Page 1

MANLEY

LABORATORIES, INC.

THE ELOP

OWNER's MANUAL

®

TUBES

brought to you by the clever folks at:

MANLEY LABORATORIES, INC.

13880 MAGNOLIA AVE.

CHINO, CA. 91710 USA

TEL: (909) 627-4256

FAX: (909) 628-2482

email: emanley@manleylabs.com

website: www.manleylabs.com

RULE

August-28-2007

Page 2

CONTENTS

SECTION PAGE

INTRODUCTION 3

FRONT PANEL 4

REAR PANEL 5

OPERATION NOTES 6 & 7

ADVANCED TRICKS 8

MAINS CONNECTIONS 9

TROUBLE SHOOTING 10 & 11

INTERNAL ADJUSTMENTS 12

SPECIFICATIONS 13

WARRANTY 14

WARRANTY REGISTRATION 15

TEMPLATE FOR USER SETTINGS 16

Page 3

INTRODUCTION

3

WARNING!

TO PREVENT THE RISK OF ELECTRIC SHOCK

DO NOT OPEN THE CABINET

REFER SERVICING TO

QUALIFIED PERSONEL

THANK YOU!...

for choosing the Manley ELOP®. This Limiter follows in the tradition of the vintage LA-2A Leveling

Amplifier using a passive electro-optical device to control gain. The advantage of a passive device

is that it eliminates the need to push the music through many transistors and/or ICs as would be the

case in a VCA based Limiter. Also like the LA-2A, the Manley utilizes a tube line amplifier for makeup gain. This is one of our favorite clean and powerful line drivers. We achieve true tube "warmth"

with fidelity rather than with distortion. Other owners of this unit love the way they can drastically

(10 dB) limit without introducing unmusical harshness. We find it extremely quick and easy to use,

mostly because it does exactly what one would expect of a good limiter when patched in. For critical

vocal tracks, this is the one to demand.

Unlike the LA-2A, we illuminate the photo-resistor with a LED rather than electroluminescent elements which are often slow and unreliable. We also use a solid state side-chain to

drive the LEDs. The Limiter also features a BYPASS switch that retains the tube section at unity gain.

Please take a few moments to read through this manual carefully as it contains information essential

to proper operation of this unit. Thank you again, and please enjoy.

GENERAL NOTES

LOCATION & VENTILATION

The Manley ELOP® must be installed in a stable location with ample ventilation. It is recommended,

if this unit is rack mounted, that you allow enough clearance on the top and bottom of the unit such

that a constant flow of air can move through the ventilation holes.

WATER & MOISTURE

As with any electrical equipment, this equipment should not be used near water or moisture.

SERVICING

The user should not attempt to service this unit beyond that described in the owner's manual.

Refer all servicing to Manley Laboratories.

!

