Page 1

INSTRUCTION AND

INSTALLATION MANUAL

EC-F2 SENSOR FOR

CARBON MONOXIDE

Model EC-F2-CO

Honeywell Analytics

405 Barclay Blvd

Lincolnshire, IL 60069

847 955 8200

800 538 0363

847 955 8208 (FAX)

detectgas@honeywell.com

www.honeywell.com

Page 2

CONTENTS

Section Title Page

1 Sensor Description 2

2 Installation 3

3 Operation 5

4 Warranty 7

SENSOR DESCRIPTION 1

A Introduction

This manual has been prepared to

help in the use and installation of the

Manning Systems’ Model EC-F2-CO

(Electrochemical-Carbon Monoxide) Sensor. This manual will convey the operating principles of the sensor, ensure proper

installation, and demonstrate start-up and

routine maintenance procedures for the

sensor.

This manual must be carefully followed by all individuals who have or

will have the responsibility for using or

servicing the sensor. Warranties made

by Manning Systems, Inc. with respect to

this equipment will be voided if the equipment is not used and serviced in accordance with the instructions in this manual.

If in doubt about a procedure, please

contact Manning Systems, Inc. before

proceeding.

B System Description

The Manning Systems’ EC-F2 Sensor is a three-wire, 4/20 mA sensor for

carbon monoxide available in ranges of

0-200 ppm, and 0-400 ppm.

The unit exhibits excellent accuracy

and precision, with negligible response to

common interference gases and dramatic

changes in relative humidity. Reliable

trip levels as low as 35 ppm can be expected with the 0-200 ppm sensor. The

unit exhibits extremely high reliability

with no moving parts.

Monitoring equipment must be configured to indicate a fault if the signal is

less than 1.5 mA. All signals over 20 mA

must be considered a high gas concentration.

System Specifications:

Electrical Power: 24 Volts DC regu-

lated, 30 mA. With a heated enclosure,

the current draw is 300 mA max.

Output: Linear 4-20 mA output into

a load resistor of 250 ohm maximum.

Cable Recommendation: Threeconductor, 18 AWG, stranded, shielded

cable with drain wire all enclosed in a

vinyl jacket (Belden #8770 or equivalent).

Cable Length to Sensor: 1,500 feet

maximum.

Unit Enclosure: NEMA 1, gasketed,

16-gauge steel. Special enclosures available for NEMA 4, explosion-proof, low

temperatures, ventilation ducts, washdown

areas, etc.

Note: The standard EC-F2 is for

use in non-classified areas only.

Serial Number

Sensor Specifications:

Type: Carbon monoxide-selective

electrochemical gas sensor/transmitter

Model EC-F2-CO

Method of Detection: Electrochemi-

cal.

Ranges Available:

0-200 ppm

0-400 ppm

Accuracy: +/- 3% of full scale.

Humidity: 5-95% RH (non-con-

densing). Modifications are available for

more severe conditions.

Operating Ambient Temperature

range: -15o F to 120o F. Modifications

are necessary for refrigerated areas.

Storage Temperature: -40o F to

+70oF. Keep sensor as cool as possible

during long-term storage to extend the life

of the cell.

Gas Sampling: Diffusion.

Weight: 3 pounds.

Dimensions: 6” high x 4” wide x

3.5” deep.

2 MANNING EC-F2-CO SENSOR 305-0112-d

Page 3

INSTALLATION 2

A Locating the EC-F2

Sensor

Each sensor is a point measurement,

and it is very important that the sensor

be located properly.

Because each sensor can only “re-

port” what it is smelling at the moment, it

is very important that the sensor be

located where leaks are most likely to

occur.

Locate the sensor close to the expected source of carbon monoxide. Carbon monoxide vapor is about the same

weight as ambient air, so for area personnel protection consider mounting the sensor in the normal breathing zone (four to

five feet above the floor).

One of the most important considerations when installing EC sensors is that

they

must be easily accessible for calibra-

tion and maintenance.

