Page 1

17.03.2011 1

OPERATING INSTRUCTIONS

MANKAR HQ

ULV- Applicator for weed control

in areas of specialised cultivation such as nurseries, orchards and

vineyards, ornamental plant and vegetable gardens, as well as

agricultural, forestry, communal and non-cultivated lands.

The unit has been developed for t he undiluted

application of ROUNDUP products (Glyphosate).

Important:

Before application, carefully read the usage instructions for the unit and the plant protective agent!

Observe safety instructions!

For questions regarding plant pr ot ec t ive agent s , c onsult t he m anufacturer!

Observe the requirements and reg ional regulations for the use of herbicides and, if necessary,

obtain approval from the responsible authorities (e. g. environmental conservation agency)!

Application is to be performed only by a competent us er .

Remarks about usage of t he unit:

Settings: This system is not suitable for the application of water.

Use herbicides for testing the spr ay action and calibrat ion of the flow rate.

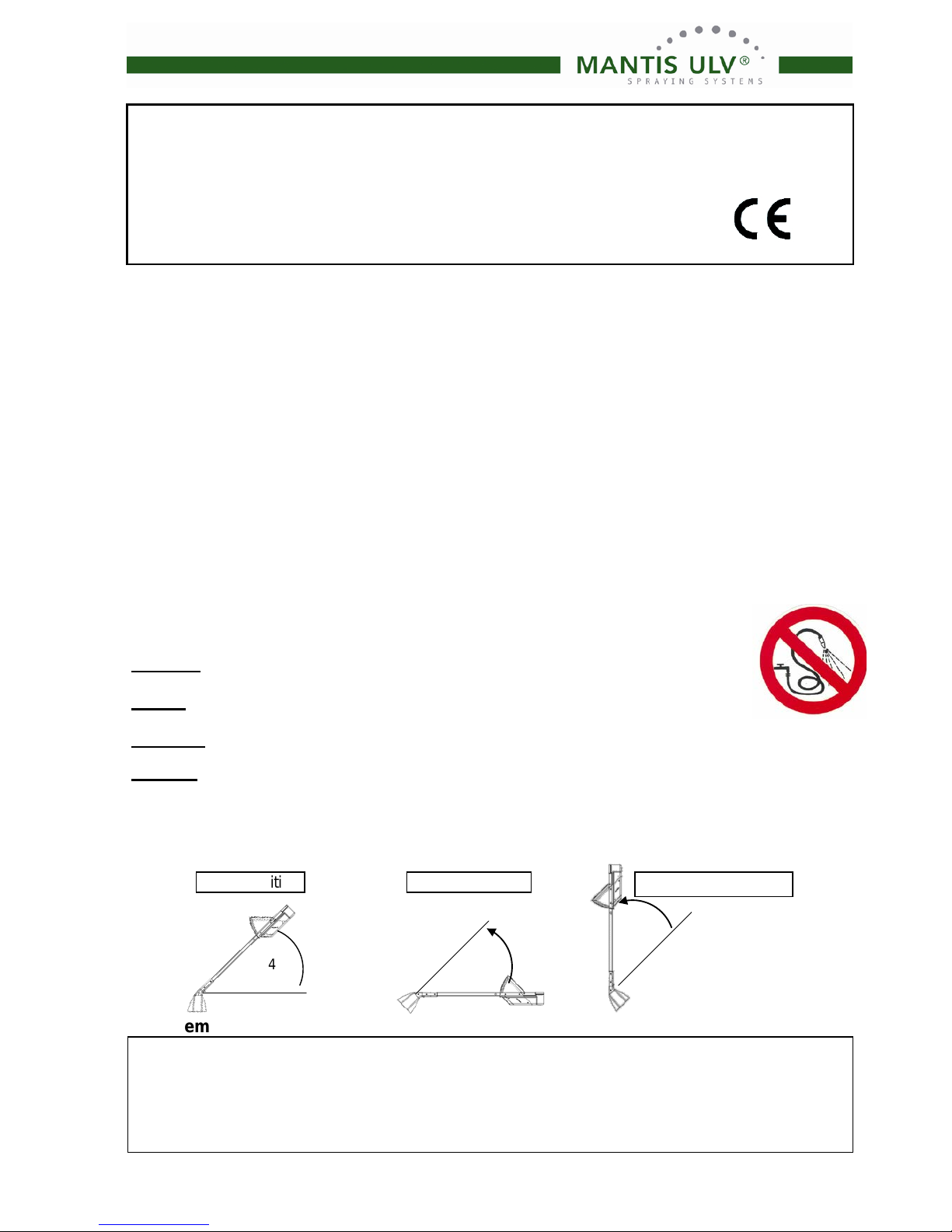

Usage: Position the spray hood directly above the ground –

if the spray hood is held too high, the danger of spray driftage exists.

Cleaning: Do not clean the unit with a high-pressure spray or an int ense water j et spray.

Storage: Store the unit at an angle of between ca. 45° (= work position) and 0° (= horizontal) to t he

floor (see picture).

Keep the applicator and pesticides out of the reach of children.

Noise emission from the unit equates to less than 70 dB(A).

