Page 1

Operating and

Instruction Manual

Manual No. YB

Revision 0-600 w/12 March 2014 Errata

MODEL YB8

STATIONARY

PERISTALTIC SAMPLERS

Manning Environmental, Inc.

101 Bar T Drive

Florence, Texas 76527-4445 USA

Office: (800) 863-9337

(254) 793-9955

Fax: (254) 793-9965

www.manningenvironmental.com

Page 2

Page 3

Manning Environmental Limited Factory Warranty

Manning Environmental, Inc., warrants this product to the original purchaser against any defects that are

due to faulty workmanship or material for a period of one year (365 days) from the date of shipment.

During the warranty period Manning Environmental, Inc. will repair or replace, at its sole discretion, any

defective equipment or parts. Manning’s liability is strictly limited to repair and/or replacement. Any

product repaired or replaced under this warranty will be warranted only for the remainder of the original

product warranty period.

This warranty does not apply to consumable products or consumable components of products such as,

but not limited to tubing, intake hose, differential pressure switches and bottles.

Items may not be returned without authorization from Manning Environmental, Inc.

This warranty applies only to products sold under the Manning trademark and is the sole express

warranty made by Manning Environmental, Inc. All implied warranties, including without limitation, the

warranties of merchantability or fitness for a particular purpose, are disclaimed.∗

Limitations:

This warranty does not cover the following:

1. Damage caused by acts of God, natural disaster, labor unrest, acts of war (declared or

undeclared), terrorism, civil strife or acts of any governmental jurisdiction

2. Damage caused by normal wear, neglect, misuse, accident, corrosion or improper application or

installation

3. Damage caused by any repair, attempted repair or modifications not authorized by Manning

Environmental, Inc.

4. Any product not used in accordance with the instructions furnished by Manning Environmental,

Inc.

5. Freight charges to return merchandise to Manning Environmental, Inc.

6. Freight charges on expedited or express shipment of warranted parts or products.

7. Travel and lodging fees associated with on-site warranty repair

8. Manning 6.1 cubic foot refrigerators, which are covered under the refrigerator manufacturer’s

warranty

9. Labor performed at the factory to clean the equipment so that it can be safely and properly

repaired

This warranty constitutes the final, complete, and exclusive statement of warranty terms. Manning

Environmental, Inc. does not authorize any other person to make any other warranties or representations

on its behalf.

In no event shall Manning Environmental, Inc. be liable for any incidental or consequential damages of

any kind for breach of warranty or negligence. The remedies of repair or replacement as stated above

are the exclusive remedies for the breach of this warranty.

A Return Material Authorization (RMA) must be obtained prior to sending any equipment to Manning for

warranty service. Contact the Manning Service Department at:

Manning Environmental, Inc.

101 Bar T Drive

Florence, Texas 76527-4445

Phone: 254-793-9955, Fax: 252-793-9965.

Some states within the United States do not allow the disclaimer of implied warranties and if this is true in your state the above

∗

limitation may not apply to you. This warranty gives you specific rights- you may also have other rights that vary from state to state.

Manning Environmental, Inc. December 2005

Page 4

Page 5

Table Of Contents

Section Contents – Installation and Ope ration

Introduction ...........................................................................................................................................Page A-1

Hardware Page ......................................................................................................................................Page A-2

Functional Specifications ..........................................................................................................Page A-2

Size ................................................................................................................................Page A-2

Weight ...........................................................................................................................Page A-2

Environmental Protection ............................................................................................ Page A-2

Sample Cooling ............................................................................................................Page A-2

Temperature Limits .......................................................................................................Page A-2

Sample Pump ................................................................................................................Page A-2

Safety ............................................................................................................................Page A-2

Pump Tubing .................................................................................................................Page A-2

Tube Life .......................................................................................................................Page A-2

Maximum Lift ...............................................................................................................Page A-2

Transport Velocity ........................................................................................................Page A-2

Sample Volume .............................................................................................................Page A-2

Accuracy .......................................................................................................................Page A-2

Repeatability .................................................................................................................Page A-2

Liquid Sensor ................................................................................................................P age A-2

Controller ......................................................................................................................Page A-3

Electronics.....................................................................................................................Page A-3

Internal Clock................................................................................................................Page A-3

Internal Battery .............................................................................................................Page A-3

Power ............................................................................................................................Page A-3

Battery Back-Up ...........................................................................................................Page A-3

Analog Input .................................................................................................................Page A-3

Subassemblies ...........................................................................................................................Page A-3

Electronics Enclosure....................................................................................................Page A-3

The Controller ...................................................................................................Page A-3

Peristaltic Pump ............................................................................................................Page A-4

Liquid Sensor ................................................................................................................P age A-5

Refrigerator ...................................................................................................................Page A-5

Wetted Parts ..................................................................................................................Page A-5

Intake Hose .......................................................................................................Page A-5

Strainer ..............................................................................................................Page A-5

Pump Tubing .....................................................................................................Page A-6

Discharge Tubing ..............................................................................................Page A-6

Bottle Full Sensor .............................................................................................Page A-6

Sample Bottles ..................................................................................................Page A-7

Assembly...................................................................................................................................Page A-8

Page 6

Assembling the Model YB8 Sampler ...........................................................................P age A-8

Refrigerator .......................................................................................................Page A-8

Electronics Enclosure........................................................................................Page A-9

Distribution Assembly Installation .............................................................................Page A-10

Single Bottle Sampling ...................................................................................Page A-10

Multiple Bottle Sampling ................................................................................Page A-10

Suspension Plate Installation ..............................................................Page A-10

Distributor Assembly ..........................................................................Page A-10

Bottle Installation ............................................................................................Page A-13

One Liter and Half-Liter Plastic Bottles Page A-13

Spout Position Page A-13

Installing The Sampler ............................................................................................................Page A-13

Connecting Power .......................................................................................................Page A-14

Sample Intake Line .....................................................................................................Page A-14

Intake Hose Placement ................................................................................................P age A-14

Running a Test Cycle ..............................................................................................................Page A-15

The Sampling Cycle ................................................................................................................Page A-15

Sample Recovery ....................................................................................................................Page A-16

External Connections ..............................................................................................................Page A-17

Contact In & Analog In Connections..........................................................................Page A-17

Bottle Full Sensor & Stepper Motor Connections ......................................................P age A-17

Bottle Full/Stepper Motor ...............................................................................Page A-17

Contact Closure ...............................................................................................Page A-18

Analog Signal (Optional) ................................................................................Page A-18

Section Contents – Programming

Introduction ........................................................................................................................................... Page B-1

Sampler Configuration .......................................................................................................................... Page B-1

Sampling Modes ................................................................................................................................... Page B-1

Multi-Bottle Sampling Modes .................................................................................................. Page B-1

Single Bottle Modes .................................................................................................................. Page B-1

<RESET> .................................................................................................................................. Page B-2

<TEST CYCLE> ...................................................................................................................... Page B-2

<BOTTLE ADV> ..................................................................................................................... Page B-2

<CLEAR> ................................................................................................................................. Page B-2

<CLOCK> ................................................................................................................................ Page B-2

<DISPLAY> ............................................................................................................................. Page B-2

*................................................................................................................................................. Page B-2

EEEE ......................................................................................................................................... Page B-2

Key Not Active ......................................................................................................................... Page B-2

Display Information .............................................................................................................................. Page B-3

Time of Day .............................................................................................................................. Page B-3

Program Status .......................................................................................................................... Page B-3

Sampler Ready .............................................................................................................. Page B-3

Page 7

Programming................................................................................................................. P age B-3

Active Program ............................................................................................................. Page B-3

Sampler Configuration Functions ......................................................................................................... Page B-4

*99 Sampler Set-Up .................................................................................................................. Page B-4

*20 Volume Calibration ............................................................................................................ Page B-7

*19 Pump Utilities .................................................................................................................... Page B-9

*91 Data Logging ................................................................................................................... P age B-11

ID Menu ...................................................................................................................... Page B-12

View Menu.................................................................................................................. Page B-12

Exit Menu.................................................................................................................... Page B-16

Download Menu.......................................................................................................... Page B-16

Clear Menu.................................................................................................................. Page B-18

*14 Clear Log Data ..................................................................................................... Page B-18

Analog Option Programming .............................................................................................................. Page B-19

Totalizing ................................................................................................................................ Page B-19

*08 Analog Display Routine ....................................................................................... Page B-20

Add-On Programming Functions ........................................................................................................ P age B-22

Multiple Bottles per Sampling Event ...................................................................................... Page B-22

Multiple Samples per Bottle ................................................................................................... Page B-22

Delay Start - Time ................................................................................................................... Page B-24

*15 - Active Sampling ........................................................................................................Page B-24-A

General Programs................................................................................................................................ Page B-25

Time Mode - *START ............................................................................................................ Page B-25

Time Mode - Single Time Interval ......................................................................................... Page B-26

Flow Mode .............................................................................................................................. Page B-28

Flow Mode - Pulse Accumulation .......................................................................................... P age B-29

Multi-Bottle Sampling Programs ........................................................................................................ Page B-30

*01 Flow Mode - Independently Time Spout Advance .......................................................... Page B-30

*02 Flow Mode - Time Interval Override............................................................................... Page B-31

*03 Flow Mode - External Event ............................................................................................ Page B-32

*04 Time Mode - Multiple Intervals ....................................................................................... Page B-33

*07 Flow Mode - Time Delay Interval ................................................................................... Page B-35

Analog Sampling Programs ................................................................................................................ Page B-36

*05 Flow Mode - Totalizing Analog ...................................................................................... Page B-36

*06 Analog Level Mode ......................................................................................................... Page B-38

*09 Hydrologic Level Event Mode ......................................................................................... Page B-41

Multi-Bottle Flow Composite Programs ............................................................................................. Page B-45

*10 Flow Mode - Multiple Bottle Composite ......................................................................... Page B-45

*11 Flow Mode - Totalizing Analog Multiple Bottle Composite........................................... P age B-47

*12 Flow Mode - Multiple Bottle Composite with Bottle Groups ......................................... Page B-49

*13 Flow Mode- Totalizing Analog Multiple Bottle Composite with Bottle

Groups ..................................................................................................................................... Page B-52

Page 8

Section Contents – Maintenance

Maintenance .......................................................................................................................................... Page C-1

Suggested Maintenance Schedule ............................................................................................. Page C-1

Peristaltic Pump ........................................................................................................................ Page C-2

Replacement of Pump Tubing ...................................................................................... Page C-3

Cleaning the Control Panel and Electronics Enclosure ............................................................ Page C-6

Cleaning the Wetted Parts ......................................................................................................... Page C-6

Intake Hose ................................................................................................................... Page C-7

Liquid Sensor ................................................................................................................ Page C-7

Bottle Full Sensor (Single Bottle Units Only) .............................................................. Page C-8

Spout (Multiple Bottle Units Only) .............................................................................. Page C-8

Sample Containers ........................................................................................................ Page C-8

Refrigerator ................................................................................................................... Page C-8

Environmental Protection ....................................................................................................... Page C-10

Removing and Replacing the Controller................................................................................. Page C-10

Troubleshooting .................................................................................................................................. Page C-11

System Non-Responsive ......................................................................................................... Page C-11

Works Inconsistently .............................................................................................................. Page C-11

Weak Draw ............................................................................................................................. Page C-11

Pump Operates but no Fluid ................................................................................................... Page C-12

Pump Rotor Does Not Rotate ................................................................................................. Page C-12

Purges Constantly ...................................................................................................................Page G-12

Low Sample Volume .............................................................................................................. Page C-12

Excessive Sample Volume ...................................................................................................... Page C-12

Controller Does not Respond to Command ............................................................................ Page C-12

