Page 1

USER INSTRUCTIONS

Thank you for choosing the Manosplint

® Safety Cutter. Every effort has been

made to bring you a precision engineered product with the promise of many

years of valuable service. In order to obtain maximum benefit from your

machine please read these instructions carefully. For advice and assistance

or replacement parts please contact your relevant Kinetec office.

PRODUCT CODE: M40SAB66M

PRODUCTDESCRIPTION: MANOSPLINT SAFETY CUTTER

Distributed by:

UK & ROI: France & International: USA & Canada:

Kinetec Medical Products UK Ltd Kinetec SAS Kinetec USA

Unit E Manawey Industrial Estate Zone Industrielle de Tournes W225N16708 Cedra Park Court

13 Holder Road Rue Maurice Perin Jackson

Aldershot F-08090 Tournes WI 53037

GU12 4RH France USA

United Kingdom

T: +44 (01252) 931980 T: +33 324 29 85 05 T: +1 (262) 677 1248

E: enquiries@kinetecuk.com E: contact@kinetec.fr E: sales@kinetecusa.com

W: www.kinetecuk.com W: www.kintetecinternational.com W: www.kinetecusa.com

Manosplint® Safety Cutter: User Manual

Page 2

1. Contents

2. Safety & Preparation

2.1 Installation Recommendations & Safety

3. Set-Up

3.1 Blades and Blade Holder

4. Operation

4.1 Cutting & Scoring Thermoplastics

4.2 Medium Duty Blade Holder – Replacing Blades

5. Maintenance

5.1 Cleaning & Lubrication

5.2 Adjusting the Cutter Head Sliding Bearings

6. Other Information

6.1 Warranty

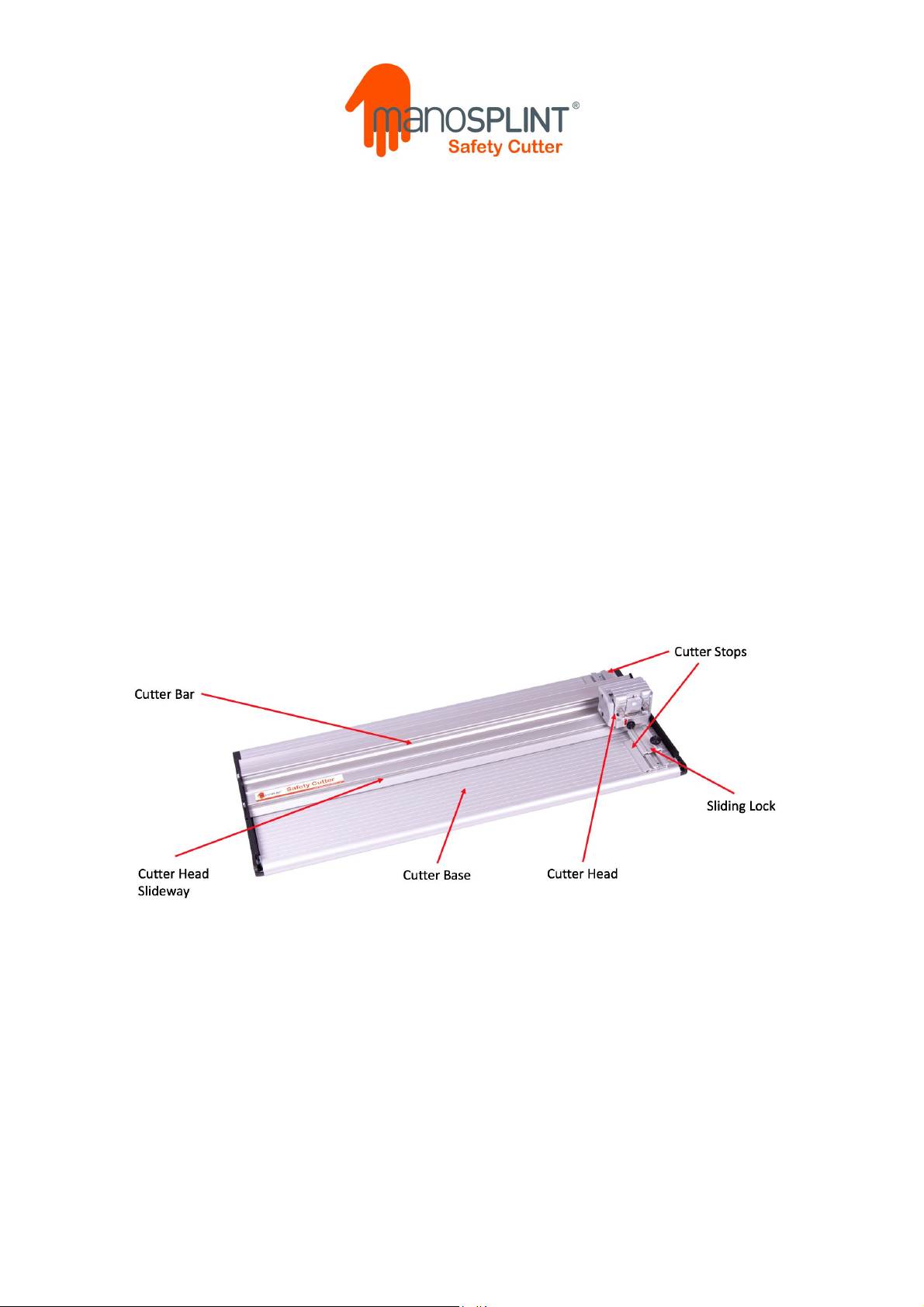

1. Contents

Manosplint® Safety Cutter: User Manual

Page 3

2. Safety & Preparation

2.1 Installation Recommendations & Safety

Checking the Flat Surface

Please note that it is essential that the cutter is used on a flat surface for accuracy. A warped

or bowed table top can induce a twist or bend in the Cutter Bar resulting in a bowed cut.

Safety

When lifting, moving or transporting the Safety Cutter, please ensure that the Sliding Lock is

engaged with the Cutter Head and the locking screw is tightened. This prevents the Cutter

Head from sliding and the Cutter Bar from lifting.

The blade must be removed before cleaning the Safety Cutter.

Do not place your fingers near the blade when using the Safety Cutter.

Do not use the Safety Cutter if there are any signs of damage to the Cutter Head or Cutter

Bar assembly.

Care should be taken when storing the Safety Cutter to ensure that the Cutter Head is

secured and cannot be damaged.

Extreme care should be taken when changing blades as they are very sharp. Please dispose

of used blades safely using a sharps bin whenever possible.

3. Set-Up

3.1 Blades & Blade Holder

Medium Duty Blades

The Safety Cutter has been supplied with Medium Duty utility blades which are the most

