Page 1

TECHNICAL INFORMATION

HOT RUNNER SYSTEMS

Page 2

Start-up Instructions

for männer Hot Runner Valve Gate Systems

Please note: use dehumidified air only. Minimum air pressure required for pin actuation: 6 bar.

MES

1 2 3 4

Turn on mold cooling and

gate cooling before heating

up the hot runner system.

During the heating cycle,

the compressed air for pin

operation must be switched

off.

In general, use the “soft-start“

function of the control system.

Heat the main manifold with

the sprue bushing to approx.

80-90% of the required production temperature.

Turn on the submanifolds

(cylinder blocks) and nozzles.

Heat up the entire system

to production temperature.

5 6 7

Maintain the system at

production temperature

for approx. 5 -10 min. prior

to operating valve pins.

air for pin

6 bar).

operation

(min.

MSS / MMS / MHS / MIS / MXS / MZS

1

Turn on mold cooling and gate

cooling before heating up the

hot runner system.

4

Maintain the system at production

temperature for approx. 5-10 minutes

prior to operating valve pins.

2 3

In general, use the “soft-start“ function

of the hot runner control system. Heat

up manifold to approx. 80-90% of the

required production temperature.

5

After the system is fully heated,

start production.

Start production.Turn on the compressed

Turn on the nozzles, and heat up

the entire system to production

temperature.

When starting up after a production

stop, purge the barrel of all remaining

resin before restarting. For start-up,

reduce the injection volume to 70%

of the required amount.

IMPORTANT!

When starting up after a production stop, purge the barrel

of all remaining resin before

restarting. For start-up, reduce the injection volume to

70% of the required amount.

IMPORTANT!

FILLING

Several injection cycles may be required

to fill the hot runner system the first

time the unit is used. Continually check

the cavities after each cycle and remove

all short shots until ultimately all parts

are completely filled.

EMPTYING THE INJECTION UNIT

To prevent the gate orifices and valve

pin s from be ing dam aged by co ld

material, do not actuate the valve pins

while setting up the injection molding

machine or while emptying the injection

unit of any remaining material.

PRODUCTION STOP

Re duce the tempera ture of t he hot

runner heating system to standby temperature (100° C to 150° C, depending

on the resin). The valve pins should be

in closed position.

SYSTEM SHUTDOWN

When shuttin g down th e hot r unner

system, switch off all control circuits at

the same time. To prevent the hot runner

system from being damaged by heat

accumulation, allow the mold cooling

system to run for another 20-30 minutes

at approx. 30° C.

REMOVING THE MOLD INSERTS

Before removing the mold inserts, make

sure that the hot runner is switched off

(temperature not exceeding 60° C) and

the valve pins are in open position.

Page 3

Maintenance Tips

for männer Hot Runner Valve Gate Systems

Polyolefins (f.e. PP/PE)

Approx. 2 million cycles*

Insulating ring

Check for leaks.

If any leaks are detected, please

contact the männer service team.

Melt flow from manifold to hot

runner nozzle

Check for leaks.

Always replace seals whenever the

components are disassembled.

Polyesters (f.e. PC/PBT/PET)

Approx. 1 million cycles*

Engineered resins (f.e. PA)

Approx. 0.5 million cycles*

Gate

If the surface quality is not satisfactory,

ensure that the valve pin and gate

orifice are not damaged.

If any damage is detected, please

contact the männer service team.

Nozzles

Clean off any dirt or deposits.

NOTE: Do not clean heating elements in high-temperature sand

baths or pyrolysis furnaces.

Pneumatic unit

Only use dehumidified air to

operate the pneumatic unit of

männer hot runner systems.

Remove heavy dirt buildup using

cleaning fluid, and apply pneumatic

grease to the contact surfaces.

Replace any brittle seals.

* The mai nte nan ce inte rva ls spec ifi ed here ar e only a n

approximation. Actual intervals may vary, depending on the

resins used, the injection parameters, and the part geometry.

We will be happy to provide you with maintenance information

for your specific hot runner system and application upon request.

Valve pin guide bushing

and valve pin

Use an ultrasonic cleaning system or

similar equipment to clean off any dirt

or deposits produced as a result of

outgassing.

NOTE: Do not use any abrasives to

clean the valve pin guide bushing or

valve pin.

If any damage is detected, please

contact the männer service team.

We recommend that you check your männer hot

runner system regularly to ensure optimum performance and long life.

Pl ease con tact the männer servic e team if any

damage to the parts is detected.