General: The location should be

chosen to protect the sensor from water,

excessive humidity, and vibration. MOST

REPLACEMENT IS DUE TO WATER

SENSOR

DAMAGE

by clean-up and maintenance crews.

closer than 3 feet from walls or 1 foot

from the ceiling. Take air movement and

ventilation patterns into account when

locating sensors.

mounted, it must be easily accessible.

bration and maintenance.

tential leak source.

mary application, mount in the “breathing

zone.”

sive humidity, and wash-down.

patterns into account.

keep sensor and wire runs away from

! Protect sensors from hose-down

As a general rule, locate sensors no

No matter where the sensor is

General Mounting Considerations:

• Must be easily accessible for cali-

• Always mount the sensor vertically.

• Mount the sensor close to the po-

• If personnel protection is the pri-

• Protect sensor from water, exces-

• Take air movement and ventilation

• To prevent electrical interference,

mercury vapor lights, variable speed

drives, and radio repeaters.

• Protect sensor from physical dam-

age (fork lifts, etc.).

• Do not mount the sensor over a

door in a refrigerated area.

• If mounting sensor outdoors, consider prevailing wind direction and proximity to the most likely source of leaks.

Protect the sensor from sun and rain as

much as possible.

• For highly critical locations more

than one sensor should be installed in

each room.

