Page 1

OWNER'S MANUAL

MANLEY

TNT

MICROPHONE

PREAMPLIFIER

MANLEY

LABORATORIES, INC.

MANLEY LABORATORIES, INC.

13880 MAGNOLIA AVE.

CHINO, CA. 91710

TEL: (909) 627-4256

FAX: (909) 628-2482

Page 2

CONTENTS

SECTION PAGE

INTRODUCTION 3

BACK PANEL & CONNECTING 4

FRONT PANEL 5,6,7,8

CREDITS 8

THE MASSIVE PASSIVE

BEGINNINGS, THE SUPER PULTEC 9

THE PASSIVE PARAMETRIC 10

WHY PASSIVE, WHY PARALLEL 11

PHASE SHIFT, WHY TUBES 12

CURVES 13 to16

TUBE LOCATIONS, ETC 17, 18

EQUALIZING

EQUALIZERS (GENERAL) 19

EQUALIZER TECHNIQUES 20 to 24

TRANSLATIONS 25

TROUBLESHOOTING 26, 27

MAINS CONNECTIONS 28

SPECIFICATIONS 29

WARRANTY 30

WARRANTY REGISTRATION 31

APPENDIX 1 - EXAMPLE SETTINGS 32

APPENDIX 1 - TEMPLATE FOR STORING SETTINGS 33

Page 3

THANK YOU !

For choosing the Manley TNT Microphone Preamplifier. The name of this mic preamplifier “TNT” is a

reference to the two different channels, one that is

for a variety of preamps as a means of getting a variety of sounds and tones from the start. Of course, mic

selection and mic position can produce a wider variety of colors, but once that is locked in, the preamp

choice can be a significant factor in some sessions and that subtle difference in others.

The designer considers the reference to TNT (the explosive) might be a bit apropos too. Both share a

reputation as a relatively powerful and particularly useful tool for the ‘difficult’ tasks while being relatively

safe (well, much safer and more stable than Nitro-Glycerine, its main component). Manley would like to

thank Steve Pogact for suggesting the name.

Most mic preamps are stereo, which is fine when one needs to record true stereo with matched mics (few

are), but the most common situations where one can compare and choose a particular preamp, are the often

the more relaxed overdubs. These are typically single miked or multi-miked where each mic might be a

different type and different distance from the source. So the TNT might be the ideal cost-effective solution

for these situations – maximum choices & minimum cost and rack space and where you need to know you

are using the one of the best.

Some people use the TNT simply because it offers two different sounds and is different from their other

preamps. Some people choose it because each channel may be a contender for the highest caliber preamp

in either the “tube category” or “solid-state category” and they demand the best. And some users just like

the unique controls and features. Of course, given a variety of sounds and features, different people will

gravitate to one side or the other and one feature or another. This is to be expected and probably encouraged,

however let us emphasize that we encourage you to dig in, use it to its fullest and form you own opinions

and methods that work for you.

INTRODUCTION

Tube and the other No Tube. We see people today hungry

GENERAL NOTES

LOCATION & VENTILATION

The Manley TNT must be installed in a stable location with ample ventilation. It is recommended, if this

unit is rack mounted, that you allow enough clearance on the top of the unit such that a constant flow of

air can move through the ventilation holes. Airflow is primarily through the back panel vents and out

through the top.

You should also not mount the TNT where there is likely to be strong magnetic fields such as directly over

or under power amplifiers or large power consuming devices. The other gear's fuse values tend to give a

hint of whether it draws major power and is likely to create a bigger magnetic field. Magnetic fields might

cause a hum in the preamp and occasionally you may need to experiment with placement in the rack to

eliminate the hum. In most situations it should be quiet and trouble free.

WATER & MOISTURE

As with any electrical equipment, this equipment should not be used near water or moisture.

SERVICING

The user should not attempt to service this unit beyond that described in the owner's manual.

Refer all servicing to your dealer or Manley Laboratories. The factory technicians are available for

questions by phone (909) 627-4256, or (928) 425-9333 or by email at <service@manleylabs.com>. Fill

in your warranty card! Check the manual - Your question is probably anticipated within these pages......

3

Page 4

THE BACK PANEL

SERIALNUMBER

+4UNBALANCED

+4 BAL

-10UNBALANCED

OUTPUT MODE

MANLEY LABORA TORIES, INC

13880 MAGNOLIA AVE., CHINO, CA 91710

PHONE (909) 627-4256 F AX(909) 628-2482

SERIAL NUMBER

FUSE 1A @ 1 17V

FUSE .5A @ 220V

www.manleylabs.com

+4UNBALANCED

CAUTION -RISK OF ELECTRIC SHOCK. DO

NOT OPEN. REFER SERVICING TO

CAUTION: RISK OF ELECTRIC SHOCK. DO

QUALIFIEDPERSONNEL ONLY

TRANSFORMER & XLR

DESIGNEDBY HUTCH

TNT

DOES NOT BYP ASS

TRANSFORMER

ISOLATED

CHANNEL 2

OUTPUT

TRANSFORMERLESS

OUTPUT

OUTPUT

MIC

MIC

N9512422

1

TRANSFORMERLESS

OUTPUT

+4 UNBALANCED

OUTPUT

DESIGNED BY HUTCH

OUTPUT

TRANSFORMER & XLR

BYPASS

DOES NOT BYP ASS

TRANSFORMER & XLR

OUTPUT MODE

+4 UNBALANCED

+4 BAL

-10 UNBALANCED

MANLEY LABORA TORIES INC

.

TNT

www.manleylabs.com

N9512423

OUTPUT MODE

+4 UNBALANCED

-10 UNBALANCED

10

+4 BAL

+4 UNBALANCED

OUTPUT

TRANSFORMER & XLR

BYPASS

67

DESIGNED BY HUTCH

5

4

SERIAL NUMBER

MANLEY LABORA TORIES INC

13880 MAGNOLIA AVE., CHINO, CA 91710

PHONE (909) 627-4256 F AX(909) 628-2482

23

.

1

FUSE 1A @ 1 17V

FUSE .5A @ 220V

CAUTION: RISK OF ELECTRIC SHOCK. DO

NOT OPEN. REFER SERVICING TO

QUALIFIEDPERSONNEL ONLY

8

TRANSFORMERLESS

OUTPUT

DOES NOT BYP ASS

TRANSFORMER & XLR

9

First connect all the cables, then turn on the power, wait 30 seconds, then have fun, as if we had to tell you....

1) POWER CONNECTOR. First verify the POWER SWITCH on the front panel is off (CCW). Use the power cable supplied with your

TNT. One end goes here and the other end goes to the wall outlet. You know all this.

2) VOLTAGE LABEL (ON SERIAL STICKER). Just check that it indicates the same voltage as is normal in your country. It should

be. If it says 120V and your country is 220V, then call your dealer up. If it says 120V and you expect 110 it should work fine.

3) FUSE. Unplug the power cable first. The Fuse Cap needs a push then turn a quarter twist CCW to pull off. Fuses are meant to "blow"

when an electrical problem occurs and is essentially a safety device to prevent fires, shocks and big repair bills. Only replace it if it has

"blown" and only with the same value and type (2A slow-blow for 120V, 1A slow-blow for 220V). A blown fuse either looks blackened

internally or the little wire inside looks broken. A blown fuse will prevent all the LEDS from lighting and will prevent any power and audio.

4) TUBE CHANNEL XLR JACK INPUT. ( Left) Accepts balanced or unbalanced sources. The pin out is as follows: PIN 2 = Positive

= Hot, PIN 3 = Negative = Low or ground, PIN 1 = Chassis Ground. Be sure that the PIN 3 is connected to the negative or ground and

not "open" or a 6dB loss or loss of signal will happen. This input is transformer coupled. Switching PHANTOM POWER on, puts

approximately 48 volts via 6.8k resistors (double regulated 46-47 vdc typical) on pins 2&3.

5) TUBE CHANNEL XLR JACK OUTPUT. (Channel One or Left) Transformer Balanced and Floating. Only for +4dBu pro levels.

The pin out is as above. NOTE: Inserting a 1/4" plug into the "UNBALANCED OUTPUT" jack disables this XLR output !

