MANONI Smarty 300 VX VE, Smarty 300 IX Maintenance Manual

Instructions for use and maintenance Models

Smarty 300 VX VE

Smarty 300 VX BV

Smarty 300 VX BVC

Smarty 300 IX

Translation of original instructions

Edition October 2011

Slicers

1

FOREWORD

1 This manual has been prepared by MANCONI to provide Clients with all possible information on

the machine and the safety precautions relating to it, as well as instructions for operation and

maintenance, which will enable them to obtain the best possible performance, and to keep the

machine working efficiently for a long time.

2 This manual should be given to all employees entrusted with the operation and periodic

maintenance of the machine.

3 The design of our machines is subject to possible revision and for this reason some models may

include parts that differ from those illustrated in this manual. This will in no way invalidate the

explanations given in the manual.

4 The technicians of the Technical Assistance Service (TAS) authorised by MANCONI represent a

wealth of experience gained during years of working in close collaboration with machines users,

and will also supply you with original MANCONI spare parts.

5 We thank you for having chosen a MANCONI product and are at your service for any other

information.

MANCONI & C. s.r.l.

1

WARRANTY CERTIFICATE

(Copy to be delivered to the TAS Manconi)

Machine mod. _________________________________ serial n. __________________

Acquired by ________________________________________________________________

Your place

Post code__________ City ____________________________Country ____________________

Street __________________________________________ Tel. number _____________________

The above-mentioned company claims to have taken note of the warranty conditions and accept

them without reservation.

Date __________________ Stamp and signature of legal representative

Stamp and signature of authorized TAS

WARRANTY CONDITIONS

The warranty is valid only with the following conditions:

a – The installation and start-up must be performed by the Technical Assistance Service (TAS) authorized dealer by

Manconi

b – For the normal use of the machine is not allowed to cut frozen foods, fish and meat on the bone, non-food product

c – Warranty will be not valid if:

1 – the machine is subjected to operate with unstable voltage (ie with variations that exceed the normal limits of

electricity supplier).

2 – the machine is subjected to cleaning with high pressure water jets, steam or water spray.

3 – the machine is tampered by unauthorized personnel.

4 – on the machine are used not genuine parts by MANCONI.

EXTENDED WARRANTY

a – Warranty will be valid till 12 (twelve) months from the first installation and testing date.

b – Warranty will be valid only with the deliver to MANCONI delaer of this certificate, completed in all parts and in

any information.

c – Warranty offer a free replacement by the dealer of defective parts, transportation charges for delivery and return

are paid by the customer.

d – Warranty doesn’t cover normal wear of components (blades, grinding wheels for sharpening).

e – Repairs made during the warranty period will not extend or renewal the warranty duration.

Ed. 09/10

Via Varese 8 - 21040 Sumirago (VA) - Italy - Tel. +39 0331 994. 292 - Fax +39 0331 995.577 - www.manconi.com - info@manconi.com

cap.soc. € 70.200,00 int. vers. C.C.I.A.A. Varese - REA n. 88580 Iscrizione Registro nazionale gestione sistemi RAEE nr. IT 08020000002345

cod.fisc./p. iva iscr. reg. imprese di Varese 00237860127 n. mecc. VA 000623

MANCONI&C Srl

2

Page intentionally left blank

3

English

EC-Declaration of Conformity

(according to 2006/42/EC, Annex II, No.1 A)

- Company name: Manconi & C. S.R.L

- Address: Via Varese 8 21040 Sumirago (VARESE)

- Mr. Manconi Paolo is authorised to compile the technical file according to Annex VII A.

- Address of the authorized person: Via Varese 8 21040 Sumirago (VARESE)

- We hereby declare that:

SLICING MACHINE Mod. __________________________________ S/N _____________________.

fulfils all relevant provisions of Directive 2006/42/EC.