Engine Rooms: The EC sensor

should be mounted in a cool part of the

room, if possible. Keep the sensor away

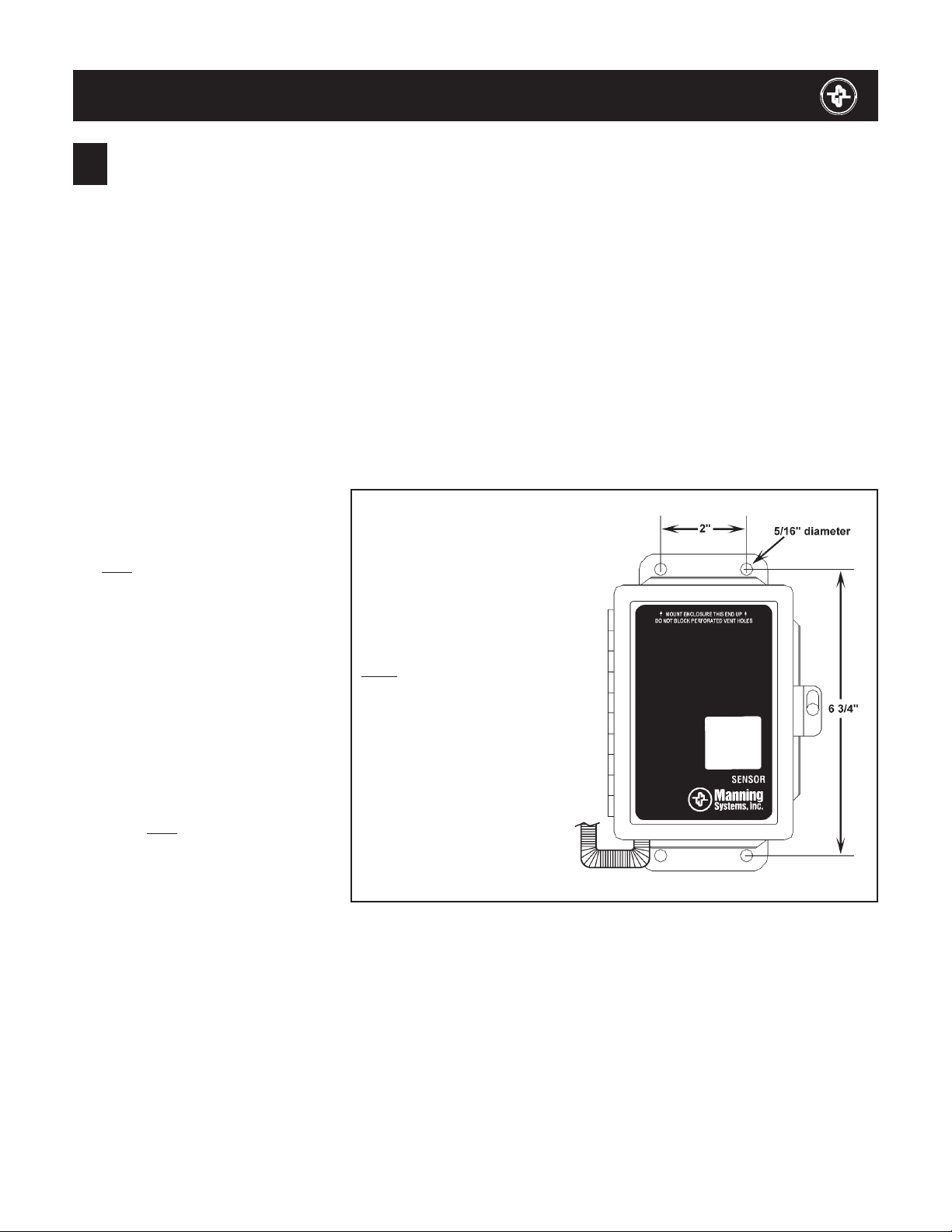

Sensor must be mounted vertically

Never mount flat on a ceiling

Enter enclosure only through existing hole in bottom

Always make a drip loop in the

conduit

Figure 1: Mounting dimensions for the EC-F2 Sensor

from hot air exhausting from electric

motors or other machinery. Usually the

best location is four or five feet above the

floor in a location where the room exhaust

fan will move air across the sensor from

the potential leak source.

Vehicles: If the unit is mounted in a

vehicle, be sure to shock mount the unit to

isolate it from vibration.

Other Locations: When mounting

EC sensors in locations such as roof top

air units, duct-work, attic spaces, makeup

air intakes, etc., contact Manning Systems for application assistance and recommendations. Figure 1 presents mounting dimensions for the EC-F2 Sensor.

3 MANNING EC-F2-CO SENSOR 305-0112-d

Page 4

INSTALLATION (CONT’D) 2

B Wiring

Figure 2 presents wiring information

for the EC-F2 sensor.

Electrical wiring must comply with

all applicable codes. Plant equipment

that may be involved and operating conditions should be discussed with local

operating personnel to determine if any

special needs should be taken into account.

Almost all start-up problems are due

to improper wiring or monitor configuration. Please follow these guidelines carefully.

Always use three conductor, insulated, stranded, shielded copper cable.

Use only three conductor cable, not two

cables of two conductor wire.

Do not pull sensor wiring with AC

power cables. This will cause electrical

interference. Be sure there are no breaks

or splices in sensor wiring runs. If cable

runs cannot be made without a splice, all

connections must be soldered. Soldering

should be done using a rosin flux to tie the

connecting ends of sensor wires to ensure

a positive and long-lasting contact.

Ground the shield at the main control

panel. Connect the shield wire in the

sensor terminal block labeled SHLD.

Tape all exposed shield wire at the sensor

to insulate it from the enclosure.

All penetrations into a refrigerated

room should be sealed to prevent condensate from forming in the conduit and dripping into the sensor enclosure. Silicone

should not be used near the sensor, because silicone can damage the sensor.

Make drip loops for cables going into

sensor housings. When heated enclosures are used, follow the special mounting instructions on the enclosure (This

End Up).

Mount sensor enclosures through the

flange holes as shown in Figure 1, and

always mount vertically.

Electrical Power: 24 VDC regulated, 30 mA. With a heated enclosure the

current draw is 300 mA max.

Output: Circuit board mounted sensor provides a linear 4/20 mA output.

Monitoring equipment may have a maximum input impedance of 250 ohms.

Cable Recommendation: No. 18/3

shielded cable (Belden #8770 or equivalent). Length of cable to sensor should be

no greater than 1,500 feet. Use only the

existing punched holes for connections to

the sensor.

Monitoring: The EC-F2 Carbon

Monoxide Sensor may be monitored by

the Manning Systems’ Model 20, GM-1,

GM-JR, GM-10, or other appropriately

configured system. Monitoring equipment must be configured to indicate a

fault if the signal is below 1.5 mA. All

signals over 20 mA must be considered a

high gas concentration.

