Page 1

VL-F7-N4-LPA-MK

Vent Line Sensor

for Ammonia and

Other Refrigerants

Instruction and

Installation Manual

MOUNT ENCLOSURE THIS END UP.

DO NOT BLOCK PERFORATED VENT HOLES.

Linear 4/20 mA Output

PRE-AMP

®

405 Barclay Boulevard

Lincolnshire, Illinois 60069

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8208

detectgas@honeywell.com

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 1

18394 VLF7LPA 07/2016 REV H

Page 2

Contents Serial number:

Section Title Page

1 Sensor Description 3

2 Installation 5

3 Operation 8

4 Limited Warranty 10

Special Caution

Always assume that a relief valve can release at any moment. Always employ a “buddy” system,

having help with you and watching what you are doing at all times. Always use safety goggles

or a safety face shield, and always use gloves and have additional protective equipment easily

available, including eye flushing equipment and a breathing apparatus.

Personnel should be well trained and protected against falling if a sudden refrigerant leak

startles the service person. Make sure there is always an escape route in case of a refrigerant

release.

Introduction

This manual has been prepared to help in the use and installation of the Manning Systems

VL-F7-LPA Vent Line Sensor. This manual will convey the operating details of the sensor,

ensure proper installation, and demonstrate start-up and routine maintenance procedures.

This manual must be carefully followed by all individuals who have or will have the

responsibility for using or servicing the sensor.

with respect to this equipment will be voided if the equipment is not used and serviced in

accordance with the instructions in this manual. If in doubt about a procedure, please contact

Manning Systems, Inc. before proceeding.

Warranties made by Manning Systems, Inc.

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 2

Page 3

1 Sensor Description

The Manning Systems VL-F7-LPA Vent Line Sensor has

a solid-state sensor imbedded in a 2" forged steel bull

plug. A NEMA 4, 16 gauge steel box is fastened to the

bull plug and houses a terminal strip. This is then

wired to the current pre-amp which transmits a linear

4/20 mA signal to the readout equipment.

The standard trip points are normally in the 5,000 ppm

to 10,000 ppm range. Manning Systems highly

recommends that trip points be in this range due to

the fact that minute amounts of a refrigerant released

in the very small volume of a relief header will cause

very high gas concentrations, normally in the percent

range. Trying to have lower setpoints almost always

results in false trips.

The solid-state sensor used in this design must be

considered “broad-spectrum,” i.e., it will detect many

gases. Normally this is not a problem due to the higher

setpoints commonly used.

The VL-F7-LPA Vent Line Sensor should only be used

in non-hazardous locations. Explosion-proof designs

are not available at this time.