The machinery is also in compliance with all relevant provisions of the following EC-directives:

Low Voltage directive 2006/95/CE

Electromagnetic compatibility directive 2004/108/CE

RoHS directive 2002/95/CE

Food Material directive 1935/2004/CE

The following harmonised standards (or parts thereof) were applied:

EN 1974:1998 Slicing machines - Safety and hygiene requirements

EN 60204-1 Safety of machinery - Electrical equipment of machines – Part 1: General requirements

EN 55014: Electromagnetic compatibility - Requirements for household appliances, electric tools and similar

apparatus

Place and date: Sumirago, 1° January 2011

DC Rev.13 Gen 11

INDEX OF CONTENTS

Via Varese 8 - 21040 Sumirago (VA) - Italy - Tel. +39 0331 994. 292 - Fax +39 0331 995.577 - www.manconi.com - info@manconi.com

cap.soc. € 70.200,00 int. vers. C.C.I.A.A. Varese - REA n. 88580 Iscrizione Registro nazionale gestione sistemi RAEE nr. IT 08020000002345

cod.fisc./p. iva iscr. reg. imprese di Varese 00237860127 n. mecc. VA 000623

MANCONI&C Srl

4

PAGE

Section 1 SAFETY INFORMATION, RISKS AND RESIDUAL RISKS

1.1 GENERAL PRECAUTIONS, RISKS AND RESIDUAL RISKS 5

1.2 MECHANICAL SAFETY 6

1.3 ELECTRICAL SAFETY 6

Section 2 TECHNICAL DATA

2.1 GENERAL DESCRIPTION 6

2.2 MAIN CHARACTERISTICS 6

2.3 DIMENSIONS AND PERFORMANCES 7

Section 3 UNPACKING

3.1 CHECKS ON RECEPTION 14

3.2 DISPOSAL OF THE PACKAGING 14

Section 4 INSTALLATION

4.1 POSITIONING OF THE MACHINE 14

4.2 ELECTRICAL CONNECTION 14

4.3 FUNCTIONAL CHECKS 17

Section 5 HOW TO USE THE SLICER

5.1 LOADING THE FOODSTUFF AND CUTTING 17

5.1.1 GRAVITY SLICER “IX SMARTY” 17

5.1.2 STRAIGHT SLICER “VX VE SMARTY” 18

5.1.3 STRAIGHT SLICER “VX BV SMARTY” 18

5.1.4 STRAIGHT SLICER “VX BVC SMARTY” 18

5.2 SHARPENING THE BLADE WITH INTEGRATED SHARPENER 19

Section 6 CLEANING

6.1 GENERAL REMARKS 20

6.2 DISASSEMBLY 20

6.3 CL EANING 22

Section 7 NORMAL SERVICE 24

Section 8 DISMALTING AND DISPOSAL 25

Section 9 TROUBLESHOTTING 25

5

Section 1

SAFETY INFORMATION, RISKS AND RESIDUAL RISKS

1.1 GENERAL PRECAUTIONS, RISKS AND RESIDUAL RISKS

The slicer should be used by trained personnel only, who must be completely familiar with the safety

regulations contained in this manual. Should it be necessary to alternate operators, training should be

provided in good time.

Despite the EC professional slicers are equipped with devices in order to prevent electrical and

mechanical risks (both during operation and during cleaning and maintenance operations), there are

residual risks not be completely eliminated, which appear in this manual in the form of CAUTION.

They concern the risk of cuts, bruises and other caused by knife or other machine components.

Provide to operator accessories needed to protect the person: metal mesh safety gloves, gloves with highgrip, gowns with elastic cuffs, caps to keep hair, safety shoes.

Even though the machine is well provided with safety devices, hands should not come near the blade or other

moving parts.

Do not use your hands to hold the product to be sliced. Always pushing the product holder with carriage

handle. Be especially careful when using the grip of the plates mod. "SMARTY IX&VX" because they have

sharp pins to hold the goods, which can cause skin damage. We recommend the use of metal mesh safety

gloves.

Avoid to wear clothes and accessories that can be caught by moving parts of the slicer (necklaces, bracelets,

ties, scarves, ear wire, scarves).

Do not let affection grippers or other accessories work.

Do not use the slicer for frozen products, meat or fish containing bones, or for anything except foodstuffs.

Do not use the machine for vegetable cutting, unless for some it is possible to use the standard holding and

pushing devices.