appropriate option for cutting thermoplastic materials. The Safety Cutter is supplied with a

pack of 100 of these blades as standard.

The vertical action Cutter Head reliably controls the blade depth and eliminates the need for

heavy downward hand pressure when cutting thermoplastic materials. The Cutter Head and

blades provide a smooth consistent cutting action.

Blades should be replaced or reversed when cutting becomes difficult because the blade

has become blunt.

The Medium Duty utility blades are double ended so can be switched round before disposal.

(See Operation 4.2 for Replacing Medium Duty Blades)

Manosplint® Safety Cutter: User Manual

Page 4

4. Operation

4.1 Cutting

Positioning of the Safety Cutter on the Cutting Surface

Place the Safety Cutter on a level surface (table, worktop). Position the Safety Cutter at a

comfortable position to allow you to get as close as possible and above the Cutter Head so

that you are not reaching too far and can apply a firm downward pressure with your palm.

Inserting Thermoplastics into the Safety Cutter

Having marked your thermoplastic with the start point from which to make your cut, lift the

Cutter Bar and insert your plastic, pushing it up against the two Cutter Stops. This will ensure

that your cut is ‘square’ to the material and easier to cut.

Aligning Cutter Head

Align the red arrow on the Cutter Head with the cutting start point. The red arrow provides a

clear visual guide to the tip of the utility blade. This is important if you are scoring the plastic

before cutting – depending on plastic thickness (see below).

Depressing the Cutter Head and Cutting

The Safety Cutter has unidirectional Medium Duty utility blades which are designed for

cutting thermoplastic materials. The best ergonomic position is to place your palm on top of

the Cutter Head, depress and engage with the plastic. Push the Cutter Head away from you

towards the Cutter Stops keeping the Cutter Head depressed.

For thinner plastics (1.6mm, 2.0mm) with firm pressure on the Cutter Head, the blade should

go through the plastic at the first attempt and the plastic will cut in one movement.

For thicker plastics (2.4mm, 3.2mm) you may need to score the surface of the plastic first with

2 – 4 movements and then the final movement should cut completely trough the plastic

material.

If you are cutting the full length of thicker plastic we recommend dropping the blade onto

the top of the plastic approximately 2mm from the edge for your first 2-4 scoring movements

and then only positioning the blade before the plastic for the final cutting movement.