Page 4

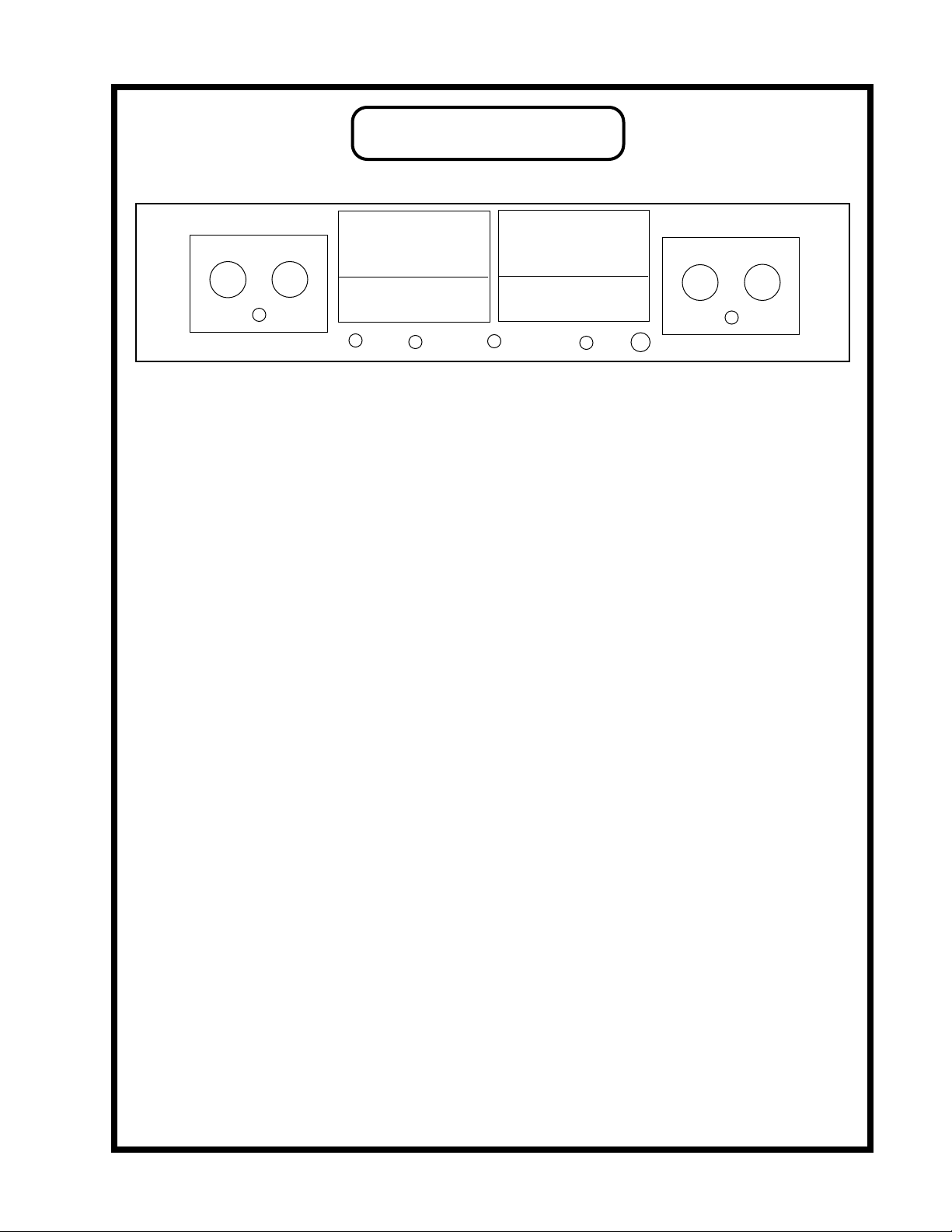

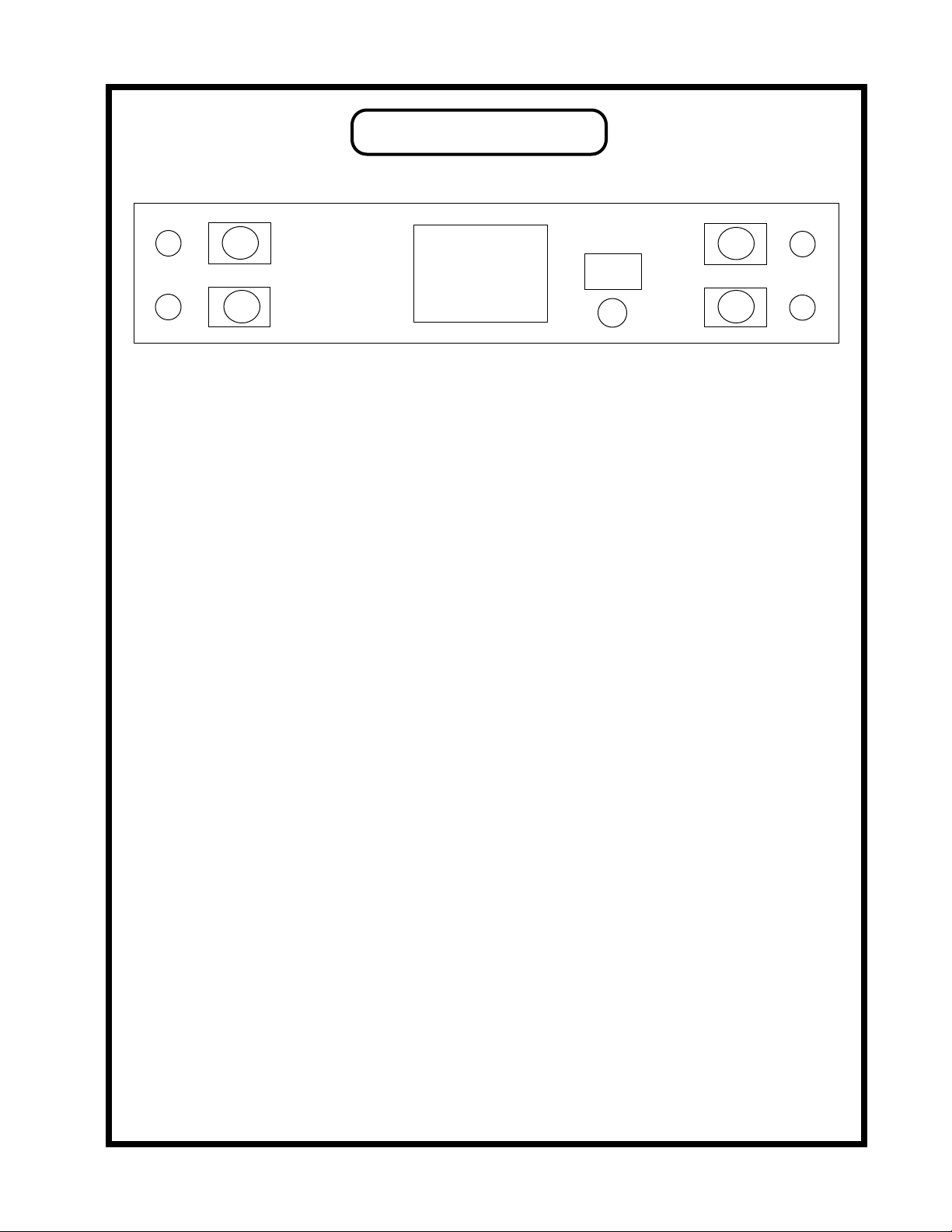

FRONT PANEL

E E

A B C D F G F H C B A

A GAIN Adjusts the gain of that audio channel. Unity gain is about the seventh marking, or 1

o'clock. Limiting usually requires some additional "make-up" gain to compare IN / BYPASS.

The Gain control can also be used as the level to tape.

B IN / BYPASS. Audio still flows through the tubes in BYPASS but at Unity Gain. Switching

to IN provides the Limiting controls and functions. Use this switch to verify that the limiting

is not messing up the original sound but enhancing it or at least leveling the volume.

C RECDUCTION Adjusts the amount of limiting in that channel. This could also be called

"threshold". Turning this clockwise introduces limiting.