Keypad Inoperative ................................................................................................................. Page C-12

*99 Self Test Indicates Error .................................................................................................. Page C-12

Section Contents - Appendices

Glossary

Appendix A ...............................................................................................................................Page D-1

How to Return Equipment ............................................................................................P age D-1

Address for Repairs.......................................................................................................P age D-1

Parts List

Errata

Page 9

MODEL YB8 INSTALLATION AND OPERATION

Installation and Operation

Section Contents

Introduction ...........................................................................................................................................Page A-1

Hardware Page ......................................................................................................................................Page A-2

Functional Specifications ..........................................................................................................Page A-2

Size ................................................................................................................................Page A-2

Weight ...........................................................................................................................Page A-2

Environmental Protection ............................................................................................ Page A-2

Sample Cooling ............................................................................................................Page A-2

Temperature Limits .......................................................................................................Page A-2

Sample Pump ................................................................................................................Page A-2

Safety ............................................................................................................................Page A-2

Pump Tubing .................................................................................................................Page A-2

Tube Life .......................................................................................................................Page A-2

Maximum Lift ...............................................................................................................Page A-2

Transport Velocity ........................................................................................................Page A-2

Sample Volume .............................................................................................................Page A-2

Accuracy .......................................................................................................................Page A-2

Repeatability .................................................................................................................Page A-2

Liquid Sensor ................................................................................................................P age A-2

Controller ......................................................................................................................Page A-3

Electronics.....................................................................................................................Page A-3

Internal Clock................................................................................................................Page A-3

Internal Battery .............................................................................................................Page A-3

Power ............................................................................................................................Page A-3

Battery Back-Up ...........................................................................................................Page A-3

Analog Input .................................................................................................................Page A-3

Subassemblies ...........................................................................................................................Page A-3

Electronics Enclosure....................................................................................................Page A-3

The Controller ...................................................................................................Page A-3

Peristaltic Pump ............................................................................................................Page A-4

Liquid Sensor ................................................................................................................P age A-5

Refrigerator ...................................................................................................................Page A-5

Wetted Parts ..................................................................................................................Page A-5

Intake Hose .......................................................................................................Page A-5

Strainer ..............................................................................................................Page A-5

Pump Tubing .....................................................................................................Page A-6

Discharge Tubing ..............................................................................................Page A-6

Bottle Full Sensor .............................................................................................Page A-6

Sample Bottles ..................................................................................................Page A-7

April 1999/Manning Environmental Inc.

Page 10

MODEL YB8 INSTALLATION AND OPERATION

Assembly...................................................................................................................................Page A-8

Assembling the Model YB8 Sampler ...........................................................................P age A-8

Refrigerator .......................................................................................................Page A-8

Electronics Enclosure........................................................................................Page A-9

Distribution Assembly Installation .............................................................................Page A-10

Single Bottle Sampling ...................................................................................Page A-10

Multiple Bottle Sampling ................................................................................Page A-10

Suspension Plate Installation ..............................................................Page A-10

Distributor Assembly ..........................................................................Page A-10

Bottle Installation ............................................................................................Page A-13

One Liter and Half-Liter Plastic Bottles Page A-13

Spout Position Page A-13

Installing The Sampler ............................................................................................................Page A-13

Connecting Power .......................................................................................................Page A-14

Sample Intake Line .....................................................................................................Page A-14

Intake Hose Placement ................................................................................................Page A-14

Running a Test Cycle ..............................................................................................................Page A-15

The Sampling Cycle ................................................................................................................Page A-15

Sample Recovery ....................................................................................................................Page A-16

External Connections ..............................................................................................................Page A-17

Contact In & Analog In Connections..........................................................................Page A-17

Bottle Full Sensor & Stepper Motor Connections ......................................................Page A-17

Bottle Full/Stepper Motor ...............................................................................Page A-17

Contact Closure ...............................................................................................Page A-18

Analog Signal (Optional) ................................................................................Page A-18

April 1999/Manning Environmental Inc.

Page 11

MODEL YB8 INSTALLATION AND OPERATION

Introduction

Congratulations on the purchase of a Manning Environmental, Inc. Model YB8 Sampler. The model

selected is the latest in a long line of state of the art equipment produced for over twenty three years by

Manning Environmental Inc. Based on this experience, if there is one thing Manning can claim it is that we

know samplers. T here are Manning samplers still used in regular service today that are over twenty years

old. I t is almost impossible to find an organization with the commitment of producing equipment with such a

history of reliability, dependability, quality and value as exhibit ed by Manning samplers. E ven so,

improvement is a never ending goal at Manning. We are always interested in the perceptions and experiences

of our users. If there are any suggestions or comments on our equipment, this manual, or anything Manning

does, please feel free to contact us.

The YB8 is a stationary peristaltic pump based model which can automatically collect and hold Non-Toxic,

Toxic, and Suspended Solid samples from a liquid source. The unit was designed from the ground up with

active user participation to ensure the features and options that are important to field use were incorporated

into the unit. It employs a high speed, peristaltic pump to draw the samples and an industrial grade

refrigeration unit to cool and maintain them at the EPA recommended 4 C. Backed by Manning’s reputation

for quality and dependability, it will provide years of reliable service.

0

Even if the sampler will not be used immediately upon receipt, unpack and examine it. This will help to

familiarize the user with the equipment. Verify that all of the parts have been received and that no damage

has occurred in shipment . I f damage is noticed, immediately report the extent of it to both the t ransportation

company and to Manning Environmental Inc. In addition, check the packing list to verify that it matches the

items sent and that all accessories ordered are included with the shipment. Manning strives for 100 percent

accuracy in the delivery of our equipment, but even with the most stringent quality assurance, mistakes do

occur. O missions, damage, or mistakes must be reported to Manning Environmental Inc. within 10 working

days of receipt of the shipment.

This manual is designed to communicate a complete understanding of the equipment, its operation,

maintenance, and functions. Manning recommends this manual and the equipment be examined completely

before placing the unit into service. M anning’s commitment to producing reliable, top quality products is

legendary, but the possibilit y of breakdown or malfunction always exists. T his manual should enable the

diagnosis and solving of many potential problems. If the problem cannot be solved, please feel free to call

our service department at 1-800-863-9337 to obtain help. Our first priority is making sure the experience

with Manning equipment is an excellent one. In almost all instances the difficulty can be addressed over the

phone, but in the rare instance it cannot, the equipment may need to be sent back to Manning for service.

Please contact our customer service department at 1-800-863-9337 to obtain a Return Authorization

Number. T hen follow the shipping instructions that will be given. P lease note the malfunction on the paper

work so a diagnosis and a solution to the problem can be arrived at with the least amount of delay.

We recommend the following steps before attempting to use the sampler:

1. Review this manual. Read the errata sheets at the end of this manual for the latest updates.

2. Follow the instructions beginning on page 1-8 to assemble the YB8.

3. Set the time and activate a test cycle.

April 1999/Manning Environmental Inc.