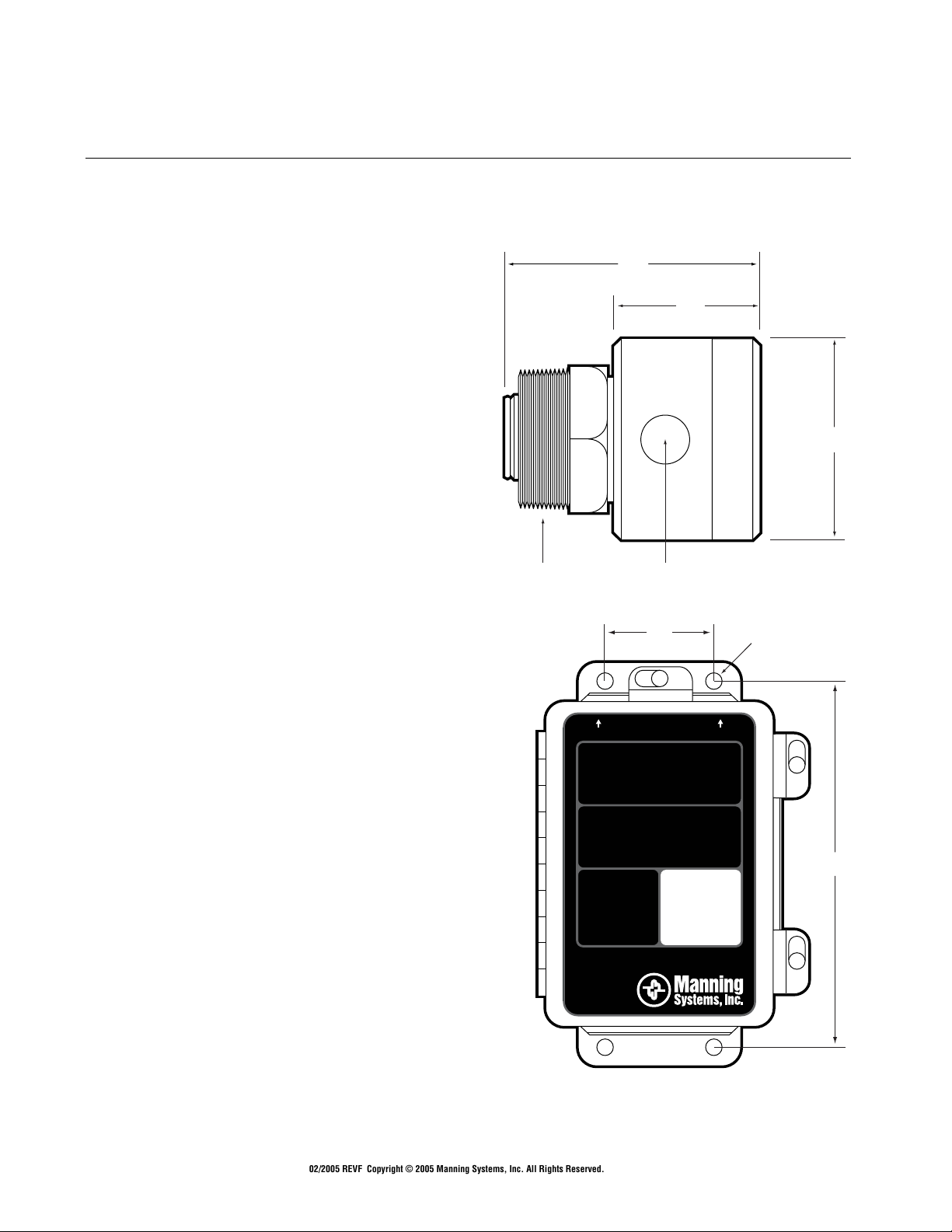

Figure 1: Dimensions of the Vent Line Sensor

and Pre-Amp

4 1/2"

2 3/8"

2" N.P.T.

pipe plug

7/8" diameter hole for 1/2"

conduit electrical connection

2"

5/16" diameter

3 1/8"

The sensors normally exhibit long life (five to eight

years) unless exposed to very high gas concentrations

for long periods or immersed in liquid refrigerant.

Proper location in mounting the vent line sensor is the

key to long and trouble-free life.

Carefully review the

mounting instruction portion of this manual.

MOUNT ENCLOSURE THIS END UP.

DO NOT BLOCK PERFORATED VENT HOLES.

PRE-AMP

6 3/4"

®

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 3

Page 4

1 Sensor Description continued

System Specifications

Method: Solid-state

Range:

• Ammonia – 0 to 10,000 ppm (1%)

• CFC/HCFC/HFCs – 0 to 1,000 ppm

(depending on refrigerant)

Output: Linear 4/20 mA – connects to all Manning

Systems readouts or other devices capable of accepting a

4/20 mA signal

Power Requirements: Powered directly from Manning

Systems readouts or, when used as 4/20 mA pre-amp

and sensor only, requires 17/24 VDC at 200 mA

Operating Temperatures: –20° F to +120° F

Enclosures:

• Sensor – Aluminum NEMA 4

• Pre-amp – Stainless Steel NEMA 4

Weight:

• 3 lbs., sensor only

• 15 lbs., with mounting kit

Dimensions:

• Sensor – 4 1/2" x 3 1/8" x 3 1/8"

• 4/20 mA pre-amp enclosure – 6" x 4" x 4"

Cable Requirements:

• Pre-amp to readout – #18/3 shielded cable

(Belden #8770), maximum run length 1,500 feet

• Sensor to pre-amp – #16 AWG, 4 conductors,

non-shielded for runs up to 25 feet

Specifications subject to change without notice.

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 4

Page 5

2 Installation

A Locating the VL-F7-LPA

in a Vent Line System

Discharging to atmosphere, vent line sensors must be

mounted within one or two feet from discharge into

the air.