Always check that the run pilot lamp lights up when the machine is switched ON.

Before any cleaning or maintenance operation, disconnect the machine from the mains.

When cleaning or servicing the slicer (i.e. when the guards have been removed) keep in mind the residual

risks

Check the power cable periodically. A worn or damaged cable constitutes a serious electrical hazard. If the

cable is damaged it must be replaced by a special cable or assembly available from the TAS authorized by

Manconi

Switch off the slicer in case of unusual noise.

Place the slicer machine in a dry place, non-slippery, with good lighting, glare or flashing, no position on the

outside.

Do not attempt any repair by yourself, but always call in the MANCONI authorised TAS.

After each use, always turn off the slicer, always close the gauge plate, do not leave the slicing machine

with removable parts or disassembled parts in a position that could cause damage.

6

1.2 MECHANICAL SAFETY

As far as safety against mechanical risks are concerned, the slicer described in this manual complies with the

Directive EN 1974: 1998 + A1 “Food processing machinery – Slicing machines – Safety and hygiene

requirements” so is compliant with machine directive 2006/42/CE.

Safety has been achieved by means of:

a) A non-removable blade guard around the blade, to protect the area not used for the cutting.

b) A food carriage that can be removed only when the gauge plate knob is at the stroke end clockwise (i.e. on

a position to protect the cutting edge of the blade) and when the carriage is at the end of its stroke towards the

operator. These conditions are blocked mechanically by the food carriage removing.

c) Removable blade cover.

d) A set of finger-guards in transparent plastic material, mounted on the food carriage.

e) The last slice device may not be stopped in the upper position for 60 mm from the blade (applicable to CE

models only).

CAUTION!

In compliance with paragraph 1.7.2 “WARNING ABOUT RESIDUAL RISKS” of directive 98/37/EC

Annex I, we draw your attention to the fact that the blade safety guard does not completely eliminate

the risk of cuts in the s harpening area, although it drastically reduces the possibility and the extent of

injury.

1.3 ELECTRICAL SAFETY

The protection against electrical risks conforms to Norm EN 60204 and so it complies with the requirements

of Directive 2006/95/EC.

The control circuit has been fitted with a relay that necessitates deliberate relighting of the slicer in the event

of accidental loss of current.

Given to the good insulation of t he electrical circuit and the excellent rust-resistance materials employed, the

slicer can be installed and used even in damp premises. It is built to resist the washing conditions created by a

rain jet of water (protection IPX3).

Section 2

TECHNICAL DATA

2.1 GENERAL DESCRIPTION

This slicer has been designed to provide:

- Possibility to cut without interruption any type of sausages, ham, meat, cheese and all the products that can

be blocked on the carriage.

- Safety in operation, cleaning and maintenance.

- Maximum hygiene, thanks to the meticulous design of components in co ntact with the foodstuff and b y the

use of rustproof materials.

- High cutting precision.

- Maximum cutting capability.

- Toughness of all the parts.

- Ergonomic and rational movements for the maximum ease of use.

- Use at temperatures between 5°C and 40°C (41.0 to 104.0 °F).

7

2.2 MAIN CHARACTERISTICS

- External parts of the machine are produced in aluminium-magnesium alloy suitable for the contact with the

foodstuff, mirror polished and anodised.

- Parts and bits in stainless steel, to avoid risks of oxidations.

- The cutting blade is driven by a completely enclosed motor with ample external ventilation, drive

transmission is obtained with a ground worm screw and helical gear.

- Noise and vibration are not considered to be significant hazards.

- Blade sharpener

Integrated sharpener: is developed for a simple and e safety use. The group is removable for an easy

cleaning operation

- Safety devices comply with current regulations; some of these are made of resistant plastic materials

suitable for contact with foodstuffs, and are transparent for easier control of the cutting operations.

- Sealed electrical parts and suitable materials make it possible to wash the outside of the slicer with a rain jet

of water.