Page A-1

Page 12

INSTALLATION AND OPERATION MODEL YB8

4. Program the YB8.

Hardware

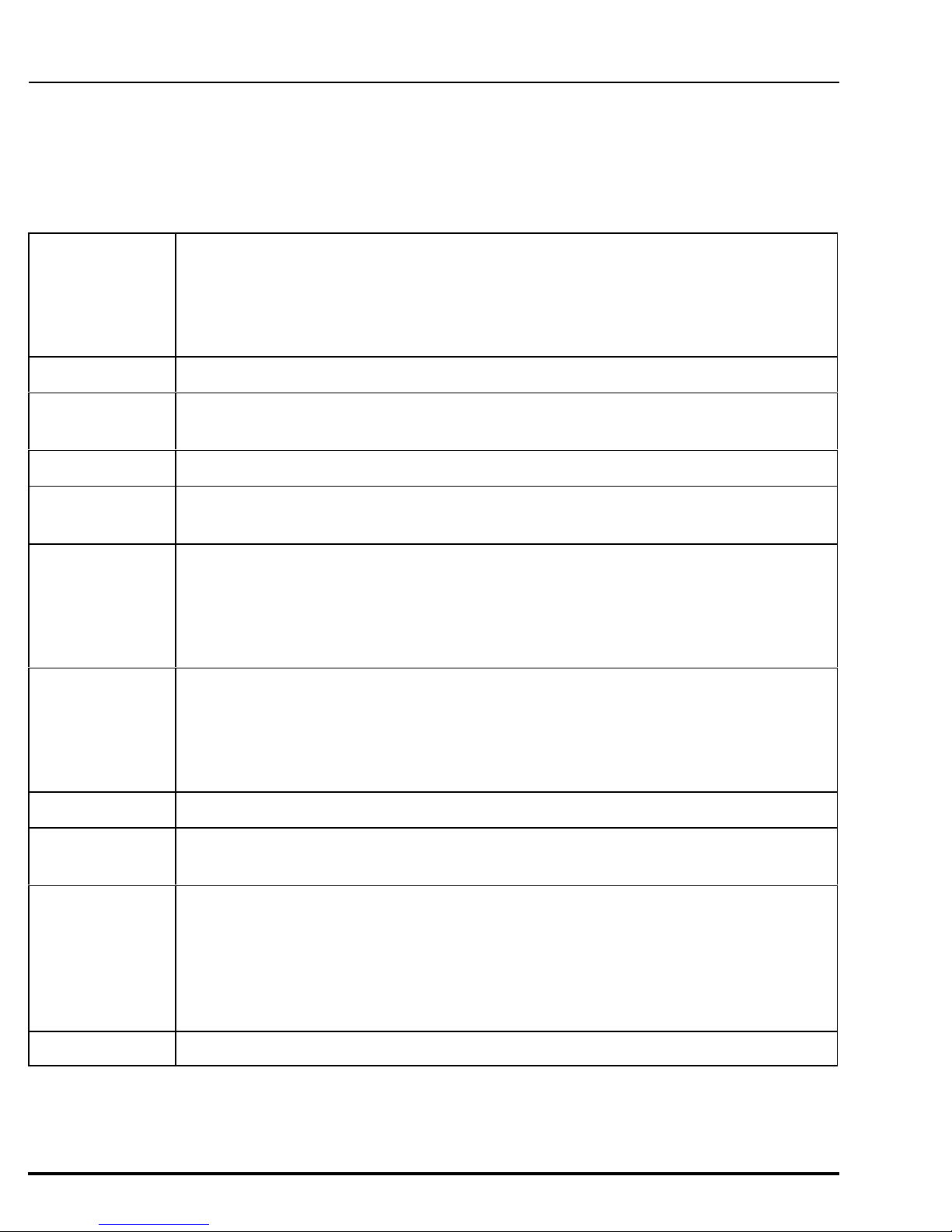

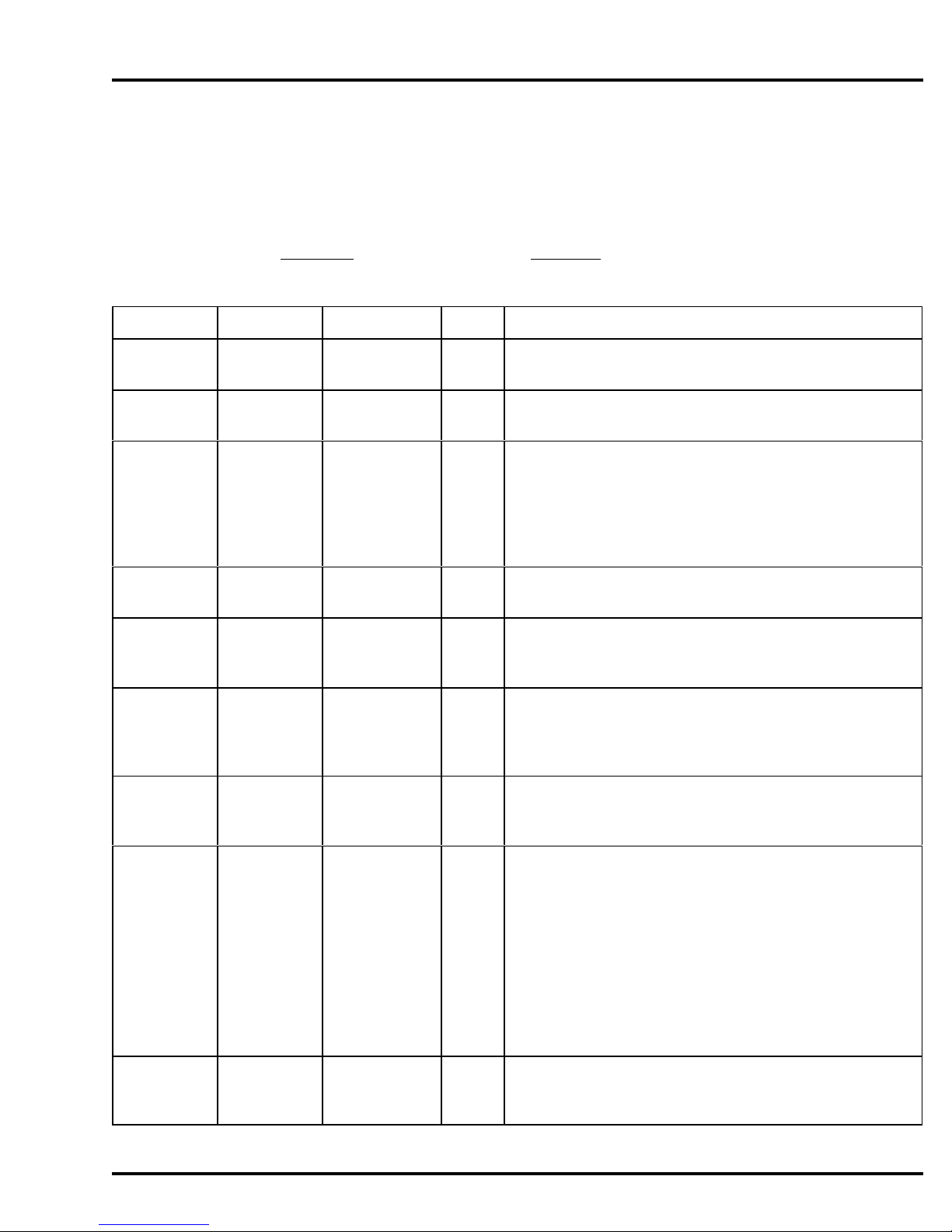

Functional Specifications:

Size Control Unit: 10.75" (27.305cm)W x 7" (17.78cm)H x 9.75" (24.765cm)D

Refrigeration Unit: 23.875" (60.65cm)W x 34.5" (87.63cm)H x 24" (60.96cm)D

Total Unit: 23.875" (60.65cm)W x 41.5" (105.41cm)H x 24" (60.96cm)D

Weight Dry Weight: 110 lb (49.89 kg) with refrigerator.

Environmental Nema 4X, 6 housing around electromechanical components.

Protection

Sample Cooling Industrial Grade refrigeration unit.

Temperature 0°C to 50°C (32°F to 122°F) without optional enclosure and heater.

Limits

Sample Pump High Speed peristaltic, dual roller design with impact and corrosion resistant Delrin

plastic pump body.

Safety Integral safety kill switch. E nsures when the clear plastic face plate is removed from

the pump, it prevents accidental powered rotation.

Pump Tubing 3/8" ID by 5/8" OD by 1/8" thick medical grade silicone rubber pump tubing.

Tube Life Recommended maximum of 1,000,000 pump revolutions based on a standard sample.

A standard sample equates to 5ft of head, 10 foot PVC intake tube, and 200 ml sample

size.

Maximum Lift 28 ft (8.5344 m).

Transport Minimum of 3 ft/s at 3 ft of lift (0.9144 m/s at 1 m) and 2.0 ft/s at 20 ft of lift (0.6096

Velocity m/s at 6.1 m).

Sample Volume Programmed directly in increments of 1 milliliter up to a maximum of 9,999 ml.

Accuracy ± 10ml or ± 10% of the programmed volume, whichever is greater.

Repeatability ± 5ml or ± 5% of the average largest and smallest sample volume in a sample set,

whichever is greater.

®

Liquid Sensor Continuity type or Ultrasonic (optional)

Page A-2

April 1999/Manning Environmental Inc.

Page 13

MODEL YB8 INSTALLATION AND OPERATION

Controller Microprocessor based 1 board system which controls all functions of the unit.

Membrane Ergonomically designed, hermetically Sealed, 24 key, multiple function, with 2 line by

Switch 20 character alphanumeric backlighted display.

Electronics 100% Solid State.

Internal Clock Indicates real time with ± 1min/month accuracy.

Internal Battery 5 year internal lithium battery to maintain program logic, RAM memory, real time

clock and date.

Power 115 volt AC, 60 Hz. - Standard

220 volt AC, 50 Hz . - Optional

Battery Back-Up Optional 12 VDC battery backup for continued operation in case of 115 volt power

failure. C ontinues to operate the sampling control unit only, n ot the refrigerator.

Analog Input 4-20 mA - Optional

Subassemblies

The sampler consists of three major subassemblies: the electronics enclosure, the refrigerator, and the wetted

parts. As a unit these subassemblies form an environmentally resistant enclosure.

Electronics Enclosure

The electronics enclosure includes the microprocessor-based controller, the

peristaltic pump, and the liquid sensor. Constructed of structural resin, the

enclosure conforms to Nema 4X,6 requirements when latched.

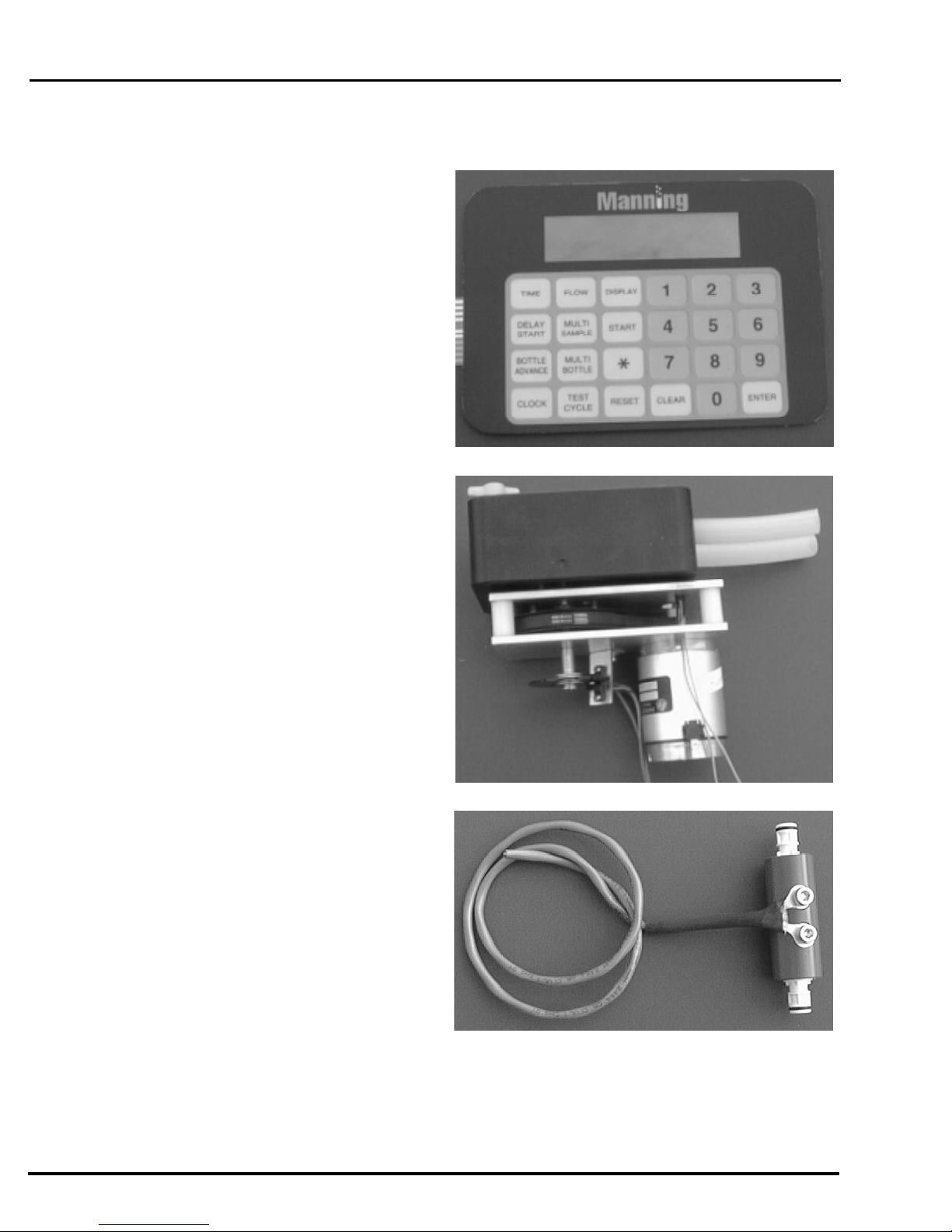

The Controller

The controller electronics consists of 1 board. The board converts outside

power to the appropriate internal use and controls the input/output signals

associated with the sampler. The CPU board contains a Z180 microprocessor,

RAM and ROM memory, and interfaces for the keyboard, and the display. The micro board also contains the

logic for the liquid sensor and the RPM counter. The user communicates to the sampler via a 24 key multiple

function membrane switch. The keys are clearly marked with their designated functions. An internal battery

maintains the program logic, RAM memory, and the controller's real-time clock and date function. T he

electronics are mounted on the back of the controller.

Figure 1 - Electronics

Enclosure

April 1999/Manning Environmental Inc.

