Page 1

Multi-Channel Gas Monitoring System

Manning AirAlertTM96d

Instruction and Installation Manual

07/09

Release C Draft

Honeywell Confidential & Proprietary

This work contains valuable, confidential, and proprietary information. Disclosure, use

or reproduction outside of Honeywell Inc. is prohibited except as authorized in writing.

This unpublished work is protected by the laws of the United States and other countries.

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 1

Page 2

Notices and Trademarks

Copyright 2009 by Honeywell International Inc.

Release C July 2009

While this information is presented in good faith and believed to be accurate, Honeywell disclaims the implied

warranties of merchantability and fitness for a particular purpose and makes no express warranties except as may

be stated in its written agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The information and

specifications in this document are subject to change without notice.

Manning is a registered trademark of Honeywell International Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell Analytics

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

1-800-538-0363

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 2

Page 3

About This Document

World Wide Web

The following Honeywell web sites may be of interest.

Honeywell Organization WWW Address (URL)

Corporate www.honeywell.com

Honeywell Analytics www.honeywellanalytics.com

Manning Gas Detection www.manningsystems.com

Telephone

Contact us by telephone at the numbers listed below.

Organization Phone Number

United States Honeywell Analytics Inc. 1-800-538-0363

1-913-712-5576

1-913-712-5580 Fax

Canada Honeywell Analytics Inc. 1-888-749-8878

Europe Honeywell PACE +44 (0)1202 676161

Asia Pacific Honeywell Asia Pacific Inc. +82 (0)2 2025 0307

Middle East Honeywell Analytics Inc. +971 4 3458 338

Sales Information

Contact us at detectgas@honeywell.com

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advise or hints for the user, often in terms of performing a task.

REFERENCE-EXTERNAL: Identifies an additional source of information

outside of this bookset.

REFERENCE-INTERNAL: Identifies an additional source of information within

this bookset.

WARNING: Indicates a potentially hazardous situation, which, if not avoided,

could result in injury or death.

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 3

Page 4

Contents Serial number:

Section Title Page

1 Introduction 6

A Safety Information — Read First 6

B Getting Started 6

2 Installation 7

A Guidelines 7

B Mounting Installation 7

3 Wiring 8

A Power 10

B Communication 10

C Relay Outputs 11

D Jumper Instructions 11

4 Initial Startup 12

A Datalogger (SDcard) 12

B User Interface 12

5 Operation 13

Normal, Single Tx, Debug, and Simulation Modes 13

6 Programming Menus 14

Controller Information 14

Sensor Information 14

Relay and Annunciator Information 14

Event Information 14

7 Configuration 15

A Main Menu 15

B Acquisition Mode 18

8 Specifications 24

9 Maintenance 24

Periodic Inspections and Calibration 24

Replacement Parts 24

Cleaning 24

Battery Disposal 24

10 Relay Module (optional) 25

11 Limited Warranty 27

Figure Title Page

1 Manning AirAlertTM96d 6

2 Installation 7

3 System Wiring 8

4 Sample Network Wiring 9

5 Power Wiring 10

6 Communications Wiring 10

7 Relay Outputs 11

8 Datalogger 12

9 User Interface 12

10 Tx Log 19

11 Manning AirAlert

12 Relay Module PCB 26

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 4

TM

96d-RMS 25

Page 5

Introduction

This manual has been prepared to help in the use and installation of the Manning AirAlertTM96d Multi-Channel Gas

Monitoring System. This manual will convey the operating principles of the sensor, ensure proper installation, and

demonstrate start-up and routine maintenance procedures.

ATTENTION: This manual must be carefully followed by all individuals who have or will have the

responsibility for using or servicing the Manning AirAlert

Honeywell Analytics with respect to this equipment will be voided if the equipment is not used and serviced in

accordance with the instructions in this manual. If in doubt about a procedure, please contact Honeywell Analytics

before proceeding.

TM

96d gas monitor. Warranties made by

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 5

Page 6

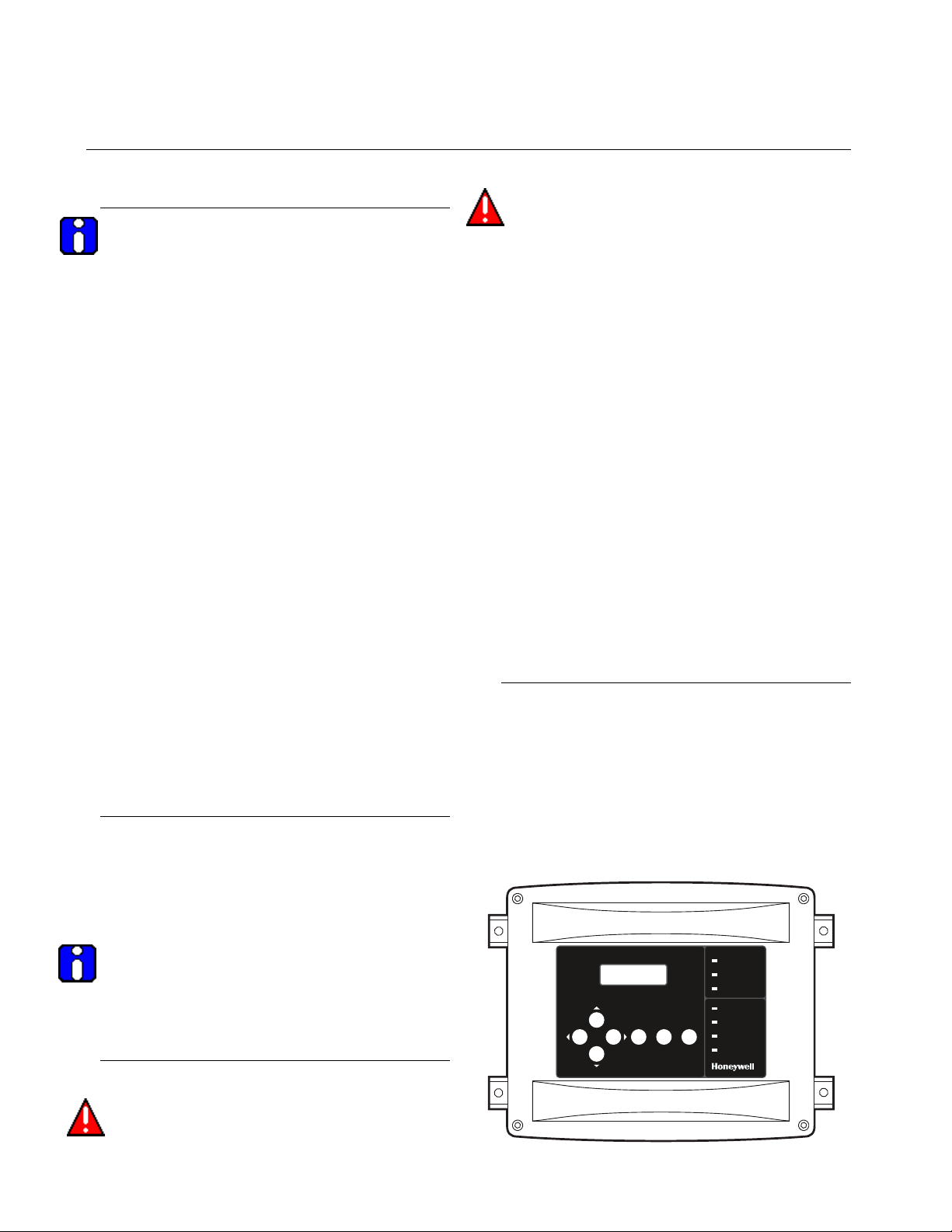

1 Introduction

Warning

To ensure your personal safety, read “Safety

Information” (below) before you use the controller.

The Manning AirAlert

TM

96d system sets new

standards in gas detection and in the measurement

of environmental parameters.

Acting as the nerve center of a modular gas detection

network, the Manning AirAlert

TM

96d provides

continuous monitoring of up to 96 connected units on

three distinct channels.