Page 4

Plug Arrangement

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

N L

Connections

on Mold Side

(EUROMAP 14

Technical Recommendation)

Female connector Male connector

1

+

2

+

3

+

4

+

5

+

6

+

7

+

8

+

9

-

10

-

11

-

12

-

13

-

14

-

15

-

16

-

Thermocouple Power

9

10

11

12

13

14

15

16

N L

in accordance with VDE guidelines

1 Thermocouple connection

2 1.5² wire with ferrule

for blocks

3 Heater band connection

1

2

3

4

5

6

7

8

with ferrule

4 Crimp contact (pin),

1.5² connection

5 Extension, 1.5² wire

6 Parallel connection

(2 tubular heating elements)

7 Parallel connection with

heat-shrink tubing

8 Ring plug

connection

9 Flat plug

connection

10 Ferrule

Grounding

conductors

on mold

connection

Power – Resistance –

Current

Table

The resistance value can vary slightly (±10%) depending on

the temperature and/or cable length.

This deviation in value, however, does not affect the heating

behavior.

Power [W]

P = U² / R

200

250

300

350

400

450

500

600

700

800

900

1000

1500

2000

2500

3000

3500

Resistance [Ω]

R = U / I

264,5

211,5

176,3

151,1

132,2

117,5

105,8

88,1

75,5

66,1

58,7

52,9

35,2

26,4

21,1

17,6

15,1

Current [A]