6) TUBE CHANNEL PHONE JACK OUTPUT. (Channel One or Left) Unbalanced output only. Factory set-up for +4dBu pro levels

and mono or 2 conductor plugs. NOTE: Inserting a 1/4" plug into this jack disables the XLR output because it switches the transformer

out of the circuit to prevent any loading. This 1/4" output should be used if the goal is to record as clean and tight a low end as possible

from tubes. This jack also should be considered if the destination or cables present a difficult load for the XLR transformer output (high

capacitance from long cables, or low resistance from 600 ohm vintage gear or more transformers).

7) COOL CHANNEL XLR JACK INPUT. ( Left) Accepts balanced or unbalanced sources. The pin out is as follows: PIN 2 = Positive

= Hot, PIN 3 = Negative = Low or ground, PIN 1 = Chassis Ground. Be sure that the PIN 3 is connected to the negative or ground and

not "open" or a 6dB loss or loss of signal will happen. This input is transformer coupled. Switching PHANTOM POWER on, puts

approximately 48 volts via 6.8k resistors (double regulated 46-47 vdc typical) on pins 2&3.

8) COOL CHANNEL XLR JACK OUTPUT. (Channel One or Left) Transformer Balanced and Floating. The pin out is as above. The

1/4" jack has no effect on this XLR (both can be used at once) but the OUTPUT MODE switch should be properly set (generally +4

Balanced for maximum headroom) however it is worth mentioning that a transformer floating output is equally happy driving balanced

or unbalanced inputs. But we will remind you that most unbalanced inputs are designed for -10 levels so in order for TNT's levels and

LEDs towork as designed, if the desination is -10 consumer level the switch should be set for "-10 unbalanced" (usually ;>)

9) COOL CHANNEL PHONE JACK OUTPUT. (Channel One or Left) Balanced or Unbalanced output so a 2way or 3way(stereo)

plug can be used. Factory set-up for +4dBu pro levels. This 1/4" output should be used if the goal is to record as clean and tight a low

end as possible (transformerless). This jack also should be considered if the destination or cables present a difficult load for the XLR

transformer output (high capacitance from long cables, or low resistance from 600 ohm vintage gear or more transformers). The OUTPUT

MODE switch should be properly set (depending on the destination and wires) because these outputs do not use cross-coupled op-amps

and are designed to properly drive either balanced or unbalanced systems providing the switch is properly set.

10) OUTPUT MODE SWITCH. Sets both the output level and whether both the XLR and 1/4" jack are balanced or unbalanced.

Normally this switch should be in the "+4 BAL" or Center position. Some PRO gear may prefer the "+4 unbalanced" position but this

style of input is becoming increasingly rare, however because the TNT loses 6 dB of headroom in this mode, it can be used for creative

"drive" cleverness. Similarly the "-10 UNBALANCED" mode loses another 6 dB of headroom when 'mismatched' in typical +4 balanced

systems. However, this mode is more likely to find service because a fair amount of semi-pro and consumer gear with RCA jack inputs

are compatible with this level and 1/4" plug to RCA plug adapters are very common.

4

Page 5

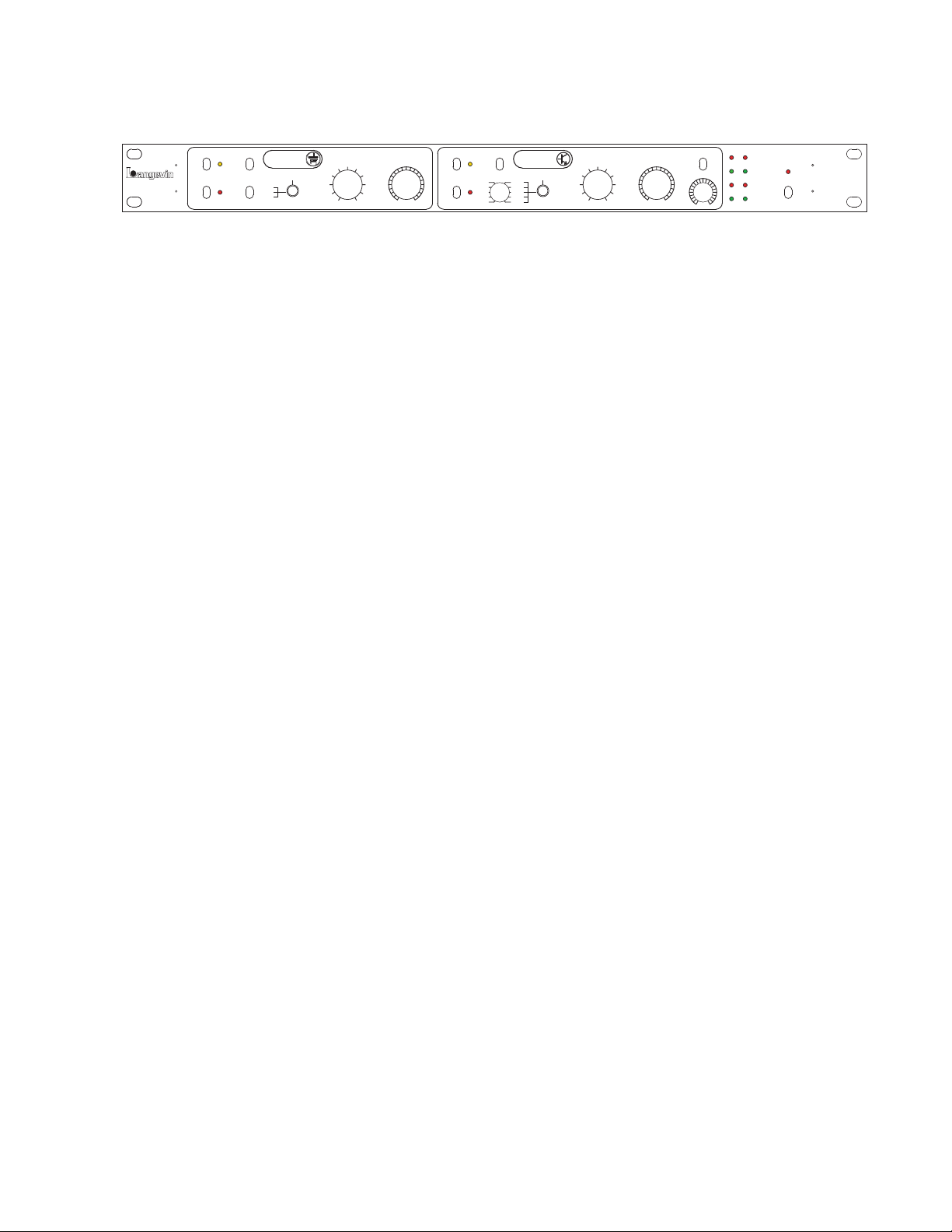

THE FRONT PANEL

5/5

/

6,*

287387

,1387

32:(5

21

2))

V

V

&/($1

,521

75,0*$,1

,167580(17

),/7(5

+]

+]

)/$7

3+$1720

3+$6(

21

2))

75,0*$,1

,167580(17

0(*

0(*

.

.

),/7(5

+]

)/$7

3+$1720

3+$6(

21

2))

F

.

0

0

.

.

0

0

%<0$1/(</$%6

78%(

&+$11(/

&22/

&+$11(/

&2/25

,03('$1&(

7

,03('$1&(

7

3

%

3

%

3

%

3

%

1

3

5

4

2

679

8

10

11 12

13

141516 1817

TUBE CHANNEL

1) PHANTOM POWER: Toggle up turns 48 volt phantom power on (and the amber LED) which is needed for most FET condensor

microphones. Turn your monitors down because it may make a big 'POP'. Avoid patching the mic lines if phantom is turned on. Some

ribbon mics can be damaged if phantom is on and cables or patches are changed, so don't use phantom with ribbons - or be careful.

2) PHASE SWITCH: Reverses the polarity (180 degrees) of the microphone signal. Sometimes needed in situations where two mics

are used and sometimes useful for vocals when headphones are used. Red LED is ON when PHASE switch is engaged.

3) HIGH PASS FILTER: Toggle up engages a basic 80 Hz filter, Used to remove excess lows, rumble and some air conditioning noise.

4) IMPEDANCE SWITCH: 3 position toggle changes the loading characteristics presented to the microphone or instrument. This can

subtly change the sound of the mic. "2400" ohms is considered normal or typical. "10K" is a lighter load and may be appropriate for some

sounds and often for ribbon mics. "600" ohms may tighten up the lows on some mics. Unlike many Impedance switches, the volume will

not change by 6 dB, and will stay relatively constant making comparisons easier. The numbers to the right of the switch indicate the

impedance given on the 1/4" Instrument Input, where 1 Meg simulateds a typical amp. Higher usually means brighter.