D STEREO LINK / NORMAL Switching the toggle UP provides the STEREO LINK. It is

used on stereo tracks so that when either channel is called to limit, both channels reduce the

same amount at the same time. This prevents image shifts and an instrument should stay

where you panned them. Limiting individual sounds is usually done with the switch down

where each side is independent of the other.

E METER Shows the amound of gain reduction in dB from the 0 dB mark. Functions as a

high quality VU meter when the switch is set to METER OUTPUT. Note that VU meters and

PEAK meters rarely agree and that digital recorders use peak meters - Rely on those for clean

recording. VU meters are standard with analog machines and big consoles because they

correspond well with perceived loudness.

F METER SELECT Switch to REDUCTION to see the amount of limiting in dB. The wider

and quicker the reduction meter swings the more likely the limiting will be audible.

Switch to OUTPUT to show the output level as a conventional VU meter.

G POWER SWITCH Switch up to turn the unit ON. Both meters will illuminate when the

power is on.

H SIDECHAIN FILTER Allows you to limit only the frequencies above the one selected.

Useful if you want to let the bass come through full-force, but limit everything else.

4

Page 5

REAR PANEL

A

C

B

G

E

D

A 1/4" INPUT (UNBALANCED) (RIGHT) TIP: HOT

B XLR INPUT (BALANCED) (RIGHT) PIN 1: GROUND

C 1/4" OUTPUT (UNBALANCED) (RIGHT) TIP: HOT

D XLR OUTPUT (BALANCED) (RIGHT) PIN 1: GROUND

E IEC MAINS CONNECTOR Standard IEC mains connector for 50 /60 Hz AC.

F MAINS FUSE Replace with only a 1 Amp slo-Blo fuse.

F

SLEEVE: GROUND

PIN 2: HOT (+)

PIN 3: GROUND

SLEEVE: GROUND

PIN 2: HOT (+)

PIN 3: GROUND

I

H

J

G XLR INPUT (BALANCED ) (LEFT) PIN 1: GROUND

PIN 2: HOT (+)

PIN 3: GROUND

H 1/4"INPUT (UNBALANCED ) (LEFT) TIP: HOT

SLEEVE: GROUND

J XLR OUTPUT (BALANCED) (RIGHT) PIN 1: GROUND

PIN 2: HOT (+)

PIN 3: GROUND

K 1/4" INPUT (UNBALANCED) (RIGHT) TIP: HOT

SLEEVE: GROUND

Old versions of the ELOP® were unbalanced only. This version has both transformer (floating

!) balanced and unbalanced (transformerless) inputs. The outputs are similar, offering

transformer (floating) balanced XLR and unbalanced 1/4 jacks. The output transformers are

"driven" either way so even using unbalanced outputs there may be a part of the "character"

caused by the iron. Recording engineers tend to prefer the sound of good transformers. If done

right, they saturate a little in the deep lows and this effect "warmth" is usually attributed to

"tubes". Its the tubes that give it that clean, immediate, musical quality. Transformers give

that rich, fat bottom end - its not a "boost" like EQ but more like a low frequency "exciter".

Analog tape also saturates this way, as does the better vintage gear - tube or discrete.

5

Page 6

OPERATION NOTES

The Manley ELOP® follows certain traits and traditions established by the UREI LA-2 and

similar leveling amplifiers. These traits can be divided into two aspects - electronic and operation. The

electronic concept is simple and rather clean. Use the audio to light up LEDs or lamps which shine onto

photo-resistors. These photo-resistors, in combination with a fixed resistor, simply act as a voltage

divider to attenuate the signal. The tube line amplifier only functions to provide extra gain to make up

for attenuation losses and then acts as a fine cable driver. Simple, elegant and minimal. Operation of this

type of design is also simple, elegant and minimal. There are usually only "threshold" and "gain" controls.

Most have no user adjustment of "attack", "release", "ratio" or functions for de-essing or external

sidechains. To put it one way, the user is "stuck" with fixed time constants and a feature list that seems

utterly anemic compared to dynamic processors costing far less...

...so why are "LA" style opto-based limiters so popular? Several reasons. To paraphrase

Letterman, "The number one reason why "LA" style limiters are favorites is because.... they work right

on vocals". This "rightness" has a few aspects. The first is that "LA" style limiters don't leave much trace

of limiting as they work. This is partly due to tubes, partly to the simplicity of the opto circuit and partly

because the user can't alter the attack and release. Almost every VCA based design seems to leave

electronic personality on that critical vocal track. This is usually undesirable. Our Opto circuit has no

active limiting in the signal path. Tube circuits have the potential to be musically more transparent than

transistors because tubes are generally more linear devices. However, there are many poor examples of

tube circuits in use, and many ways to butcher the quality. We chose to use our favorite simple tube line

amplifier circuit which we also use in our Mono and Dual Mono Micpres and Enhanced Pultec Equalizers

(rather than copy UREI designs) because frankly our circuit sounds better and cleaner.

Back to this matter with fixed time constants. We get requests to modify our ELOP® for more

controls, but we get even more people raving about how great and useful the ELOP® is now. The attack,

release, knee and ratio (curve) are a function of the Vactrol Cell we chose to use. The choice was based

on the attack and release characteristics. Changing the time values in this circuit involves different

choices of Vactrols. In the VOXBOX® we spend a lot of effort to get attack and release controls and it

required a radical departure from conventional approaches. There is a major advantage to fewer controls

and a reason for the coolness of LA type limiters. You simply adjust the Threshold for the desired limiting

amount and adjust the Gain for the desired level to tape - then record. The limiter does what its supposed

to do - nothing more, nothing less. Kinda like automatically right, strangely quick and easy, and pretty

much non-distracting. We use the phrase "Set it and forget it". This is a very important feature that would

be lost with a variety of controls. A good engineer wants to be ready to record "now" and does not want

to be fussing with controls while a lead vocal is going to tape. Unfortunately most compressors drag the

engineer's attention away (and often the singer's and producer's attention away as well).

