Mannhart FP300 Installation Manual

FP300 FOOD PROCESSOR

MODEL FP300 ML-104495

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

F-19157 Rev. C (August 2008)

Installation, Operation and Care of

MODEL FP300 FOOD PROCESSOR

SAVE THESE INSTRUCTIONS

GENERAL

The FP300 Food Processor is used for slicing, shredding, grating, Julienne cutting and dicing vegetables,

fruits, or cheese. The compact unit is designed for ease of operation and quick cleaning. A Work Table, a

Wall Rack, and a wide range of slicer, shredder, and dicing plates are available options.

INSTALLATION

UNPACKING

Immediately after unpacking the FP300, check for possible shipping damage. If the Food Processor is

found to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, test the electrical service to assure that it agrees with the specifi cations on the data

plate located at the rear.

Do not lift the unit with any hinged or extended parts; lift only with one hand under the protruding lip at the

rear near the base of the motor compartment and the other hand underneath the chute.

LOCATION

The FP300 should be operated on a suitable counter height surface. A pan (not provided), suitable for

kitchen use, can be used to capture the product at the exit chute.

ELECTRICAL CONNECTIONS

The electrical cord on this machine is equipped with a grounding- type plug which

must be connected to a properly grounded receptacle. If the receptacle is not the proper grounding

type, contact an electrician. Do not remove the grounding prong from the plug.

ELECTRICAL DATA

Model Volts Hertz Phase Amps

FP300 120 60 1 10

© HOBART, 2008

– 2 –

OPERATION

Rotating knives inside. Always use pusher plate. Keep hands out.

Proper assembly of the FP300 including selection of the appropriate cutters is necessary for correct

operation of the food processor (Figs. 1 & 2). Refer to the Cutting Tool Guide for sizes of cutters and refer

to the appropriate operation instructions.

CONTROLS

START (Green) — Push to start.

STOP (Red) — Push to stop.

Interlock switches prevent the machine from operating when the feed hopper is out of position or the

pusher plate is raised above the feed hopper. If these features do not function as described, contact your

local Hobart service offi ce.

During operation, when the pusher plate is fully raised above the feed hopper, the machine stops and allows

the pusher plate to be rotated counterclockwise for loading. To continue operation, rotate the pusher plate

clockwise until it is directly above the feed hopper; as the pusher plate begins to lower into the hopper,

the machine will restart — you do not need to push the green START switch unless STOP was pressed.

Always push the red STOP switch before changing cutters or cleaning.

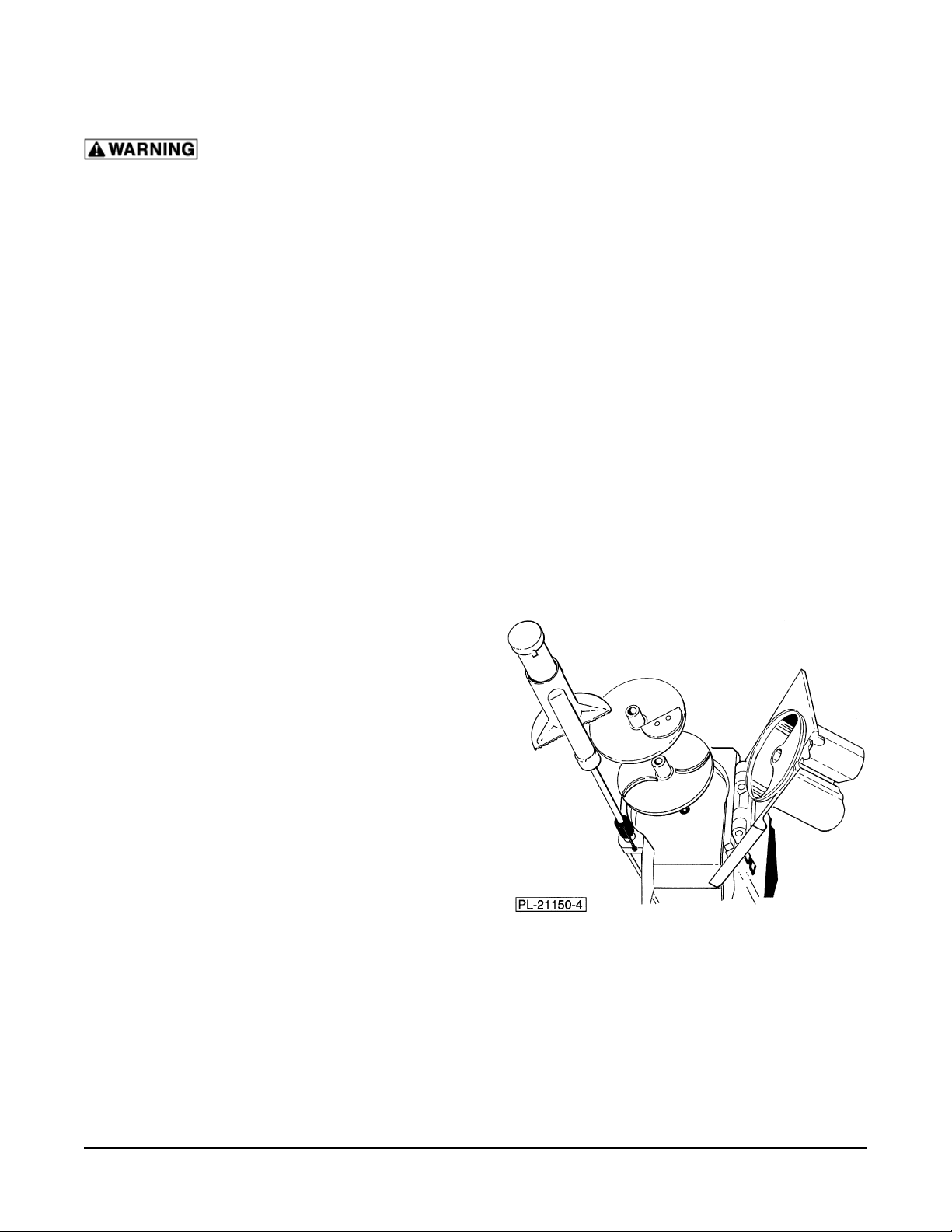

OPERATIONS WITH A SINGLE PLATE — (FIG. 1)

Slicing, Shredding, Grating, and Julienne Cutting

1. Raise the pusher plate using the pistol grip handle

and turn it to the left.

2. Release the feed hopper lock by turning the fi nger

paddle counterclockwise. Then raise the feed

hopper.

3. Lower the fl inger plate on the knife shaft until the

fl inger plate seats on the shaft pin.

4. Select the appropriate plate for the job. Place the

plate on the shaft, turning until engaged.

5. Lower the feed hopper.

NOTE: When the pusher plate is rotated and lowered,

the feed hopper will automatically be locked.

Fig. 1

– 3 –

Loading...

Loading...