Page A-3

Page 14

INSTALLATION AND OPERATION MODEL YB8

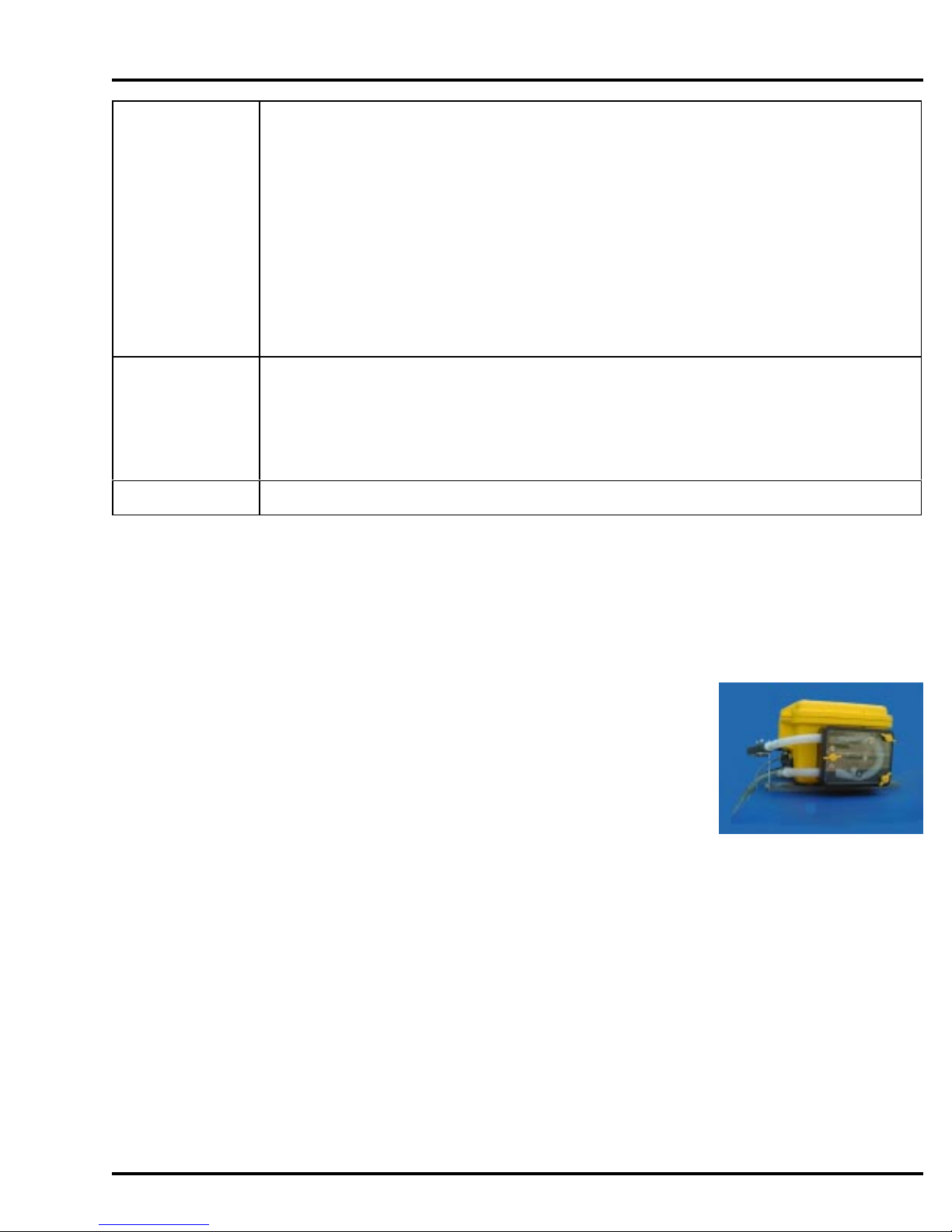

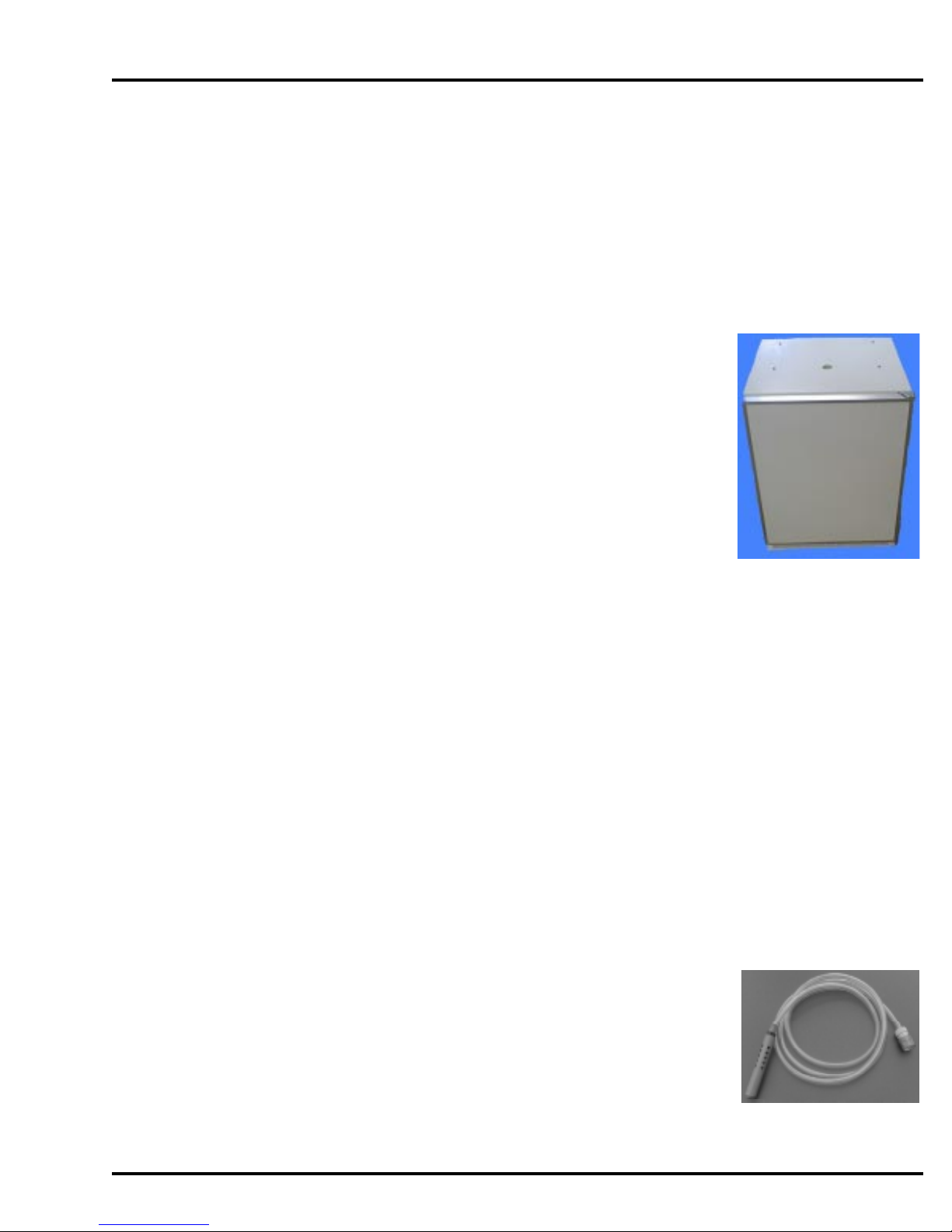

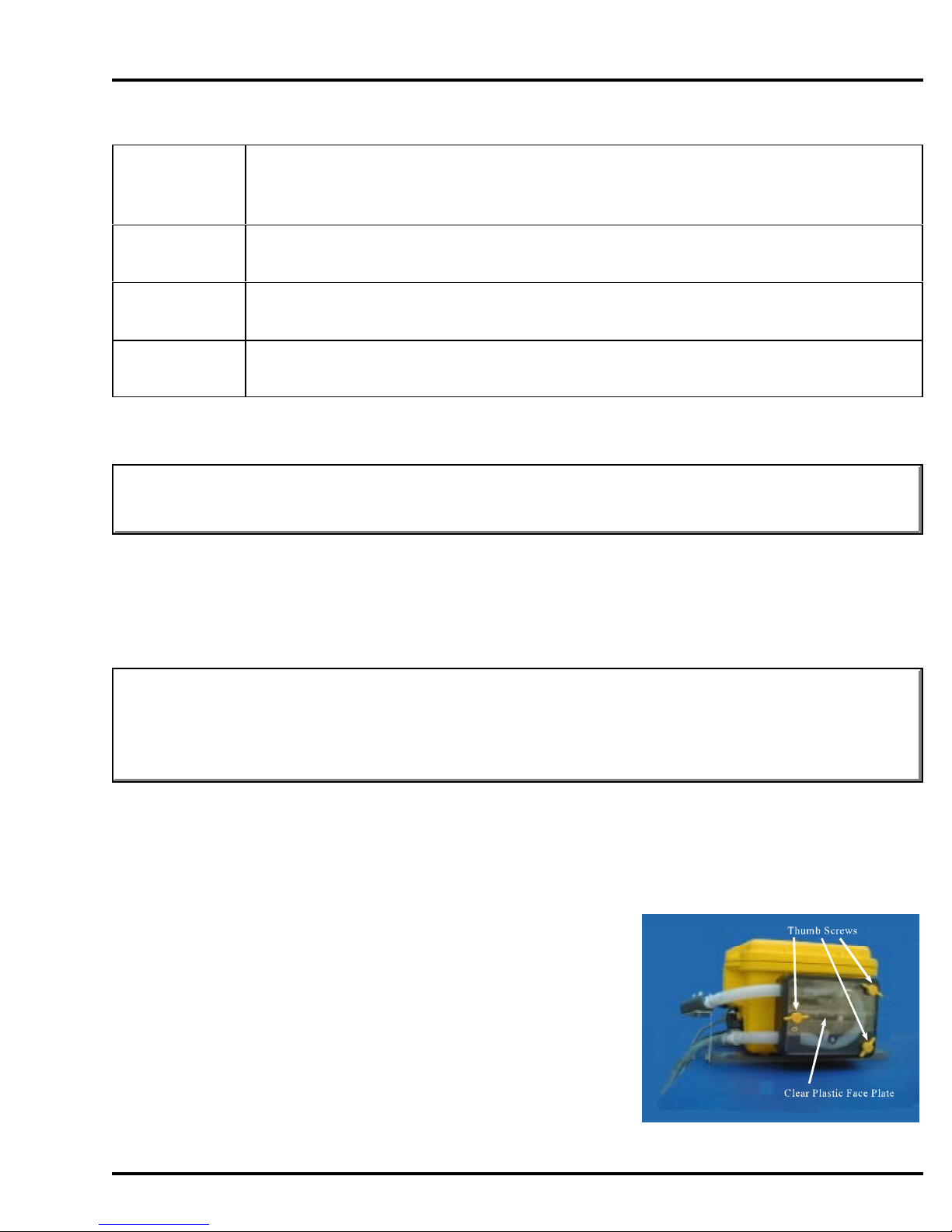

Peristaltic Pump

The Manning Model YB8 employs a high speed, dual

roller, vertically mounted, peristaltic pump. The pump is

belt driven by a 12VDC industrial grade motor. T his

ensures quite, smooth performance even while the unit is

subjected to very intense performance conditions. It

utilizes a face plate constructed of clear PVC for easy

visual identification of pump parameters, such as tube

alignment, and spindle and roller operation. The pump

body is made of impact and corrosion resistant Delrin

plastic for long life. It securely holds the pump tubing in

place by firmly clamping the two halves of the pump

case together. The pump is capable of vertical lifts of up

to 28 feet and produces sample transport velocities of

2.0 feet per second over a wide range of draw heights

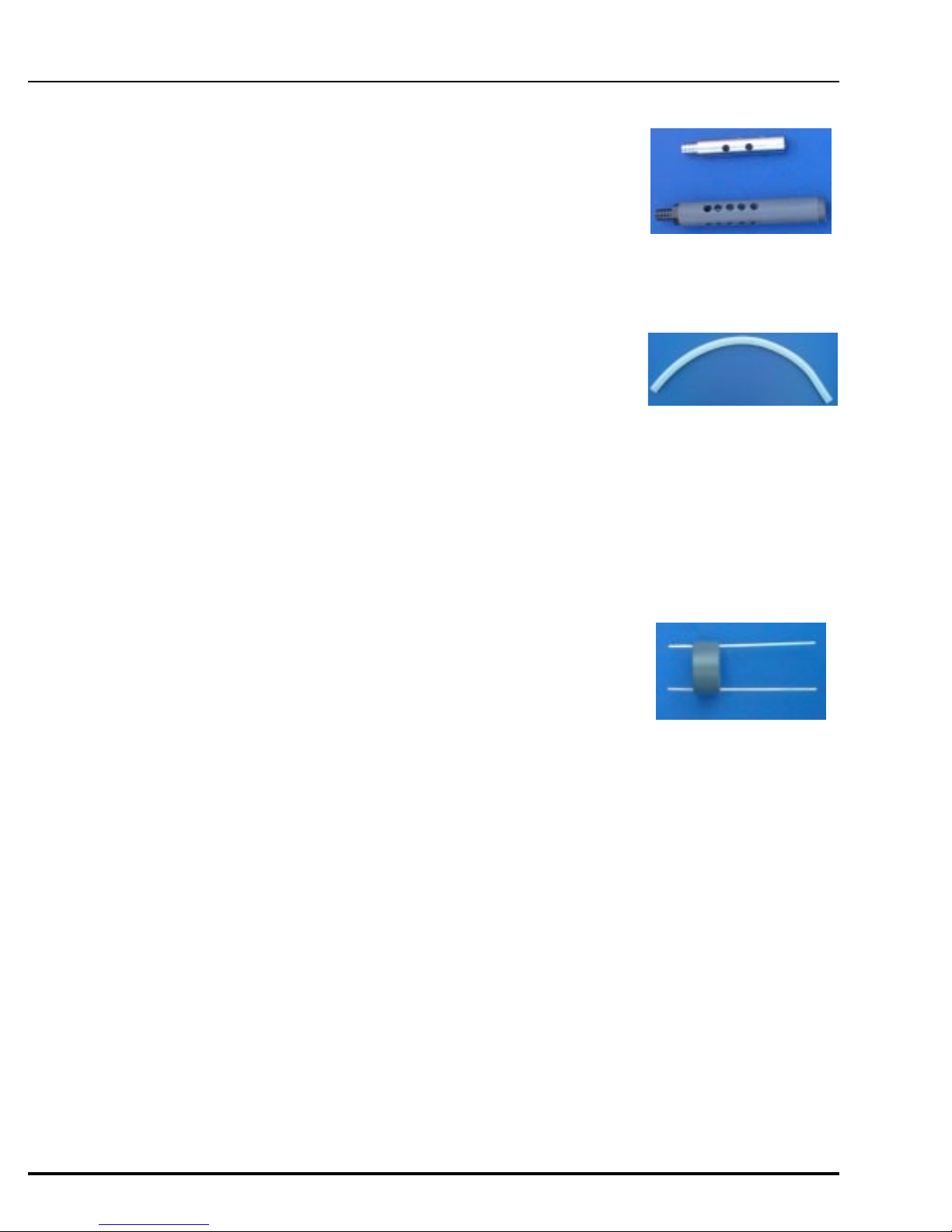

Liquid Sensor

®

Figure 3 - Keypad

The Model YB8 utilizes a liquid sensor, located near

the entrance to the peristaltic pump, which is capable of

detecting the presence of source fluid as it approaches

the pump inlet. The sensor is either a continuity type

probe (base) or an ultrasonic sensor (optional).

The liquid sensor is used for two reasons.It enables the

sampler to rinse the intake line. After the initiation of a

sampling sequence the first operation is to turn on the

peristaltic pump. The pump begins rotating

counter-clockwise causing air to be forced out of the

intake tubing. After the set amount of purge time has

elapsed, the unit will reverse the pump so the rollers are

moving in a clockwise direction. This creates vacuum in

the pump tube, which in turn causes the source liquid, to

begin traveling up the intake line. As soon as the fluid

reaches the liquid sensor, the sampler will immediately

recognize that fluid has reached the inlet to the pump. It

will instantaneously reverse the direction of the pump

(rollers will be moving in a counter-clockwise rotation),

sending the water that had been drawn up back out of

the intake line. This in effect rinses the line. When the

unit has performed the set number of rinses, a sample

will be drawn. The rinse option is set in *99

(configuration mode). The sampler can be programmed

to not rinse the line or to rinse the line up to 3 times.

Figure 2 - Pump Assembly

Figure 4 - Liquid Sensor - Continuity Type

It makes it possible for the sampler to deliver precise, repeatable samples even in changing lift conditions.

Page A-4

April 1999/Manning Environmental Inc.

Page 15

MODEL YB8 INSTALLATION AND OPERATION

Whenever a sampling sequence is initiated the sampler follows the steps outlined above, and draws a sample.

The controller then determines the transit time of the sample to reach the liquid sensor. Assume for example

there was an increase in the amount of lift from the source liquid to the unit. This would increase the time

needed for a sample to reach the liquid sensor and the pump. The controller, in a case such as this, will

automatically compensate for the change in lift by increasing the amount of time the peristaltic pump is able

to pull source liquid. This ensures the sampler has enough time to collect the correct amount of sample fluid.

The compensation applies to either an increase or decrease in lift height.

Refrigerator

The refrigerator is an industrial grade unit with the ability t o cool and maintain

samples at the EPA recommended 4ºC. Modifications have been performed on the

refrigerator that enable it to withstand event the harshest environments. The

condenser has been baked dip-coated with enamel and the copper refrigerant lines

are coated with asphalt cork tape to prevent hydrogen sulfide gas from attacking

the copper lines and the brazed joints. The thermostat is located inside the

refrigerator which affords it additional protection from the environment. The

evaporation coils and cabinet both have two coats of baked on acrylic enamel with

the cabinet having the additional protection of an iron phosphate pre-treatment.

Both the fan motor and t he compressor are designed for greater durability and

resistance to atmospheric attack. The unit boasts extensive insulation for

maximum cooling retention, and a full perimeter magnetic door gasket with a

urethane coating to resist corrosion and seal the cold inside. The door is also

available with an optional locking hasp to prevent unauthorized entry. The sample containers, suspension

plate, and distributor arm for multiple bottle operation are located within the environmentally controlled

chamber of the refrigerator.

Figure 5 - Refrigerator

Wetted Parts

Wetted parts are those pieces of the sampler that come in direct contact with the sample liquid. The main

components of the wetted parts for the Manning Model YB8 are the intake hose and strainer, the pump

tubing, the discharge tubing, the bottle full sensor (in single bottle units) the distribution assembly (in multiple

bottle units) and the sample bottles. If the source liquid t o be sampled is a non-priority pollutant (NonToxic) then all parts that touch the liquid are either PVC (Polyvinyl Chloride), medical grade silicone rubber,

ABS (Acrylonitrile Butadiene Styrene) plastic, or Stainless Steel. Parts in contact with a sample source that

is a priority pollutant (Toxic) are required to be Teflon , glass, stainless steel, or medical grade silicone

®

rubber. These materials are recognized and accepted as non-contaminating materials. This permits the

sampling of a wide variety of toxic pollutants such as hydrocarbons and chlorine-based compounds.

Intake Hose

The 3/8" ID by 5/8" OD intake hose is constructed of either PVC (Polyvinyl

