Page 1

Manning Systems, Inc. provides a complete

line of industrial quality Gas

Alarm

Monitoring Systems for equipment

rooms,

refrigerated spaces, storage facilities,

laboratories and process areas.

Honeywell Analytics

23500 West 105th St., MD400

Olathe, Kansas 66061

1.800.444.9935 or 913.712.5576

fax 913.712.5580

www.honeywellanalytics.com

The Manning Systems GM-JR is a readout/alarm unit that can

be configured in a variety of ways to solve many gas concentration

and alarm needs at a very affordable price. The readout provides

a calibrated 20-segment LED bargraph, alarm and fault LEDs,

plus a relay output with easy trip point adjustment.

T

he GM-JR standard configu-

ration is composed of a single,

rugged, miniaturized board

mounted inside the door of the

enclosure, and a separate

terminal board for the sensor

and/or power cable connections.

The 20-segment LED bargraph

has a calibrated scale that is

specified when ordered. Alarm

trip adjustments are made

easily at 5% increments by a

shorting bar on the back of the

display board.

On power up or after momentary

power loss, the bottom bargraph

segment blinks during a oneminute power-up delay period.

During this time the alarm relay

is forced into its “no alarm”

condition to allow the sensor to

stabilize. After this time delay,

the bargraph will stop blinking,

indicating the readout is armed.

The GM-JR continuously

monitors the incoming 4/20 mA

signal from the sensor. If the

signal drops below 1.4 mA, the

fault LED will illuminate and

the alarm relay will trip. The

alarm relay is always energized

in its normal state, providing

additional safety.

The GM-JR has an easily

adjusted set-point and relay

output in either the “stand-

alone” or “feed through” configuration, plus 4/20mA output in

the “feed through” design. With

its own plug-in power supply,

the GM-JR/ Manning sensor

combination provides an

economical answer for local

concentration level information

and control capability

GM-JR

Gas Monitor

Readout /Alarm

Applications

The GM-JR offers unique configuration possibilities for clients

who have their own computer

control system, OEMs who want

to incorporate gas sensing in

their design and existing

Manning Systems customers

who want remote indication

other than at their main readout.

Key Features

20-segment calibrated bargraph

Power-up delay

Fail-safe design

Easy Trip setting

Relay Output is time delayed

Downscale Alarm Configuration

available for oxygen

Rugged NEMA 1, steel gasketed

enclosure

Continuous fault monitoring

Feed-through Configuration

allows remote readout capability while being powered

from instrument cable (no

remote power supply needed)

Page 2

Gas Monitor

Readout /Alarm

GM-JR

Power Requirement:

15-24 VDC regulated

Signal Input:

4/20 mA precision differential input

allows this unit to be mounted remotely

and powered from sensor power

(internal resistance drop, 100 ohms)

Maximum Current Draw:

300 mA (in standard configuration and no

upscale indication, the standby current

draw is 100 mA.)

Display:

20-segment LED bargraph, bottom segment

flashes to indicate power up delay, lights

continuously to indicate power on

Trip Setting:

5% increments by use of shorting tab

Alarm Indication:

Red LED

Fault Indication:

White LED (at 1.4 mA or below)

Accuracy:

LED readout provides 5% of full scale resolution – trip accuracies at these 5%

increments are within ±1% of set point

Time Delays:

Alarm relay is 10 second delay ON,

30 second delay for RESET after alarm

condition clears.

Power Up Time Delay:

On application of power the alarm relay

will be held in the normal state for one (1)

minute to allow the sensor to stabilize.

Relay Alarm Output:

Relay is rated at 0.5 amp at 24 VDC or

24 VAC – relay will trip on Alarm and Fault

conditions.

Operating Temperatures:

0˚F to 120˚F; Storage, -40˚F to 160˚F

Operating Humidity:

5-95% RH, non-condensing

Weight:

3 lbs.

Dimensions:

6"H x 4"W x 3.5"D

Cable Requirements:

#18/3 shielded cable (Belden #8770) for

runs up to 1,000' – high current draw

sensors may require larger cable

(contact Manning Systems for details)

Enclosure:

16 gauge steel, gasketed, painted

NEMA 1 rated

Options:

Down Scale Alarm for oxygen

Can be mounted in most Manning

Systems sensors

Specifications subject to change without notice.

Specifications

Possible Applications

Calibration Gas Kits are always available

from Manning Systems to maintain and

verify the highest level of total system

performance.