The Manning AirAlert

TM

96d provides a full array of

displays. At a glance, it is possible to determine the

status of the entire network. Field modifications are

straightforward. A menu driven program allows for

minor fine-tuning of the sequence of operation all the

way to the reconfiguration of the entire network.

Since no two projects are alike, the Manning

AirAlert

TM

96d is designed to be highly customized.

Combined with ease of installation, this unit

represents the most affordable gas monitoring

solution for institutional, commercial and light

industrial applications.

For more advanced applications, the Manning

AirAlert

TM

96d controller provides datalogging

capacity within a cast aluminum enclosure. The

perfect solution for even the most complex of

industrial applications.

A Safety Information — Read First

Use the controller only as specified in this manual,

otherwise the protection provided by the controller

may be impaired.

• Warning: To prevent ignition of flammable

or combustible atmospheres, disconnect

power before servicing.

• Do not use the controller if it is damaged.

Before you use the controller, inspect the

case.

• If the controller is damaged or something is

missing, contact Honeywell Analytics

immediately.

To avoid possible damage to the controller:

• Do not expose the controller to electrical

shock and/or severe continuous mechanical

shock.

• Do not attempt to disassemble, adjust, or

service the controller unless instructions for

that procedure are contained in the manual

and/or that part is listed as a replacement

part. Use only Manning replacement parts.

The controller Warranty could be voided if customer

personnel or third parties damage the controller

during repair attempts.

B Getting Started

Intended Use

The Manning AirAlert

around the clock monitoring of the gas detection

network. Moreover, a log of all the sensors

concentrations and alarms will be created for analysis

with the datalogger option. Also, the grouping/zoning

capabilities will result in energy cost savings.

Figure 1. Manning AirAlertTM96d

TM

96d controller will provide

Read the Warnings and Cautions on the following

pages before using the controller.

Note: This instrument contains a lithium battery.

Do not mix with the solid waste stream. Spent

batteries should be disposed of by a qualified

recycler or hazardous materials handler.

Caution

To avoid possible personal injury:

Manning AirA lert 96d

Enter ESC Silence

Warn

Alarm

High Alarm

Power

Fault

TX

RX

• Warning: Substitution of components may

impair intrinsic safety.

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 6

Page 7

2 Installation

A Guidelines

These guidelines must be strictly observed to assure

that the equipment will work properly. If they are not

applied, Honeywell Analytics will not recognize any

liability in case of improper operation.

• Make sure to locate all units easily accessible

for proper service.

• Avoid any location where units could be

subject to vibrations.

• Avoid any location close to any electro-

magnetic interference.

• Avoid any location where there are large

temperature swings.

• Verify local requirements and existing

regulations, which may affect the choice of

location.

Warning

A cable with more than one pair of wires is

unacceptable for communication use.

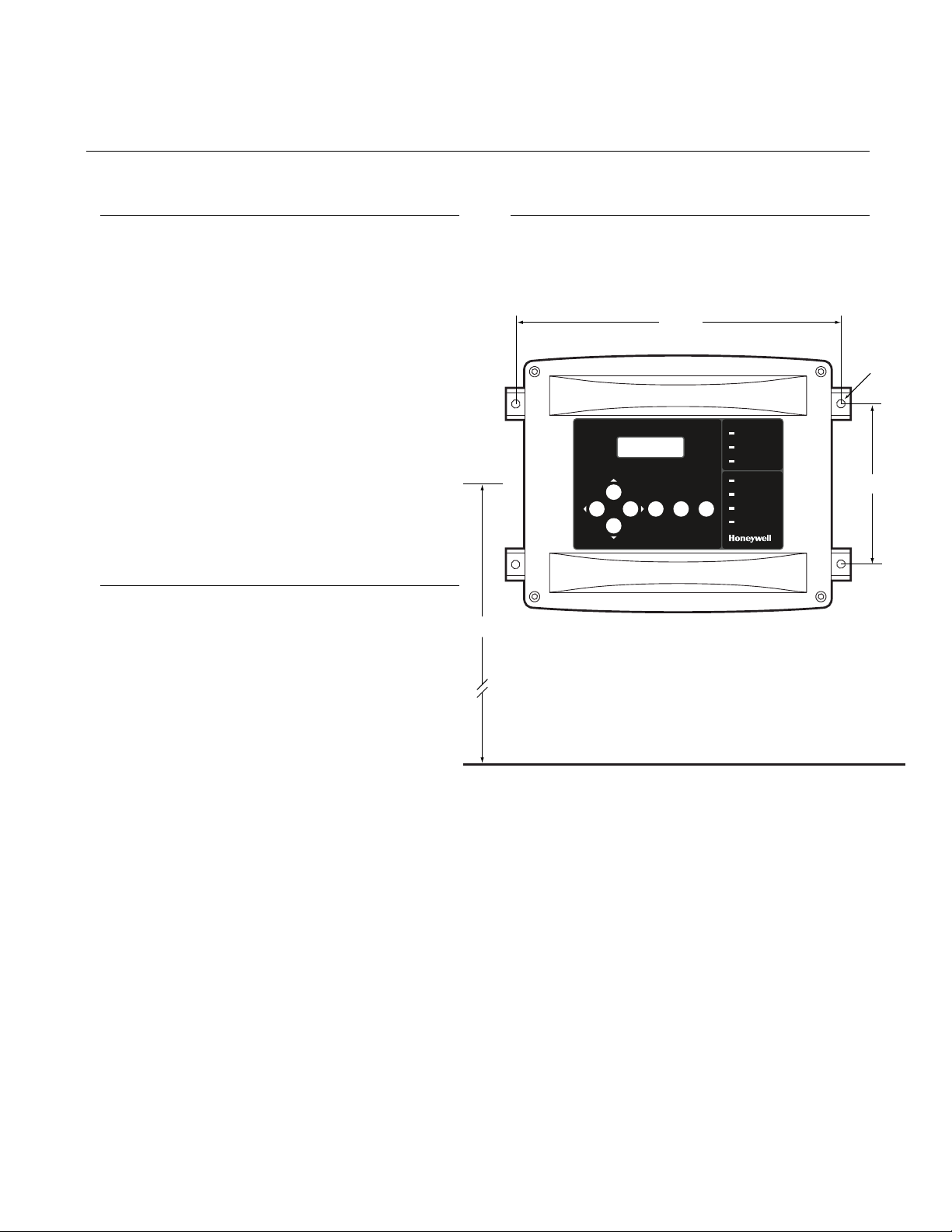

B Mounting Installation

The suggested height for controller installation is

5 feet from the floor.

Figure 2. Installation

Manning AirA lert 96d

5’

13.2”

Enter ESC Silence

Warn

Alarm

High Alarm

Power

Fault

TX

RX

0.28” diameter

6.25”