Chloride) or PTFE. Y ou can differentiate the hoses by

their physical characteristics. The PVC is flexible and slightly tacky to the

touch. T he PTFE is not very flexible and is also very

smooth and slick to the touch.

Figure 6 - Intake Hose

April 1999/Manning Environmental Inc.

Page A-5

Page 16

INSTALLATION AND OPERATION MODEL YB8

Bottle Full Sensor

Strainer

The 3/8" ID strainer is available in stainless steel, or PVC. By placing

holes no larger than 3/8" ID along the length of the strainer, the intake of

large particles that can plug the hose or any part of the sampler is

prevented. Since the strainer is also weighted, it keeps the hose inlet at the

desired level in the source liquid.

Pump Tubing

The pump tubing Manning Environmental Inc. supplies for the Model

YB8 is medical grade silicone rubber.

Discharge Tubing

The 3/8" ID by 5/8" OD discharge tubing is also medical grade silicone rubber.

Figure 7 - Strainers

Figure 8 - Pump Tubing

Bottle Full Sensor

The bottle full sensor is only used on single bottle applications. It is a

cylinder, with a hole in the middle, to allow the discharge tube to pass

through. Constructed of PVC it has two stainless steel rods that protrude

vertically downward from the main body of the sensor. The user positions

the bottle full sensor in the container with the ends of the rods at the highest

point water should be allowed t o rise. O nce the water level has risen and

contacts the rods, a change in continuity is detected alerting the sampling

unit that the liquid in the container has reached the maximum level allowed by the user.

This ends the sampling cycle

Page A-6

April 1999/Manning Environmental Inc.

Page 17

MODEL YB8 INSTALLATION AND OPERATION

Sample Bottles

The bottles are constructed of either polyethylene or glass.

NOTE: The sampler is field convertible from multiple bottle to single bottle.

Contact the Manning Environmental Parts Department for assistance.

Single Bottle Sampling Multiple Bottle Sampling

One (1) - 5 gallon HDPE carboy Twenty-four (24) - 500mL Polyethylene bottles

One (1) - 4 gallon polyethylene carboy Twenty-four (24) - 1000mL Polyethylene bottles

One (1) - 2.5 gallon glass bottle

One (1) - 2.5 gallon polyethylene

April 1999/Manning Environmental Inc.

Page A-7

Page 18

INSTALLATION AND OPERATION MODEL YB8

Assembly

Assembling the Model YB8 Sampler

The unit is normally shipped assembled with accessories packed inside the refrigerator.

Refrigerator

There are several things to keep in mind before installing the refrigerator. T he location is important.

It is best to locate the unit out of direct sunlight and away from heat sources. It is best to locate the

unit at least two inches away from any kind of wall. Ventilation is required from the bottom front

section of the unit. Keep this area open and clear of any obstructions. It is recommended not to use

a power cord to power the unit. It is best if the unit can be plugged directly into the appropriate

power supply outlet. The refrigeration system is equipped with a power supply cord that has a threepronged grounded plug. It must be plugged into a mating grounding type receptacle in accordance

with the National Electrical Code and applicable local codes and ordinances. If the circuit does not

have a grounding type receptacle, it is the responsibility and obligation of the customer to exchange

the existing receptacle in accordance with the National Electrical Code and applicable local codes an

dordinances. Th ethird ground prong should not under any circumstances, be cut or removed. All

U.L listed refrigerated products are equippedd with this type of plug, except hazardous location

models which are to wired to comply with the National Electrical Code, Article 501-4 for Class I

Divisions 1 and 2

Things to remember about the refrigerator:

A. Allow 24 hours for your refrigerator to reach a new temperature setting.

B. The motor will start and stop often. I t must do this to maintain the temperature you

select.

C. Keep you refrigerator as level as possible

D. Unplug the refrigerator before working on anything with the electrical system.

E. Exercise caution when sweeping, vacuuming or mopping near the front of the unit.

Damage to the grill can occur.

F. For all cleaning of the refrigerator, mix 2 tablespoons baking soda into 1 quart warm

water or use mild soap. D o not use strong cleaners or scouring powders or pads.

G. Keep all flame or sparks away from flammable material storage refrigerators when

opening the door to remove or store commodities.

H. Disconnect electrical power before removing electrical plug

Unpack the refrigerator by removing the bands at the top and bottom of the refrigerator box and

lifting the box off of the refrigeration unit. Open the refrigerator door and check for various

components that might be inside the refrigerator. I t ems are often packed inside the unit to minimize

shipping space. Check the items you have received against the packing list. Call Manning

immediately if yo u cannot match the packing list to the items shipped. M anning strives for 100%

accurate shipments, but mistakes do happen, so please call Manning immediately if t here is a

discrepancy.

Page A-8

April 1999/Manning Environmental Inc.

Page 19

MODEL YB8 INSTALLATION AND OPERATION

Plus Nuts

Discharge Hole

Figure 12 - Refrigeration Hole Placement

1. Once you have unpacked the unit, locate the four feet

for the refrigerator (they are in a small plastic bag inside

Leveling Feet (2 front, 2 back)

2. With the refrigerator empty, carefully tip it and screw a

Figure 10 - Refrigerator

3. Adjust the feet so the refrigerator is level and does not

the refrigerator, with the refrigerator owners manual).

foot into the threaded hole in the bottom of each

corner.

rock.