Over 95% of all problems experienced with the VL Vent

Line Sensor have been due to mounting the sensor away

from the discharge, usually lower into the system, below

the roof line. In this lower area you will encounter

residual oil from previous releases, bacterial action due

to moisture and heat, pipe coating residuals and minute

relief valve weeping. All this action is additive and is a

sure cause for trouble.

See Figure 2 which shows where to mount the vent line

sensor. Important mounting considerations:

• Make sure discharge does not come down on top

of sensor, i.e., hit the sensor or maintenance

personnel when working on sensor.

• Weld nipple to a vertical pipe.

• Do provide a plug or means of inducing a draft

through the vent header to remove residual

refrigerant after a leak. (Check with local codes to

see what is allowed in your area before doing

this.) Inducing an easy means of clearing the

header will help in troubleshooting a weeping

relief valve.

•

Safety – Always follow accepted industry

practice by using a face shield and gloves when

working on the vent line sensor or any part of the

vent line system. Always

could release at any moment. Always

line systems with extreme caution (see Figure 2).

assume a relief valve

treat vent

B Mounting the VL-F7-LPA

in a Relief System Venting

Directly into a Water Tank

Due to numerous code requirements a common practice

is to plumb vent line systems to discharge directly into a

water tank. Even though this seems like a very simple

and safe way to protect from atmospheric discharge, it

presents some unique challenges to the refrigeration

designer in assuring a safe relief system. It also presents

challenges in where to mount the vent line sensor.

The vent line sensor was developed over the years for

monitoring atmospheric discharge of vent lines. When

properly mounted as described in Section A, it is an

extremely reliable method of detecting releases to the

atmosphere.

Figure 2: Mounting the Vent Line Sensor

Make sure discharge

does not hit the vent

line sensor housing

Vent line header

Roof line

IMPORTANT: The vent line sensor must be

mounted no further than 1 to 2 feet from discharge

Nipple Tee

2" plug

3/4" plug for testing

25' max between sensor and pre-amp

Mount pre-amp for easy access

NEMA 4 design

(keep away from

discharge)

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 5

Page 6

2 Installation continued

The advent of the water dump tank utilizing a standard

water level covering the relief header discharge presents

the vent line sensor with some unique challenges. There

are several possible mounting locations as follows:

Water tank atmospheric vent. The simplest and

•

most trouble-free method of mounting a vent line

sensor is in this location. This location will not catch

the small weepers but only the larger discharges

resulting in NH

vapor escaping from the water tank.

3

This method requires no compressed air venting

and the resulting problems this can cause. To help

eliminate water condensation on the sensor, remove

the 3/4" test plug to allow ventilation across the

sensor (see Figure 3).

•

Mounting the sensor between the water seal and

relief valves.

After years of actual field experience

this location has proven the most difficult. There

have been occasions where the water has been

siphoned back into the vent header, completely

immersing the vent line sensor and relief valves.

Mounted with compressed air purge. The most

•

successful systems have used compressed air

venting into the header as shown in Figure 4. It is

essential that this is dry air. Small compressors

dedicated to this have been marginally effective due

to the water condensed during the compression

cycle. It is essential the compressed air be dry in

order to help purge the complete vent line header

and also to compensate for the moisture migration

from the water seal. Process facilities that have

plant compressed air work the best when utilizing a

large dedicated dryer for the air injection.

The purge air will cause a small pressure to build

due to the water “head” of the tank. A water head of

15 feet to 20 feet will cause the sensor to be 30 to

40 percent less sensitive due to the higher air

pressure. This is normally not a problem due to the

high refrigerant concentrations needed for a trip

condition (see Figure 4).

In summary, if at all possible mount the vent line sensor

on the tank atmospheric vent and utilize a water

monitoring method such as pH in the water tank.

Figure 3: Mounting the Vent Line Sensor when

using a water tank atmospheric vent

Suggest removing 3/4" plug to

allow ventilation across sensor to

minimize water condensation

Water level

Relief header

Water purge tank

Figure 4: Compressed air purge system for the

Vent Line Sensor

1 to 5 liters per minute

Relief header

Check valve

Tie in at lowest point

Flow meter Regulator Compressed

Needle valve

air supply

Filter

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 6

Page 7

2 Installation continued

C Wiring

Figure 5 presents wiring information for the VL-F7-LPA.