The time and slope characteristics of Opto elements are not easy to describe and probably even

more difficult to simulate. The attack is fast; not super-fast "brick wall", but fast enough to "catch"

consonants. It is also a function of level. At lower reduction levels and lower peaks the Vactrol is slower.

It becomes faster with sharp peaks and heavier levels of reduction. Release is similar but 10 to 20 times

slower. Quick peaks are handled with quick release and as gain reduction nears zero the Vactrol gets

slower like gentle braking to a stop. While normal cheapo VCA limiters are much simpler the best

approximation is 10 ms attack and 500ms release. We spec 2.5 sec for release which accounts for that

slow down near zero. The attack spec number is similarly an approximation. Who cares - it works.

6

Page 7

The slope or ratio is also difficult to simulate. The initial ratio is low and becomes higher

with more gain reduction until the LEDs light up fully and further reduction is not easy. This upper

limit of reduction is in the area of 20 dB or at the bottom of the GR meter where the ratio becomes

low again but this would be a severe setting that few engineers could use. Distortion becomes

audible at very deep limiting. In a tech shop, it is easy to drive the limiter to 20 dB of reduction and

beyond where the GR meter shows a flaw in that it "folds back". We put a higher priority on having

the meter show what the Opto was doing accurately with "normal settings" than extreme test bench

observations. Test benches don't make hit records.

So the Opto Limiters seem to be great for vocals, but what else are they used for - and what

about sounds where the time constants are less than optimum ? Historically, "LA" style limiters were

often used for bass and guitar tracks. They can be ideal for brass, saxes, synths and similar sounds

with superb results. There are other compressors that work well for these instruments but few that

are as transparent. Usually, when you hear of an engineer using a non-Opto compressor for these

instruments it is usually framed with "for the crunch" or because they add some desired color. There

are only a very small number of "clean" general purpose variable time compressors which seem to

give Opto units competition - our Variable MU® is at the top of that list. Where the "LA" style

limiters are not always appropriate is for percussion and for mixes where the percussion is just right.

The Opto typically reacts fast to peaks - fast enough to remove drums from a mix but not quite fast

enough to be called "brick wall". Individual drums tend to have a little of the initial transient let

through but the desirable tone of the drum is diminished. If used gently, this can be applied to

brighten up the attack of the drum, but it is difficult to apply in practice because drums can be very

dynamic. One great use is on the room mics. The initial drum sound is pulled down, then the natural

reverb is increased. Shades of early Led Zep. While we mentioned that "LA" style limiters are not

what we suggest for mixes, there are times when the drums are too loud or when the engineer can

mix "into" the limiter. Both techniques are possible but not necessarily easy. One trick is very little

movement on the GR meter. Some of our clients use the Opto on mixes as an effect. This application

is valid as long as the effect given and the effect desired are the same. There is not many options for

adjustment and fine tuning. The good news is that at least the Manley is clean enough to pass a good

mix. In a live sound setting the Opto will perform as a fine speaker protection device. Once again the

Threshold is set for minimal limiting with music and is just adjusted to encourage the pyrotechnician

to try harder tomorow to kill a few woofers.

Manley also offers Mastering Versions of our limiters with 1/2 dB stepped controls. We

intend to offer a second stereo opto compressor with attack and release based on the mic pre/

compressor in the VOXBOX®. Expect it to cost more than the ELOP®. Call us for details.

7

Page 8

Advanced Tricks

Here are a few tricks that are not really for rookies. They come from guys doing major records for years

and won't work unless you've mastered the basics. In other words if we gave you a Strat and Marshall it

won't make you another Jimi. Also we don't suggest that you try these out while paying big-time studio

rates - they may not be easy to get right at first. OK, you have been warned.

Trick#1. Each compressor or device in the chain has certain flavours and characteristics and with

experience we grab the ones we like because of the sound - not because "it is a compressor". The idea is to

use several cool compressors in a chain getting flavours from each depending on how much GR (gain

reduction) is used in each and how hard they are driven. It's this second concept that can be tricky. How far

to turn up each Make-up Gain to overdrive or not overdrive the next unit - and still not get flooded with

noise when the music stops. You can chain the two channels of the ELOP® and turn up the make-up of the

first channel. This works best with classic discrete and tube units and usually IC units are to be avoided.

The finesse comes from which order they are patched. See how long it might take to get best results .....

Trick#2. This one is easier but also requires serious listening. Rather than just "inserting" a limiter, try

driving the limiter from the tape patch (pre EQ), returning it to a spare fader and mixing it with the original.

So what is so tricky ? How you EQ and automate and add effects to these channels. You can also have fun

phase reversing one of the channels. You get cancellation but only at a certain level. It is sort of like gating

but different - it is a way of controlling the "ambiance".

Trick#3. Using one track to "duck" another. This may work better with compressors with attack and release

and ratio controls if you are thinking drums. Bass and vocal is very cool with the ELOP®. Set it up like

trick#2 with bass in one channel and vocal in the other (in LINK mode) and experiment with each

threshold. Two guitar tracks also work here sometimes. Obviously we pull out this trick when two tracks

are stepping on each other and EQ isn't making enough room for clarity.