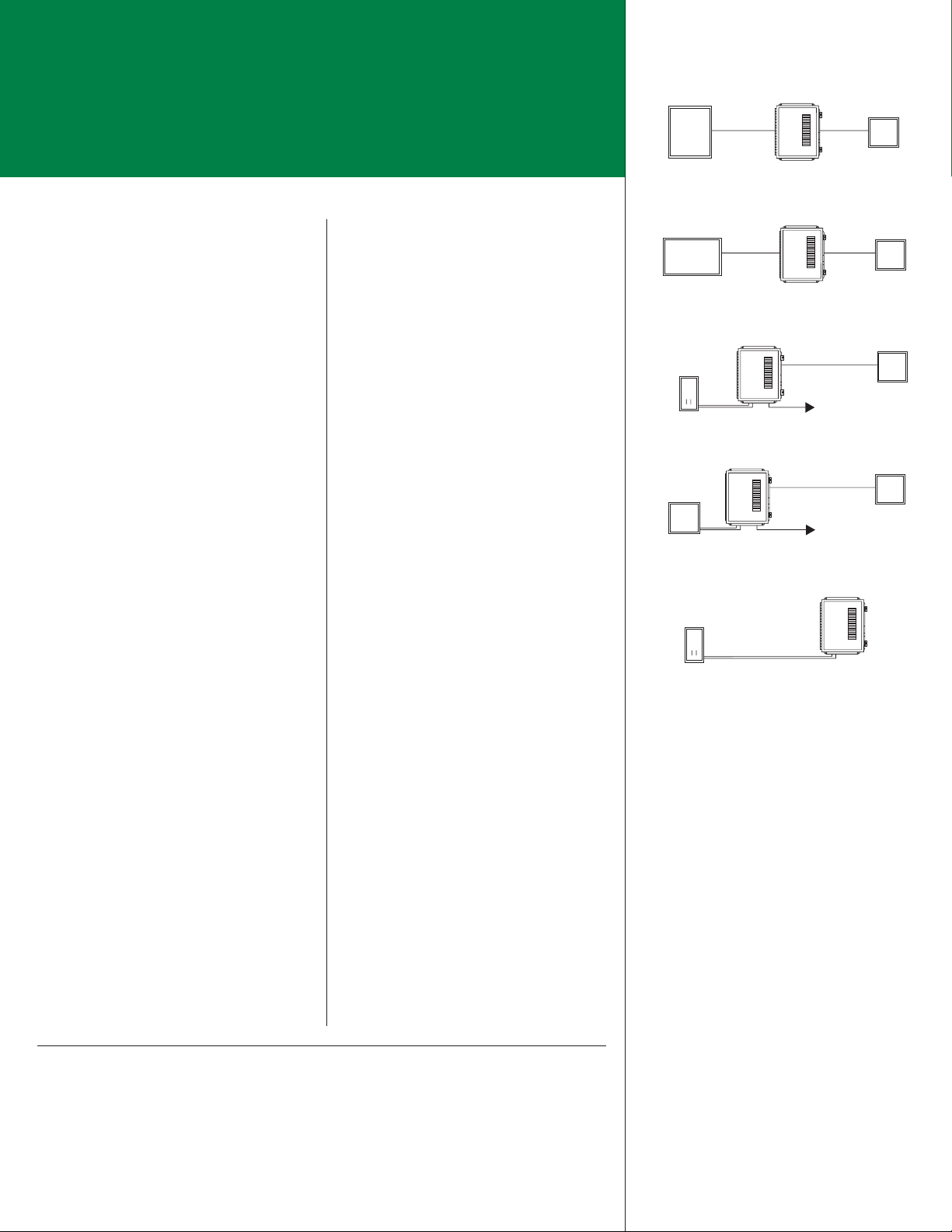

GM-JR in Sensor enclosure

Concentration Display at Sensor

Plug-in Transformer

GM-JR Sensor

OEM Installation

Output to shut

down equipment

24 VDC Supply

GM-JR Sensor

Stand Alone Configuration

120 VAC Plug-in

Power Supply

Relay Output

GM-JR Sensor

Used with Computer

Customer Computer

Monitor at selected

locations

GM-JR Sensor

Used with Manning Systems Main Readouts

GM-10 Readout

Unit located in

maintenance office

Located outside

machine room

Sensor in

machine room

GM-JR 19546 07/ 2009

Copyright © 2009 Honeywell Analytics. All Rights Reserved.

Honeywell Analytics

1-800-538-0363 USA

1-888-749-8878 Canada

+44 (0)1202 676161 Europe

+82 (0)2 2025 0307 Asia Pacific

+971 4 3458 338 Middle East

Corporate Headquarters

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Phone: 1-847-955-8200

Fax: 1-847-955-8210

E-mail: detectgas@honeywell.com

www.honeywellanalytics.com

Loading...

Loading...