Mannesmann Rexroth Indramat ECODRIVE DKC01.1, Indramat ECODRIVE DKC11.1 Project Planning Manual

Page 1

engineering

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

mannesmann

Rexroth

ECODRIVE

DKC01.1/DKC11.1 Drive Controllers

Project Planning Manual

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

270950

Indramat

Page 2

About this documentation ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Title

Type of document

Document code

Internal file reference

Editing sequence

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Project Planning

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

•

209-0069-4390-03

Document identification of

Date Remark

previous editions

209-0069-4390-00 EN/05.96

209-0069-4390-01 EN/06.96

DOK-ECODRV-DKC01/11.1*-PRJ1-EN-P

DOK-ECODRV-DKC01/11.1*-PRJ1-EN-P

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

May 96

June 96

July 96

May 97

Feb. 98

First edition

Revision

2nd edition

2nd Revision

new edition

Copyright

INDRAMAT GmbH, 1996

The reproduction and transm ission of this document, the use and c ommunication of its content to thir d parties without the expr essed c onsent of

INDRAMAT GmbH are forbidden. Violators are liable for the payment of

damages. All rights are reserved in the event a patent is gr anted or a utility model is registered (DIN 34-1).

Publisher

INDRAMAT GmbH • Bgm.-Dr.-Nebel-Str. 2 • D-97816 Lohr a. Main

Telephone +49 (09352) 40-0 • Telex 689421 • Fax +49 (09352) 40-4885

Dept. ENA (VS, HE)

Validity

The contents of this documentation and the availability of the product are

subject to change.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 3

ECODRIVE DKC01.1/DKC11.1 Drive Controllers About this documentation

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

What is this

documentation for?

Supplementary documentation

It supplies information on:

•

planning the mechanical control cabinet

•

planning the electrical system in the control cabinet

•

logistic handling of the equipment

•

preparing the resources for start-up

"ECODRIVE DKC Servo Drives with MKD"

- Selection Lists DOK-ECODRV-DKC+MKD****-AUS1-EN-P

for selecting the motor controller combination.

"MKD Digital AC Motors"

- Project Planning Manual DOK-MOTOR*-MKD********-PRJ2-EN-P

for a detailed description of the ser vomotors and for the selec tion of the

required cable.

"ECODRIVE DKC01.1/DKC11.1 Drive Controllers"

- Description of Functions DOK-ECODRV-DKC01/11.1-FKB1-EN-P

for testing and selecting the functions.

"EMC in Drive and Control Systems"

- Project Planning 209-0049-4305-02 EN/04.96

for the EMC-compliant planning and installation of the drive system ( EMC

= Electromagnetic Compatibility).

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 4

About this documentation ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Notes

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 5

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Table of contents I

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Table of contents

1 Introduction to the system 1-1

1.1 Application features..............................................................................................................................1-1

1.2 Overview of the functions.....................................................................................................................1-1

2 Safety instructions for electrical drives 2-1

2.1 General ................................................................................................................................................ 2-1

2.2 Protection against contact with electrical parts....................................................................................2-2

2.3 Protection agains t shock s caused by safety extra-low voltage (SELV)......................................... 2-3

2.4 Protection against dangerous movements........................................................................................... 2-4

2.5 Protection against magnetic and electromagnetic fields during operation and assembly ................... 2-6

2.6 Protection during handling and assembly............................................................................................2-7

2.7 Safe battery usage............................................................................................................................... 2-7

3 Selecting the components 3-1

3.1 Overview of the required components.................................................................................................3-1

3.2 Selection procedure.............................................................................................................................3-2

3.3 Compiling the required data................................................................................................................. 3-3

4 ECODRIVE DKC drive controllers 4-1

4.1 Hardware..............................................................................................................................................4-1

View of unit....................................................................................................................................4-1

Dimensional sheets and installation dimensions...........................................................................4-2

Technical data............................................................................................................................... 4-4

Type code and rating plate............................................................................................................ 4-7

4.2 Firmware..............................................................................................................................................4-8

4.3 An overview of the electrical connections............................................................................................4-9

Front view with supply terminals................................................................................................... 4-9

Overall connection diagrams....................................................................................................... 4-10

4.4 Electrical connection to the supply terminal strips.............................................................................4-14

Serial interface X1....................................................................................................................... 4-14

X2 positioning or stepper interface.............................................................................................. 4-18

X3 analog inputs and outputs...................................................................................................... 4-25

X4 terminals for the control circuit............................................................................................... 4-29

X5, X6, X7 motor connections ....................................................................................................4-30

X9 DC bus connection ................................................................................................................4-30

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 6

II Table of contents ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

5 BZM auxiliary bleeder module 5-1

5.1 Dimensioning the components relevant for regeneration ....................................................................5-1

5.2 Dimensional data and installation dimensions.....................................................................................5-5

5.3 Technical data......................................................................................................................................5-6

5.4 Front view.............................................................................................................................................5-6

5.5 Electrical connections.......................................................................................................................... 5-7

5.6 Type code and rating plate...................................................................................................................5-7

6 CZM Auxiliary Capacitance Module 6-1

6.1 Dimensioning ....................................................................................................................................... 6-1

6.2 Dimensional data and installation dimensions.....................................................................................6-3

6.3 Front view.............................................................................................................................................6-4

6.4 Electrical connection............................................................................................................................6-4

6.5 Type code and rating plate...................................................................................................................6-5

7 DC24V NTM power supplies 7-1

7.1 Application recommendations.............................................................................................................. 7-1

7.2 Technical data......................................................................................................................................7-1

7.3 Dimensional data and installation dimensions.....................................................................................7-2

7.4 Front views...........................................................................................................................................7-2

7.5 Electrical connection............................................................................................................................7-3

7.6 Type code ............................................................................................................................................ 7-4

8 NFD / NFE line filter 8-1

8.1 Selection .............................................................................................................................................. 8-1

8.2 Dimensional data and installation dimensions.....................................................................................8-2

8.3 Electrical connection............................................................................................................................8-3

8.4 Line filters for DC24V NTM power supplies.........................................................................................8-5

8.5 Type code ............................................................................................................................................ 8-5

9 DST / DLT transformers 9-1

9.1 Selection .............................................................................................................................................. 9-1

9.2 Autotransformers for DKC**.*-040-7-FW............................................................................................. 9-1

9.3 Autotransformers for DKC**.*-030-3-FW............................................................................................. 9-4

9.4 Electrical connection of the DKC via transformer ................................................................................9-6

9.5 Type code ............................................................................................................................................ 9-7

10 Planning the control cabinet 10-1

10.1 Notes on installing the control cabinet.............................................................................................10-1

Power dissipation........................................................................................................................10-1

10.2 Using heat-exchange units in the control cabinets ..........................................................................10-2

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 7

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Table of contents III

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

11 Power connection 11-1

11.1 Direct power connection...................................................................................................................11-1

11.2 Line contactor/fuse protector ...........................................................................................................11-2

Calculating the phase current at the power connection..............................................................11-2

Selecting fuse protector Q1 and line contactor K1...................................................................... 11-3

11.3 Control circuit to the power connection............................................................................................ 11-4

11.4 Protection against indirect contact...................................................................................................11-5

12 Preparing for Startup 12-1

Required equipment.................................................................................................................... 12-1

13 Condition of the drive components on delivery 13-1

Packaging ...................................................................................................................................13-1

Accompanying documents..........................................................................................................13-1

Identification of the components .................................................................................................13-1

14 Index 14-1

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 8

IV Table of contents ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Notes

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 9

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Introduction to the system 1-1

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

1 Introduction to the system

1.1 Application features

The drive system with the ECODRIVE drive controllers is the most c osteffective solution off ering the highest functionality for almost any field of

application in which translatory or rotary motions are to be automated.

Outstanding performanc e data, an ex tensive r ange of f unc tions as well as

an excellent price-to-performance ratio represent the salient features of

this drive system.

Product features in terms of the technical applications are:

•

universal implementation

•

lower total costs

•

digital drive concept

•

highly dynamic operation

•

cost-effective direct connection to the power connection

•

software travel limit switch

•

absolute or incremental position detection

•

absolute or incremental position output

•

integrated holding brake control

•

increased operating safety

•

adjustable error response

•

automatic parameter matching

•

easy startup operation

1.2 Overview of the functions

The functions of the digital, intelligent drive system are dif ferentiated primarily according to the interface of the higher -level control. The fields of

application for the ECODRIVE drive controllers vary accordingly.

The drive controller DKC01.1 is used as a:

•

servodrive with integrated position control

•

servodrive with analog speed interface and integrated actual position

detection

•

servodrive with stepper interface.

•

servodrive with electronic gearbox function

The drive controller DKC11.1 repr esents a partic ularly cost-eff ective solution. It is used as a:

• servodrive with analog speed interface and integrated actual position

detection

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 10

1-2 Introduction to the system ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