4. Plug the refrigerator in and begin the cooling the unit down. Manning recommends using a

water proof thermometer and a liter of water to monitor the temperature of the water within

the refrigerator. T his will give a more accurate representation of the actual temperature of the

samples once sampling begins. Y ou should allow at least 24 hours for the refrigerator to

reach a stable condition.

NOTE: Be careful not to scratch any painted surfaces. The surfaces are painted with corrosion

resistant paint. S cratches in the paint minimize this protection.

Electronics Enclosure

1. On top of the refrigerator there will be 4 screws inserted into 4 plus nut holes. Remove the

screws from the holes and set them aside in a safe place.

2. Place the electronics enclosure on top of the refrigerator so the holes in the PVC mounting

bars match up with the threaded inserts in the refrigerator. The front (latches are in the front)

should be facing the door of the refrigerator and the peristaltic pump should be on the right.

3. Insert the screws and tighten snugly.

4. Thread the discharge tube into the center hole in the refrigerator. There

will be a black rubber plug that fits into the discharge hole. T his plug is

split to accept either the bottle full sensor cable or the stepper motor

cable depending on the configuration that you ordered. The cable fits

inside the plug.

Refrigerator Plug

Figure 11 -

April 1999/Manning Environmental Inc.

Page A-9

Page 20

INSTALLATION AND OPERATION MODEL YB8

Distribution Assembly Installation

Single Bottle Sampling

1. Center the sample bottle in the refrigerator.

2. Run the discharge hose through the Bottle Full sensor ring and then place it at the

desired height in the bottle. T o adjust the position simply slide the bottle full

sensor either up or down the discharge hose.

3. Connect the Bottle Full sensor probes to the female contacts on the bottle full

cable comming from the electronics enclosure into the refrigerator.

Multiple Bottle Sampling

Figure 13

Suspension Plate Installation

Position the suspension plate so the handles are on the sides. Slide the plate onto the top

rails in the refrigerator. The plate should be flush with the front of the refrigerator so it

does not interfere with the drain trough in the rear.

- Bottle

Full

Sensor

Distributor Assembly

1. Verify that the spout is correctly aligned on the distribution bracket. The spout should be centered

on the bracket side when the spout is rotated to the side (3 o'clock position).

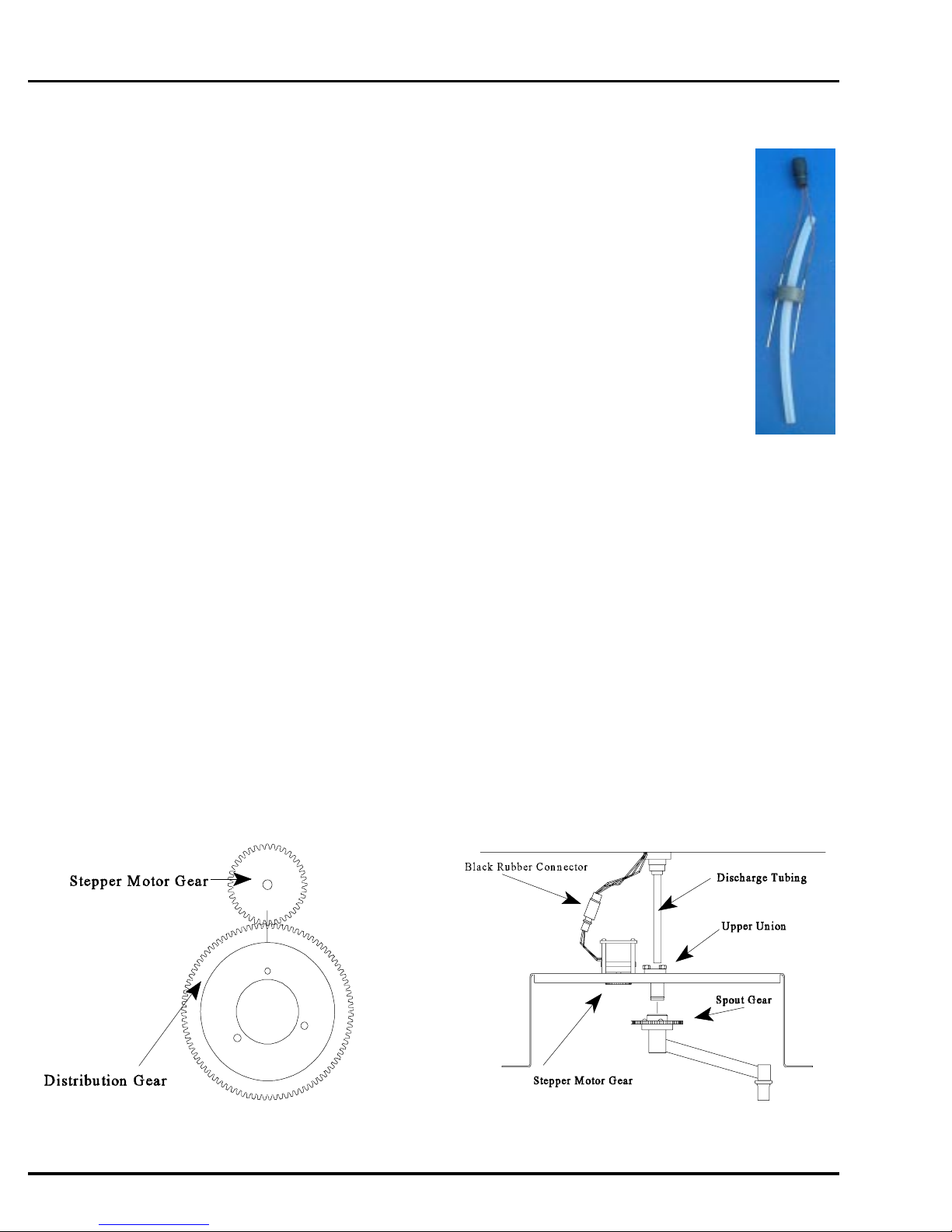

Figure 14 - Gear Arrangement

Page A-10

Figure 15 - Distribution System

April 1999/Manning Environmental Inc.

Page 21

MODEL YB8 INSTALLATION AND OPERATION

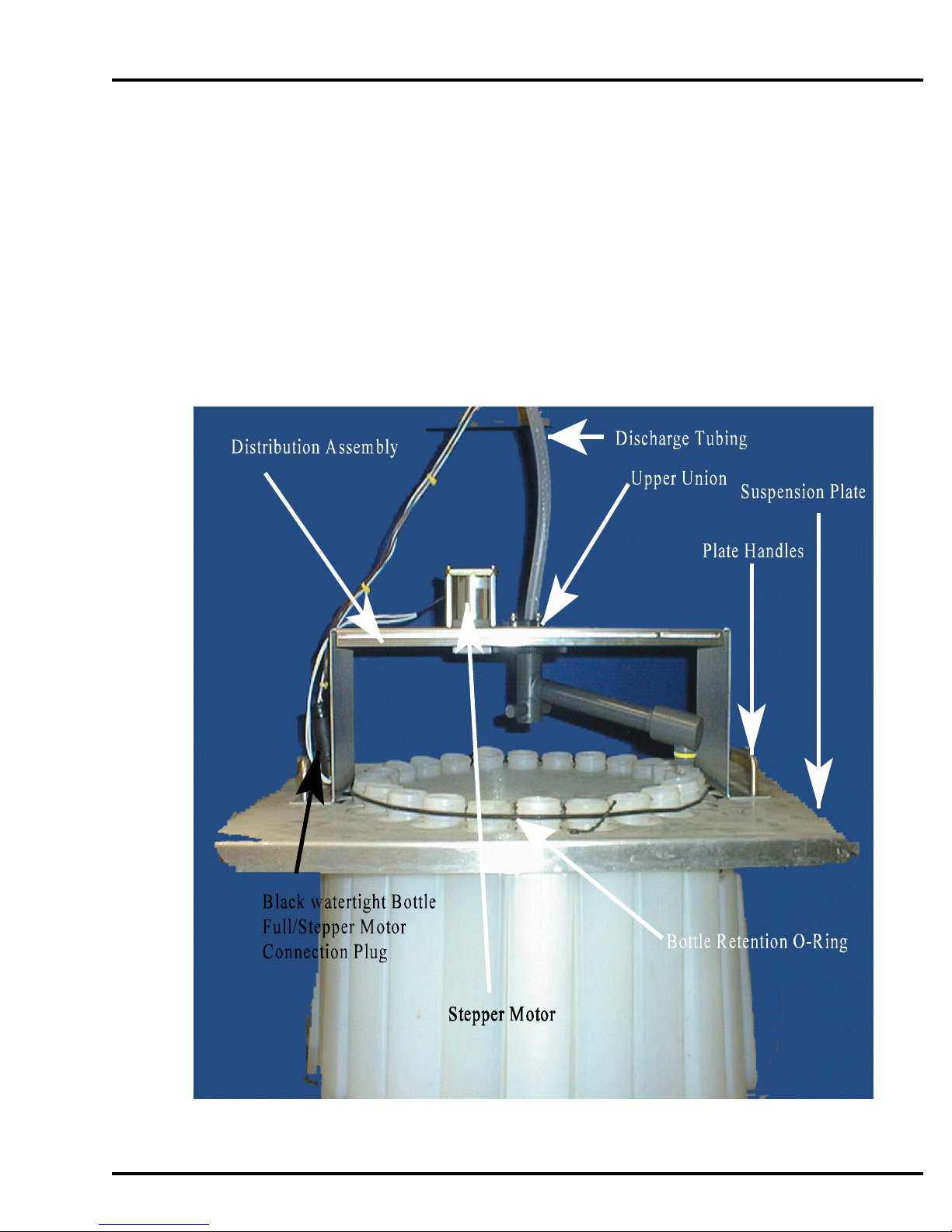

2. Place the distribution assembly on the suspension plate with the plate handles poking through

the slots in the distribution assembly.