Connects to signal input of monitoring equipment

Connects to 24 VDC power supply positive side (40300 mA depending on environment)

Connects to 24 VDC ground side

Connects to case ground of monitoring equipment (earth ground)

Figure 2: Wiring diagram for the EC-F2 Sensor

4 MANNING EC-F2-CO SENSOR 305-0112-d

Page 5

OPERATION 3

A Start-Up Procedures

Before applying power, make a final

check of all wiring for continuity, shorts,

grounds, etc. (see Figure 3, Note 5). It is

usually best to disconnect external alarms

and other equipment from the sensor until

the initial start-up procedures are completed.

After power-up, allow 24 hours for

the system to stabilize before testing the

sensors. Because sensors are normally

located at a distance from the main unit,

the test time required and accuracy of the

response checks will be improved if two

people perform the start-up procedures

and use radio contact.

Start-Up Test:

1) One person exposes each sensor to

a small amount of the gas that is being

monitored.

2) The second person stays at the

control unit to determine that each sensor,

when exposed to the gas fumes, is connected to the proper input and responds,

causing appropriate alarm functions.

• Perform zero adjustment before

spanning.

• Apply span gas at 0.8 L/min (span

gas must be in air, not nitrogen or other

carrier).

• After span gas has been on sensor

for two minutes, adjust the span pot until

the correct output is achieved (see Figure

3, Note 1).

Calibration kits are available from

Manning Systems.

Note 1: Span Adjustment

Note 2: Zero Adjustment

Note 5: Sensor cable plugs in here.

Verify that sensor is plugged in

properly and cable is secured

B Calibration

The EC-F2 Sensor comes factory calibrated and should require minimal adjustments after installation. There are two

pots on the pre-amp that are used for

calibrations.

Zero Calibration: After the unit is

installed and has been powered up for a

minimum of 24 hours, the unit should be

zero calibrated by the following:

• Be sure the unit is in clean air.

• Adjust the zero pot until the sensor

outputs 4.0 mA (40 mV from Test [-] to

Test [+]) (see Figure 3, Note 2 and 4).

Span Calibration: The unit is fac-

tory calibrated and normally does not

need to be spanned upon initial installation. DO NOT ADJUST THE SPAN POT WITHOUT

CERTIFIED

ment is required, the following procedure

will span the unit:

CALIBRATION GAS! If span adjust-

Note 4: Sensor Output

Note 3: Power Supply Voltage

Figure 3: Checking sensor output, power supply voltage, and zero

and span adjustments to the EC-F2 Sensor

5 MANNING EC-F2-CO SENSOR 305-0112-d

Page 6

OPERATION (CONTINUED) 3

C Troubleshooting

If the sensor output is 0 mA: First,

verify +24 VDC at the sensor terminal

block (see Figure 3, Note 3).

Second, check voltage between Test

(-) and Test (+) (see Figure 3, Note 4).

Voltage should be in the range of 40 mV

to 200 mV corresponding to an actual

current flow of 4 to 20 mA. If this voltage

is 0 mV, the signal has no path to ground.

Check monitoring equipment connections

and configuration. Input impedance must

be 250 ohms or less.

Electrical Interference: This sensor has been designed to be highly resistant to EMI/RFI using multiple stages of

filtering and protection. However, in

extreme environments, some noise pickup

can occur directly through the sensor.

Ensure that the bare shield wire of the

instrument cable is connected to the terminal block marked SHLD at the sensor

(not touching the metal enclosure) and

properly grounded at the readout unit.

Interference Gases: The EC-F2CO is designed to be quite specific to

carbon monoxide. However, hydrogen

can give a slight upscale indication. Carbon monoixide is a colorless, odorless gas

which can’t be sensed by humans at these

levels. Always double check with another

instrument before assuming carbon monoxide is not present.

D Maintenance

For proper operation it is essential

that the test and calibration schedule be

adhered to. Manning Systems recommends the following maintenance schedule:

• Response test once per month. Expose sensor to carbon monoxide to verify

proper sensor response and alarm functions. Test more frequently in highly

critical applications.

• Calibration should be performed

with certified calibration gas every six

months. Calibration kits are available

from Manning Systems.

• All tests and calibrations must be

logged

Sensor Life: These electrochemical

cells are extremely reliable, but several

things can cause the cell chemicals to

become depleted including:

• a period of time,

• exposure to high temperatures,

• exposure to varying concentrations

of the target gas,

• exposure to high moisture for

extended periods without proper

sensor enclosure.