5) INSTRUMENT INPUT: Plug your guitar or bass in here. A plug inserted in this jack will disable the XLR Microphone Input.

6) GAIN SWITCH: This rotary switch sets the gain for the first amplification stage. The steps range from +20 dB to +70 dB and when

used with the TRIM (below) provides a range of +10 to +80 dB of gain. The bottom two LEDs (see #17) indicate "signal present" and

"overload" of this first stage. If internal jumpers are properly set, one can turn this switch higher for overdrive and turn down the GAIN

TRIM to optimise the level again. If the jumpers are set for "clean" then it may be difficult to overdrive this stage.

7) GAIN TRIM POT: This pot is typically used to finely adjust the gain as needed for the recording device or converter. The two top

LEDs are associated with this knob, and are intended to help set optimal levels, which are well (about 10dB) below when the TNT clips.

COOL CHANNEL

8) PHANTOM POWER: Toggle up turns 48 volt phantom power on (and the amber LED) which is needed for most FET condensor

microphones. Turn your monitors down because it may make a big 'POP'. Avoid patching the mic lines if phantom is turned on. Some

ribbon mics can be damaged if phantom is on and cables or patches are changed, so don't use phantom with ribbons - or be careful.

9) PHASE SWITCH: Reverses the polarity (180 degrees) of the output signal.

10) HIGH PASS FILTER: Toggle middle position is a 120 Hz HP filter, Toggle up engages a less drastic 60 Hz filter.

11) IMPEDANCE SWITCH: This is a 5 position rotary switch that both controls the loading on a connected microphone and internally

directs and shares the signal between two different preamp circuits or topologies. The least amount of loading is the 2 MEG setting and

the next setting marked 2K (2000 ohms) might be considered traditional or typical (most preamps were designed for 2000 to 3000 ohms).

Both of these two only use the cascode FET preamp. The next two settings share both the cascode FET preamp and the current mode

preamp, 600 and 300. The final setting, 300C, only uses the current mode preamp and relays bypass the sub-circuit used for mixing the

preamps, so it has some purist function.

12) INSTRUMENT INPUT: Plug your guitar or bass in here. A plug inserted in this jack will disable the XLR Microphone Input.

13) GAIN SWITCH: This rotary switch sets the gain for the first amplification stage. The steps range from +20 dB to +70 dB and when

used with the TRIM (below) provides a range of +10 to +80 dB of gain. The bottom two LEDs (see #17) indicate "signal present" and

"overload" of this first stage. Use this switch in conjunction with the 60's-70's switch and the LEDs to control the amount of color or

distortion. In this situation the GAIN SWITCH becomes a "drive" control too.

14) GAIN TRIM POT: This pot is typically used to finely adjust the gain as needed for the recording device or converter. The two top

LEDs are associated with this knob, and are intended to help set optimal levels, which are well (about 10dB) below when the TNT clips.

15) COLOR SWITCH: With the switch in 60's or 70's, a circuit is added that is designed to clip in an interesting way that somewhat

simulates the way magnetic tape, and guitar amps clip. Use the GAIN SWITCH to control the depth of distortion. In general best results

are obtained when the desired effect is subtle and this circuit is just lightly driven and obvious distortion is minimal. Of course, sometimes

more drastic effects are desired and the GAIN SWITCH can be turned up. Thicker distortion may take several processors.

The 60's - 70's switch can alter the highs depending on drive levels.

16) IRON EFFECT: This knob adjusts how audible the output transformer may be from exagerated at +3 to near zero at 0 and even

becoming inverse or the opposite of a transformer at -1. This control is essentially "out-of-circuit" with the knob straight up (12:00) (like

an EQ). The knob controls several subtle effects including low frequency level, low frequency distortion, high frequency level and high

frequency dynamics. This control is often subtle and somewhat signal dependent.

17) LED LEVEL INDICATORS: Simple indicators to show signal presence, first stage clipping, and more or less appropriate levels

for the next device. See page 000 for more deatails.

18) POWER SWITCH: With this switch UP, LEDs should come on and maybe sounds might come out the back XLRs......

5

Page 6

6

Page 7

7

Page 8

BEGINNINGS

The TNT project began due to requests from fans of the

SLAM! and in particular Lynn Fuston of 3D Audio Inc.

The request was simply “Can you bring out just the

SLAM! Mic preamps without the Limiters and other

features. Then came the 3D Audio bulletin board "Dream

Pre-Your ideas wanted" thread which had a lot of great

ideas and diverse opinions. Perhaps the most obvious

theme was that engineers were now using several mic

preamps at their disposal for a variety of colors like they

had always done with mics. This was actually a pretty

new trend in '92. How about a box with a few different

preamp topologies for different sounds?

At the 3D Preamp Summit, the topic of "vintage-style"

electronics came up, not because of huge desire from the

engineers but more as a designer topic relating the

headaches of recreating transformers and obsolete parts

accurate enough to be comparable to the original.

However where there was interest in old school style was

when the recording engineers began to talk about how

they did those classic 60's sessions, and the focus was on

production technique and war stories rather than

components and gear. Maybe the engineers were

saturated with recreations of old gear and were craving

both the magic of old sessions and yet new exciting toys

to do their job with tomorrow. A bit of both.

We began to experiment with some simple discrete

preamp design concepts and breadboarded a few

approaches. Hutch had also had developed the "Rapture"

gain stage intended for a proposed digital converter that

was impressively un-colored and which became the

standard against which other 'experiments' were

compared.

Then the 3D mic preamp summit "Preamps in Paradise"

happened January 2004. This was a historic event in

Tennessee with a panel of 10 notable preamp designers,

and 7-10 famous engineers known with reputations as

preamp connoisseurs. Amongst fascinating stories and

a sharing of approaches, this designer was hearing a

chorus of requests, a short list that included “variable

impedance – but minus the typical gain changes” and

“some new useful control or knob”. Up to then, the solid

state preamp we were working on was envisioned as a

typical minimalist ‘2 knob’ discrete channel in some

ways similar to the tube side borrowed from SLAM!.

But the engineers were asking for more control, and

were describing approaches based on sonic

characteristics such as clean / not so clean, bright / not

so bright, transformer or transformerless and this

resonated with the designer’s session experience.

Designers talk about discrete topologies, tube types and

transformer details but recording engineers talk about

sounds and controls and session techniques.

The initial concept of the TNT was to put two very

different mic preamp technologies in the same box, and

that each were to be as simple as "plug in a mic and it

sounds fine", without a lot of controls to get in the way.

In the end, the TNT did get new features and controls

such as the IRON knob, 60's - 70's switch and its unique

impedance control. And these were largely due to

engineer's requests from the "Preamps in Paradise"

event.

So we went back to the ol' drawing board and back to the

lab bench and experimented with a variety of circuits

and topologies, but this time holding truer to the end

result the user would appreciate rather than the internal

workings that might have buzz word appeal. Already the

SLAM! preamp was not "all-tube" but more of a hybrid

FET-Tube cascode, so why stick to "all-discrete" or

"vintage-clone" when the engineers seemed to be just

concerned with sound or tone and occasionally hoped

they could get a few new controls if possible.

The TNT solid state side evolved into a mix of discrete,

and op-amps plus it ended up with the Rapture Amp for

the line driver. Why this mix? Just our choice based on

listening comparisons where our choices generally

favored the cleaner or most true to the source as a base.

The users could always add stuff that gave some color

or texture onto that base and we provided a few too.

We did come up with a few controls that gave some

possibilities for "tints" or "flavors" that could be dialed

in. For the most part these were designed to be subtle

rather than drastic because the TNT is a mic preamp and

not an EQ or a typical processor. In fact even the

IMPEDANCE switches were designed to not mangle

the sound in unintended ways - they should be "just"

impedance controls without baggage. Some users may

expect bigger sonic changes from huge impedance

changes or major audible effects from varying the IRON

content, but the folklore surrounding those ideas is

maybe more dramatic than reality. These controls were

designed to reflect reality which seemed appropriate on

a high end Mic Pre and tend to be more like tweaks and

trims. And this was more in-line with the original

concept of a basic good plug in a mic and go preamp.

