Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

FP250

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Red OFF, Green ON Buttons

■ Compact Design

■ Angled Front

■ Planetary Drive

■ Large Full Size Feed Hopper

■ All Aluminum Hopper and Housing

■ Double Interlock Switch

■ Plate Speed 420 RPM

■ Decoring Screw

■ Hobart Ergo Loop Pusher Plate

■ Powerlink Lever

OPTIONS

❑ Maximum Security Correctional Package

FOOD PROCESSOR

MODEL

❑ FP250 Continuous Feed Full Hopper

Food Processor

Specications, Details and Dimensions on Inside and Back.

ACCESSORIES

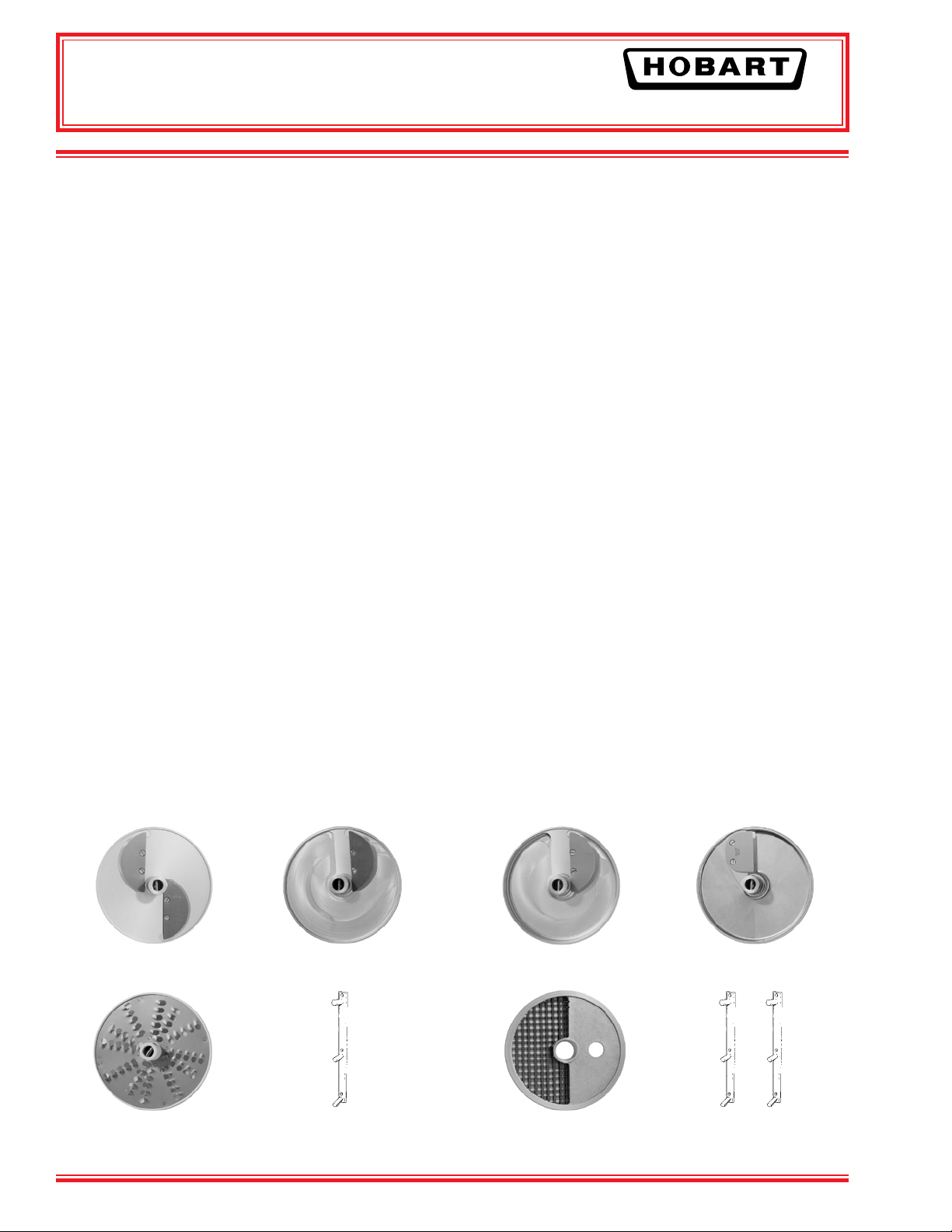

❑ 3-Pack Plates: 1⁄16, 5⁄32 slicer plates, 3⁄16 shredder

plate, 1 wall rack

❑ 6-Pack Plates: 1⁄16, 5⁄32, 3⁄8, 7⁄32 slicer plates,

3

⁄16 shredder plate and 3⁄8 dicer plate, 2 wall racks

❑ 3-Peg Wall Rack: designed to hold three plates

for additional plate storage

❑ Slicer Plates: 1⁄16, 3⁄32, 1⁄8, 5⁄32, 7⁄32, 3⁄8, 1⁄2, 5⁄8*;

3

⁄16 crimping plate

❑ Julienne Plates: 3⁄32, 3⁄16, 5⁄16

❑ Dicer Grids: 9⁄32, 3⁄8, 1⁄2, 5⁄8*, 3⁄4*; soft dice 5⁄16, 3⁄8, 1⁄2, 5⁄8

*NOTE: The 5⁄8 LOW (15Dice-5/8L) Dicer or

3

⁄4 (15Dice-3/4) Dicer grid should be used

with the 5⁄8 Slicer plate only.