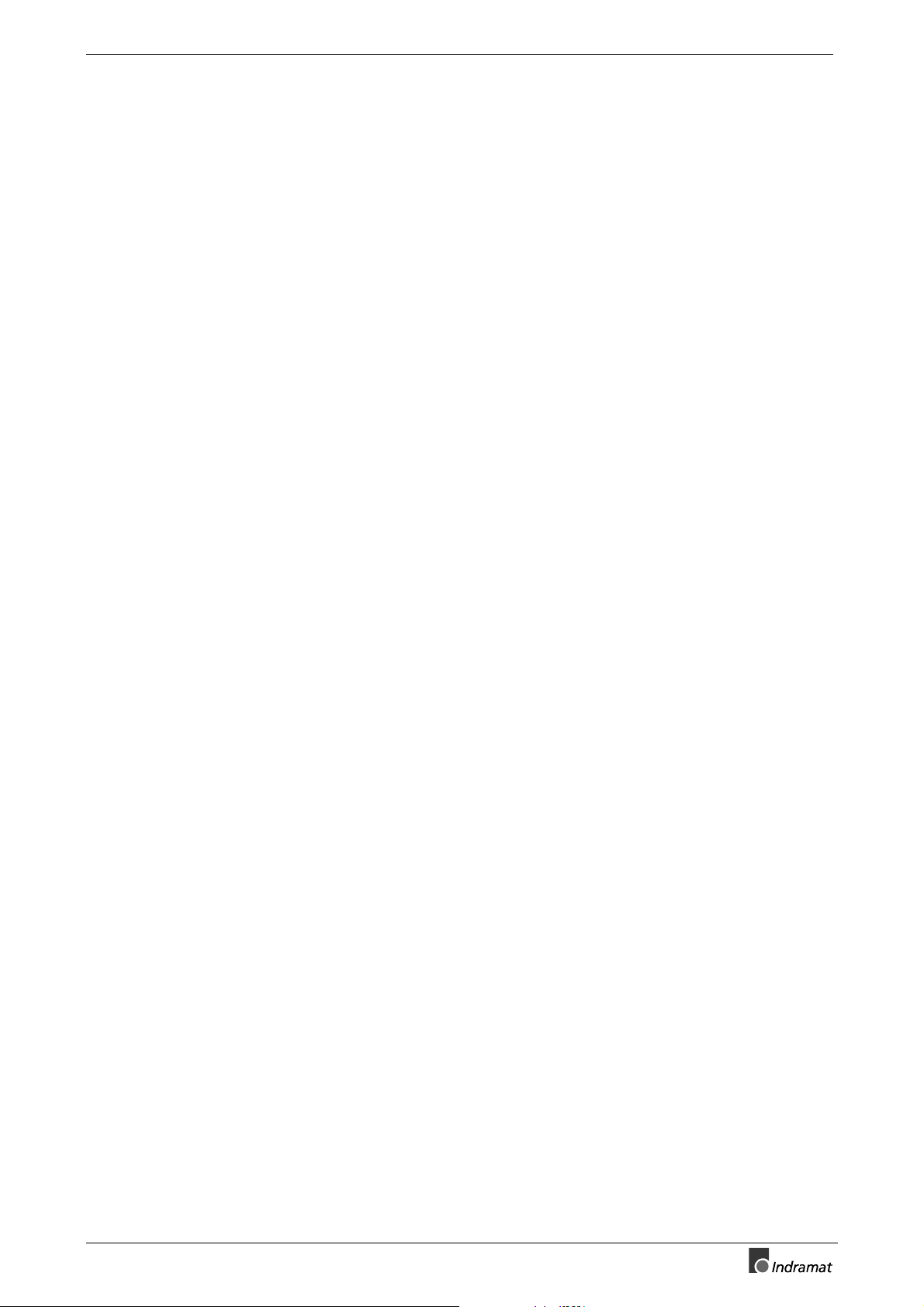

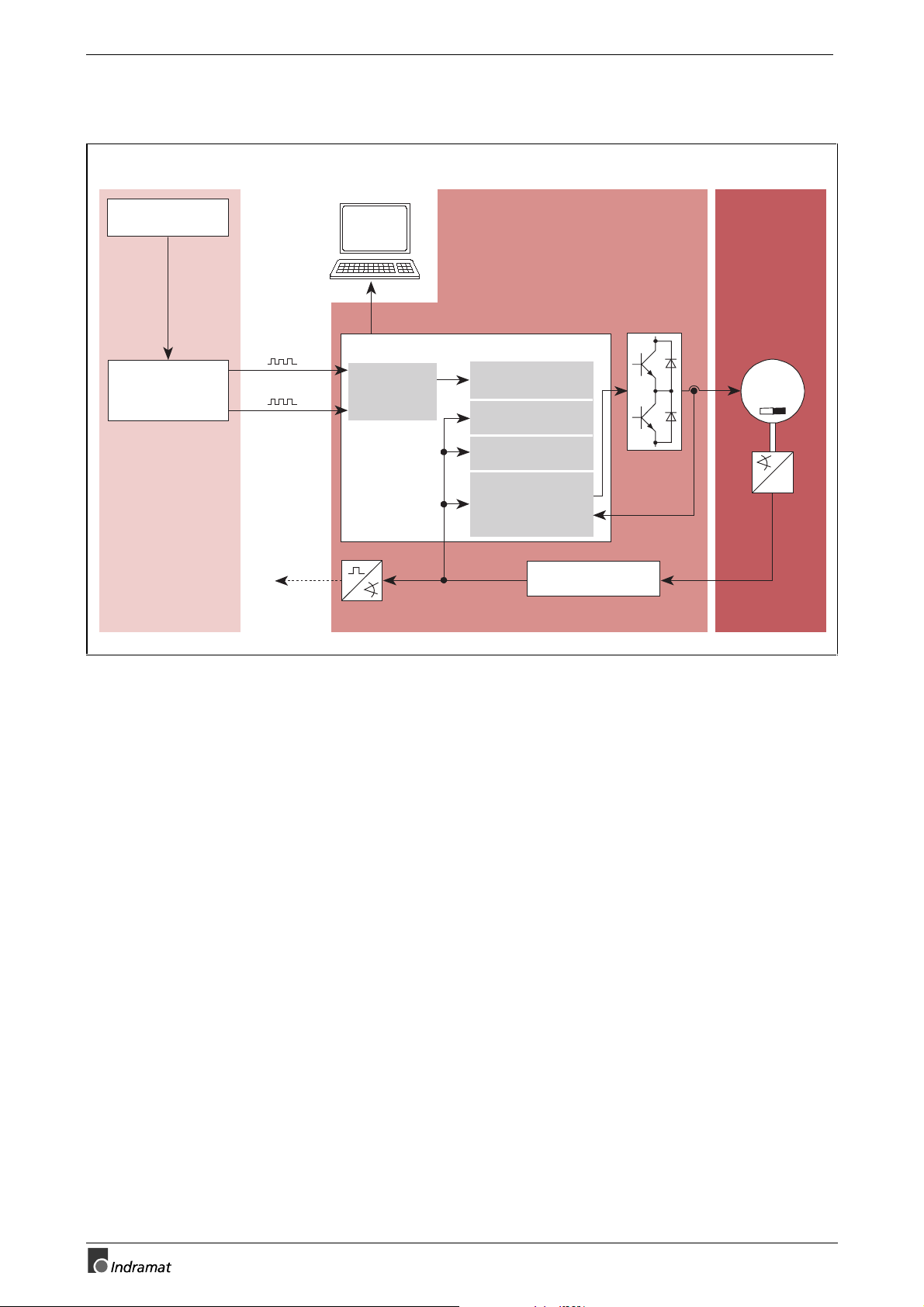

Servodrive with integrated position control

SPS-Control

I/O _ card

Selection

of the

positioning

records

Control inputs

Status outputs

Actual

position

value

MS-DOS - PC

Parameters

Diagnosis

Operating data

RS 232

RS 485

Stored

positioning

records

2° position 1

1

position 2

2

2

.

2

.

4

position 32

2

®

Drive processor

DKC01.1Drive controller

with POSITIONING-interface

Fine interpolation

Position control

Speed control

Field-orinted

stator current

control

High-resolution

positioning interface

AC-servo motor

MKD

M

~

3

~

~

FS0200.fh5

Fig. 1-1: Servodrive with integrated position control

•

Up to 32 positioning blocks can be stored in the drive controller and

selected over parallel inputs. The positioning block is executed

autonomously.

•

Mechanical translatory elements such as gear ratios or f eed constants

are adapted in the drive.

•

All position, speed, and acceleration data can be weighted independently of the axis kinematics.

•

A drive-internal referencing pr ocedure is available for cr eating a reference dimension.

•

The axis can be moved with the jog function during setup operation.

•

The positioning speed can be influenced via the feedrate override.

•

Travel limit switch inputs and axis limit values which can be parameterized are available for limiting the travel range.

• The drive status can be detected via status outputs.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 11

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Introduction to the system 1-3

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

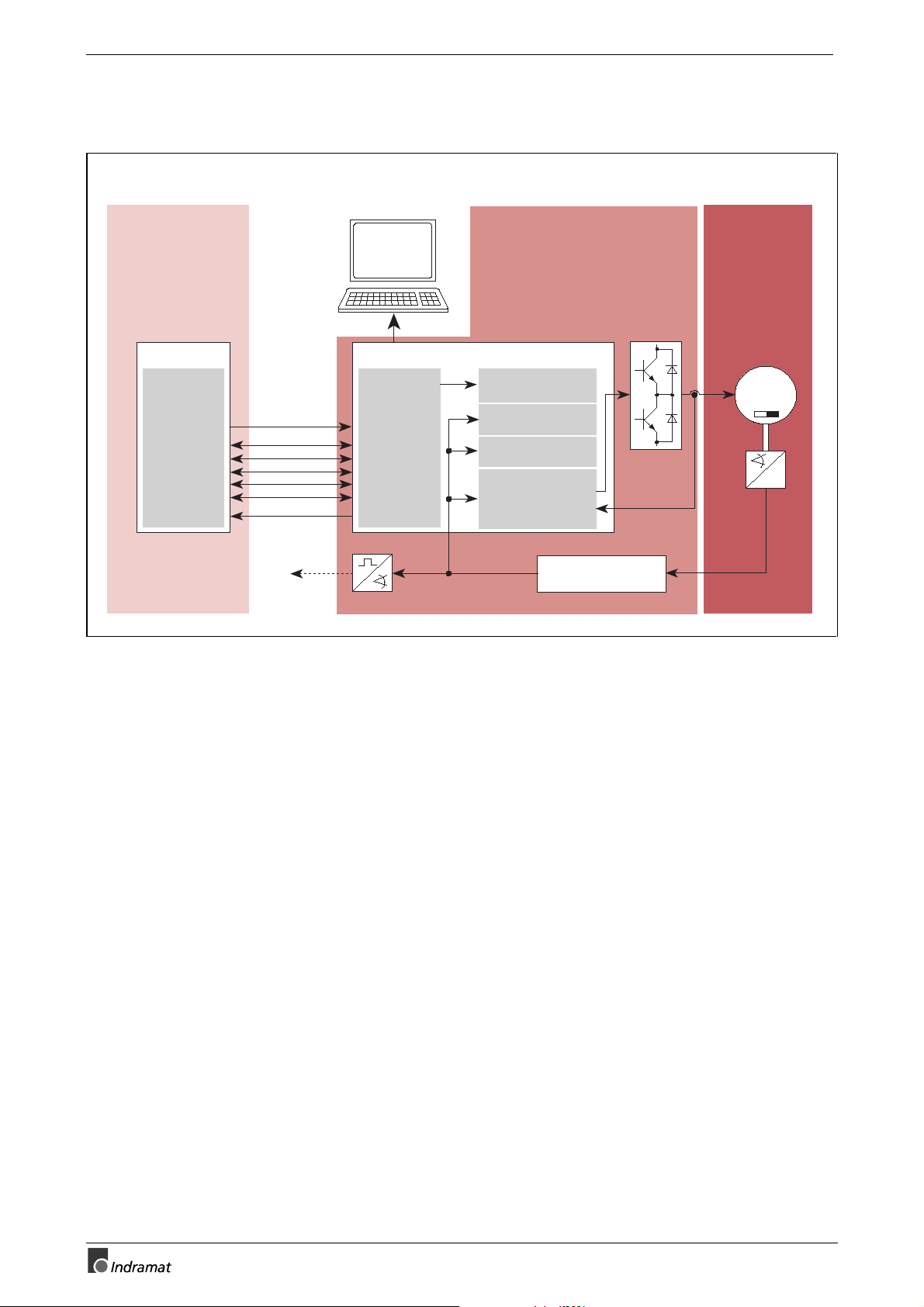

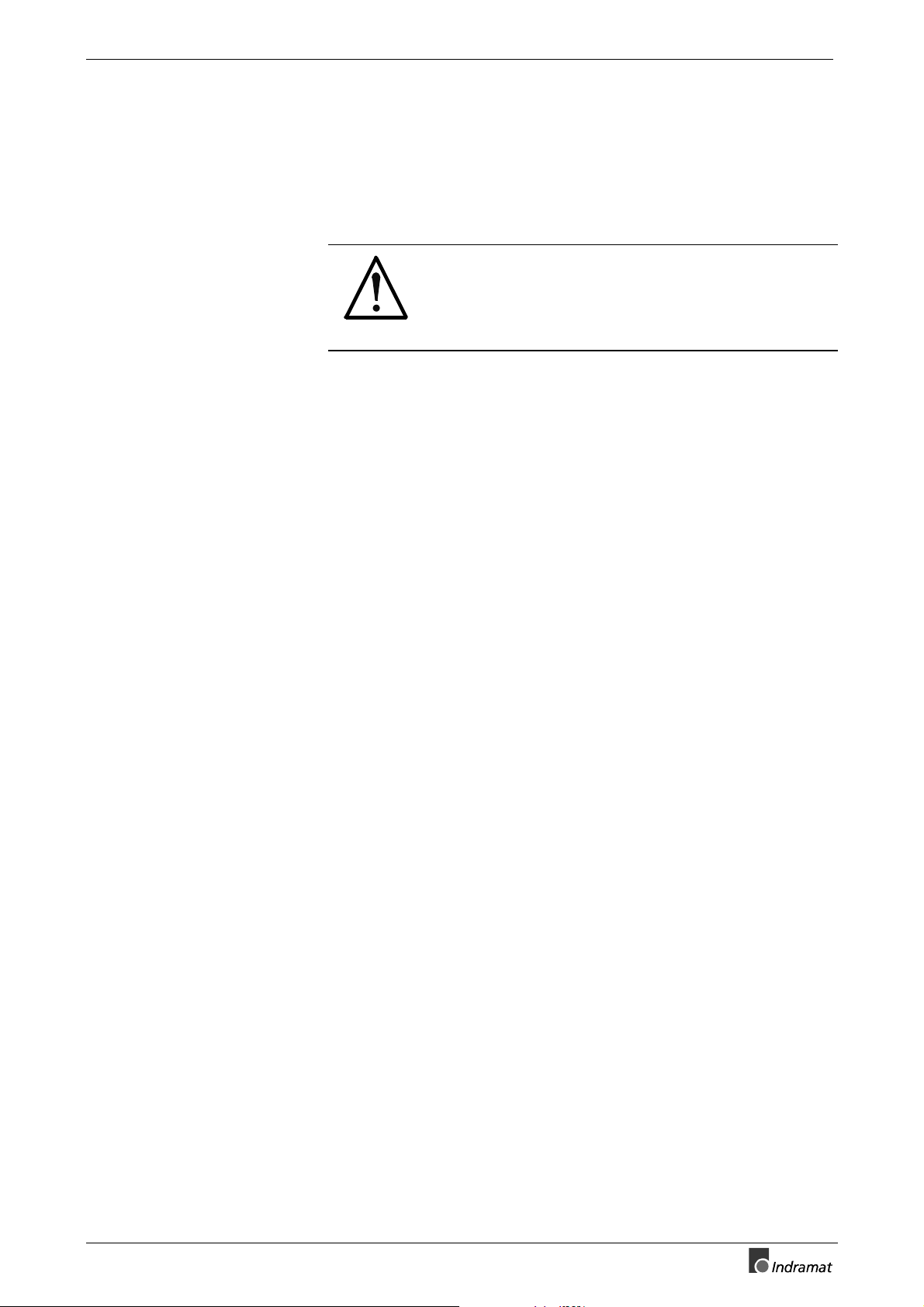

Servodrive with analog speed interface and integrated actual

position detection

Control unit

with position control

Parameters

Diagnosis

Operating data

Position

command

value

+W

-X

Positioning

interface

AC servo motor

MKD

MS-DOS - PC

Parameters

Diagnosis

Operating data

RS 232

DKC01.1 or DKC11.1 drive

controller with ANALOG interface

®

RS 485

Drive processor

M

3

Speed

command

value

K

v

DA

analog

A

D

± 10V

Speed control

Field-oriented

stator current

control

Actual

position

High-resolution

positioning interface

value

~

~

~

Linear scale

FS0201.fh5

Fig. 1-2: Servodrive with analog speed interface and integrated actual position

detection

•

The analog speed command value can be set to any value.