8

Page 9

The TNT was getting interesting. We now had a tube

preamp from the SLAM! on one side plus two solid state

preamps working together on the other side, and each of

those 3 circuits had a unique sound or subtle flavor yet

there was some common theme or style.

The tube channel is based on a JFET / Vacuum Tube

Triode cascode circuit that is quite unusual in that it is

a blend of old and new components. The cascoded

combination allows for high gain, low noise and low

distortion without using negative feedback.

On the solid state channel, one of the preamps also uses

JFETs in a cascode topology. The high impedance

circuit operates in the voltage mode. The ideal voltage

amplifier would have infinite input impedance and the

current flow would be zero. We use a paralleled cascaded

ultra-low-noise FET / op-amp circuits and the TNT

requires a pair of those hybrids for balancing (8 discrete

matched FETs). There are a few interesting twists here

too. When phantom power is engaged, it uses the

conventional 6.8 k-ohm phantom power resistors plus

the usual DC blocking capacitors. So even if the

impedance switch is set to 2 Meg Ohms, the phantom

circuit limits the impedance down to about 14 kohms.

But if phantom is turned off, TNT removes those

resistors (rather than switching them to ground, as is

standard procedure) and bypasses the DC blocking

caps, so that you truly have 2 meg input impedance and

DC coupling restored. And no free lunch here either.

Compared to the current mode amplifier, the voltage

mode amplifier typically tends to have opposite

characteristics in terms of its strengths and weaknesses.

The low impedance circuit is based on a special Lundahl

transformer designed to operate in the current mode.

This allows the transformer to work down to near DC

yet be very small physically. This was paired with an

ultra-low noise, ultra-low distortion op-amp that won in

our listening tests.

By combining the JFET and Current mode preamps we

were able to create a variable impedance that uniquely

sensed and amplified both voltage and current. And this

in turn provided much better gain consistancy while

usually sounding a bit better than either approach alone.

In other words the volume didn't jump or shift as the

impedance control was changed unlike most (or all)

other approaches. Some switch transformer taps, but

transformer frequency response is very source dependent.

And some preamps had 20 dB gain changes as the

impedance knob was adjusted.

Now that users can accurately hear and compare the

effect of variable impedance without huge gain changes

and without significant frequency response changes, it

becomes truly interesting to hear what effects there are.

In most cases these effects are not life changing. Even

where low impedance settings seem to affect the damping

or tightness a dynamic or ribbon mic might exhibit, one

then may be faced with an unfamiliar sound from a

familiar mic. This may be a good thing sometimes, but

often one picks a familiar mic for its familiar sound. And

one may hear similarly questionable highs in the high

impedance settings. One might hear excess sibilance or

harshness that may be due more to cables and cable

distance than anything else. In the end, one may be most

comfortable with the two middle settings of 600 and

2400 as the idea of extreme impedances gradually lose

appeal.

Maybe the TNT might be viewed as a bit of a mythbuster in regards to "variable impedance". Yes, it is

sometimes useful - but can often be subtle - not exactly

the most important feature for a mic preamp.

And then the basic premise of a tube preamp and solid

state preamp being very different sounding animals

might be a myth too. At one time we had both preamps

tuned and adjusted to be extremely clean and transparent.

One might guess that two transparent gain stages

regardless of the technologies might sound the same,

which was essentially inaudible. We had to go backward

and re-introduce some of the "flaws" to recreate some of

the creative differences that we all expected. We added

some internal jumpers that essentially un-trim the tube

bias trimmer pots that are tweaked to set up minimum

distortion.

Same thing with the IRON control..... So much has been

said about the sound of transformers lately that many

people expect that one component to almost be responsible

for every products signature sound - wrong ! Sorry

another myth. Most modern transformers are pretty

transparent when used properly.

In fact, we had to use several techniques just to make the

IRON control 'audible' including designing the

transformer with unusually low permeability laminations,

driving it with a non-optimum source, and forcing DC

into a tertiary winding to create more distortions. In other

words it was a bit of a fight to make it audible enough to

wrap a control circuit around it.

9

Page 10

Perhaps it is because those near opposite characters of

the two circuits, that when combined or blended the

audible benefits and strengths of each prevail, while the

weaknesses of each are minimized. Of course, the better

each circuit is optimized, the closer they tend to meet in

the middle (transparency). Perhaps it is because the

approach of respecting both voltage and current, it

results in a form of optimal power transfer. Optimal

power transfer is a very old topic in electronics and it

relates to the old 600 ohm impedances pro audio inherited

from the telephone industry and the 75 ohm terminations

we need to be concerned with for word clock and video

lines. Maybe with complex sources, there is valuable

information carried both in voltage and in current and

maybe most mic pre inputs are not as simple as a basic

resistor. In other words, to some degree a typical

microphone is a complex source (especially dynamic,

ribbon and transformer coupled condensor mics) and a

typical mic preamp input may also be a complex load

(especially if it is transformer coupled) and the cable and

connections between the two might also be viewed as a

combination of resistance, capacitance, inductance and

distance. So maybe it is all too complex to grasp without

some serious computer modelling, but maybe it can be

easy enough just to hear in some situations - and we''ll

leave that up to you.

We would like to speculate that one of the complexities

that you might experience will be cable length. While we

were designing the TNT we noticed excess high frequency

sibilence coming in at the highest impedance settings.

We finally traced it to the mic cables that we were using.

If we doubled the length, the problem doubled and if we

used a very short cable the problem disappeared. And

the problem wasn't apparent at low impedance settings.

OK but why? Here is where we have to speculate.

At low Z settings, it may be akin to our old 600 ohm

terminated lines that pro audio inherited from the

telephone industry. And that standard was set up to

reduce echoes in early long distance lines. It also

resembles the 50 ohm or 75 ohm terminated lines used

for video and word clock where cable reflections impact

high frequencies. Normally we don't consider audio

frequency cable reflections to be a concern because they

don't seem to affect the 20 kHz frequency response or

square waves on our 'scopes. So our speculation might

be a question. How far do these cable reflections need to

decay (in dBs given that -60 dB is 1/1000) before they

do not intersect with our abilities to perceive transients?

Or how many microseconds of reflections and down to

what dB? Just use a shorter cable.

Impedance Issues and Microphones

OK, the above might be a bit of technical mumbo-jumbo

and what you really want to know is what to expect and

listen for when you change the impedance switch in your

session. Simply, at very high impedance settings, there

are usually a little more highs. At low impedance

settings, with dynamic and ribbon mics the bottom often

tightens up. In the middle impedance settings, the preamp

may sound closest to what you have grown to expect

with that mic because most mic preamps are medium

impedance and typically 1000 – 3000 ohms.

With high impedance settings, one may be affecting the

mic and cable in a few ways. First, with transformer

coupled mics like most dynamic, ribbon and tube

condenser mics, one might be setting up a high frequency

peak in the mic’s transformer that may have been

intended for 1 kohm to 3 kohm preamp impedances. The

opposite is also common, where very low impedances

may cause the transformer to roll-off highs earlier than

the designer intended (yeah, but its your mic and your

session, so choose the setting with your ears). The other

effect, goes back to that rambling about cables and time

domain effects. Listen carefully for excessive sibilance

and what might be described as an artificial harshness,

and what perhaps the most finely honed ears will hear as

time-smearing in the top octaves. This effect is directly

related to cable type and length, and once you lock into

it, you can prove it by doubling (or halving) the cable

length. Even better is moving the TNT into the studio

once you have your settings, and using a 4 to 8 foot cable

from the mic to the preamp. It seems puny low level mic

signals are more fragile to these effects than hotter line

level (and robust line driver driven) signals but we don’t

know why. Give it a try. If this seems a bit inconvenient

for level tweaks, add a simple passive variable attenuator

(fader or pot) in the control room near your converter (if

it has inconvenient input level adjustments) if you are a

purist, or use the compressor or EQ gain controls, if

you’re not. The TNT has quite a bit of headroom (except

in 60’s / 70’s mode) so there won’t be much chance of

overloading it and the real thing to keep an eagle eye on

is the analog to digital converter at the end of the chain

Away from the extremes, the 2K (2000 ohms) setting

represents the standard impedance of most mic preamps

and what most microphones are designed to drive. In

other words, its safe, and maybe a bit ‘vanilla’ and this

isn’t a bad thing. The 600 ohm setting is also pretty safe

and may have some advantages because it gets closer to

a 50/50 blend of voltage and current mode preamps.