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 7

Page 8

3 Wiring

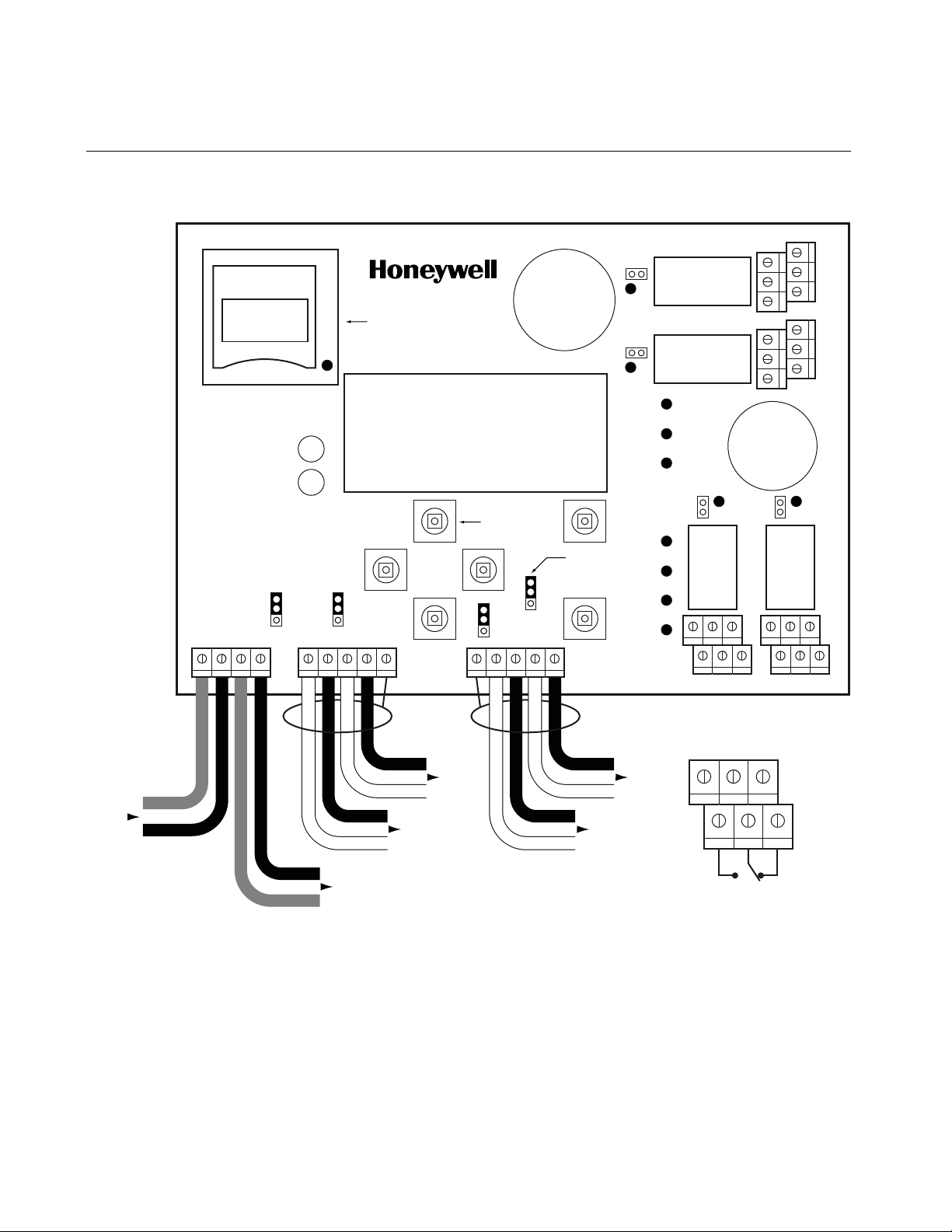

Figure 3. System Wiring

In Out

J22

V+ V-

V+

EOL2

V-

RC

R

J23

A1 B1 SHLDA2B2

EOL3

SD card datalogger

RC

R

Pushbutton

EOL4

RC

R

J24

SHLD A3 B4B3A4

EOL1

RC

R

End-of-line

jumper position

Relay 4

Relay 3

Warn

Alarm

System status LEDs

High Alarm

Power

Relay 1 Relay 2

Fault

TX

RX

NO NC NO NC

J26

J3

J7

NC

NO

NC

NO

J25

Relay Outputs (J3-J7-J25-J26)

5A, 30 Vdc or 120 Vac (resistive load)

Previous

Channel 2

Channel 1

Channel 4

642

Channel 3

531

Next

Power Requirements (J22): Communication Requirements (J23 - J24):

• 24 Vdc, 500 mA • 24 AWG twisted pair, shielded (Belden 9841 or equivalent)

• 14 AWG, 2 conductor, stranded cable

(Belden 5100UE or equivalent)

• Up to 10 sensors per power supply

• Up to 1,000 feet max power cable length per power supply

• Larger power cable and/or additional power supplies

may be required for longer cable runs and/or increased

number of sensors

Contact Honeywell Analytics for help with all power requirements.

• Network can be up to 2,000 feet per channel

• Avoid “T-taps” if possible

• Do not exceed 65 feet per T-tap

• Do not exceen 130 feet total of all T-taps

• Communication wire shield must be connected to shield

terminal(s) of controller (J23-J24)

• Channels 1-2-3: Modbus protocol — Communicates only

with Modbus devices

• Channel 4: Modbus output only — No sensor can be

connected to Channel 4

Normally

open

Normally

closed

3+5

4+6

1+3

2+4

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 8

Page 9

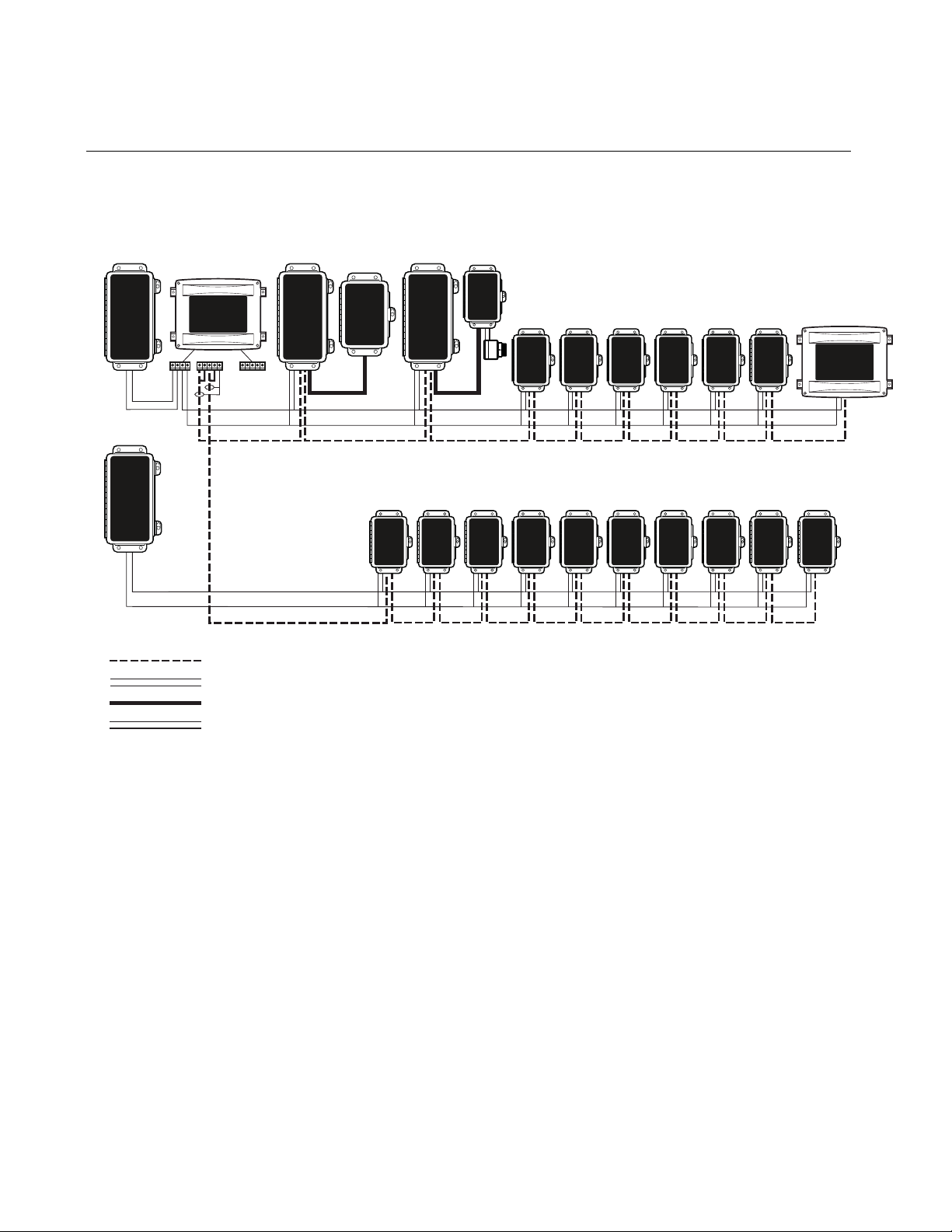

3 Wiring continued

Example of system wiring with network devices:

Figure 4. Sample Network Wiring

Supply

V+ V-

AirAlert 96d

V+

V-

A1 B1 SHLDA2B2

SHLD A3 B4B3A4

Power cable (V+)

Power cable (V-)

Channel 1 (A1 and B1 twisted pair)

Power

Supply

IRIM IMPower

VL

EC EC EC EC EC EC

VL

EC EC EC ECEC EC EC EC EC EC

Relay

Module

RS-485 comm cable; Twisted pair, 24 AWG, shielded (Belden 9841)

Power cable; Two conductor, 14 AWG (Belden 5100UE)

4/20 mA comm cable; Three conductor, 18 AWG, shielded, stranded (Belden 8770)

VL sensor cable; Four conductor, 16 AWG, non-shielded

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 9

Page 10

3 Wiring continued

r

A Power

B Communication

The power requirement range for the Manning

AirAlert

TM

96d controller is 24 Vdc, 500 mA. The

system must be grounded to the power supply. A

dedicated circuit breaker should be used. Use 14

AWG two conductor, stranded cable (Belden

5100UE or equivalent), up to 1,000 ft.