•

The actual position value is output either incrementally or absolutely.

•

Using a switching input, the drive can be shut down independent of the

command value and stopped free of drift during active control.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 12

1-4 Introduction to the system ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

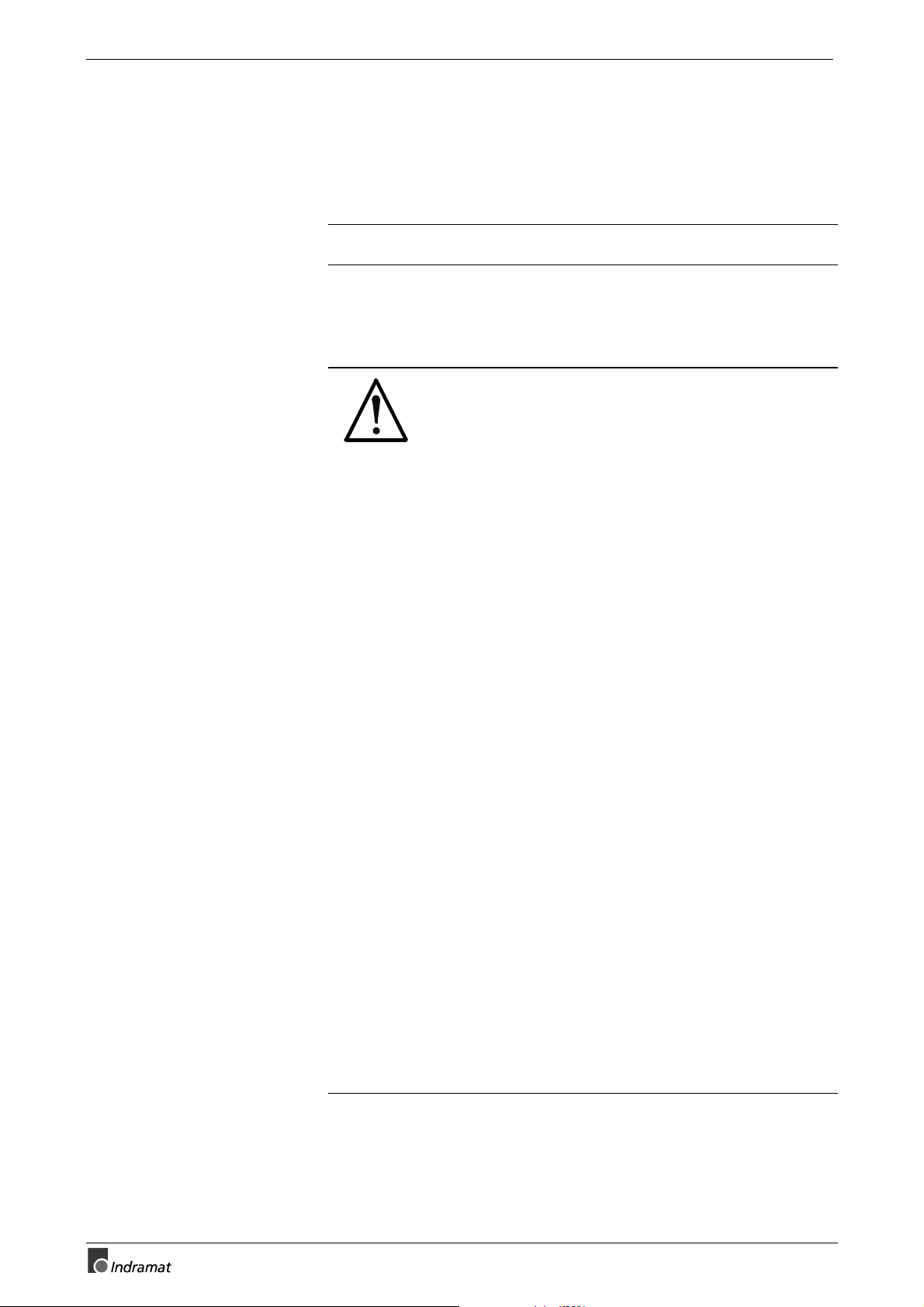

Servodrive with stepper interface

Control unit

with step pulse generation

Interpolation

Step pulse

generation

forwards

backwards

Actual

position

value

MS-DOS - PC

Parameters

Diagnosis

Operating data

RS 232

®

RS 485

Stepper

interface

DKC01.1 drive controller

with STEPPER interface

Drive processor

Fine interpolation

Position control

Speed control

Field-oriented

stator current

control

High-resolution

position interface

AC servo motor

MKD

M

3

~

~

~

FS0202.fh5

Fig. 1-3: Servodrive with stepper interface

•

The number of steps per rotor rotation can be set to any value between 16 and 65536.

•

The maximum step frequency is independent of the load. It is technically impossible to "skip" steps due to the position controlled operation.

•

The stepper interface can be set to three standard signal definitions for

exchanging signals between the control and the drive controller.

- quadrature signals

- forwards/backwards signals

- step and direction signal

•

A drive-internal referencing pr ocedure is available for cr eating a reference dimension.

•

The axis can be moved with the jog function during setup operation.

•

The referencing and jog speed can be influenced via the feedrate

override.

• Travel limit switch inputs and axis limit values which can be parameterized are available for limiting the travel range.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 13

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Introduction to the system 1-5