Electrical wiring must comply with all applicable codes.

Plant equipment that may be involved and operating

conditions should be discussed with local operating

personnel to determine if any special needs should be

taken into account.

Nearly all start-up problems are due to improper wiring

or monitor configuration. Please follow these guidelines

carefully.

Between the current pre-amp and monitoring equipment

use three conductor, #18 AWG, insulated, stranded,

shielded copper cable. Between the vent line sensor and

current pre-amp use #16 AWG, four conductors, nonshielded.

Do not pull sensor wiring with AC power cables. This

will cause electrical interference. Be sure there are no

breaks or splices in sensor wiring runs. If cable runs

cannot be made without a splice, all connections must

be soldered. Soldering should be done using a rosin flux

to tie the connecting ends of sensor wires to ensure a

positive and long-lasting contact.

Ground the shield at the main control panel. Tape all

exposed shield wire at the sensor to insulate it from the

enclosure.

conduit and dripping into the sensor enclosure. Silicone

should not be used near the sensor, because silicone can

damage the sensor.

Make drip loops for cables going into sensor housings.

Follow the mounting instructions on the Pre-Amp

enclosure (…This End Up). See Figure 2.

Electrical Power: 24 VDC regulated, 300 mA.

Output: Linear 4/20 mA output corresponding to 0–1%.

Monitoring equipment may have a maximum input

impedance of 250 ohms.

Cable Recommendation, Pre-Amp to Monitoring Device:

#18/3 shielded cable (Belden #8770 or equivalent). Length

of cable to pre-amp should be no greater than 1,500 feet.

Use only the existing punched holes for connections to the

pre-amp.

Cable Recommendation, Vent Line Sensor to Pre-Amp:

#16 AWG, 4 conductors non-shielded. Length of cable

from vent line sensor to pre-amp should be no greater

than 25 feet. Use only the existing punched holes for

connections to the pre-amp.

Monitoring: The VL-F7-LPA Sensor may be monitored

by the Manning Systems GM-10, GM-4, GM-1, GM-JR or

other appropriately configured system. Monitoring

equipment must be configured to indicate a fault if the

signal is below 1.5 mA.

All penetrations into a refrigerated room should be

sealed to prevent condensate from forming in the

A signal above 20 mA must be considered a high gas

concentration.

Figure 5: Wiring diagram for the Vent Line Sensor

TEST +

40 TO 200

TEST –

MVDC

SHD

12 TO 24 VDC

CAL

FLT

4 - 20 mA

GND

SPAN

ZERO

+24

GND

MANNING SYSTEMS, INC.

MSI LSS 400

REV 0

––

CAL

SIG

S

Gas sensor

2" N.P.T.

+

O

pipe plug

+

7/8" Diameter hole for 1/2"

conduit electrical connection.

Conduit hole should always be

mounted pointing down

R

R

O

RED

RED

ORANGE

ORANGE

VL sensor

VL sensor junction box cover

(cover removed)

R

R

O

O

Junction box may be rotated

1/2 turn either direction

relative to pipe plug to align

conduit hole as required to

facilitate electrical connection

Existing sensor wires

O-Ring seal gasket

for CEMA/NEMA 4

applications

25' maximum— 16 AWG,

4 conductors, non-shielded

Linear Pre-Amp

White— Connects to signal

input of monitoring equipment

Red— Connects to 24 VDC

power supply positive side

(300 mA)

Black— Connects to power

supply ground side

Bare— Connects to case

ground of monitoring

equipment (earth ground)

1500' maximum—

3-conductor #18 AWG shielded

(Belden #8770 or equivalent)

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 7

Page 8

3 Operation

A Start-Up Procedures

Before applying power, make a final check of all wiring

for continuity, shorts, grounds, etc. It is usually best to

disconnect external alarms and other equipment from

the sensor until the initial start-up procedures are

completed.

After power-up, allow 24 hours for the system to

stabilize before testing the sensors. Because sensors are

normally located at a distance from the main unit, the

test time required and accuracy of the response checks

will be improved if two people perform the start-up

procedures and use radio contact.

Start-Up Test:

• One person exposes each sensor to a small

amount of the gas that is being monitored.

• The second person stays at the control unit to

determine that each sensor, when exposed to the

gas fumes, is connected to the proper input and

responds, causing appropriate alarm functions.