I = U / R

0,8

1,0

1,3

1,5

1,7

1,9

2,1

2,6

3,0

3,4

3,9

4,3

6,5

8,6

10,8

13,0

15,2

Page 5

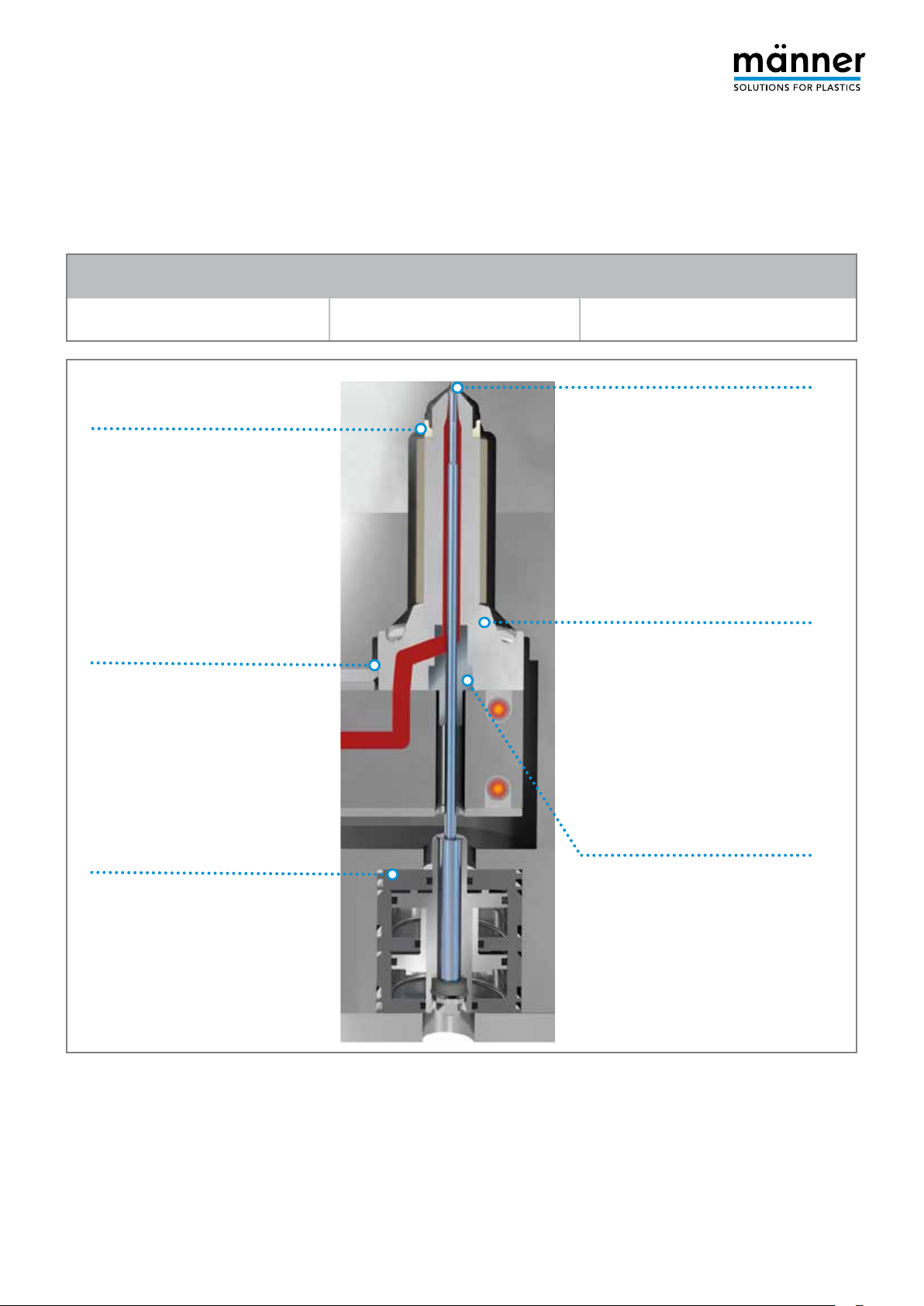

Thermocouples

Extension / Compensating Cables

Overview

Thermocouple

Type Material

+

Platinum/13% Rhodium

-

Platinum

R

+

Platinum/10% Rhodium

-

S

Platinum

+

Platinum/20% Rhodium

B

-

Platinum/6% Rhodium

+

Iron

J

-

Copper-nickel

+

Copper

-

Copper-nickel

T

+

Nickel-chromium

E

-

Copper-nickel

IEC 60584 DIN IEC 58 4 DIN 43710 BC 4937

RCA/SCA

RCB/SCB

SoPtRh/

SoPt

BC

JX

TX

See LX

See UX

EX

ANSI MC 96 .1

SX

BX

JX

TX

EX

NF-C 42-32 4

JX/JC

TX/TC

EX/EC

SC

BC

Color coding

not specified

RX/SX

BX

JX

TX

EX

KX

+

K

Nickel-chromium

-

Nickel

KCB

KCA

+

Nickel-chromium-silicon

-

N

Nickel-silicon

+

Copper

-

U

Copper-nickel

+

Iron

L

-

Copper-nickel

NX/NC

* Type J is used for männer thermocouples.

COMPENSATING CABLES

To ensure proper temperature measurement, please note the following.

When connecting the hot (measuring)

junction to the cold (reference) junction

in the control unit, make sure you use

a compensating cable whose wires are

made of original thermocouple material.

Explanation : Wires made of original

the r moco uple mat e rial ex h ibit th e

same thermoelectric behavior as the

KX

NiCr

Ni

Fe

CuNi

VX

UX

LX

thermocouple pair at the hot junction.

As a result, the thermocouple voltage

remains constant all the way to the cold

junction in the control unit.

Thi s c old ju nct ion co mpensat ion is

necessary, since thermocouples measure

the temperature difference between the

hot junction and the cold junction (see

diagram on right). This helps to prevent

parasitic thermocouple voltages.

Insulated

thermocouple wire

Plug connector or

direct connection

KX/KC

VC

WC

Compensating

wire

Color coding

not specified

Measuring unit

control system

Cold junction

KX

VX

NX

of hot runner

Page 6

Voltage Values in µV

for Type J Thermocouple (iron/copper-nickel)