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

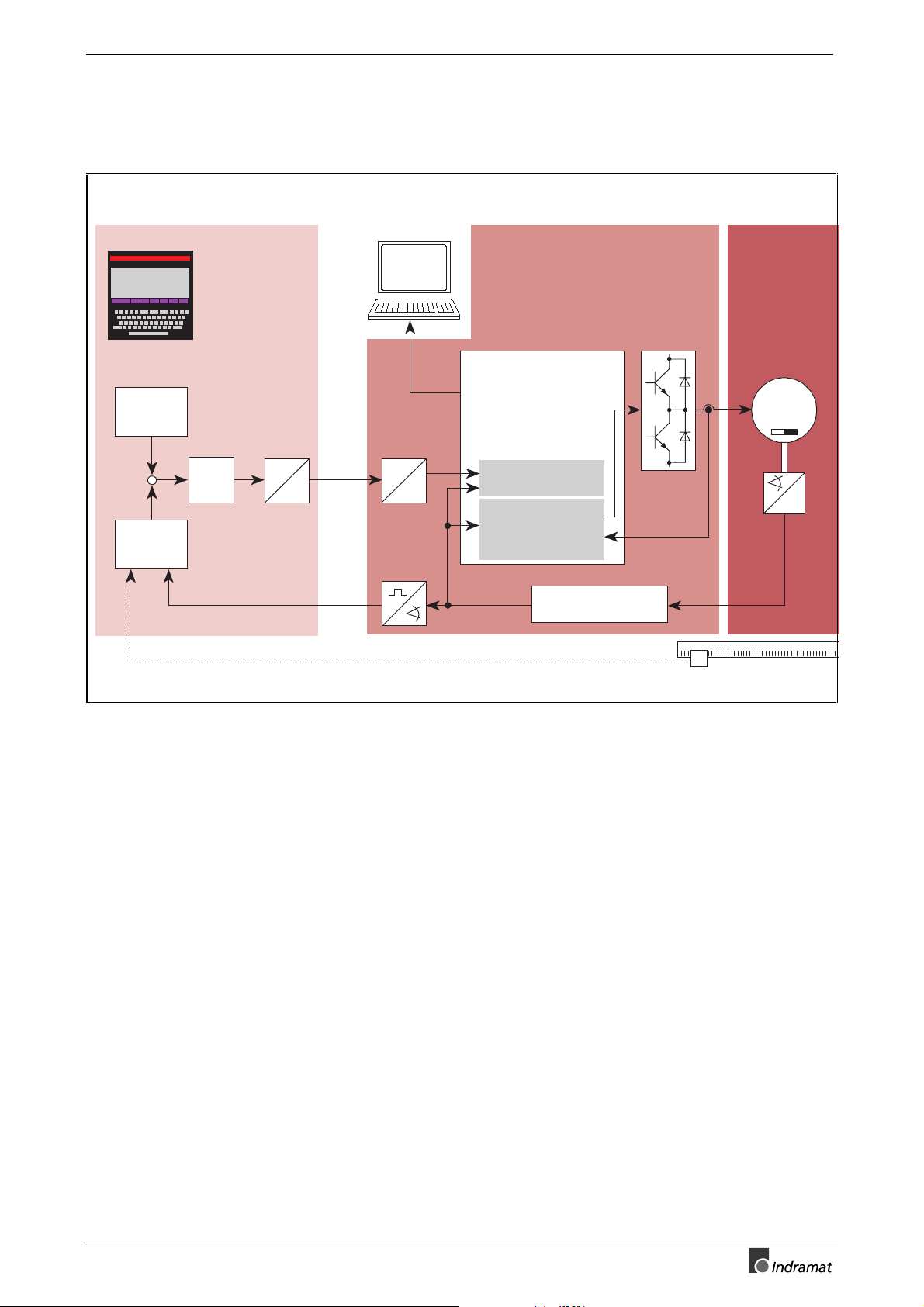

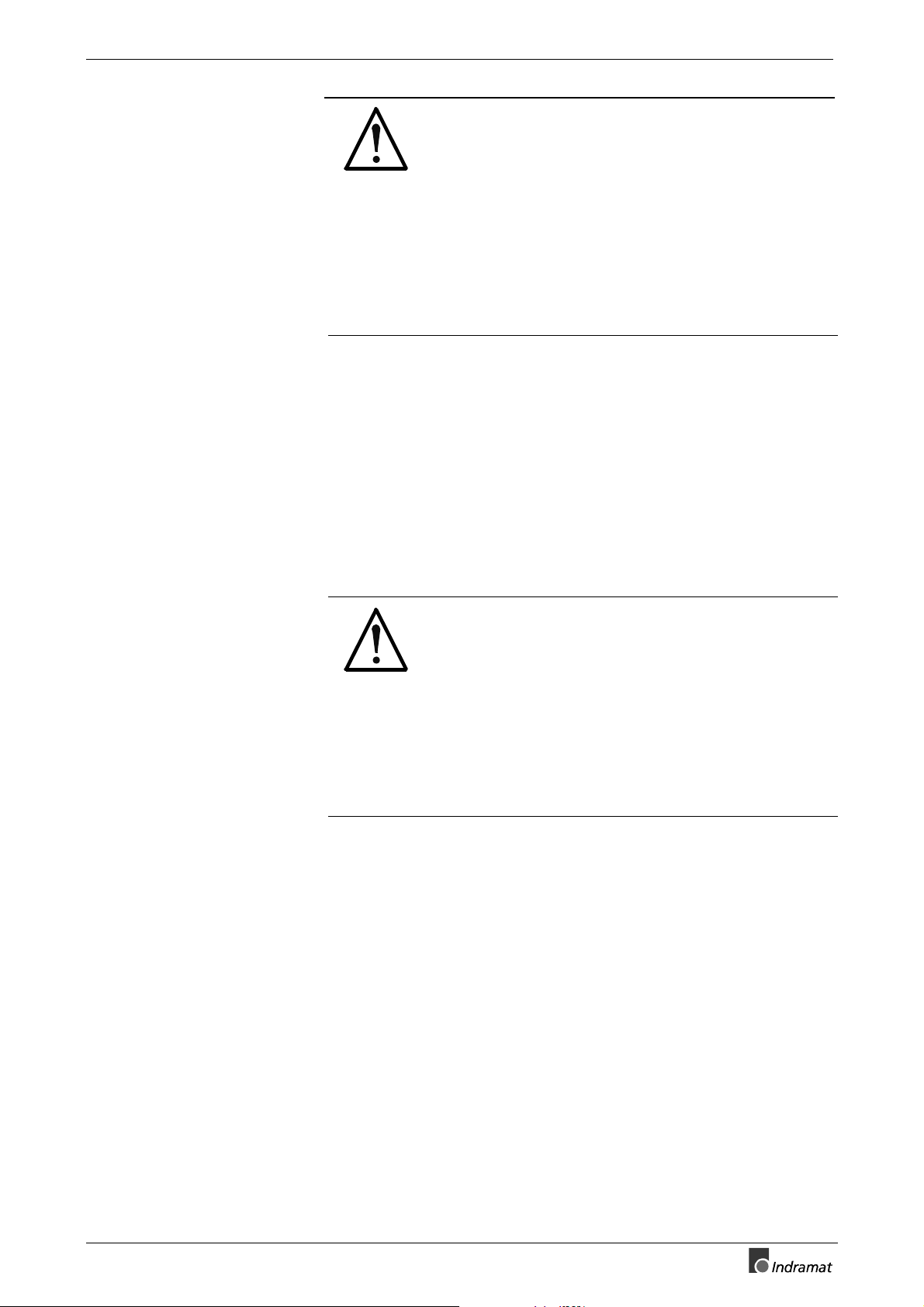

Servodrive with electronic gearbox function

Lead axis

transmitter

Lead axis

position

MS-DOS - PC

Parameters

Diagnosis

Operating data

RS 232

Step motor

interface

®

RS 485

Servodrive DKC01.1

with electronic gearbox function

Drive processor

electronic gearbox

Position control

Speed control

Field-oriented

stator current

control

High-resolution

position interface

AC-Servomotor

MKD

M

3~

~

~

FS0203.fh5

Fig. 1-4: Servodrive with electronic gearbox function

•

Operating modes

Speed synchronization

Angle synchronization

•

The lead axis position is given in degrees (360 degrees repres ent one

lead axis encoder revolution)

•

The lead axis encoder must be connected to the DKC stepper interface.

The maximum allowable signal frequency f

limits the number of lines Z

which can be emulated.

l

on the stepper interface

max

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 14

1-6 Introduction to the system ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Notes

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 15

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Safety instructions for electrical drives 2-1

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

2 Safety instructions for electrical drives

Please read the following instructions carefully before initial startup.

These safety instructions must be observed at all times.

If the product is transferred to a third-party, the safety instructions must be

included.

Improper use of this equipment and non-compliance

with the safety instructions provided can result in

damage, personal injury or, in extreme cases, death.

WARNING

2.1 General

INDRAMAT GmbH is not liable for any damages resulting from failure

to observe the safety instructions in this document.

•

Documentation in the relevant national language should be obtained

before initial startup if the language in this doc umentation is not perfectly understood.

•

Proper transport, correct s torage, ass em bly, and installation as well as

care in operation and maintenance are prer equisites for optimum and

safe operation of this equipment.

•

Qualified personnel:

Only qualified personnel should be permitted to operate this equipment

or work in its imm ediate vicinity. Personnel is considered qualified if it

has sufficient knowledge of the ass embly, installation, and operation of

the product as well as all warnings and precautionar y meas ures in this

documentation.

Furthermore, personnel should be trained, instructed or author ized to

switch electrical circuits on and off and to ground and m ark them in

accordance with the requirements of safety engineering. Personnel

should possess adequate safety equipment and be trained in first aid.

•

Use only replacement parts approved by the manufacturer.

•

All safety regulations and requirements for the specific application

must be followed.

•

The equipment is designed to be ins talled in mac hines for com merc ial

use.

•

Startup is only permitted once it is sure that the machine in which the

products are installed com plies with the requirements of the national

safety regulations and safety specifications of the application.

European countries: EC Directive 89/392/EEC (Machine Guideline)

• Operation is only permitted if the national EMC regulations f or the s pecific application have been met. European countries: EC Directive

89/336/EEC (EMC Guideline)

The instructions for installation in accordanc e with EMC requirements

can be found in the document "EMC Drive and Control Systems."

The responsibility for adherence to the lim iting values required by national regulations lies with the manufacturer of the equipm ent or machine.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 16

2-2 Safety instructions for electrical drives ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

•

Technical specif ications as well as the connection and installation re quirements can be found in the produc t documentation and must be

observed under all circumstances.

2.2 Protection against contact with electrical parts

Note: Only relevant for devices and drive components with voltages ex-

ceeding 50 volts.

Coming into contact with components carrying voltages greater than 50

volts can be dangerous. Certain parts are under dangerous voltage when

operating electrical devices.

High Voltage!

Danger to life or risk of bodily injury!

⇒

Follow general construction and safety regulations

DANGER

when working on electrical installations.

⇒

Before switching on power, be sure that the ground

wire is permanently connected to all electrical units

according to the connection diagram.

⇒

At no time may electrical equipment be operated if the

ground wire is not permanently connected to the

proper terminals, even for brief measurements or

tests.

⇒

Disconnect the equipment from the power supply line

or the voltage source before beginning work. Secure

equipment from reclosure.

⇒

Wait 5 m inutes after switching off power to allow capacitors to discharge before using the equipment.

Measure the voltage of the capacitors before beginning work in order to eliminate dangers arising from

touching components.

⇒

Never touch the electrical connection points of a com ponent while the power is turned on.

⇒

Cover live parts properly before switching the equipment on so they cannot be touched. Covers provided

with the equipment must be installed bef ore operating

the equipment to prevent contact with live parts . The

equipment may only be operated with the covers designed for shock-hazard protection.

⇒

A GFCI protective device (ground fault circuit interrupter) cannot be used for AC drives! Protection

against indirect contact must be ensured by other

means, for exam ple, by using an overcurrent protection device in accordance with relevant standards.

European countries: in accordance with EN

50178/1994, section 5.3.2.3

⇒ For installation equipment protection against indirect

contact must be ensured using an external housing,

such as a control cabinet. European countries : in accordance with EN 50178/1994, section 5.3.2.3

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 17

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Safety instructions for electrical drives 2-3

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

High discharge current!

Danger to life or risk of bodily injury!

⇒

All units and the motors m ust first be connected to a

WARNING

grounding point with the ground wire or must be

grounded themselves before switching on power.

⇒

The discharge current is greater than 3.5 mA. A permanent connection to the power supply line is therefore required for all units. European countries (EN

50178/1994, section 5.3.2.3)

⇒

Before startup operation always connect the protective conductor or the ground conductor. Otherwise the

housing may harbor high voltages.

2.3 Protection against shocks caused by safety extra-low voltage (SELV)

All connectors and terminals on INDRAMAT products with voltages from

5 to 50 volts are safety extra-low voltages offering a shock proof design to

meet the following standards:

•

international: IEC 364-4-411.1.5

•

European countries in the EC: EN 50178/1994, section 5.2.8.1

WARNING

High electrical voltages due to incorrect connections!

Danger to life or risk of bodily injury!

⇒

Only equipment and lines carrying protective extra low

voltage (PELV) may be connected to connectors and

terminals with voltages ranging from 0 to 50 volts.

⇒

Connect only voltages and circuits safely isolated from

dangerous voltages. Isolation can be achieved, for

example, by using safe isolation transformers, optocouplers or power supply independent battery operation.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 18

2-4 Safety instructions for electrical drives ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

2.4 Protection against dangerous movements

Dangerous movements can be caused if the connected motors are not

controlled correctly.

There are various causes of dangerous movements:

•

faulty wiring or cable connections

•

operating the components improperly

•

defective measured value transmitters and primary detectors

•

defective components

•

errors in the software

These errors can occur just after the equipm ent has been switched on or

after an indefinite period of time.

The monitors in the dr ive components virtually exclude failur e in the connected drives. However, personnel safety requires that additional measures be taken to ensure corr ect operation. Faulty drive motions which are

influenced by the type of control and the operating status cannot be entirely excluded until the installed monitors take effect.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 19

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Safety instructions for electrical drives 2-5

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Dangerous movements!

Danger may result in equipment damage, personal injury

or death!

⇒

DANGER

Personal safety must be ensured by higher-level,

monitoring at the installation or precautionary measures for the reasons listed above. T hese are provided

by the plant manufacturer according to the specific

conditions of the plant based on a danger and malfunction analysis. The safety regulations in effect for

the plant are included herein.

Avoiding accidents:

⇒

Stay away from the machine’s movem ent area. Possible measures to be taken to prevent access by unauthorized persons:

- protective fence

- protective railing

- protective covering

- light barrier

⇒

Fences and coverings should be strong enough to

withstand the maximum possible momentum.

⇒

Mount the emergency stop switch (E-stop) at an easily

accessible place in the imm ediate vicinity. Verify that

the E-stop switch works before starting operation.

⇒

Isolate the drive power connection by means of an Estop circuit or use a starting lock-out to prevent unintentional startup.

⇒

Make sure that the drives have been shut down before accessing or entering the danger zone.

⇒

Disable electrical power to the equipment using a

master switch and secure against reclosure during:

- maintenance and repair work

- equipment cleaning

- long downtime periods

⇒

Avoid operating high-frequency, remote control, and

radio equipment near electrical equipment and their

supply leads. If the use of such equipment cannot be

avoided, verify that the system and plant are in perfect

working order in all working situations before initial

operation. If necessary, the plant must undergo special EMC testing.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 20

2-6 Safety instructions for electrical drives ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

2.5 Protection against magnetic and electromagnetic fields during operation and assembly

Magnetic and electromagnetic f ields near cur rent- c arr ying conductors and

permanent magnets pos e a serious health hazard for persons with pacemakers, metal implants and hearing aids.

Health hazard for persons with pacemakers, metal

implants and hearing aids in the immediate vicinity

of electrical equipment.

⇒

WARNING

Persons with pacemakers and metal implants must

not be permitted access to the following areas:

−

Areas in which electrical equipm ent and parts are

mounted, operated or put into operation.

−

Areas in which motor parts with permanent magnets are stored, repaired or mounted.

⇒

If it becomes necessary for a person with a pacemaker to enter suc h an area, this must be approved

by a physician beforehand.

Implanted pacemak ers or those to be im planted have

a varying degrees of resistance to interference, making it impossible to establish any general guidelines.

⇒

Persons with metal implants or m etal splitters as well

as hearing aids should consult a physician before entering such areas since they represent a health hazard.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 21

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Safety instructions for electrical drives 2-7

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

2.6 Protection during handling and assembly

Handling or assembling drive components improperly may lead to personal injury.

Risk of injury due to improper handling!

Bodily injury may be caused by crushing, shearing, cutting, and pounding forces.

⇒

CAUTION

Observe general construction and safety regulations

when working on electrical installations.

⇒

Use suitable assembly and transport equipment.

⇒

Take precautions to prevent pinching and crushing.

⇒

Use only suitable tools. Use special tools as prescribed.

⇒

Employ lifting devices and tools according to the

manufacturers’ instructions.

⇒

If necessary, use suitable protective equipment (for

example goggles, safety shoes, protective gloves).

⇒

Do not stand under suspended loads.

⇒

Remove any leaking liquids on the floor immediately

to prevent slipping.

2.7 Safe battery usage

Batteries consist of reactive chemicals contained in a solid case. Improper use can therefore lead to injuries or equipment damage.

CAUTION

Note: Environmental protection and disposal! The batteries con-

Risk of injury due to improper handling!

⇒

Do not attempt to reactivate em pty batteries by heating them or by any other means (danger of explosion

or corrosion).

⇒

Do not recharge batteries because they may leak or

explode.

⇒

Do not dispose of batteries by throwing them into a

fire.

⇒

Do not attempt to disassemble batteries.

⇒

Do not damage the electrical com ponents installed in

the equipment.

tained in the product are considered hazardous material for

land, sea, and air transport according to the legal regulations

(danger of explosion). Dispose used batteries separately from

other waste. Observe the national regulations in the country of

installation.