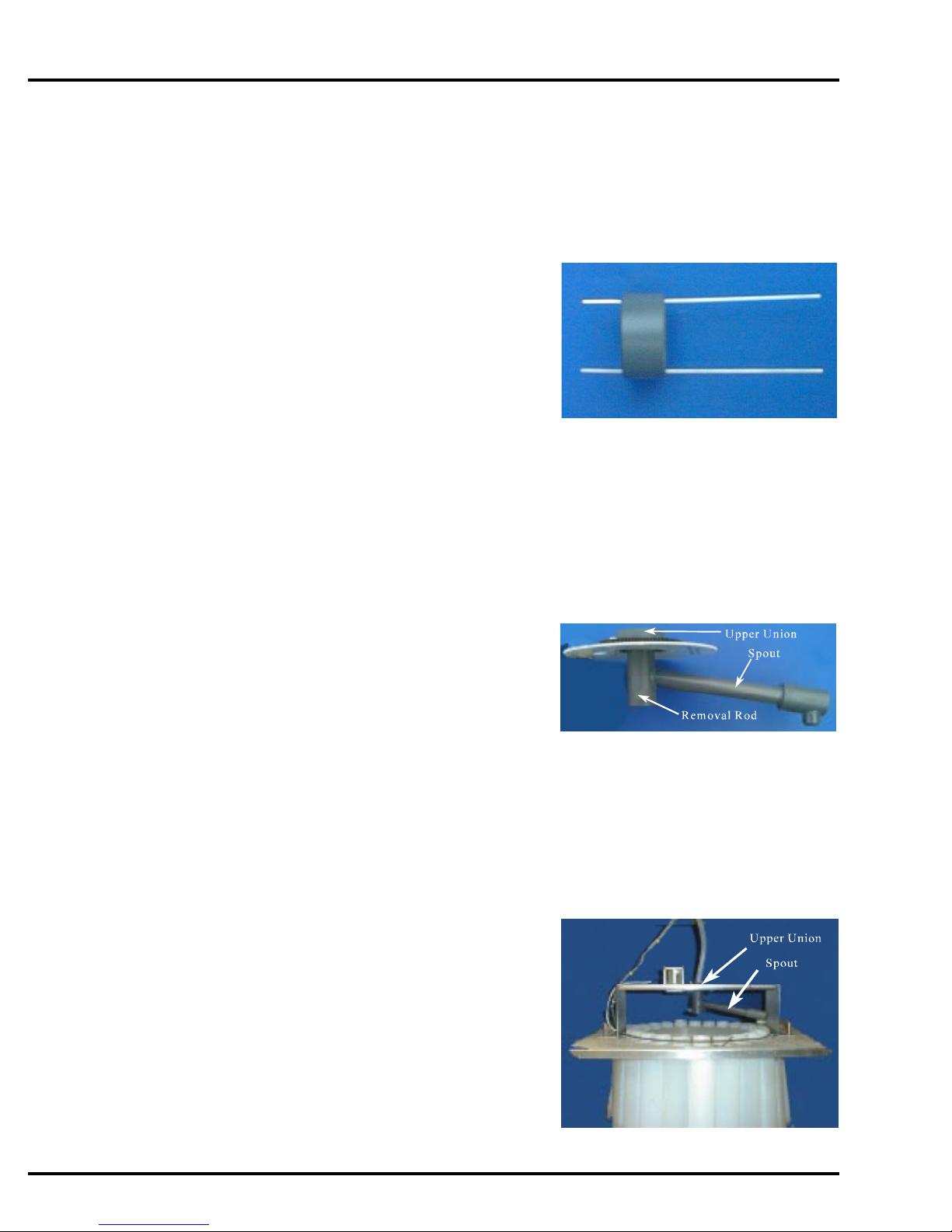

3. Insert the discharge tube into the upper union. The discharge tube must be flush against the

union to prevent leaking.

4. Mate the black connectors. ( Applying non-conductive grease will help if d isassembly

is required later.)

There are wire racks inside the refrigerator so the distribution assembly can be parked out of the way when

removing the suspension plate and/or bottles. This makes it unnecessary to remove the discharge tube from

the spout union or to de-mate the connector when removing the plate.

April 1999/Manning Environmental Inc.

Figure 16 - Distribution Assembly Picture

Page A-11

Page 22

INSTALLATION AND OPERATION MODEL YB8

Page A-12

April 1999/Manning Environmental Inc.

Page 23

MODEL YB8 INSTALLATION AND OPERATION

The bottles can be installed with the suspension plate in the refrigerator, or the plate can be removed,

the bottles installed, and the plate positioned back in the refrigerator.

Follow the instructions below fro the type of bottles being installed.

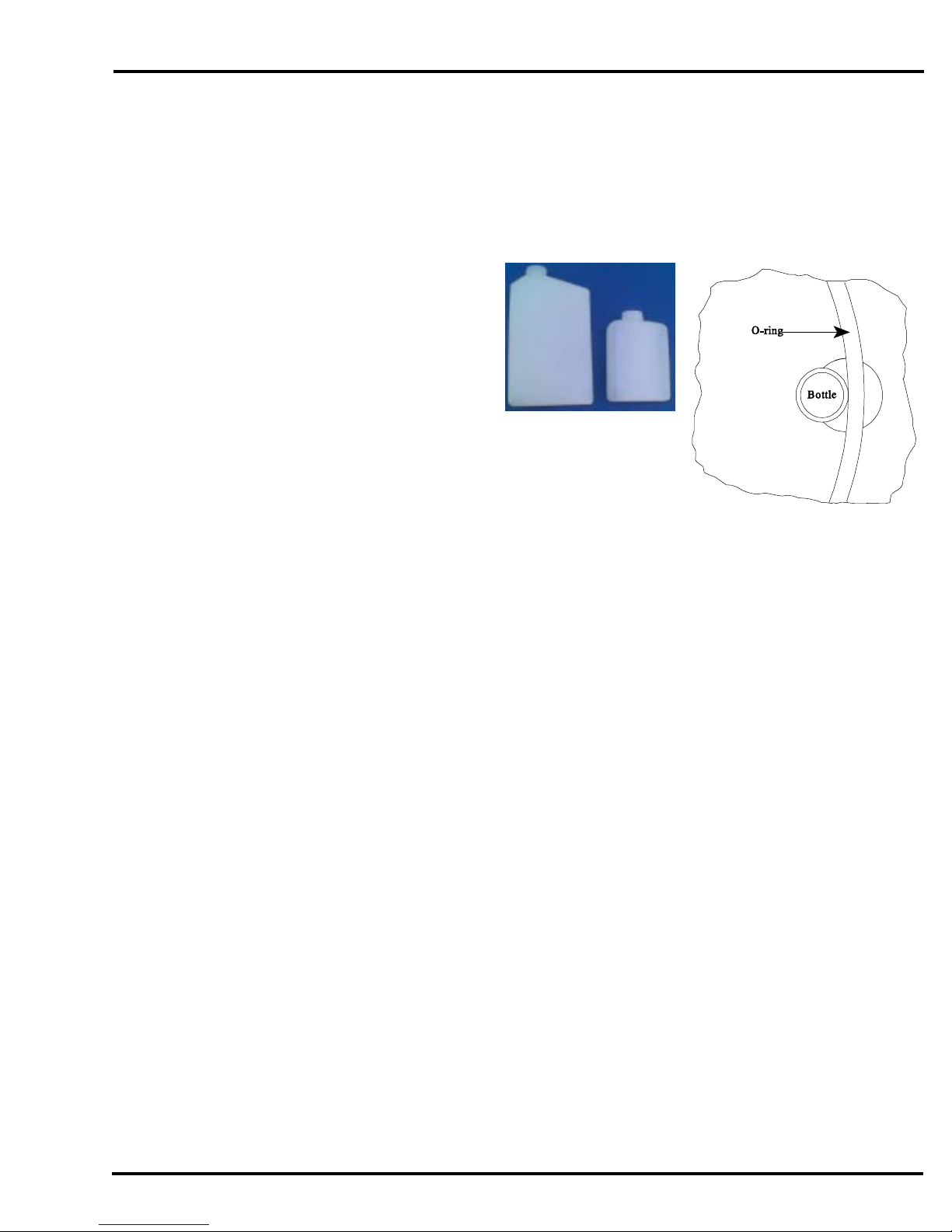

One Liter and Half-Liter Plastic Bottles

1. Insert the bottles through the larger

part of the hole in the suspension

plate.

2. Place the bottles so the smaller angled

part of the bottles points in toward the

middle of the case. Snap each bottle

into place in the smaller part of the

hole. Be sure the bottles are held

below the threaded section.

Figure 21 - 1 liter

(left) and 500ml

(right) bottles

3. Secure bottles by placing the o-ring around them

.

Figure 20 -

Bottles Installed in Suspension

1 Liter and 1/2 Liter

Plate

Spout Position

If the suspension plate was removed from the refrigerator,

replace it. Place the spout over the last bottle in the series,

since the first action of the sampling cycle is a spout

advance.

Installing The Sampler

Install the sampler on a firm, level surface adjacent to the sampling point. If the sampler is installed outdoors,

consider enclosing it in a shelter or under some sort of protection. T his will improve the performance and life

of the unit. The Manning Parts Department can supply an optional full-size NEMA 3R insulated fiberglass

enclosure designed for this purpose.

Connecting Power

The YB8 sampler was designed with components which operate on 12 VDC power. Recognizing

that 115 VAC power has to be available to run the refrigerator, the sampler takes advantage of the

constant supply by employing an AC/DC converter to provide power to the system. The converter is

located inside the electronics enclosure. It comes equipped with a power cord, but it can be hard

wired if desired. A power switch, which controls flow of current to the controller and peristaltic

April 1999/Manning Environmental Inc.

Page A-13

Page 24

INSTALLATION AND OPERATION MODEL YB8

pump, is located on the front of the electronics enclosure. The refrigerator has its own individual

power cord. By using the AC/DC converter the user does not have to be concerned with replacement

of batteries, charging of batteries, or any other factors which affect 12 VDC systems. The system has

been thoroughly tested using 115 VAC and will provide outstanding service, reliability, and longevity.

To power t he unit up follow these simple steps:

1. Check to make sure that the pump cover is

securely fastened to the pump housing and that

the unit is ready to be powered up.

2. Locate the power plug coming out of the

electronics enclosure.

3. Plug the AC/DC converter into the appropriate

receptacle.

4. Turn the power switch, located on the right side

of the electronics enclosure, to "ON". Verify, by

looking at the display, that power is being

applied to the system. If the display does not light up, confirm that the appropriate

connections have been made. I f the unit does still not power up, call the Manning Service

Department. T hey will be able to provide assistance in getting the unit operat ional.

WARNING: Hard-wiring should only be done by a certified electrician.

Sample Intake Line

Attach the intake hose to the connector at the end of the pump tubing.

Intake Hose Placement

Place the intake hose strainer directly in the channel flow, not in an eddy or at the edge of the flow.

In channels with debris, provide deflection to prevent clogging of strainer holes. The weight supplied

with the intake hose is usually sufficient to prevent the intake from being pulled to the surface of a

fast channel.

The correct vertical position of the strainer depends on the type of sample being taken. Placing the

strainer at the bottom of the flow results in a heavier concentration of solids in the sample, while

placing the strainer at or near the top of the flow results in heavier concentration of oils, fats, and

other floating or suspended contaminants.

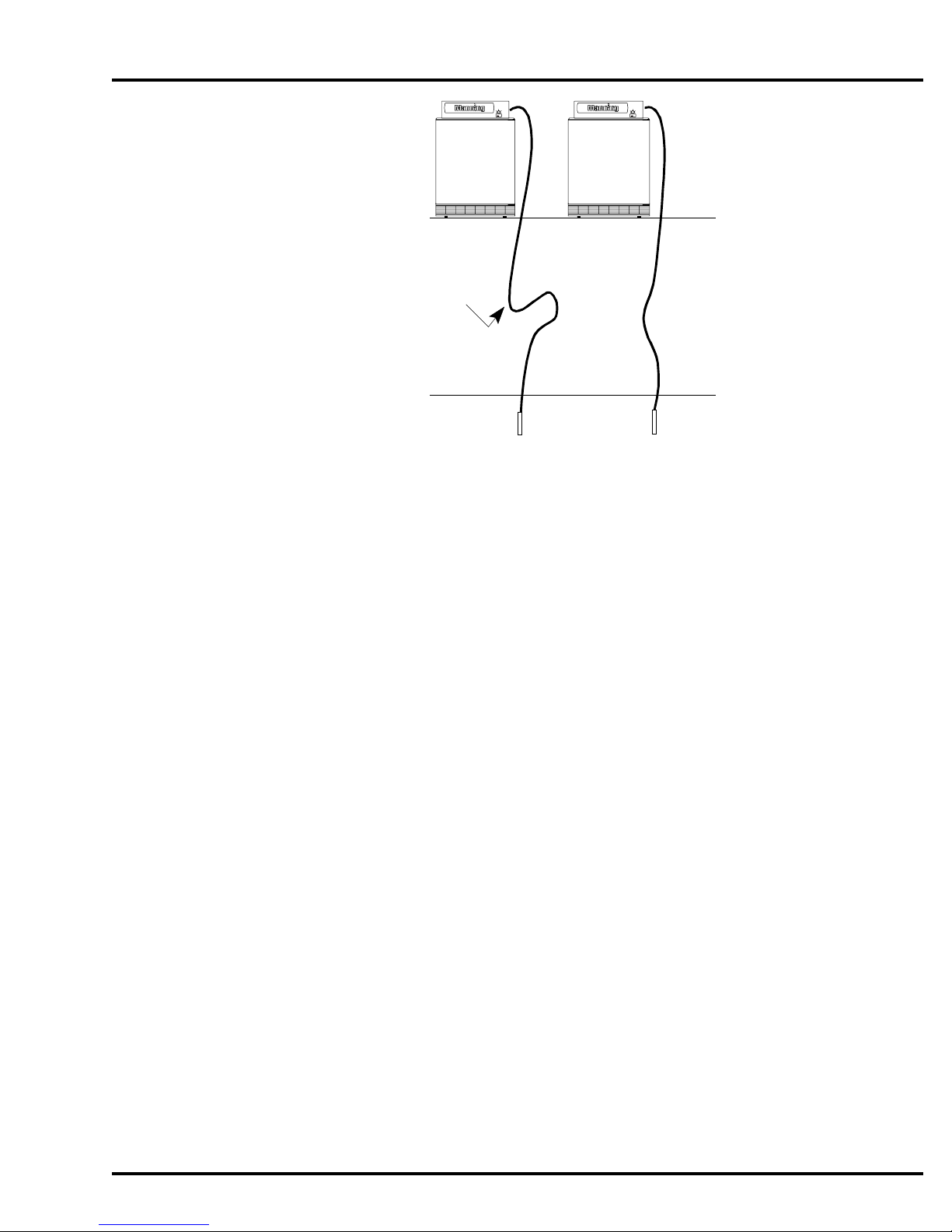

The intake hose should be positioned so the hose can drain between sample cycles and no low spots

exist which would trap water. The correct and incorrect hose placements are shown below.