To do this preliminary check, there are two simple

possibilities:

• Remove the full 2" test plug in the tee. Soak a

small rag in “Parsons Ammonia Cleaner” and stuff

this rag up the 2" tee to expose the sensor.

• Remove the small 3/4" plug in the tee and inject a

small amount of propane/butane from an unlit

plumber’s torch.

Either of the above methods will work for the ammonia

or halocarbon vent line sensor as they both use broadspectrum sensors.

B Calibration

Each Vent Line Sensor has been factory tested with a

calibrated gas sample. Information is noted on the data

sheet provided with each sensor.

Zero Calibration: After the unit is installed and has

been powered up for a minimum of 24 hours, the unit

should be zero calibrated by the following:

• Be sure the unit is in clean air, or apply zero air

at 0.8 L/min.

• Adjust the zero pot until the sensor outputs

4.0 mA (40 mV from Test [–] to Test [+]).

Span Calibration: The unit is factory calibrated and

normally does not need to be spanned. Do not adjust the

span pot without certified calibration gas! If span

adjustment is required, the following procedure will

span the unit:

• Perform zero adjustment before spanning

• Apply span gas at 0.8 L/min (span gas must be in

air, not nitrogen or other carrier).

• After span gas has been on sensor for two

minutes, adjust the span pot until the correct

output is achieved.

Calibration kits are available from Manning Systems.

Calibration of vent line sensors is normally done in the

field by using the simple method described under “StartUp Procedures” where the sensor is challenged with a

gas and the proper outputs and trips are observed.

(The challenge gas must cause a proper alarm trip.)

In a vent line the recommended trip point level is

approximately 17 mA. Lower setpoints can result in

false trips. Never set alarm points higher than 20 mA.

If certified gas samples are required, contact Manning

Systems for gases available and to discuss techniques in

calibration depending on how the vent line sensor is

mounted.

Due to environmental differences and background

gases, the installed clean air signal may be different

than it was during factory calibration. This difference

can be zeroed out.

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 8

Page 9

3 Operation continued

C Troubleshooting

The greatest probability for trouble is reversed or

incorrect wiring. Always be consistent with color codes

and double-check terminal screw tightness.

If sensor output is 0.5 mA: The vent line pre-amp

continuously monitors the status of the sensor and, if

fault conditions arise, the red FLT LED in the pre-amp

will light (see Figure 6). After a short time delay, the

pre-amp will output a signal of 0.5 mA. Monitoring

equipment must be configured to indicate a fault if the

signal is less than 1.5 mA.

First, check for proper color codes or loose wires to

sensors labelled “O O R R” on both the pre-amp and

vent line sensor.

Second, if the FLT LED is lit continuously, remove the

Vent Line Sensor junction box cover (see Figure 5). With

power off, measure the resistance across the “RR” (Red

Red) terminals which should be approximately 30 ohms.

If this is an open circuit, a replacement sensor is

required. Contact Manning Systems. If the FLT LED is

flashing, this indicates a faulty sensor. Contact Manning

Systems for a replacement sensor.

If the sensor output is 0 mA: First, verify +24 VDC at

the sensor terminal block (see Figure 6, Note 2).

Second, check voltage between Test– and Test+ (see

Figure 6, Note 1). Voltage should be in the range of 40 mV

to 200 mV corresponding to an actual current flow of 4 to

20 mA. If this voltage is 0 mV, the signal has no path to

ground. Check monitoring equipment connections and

configuration. Input impedance must be 250 ohms or less.

If sensor output indicates a gas concentration when the

vent line appears clean:

bushing carefully and you should observe a signal

decrease. Weeping pressure relief valves could be the

problem. Remove the full 2" plug for greater ventilation.

Always do the testing at the sensor with special

caution as all vent line systems could discharge at any

Always be prepared and wear appropriate

time.

protective gear such as a face shield and gloves.

Remove the 3/4" vent plug

A high signal can also be caused by lack of oxygen if the

sensor is located more than two feet from the atmospheric discharge. See the mounting instructions for

proper mounting techniques.

Contact Manning Systems for more details if you cannot

identify the problem.

D Maintenance

Manning Systems recommends that as a minimum

each sensor be challenged with a gas sample once each

six (6) months.