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 22

2-8 Safety instructions for electrical drives ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Notes

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 23

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Selecting the components 3-1

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

3 Selecting the components

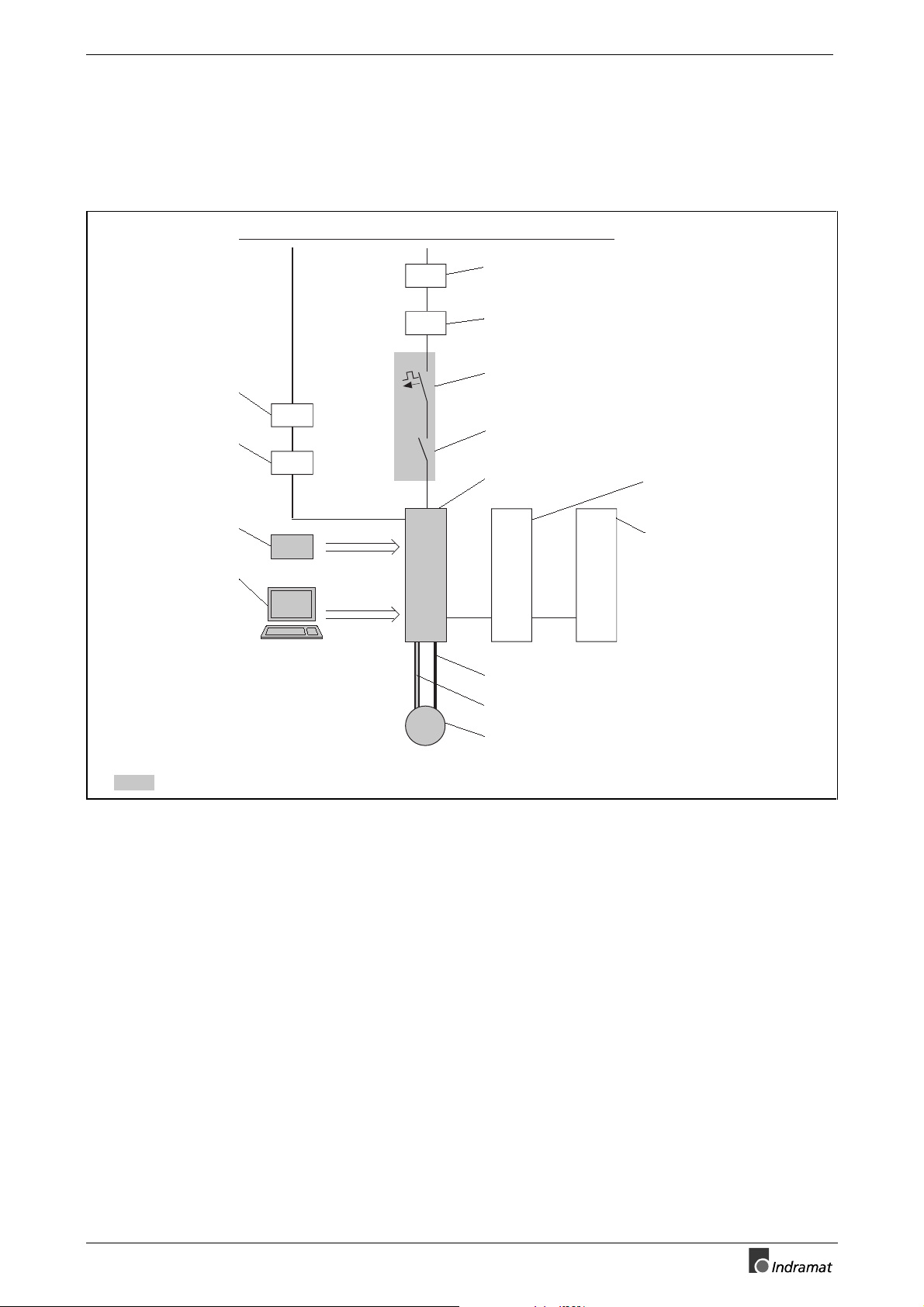

3.1 Overview of the required components

System voltage

Mains filter for

power supply unit

Power supply unit

Firmware

Drive Top

commissioning

program

NFE

NTM

FWA

PC

DC 24 V

NFD

DST

Q1

K1

DKC

MKD

Mains filter for

power connections

Transformer

Fuse

Mains contactor

Drive controller

BZM CZM

IKS - ready-made feedback cable

IKG - ready-made power cable

Servo motor

Auxiliary bleeder module

Auxiliary capacitance

module

Those components shown with a gray-shaded background are absolutely necessary.

Fig. 3-1: Overview of the required components

EB0202D4.fh5

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 24

3-2 Selecting the components ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

3.2 Selection procedure

Dimensioning and selecting the

servo drive

Compiling the required data

Selecting the required

components

Determining components which

may be additionally required

⇒

Dimension the drive according to how it is to be used. A document f or

this is under preparation.

⇒

Select motor/drive combination (DKC + MKD) using the "Selection

Data" documentation (see pg. 3, supplementary documentation)."

⇒

Enter the values obtained from dim ensioning and enter the drives selected into table Fig. 3-2 .

⇒

Calculate the continuous regenerative power according to the specifications in Chapter 5 and enter them in table Fig. 3-2 .

⇒

Use firmware "FW A-ECODRV-ASE-02VRS-MS" for DKC01.1-*** and

DKC11.1-*** (no selection required at this time)

⇒

"Select ready-made cables for the connection between the DKC and

MKD by using the document "MKD Servomotors - Project Planning

Manual" (see pg. 3 of supplementary documentation)."

⇒

Select fuse protector Q1 (see Chapter 11.2).

⇒

Select line contactor K1 (see Chapter 11.2).

⇒

Check the rated line voltage.

•

If, in the case of the DKC**.*-040-7, the rated line voltage f alls below

or exceeds 3xAC (380-460)V ±10%, select a DST transfor mer (see

Chap. 9.2).

•

If, in the case of the DKC**.*-030-3, the rated line voltage f alls below

or exceeds 3xAC230V ±10%, select a DST transfor mer (see Chap.

9.3).

⇒

Check the DC24V control voltage supply for the DKC. If a voltage of

DC24 Volt ± 20 % is not available, select a suitable NTM power supply

(see Chap. 7).

⇒

Check the DC24V voltage for the m otor holding brake. If a voltage of

DC24 Volt ± 10 % is not available, then select a s uitable NTM power

supply (see Chap. 7).

⇒

Check the continuous regenerative power. If it exc eeds 0.15 kW , then

consider option with BZM auxiliary bleeder module (see Chap. 5).

⇒

Check the peak regenerative power. If it exceeds 5 k W , then consider

option with DKC**.*-040-7 and if needed, the BZM auxiliary bleeder

module (see chapter 5).

⇒

If the continuous regenerative power exceeds appr ox. 0.1 kW and the

drive system energy content is less than 200W, the use of an auxiliary

capacitance module CZM can be econom ical. This mak es it possible

to reduce the dissipated energy for the control cabinet by an amount

equal to the continuous regenerative power (see Chap. 6).

⇒ Check the EMC conditions. INDRAMAT recomm ends the use of NFD

or NFE mains filters to maintain EMC limiting values (see Chap. 8).

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 25

ECODRIVE DKC01.1/DKC11.1 Drive Controllers Selecting the components 3-3

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

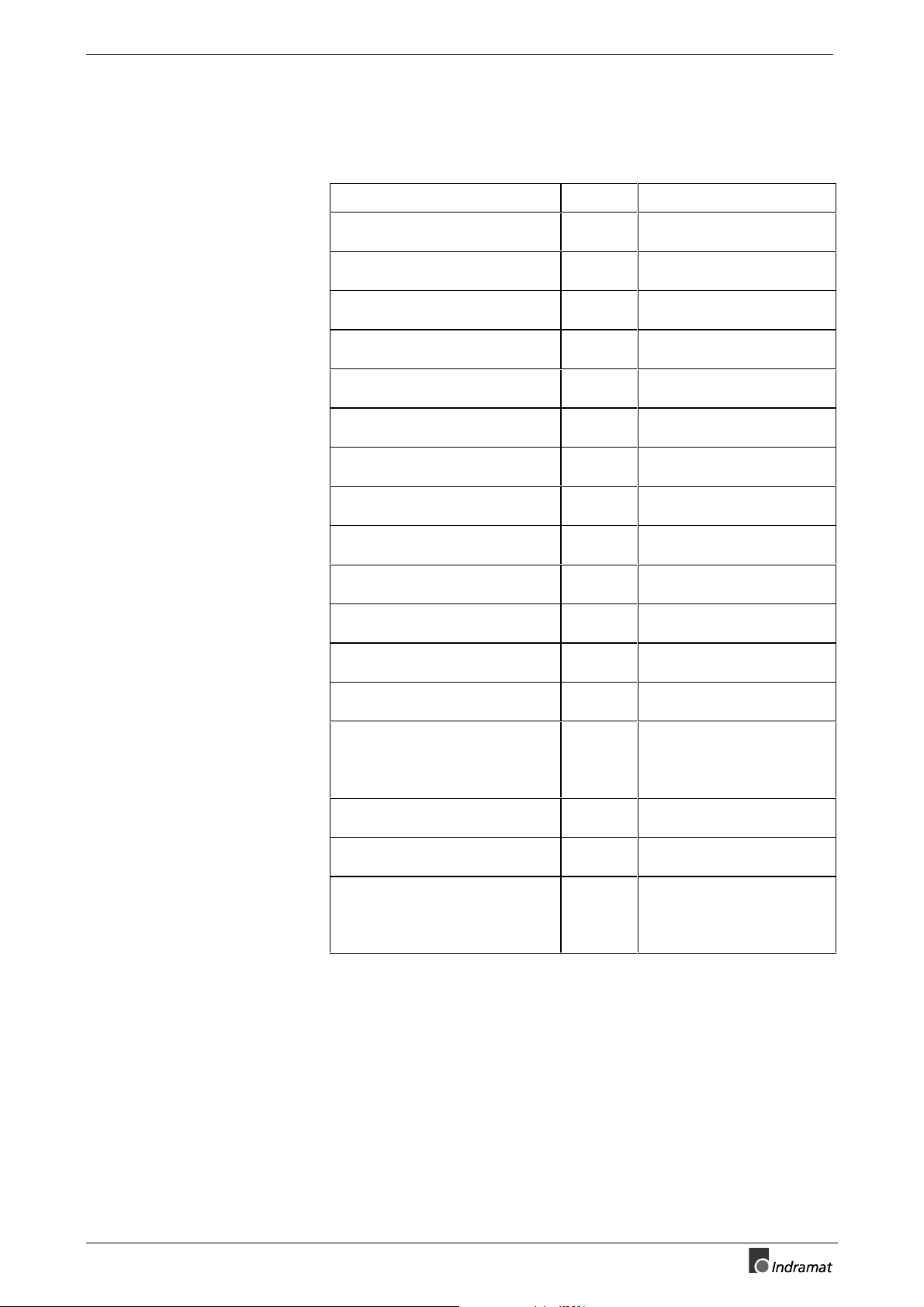

3.3 Compiling the required data

Designation Symbol Values/Units

Effective load torque

Acceleration torque

Operating torque

Motor speed used

Load moment of inertia

Maximum rotary energy in the

mechanical system (E-stop case)

Continuous regenerative power

Continuous torque at standstill

Maximum torque

Short-term operation torque

Maximum motor speed

Required power connection ouput

Required mains rated voltage

Motor/controller combination

M

M

M

n

J

W

P

M

M

M

n

S

U

EFF

ACC

BEARB

NUTZ

LAST

RD

DN

MAX

KB

MAX

AN

N

.............................. in Nm

.............................. in Nm

.............................. in Nm

.............................. in min-1

.............................. in kgm²

ROT,MAX

.............................. in Ws

.............................. in kW

.............................. in Nm

............................. in Nm

............................. in Nm

............................. in min-1

............................. in kVA

............................. in V

DKC...................................

Motor moment of inertia

DKC current consumption

Power consumption of the motor

J

I

N,DC

I

N,HB

M

holding brake (if present)

refer to the project planning

manual MKD Motors

Fig. 3-2: Data required for selecting the components

MKD...................................

