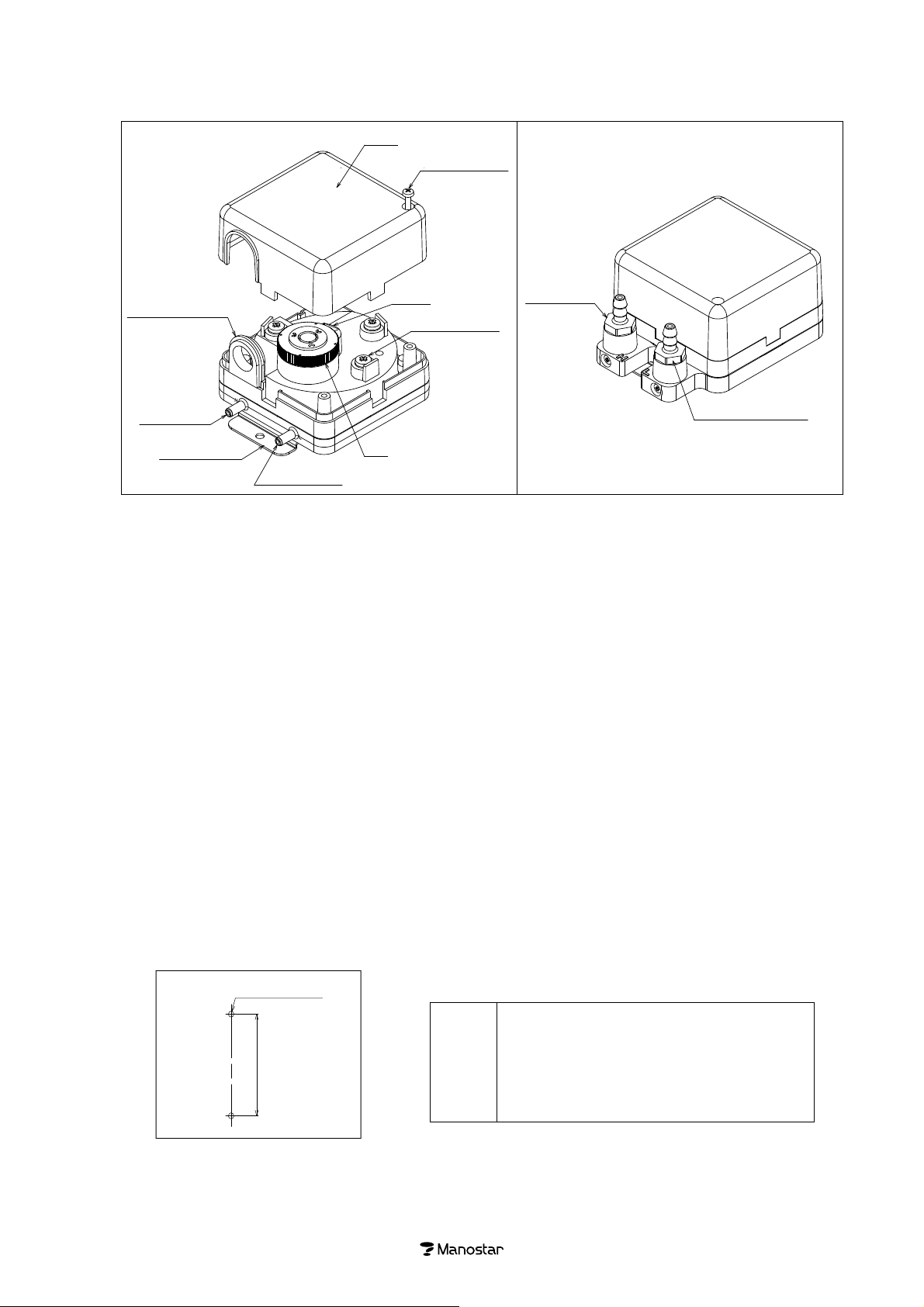

Ⅱ.THE NAME OF EACH PART

・Type V ・Type C

Cable clamp holder

Cover

Installation screw

for cover

Pointer

Terminal screws

High pressure

side piping

connector

(Interchangeable)

High pressure

side tube tap

Installation plate

Ⅲ.INSTALLATION

Low pressure

side tube tap

Dial

(All except for the piping connector part is

common with type V)

Low pressure

side piping connector

(Interchangeable)

Before using this instrument, make sure if it is the type that you requested and meets the demand of the

environment, pressure and piping conditions where it is used, by specification.

1. Caution of service condition

a) Do not use the instrument in a place subjected to direct sunlight, vibration or shock, or excessive

moisture. In particular, vibration and shock to the instrument should shorten its life.

b) Use under the medium and ambient temperature from - 10 to + 50 ℃.

c) The instrument is not waterproof. Do not use it in a place subjected to rain, or other splashing water.

The product is equivalent to the protection class IP54, when mounted as below.

1)Use the cable clamp which matches the wire diameter of the wiring.

2)Please install it so that a gap doesn't occur between a cover and the body by a screw for cover

installation of an accessory.

※Please refer to the item of p.3 "5. Accessory for MS99" about cable clamp.

d) In installing the instrument, select the place where the ground is smooth and flat.

2. Installation of MS99

Panel cut size

2×φ5 or M4

・The tightening torque of the screw is 1 N・m.

・Do not apply excessive torque more than

!

△

90±0.3

Caution

stipulated value, otherwise it will damage the

body of the instrument.

2

Loading...

Loading...