Trick#4. Drive the compressor from an AUX send and return it to a channel. Once you have some limiting,

carefully turn up that aux send on the return channel to "feed back" into the limiter. Watch out for real

howling feedback and over the top limiting. If you are lucky it won't scream during the quiet parts. The key

is balancing the faders, track auxes, the return auxes, the thresholds and make-up gains. The technique can

get pretty crunchy and wild. Works best with not-so-clean compressors but is interesting with the ELOP®.

Trick#5. This one is a way to get a very good single channel De-esser from the ELOP® or other compressor

good enough for lead vocals. Mult the Insert send of the vocal to the ELOP® and to a spare channel. EQ the

snot out of that second channel -boosting the 5 or 6KHz band and chopping everything below that. Use the

insert from this channel to drive the other channel of the ELOP® but it is unlikely that you want this fader

up. Set the ELOP® to Link. The threshold of the first channel sets compression and the second channel sets

de-essing. Unlike some de-essers it will not chop highs but reduce wide-band which is less obvious. The

only drag is that the release is a little slow. Remember good de-essing is not to remove esses - the idea is to

reduce esses and make them natural sounding. BTW if you need to de-ess, you might want to re-think your

choice of gear. There are 3 main reasons we get horrible esses: 1) a gap in the singer's teeth or just a

strange voice, 2) too much or wrongly choosen EQ, or, 3) gear that distorts the highs. If the cause is "1", try

sticking some dental wax in the gap. No joke. If the cause is "2" then we can tell you some EQs allow one

to boost highs with less problems with the esses or you might try boosting a higher freq, or less during

tracking. If it is "3" you may want a better mic or sell off some of that cheap IC gear that seems to be

distorting the top in a way that you don't like. Actually we have heard some pretty expensive gear - both

tube and solid state - that has this particularly ugly distortion. If in doubt, try some tough percussion

through it like shakers or tamborines, and see how they sound...

8

Page 9

MAINS CONNECTIONS

Your ELOP® has been factory set to the correct mains voltage for your country. The voltage

setting is marked on the serial badge, located on the rear panel. Check that this complies with

your local supply.

Export units for certain markets have a moulded mains plug fitted to comply with local requirements. If your unit does not have a plug fitted the coloured wires should be connected to

the appropriate plug terminals in accordance with the following code.

GREEN/YELLOW EARTH terminal

BLUE NEUTRAL terminal

BROWN LIVE terminal

As the colours of the wires in the mains lead may not correspond with the coloured marking

identifying the terminals in your plug proceed as follows;

The wire which is coloured GREEN/YELLOW must be connected to the terminal in the plug

which is marked by the letter E or by the safety earth symbol or coloured GREEN or GREEN

and YELLOW.

The wire which is coloured BLUE must be connected to the terminal in the plug which is

marked by the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the terminal in the plug which is

marked by the letter L or coloured RED.

DO NOT CONNECT/SWITCH ON THE MAINS SUPPLY UNTIL ALL OTHER

CONNECTIONS HAVE BEEN MADE.

Note: This unit has been factory wired for your country. If you plan to take the unit to

countries with a different mains voltage you will need to send the ELOP® to Manley Labs

for the correct power transformer - or use AC voltage converters.

9

Page 10

TROUBLE-SHOOTING

There are a number of possible symptoms of something not quite right, some may be interfacing, others we will touch

on as well. The preceding page shows that all the inputs and outputs of the ELOP® are unbalanced. No need to panic. We have

sold hundreds of these units and less than 1% ever had a problem with hum or interfacing to balanced consoles or other gear.

However if you suspect a problem the following paragraphs should help.

NO POWER, NO INDICATORS, NADA - Probably something to do with AC power. Is it plugged in? Check the fuse on

the back panel. A blown fuse often looks blackened inside or the little wire inside looks broken. A very blackened fuse is a

big hint that a short occured. Try replacing the fuse with a good one of the same value and size. If it blows too then prepare

to send the unit back to the dealer or factory for repair. The fuse is a protection device and it should blow if there is a problem.

If the unit works with a new fuse, fine. Check the MAINS VOLTAGE SELECTOR if one is fitted. Some of our models are

able to have them and some don't. It should be set correctly for your mains voltage.

LIGHTS BUT NO SOUND - First try plugging the in and out cables into some other piece of gear to verify that your wires

are OK. Next check the front panel, try BYPASS. If you have sound now it might be a good idea to turn up the output levels

to about 1 o'clock (rather than fully counterclockwise which is "minus infinity". The XLR inputs and outputs are transformer

balanced and floating. "Floating" refers to a very useful feature of transformers where they can be used without a ground

reference - this prevents ground loops before they happen rather than electronically cancel them. It does require that both PIN

2 and PIN 3 be connected (but not to each other). To interface to unbalanced units you should connect PIN 3 to Ground or

PIN 1. Brainless solution - use the 1/4" unbalanced inputs and outputs to interface to unbalanced gear.

LEVELS SEEM TO BE WRONG, NO BOTTOM - Several possible scenarios. Manley uses the professional standard of

+4 dBm = Zero VU = 1.23 volts AC RMS. A lot of semi-pro gear uses the hi-fi reference of -10 dBm = Zero VU. This is a

14 dB difference that will certainly look goofy and may tend to distort. Often there are switches on the semi-pro gear to choose

the pro reference level. We do not provide that kind of switch because of inevitable compromises in the signal path. If the

loss looks close to 6 dB and it sounds thin then one half of the signal is lost. The cause is probably wiring again. One of the

two signal carrying wires (the third is ground / shield on pin 1) is not happening. Check the cables carefully because

occasionally a cable gets modified to work with a certain unit and it seems to work but its wrong in other situations. If only

one side of the Limiter exhibits this problem, it may be a problem in the Limiter. See the next item.