............................. in kgm²

0.7 in A

............................. in A

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 26

3-4 Selecting the components ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Notes

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 27

ECODRIVE DKC01.1/DKC11.1 Drive Controllers ECODRIVE DKC drive controllers 4-1

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

4 ECODRIVE DKC drive controllers

4.1 Hardware

View of unit

DKC**.*-030-3-FW

(I

= 30 A)

Typ

Mains connection

1 x AC 230 V

oder

3 x AC 230 V

DKC**.*-040-7-FW

(I

= 40 A)

Typ

Mains connection

AC (380...460) V

Intermediate circuit connection

for

BZM auxiliary bleeder module

or

CZM auxiliary capacitance module

or

further DKCs

Fig. 4-1: Main distinguishing hardware features of the DKC controllers

PI0200.fh5

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 28

4-2 ECODRIVE DKC drive controllers ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

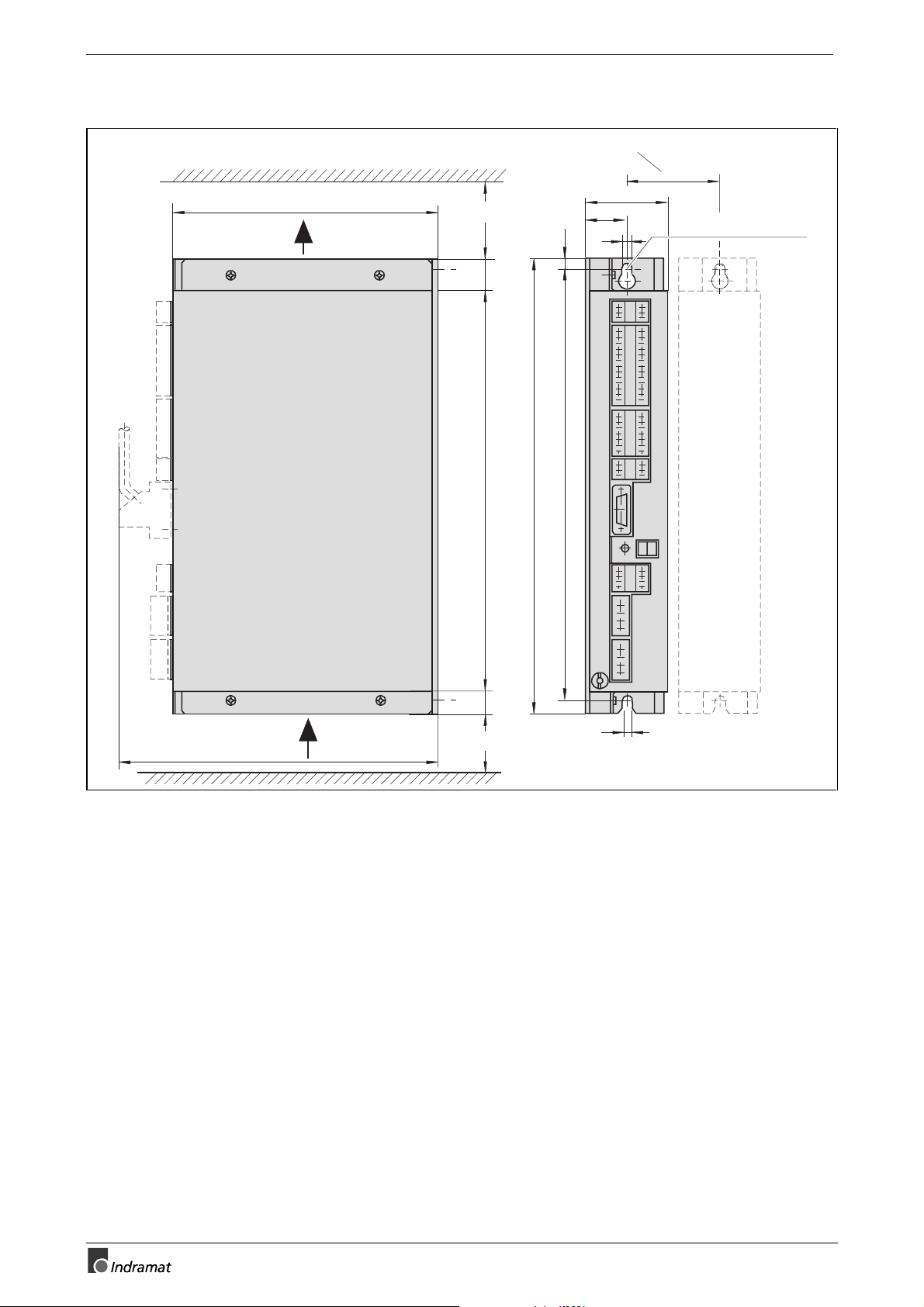

Dimensional sheets and installation dimensions

distance to adjacent unit

70

210

cooling air outlet

min. 80 mm

25

360

8

343

32,5

7

X1

X2

X3

X4

65

M6 in mounting panel

258

X6

S1

X5

H1

X7

X8

318

17

7

cooling air inlet

min. 80 mm

MB0201.fh5

Fig. 4-2: Dimensional data and installation dimensions DKC01.1-030-3-FW

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 29

ECODRIVE DKC01.1/DKC11.1 Drive Controllers ECODRIVE DKC drive controllers 4-3

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

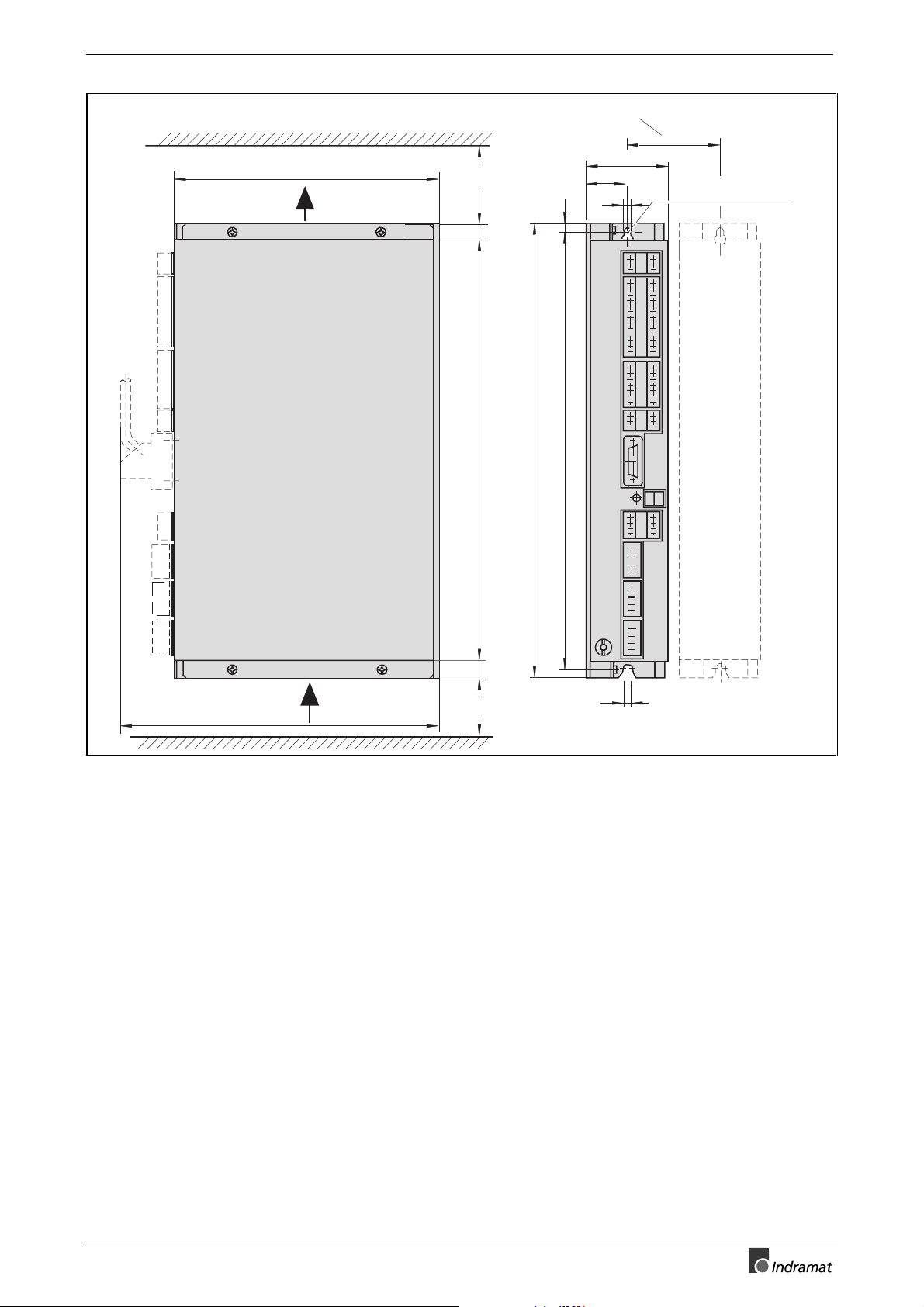

distance to adjacent unit

70

210

cooling air outlet

min. 80 mm

8

32.5

7

65

M6 in mounting panel

258

cooling air inlet

13

333

14

min. 80 mm

360

X1

X2

X3

X4

X5

343

H1

S1

X6

X7

X8

X9

7

MB0202.fh5

Fig. 4-3: Dimensional data and installation dimensions DKC01.1-040-7-

FW/DKC11.1-040-7-FW

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 30

4-4 ECODRIVE DKC drive controllers ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

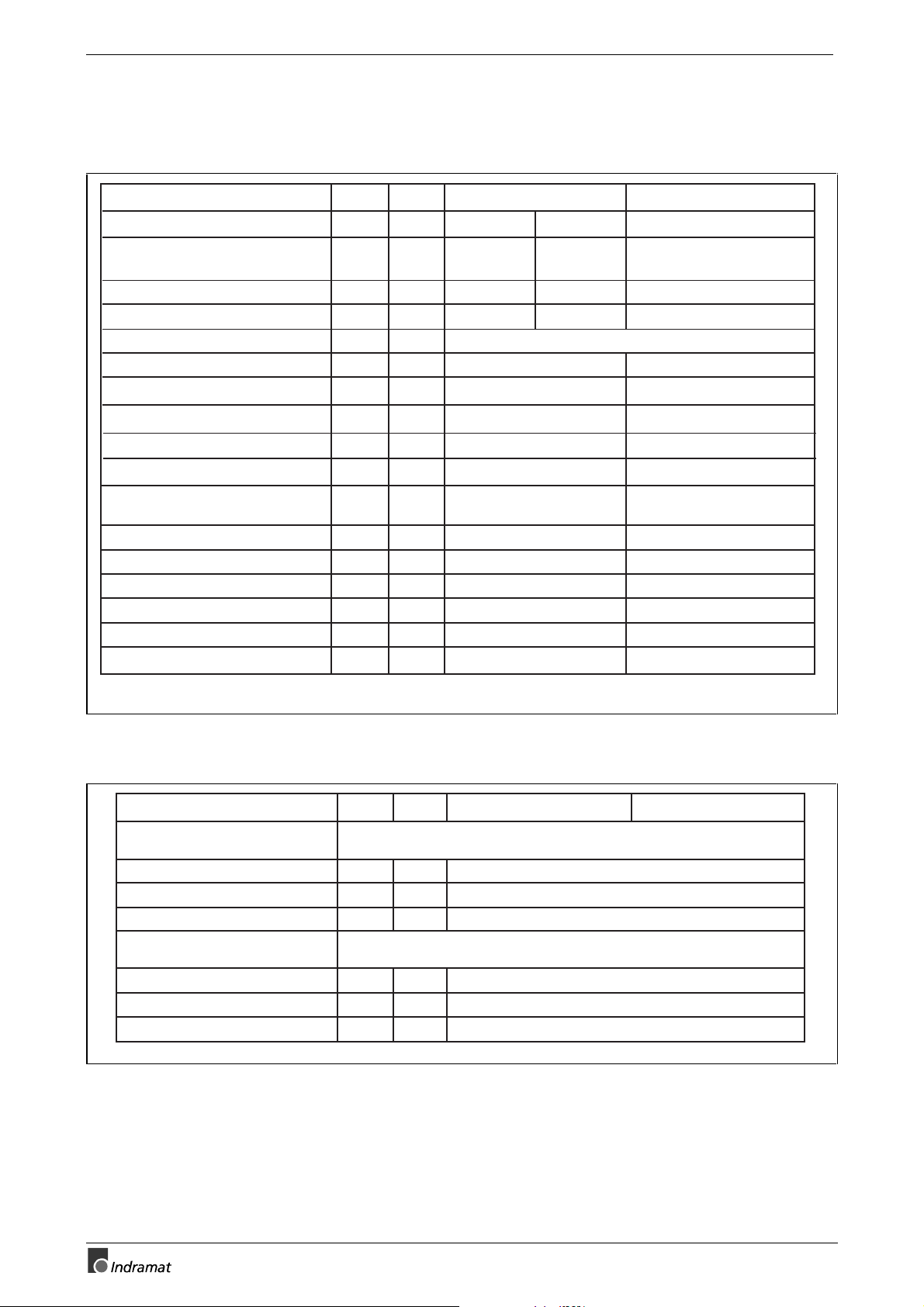

Technical data

Power connection / Power section

Designation

Symbol

Unit

Operating mode at the mains

Mains input voltage

Maximum conn. voltage

Making current

Mains frequency

Switching frequency (selectable)

= 4 kHz

Continous current at

Continous current at

f

S

= 8 kHz

f

S

Rated current

Peak current

Power disspation, without

bleeder dissipation

Peak bleeder output DKC

Continous bleeder output DKC

Maximum feedback energy DKC

Storage energy DKC

DC bus capacitance

DC bus voltage

1) The drive data for 4 and 8 kHz switching. frequencies are listed in the document "ECODRIVE DKC servo drive" - Selection Data.