If the controller is sharing a power supply

with multiple sensors on the network, care

must be taken to observe voltage drops (line loss)

on the power cable. Supply voltages less than 17

Vdc can render some network devices inoperable.

Any supply voltage less than 17 Vdc requires the

installation of an additional power supply at that

point on the power cable.

Depending on total power consumption, avoid

powering more than 10 network devices with one

power supply. Additional power supplies and/or

decreased number of network devices may be

required to compensate for line loss. Contact

Honeywell Analytics for help with all power

requirements.

Note: Terminal J27 must be grounded to

mechanical ground.

Figure 5. Power Wiring

The communication cables have to be grounded

using the shield terminal. Up to 32 network devices

can be installed on each channel.

Use 24 AWG two conductor, twisted and shielded

cable (Belden 9841 or equivalent) for the connection.

The network can be up to 2,000 feet per channel.

The length of a T-tap can be a maximum of 65 feet

(20 m). A maximum of 130 feet (40 m) for all the

T-taps must be respected.

The communication cables have to be grounded

using the shield terminal. Use twisted and shielded

cable #24/2 AWG (Belden 9841) for the connection.

Note: Channel 4 is the slave communication

channel to retransmit the MODBUS signal to

PLC. No sensor can be connected to this channel.

Figure 6. Communications Wiring

RC

R

J23

A1 B1 SHLDA2B2

EOL3

RC

R

EOL4

RC

R

J24

SHLD A3 B4B3A4

EOL1

RC

R

End-of-line

jumper position

Powe

Fault

TX

RX

EOL3

A1 B1

RC

R

Channel 2

A2

Channel 1

Communication Requirements:

• 24 AWG twisted pair, shielded

(Belden 9841 or equivalent)

• Network can be up to 2,000 feet

per channel

• Avoid “T-taps” if possible

End-of-line

specification:

The E.O.L. jumper

for channels 1-2-3-4

must alwaysbe in

E.O.L. position

Channel 4

Channel 3

RC

R

J23

Previous

J22

V+ V-

In Out

V+

EOL2

V-

• Do not exceed 65 feet per T-tap

• Do not exceen 130 feet total of all T-taps

Next

• Communication wire shield must be connected

to shield terminal(s) of controller (J23-J24)

• Channels 1-2-3: Modbus protocol —

Communicates only with Modbus devices

• Channel 4: Modbus output only — No sensor

can be connected to Channel 4

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 10

Page 11

3 Wiring continued

C Relay Outputs

The relay outputs will withstand up to 5 amps at

30 Vdc (resistive load only). They can be used to

activate horns and strobes. Refer to Figure 7 for

proper wiring. Each relay can be configured in the

PROGRAMMING MENU.

Default setting is:

Relay 1 (J25) = Warn

Relay 2 (J26) = Alarm

Relay 3 (J3) = High Alarm

Relay 4 (J7) = Fault

Relay rating: 5 A, 30 Vdc (resistive load)

D Jumper Instructions

Figure 7. Relay Ouputs

Relay 4

Relay 3

Warn

Alarm

System status LEDs

High Alarm

J3

J7

NC

NO

NC

NO

The different jumpers on the PCB enable the user

to make different operations manually.

Jumper EOL1, EOL2, EOL3, EOL4

: Enable the

user to add an END-OF-LINE jumper to improve

the communication signal. Two positions are

possible, R or RC. It can vary in accordance with

the system constraints. See the wiring detail for

the EOL position.

Jumper RELAY J29, J30, J31, and J32

used to test the relay. Short pins to test.

: They are

Power

Relay 1 Relay 2

Fault

TX

RX

NO NC NO NC

Relay Outputs (J3-J7-J25-J26)

5A, 30 Vdc or 120 Vac (resistive load)

J26

642

531

J25

Normally

open

Normally

closed

Relay Jumpers:

Short jumper to

test relay

End-of-line

specification:

The E.O.L. jumper

for channels 1-2-3-4

must always be in

E.O.L. position

3+5

4+6

1+3

2+4

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 11

Page 12

4 Initial Startup

Be sure to connect the system as shown in the wiring

detail before powering up the unit. Apply power to

the controller and all network devices. Then remove

the SHDN jumper to start the unit.

A Datalogger (SDcard)

The DLC option for the controller collects data

automatically and stores it on a digital flash MultiMediaCard (SDcard). If the SDcard becomes full:

• The information logging is stopped

• No Sdcard flag is displayed on the screen

• The Sdcard LED blinks

Note: For log activation or deactivation,

please refer to the Acquisition section.

Warning

Always deactivate datalogging function

before removing the SDcard. Never

remove the SDcard when the red LED is on.

B User Interface

The main display indicates the firmware revision

number, time and date, number of sensor/events/

groups programmed in the controller, etc.

LED Definition:

Warn, Alarm and High Alarm — Red LEDs indicate

that one or more sensors have reached the

corresponding alarm level. If LED Warn is blinking,

an Event is activated (no alarm).

Power: Green LED indicates that the controller is

powered on and functioning properly.

Fault: Yellow LED indicates a fault (communication

problem with a network device).

TX: Yellow LED will blink when the controller is

sending information on the communication channel.

RX: Green LED will blink when a sensor sends

information to the controller.

Figure 9. User Interface

Figure 8. Datalogger

SD card

Card in use

LED1

Keypad

The keypad is used to move

the cursor into the various

programming fields (up, down,

left and right) or to adjust

the display contrast.

Enter key

The enter key is used to access

the programming menu [which

requires a password (default

password is 9935)] and to modify

the programming fields.

Manning AirAlert 96d

Enter ESC Silence

ESC key

The escape key is used to

exit the programming menu

or to cancel an input.

Warn

Alarm

High Alarm

Power

Fault

TX

RX

Silence key

Will turn off the buzzer

of AirAlert 96d

(see latching option).

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 12

Page 13

5 Operation

The available system operations are based on four

different modes: normal mode, single Tx mode,

debug mode, and simulation mode. These system

modes enable the user to use, analyze, debug, and

simulate actions that can be taken by the system.

Password is needed to access the different

programming menus. The system services might be

interrupted by some menu operations.

A Normal Mode

When the system is in Normal Mode, some values

can be changed without interrupting the system

service. After changing a value in the menu fields,

the new value will take effect right after the user gets

back to the MAIN MENU. The Normal Mode is the

normal system operation.

Note: Entering the EVENT MENU will disable

Event evaluation and reset their status —

during that time, the system is out of service until the

user goes back to the MAIN MENU.

Normal Mode Menu

1 Tx Info

2 Groups

3 Events (block Event evaluation if acceded)

5 Copy

7 Network

Warning

Any actions taken in these menus reset

the Event status.

C Debug Mode

This mode is very helpful to evaluate the system, test

the system operation without stopping any system

services and calibrate the connected sensors. In

fact, everything stays in operation except that no

actions are taken by the Event. This way no relay is

activated.