Also, the signal being sent by the sensor should be

logged on a monthly basis.

During the gas challenge test, all alarm outputs should

be confirmed and logged to insure system integrity.

E Replacement Parts

For replacement parts, contact Manning Systems, Inc.

Be sure to give serial number of unit.

Figure 6: Troubleshooting the 4/20 mA Vent Line

Sensor and Pre-Amp

Note 1: Checking signal

40-200 mV

mVDC

Black-Red

Note 2: Verifying +24VDC

Black-Red

+

17-24

VDC

+

TEST+

40 TO 200

TEST–

SPAN

ZERO

CAL

FLT

MVDC

SHD

GND

12 TO 24 VDC

4 - 20 mA

+24

MANNING SYSTEMS, INC.

MSI LSS 400

REV 0

GND

––

CAL

SIG

S

+

+

R

O

O

R

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 02/2005 REVF Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 9

Page 10

4. Limited Warranty

4 Limited Warranty

1. Limited Warranty

Honeywell Analytics, Inc. (”Honeywell”) warrants to

the original purchaser and/or ultimate customer

(”Purchaser”) of Honeywell’s products (”Product”) that

if any part thereof proves to be defective in material

or workmanship withing eighteen months of the date

of shipment by Honeywell or twelve months from the

date of rst use by the purchaser, whichever comes

rst, such defective part will be repaired or replaced,

free of charge, at Honeywell’s discretion if shipped

prepaid to Honeywell Analytics at 405 Barclay Boulevard,

Lincolnshire, Illinois 60069, in a package equal to or in

the original container. The Product will be returned

freight prepaid and repaired or replaced if it is

determined by Honeywell that the part failed due to

defective materials or workmanship. The repair or

replacement of any such defective part shall be

Honeywell’s sole and exclusive responsibility and

liability under the limited warranty.

2. Exclusions

A. If gas sensors are part of the Product, the gas

sensor is covered by a twelve month limited

warranty of the manufacturer.

B. If gas sensors are covered by this limited warranty,

the gas sensor is subject to inspection by Honeywell

for extended exposure to excessive gas

concentrations if a claim by the Purchaser is made

under this limited warranty. Should such inspection

indicate that the gas sensor has been expended

rather than failed prematurely, this limited warranty

shall not apply to the Product.

C. This limited warranty does not cover consumable

items such as batteries or items subject to wear or

periodic replacement including lamps, fuses, valves,

vanes, sensor elements, cartridges, or lter

elements.

3. Warranty Limitation and Exclusion

Honeywell will have no further obligation under this

limited warranty. All warranty obligations of Honeywell

are extinguishable if the Product has been subject to

abuse, misuse, negligence, or accident or if the

Purchaser fails to perform any of the duties set forth

in this limited warranty or if the Product has not been

operated in accordance with the instructions, or if

the Product serial number has been removed or

altered.

4. Disclaimer of Unstated Warranties

THE WARRANTY PRINTED ABOVE IS THE ONLY

WARRANTY APPLICABLE TO THIS PURCHASE. ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE ARE HEREBY

DISCLAIMED.

5. Limitation of Liability

IT IS UNDERSTOOD AND AGREED THAT HONEYWELL’S

LIABILITY, WHETHER IN CONTRACT, IN TORT, UNDER

ANY WARRANTY, IN NEGLIGENCE OR OTHERWISE

SHALL NOT EXCEED THE AMOUNT OF THE PURCHASE

PRICE PAID BY THE PURCHASER FOR THE PRODUCT

AND UNDER NO CIRCUMSTANCES SHALL

HONEYWELL BE LIABLE FOR SPECIAL, INDIRECT, OR

CONSEQUENTIAL DAMAGES. THE PRICE STATED FOR

THE PRODUCT IS A CONSIDERATION LIMITING

HONEYWELL’S LIABILITY. NO ACTION, REGARDLESS

OF FORM, ARISING OUT OF THE TRANSACTIONS

UNDER THIS WARRANTY MAY BE BROUGHT BY THE

PURCHASER MORE THAN ONE YEAR AFTER THE

CAUSE OF ACTION HAS OCCURRED.

Manning VL-F7-LPA Gas Sensor 18394 VLF7LPA 07/2016 REVH 10

Loading...

Loading...