2) Value dependent on power input voltage

2)

U

N

S

MAX

I

EIN

f

N

f

S

1)

I

CONT

1)

I

CONT

I

TYP

I

PEAK

P

V

P

BM,DKC

P

BD,DKC

W

W

C

DKC

U

ZW

MAX,DKC

ZW,DKC

V

kVA

A

Hz

kHz

A

A

A

A

W

kW

kW

kWs

Ws

mF

V

DKC01.1-030-3-FW

single-phase

1 x AC 230

three-phase

3 x AC 230

± 10%

1,8

10

4 or 8

12

11

30

30

100

5 (for 1 s)

0,15

5,0

15

0,15

not lead to the outside

± 10%

3,2

10

DKC**.1-040-7-FW

50...60

three-phase

3 x AC

(380 ... 480)

4,8 ... 9

9 ... 12

4 or 8

16

12,5

40

40

180

10 (for 0,5 s)

0,15

5,0

15

0,15

DC 500...800

± 10%

TB0202.fh5

Designation

Control voltage connection

for DKC

Input voltage

Maximum ripple content

Current consumption

Voltage connection for

holding brake

Input voltage

Maximum ripple content

Current consumption

Fig. 4-4: Technical data for the power connection and power section

DC24V Power supply

N,DC

N,HB

Unit

V

%

A

V

%

A

Symbol

U

w

I

N,DC

U

w

I

N,HB

Fig. 4-5: Technical data for the DC24V power supply

DKC01.1-030-3-FW

DKC**.1-040-7-FW

DC (19,2 ... 28,8) V

must not exceed the input voltage range

0,7

DC 24

± 10%

must not exceed the input voltage range

please see MKD dokumentation

TB0203.fh5

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 31

ECODRIVE DKC01.1/DKC11.1 Drive Controllers ECODRIVE DKC drive controllers 4-5

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Additional connection of the DC24 power supply

The DKC drives should be firm ly connected to the DC24V power supply;

preferred method Fig. 4-6

They can also be connected to the DC24V power supply in a switchable

manner Fig. 4-7

Preferred method:

The power supply is firmly

connected to the attached DKC

The power supply is connected

to the attached DKC in a

switchable manner

DKC

power supply

L1

24V

X4/1

L2

L3

Q2

0V

DC24V

X4/4

V01DCC1P.fh5

Connecting additional DKC`s

Fig. 4-6: Principle for connecting the DC24V control voltage by switching on the

power supply via Q2, preferred method

DKC

X4/1

X4/4

L1

L2

L3

power supply

DC24V

24V

0V

K1

K1

S1

Rv

K1 closing delay >100 ms, DC1≥10A

Rv = 2,2Ω / 5W (wire resistance)

S1 Cotact, DC1≥ 6 A

Connecting additional DKC x.1,DKC x.2

(max. 6 DKC + 6BZM01.1)

V02DCC1P.fh5

Fig. 4-7: Principle for connection the 24V via S1 with a starting current limiter

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 32

4-6 ECODRIVE DKC drive controllers ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Ambient and installation conditions

Ambient temperature and

installation altitude

Selection lists are specified f or each motor/drive documentation. Please

refer to the documentation "ECODRIVE Servodrives DKC with MKD Selection Lists -

The selection lists apply within the given ambient and installation conditions (see Fig. 4-9).

For different conditions, the short-term operating torque is reduced according to the diagrams (see Fig. 4- 8). If deviating am bient temperatur es

and higher installation altitudes occur simultaneously, both load factors

must be multiplied.

Load with higher

ambient temperatures

1

0,8

Load factor

0,6

40 45 50 55

Ambient temperature in °C

1

0,8

Load factor

0,6

00

Load with higher

installation elevations

1000 2000 3000 4000 5000

Installation altitude meters

above sea level

DG0200.fh5

Designation

Ambient and installation

conditions

Cooling the power section

Permissible ambient temperature

with nominal data

Max. permissible ambient

temperature with reduced

nominal data

Storage and transport

temperature

Max. installation elevation

with nominal data

Max. permissible relative humidity

Max. permissible absolute humidity

Degree of contamination

Protection category

Weight

Fig. 4-8: Load utilization as a value dependent upon ambient temperature and

installation altitude

Symbol

T

UM

T

UM,MAX

T

L

Unit

°C

°C

°C

m

%

g/m

DKC01.1-030-3-FW

natural air cooling

3

DKC**.1-040-7-FW

internal blower cooling

+0...+45

+55

The values indicated in the selection data

and MKB, drop in the range of +45

for M

DN

to +55°C by 2% per °C of rise in temperature.

-30...+85

1000

95

25

Non-conductive dirt contamination, no condensation

IP20, as per EN 60529 = DIN VDE 0470-1-1992 (IEC 529-1989)

stationary use in control cabinets

mkg

4.4

TB0204.fh5

Fig. 4-9: Ambient and installation conditions

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 33

ECODRIVE DKC01.1/DKC11.1 Drive Controllers ECODRIVE DKC drive controllers 4-7

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Type code and rating plate

Type code fields:

Drive controller

Series

Version

Type

30 A

40 A

Rated intermediate circuit voltage

300 V

700 V

Firmware FW

A firmware specifying the functions of the

drive must be ordered separately.

Fig. 4-10: DKC type code

Type of machine

Part no.

DKC01.1-040-7-FW

253158

Example:

DKC

030

040

K16/96

DKC 01.1 - 040 - 7 - FW

01

11

1

3

7

TL0200.fh5

Production week

Barcode

SN253160-01708

Serial number Change index

Fig. 4-11: DKC rating plate

A03

TS0200.fh5

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 34

4-8 ECODRIVE DKC drive controllers ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

4.2 Firmware

The firmware located in the drive controller determines the functional

features of the ECODRIVE drive controller.

The firmware "FWA-ECODRV-ASE-02VRS-MS" is for the drive controllers DKC01.1-*** and DKC11.1-***.

The firmware has its own order num ber. T his m eans that it is always possible to order the identical firmware version.

The firmware is updated cons tantly to eliminate any bugs without altering

the functionality. It is identified on the type code as the firmware release

version.

If newer functions are added, the index of the f irmware version is incremented (see type codes).

Type codes:

Item i. d.

Firmware

Class

Product (machine)

Name of product

Product: ECODRIVE

Firmware-type

Firmware-Version

02

Firmware type

Test version

Standard

Firmware-release-status (Update)

The status at the time of

delivery.

Language (abbrev. see

INN 09.04, sec. 1)

Multilingual

(alphnumeric)

Example:

FW

ECODRV

ASEParallel interface

(01...99)

FW A-ECODRV-ASE-02 V RS-MS

A

02

T

V

RS

MS

TL0202.fh5

Fig. 4-12: ECODRIVE firmware type code

Firmware-type

Part no.

Barcode

Fig. 4-13: Firmware rating plate

FWA-ECODRV-ASE-02VRS-MS

266285

SN266285-06394

Serial number

Release status

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Production week

K19/96

V01

TS0201.fh5

Page 35

ECODRIVE DKC01.1/DKC11.1 Drive Controllers ECODRIVE DKC drive controllers 4-9

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

4.3 An overview of the electrical connections

Front view with supply terminals

X1 X1

RS 232 serial

interface

Positioning record

selection or inputs

for stepper interface

Positioning record

acknowledgement

Analog command

value input

Torque reduction

Analog outputs

Control voltage

Controller enable

Drive stop

Motor feedback

connection

Motor temperature

monitoring

Holding

brake control

Motor connection

RxD

TxD

POS1/SM1+

POS2/SM1-

POS3/SM2+

POS4/SM2-

POS5

POS Q1

POS Q2

POS Q3

POS Q4

POS Q5

Shield

IRED1

IRED2

AK1

AK2

Shield

24V

AH/Start

SDI

15

FS

14

R3

13

R1

12

0V

11

10S2

9S1

TM+

TM-

Br+

Br-

A1

A2

A3

0V

0V

RF

1

2

3

X2

1

2

3

4

5

6

7

8

9

10

11

12

X3

E1

E2

0V

1

2

3

4

5

6

7

8

X1

X2

X3

X4

1

2

3

X4

X5

8 SDO

7 SCL

6 R3

5 R1

4 0V

3 S4

2 S3

1 Shield

X6

X7

1

2

3

4

1

2

3

X5

H1

S1

X6

X7

X8

RS 485+

4

RS 485-

5

Shield

6

1)1)

X2

NF

13

NS

14

15

LIMIT+

16

LIMITJOG+

17

JOG-

18

WSP

19

20

INREF

INBWG

21

INPOS

22

23

0V

24

Shield

RS 485 serial

interface

Go to zero point

Zero switch

Travel limit switch

Jog inputs

Path control point

Homing in

Movement in

Position in

X3

UA0+

9

10

11

12

13

14

15

16

UA0UA1+/Data+

UA1-/DataUA2+/CLK+

UA2-/CLK0VM

Shield

X4

0V

4

Bb

5

Bb

6

Actual

position value

(incremental

or SSI)

Ready to operate

Fault clearance button

Diagnosis indicator

X6

24V

5

0V

6

Shield

7

8

Shield

Voltage connection

for holding brake

X8

1

L1

2

L2

3

L3

Power connection

Ground wire connection

X9

and connection for shielding

the motor power cable

X5:

15-pole D-Sub connector (INS 439)

X1, X2, X3, X4, X6:

Screw-down push-in terminals

0.2...2.5 mm², AWG 24-12

X7, X8, X9:

Screw-down push-in terminals

0.2...4 mm², AWG 24-10

1) not on DKC11.1-040-7-FW

Fig.. 4-14: Front view of the DKC with supply terminals

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

X9

1

L+1

2

L+2

3

L-1

4

L-2

Intermediate circuit connection

(not on DKC01.1-030-3)

SB0200.fh5

Page 36

4-10 ECODRIVE DKC drive controllers ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

Overall connection diagrams

DKC01.1 drive controller

X4

1

contr. volt. for DKC

drive enable

start signal

zero ref. to contr. volt.

ready to

operate

+24V

2

RF

3

AH/Start

4

0V

5

Bb

6

Bb

X2

Positioning

input signals

acknowledge

positioning

input signals

homing

homing switch

travel range

limit switch

Sensor inputs

positive jogging

negative jogging

path switch point

in reference

in motion

in position

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

POS1

POS2

POS3

POS4

POS5

POS Q1

POS Q2

POS Q3

POS Q4

POS Q5

0V

NF

NS

LIMIT+

LIMITJOG+

JOGWSP

INREF

INBWG

INPOS

0V

X3

1

E1

Feedrate Override

torque

reduction

analog

outputs

output

act. pos. value

(incremental

or SSI)

2

E2

3

IRED 1

4

IRED 2

5

AK1

6

0V

7

AK2

8

9

UA0

10

11

UA0

UA1/Data+

12

UA1/Data-

13

UA2/CLK+

14

UA2/CLK-

15

0V

16

X8

1

L1

power connection

L2

L3

PE

3)

PEprotective conductor

connection

Symbols:

1) Switching capacity DC 24 V/ 2,5 A

2) Specifications for ready-made cables, connectors, and types of cables can be found in the documentation "Connection Accessories for

INDRAMAT drives" cable document no. 209-0050-4399-XX or in the motor project planning manuals.