10

Page 11

At very low impedance settings with dynamic and

ribbon mics another effect can come into play. Damping

is a term normally associated with speakers that refers

to the fact that a dynamic speaker comes to rest faster

and is better controlled when connected to a very low

impedance amp. (It was one of the biggest selling-point

features when early solid-state amps with tons of negative

feedback first came out.) Damping often has a dramatic

effect on a speaker’s frequency response and is one

reason why some speakers work better with solid state

and some better with tube amps (they were designed to,

or what they were designed with). A similar effect often

happens with dynamic mics and the bottom tightens up

at low impedances. Whether this is desirable tends to

depend on whether you are aiming for a tight and

probably ‘truer-to-the-source’ sound or the sound of the

mic that you and the world is more familiar with and

might be viewed as more authentic or traditional. You

might even use the tight 300 ohm settings for tubby

instruments and the 2K setting for drier sources and

mics.

To complicate matters further, it depends on the mic.

Modern FET condenser direct coupled (transformerless)

mics are mostly immune to whatever setting impedance

you select, (though you might isolate some of those cable

and preamp circuit effects described above) so expect

generally very subtle or negligible differences. At worst,

with loud sources and lowest impedances you might

introduce early clipping with the occasional FET

condenser mic. Tube condenser mics are fairly immune

but the impedance may affect the frequency response of

the transformer. And with ribbon mics, one concern

might be getting enough highs to start with, so you might

want to especially watch out for losing highs while you

focus on the tighter bottom with low impedances. But

the good news is that ribbon mics tend to be famously

forgiving when boosting the highs with a good EQ so it

may be easy to “get the cake and eat it” this time.

And for those who just don’t want to be bogged down by

any technical issues and complications: you are in luck

again – just turn the knob and pick the setting that

sounds best for this track. In fact, this is the best advice

for those that love all the technical explanations too, and

when you get down to the session, the most important

thing is to listen and choose based on the heart and the

tapping foot rather than the intellect and some words in

a manual or web-site. Remember the music, remember

to listen. The old adage remains valid “If it sounds good,

it is good”.

We touched on using the impedance switch by ear and

how the low impedance settings may be tighter in the

lows, the medium impedance settings might be the ticket

for the advantages of blended preamp those settings

represent typical mic pre impedances and how the

highest impedance may be useful for squeezing the last

drop of highs (but not necessarily the most accurate

highs).

One way (not the only way) to approach the

IMPEDANCE switch is to begin at the middle or “600”

setting. Listen to what you get. If the sound strikes you

as OK but already a bit bright, then try the lower

impedance settings. If your first impression is that this

instrument/mic sounds good but a little dark, then try the

higher settings. Quite likely, your first impression is that

it won’t sound exactly OK or good enough, so the best

advice, is that you should be really be out in the studio

adjusting the mic position and you are not at a point

where the subtle effects of adjusting preamp impedance

will help enough. Maybe you started off on the wrong

foot, or wrong mic in this case. You might try approaching

mics the same way as the IMPEDANCE switch. If the

instrument is hard sounding, try a softer sounding mic,

and vice versa. When you have a bright stinging

instrument, maybe you don’t want to use the brightest

mic in the brightest position and coupled to a bright

preamp in its brightest setting, followed with EQ in

maximum “air” settings. The real trick to getting “air”

is letting that track and the others to “breathe”, give it

some room to move, rather than add some electronic

artifacts. It doesn’t take Einstein to suggest sounds or

tones in a song are “relative” (and so is volume).

A proven approach, is first to listen to the instrument in

the studio, walking around, getting a handle on where it

sounds best and how the tone changes around the

instrument. We do that because instrumental projection

isn’t necessarily obvious and because it gives you a

starting point and the information needed to tweak mic

positions. Then one might choose a microphone or 3 and

maybe based on complementary characteristics. We

might also suggest experimenting with mic positions by

ear rather than by the eyes, or ego. One might say the

first task of an engineer is re-creating the sound that the

musician is hearing and intended. The second task might

be understanding the musician intended it to sound

better than what he got in the room and that maybe

something larger than life (as opposed to squashed and

smaller) might be what the sound becomes in the mix.

Some of you laugh and say "Not my clients, not my

mixes!" One can hope.

11

Page 12

The Tube Channel

The left side (T) or channel one, is almost an exact

replica of the SLAM! Mic Preamplifier and audio path.

The only differences are the addition of the Impedance

switch and an additional shunt regulator on the phantom

power. The latter reduces noise and provides a softerstart & off with the phantom power switching – less

thump and less chance of input transformer

magnetization.

After being introduced, the SLAM! Immediately

developed a reputation as one of the best and easiest to

use tube mic pres. It seems to particularly shine on the

traditionally most difficult sources like sax, brass, raspy

vocals and most percussion. It might not be the first

choice for those looking for a dramatically colored

preamp or those looking for gobs of tube-warmth

(distortion) and it isn’t a one-trick-pony that stamps its

own personality on every sound. However, it does have

both an input transformer (Lundahl) and output

transformer (the one we developed for the SLAM!) and

it does have two stages using tubes and it is true classA from input to output, so yeah, it does have some

character and tube-magic, and a tasteful amount of

warmth. In other words, clean but not sterile, and it is

neither flavor-less nor overbearing. Perhaps, the simplest

description from a reviewer both describes this tube

preamp’s ‘sound’ and the designer’s actual intention –

“Just plug in a mic and it sounds great”.

There are twin tube gain stages based on one of most

rave-reviewed hi-fi phono preamps ever, “the Manley

Steelhead”. These gain stages can be described as JFETTube cascode amplifiers. The FET is the first stage to

keep the noise floor low, and the tube provides the bulk

of the voltage gain. The beauty is that the FET and tube

are so arranged to cancel the distortion of the other

(complementary). The topology and balancing of this

circuit has such low distortion that there is no need for

negative feedback, (which might be appreciated by

audiophiles). The circuit is also set up to compensate for

both FET and tube variations and their drift.

This preamp also tends to have a great deal of headroom

in most situations. While one can push the first stage

hard to get some clipping when desired, one really has to

try hard – this preamp wasn’t designed to be an expensive

fuzz-box. On the other hand, this is why it tends to work

so well with difficult complex-wave sources and why it

succeeds as a “plug the mic in and hit record” preamp.

Are there any tricks to using it, anything in particular to

be concerned about or suggestions about its care and

feeding? Practically none. Set the GAIN TRIM knob to

near the middle or straight up as a starting point, turn the

monitors down when plugging in a mic cable or switching

phantom on or off (as usual), adjust the GAIN rotary

switch to get an good level, hit record. The 4 LEDs on

the far right are intended as a rough starting point to set

that “good level” but there is ample headroom and low

noise in the preamp that the LEDs mostly serve as

‘signal present’ and ‘overload indicators’.

The IMPEDANCE switch can be set to taste. Probably

the 4K setting may be the brightest or hardest, and the

600 setting the softest or phat-est. It affects the instrument

¼” jack that way too when fed by magnetic pick-ups. It

probably won’t have any effect on guitars or basses that

have internal preamps, or after pedals, and probably no

effect on synths. And on that note, before you write off

a mono preamp as a last resort for synths because they

all have stereo outputs – usually you can plug into just

its left output and get the full sound, save a track, and not

be semi-forced into yet another wide spread left-right

synth sound. In the mix, give it a position, and add some

good convolution reverb (especially authentic rooms),

and maybe it will begin to resemble a real-life instrument

and not a ‘stereo-type’ wash.

There are two outputs, a balanced XLR and an

unbalanced ¼” jack. They sound a bit different and you

can get a little variation of tone that way too. The XLR

has a transformer in the path so it may sound a little

“warmer”, softer, rounder and fatter, more ‘vintage’ or

‘classic’. The ¼” output interrupts the feed to the

transformer and the XLR, and sonically it might be

called a hair brighter, harder, more transparent, or

accurate, depending on who is trying to describe subtle

little details in sounds, what aspect they are focusing on

and what instrument is being fed through it. Of course

life is never quite that simple, there is a variable that can

affect the XLR output and cause all the above

generalizations to be thrown out the window.

Transformers are dependant on the load. For example,

if there is appreciable capacitance in the cable because

it is a few hundred feet long, it’ll probably cause some

high frequency resonance (a few dB boost). label it or

defining hard and fast rules for recording music (other

than to impress your clients, of course).