When the cell becomes depleted, the unit

will give no indication of failure other

than that the sensor will not respond. For

this reason it is absolutely essential that

these units be exercised with a gas

sample on a regular and timely basis.

Typical sensor life in a refrigerated

area will be 18 months to 2 years or more.

Typical life in a non-refrigerated area will

be 12 months or less. Exposure to high

levels of carbon monoxide will shorten

these times. In addition to timely response checks, a preventative maintenance

program of periodic cell replacement

should be implemented.

When the cell becomes depleted, a

replacement cell can be obtained from

Manning Systems. Simply unplug the

ribbon cable from the pins labeled Sen-

sor, pull the old cell from the spring clip,

discard the old cell and replace it with a

new one.

The sensor should be calibrated after

a 24 hour warm-up period.

E Replacement Parts

For replacement parts, contact Manning Systems. Be sure to give serial

number of unit and model number.

6 MANNING EC-F2-CO SENSOR 305-0112-d

Page 7

WARRANTY 4

Limited Warranty

1. Limited Warranty. Manning Systems, Inc. (“Manning”) warrants to the

original purchaser and/or ultimate customer (“Purchaser”) of Manning’s Products (“Product”) that if any part thereof

proves to be defective in material or workmanship within eighteen (18) months of

the date of shipment by Manning or twelve

(12) months from the date of first use by

the purchaser, whichever comes first, such

defective part will be repaired or replaced,

free of charge, at Manning’s discretion if

shipped prepaid to Honeywell at 405

Barclay Blvd, Lincolnshire, IL 60069, in a

package equal to or in the original container. The Product will be returned freight

prepaid and repaired or replaced if it is

determined by Manning that the part failed

due to defective materials or workmanship. The repair or replacement of any

such defective part shall be Manning’s

sole and exclusive responsibility and liability under this limited warranty.

2. Exclusions.

A. If gas sensors are part of the

Product, the gas sensor is covered by a

twelve (12) month limited warranty of the

manufacturer.

B. If gas sensors are covered by this

limited warranty, the gas sensor is subject

to inspection by Manning for extended

exposure to

if a claim by the Purchaser is made under

this limited warranty. Should such inspection indicate that the gas sensor has

been expended rather than failed prematurely, this limited warranty shall not apply to the Product.

cover consumable items, such as batteries, or items subject to wear or periodic

replacement, including lamps, fuses,

valves, vanes, sensor elements, cartridges,

or filter elements.

3. Warranty Limitation and Exclusion. Manning will have no further obli-

gation under this limited warranty. All

warranty obligations of Manning are extinguishable if the Product has been subject to abuse, misuse, negligence, or accident or if the Purchaser fails to perform

any of the duties set forth in this limited

warranty or if the Product has not been

operated in accordance with instructions,

or if the Product serial number has been

removed or altered.

4. Disclaimer of Unstated Warranties. THE WARRANTY PRINTED

ABOVE IS THE ONLY WARRANTY

APPLICABLE TO THIS PURCHASE.

ALL OTHER WARRANTIES, EX-

excessive gas concentrations

C. This limited warranty does not

PRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

5. Limitation of Liability. IT IS UNDERSTOOD AND AGREED THAT

MANNING’S LIABILITY, WHETHER

IN CONTRACT, IN TORT, UNDER

ANY WARRANTY, IN NEGLIGENCE

OR OTHERWISE SHALL NOT EXCEED THE AMOUNT OF THE PURCHASE PRICE PAID BY THE PURCHASER FOR THE PRODUCT AND

UNDER NO CIRCUMSTANCES

SHALL MANNING BE LIABLE FOR

SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES. THE PRICE

STATED FOR THE PRODUCT IS A

CONSID ERATION LIMITIN G

MANNING’S LIABILITY. NO ACTION, REGARDLESS OF FORM, ARISING OUT OF THE TRANSACTIONS

UNDER THIS WARRANTY MAY BE

BROUGHT BY THE PURCHASER

MORE THAN ONE YEAR AFTER THE

CAUSE OF ACTION HAS OCCURRED.

7 MANNING EC-F2-CO SENSOR 305-0112-d

Loading...

Loading...