ONE SIDE WORKS FINE BUT THE OTHER SIDE IS DEAD - Let's assume this is not wiring. We are pretty sure it is

the Limiter. If it were solid state you would generally send it back for repair. Being a tube unit, you can probably find the

problem and fix it in a few minutes. Not too many years ago, people could "fix" their own stuff by taking a bag of tubes down

to the corner and checking said tubes on a tube tester. These are practically extinct but no prob'. Most Manley gear is two

channel, meaning you can swap tubes to determine the bad boy. Do two at a time just watching that they are the same number.

Be careful - there are some high voltages inside the chassis and tubes can get pretty warm, but if you can replace a light bulb

you should be able to cruise through this. Before you remove a tube, just take a look at them powered up. They should glow

a bit and they should be warm. If one is not, you have already found the problem. The tube's filament (heater) is burnt out

or broken like a dead light bulb. The other big visual symptom is a tube that has turned milky white - that indicates air has

gotten into the tube, or "the vacuum leaked out". Either way, replace the tube. Call us, or look for a tube supplier on the internet.

Manley can ship you a tested one. Back to swapping - before you pull a tube, pull the power out, let the unit sit and cool and

discharge for a minute or two, then swap, then power, then check. Gentle with those tubes, don't bend the pins by trying to

insert them not quite right. A little rocking of them as you pull them out or put them in helps. When the problem follows the

tube you found the problem - a bad tube. No soldering, no meters, one screwdriver - easy.

HUM - Let's assume it knows the words. Once again - several possibilities - several cures. Most likely it is a ground loop.

The two most common procedures are: try a 3 pin to 2 pin AC adapter (about a dollar at the hardware store) which is better

than messing up the power cable by bending the ground pin until it breaks off. Method two - cutting the shield on one side

of the cable (PIN 1). This is done by some studios at every female XLR to "break" all loops. You may get a loop simply from

the rack. All the other gear in the rack is "dumping" ground noise onto the rack rails. Try removing the ELOP® from the rack

so that it is not touching any metal. You may have cured a non-loop hum. Some gear radiates a magnetic field and some gear

(especially if it has transformers) might receive that hum. A little distance was all it took. A cool method of reducing all sorts

of hum and noise is to use the new 60-0-60 balanced AC power transformers available from Equi=Tech and Furman. It costs

more but works best. Hum is more likely with the unbalanced inputs and outputs because these signals are ground referenced.

A common situation is using the limiter in a way that significantly boosts the low level signals and what may have started

out as a little hum becomes nasty. Check out the gear feeding the Manley or use less limiting and make-up gain.

10

Page 11

IT MAKES NOISES WHEN THE FRONT PANEL IS TAPPED - An easy one. Some tubes become microphonic over

time. That means they start acting like a bad microphone. Vibration has caused the supports for the little parts in the tube to

loosen and now the tube is sensitive to vibration. Easy - Replace the tube. Which one? The one that makes the most noise when

you tap it. It will have to be on , connected and speakers up but not too loud for the sake of your speakers.

IT GOT HISSY - Also easy. This is again a common tube symptom. You could swap tubes to find the culprit but an educated

guess is OK too. Generally the first tube in the path is the one with the most gain and dealing with the softest signals. The

usual suspect is the tube that is usually located closest to the front panel volume pot or the 5814 (or 12AX7, 12AT7, 12AU7,

6072 on other models). You may find that you need to choose the quietest tube out of several of that type.

DISTORTION - This might be a tube. Swapping is a good way to find out. It may be a wiring thing or mismatch as well.

Wiring problems usually accompany the distortion with a major loss of signal. Mismatches are a bit tougher. The ELOP® has

a high input impedance (HI Z) but some of our gear has a reasonably low input impedance. Without even explaining the term

"impedance" it is enough to say that a lot of gear is simply not capable of driving pro levels and low impedances. It will sound

like lost headroom, early clipping, distortion on peaks. Often changing the order of processors will do the trick. Another not

so rare place to look is the patchbay, your settings, the meter levels - it happens.

DC OR SOMETHING AT THE OUTPUT THAT IS INAUDIBLE - This might happen and it might be accompanied with

a strange hum or little whistles as it warms up. It only seems to occur with long cables. It happens on an older unit but not

on the newer one. Years ago we found a problem with our line driver section when it fed very long or cheap wire. The output

would tend to oscillate in the inaudible ultrasonic frequencies ( 200 kHz to 500 kHz) into high capacitance like a long cable.

We cured it by adding a simple 47 ohm resistor at the XLR. Newer units should not have a problem but if you have an old

one, we can FAX you a 25¢ fix. Real DC at the output would be such a rare find that we would be pretty surprised. We use

a $30 output cap to block DC. Most manufactures use a 30¢ electrolytic cap but we don't like the sound or reliability of these.

We invest more in these two output caps than most limiters spend on the entire parts list. A little very low frequency noise

might be seen at the output if you use a scope. This is generally very low level and caused by AC power fluxuations.

THE METERS ARE OUT OF CALIBRATION - If the problem only seems to be when the unit is just turned on it's normal.