❑ Shredder Plates: 1⁄16, 3⁄32, 1⁄8, 3⁄16, 5⁄16, 7⁄32, 3⁄8

❑ Grater Plate: Fine, Extra Fine

❑ Machine Table: Adjustable height table to hold

Food Processor

❑ Adjustable height stainless steel lug cart

❑ Stainless steel receiving pan

❑ Plastic receiving pan

FP250 FOOD PROCESSOR

F-40029 – FP250 Food Processor Page 1 of 4

Page 2

FP250

FOOD PROCESSOR

SOLUTIONS/BENEFITS

Red OFF, Green ON Button

Ease of use

■ Operator can readily recognize

Compact Design

Ease of use, small footprint, reduced labor,

increased sanitation and productivity

■ Occupies minimal counter space

■ Unit and receiving pan t on 23" deep counter

■ Plates remove in seconds

■ Feed hopper removes without tools for ease of

cleaning

■ Produces consistent quality product results in

seconds

■ Production capability for 17 lbs. per minute

Angled Front

Operator convenience, ease of use

■ 50° angle for ease of product loading

■ Helps to reduce operator fatigue

Planetary Drive

Performance, reliability

■ Helps to prevent stalling under heavy loads

■ No rest times required between loads

Large Full Size Feed Hopper

Flexibility, convenience, reduced labor

■ Supports processing capabilities for large

variety of products

■ Design permits continuous cutting of long

products

■ Eliminates precutting

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

All Aluminum Hopper and Housing

Durability, sanitation

■ Anodized nish resists harsh cleaners

■ Easy clean up

Double Interlock Switch

Protection

■ Prevents machine from running when pusher

plate swings away or is open

Plate Speed of 420 RPM

Product quality and consistency

■ Precise cutting and dicing action without

bruising or mashing of products

Decoring Screw

Quality, consistency

■ Deects products away from the plate hub for

complete processing

Ergo Loop

Flexibility, operator convenience

■ Operator can use either hand to push feeder

and load product

Powerlink

Leverage

■ Less downward pressure needed to process

dense products

6 PAK

3 PAK

1

⁄16" Slicing Plate

5

⁄32" Slicing Plate

3⁄16" Shredder Plate Wall Rack

Page 2 of 4 F-40029 – FP250 Food Processor

7

⁄32" Slicing Plate

3

⁄8" Dicing Plate (2) Wall Racks

3 Pack Plus

3

⁄8" HD Slicing Plate

Page 3

FP250

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

SPECIFICATIONS

DESIGN: Compact, conveniently designed at

50° angle for operator convenience. Small base

occupies minimal counter space. Carrying handle

on back of housing designed for ease of moving

unit. Housing constructed of anodized aluminum

with rubber feet on base to prevent movement or

skidding. Feed hopper cover is burnished aluminum.

Cylindrical feed hopper, pusher and deector plate of

acetal thermoplastic.

ELECTRICAL: 120/60/1, 3 Conductor power cord

(18 AWG) is 6 feet in length.

MOTOR: 8 amps. Planetary gear driven operating at

420 rpm output. 3⁄4 H.P. with overload protection.

SWITCHES: Easy to operate (red) OFF and (green)

ON switch. Pusher plate and feed hopper interlocks.

FOOD PROCESSOR

STANDARD EQUIPMENT: Basic unit with deector

plate, decoring screw and cleaning brush.

WARRANTY: Unit has full one-year warranty on

parts, labor and mileage against manufacturer’s

defects. Service contracts are available.

CUTTING TOOLS: Slicer, julienne and dicer plates

feature cast aluminum plates with cutlery-grade

stainless steel knives. Shredder and grater plates

feature stainless steel cutting plates with acetal

thermoplastic support hubs. Cutting plates are

protected from food acids and warewashing

chemicals by diwash™.

WEIGHT: Net - 45 lbs. Approximate Shipping -

51 lbs.

Bulk Feeding

PRODUCT LOADING

Directional for

Denitive Cuts

Tube Feeding for

Long Products

F-40029 – FP250 Food Processor Page 3 of 4

Page 4

FP250

FOOD PROCESSOR

DETAILS AND DIMENSIONS

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Hopper Diameter 63⁄8"

Max. Slice Size 3"

Usable Depth 7"

Feed Tube Dia. 25⁄16"

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

Page 4 of 4 F-40029 – FP250 Food Processor

F-40029 (REV. 03/10) LITHO IN U.S.A. (H-01)

Loading...

Loading...