Note: If one of these modes is accessed,

the system will automatically return to Normal

Mode after 15 minutes.

D Simulation Mode

• The Simulation Mode deactivates information

update from the network communication.

• This mode simulates the gas concentration

over associated scale range for each sensor,

one after the other.

• The alarm level (A, B, C) are evaluated in

accordance to the gas concentration

simulated.

• Events are evaluated and actions are taken.

• During the simulation, the controller is unaware

of the current status of the network device.

• Simulation Mode can be stopped in the TEST

MENU at any time.

Note: Simulation Mode can be combined

with any of the three previous ones (i.e.,

Normal Mode, Single Tx Mode, or Debug Mode). No

other combinations are possible.

Note: Displays details in the following pages.

B Single Tx Mode

The Single Tx Mode doesn’t prevent Event

evaluation. By entering this mode, the user is able to

analyse one sensor at a time. Only the displayed

device is interrogated by the controller, thus has its

information updated.

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 13

Page 14

6 Programming Menus

G

r

t

y

Controller Information

Number of

Sensors

Accessible

Memory Card

Number of Groups

Product Name Firmware Version

AirAlert-96d

ver 2.016

Ad:12 Gr:1

Ev:1

Date Number of Events Time

Sensor Information

Label

Type of Gas Unit of Measuremen

Engine Room

NH3 0

PPM

Address Gas Concentration

Status:

-COMM (no

communication)

-A (Warn)

-B (Alarm)

-C (High Alarm)

-Normal

Relay and Annunciator Information

Label

uard Shack

Active Relays

- - 2 - - 4 AD:85

Address

Active Relays

Status

Event Information

Event Source

Event Numbe

EVENT

001

-Sources- Action-

Activated Rela

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 14

Page 15

7 Configuration

s

EC-

F

A Main Menu

To access the MAIN MENU, press the Enter key and

enter the password. The MAIN MENU offers the

following eight programming fields:

1. Tx Info

3. Events

5. Copy

Men

Men

7. Network

The cursor to the left of a field on the display

indicates that this field is accessible. The arrows in

the upper left and right corners indicate that a

window is accessible at the left and right of the active

window respectively. The keypad’s four arrows serve

to move the pointer in the MAIN MENU, and the Enter

key is used to access the selected field.

Tx INFO (Programming the Parameters

of a Sensor)

Sensor parameters are programmed via several different

windows. There is also an additional information window

indicating sensor life available for some sensors.

• Ident • Alarm A

• Com • Alarm B

• Detection • Alarm C

• Display • Servicing

The upper right-hand corner of each window indicates

the address of the first sensor. When the Tx INFO field

is accessed, the pointer is located to the left of the

sensor address, thus signifying that the address could

be put into editing mode in order to access the

parameters of another sensor. The sensor address is

put into editing mode using the Enter key, and the

address begins to flash when it is editable. The keypad’s Up and Down arrows are used to increment or

decrement the address value. Once the correct value

is obtained, the Enter key validates the address. The

address then leaves the editing mode and stops

flashing.

The following windows are accessible with the Left

and Right arrows.

Ident (Identification of the Network Component)

1. Tx Info

001

-Ident-

The identification of the network component is

comprised of two parameters: the sensor name and

the sensor type. A pre-programmed list of sensors is

available for both.

Com (Communication Protocol)

1. Tx Info

9

001

O-C M-

Mdbs RTU 8D 2S

Each sensor’s communication protocol is automatically established by the Manning AirAlert

controller.

If a sensor is compatible with several protocols, it

can be modified by the programmer in accordance

with one of the following four choices.

1 Vulbus

2 Mdbs ASCII 7D 2S NP 9600 bauds

3 Mdbs RTU 8D 2S NP 9600 bauds

4 Mdbs RTU 1S EP 9600 bauds

Note: For MODBUS equipped sensors, the controller

must be put into Vulbus mode to allow configuration.

Once configuration is complete, return to MODBUS

mode for normal operation. MODBUS sensors should

be set at even parity, one bit-stop.

Detection (Detection Range and Unit of Measure)

1. Tx Info

001

TM

96d

-Detection-

The DETECTION MENU does not appear for an

Manning AirAlert

AirAlert

cale: 0-100.0

TM

TM

96d-AP annunciator panel.

96d-RM8 relay module or Manning

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 15

Page 16

7 Configuration continued

(

E

<

[

---]

Display (programming the label)

1. Tx Info

001

-Display-

edit

The “label” is a descriptive message of up to 20

characters appearing on the display for a network

component. It applies to sensors, relay modules and

annuciators panels and is located on the first line of

the display. For a MODBUS sensor, the default label

is composed of the name of the sensor or network

component followed by the sensor type (if

applicable) and the component address.

Alarm A (Programming Warning Levels)

1. Tx Info

001

20

-Alarm A-

MIN

The MAX value is the level at which Alarm A (Warn) is

activated (set). The MIN value is the level at which

Alarm A (Warn) is deactivated (rest).

Alarm B (Programming Alarm Levels)

1. Tx Info

001

-Alarm B-

MIN

The MAX value is the level at which Alarm B (Alarm)

is activated (set). The MIN value is the level at which

Alarm B (Alarm) is deactivated (rest).

Alarm C (Programming High Alarm Levels)

Erase Current Tx (Erase Current Displayed

Tx Configuration)

1. Tx Info

001

Groups (Programming Groups of Sensors)

The programming of groups of sensors serves to

combine several units in order to be able to take

actions (events) based on a series of units rather

than each individual one at a time. It is possible to

program 126 distinct groups. Another group (GrAII)

contains all the sensors within a network by default.

rase

2. Group

001

[001] [004]

end>

A group is comprised of a stack containing the

address of each sensor included in the group. The

pointer is represented in the stack by the flashing

triangular brackets < >. The address within these

brackets is editable. When the Enter key is pressed,

the address begins to flash, and the brackets stop

flashing. The address can then be modified using the

up and down arrows. The address of each sensor

programmed in 1. Tx INFO is available. The <DEL>

function can be used to delete a particular sensor.

The <END> indicator represents the bottom of the

stack. To add a sensor to the group, simply move the

pointer towards that position and replace <END>

with the address of the new sensor. The end of the

stack will then move over one position.

1. Tx Info

001

The EMPTY ALL GROUPS function deletes all groups

programmed in the Manning AirAlert

TM

96d controller.

-Alarm C-

MIN

The MAX value is the level at which Alarm C (High

Alarm) is activated (set). The MIN value is the level at

which Alarm C (High Alarm) is deactivated (reset).

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 16

Page 17

7 Configuration continued

B

g

Event (Programming Events)

Default event configuration (EVENT MENU):

• Relay #1 will be activated when alarm A is

reached.

• Alarm B will trigger relay #2.

• The buzzer will also be activated for any

sensors that reach alarm B.

• Relay #3 will be activated when alarm C is

reached.

• Pressing the silence key will acknowledge the

latched Events and silence the buzzer.

• Relay #4 will be activated for any fault status.

Event programming serves to define particular

actions. The following specific windows are used for

such programming:

• Action

• Delay (Condition 1) (Condition 2)

• Delete

Action (Definition of Actions)

3. Event

001

-Action-

Tar

Actions are comprised of two parameters. TARGET

identifies the component that will perform the action.

The following three components may be

programmed:

• Tx (Transmitter (sensor))

• Re (Relay Pack/Annunciator Panel)

• Ctrl (Controller)

RELAY identifies the output, which will be activated

when the event is true. The output may be one of the

following three:

et:

Delay (Programming of Delays)

BEFORE and AFTER delays are used to retard the

activation or deactivation of an action. The BEFORE

delay retards the activation of an action. When an

event becomes true, the action will only be activated

after the indicated delay. The AFTER delay retards

the action’s deactivation. When the event is no longer

true, the action remains until after the delay period.

3. Event

001

-Delays-

efore: -- - -

The BEFORE and AFTER delays may be

programmed at 30 seconds, 45 seconds, or from

1 to 99 minutes by increments of 1 minute. The five

dashes (- - - - -) indicate that no delay had been

programmed. The AFTER delay can also be put into

latch mode.