It should warm up. It might be a half dB out for 15 minutes - relax. If they drift a tenth of a dB over the course of a day it is

because of bad AC power fluxuations - chances are other gear is doing worse, you just haven't found out yet. Your unit will

have been factory calibrated and tested twice before you received it. Sometimes parts drift a bit in value over the years, or

you have repaced tubes and want the unit calibrated at the same time, or you just want it as perfect as it can be. These are good

reasons to turn the page and go through the calibration procedure or sent it to a technician or the factory for a tweak. If you

send the unit to a tech, you should include this manual because they will need it. If you do it yourself, you will need an

Oscillator and a few screwdrivers and it would be nice to have a VOM meter and Scope but not necessary.

Once in a while we get a call from a client with a "digital studio" with confusion about levels. They usually start out by using

the digital oscillator from their workstation and finding pegged VU meters the first place they look and they know it can't be

the workstation. Even a -6 level from their system pegs the meters. Some of you know already what 's going on. That -6 level

is referenced to "digital full scale" and the computer might have 18 or 18.5 or 20 dB of headroom built in. That -6 level on

the oscillator is actually a real world analog +12 or +14 and those VU meters don't really go much further than +3. There are

a few standards and plenty of exceptions. One standard is that pro music (non-broadcast) VU meters are calibrated for 0VU

= +4 dBm =1.228 volts into 600 ohms. Another standard is that CDs have a zero analog reference that is -14 dB from digital

full scale or maximum. This allows sufficient peak headroom for mixed material but would be a bad standard for individual

tracks because they would likely distort frequently. This is why digital workstations use higher references like 18 and 20 to allow for peaks on individual sounds. It may be too much in some cases and too little in others. Add two other sources of

confusion. Peak meters and VU meters will almost never agree - they are not supposed to. A peak meter is intended to show

the maximum level that can be recorded to a given medium. VU meters were designed to show how loud we will likely hear

a sound and help set record levels to analog tape. By help, I mean that they can be only used as a guide combined with

experience. They are kinda slow. Bright percussion may want to be recorded at - 10 on a VU for analog tape to be clean but

a digital recording using a good peak meter should make the meter read as high as possible without an "over". Here is the

second confusion: There aren't many good peak meters. Almost all DATs have poor peak meters that do not agree with each

other. One cannot trust them to truly indicate peaks or overs. Outboard digital peak meters (with switchable peak hold) that

indicate overs as 3 (or 4) consecutive samples at either Full Scale Digital (FSD) are the best. They won't agree with VU meters

or Average meters or BBC Peak meters either. Each is a different animal for different uses. The Limiter should help digital

and analog achieve consistent levels but use each meter for it's own strength. The Reduction mode is useful with everything.

11

Page 12

INTERNAL ADJUSTMENTS

6414

12AU7WA

IC

2

1

6

4

8

1

IC

7

5

9

6414

3

12AU7WA

10

1

1) You will have to start out by setting front panel controls to these settings. BYPASS mode, SEP

(LINK OFF), REDUCTION controls counter clockwise (MIN), GAIN to 1:00 or unity, S.C. at "Flat".

The top will need to be open. There are two screws on the top that hold the top perforatedpanel to the

back. Remove these and the perforated top will slide back. Be careful! THERE ARE HIGH

VOLTAGES INSIDE THE LIMITER. DO NOT HOLD THE METAL PART OF THE

SCREWDRIVER. DO NOT PROBE AROUND WITH THE SCREWDRIVER OR FINGERS. The

unit should be on for about 15 minutes to allow for "warming up".

2 & 3) This adjusts the tube amplifier gain in all modes. 1 KHz sine at 1.23 volts RMS (+4 dBm, 0 VU) to

both inputs. BYPASS mode. Adjust 2 & 3 for unity gain at outputs.

4 & 5) This adjusts VU meter calibration for OUTPUT. Same input, Meter switches to OUTPUT. Adjust for

0 VU on the Meters.

6 & 7) This adjusts the meter zero for Reduction mode. Meter switches to REDUCTION. Adjust for 0 VU on

the Meters.

8 & 9) This adjusts the meter in Reduction mode to reflect the actual gain reduction accurately. You will

probably need to increase the oscillator 10 dB to get Limiting. Switch from BYPASS to IN. Meter

switches to OUTPUT. Adjust GAIN controls to get 0 VU on the METERS again, then adjust

REDUCTION controls to reduce the signal to -4dB. Switch METERS to REDUCTION. Adjust 8 &

9 to get -4 dB on the METERS.

10) This adjusts the gain of the right side chain and adjusts the side chain balance in Link. Switch the

LINK ON. There should be 1 to 2 dB change in the Meters. Adjust 10 so that the meter is the

same for both sides. You may have to re-adjust 8 and 9. Check that both in LINK and

SEPARATE that both channels show the same reduction.

This is a final check to verify that all adjustments are OK and the unit is ready for use. Confirm that 0

VU on the meters is +4 dBm with an external VU meter or VOM that reads between 1.22 and 1.23

volts AC and that gain reduction reads the same on OUTPUT and REDUCTION and that LINK or

UN-LINK does not reduce the gain unevenly on the two sides. Remove the power and slide the top in

all the way where it will fit into a groove in the front panel and put those two top screws back in.

Done !