Page A-14

April 1999/Manning Environmental Inc.

Page 25

MODEL YB8 INSTALLATION AND OPERATION

Trap

Incorrect

Installation

Correct

Installation

Water Level

Figure 24 - Intake Hose Placement

Running A Test Cycle

While it is not mandatory to run a test cycle, it is recommended to assure proper operation and to become

familiar with the various functions and modes of operation. Run a test cycle before programming any

operational modes into the sampler.

1. Turn the main power switch to the “ON” position. The display should read “Sampler Ready”.

2. If the multiple bottle option is being used, rotate the spout so it is over a bottle.

3. Submerge the strainer of the intake hose in a container of clean water. The amount of water

should be enough to keep the strainer covered completely for several test cycles.

4. Press the TEST CYCLE key on the keypad to initiate the test cycle. Y ou will be prompted

for the number of samples you want to take. Enter the number and press <ENTER>.

The Sampling Cycle

Refer to the errata (pages 9-11) at the end of this manual for sampler theory of operation.

There are two types of sample events. The first is time-based. In this type a time interval is defined and the

sampler places a sample in each bottle based on that time interval.

The second type of sample event is flow-based. In this type an external flowmeter provides one of two types

of signals: a contact closure when a specified amount of liquid has flowed past the measurement point; with

the analog option, an analog signal proportional to flow rate.

April 1999/Manning Environmental Inc.

Page A-15

Page 26

INSTALLATION AND OPERATION MODEL YB8

Whether the sample event is triggered by a flowmeter or by a time interval, the actual sampling cycle is the

same. For the multiple bottle option, the first action is the advance of the spout to the next bottle. (For single

bottle samplers, this step is omitted.) Next, the sampler turns on the peristaltic pump. The pump begins

rotating counter-clockwise causing air to be forced out of the intake tubing. This clears the intake hose of

any contents or obstructions that may inhibit proper sample collection. After the set amount of purge time

has elapsed, the unit will then reverse the pump so that the rollers are now moving in a clockwise direction.

This causes vacuum to be created in the tube, which causes the source liquid, to begin traveling up the intake

line. I f the unit was programmed to rinse, as the source liquid rises in the intake line it will reach the liquid

sensor. T he sampler will immediately recognize that fluid has reached the inlet to the pump. It will

instantaneously reverse the direction of the pump (rollers will be moving in a counter-clockwise rotation),

sending the water that had been drawn up back out of the intake line. This in effect rinses the line. If the unit

was not set for a rinse the above steps wil be ommited. U pon completion of the last rinse, source liquid will

again be drawn up the intake line. The system monitors the flow of liquid and when the preset amount has

passed through, the pump will reverse operation again (rollers moving counter-clockwise). T his purges

excess fluid out of the pump and clears the intake line. Depending on how the unit is programmed or

configured, after completing the post sample purge, the sampler will now stop operation or continue

performing those functions which it has been programmed. F or a complete description of programming the

sampler see the programming section in this manual.

If the multiple bottle option is being used, the distribution spout remains stationary until the next sample

event. This delay prevents cross-contamination of the next sample.

Sample Recovery

Immediate sample recovery is not required since the sampler will automatically shut down when the sample

container is full (single bottle only), a pre-set number of samples have been taken, or when the program is

complete. However, sample analysis may require quick recovery to maintain sample freshness or to add

chemicals.

If the intent is to leave the containers in the suspension plate, caps can be installed over the suspension

collars. Remove the suspension plate (with bottles) from the refrigerator. Lift the distribution assembly off

the suspension plate and place it on the wire racks mounted in the refrigerator.

It may be easier to remove the distribution assembly first, and then install the bottle caps. To seal the 350ml

glass bottles, replace cap liners, then place caps on bottles.

Page A-16

April 1999/Manning Environmental Inc.

Page 27

MODEL YB8 INSTALLATION AND OPERATION

External Connections

Refer to the errata (page 3) for more information on connecting to an external device.

DANGER: Turn the sampler off at the power switch and unplug the power supply before

making connections. Injury can result if the power is present when making

connections.

The following chart describes the external connections which are necessary to operate the sampler:

Contact In & Analog In Connections

Purpose Connector Designation Color Polarity

Contact In A Red No Polarity

Contact In B Black No Polarity

Analog In (+)

Analog In ( - )

Bottle Full/Stepper Motor

The Model YB8 can utilize both a Bottle Full Sensor and Stepper Motor (not at the same time).

Connections for the Bottle Full Sensor and the Stepper Motor are hardwired to the unit. If the unit was

purchased as a single bottle unit only, the wires for multiple bottle operation are not run. If multiple bottle

operation is desired, a conversion of the unit to multiple bot tle operation will need to be done at the factory.

To connect them follow the instructions listed below:

D White Positive

C Green Negative

A) Locate the cable comming out of the bulk head fitting on the left front of the electronics

enclosure. It runs down through the top of the refrigerator. For single bottle units, there are two

female contacts on the end. For multi-bottle units, there is a black connector.

April 1999/Manning Environmental Inc.

Page A-17

Page 28

INSTALLATION AND OPERATION MODEL YB8

B) Connect either the bottle full sensor or the stepper

motor to the cable.

NOTE: I f this connection is not made, neither the Bottle

Full Sensor nor the Stepper Motor will function.

Figure 25 - Electronics Enclo

sure

Contact Closure

This enables the sampler to accept a contact closure from, an external device. The parameter to be measured

is set, recorded, and totalized by the external device. When the set limit is met, a contact closure will be sent to

the sampler. T his in turn will initiate the sample collection process.

The sample comes standard wtih a 3 foot cable for connecting to external devices.

To connect the external device to the sampler follow the steps listed below:

A) Locate the connector on the left side of the electronics enclosure.

If the sampler has the Analog Option, it will be labeled Contact In/Analog In.

B) Wire the red and black wires to the external device's contact closure output.

C) Re-connect the cable to the connector on the enclosure.

This should complete the installation of the contact closure. Test the connection by

initiating a closure through the external device to verify the wiring is correct and the

sampler is initiating a sampling cycle when a closure is received.

Figure 27 - Contact

In/Analog In Cable

Analog Signal (Optional)

With this option, the sampler can accept an external 4-20mA signal from an external device. The flow

volume is internally totalized by the sampler*s controller. The analog option is not available as a field retrofit.

Contact the Manning Parts Department to discuss a factory modification. To connect the external device to

the sampler follow the steps listed below:

A) Locate the connector on the left side of electronics enclosure which is labeled "Contact/Analog In".

Page A-18

April 1999/Manning Environmental Inc.

Page 29

MODEL YB8 INSTALLATION AND OPERATION

B) Wire the white (+) and green (-) wires to the external device’s analog output.

C) Re-connect the cable to the "Contact/Analog In" connector.

This should complete the installation of the contact closure. Test the connection through the external device

to verify the wiring is correct and the sampler is initiating a sampling cycle when the signal is received. See

the *08 Mode in the Programming section for additional information.

This completes the installation of the sampler. The unit should now be operational. Proceed to the

programming instructions to program the sampler for operat ion.

April 1999/Manning Environmental Inc.

Page A-19

Page 30

Page 31

MODEL YB8 PROGRAMMING

Programming

Section Contents

Introduction ........................................................................................................................................... Page B-1

Sampler Configuration .......................................................................................................................... Page B-1

Sampling Modes ................................................................................................................................... Page B-1

Multi-Bottle Sampling Modes .................................................................................................. Page B-1

Single Bottle Modes .................................................................................................................. Page B-1

<RESET> .................................................................................................................................. Page B-2

<TEST CYCLE> ...................................................................................................................... Page B-2

<BOTTLE ADV> ..................................................................................................................... Page B-2

<CLEAR> ................................................................................................................................. Page B-2

<CLOCK> ................................................................................................................................ Page B-2

<DISPLAY> ............................................................................................................................. Page B-2

*................................................................................................................................................. Page B-2

EEEE ......................................................................................................................................... Page B-2

Key Not Active ......................................................................................................................... Page B-2

Display Information .............................................................................................................................. Page B-3

Time of Day .............................................................................................................................. Page B-3

Program Status .......................................................................................................................... Page B-3

Sampler Ready .............................................................................................................. Page B-3

Programming................................................................................................................. P age B-3

Active Program ............................................................................................................. Page B-3

Sampler Configuration Functions ......................................................................................................... Page B-4

*99 Sampler Set-Up .................................................................................................................. Page B-4

*20 Volume Calibration ............................................................................................................ Page B-7

*19 Pump Utilities .................................................................................................................... P age B-9

*91 Data Logging ................................................................................................................... P age B-11

ID Menu ...................................................................................................................... Page B-12

View Menu.................................................................................................................. Page B-12

Exit Menu.................................................................................................................... Page B-16

Download Menu.......................................................................................................... Page B-16

Clear Menu.................................................................................................................. Page B-18

*14 Clear Log Data ..................................................................................................... Page B-18

Analog Option Programming .............................................................................................................. Page B-19

Totalizing ................................................................................................................................ Page B-19

*08 Analog Display Routine ....................................................................................... Page B-20

Add-On Programming Functions ........................................................................................................ P age B-22

April 1999/Manning Environmental Inc.

Page 32

MODEL YB8 PROGRAMMING

Multiple Bottles per Sampling Event ...................................................................................... Page B-22

Multiple Samples per Bottle ................................................................................................... Page B-22

Delay Start - Time ................................................................................................................... Page B-24

*15 - Active Sampling ........................................................................................................Page B-24-A

General Programs................................................................................................................................ Page B-25

Time Mode - *START ............................................................................................................ P age B-25

Time Mode - Single Time Interval ......................................................................................... Page B-26

Flow Mode .............................................................................................................................. Page B-28

Flow Mode - Pulse Accumulation .......................................................................................... P age B-29

Multi-Bottle Sampling Programs ........................................................................................................ Page B-30

*01 Flow Mode - Independently Time Spout Advance .......................................................... Page B-30

*02 Flow Mode - Time Interval Override............................................................................... Page B-31

*03 Flow Mode - External Event ............................................................................................ Page B-32

*04 Time Mode - Multiple Intervals ....................................................................................... Page B-33