Latch Mode

• The latch function is executed on an EVENT

state.

• It is possible to select the latch mode by editing

the after-delay to the latch value.

• The EVENT stays activated until the SILENCE

key is pressed.

• The silence key has two functions: silence the

buzzer and unlatch the Event.

When the silence key is pressed, events in latch

mode are unlatched and re-evaluated. If the Event

conditions are still true, the given Event stays

activated and returns into latch mode. If not, the

Event is deactivated.

• #XX (Activation of the component’s relay #XX)

• Buzzer (Activation of the component’s audible

alarm)

• ALL (activation of all the component’s relays

and audible alarm)

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 17

Page 18

7 Configuration continued

S

Conditions

Conditions serve to define which premises make an

event true.

Each condition is defined by four elements, and two

conditions may be combined to provide for greater

flexibility.

The element in the lower right-hand corner of a

condition indicates the source of the event. The

source may be a sensor (Tx001), a group (Gr001), all

sensors (GrAll), or the controller’s clock (Time). The

magnifying glass appearing to the right of the group

number provides quick access to this group in order

to view or edit it. Access to the GROUP MENU with

the magnifying glass symbol. The ESC key returns

the display to the condition’s window.

3. Even

t

001

(

= Alarm

TX010

)

3. Event

001

Clock

(

AND sta:

)

B Acquisition (Programming

the Acquisition Mode)

Note: Only available with Datalogging option.

4.

Acquisition

10 s delay mode

tart Tx logging

Acquisition Mode for Tx Logging

The ACQUISITION MENU is only accessible when an

SDcard is present. This menu is used to enable or

disable the logging of the system event or sensor

information. This information is stored on the SDcard,

however, the acquisition interval or condition must be

defined first.

Acquisitions delay mode may be made at intervals of

10 to 59 seconds or 1 to 60 minutes. A threshold

mode acquisition may also be made when a sensor’s

reading varies by 3% or more, 5% or more or 10% or

more of its detection range.

Note: Due to system latency, threshold

values can be greater (but never less) than

the selected one.

The element in the lower left-hand corner indicates

the quantifier of the source (applicable only to

groups). The quantifier may be indicated as the

average (mean), (max), (min), (3/4), (2/3), (1/2), (1/3),

(1/4), (1or+) or (all) — applicable only to groups.

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 18

3. Event

001

Enable event

Erase current

• 10 to 59 seconds interval

• 1 to 60 minute interval

• 3% threshold (acquisition if variation of 3% of

the scale from the last logged value)

• 5% threshold (acquisition if variation of 5% or

more of the scale from the last logged value)

• 10% threshold (acquisition if variation of 10% or

more of the scale from the last logged value)

Example of Threshold Log Mode

2006-01-22 11:05:20;1;NH3;0;ppm;-normal-;

2006-01-22 11:06:02;1;NH3;12;ppm;-normal-;

2006-01-22 11:06:15;1;NH3;18;ppm;-normal-;

2006-01-22 11:06:28;1;NH3;6;ppm;-normal-;

2006-01-22 11:06:39;1;NH3;0;ppm;-normal-;

2006-01-22 11:30:45;1;NH3;15;ppm;-normal-;

2006-01-22 11:30:57;1;NH3;23;ppm;-normal-;

2006-01-22 11:31:08;1;NH3;20;ppm;-normal-;

Page 19

7 Configuration continued

Start/Stop Tx Logging

When the display indicates Start log Tx, the

acquisition mode is inactive. Acquisition will start by

pressing Enter. The log message displays on the

screen in accordance to the Mode that has been

choose. LED1 turns ON.

• Start log Tx (starts sensor acquisition)

Opens an ad1_48.log and ad49_96.log file.

• Stop log Tx (stops sensor acquisition)

The ad1_48.log and ad49_96.log files contain a

record of sensors 1 to 48 (ad1_48.log) and 49 to 96

(ad49_96.log). This register includes the date, time

and address of the sensor(s), the sensor type, the

concentration read, as well as the alarm status. See

example in Figure 10 below.

Start/Stop Event Logging

In addition, event information may also be acquired.

As it is the case for sensor acquisition, the display

indicates the function of the ENTER key.

• Start log even. (starts event acquisition)

Opens an events.log file.

• Stop log even. (stops event acquisition)

The events.log file contains a record of the

controller’s events and key entries.

Example:

2006-01-21 16:27:51; Event logging enabled

2006-01-21 16:27:53; Menu exited

2006-01-21 16:28:11; Event accessed

2006-01-21 16:28:43; Event 1 setup modified

2006-01-21 16:28:45; Menu exited

The event file indicates the date and time, menu access

and modifications, as well as events that were activated.

List of Events

List of Events English

Power-up “System Power-up”

Power-down “System Power-down”

Menu accessed “Menu accessed”

Menu exited “Menu exited”

Event logging enabled “Event logging enabled”

Event logging disabled “Event logging disabled”

Transmitter logging “Transmitter logging

enabled enabled”

Transmitter logging “Transmitter logging

disabled disabled”

Transmitter info setup “Transmitter X setup”

Alarm setup “Tx X alarm level setup”

Event setup “Event X setup”

Group setup “Group X setup”

Clock setup “Clock setup”

Language setup “Language setup”

Scroll mode setup “Scroll mode setup”

Silence activated “Silence activated”

Event status changed “Event X now True/False”

Alarm A, B, C, Fault, and “Transmitter X

X status changed Alarm X True/False”

Figure 10. Tx Log

Example:

2004-01-23 17:54:25; 001; NH3; 0: ppm:--------;002; CL2; 1.5; ppm;AL:-A;003; NH3; 0 ppm--------;004; CL2; 0.0; ppm;--------;005; NH3; 0; ppm;--------;

2004-01-23 17:55:25; 001; NH3; 0: ppm:--------;002; CL2; 7.5; ppm;AL:-A;003; NH3; 0 ppm--------;004; CL2; 0.0; ppm;--------;005; NH3; 0; ppm;--------;

2004-01-23 17:56:25; 001; NH3; 0: ppm:--------;002; CL2; 6.5; ppm;--------;003; NH3; 0 ppm--------;004; CL2; 0.0; ppm;--------;005; NH3; 0; ppm;--------;

2004-01-23 17:57:25; 001; NH3; 0: ppm:--------;002; CL2; 0.5; ppm;--------;003; NH3; 0 ppm--------;004; CL2; 0.0; ppm;--------;005; NH3; 0; ppm;--------;

2004-01-23 17:58:25; 001; NH3; 0: ppm:--------;002; CL2; 0.0; ppm;--------;003; NH3; 130; ppm;AL:-A-;004; CL2; 0.0; ppm;--------;005; NH3; 0; ppm;--------;

Note: In this case, there is a reference to five sensors (addresses #1 to #5) — three NH3 and two CL2. We can see

that the CL

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 19

at address #2 goes in alarm A and a few minutes later it’s the NH3 at address #3 that goes in alarm A.

2

Page 20

7 Configuration continued

Copy (Transferring Data and Copying

Parameters)

The COPY function serves to transfer data and copy

parameters within the following windows:

• Configuration

• Parameters

Configuration (Data Transfer)

-configuration-

5. Copy

Controller to

SDcard

This section of the COPY MENU is only accessible if

an SDcard is present. Data can be transferred from

the controller to the SDcard, or from the SDcard to

the controller. Thus, an image of the controller’s

programming may be transferred and stored on a

computer. Similarly, the controller’s programming

may be executed on a computer and then

transferred to the controller.

• Controller to SDcard (transfer from the

controller to the SDcard)

• SDcard to controller (transfer from the SDcard

to the controller)

Moreover, at card insertion, the controller system

looks for an existing ‘config.ini’ file containing a tag

named “autoload” equal to ‘1’ (meaning true). If so,

the system will automatically load the content of the

file and set “autoload” to ‘0’ (meaning false). This

feature is useful when you edit the file on a computer

and want to avoid “menu manipulations” on the

controller.