12

Page 13

SPECIFICATIONS

Manley ELOP

Maximum Input (Bypass through Line Amplifier) +30 dBv

(with Limit "IN" the maximum is entirely variable)

Maximum Output +30 dBv

Headroom (referenced to +4 dBv) 26 dB

Frequency Response: 10 Hz to 70 kHz +/- 0.5 dB

THD & Noise (1kHz @ +4 dBm) .015%

Noise Floor (Gain set to minimum) -80 dB Wideband

Signal to Noise 126 dB typical

Maximum Gain 15 dB

Maximum Limiting 22 dB

®

Maximum Limiting with +4 dBm sine 15 dB

Attack Time 10 mS for 6 dB GR

Release Time 2.5 Seconds for 6 dB GR

Power Consumption .35 Amps @ 115 VAC

Fuse 1 Amp Slo-Blo

Size (2U) 19" x 3.5" x 10"

Actual Weight 11.5 Lbs

Shipping Weight 14 Lbs

Replacing Meter Bulbs: New units like this use very long-life LEDS. For older units, lamps

are available from Manley (12 volt Festoon) and available from Selco (part number 19-29-39/

12V). You remove the two small Phillips screws (back, top, center) which allows you to pull the

white light cover panel away. Gently pry out the old bulb, insert the new one and screw the

panel back on. Note that a few of the very first units used 26V lamps and if in doubt, the volts

are marked on the bulb.

13

Page 14

All Manley Laboratories equipment is covered by a limited warranty against defects in materials and

workmanship for a period of 90 days from date of purchase to the original purchaser only. A further

optional limited 5 year transferrable warranty is available upon proper registration of ownership within

30 days of date of first purchase.

Proper registration is made by filling out and returning to the factory the warranty card attached to this

general warranty statement, along with a copy of the original sales receipt as proof of the original date

of purchase, or registration can be made online in the Tech Support section of www.manleylabs.com.

This warranty is provided by the dealer where the unit was purchased, and by Manley Laboratories,

Inc. Under the terms of the warranty defective parts will be repaired or replaced without charge,

excepting the cost of tubes. Vacuum tubes and meter or badge lamps are warranted for six months

provided the warranty registration is completed as outlined above.

If a Manley Laboratories product fails to meet the above warranty, then the purchaser's sole remedy

shall be to first obtain a Repair Authorisation from Manley Laboratories and return the product to

Manley Laboratories, where the defect will be repaired without charge for parts and labour. All returns

to the factory must be in the original packing, accompanied by the Repair Authorisation, and must be

shipped to Manley Laboratories via insured freight at the customer's own expense. Factory original

packaging can be ordered from Manley Labs. Customer will be charged for new factory original

packaging if customer fails to ship product to Manley Labs in the original factory packaging. After

repair, the product will then be returned to customer via prepaid, insured freight, method and carrier to

be determined solely by Manley Laboratories. Manley Laboratories will not pay for express or

overnight freight service nor will Manley Laboratories pay for shipments to locations outside the USA.

Charges for unauthorized service and transportation costs are not reimbursable under this warranty,

and all warrantees, express or implied, become null and void where the product has been damaged by

misuse, accident, neglect, modification, tampering or unauthorized alteration by anyone other than

Manley Laboratories.

The warrantor assumes no liability for property damage or any other incidental or consequental

damage whatsoever which may result from failure of this product. Any and all warrantees of

merchantability and fitness implied by law are limited to the duration of the expressed warranty. All

warrantees apply only to Manley Laboratories products purchased and used in the USA. All

warrantees apply only to Manley Laboratories products originally purchased from an authorised

Manley dealer. Warranties for Manley Laboratories products purchased outside the USA will be

covered by the Manley Importer for that specific country or region. "Grey Market" purchases are not

covered by any warranty. In the case that a Manley Laboratories product must be returned to the

factory from outside the USA, customer shall adhere to specific shipping, customs, and commercial

invoicing instructions given with the Return Authorisation as Manley Laboratories will not be

responsible for transportation costs or customs fees related to any importation or re-exportation

charges whatsoever.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitations

may not apply to you. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above exclusion may not apply to you. This warranty gives you specific

legal rights and you may also have other rights which vary from state to state.

For Tech Support and Repair Authorisation, please contact:

MANLEY LABORATORIES, INC.

13880 MAGNOLIA AVE.

CHINO, CA. 91710 USA

TEL: (909) 627-4256

FAX: (909) 628-2482

email: service@manleylabs.com

WARRANTY

Page 15

WARRANTY REGISTRATION

We ask, grovel and beg that you please fill out this registration form and send the bottom half to:

MANLEY LABORATORIES

REGISTRATION DEPARTMENT

13880 MAGNOLIA AVE.

CHINO CA, 91710 USA

Or you may FAX this form in to: +1 (909) 628-2482 or you may fill in the online warranty

registration form found in the Tech Support section of our website www.manleylabs.com or

you can be really diligent and register your warranty three times to see if we get confused!

Registration entitles you to product support, full warranty benefits, and notice of product

enhancements and upgrades, even though it doesn't necessarily mean that you will get them (Just

kidding!) You MUST complete and return the following to validate your warranty and registration.

Thank you again for choosing Manley gear and reading all the way through The Owner's Manual.

(We really mean that sincerely, the bit about thanking you for choosing our gear. THANK YOU!!!)

MODEL MANLEY ELOP® SERIAL #__________________

PURCHASE DATE ______________ SUPPLIER ______________________

--------------------------------------------------------------------------------------------------------

PLEASE DETACH THIS PORTION AND SEND IT TO MANLEY LABORATORIES

MODEL _______________ SERIAL #__________________

PURCHASE DATE ______________ SUPPLIER ______________________

NAME OF OWNER _______________________________________________

ADDRESS ______________________________________________________

CITY, STATE, ZIP ________________________________________________

EMAIL: ________________________________________________________

TELEPHONE NUMBER___________________________________________

COMMENTS OR SUGGESTIONS?__________________________________

________________________________________________________________

Page 16

Loading...

Loading...