12

Page 13

Tube Channel Contunued

If the transformer is driving some heavy resistive load

like some piece of vintage gear still set up for 600 ohms

then you can expect some high frequency roll-off and

maybe a shift in the distortion and clipping towards the

tubes and away from the transformer. Maybe the best

approach, is just to listen and compare, pick the best

sounding output for this track, and don’t worry about

trying to label it or defining hard and fast rules for

recording music (other than to impress your clients, of

course).

Tubes will need to be replaced occasionally. Sometimes

they last a few months, sometimes 30 or 40 years so

about the only thing we can tell you is replace them when

they get noisy, microphonic or the preamp stops passing

signal. Generally, there won’t be a major advantage with

new tubes, broken in tubes, or esoteric and rare expensive

tubes and in fact any of these might be worse. Here is the

thing – there are 2 trims for the 2 JFET-Tube stages that

adjust the bias and thus set the distortion null point.

Inserting a fresh tube might require adjusting both of

those trims, and that really should be done by a technician

with a distortion meter for the best results. And there are

another two trimmers that are “fine gain adjustments”

for each stage, and while less critical, should be tweaked

with fresh tubes. In other words, the performance of this

preamp is equally dependent on the tubes and the

trimmer tweaks, and the tweaks are there to get ideal

performance from a variety of tubes and compensate for

drift in a tube over decades. The JFETS used as the first

stage relax the requirements for a super-low-noise, lowmicrophonic, expensive esoteric tube and allow those

pesky trimmers that should optimize for a good variety

of 12AX7A’s.

So the preceding paragraph was aimed at those who like

to buy $300 tubes on ebay, and that’s OK, but most of

us (and Manley Labs) tend to just use the $15 to $30 ones

and get as good performance because we follow the

procedures. And those who just need to change a 12AX7A

and don’t have access to a distortion meter or don’t have

the time, generally, it will work just fine and the difference

between tweaked-out and not, will be negligible – You

see, the circuits are also set up to self-adjust to a large

degree, so you can sweat the details or not, and usually

be OK. And changing tubes is almost as easy as changing

a light bulb, about as easy as changing a 9 volt battery

in stomp-box and a whole lot easier than changing a

transistor or chip, especially if its surface-mount. Your

grandfather probably fixed the family TV any number

of times. Relax.

About the only other “tricks” we might add here are

more general and apply to most preamps and not just the

TNT. Avoid plugging in mics, cables, mic patches, etc

when phantom power is turned on (and especially if the

monitors are up). What can and often does happen is that

one “leg” of the balanced line (Pin 2 or Pin 3) connects

first, which can put a spike of 48 volts through a

transformer and magnetize it. This has been known to

damage ribbon mics and there are usually transformers

in ribbon mics, dynamic mics, many condenser mics and

of course many preamps, the TNT Tube side included.

There are some engineers that like to demagnetize input

transformers on preamps before big sessions. Probably

a small, weak cassette tape-head demagnetizer won’t be

too effective because virtually all mic pre input

transformers are mu-metal shielded, but the bigger pro

head de-magnetizers, carefully and slowly brought near

and away from the transformer is probably a good thing

to do as yearly maintenance. One might also feed in a

strong (say +25 dB) low frequency tone and slowly

decrease its level to zero once in a while and get similar

benefits. As far as those dynamic and ribbon mics and

their transformers, best not to try because they also need

those permanent magnets (in the capsules). It might be

worth checking with the manufacturer on transformer

coupled condenser mics, but probably they would rather

you not take a chance or risk breaking something. So lets

repeat, avoid plugging in mics, mic patches etc with

phantom on so that you never have to worry about it.

And lets also take the devil’s advocate point of view to

balance the issue. Originally phantom power was called

“phantom” for a reason and most consoles of the 70’s

and 80’s (before external mic pres) didn’t have an on-off

switch for phantom power, per channel or even global –

it was always on. For 99% of us who were there, we

always turned down monitors when changing mics, and

we didn’t think to de-mag anything except tape heads

and we occasionally made great sounding records. Back

then, we weren’t looking for ‘air’, ‘warmth’ or ‘loud’,

we were just having fun capturing first takes, hopefully

exciting performances, and experimenting with mic

choice and positions.

A real good trick with mic preamps, console channels,

etc that isn’t mentioned nearly enough has to do with the

PHASE switch. It is relevant here because we expect the

TNT will often be a first choice for vocals and many

simple overdubs. In a single mic situation, you in the

control room probably won’t be able to hear any

difference with the phase switch in one position or the

other so you might write it off as insignificant.

Page 14

Consider the singer, headphones on, and getting a blend

of their voice through bone conduction and those phones.

All too often there is something in the chain with a

polarity problem and it is usually a vintage mic or the

headphones but can also be caused by a wiring mistake

or a power amp. Did you ever get one of those vocalists

that continually complained about her voice in the cans?

Did you try flipping the phase? One way will be thin and

weird and the other will be hopefully better, but only the

person in front of the mic can say. Might be worth

singing into the mic yourself, phones on, before the

session while somebody in the control room flips the

switch for you. And while you’re there, check out that

headphone mix and level, and the room temperature and

creature comforts. This will give you a bit more chance

to work with the talent in the beginning of the session to also see if there is some choice reverb in the phones

that helps her perform and hit those notes. Either that or

spend more time auto-tuning later. These ‘tricks’ are not

only limited to vocal sessions because a lot of times, the

talent is hearing a blend between the live room sound and

the headphone feed, but the benefits of good sound in the

talent’s phones can be subtle, if you as the engineer are

focused on the ‘sounds’ in the control room, because the

benefits tend to be in the performances. One might also

consider that one’s skills as an engineer is often more

related to the performances and hit records that they

have been ‘lucky’ enough to record, than how great the

mix was. Makes one wonder about little things like

phase switches, and using gear versus choosing gear.

As a matter of fact, one can view the TNT as a single

piece of relatively simple gear that offers a fair number

of tints to explore and use. But that is the key! One has

to really dig in and explore the options and approach it

like an instrument with many possibilities. Though it

may be just another preamp that you try for 1 minute and

see if it delivers a sound that you like, it should be

approached as an instrument that needs some time to

learn. After all there is a variety of settings on the Tube

Channel, another bunch of settings to explore on the

Cool Channel and maybe the sound that you are looking

for is really there with a little coaxing in mic choice and

positioning choice and maybe even some coaching of the

talent to get that sound. Maybe one of the biggest tricks

that we can share is that it isn't just the gear, it is how one

uses it. And before that, it is about the source, the

musician, the music and the instrument and the room,

and you working with all those factors before going

crazy with choosing between 8 different preamps. The

preamp does represent many tints, but not prime colors.

More "Techniques" from other sources

For a really great source of tricks and techniques like

these, there are too few books. An Australian engineer,

who worked at Air Studios with Sir George Martin and

even has a forward by him, has written one of the best

books. The author is Michael Paul Stavrou and it is

called “Mixing with your Mind”

www.mixingwithyourmind.com, (Flux Research Pty

Ltd, P.O. Box 397, Mosman NSW 2088 Australia) The

inspiring part is that much of his focus deals with the

counter-intuitive and non-geeky approaches that were

learned the hard way through 20+ years of experience.

For those struggling with technology, it may suggest

that some fresh techniques that reduce technodependence, and for those that “just go for it” it may

enlighten them to very practical acoustic and signal flow

thoughts explained in easy visual metaphors. You may

be approaching the task of recording in one way, and this

book can pull you into a completely opposite alternative,

which of course lets you then roam that entire space

between your preconceptions and his. And because it

really is difficult to describe sounds in ways that

everybody understands, some of the labels and

categorizations tend to be personalized and this makes

for a great read.

Beyond that, it helps to know that "Stav" tends to be a

brilliant recordist who truly gets results on tape that

most of us would be jealous of - so he knows and has

taken the time to share in print - very rare.

On the other hand, we might suggest avoiding the dry

technical literature that seems to be the majority of the

recent texts on recording technology. Those might be

handy if you can make a living debating math minutiae

or you are curious about those chips in the box you

bought. However most of them are almost useless for

both the recording engineer and the gear designers, and

often cloud the real issues rather than help. When it

comes to audio engineering, it mostly comes down to the

ears and making tasteful decisions. It may be more an art

than a science. It is not "paint-by-numbers".