On a closer look, ‘config.ini’ is a text editable

Windows .ini-style file. It can be accessed by any

word processing software, but the simpler Notepad

should be favored. The content of the file has the

following format:

[section 1]

tag 1 = “string value 1”

tag 2 = “string value 2”

tag 3 = 53

[section 2]

tag 1 = true

tag 2 = -12.3

[…]

See example on the next page.

In order, the first command enables the user to save

the controller configuration and parameters into a file

named ‘config.ini’. The second command enables the

user to load the configuration and parameters from

the same file. Keep in mind that the content of the

‘config.ini’ file can always be edited on a computer.

Before saving the current configuration and

parameters, the system will look for the existence of

any previous configuration. The following steps will

be performed:

1 If a file named ‘config.ini’ already exists, the

system looks for a file named ‘config.bak’;

2 If a file named ‘config.bak’ is found, it is

deleted;

3 Then, the existing ‘config.ini’ file is renamed

‘config.bak’, thus keeping a backup of the

previous configuration;

4 At last, a new ‘config.ini’ file with the current

configuration is created.

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 20

Page 21

7 Configuration continued

g

C

6

S

Example of saving a controller configuration

AirAlert96d = “Configuration”

Date = “2006-01-09 13:51:57:”

[CONFIG]

language = 1

scrollmode = 0

relaymode = 0

password = "2967"

cie = 0

priority = 0

autoload = 1

[SLAVE]

address = 1

protocol = 1

baudrate = 38400

databits = 8

stopbits = 2

parity = 0

[ADDRESS_1]

txtype = 1

display = "ECF9 NH3 AD:01"

protocol = 1

baudrate = 9600

databits = 8

stopbits = 2

parity = 0

sensortype = 65

fullscale = 102.000000

unit = 0

alarmAmin = 20.1000003

alarmAmax = 25.0000000

alarmBmin = 45.000000

alarmBmax = 50.000000

alarmCmin = 85.000000

alarmCmax = 90.000000

Parameters (Copying Parameters)

5. Copy

001

-parameters

Tx info to Tx

[ADDRESS_2]

txtype = 17

display = "ECF9 NH3 AD:02"

protocol = 1

baudrate = 9600

databits = 8

stopbits = 2

parity = 0

sensortype = 2

fullscale = 250.000000

unit = 1

alarmAmin = 20.0000000

alarmAmax = 25.0000000

alarmBmin = 180.000000

alarmBmax = 200.000000

alarmCmin = 218.000000

alarmCmax = 225.000000

databits = 7

stopbits = 2

parity = 0

Event to Event

Event to Event

source #001

target #002

[GROUP_1]

tx_0 = 1

tx_1 = 2

tx_2 = 0

[EVENT_1]

actiontarget = 14

actionrelay = 1

delaybefore = 0

delayafter = 0

cond1source = 1

cond1logic = 1

cond1alarm = 0

[EVENT_2]

actiontarget = 0

actionrelay = 1

delaybefore = 255

delayafter = 255

cond1source = 129

cond1stat = 9

cond1logic = 7

cond1min = 10.0000000

cond1max = 15.0000000

[FIN]

OPY

The copying of parameters serves to transfer one

sensor’s configuration to another, or one event to a

second event. This function accelerates

programming on the display when two entities have

identical or close properties. Tx Info to Tx Info

copies a sensor’s parameters, and Event to Event

copies the parameters of one event to another.

TxINFO to TxINFO

(copies the parameters of a sensor)

Tx info to Tx

info

Config (Programming Display Parameters and the

Access Code)

Manual scroll

. Config

mo de

The CONFIG MENU is used to program the display

mode, adjust the time and date, select the display

language in the first window, and to edit the

password in the second window.

et Date and

source tx001

tar

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 21

et tx002

Page 22

7 Configuration continued

7

R

7

The scroll mode is used to set the scroll interval of

the information pages displayed on the screen. Scroll

mode may be set to at three or five seconds, or it

may be set to manual only. The information page

displayed can always be controlled manually using

the arrow keys. The display will remain on the last

component selected only in manual mode.

• 3-Second Scroll

• 5-Second Scroll

• Manual Scroll

The date and time are displayed in the following

format:

yyyy-mm-dd hh:mm:ss

(ISO 8601 standard, 24 hours format)

The desired display language is selected via Menu

Francais and English Menu. The selection is made

with the Enter key. When the display shows Menu

Francais, the current display language is English.

The language may be changed by pressing the

Enter key.

The user password can be edited and comes with a

default value of 9935 (last four digits of Manning’s toll

free phone number).

Set User

Passwor

The Config window also features an option to

configure the slave port.

Address: 00

6. Conf

d

-9935-

Slave Port Cnfg1

ig

38400 bauds

Mdbs RTU 8D 2S

Network (Auto-Programming of NetworkRelated Parameters)

The functions of the Network menu serve to reset or

program information related to the network devices.

• Reset Database (Resets all Tx Info database —

network device)

• Network Scan (Auto detection of the network

devices)

• Reset & Scan (Resets all Tx info database and

auto detection of the network devices)

o

Resetting the network device affects only the Tx

information: groups and events are not affected by

these function.

Network scan serves as an auto detection service of

network devices to configure the Tx information

database.

St

. Network

Scan Netw rk

eset and Scan

. Networ

k

atistics

e Reset Databas

The statistics function allows the user to view details

about the 16 last entries such as:

• Valid responses

• Communication errors

• Timeouts (no response)

Relay configuration allows the relays to be set to

normal or failsafe mode. In the event of loss of power

to the controller, relays will change states if set to

failsafe mode.

Relay

Co i

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 22

6. C

nf guration

AP Brdcst: auto

onfig

Page 23

7 Configuration continued

8

q

Tests (Sequential Test Mode)

Test Sequence

This simple test sequence enables the user to

activate each output and validate the operation of

each controller key and all display pixels, as well as

the different communication protocols.

Start Sim. Sequ. & Stop Sim. Sequ.

(Stop Simulation)

8. Tests

ce Test Sequen

Start Sim

Se

uence

See Simulation Mode section on page 13 for more

details.

The simulation mode allows for the simulation of gas

concentration over associated scale range on all

sensors. The simulated gas concentration values are

local to the controller.

• Start with Tx00X (simulation starts with

sensor 00X)

• Confirm (simulation activation)

Maximum Load (Activation of All Controller

Components)

Oprt Mode (Controller Operating Mode)

Oprt Mode:

. Tests

normal

1 Normal (normal controller operating mode)

2 Single Tx (activation of interrogation mode for a

single sensor)

3 Debug (activation of service mode to allow for

calibration without affecting events)

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 23

Page 24

8 Specifications

Power Requirements:

Operating Environment: Ordinary location

Operating Temperature Range: —4°F to 122°F

(—20°C to 50°C)

Operating Humidity Range: 0 to 95% RH,

(non condensing)

Operating Altitude: Up to 9843 ft. (3,000 m)

Network Capacity:

Up to 96 sensors, 32 per channel

Channel 1, 2, and 3: MODBUS

Channel 4: Modbus output to PLC

Communication (length of lines):

Up to 2,000 feet (600 m) per channel 24 AWG

#9841 Belden Cable

T-tap: 65 feet (20 m) maximum per t-tap,130 feet

(40 m) total

User Interface:

Graphic 122 x 82 dot matrix backlit display

User friendly keypad

24 Vdc, 500 mA

Visual Indicators:

Power On Green LED

Warn Red LED (blinking upon an event)

Alarm Red LED

High Alarm Red LED

Fault Yellow LED

Tx Amber LED (blink when used)

Rx Green LED (blink when used)

Outputs:

4 DPDT relays

5A, 30 Vdc or 250 Vac (resistive load)

Time Delays: 0, 30, and 45 seconds, and1 to 99

minutes before and after alarm

Battery: Lithium battery, 3 volts

Enclosure: NEMA 4x, cast aluminium #A356.0T6

Overvoltage Category: II

Dimensions: 9.50” (W) x 14.00” (H) x 3.50” (D)

Weight: 11.4 lbs (5.2 kg)

9 Maintenance

The Manning AirAlert

controller. Only the sensors need periodic inspection

and calibration (see sensor manual).