3) The ground connector of units with discharge currents > 3.5 mA must be at least 10mm2 for mechanical reasons. (DIN VDE 0160/EN 50178)

2

≥

10 mm

Plug-in screw terminal, female

Plug-in screw terminal, male

L1

2

L2

3

L3

in operating mode

POSITIONING interface

1)

Plug-in connector, female

Plug-in connector, male

RxD

TxD

RS485+

RS485-

X5

0V

S3

S1

S4

S2

R1

FS

SCL

SDI

SDO

TM

TMTM+

TM-

0V

Br+

Br-

X1

X7

A1

A2

A3

X6

X9

L+1

L+2

L-1

L-2

1

2

3

4

5

6

4

WH 0,5

GN

2

9

BN

3

PK

GY

1

BN 0,5

1

1

BK

RD

7

1

BU

8

VT

1

1

2

3

GN/YE

4

1

2

3

4

8

7

0V

6

24V

5

+

+

Plug-in terminal

TxD

RS 232-

RxD

interface

0V

RS485+

RS 485interface

RS485-

MKD-

U1

V1

W1

1

2

+

servomotor

X

1

5

3

9

7

Resolver-

10

feedback

2

4

6

8

X1

U1

V1

W1

X2

1

2

+

U

holding brake

AP0200.fh5

2)

2

2

1

2

3

5

6

7

8

voltage connection

for holding brake

DC bus connection

(not with DKC01.1-030-3)

M

3

PTC

Fig. 4-15: DKC01.1 with POSITIONING interface

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 37

ECODRIVE DKC01.1/DKC11.1 Drive Controllers ECODRIVE DKC drive controllers 4-11

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

DKC01.1 drive controller

in operating mode

ANALOG interface

1)

RxD

TxD

RS485+

RS485-

X5

0V

S3

S1

S4

S2

R1

FS

SCL

SDI

SDO

TM+

TM+TM+

TM-

0V

Br+

A1

A2

A3

Br-

L+1

L+2

L-1

L-2

X1

X7

X6

X9

1

TxD

2

RxD

3

0V

4

RS485+

5

RS485-

6

2)

4

2

9

3

10

12

14

7

15

8

1

1

2

3

4

1

2

3

4

8

7

6

5

+

+

2

WH 0,5

GN

BN

PK

GY

2

BN 0,5

BK

RD

BU

VT

1

2

3

GN/YE

5

6

7

8

0V

24V

DC bus connection

(not with DKC01.1-030-3)

RS 232interface

RS 485interface

MKD-

servomotor

X3

1

5

3

9

7

10

2

4

6

8

X1

U1

U1

V1

V1

W1

W1

X2

1

1

2

2

+

+

U

holding brake

voltage connection

for holding brake

Resolverfeedback

M

3

PTC

contr. volt. for DKC

drive enable

start signal

zero ref. to contr. volt.

ready to

operate

homing

homing switch

travel range

limit switch

Sensor inputs

path switch point

analog

com. val. input

torque

reduction

analog

outputs

output

act. pos. value

(incremental

or SSI)

power connection

protective conductor

connection

≥

10 mm

X4

1

+24V

2

RF

3

AH/Start

4

0V

5

Bb

6

Bb

X2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

0V

NF

NS

LIMIT+

LIMIT-

WSP

0V

X3

1

E1

2

E2

3

IRED 1

4

IRED 2

5

AK1

6

0V

7

AK2

8

9

10

11

12

13

14

15

16

UA0

UA0

UA1/Data+

UA1/DataUA2/CLK+

UA2/CLK0V

X8

1

L1

L2

L3

PE

3)

PE

2

L1

2

L2

3

L3

Symbols:

1) Switching capacity DC 24 V/ 2,5 A

2) Specifications for ready-made cables, connectors, and types of cables can be found in the documentation "Connection Accessories for

INDRAMAT drives" cable document no. 209-0050-4399-XX or in the motor project planning manuals.

3) The ground connector of units with discharge currents > 3.5 mA must be at least 10mm2 for mechanical reasons. (DIN VDE 0160/EN 50178)

Plug-in screw terminal, female

Plug-in screw terminal, male

Plug-in connector, female

Plug-in connector, male

Fig. 4-16: DKC01.1 with ANALOG interface; Supply terminal assignment

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Plug-in terminal

AP0204.fh5

Page 38

4-12 ECODRIVE DKC drive controllers ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

DKC011.1

drive controller with

ANALOG interface

RxD

TxD

0V

RS485+

RS485-

X5

0V

S3

S1

S4

S2

R1

FS

SCL

SDI

SDO

X1

1

TxD

2

RxD

3

0V

4

RS485+

5

RS485-

6

RS 232interface

RS 485interface

MKD-

servomotor

2)

WH 0,5

GN

BN

PK

GY

BN 0,5

BK

RD

BU

VT

2

2

4

2

9

3

10

12

14

7

15

8

1

X3

1

5

3

9

7

10

2

4

6

8

Resolverfeedback

contr. volt. for DKC

drive enable

start signal

zero ref. to contr. volt.

ready to

operate

X4

1

+24V

2

RF

3

AH/Start

4

0V

5

Bb

6

Bb

analog

com. val. input

torque

reduction

analog

outputs

output

act. pos. value

(incremental

or SSI)

power connection

protecxtive conductor

connection

≥

10 mm

X7

X6

X9

1

2

3

4

GN/YE

1

2

3

4

8

7

0V

6

24V

5

+

+

A1

X3

1

E1

2

E2

3

IRED 1

4

IRED 2

5

AK1

6

0V

7

AK2

8

9

10

11

12

13

14

15

16

UA0

UA0

UA1/Data+

UA1/DataUA2/CLK+

UA2/CLK0V

1)

TM+

TM+TM+

TM-

Br+

A2

A3

Br-

X8

1

L1

L2

L3

PE

3)

PE

2

L1

2

L2

3

L3

L+1

L+2

L-1

L-2

U1

1

V1

2

W1

3

5

1

6

2

7

+

8

voltage connection

for holding brake

DC bus connection

X1

U1

V1

W1

X2

1

2

+

U

holding brake

3

M

PTC

Symbols:

1) Switching capacity DC 24 V/ 2,5 A

2) Specifications for ready-made cables, connectors, and types of cables can be found in the documentation "Connection Accessories for

INDRAMAT drives" cable document no. 209-0050-4399-XX or in the motor project planning manuals.

3) The ground connector of units with discharge currents > 3.5 mA must be at least 10mm2 for mechanical reasons. (DIN VDE 0160/EN 50178)

Plug-in screw terminal, female

Plug-in screw terminal, male

Plug-in connector, female

Plug-in connector, male

Fig. 4-17: DKC11.1-040-7-FW with ANALOG interface

Plug-in terminal

AP0205.fh5

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 39

ECODRIVE DKC01.1/DKC11.1 Drive Controllers ECODRIVE DKC drive controllers 4-13

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

DKC01.1 drive controller

X4

1

contr. volt. for DKC

drive enable

start signal

zero ref. to contr. volt.

ready to

operate

+24V

2

RF

3

AH/Start

4

0V

5

Bb

6

Bb

X2

homing

homing switch

travel range

limit switch

Sensor inputs

positive jogging

negative jogging

path switch point

in reference

in motion

in position

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

SM1+

SM1SM2+

SM2-

0V

NF

NS

LIMIT+

LIMITJOG+

JOGWSP

INREF

INBWG

INPOS

0V

X3

1

E1

Feedrate Override

torque

reduction

analog

outputs

output

act. pos. value

(incremental

or SSI)

2

E2

3

IRED 1

4

IRED 2

5

AK1

6

0V

7

AK2

8

9

UA

10

UA0

11

UA1/Data+

12

UA1/Data-

13

UA2/CLK+

14

UA2/CLK-

15

0V

16

X8

1

L1

L2

power connection

L3

PE

3)

protective conductor

connection

Symbols:

1) Switching capacity DC 24 V/ 2,5 A

2) Specifications for ready-made cables, connectors, and types of cables can be found in the documentation "Connection Accessories for

INDRAMAT drives" cable document no. 209-0050-4399-XX or in the motor project planning manuals.

3) The ground connector of units with discharge currents > 3.5 mA must be at least 10mm2 for mechanical reasons. (DIN VDE 0160/EN 50178)

≥

10 mm

PE

2

Plug-in screw terminal, female

Plug-in screw terminal, male

L1

2

L2

3

L3

in operating mode

STEP MOTOR interface

1)

Plug-in connector, female

Plug-in connector, male

RxD

TxD

RS485+

RS485-

X5

0V

S3

S1

S4

S2

R1

FS

SCL

SDI

SDO

TM

TMTM+

TM-

0V

Br+

X1

X7

A1

A2

A3

Br-

X9

L+1

L+2

L-1

L-2

X6

1

2

3

4

5

6

4

WH 0,5

GN

2

9

BN

3

PK

10

GY

BN 0,5

12

14

BK

RD

7

15

BU

8

VT

1

1

2

3

GN/YE

4

1

2

3

4

8

7

0V

6

24V

5

+

+

Plug-in terminal

TxD

RS 232-

RxD

interface

0V

RS485+

RS 485-

RS485-

interface

MKD-

2)

2

2

1

2

3

5

6

7

8

voltage connection

for holding brake

DC bus connection

(not with DKC01.1-030-3)

Servomotor

U

V

W

1

2

+

X3

1

5

3

9

7

Resolver-

10

feedback

2

4

6

8

X1

U1

V1

W1

X2

1

2

+

U

holding brake

AP0203.fh5

M

3

PTC

Fig. 4-18: DKC01.1 with stepping interface

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 40

4-14 ECODRIVE DKC drive controllers ECODRIVE DKC01.1/DKC11.1 Drive Controllers

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

4.4 Electrical connection to the supply terminal strips

The description of the electrical connections below are f irst grouped according to numbers of the supply terminal strips (e.g. X1, X2 etc.) and

then according to the functions.

Serial interface X1

The serial interface is generally used for programm ing, parameterization

and diagnoses during startup operation and service procedures.

It can be alternatively operated as a RS 232 or RS 485.

RS-232 interface

The RS-232 interface is needed f or program ming, param eterizing and diagnosis during startup operation and service procedures.

It is also used when setting the drive addresses as a requirement for operations via RS-485.

With the RS 232, it is possible to param eterize only one dr ive at a time

when using the DriveTop startup program.

max. 15 meters

cable: IKS 0101

X1

1

RxD

2

TxD

3

0 V

6

5

4

DKC

X1

1

RxD

2

TxD

3

0 V

6

5

4

DKC

PC with 9-pin

D-subminiature

connector

PC with 25-pin

D-subminiature

connector

1)

1)

RxD

TxD

GND

DTR

DSR

RTS

CTS

RxD

TxD

GND

DTR

DSR

RTS

CTS

2

3

5

4

6

7

8

max. 15 meters

cable: IKS 0102

3

2

7

20

6

4

5

1) External shield on PC must be attached to unit chassis.

Fig. 4-19: Connecting a PC to a RS-232 interface on a DKC

AP0224.fh5

DOK-ECODRV-DKC01/11.1*-PRJ3-EN-P

Page 41

ECODRIVE DKC01.1/DKC11.1 Drive Controllers ECODRIVE DKC drive controllers 4-15

Buy: www.ValinOnline.com | Phone: 844-385-3099 | Email: CustomerService@valin.com

RS-485 interface

Interface converter PSM-EG-

RS232/RS485-P/2D

The RS-485 interface is needed f or program ming, param eterizing and diagnosis during startup operation and service procedures.

The RS 485 interface allows :

•

the implementation of a serial bus with up to 31 stations connected by

means of a twisted pair cable (half duplex mode),

•

a transmission length of up to 500 meters

•

data rates of 9600/19200 baud and

•

the implementation of a central PC-based visualization unit.

Via the RS-485 several DKCs can be put into operation with Drive Top

without reconnecting the interface cable.

To operate DriveTop with several ECODRIVEs, a RS- 232/485 converter

is required between the PC and the drives.