The point is this: If you are hungry for knowledge and

you search books and bulletin boards and magazines, it

all helps. What helps most is advice from guys doing

what you want to do and are experienced in deeply and

(importantly) are getting obviously good sounding results.

Artistic mentorship is at least as valuable as it ever was,

and is a huge advantage if you can get it.

Page 15

THE COOL CHANNEL

Solid State or Right Channel

The No Tubes side of the TNT gives you a range of

colors and might even be considered a contrast to the

Tube side. Or maybe not - If one has strong ideas that

tubes and transistors sound vastly different then the

TNT might be a little unsettling. For what it is worth

both the Tube side and Solid State side of the TNT are

pretty clean representatives of their technologies.

The IRON control may also be subtle in many situations

because it uses the actual output transformer (which

starts off pretty good) rather than a fake simulation just

labeled to suggest a sound. The IRON control practically

removes all audible effects of the real output transformer

in the "0" setting and that can be easily verified by

comparing the ¼” transformerless output to the XLR

transformer output.

On the other hand it is extremely easy to find a variety

of "personality preamps" using tubes (we make a few

too) that all sound different from each other. Similarly

there are many different solid state or discrete sounds. It

largely depends on topologies, parts choice (especially

transformers) and a variety of other choices a desinger

might make (or a cloner might copy).

As a “clean” preamp (CLEAN setting and IRON set

fully counter-clockwise) we think the TNT Cool Channel

may be hard to beat for sheer transparency and lack of

electronic artifacts, especially in the 300 and 600 ohm

impedance settings. It is also designed to be useful as a

fuzz-box or distortion device (60’s or 70’s setting,

INPUT GAIN hot, GAIN TRIM fully counter-clockwise.

It won’t simulate a Marshal stack or analog tape with

VU’s buried deep in the red but it shares some of those

characteristics and might be an alternative sound and at

least sounds better than most preamps driven hard. Or

it can give you a range of subtle flavors just as a basic

preamp with the IMPEDANCE and IRON knobs, and/

or by using the 60’s & 70’s settings but driven lightly

and before obvious distortion. These colors are set up to

be easy and obvious to use, even though they are for the

most part subtle. In fact, considering that this is really

just a Mic Pre, and not a compressor or EQ, it seemed

most appropriate to not go overboard and make it into an

full blown processor, but rather give the user more

control than is usual yet keeping it within a ‘safe’ realm

where it is unlikely one will screw up a recording doing

something that can’t be un-done. That ‘subtlety’ might

be obvious in the IMPEDANCE switch, that unlike

other preamps that may have a 6 dB gain change from

one setting to the next, and again, the TNT is designed

to have maybe one dB of gain change from one extreme

to the other, with most mics. We consider this important

for selecting which impedance to use. Alternatively,

comparing settings with radically different volumes

makes the process near impossible to do especially when

the differences tend to be subtle.

Just a little note on the subtleties of the Impedance and

Iron controls: Maybe other units have more dramatic

changes when you adjust similarly labeled controls and

maybe what you are hearing then is flaws in the

implementations or parts they use. We try not to do that,

and we won’t con you and we did put some effort into

maintaining constant levels as these controls are adjusted.

We also try to maintain similar frequency responses

when impedance is changed, where others don’t. So the

TNT knobs do what they say they do, and don’t add

strange misleading effects (for a change).

The NT preamp starts as 3 gain stages. 2 are identical

and symmetrically used for opposite phases (XLR pin

2 and pin 3, ie; balanced) and are voltage amplifiers like

99% of all mic preamps. Unlike 99%, these voltage

amplifiers are very high impedance (2 meg ohms) and

exhibit very low capacitance and inductance, not that

microphones need or are designed for that light of a load,

but occasionally there are audible benefits. The third

initial gain stage is a transformer input current-mode

amplifier, which might be considered a rare technology

in a mic pre and nearly opposite to the voltage amplifier

topologies. These 3 preamps are variously selected and

combined with the deceptively simple IMPEDANCE

switch. Rather than a resistor that just shorts out the

signal for lower Z, that resistor feeds the current mode

amplifier in the TNT, and the part of the signal that is

normally thrown away is amplified and mixed back in.

On the IMPEDANCE switch there are 5 positions.

Furthest counter-clockwise is the “300C” setting , and

next is the “300” setting. What is the difference? The

“300C” position is only the current mode preamp by

itself. The “300” setting uses both the current mode and

the voltage mode preamps and is closest to a good 50/50

blend. The next setting “600” restricts some of the mic’s

signal from going into the current stage and more is

available for the voltage stage, and the blend is closer to

30/70. The 2000 ohm setting and the 2 meg settings only

use the voltage preamp.

Page 16

The Impedance switch also has markings on the right

hand side that are for the INSTRUMENT input only.

How a magnetic pick-up reacts somewhat depends on

the impedance it is driving. This effect is diluted because

most guitars and basses have those volume and tone

controls that pretty much set the maximum impedance

the pickup will ‘see’. The pickups also have to drive a

length of cable, which often has appreciable capacitance

and may roll off some highs. A fun trick for a session

instrument is to bypass the volume and tone controls

(maybe on a switch??), just leaving the pickup switch

and jack, and then using a fairly short low capacitance

cable into a variable impedance preamp like the TNT. In

that situation the IMPEDANCE switch becomes very

dramatic and the high impedance settings like “3 meg”

and “10 meg” often get bright enough to sound much

more acoustic-like. Typical authentic guitar amp tones

are the 300K and 1 meg settings. The 100K setting may

be similar (thick and un-bright) whether the volume

control bypass mod is there or not. Guitars and basses

with “active pickups” (battery included) and guitars

feeding stomp boxes before the TNT, should be mostly

immune to the IMPEDANCE switch settings and the

100K setting may have marginally less noise.

After the preamps are selected or are combined in a very

transparent summing amp, the next stage is the “60’s /

70’s module” that contains a fairly simple class-A alldiscrete circuit, and is inserted when the 60’s or 70’s

switch selected or relay-bypassed when that switch is set

to “CLEAN”. The module is meant to simulate some of

the qualities of vintage discrete non-linearities, tape

overload (what some call tape compression), and changes

the frequency response slightly. It is not meant as a

straight simulation of any particular piece of vintage

gear, and is meant to evoke some general characteristics

of those eras and give the user a few more variations in

the ol’ tool-kit. The 60’s/70’s switch also adds DC bias

to the output transformer to further simulate some old

technologies (and which can be further adjusted with the

IRON control). If sufficient interest is shown, Manley

may be able to offer alternative “modules”, as this block

is easily removed and replaced.

One is the IRON knob, which compares the input and

output of the transformer, derives an error signal, which

is then sent to the IRON pot, that acts much like an EQ

boost/cut pot with zero ‘effect’ at 12:00 or straight up.

This way the user can reduce the effect of the transformer

to near inaudibility or exaggerate it or just leave it as it

is where this addional circuit is essentially bypassed and

the transformer output is just pure conventional

transformer and the ¼” output is just clean and unaffected.

In fact, if you use the ¼” output and adjust the IRON

control counter-clockwise, you get an effect that might

be called “Anti-Iron” and could practically reduce the

effect of a transformer in the next piece of gear following

TNT, such as a compressor – kind of like “cleaner than

clean”.

The other circuit wrapped around the RAPTURE AMP

is the OUTPUT MODE switch on the back panel.

Rather than use the conventional cross-fed feedback

output that many use to make a balanced output a bit

fool-proof and simulate a transformer and how it

accommodates balanced and unbalanced inputs, we

have this switch. Why? For one thing, we have the real

transformer, for another, those circuits are inherently

usually within .5 dB of being called an oscillator, and

thirdly, the switch is 3 position, so we can properly

accommodate +4 unbalanced, +4 balanced, and –10

unbalanced – all driven low impedance, high current

(full headroom down to 50 ohms) and unconditionally

stable. One might also note that these two outputs are

isolated and can serve to drive two separate distant

destinations easily.

The RAPTURE AMP itself was the result of months of

auditioning almost every discrete op-amp and gain stage

and every chip op-amp known to us to ever be used for

an audio product or published DIY project. And we

experimented with most of the tricks used to further

enhance all of these op-amps. In the end, we found a

circuit that was practically unique in its lack of artifacts

and sonic purity. After all those months of R&D, it was

decided that it should go in a block of epoxy.