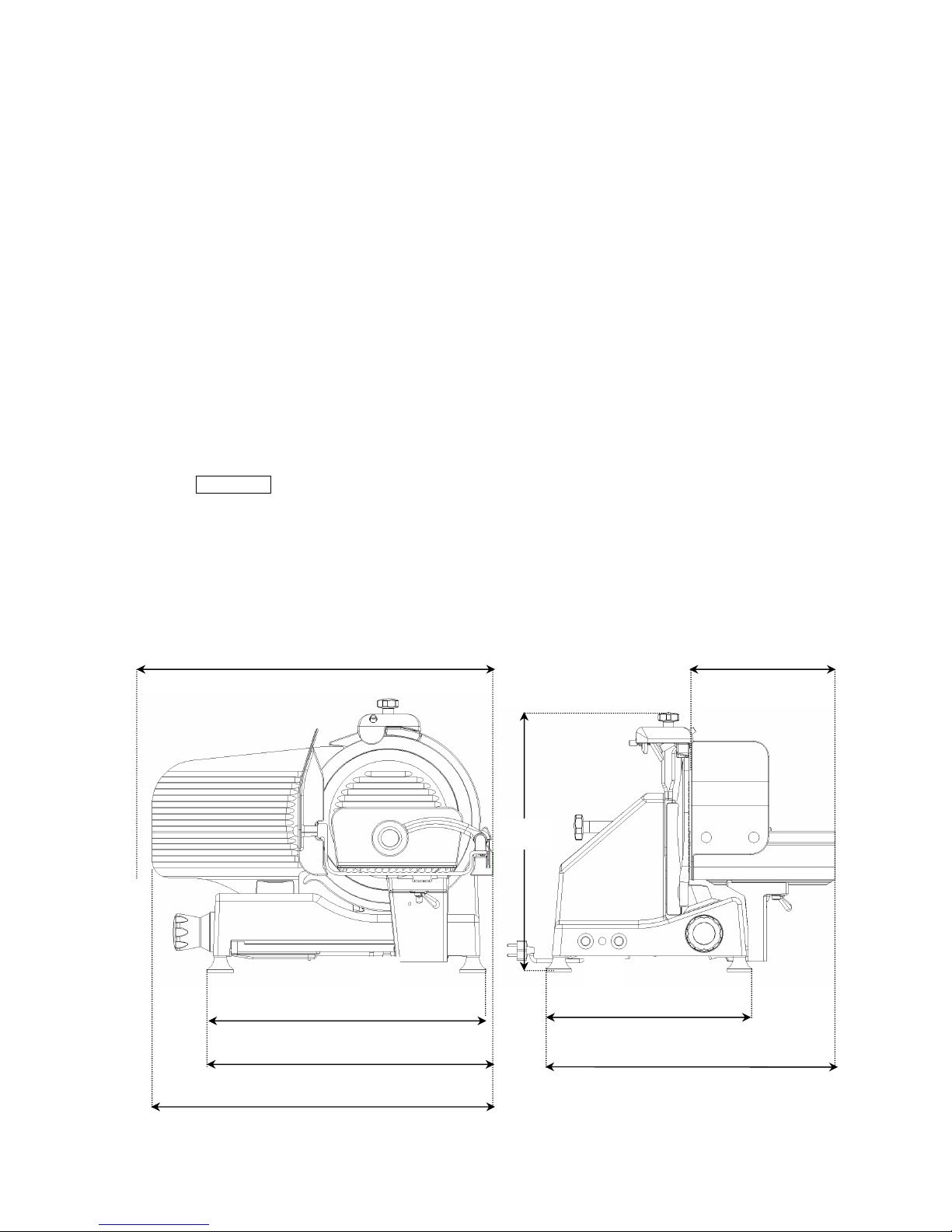

2.3 DIMENSIONS AND PERFORMANCES

CAUTION!

The electrical characteristics of the machine are indicated on the identification label. Before making

this connection see 4.2 “ELECTRICAL CONNECTION”.

OVERALL DIMENSIONS

Picture 1 – Overall Dimensions “VX VE SMARTY”

* Overall dimensions with carriage support at the end of its stroke.

657*

501

512

610

389

547

275

492

Loading...

Loading...