Periodic Inspections and Calibration

Honeywell Analytics provides its customers with

specialized gas detection equipment. Beyond the

warranty period, the systems must be maintained and

calibrated on a regular basis (normally two times a year).

Honeywell Analytics will not assume responsibility for

the interruption of service or malfunctioning of its

equipment as a result of the discontinuance of

maintenance and calibration services.

If unit span or zero cannot be adjusted, the sensor

may be approaching its end-of-life and must be

replaced. Keep an operation log of all maintenance,

calibrations and alarm events.

TM

96d is a maintenance free

Replacement Parts

A replacement 3V lithium battery is also available. If

the memory card option is present, spare SDcards

are also available.

Due to continuous evolution of our products, please

contact our service department for ordering parts or

for more details.

Cleaning

Clean the exterior with a soft, damp cloth. Do not use

solvents, soaps or polishers.

Battery Disposal

This instrument contains a lithium battery. Do not mix

with the solid waste stream. Spent batteries should

be disposed of by a qualified recycler or hazardous

materials handler.

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 24

Page 25

10 Relay Module (optional)

The Manning AirAlert

an output to the Manning AirAlert

TM

96d-RM8 relay module acts as

TM

96d controller. The

relay module provides eight programmable relays for

the activation of ventilation and audible/visual alarm

output devices at programmable alarm levels. Since

the relay module is an output to the controller, it can

be located at any point within the gas detection

network.

Manning AirAlert

• Fully compatible with the Manning AirAlert

TM

96d-RM8 Features:

TM

96d

controller

• Equipped with 8 programmable DPDT relays

• RS-485 daisy chain installation

• LED visual indication status of each relay

Specifications

Power Requirements: 17 to 27 Vdc, 250 mA

Operating Temperature Range: 32°F to 100°F

Operating Humidity Range: 0 to 95% RH

(non-condensing)

Outputs:

8 DPDT relays; 5A

30 Vdc or 250 Vac (resistive load)

Maximum Distance between Relay Module

and Controller: 2,000 feet

Enclosure: NEMA 4x, cast aluminium #A356.0T6

Figure 11. Manning AirAlertTM96d-RM8

Manning AirAlert 96d

Relay Module

Power

TX ModBus

Dip Switches

The DIP switches are used to change the relay module

addresses. The address ranges available begin at 81.

Modbus

address

081

082

083

084

Position of the DIP switches

Dip 1 Dip2 Dip 3 Dip 4

Off

On

Off

On

Off Off Off

Off Off Off

On Off Off

On Off Off

Dimensions: 9.50” (W) x 14.00” (H) x 3.50” (D)

Weight: 11.4 lbs (5.2 kg)

LEDs

Two LEDs indicate the status of the relay module.

The Power LED (green) indicates that the relay

module is powered on. The Tx Modbus LED blinks

when there is a data transfer between the relay

module and the controller. If the communication

breaks down, that LED will turn off.

085

086

087

088

089

090

091

092

093

094

095

096

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 25

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off On Off

Off On Off

On On Off

On On Off

Off Off On

Off Off On

On Off On

On Off On

Off On On

Off On On

On On On

On On On

Page 26

10 Relay Module (optional) continued

Wiring Details

Power Supply Cable

• 14 AWG stranded cable or larger (see your network

diagram provided by Honeywell Analytics sales

department).

Communication Cable

24 AWG twisted pair (Belden # 9841 or equivalent).

•

Figure 12. Relay Module PCB

off

1

2

DIP switches

3

4

End of Line Resistor

On the last device of the

communication network,

a jumper must be

installed as shown.

From +24VDC terminal

of power supply

From Ground terminal

of power supply

EOL1

RC

R

J10

J10

V+ V- SHLDAB

Relay 8

J8

NO NC

From “B” terminal of controller

to “B” terminal of next device

From “A” terminal of controller

to “A” terminal of next device

Relay 7 Relay 5

J7

NO NC

Relay 6

Power

Tx Modbus

Relay 4

NO NCNO NC

NO NC

Relay 3 Relay 1

NO NC

Relay Outputs (J1-J8)

5A, 30 Vdc or 120 Vac (resistive load)

Power and TX

status LEDs

Relay 2

J2

642

531

J1

NO NCNO NC

Normally

open

Normally

closed

3+5

4+6

1+3

2+4

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 26

Page 27

11 Limited Warranty

1. Limited Warranty

Honeywell Analytics, Inc. warrants to the

original purchaser and/or ultimate customer

(“Purchaser”) of Manning products (“Product”)

that if any part thereof proves to be defective in

material or workmanship within eighteen (18)

months of the date of shipment by Honeywell

Analytics or twelve (12) months from the date of

first use by the purchaser, whichever comes first,

such defective part will be repaired or

free of charge, at Honeywell Analytics’

if shipped prepaid to Honeywell Analytics at

405 Barclay Blvd., Lincolnshire, IL 60069,

in a package equal to or in the original container.

The Product will be returned freight prepaid and

repaired or replaced if it is determined by

Honeywell Analytics that the part failed due to

defective materials or workmanship. The repair

or replacement of any such defective part shall

be Honeywell Analytics’ sole and exclusive

responsibility and liability under this limited

warranty.

2. Exclusions

A. If gas sensors are part of the Product, the

gas sensor is covered by a twelve (12)

month limited warranty of the manufacturer.

B. If gas sensors are covered by this limited

warranty, the gas sensor is subject to

inspection by Honeywell Analytics for

extended exposure to excessive gas concentrations if a claim by the Purchaser is

made under this limited warranty. Should

such inspection indicate that the gas sensor

has been expended rather than failed

prematurely, this limited warranty shall not

apply to the Product.

C. This limited warranty does not cover consum-

able items, such as batteries, or items

subject to wear or periodic replacement,

including lamps, fuses, valves, vanes, sensor

elements, cartridges, or filter elements.

replaced,

discretion

3. Warranty Limitation and Exclusion

Honeywell Analytics will have no further obligation

under this limited warranty. All warranty obligations

of Honeywell Analytics are extinguishable if the

Product has been subject to abuse, misuse,

negligence, or accident or if the Purchaser fails to

perform any of the duties set forth in this limited

warranty or if the Product has not been operated in

accordance with instructions, or if the Product

serial number has been removed or altered.

4. Disclaimer of Unstated Warranties

THE WARRANTY PRINTED ABOVE IS THE ONLY

WARRANTY APPLICABLE TO THIS PURCHASE.

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE ARE

HEREBY DISCLAIMED.

5. Limitation of Liability

IT IS UNDERSTOOD AND AGREED THAT

HONEYWELL ANALYTIC’S LIABILITY, WHETHER

IN CONTRACT, IN TORT, UNDER ANY

WARRANTY, IN NEGLIGENCE OR OTHERWISE

SHALL NOT EXCEED THE AMOUNT OF THE

PURCHASE PRICE PAID BY THE PURCHASER

FOR THE PRODUCT AND UNDER NO

CIRCUMSTANCES SHALL HONEYWELL

ANALYTICS BE LIABLE FOR SPECIAL, INDIRECT,

OR CONSEQUENTIAL DAMAGES. THE PRICE

STATED FOR THE PRODUCT IS A CONSIDERA-

TION LIMITING HONEYWELL ANALYTICS’

LIABILITY. NO ACTION, REGARDLESS OF FORM,

ARISING OUT OF THE TRANSACTIONS UNDER

THIS WARRANTY MAY BE BROUGHT BY THE

PURCHASER MORE THAN ONE YEAR AFTER

THE CAUSE OF ACTIONS HAS OCCURRED.

Manning AirAlert-96d Gas Monitor 19546 AIRALERT96D 07/09 Prelim REVC Copyright © 2009 Honeywell Analytics. All Rights Reserved. 27

Loading...

Loading...