Thermoplastics – Dealing with Different Thicknesses/Toughness

Consideration should be given to the thickness and toughness of the thermoplastic that you

are cutting. Thin materials (for example 1.6mm, 2.0mm) may be cut with one stroke of the

Cutter Head. Thicker materials such as 2.4mm or 3.2mm may need to be scored 2 to 4 times

before the final cut is performed.

Manosplint® Safety Cutter: User Manual

Page 5

Blade Height

The Safety Cutter has been supplied with a pin in the Cutter Head that controls the height of

the blade and prevents it from running along the bottom of the cutting channel. This helps to

prevent the tip of the blade from wearing or getting damaged by incorrect blade setting

whilst providing a perfect cutting height.

Storage

When storing the Safety Cutter move the Cutter Head to the end of the rail and engage the

Sliding Lock in the depression beneath the blade. Once this has engaged, tighten the screw

on top of the Sliding Lock. This will prevent the Cutter Head and Cutter Bar from moving

during transportation and storage.

Making the Safety Cutter Ready for Use

To make the Safety Cutter ready for use, undo the screw on the Sliding Lock slightly and pull

away from the Cutter Head. Tighten the screw on the Sliding Lock when it is withdrawn away

from the Cutter Head to keep it secure.

4.2 Blade Holder – Replacing the Blade

Fitting a New Blade

Remove the magnetic blade guide by releasing the Blade Clamping Knob .

Place the new blade onto the guide ensuring that the blade notches are properly located

and the back face of the blade is lying flat on the Blade Guide. (We recommend placing

the blade with the etched description ‘Medium Duty’ facing outwards so when it needs to

be replaced, it can first be reversed to make use of both ends of the blade).

Manosplint® Safety Cutter: User Manual

Page 6

Lower the Blade Guide into position feeding the blade behind the Clamping Bar.

Slide the Blade Guide down as far as it will go and secure in place using the Blade Clamping

Knob .

5. Maintenance

5.1 Cleaning & Lubrication

It is good practice to keep a dust sheet over the cutter if it is not to be used for extended

periods. In any event, regularly clean it with a dry cloth or to remove any stubborn stains use

a cloth dampened with a little water or detergent. In a clinic setting, the device may be

cleaned with an anti-bacterial wipe, but please avoid the yellow silicon strips on the

underside of the Cutter Bar and on the surface of the Cutter Base.

Should the Cutter Head Slideway require lubrication, use a silicon spray or silicon

impregnated sponge.

Please note! Do not use oil or solvents to lubricate or clean the cutter because the plastic

components and bearings will be damaged.

Manosplint® Safety Cutter: User Manual

Page 7

5.2 Adjusting the Cutter Head Sliding Bearings

The bearings that control the sliding motion of the Cutter Head are manufactured from a

high grade polymer and under normal use will last for an extremely long time. As they settle

into position you may find a slight amount of side play which can be removed by tightening

the two adjustment screws.

Tightening the Adjustment Screws

Place the long end of the 2mm Allen key provided into either of the two screw heads and

very gradually tighten it with one hand whilst moving the Cutter Head up and down the

Cutter Head Slideway with the other. Once you feel the sliding motion start to tighten undo

the screw very slightly so the Cutter Head slides easily.

Repeat this process with the second screw. Further fine adjustment may be needed to

achieve an easy sliding movement with zero side play.

Liability

Kinetec accepts no liability if the product is not assembled or used in the correct way, in

accordance with instructions.

6. Other Information

6.1 Warranty

The Manosplint Safety Cutter has a 5 year warranty.

6.2 Pack Contents

The Safety Cutter is supplied with a pack of 100 of Medium Duty blades, 2mm Allen Key and

User Instructions.

6.3 Video

For videos of the Safety Cutter being used and instructions, please visit: ….

Manosplint® Safety Cutter: User Manual

Page 8

Distributed by:

UK & ROI: France & International: USA & Canada:

Kinetec Medical Products UK Ltd Kinetec SAS Kinetec USA

Unit E Manawey Industrial Estate Zone Industrielle de Tournes W225N16708 Cedra Park Court

13 Holder Road Rue Maurice Perin Jackson

Aldershot F-08090 Tournes WI 53037

GU12 4RH France USA

United Kingdom

T: +44 (01252) 931980 T: +33 324 29 85 05 T: +1 (262) 677 1248

E: enquiries@kinetecuk.com E: contact@kinetec.fr E: sales@kinetecusa.com

W: www.kinetecuk.com W: www.kintetecinternational.com W: www.kinetecusa.com

Manosplint® Safety Cutter: User Manual

Loading...

Loading...