ºC 0 +1 +2 +3 +4 +5 +6 +7 +8 +9

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

0

507

1019

1537

2059

2585

3116

3650

4187

4726

5269

5814

6360

6909

7459

8010

8562

9115

9669

10224

10779

11334

11889

12445

13000

0

50

558

1071

1589

2111

2638

3169

3703

4240

4781

5323

5868

6415

6964

7514

8065

8618

9171

9725

10279

10834

11389

11945

12500

13056

101

609

1122

1641

2164

2691

3222

3757

4294

4835

5378

5923

6470

7019

7569

8120

8673

9226

9780

10335

10890

11445

12000

12556

13111

151

660

1174

1693

2216

2744

3275

3810

4348

4889

5432

5977

6525

7074

7624

8175

8728

9282

9836

10390

10945

11501

12056

12611

13167

202

711

1226

1745

2269

2797

3329

3864

4402

4943

5487

6032

6579

7129

7679

8231

8783

9337

9891

10446

11001

11556

12111

12667

13222

253

762

1277

1797

2322

2850

3382

3918

4456

4997

5541

6087

6634

7184

7734

8286

8839

9392

9947

10501

11056

11612

12167

12722

13278

303

814

1329

1849

2374

2903

3436

3971

4510

5052

5595

6141

6689

7239

7789

8341

8894

9448

10002

10557

11112

11667

12222

12778

13333

354

865

1381

1902

2427

2956

3489

4025

4564

5106

5650

6196

6744

7294

7844

8396

8949

9503

10057

10612

11167

11723

12278

12833

13389

405

916

1433

1954

2480

3009

3543

4079

4618

5160

5705

6251

6799

7349

7900

8452

9005

9559

10113

10668

11223

11778

12334

12889

13444

456

968

1485

2006

2532

3062

3596

4133

4672

5215

5759

6306

6854

7404

7955

8507

9060

9614

10168

10723

11278

11834

12389

12944

13500

250

260

270

280

290

300

310

320

330

340

350

360

370

380

390

400

410

420

430

440

450

460

13555

14110

14665

15219

15773

16327

16881

17434

17986

18538

19090

19642

20194

20745

21297

21848

22400

22952

23504

24057

24610

25164

13611

14166

14720

15275

15829

16383

16936

17489

18041

18594

19146

19697

20249

20800

21352

21903

22455

23007

23559

24112

24665

25220

13666

14221

14776

15330

15884

16438

16991

17544

18097

18649

19201

19753

20304

20855

21407

21958

22510

23062

23614

24167

24721

25275

13722

14277

14831

15386

15940

16493

17046

17599

18152

18704

19256

19808

20359

20911

21462

22014

22565

23117

23670

24223

24776

25331

13777

14332

14887

15441

15995

16549

17102

17655

18207

18759

19311

19863

20414

20966

21517

22069

22620

23172

23725

24278

24832

25386

13833

14388

14942

15496

16050

16604

17157

17710

18262

18814

19366

19918

20469

21021

21572

22124

22676

23228

23780

24333

24887

25442

13888

14443

14998

15552

16106

16659

17212

17765

18318

18870

19422

19973

20525

21076

21627

22179

22731

23283

23835

24389

24943

25497

13944

14499

15053

15607

16161

16715

17268

17820

18373

18925

19477

20028

20580

21131

21683

22234

22786

23338

23891

24444

24998

25553

13999

14554

15109

15663

16216

16770

17323

17876

18428

18980

19532

20083

20635

21186

21738

22289

22841

23393

23946

24499

25053

25608

14055

14609

15164

15718

16272

16825

17378

17931

18483

19035

19587

20139

20690

21241

21793

22345

22896

23449

24001

24555

25109

25664

Page 7

Control Parameters

männer HCS Hot Runner Temperature Control Systems

männer HCS hot runner temperature control systems

(for example, HCS-TS, HCS 2) use a two-position PID

controller. Its monitoring characteristics are comprised of

proportional, differential and integral control actions.

Proportional band Xp

(Pb1)

Derivative (rate) Tv1

The proportional control action delivers

a control output, which is an undelayed

signal that is proportional to the error.

A small error results in a low control

output, which, however, is not sufficient

to correct the error.

Large proportional action

The derivative control action calculates

the rate of change of the error and

delivers a control output. This signal

is proportional to the rate of change of the error. If the process output

moves away from the setpoint, the

control output increases more rapidly

Large derivative action

IMPORTANT: Control parameters should only

be changed if a desired improvement in quality

cannot be achieved with self-optimization.

The sensitivity of the controller and,

thus, the adjustment to the process are

defined by the gain factor. The inverse

value of the gain is called the proportional band (Xp). The proportional band can

be set to a value from 0.0% to 999.0%.

Fast response by the controller;

possible oscillations

compared to that of a proportional

controller. This is called predictive control. The characteristic parameter is the

derivative (rate) Tv, which can be set to

a value from 0.0 to 999.0 seconds.

Fast response to temperature changes

Integral (reset) Tn1

Cycle time T1

Duty cycle

Small derivative action

The integral control action calculates

the sum of all past errors and delivers

a control output. The integral controller adds together small deviations

between the setpoint and actual process output and increases or decreases

the control output until the deviation is

Large integral action

Small integral action

The cycle time is the time required

to complete the heating and pause

actions for a specific power setting.

The cycle time can be set to a value

from 0.0 to 999.0 seconds.

A duty cycle of 100% means that full

power is delivered to the heating

circuit; a duty cycle of 50% means that

Slow response to temperature changes;

may result in overshoot during start-up

zero. The control output is maintained

until a new error arises. The characteristic parameter is the reset time Tv,

which can be set to a value from 0.0 to

999.0 seconds.

Slow, damped response

Faster response; may result in oscillations

Example: if the cycle time is 60 seconds

and the power setting is 50%, the

heating elements are on for 30 seconds

and then off for 30 seconds.

only half of the power is delivered.

The duty cycle can be set to a value

between 0% and 100%.

Page 8

Otto Männer GmbH

Unter Gereuth 9-11

79353 Bahlingen a. K.

Germany

Phone +49 (0) 7663 609-0

Fax +49 (0) 7663 609-299

info@maenner-group.com

www.maenner-group.com

02/12. Technical specifications subject to change. Actual colors may differ.

Loading...

Loading...