Then the signal hits the GAIN TRIM conductive plastic

pot, and is routed to the RAPTURE AMPS, which are

the final line drivers in this preamp. It drives the ¼”

output directly and the output transformer (custom

designed and manufactured in house for the TNT) for

the XLR output Two controls are wrapped around the

RAPTURE AMP.

A similar routine of comparing the whole TNT preamp

to a lot of known expensive reference preamps was

performed while also continually comparing the raw

source to the preamps attenuated. Lets just say we are

confident that it is a winner and particularly true to the

source. Hope you like it

Page 17

Any particular tips using the NT channel?

Techniques specific to the solid-state side of the TNT

are not daunting. Most likely the first thing to get your

attention will be the LED metering because it is a bit

unusual. The two bottom LEDs show the first few stages

of the preamps or what is going on with the stepped gain

switch but BEFORE the Gain Trim knob. The top two

LEDs show that Gain Trim Knob and the final output.

The bottom GREEN LED shows "SIGNAL PRESENT".

The RED LED above it shows when one is beginning to

distort the preamp or the 60's - 70's circuit. So use this

RED LED to help set how much "OVERDRIVE" and a

typical setting makes that LED flash about 50% of the

time - but trust your ears - too much overdrive may be

hazardous to ones career as an engineer. You can't undo

mic pre distortion.

The top two LEDs are for the final output and the Green

LED is intended to show a good level to your converter

and the RED LED is intended to indicate probable A to

D converter overload. Originally we had that RED LED

indicate when the Preamps began to clip but they tended

to stay dark, so now they just help set a level for the next

piece in the chain.

A good starting point for the 11 position GAIN switch

is “counter-clockwise” and the GAIN TRIM should be

set at roughly 12:00 or straight up. Turn up the GAIN

switch until you are getting a good level. You might use

the 4 LEDs on the TNT. The first or bottom is a “signal

present indicator” and lights up about 20 dB below

optimum levels. The second from the bottom LED

shows clipping in the first stages and follows the GAIN

switch but is before the GAIN TRIM pot. In normal

clean operation this LED shouldn’t light up and is

typically ‘skipped’. Where it will come in particularly

handy is if you are operating the preamp to deliberately

over-drive it by turning down the GAIN TRIM pot and

turning up the GAIN switch. It should be kept in mind

that this won’t be easy in CLEAN mode but it becomes

quite easy in 60’s and 70’s modes. An interesting sound

is when that second LED is just occasionally flashing in

the 60’s/70’s modes, and the distortion is subtle, and

creates a psycho-acoustic effect of “character”,

“richness” and a 3D effect. When that LED is glowing

steadily, the distortion should pretty obvious. The LEDs

are designed to flash on both positive and negative

peaks, and slowly fade. A lot of peaks are too fast to see

when the LED directly displays peaks and the fade gives

some clues to the duration and musicality.

The top two LEDs are set to show output levels at the

output jacks. These are factory set up for +14 dB and

+20 dB over our standard +4 dBm so are technically at

+18 dBm and +24 dBm. Most A to D converters are set

up for +16, +18 or +20 so those two LEDs should get

you to a reasonable starting point and give you a pretty

good idea when clipping is likely. Of course, you really

do need to watch those A to D meters, or tape machine

VU meters as the final judge, especially when you have

processing between the preamp and recording device.

However, if need be, there are internal trims for the LED

thresholds, so one can set up the LEDs for particular

needs. It might be noted that there is no LED to indicate

when the TNT clips – because it clips at over +30 dBm

which is probably higher than 98% of the gear it might

be driving. It seemed more useful to indicate where the

next device is likely to run out of headroom, besides

using the TNT for its own overdrive effects is covered

by LED #2.

If you tend to want the Cool Channel to be generally your

"clean preamp" and intend to use it as a reference

especially for acoustic instruments, then you might want

to consider using the 1/4" output as the main output

because the output transformer is not in that path. And

keeping it clean, you may want to leave the "IRON"

knob set at 12:00 or straight up. Turning the knob either

counter clockwise or clockwise introduces some subtle

transformer color. Now if there is another transformer

down the chain in another piece of gear (or even a

magnetic tape recorder), the counter clockwise settings

may help minimize it's contribution. You might be able

to use the 60's - 70's switch if you keep the Input OL

(overload) LED off by keeping the Gain Switch lower

and the Gain Trim higher or near its max of +10 dB.

If you want the Cool Channel to be multi-tinted then

maybe the XLR output should be your choice. Then

experiment with all the preamp's controls keeping in

mind that moving a microphone by a few inches might

affect the color more, maybe a different mic might be

more significant a variation, and once you hit "record"

the player's tone and volume usually change anyways.

Page 18

Like most mic preamps, the TNT has high-pass filters to

remove unwanted low frequencies. The most common

situations to use it is for vocals to minimize “pops”,

wind noise and air conditioning rumble or leakage, or for

sounds that have little low frequency information

anyways, like acoustic guitar or high hats. The basic

idea is removing the garbage before it gets recorded.

You just might want to compare the effect of a good

analog high pass filter compared to the standard digital

ones and also check out what happens when both are

used, from time to time. There are some engineers that

use a combination of a high pass filter and a low

frequency boost EQ, to get a tight fat bottom. For that

situation, we might suggest, auditioning the combination

but recording only the high pass filter, saving the boost

EQ for playback and refining in the mix.

There is a 3 way toggle labeled “CLEAN”, “70’s”,

“60’s”. The CLEAN setting has the TNT operate in a

standard clean mode. In fact, we probably could have

labeled it “damn stunningly clean” if there was enough

panel space. Tell tale things to listen for if you want to

compare clarity are ‘harshness in the highs’ ‘smoothness

and liquidity in the mids’ but also ‘snap and punch’ and

‘dynamics in the deep lows’. It is hard to overdrive this

mode. We should point out, that for “absolute clean” use

the ¼” output, and the IRON knob set to 1 (12 o-clock,

straight up) to avoid any transformer coloration. And

“virtually absolute clean” is using the XLR transformer

output along with the IRON knob set to –1 or fully

counter-clockwise. This method compensates for the

transformer. Often the 300 setting on the IMPEDANCE

switch sounds slightly clearer as well. And while we are

at it, if pure-clean is the goal, choose your mic carefully,

and avoid processing or choose it extra carefully because

it all adds up, and nothing is perfect – in other words,

maybe use nothing, except a great passive ribbon mic,

TNT and a great converter running at 192K.

So if you are comparing preamps someday, your natural

tendency may be to set everything as flat and level as

possible on each one, use the same mic and try to judge

which basic sound you prefer. If it seems you tend to

pick expensive transformerless discrete preamps, the

TNT should do well that way. However if you tend to

prefer color boxes, then maybe you should be working

with the TNT controls, setting up modes and gains

appropriately. Otherwise it would be like comparing a

several different cars without adjusting the seats or

mirrors. Even if the range of colors isn't drastic, one is

still expected to adjust to taste.

While the CLEAN mode is a relay bypass of an additional

module, simply selecting “60’s” or “70’s” engages this

special module. It is a discrete class-A circuit meant to

simulate some of the stronger characteristics of circuits

and analog tape of those eras. The most important thing

that we must point out is that it is purposely very level

dependent and that it is between the two gain controls so

that the user can drive it as hard or soft as they want to

get a pretty wide variation in tones. Driving it very

lightly by keeping the GAIN switch lower and the GAIN

TRIM way up, mostly affects the EQ and introduces a

faster roll-off in the deep lows and some shaping in the

highs, so that there is a subtle “presence” boost. Driving

it a little harder is particularly interesting and one begins

to hear typical vintage sounds including 3D depth,

richness and edge and a little further becomes a bit

ballsy, aggressive and forward. The trick is careful

adjustments of those gain controls and mic technique to

land in the “sweet spot”. This module can also be driven

quite hard and be used for some obvious dirt and you

may find that that the character of the distortion is unlike

most clipped electronics and perhaps smoother, like

analog tape or a guitar amp. For the best overdriven

guitar effects, you may want to combine TNT with some

good stomp boxes driving into the instrument input, and

some EQ at the TNT output, and you might try feeding

a real speaker/room/mic or convolution reverb so that it

doesn’t end up too dry and clinical.

There isn’t much that can be said about the difference