Manufacturer:

Mantis ULV-Sprühgeräte GmbH

Germany 21502 Geesthacht, Vierlander Str. 11 a

Telephone +49(0)4152-8459-0, FAX +49(0)4152-8459-11

Web: www.mantis-ulv.eu Email: mantis@mantis-ulv.eu

Work posit ion

Storage: correct

Storage: incorrect

max. 45°

over 45°

45°

Page 2

16.08.2013 2

MANKAR HQ

Noise emission from the unit equates to less than 70 dB (A).

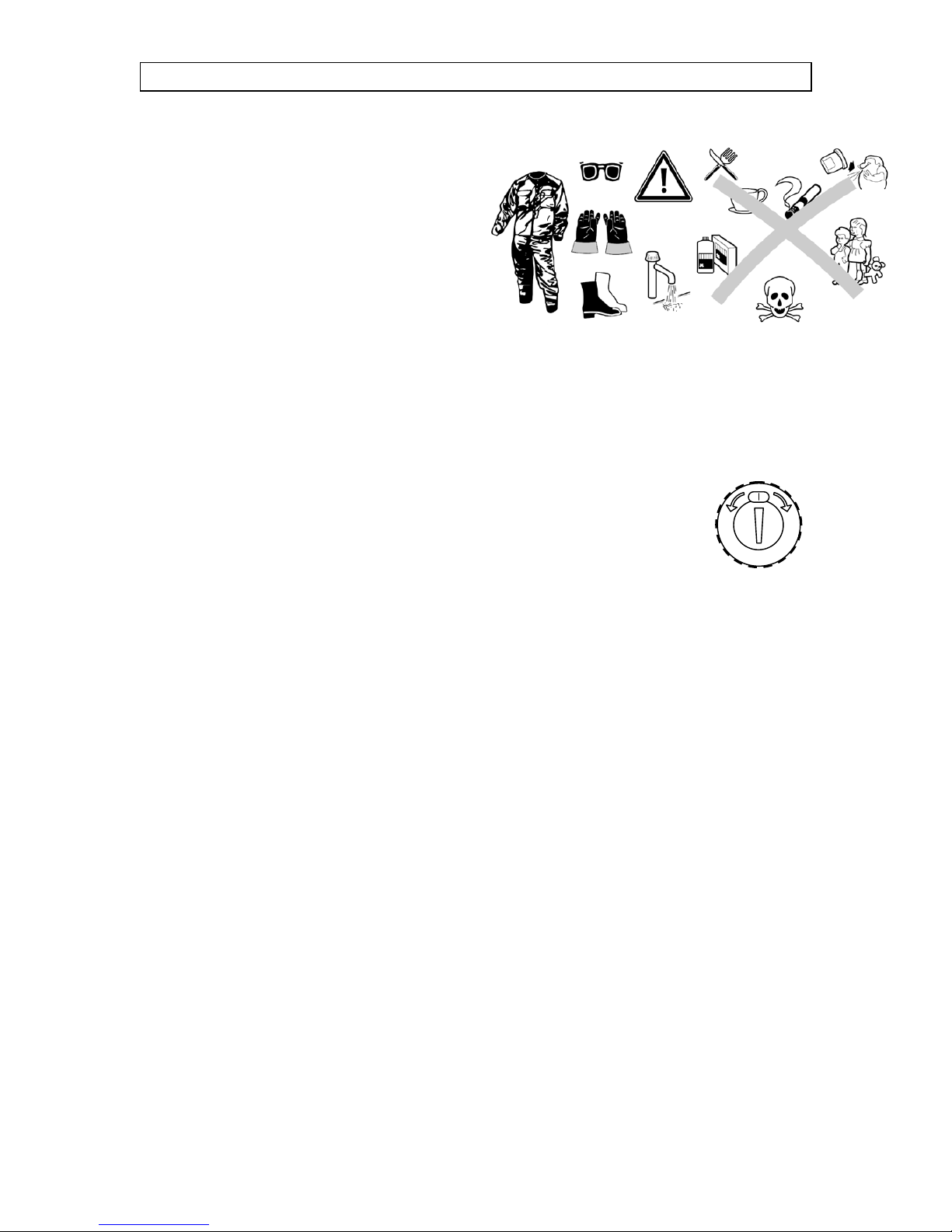

Protective measures

Observe remarks in the usage instructions for the

pesticide regarding the safety of the user; wear

recommended body protection. Wear protective gloves

when filling the chemical.

Do not eat, smoke or drink while working with

pesticides.

Avoid chemical spillage without fail. After completion of the

work, thoroughly clean hands and face.

Thoroughly clean and dry the unit immediately following its

usage. Never use the mouth to blow out nozzles or other

small parts!

Keep pesticides and applicators away from children.

Assembly and preparation for the first application

Assembly of this unit is described on page 3.

Before the first application of the unit, allow the battery to charge for at least 8 hours. First plug the applicator plug into the

loading socket, then plug the charging device into the 230 V power outlet. After ca. 8 hours charging time, the battery has

reached its full voltage capacity. When the charging process is complete, first unplug the charging device from the 230 V

power outlet, then unplug the unit plug from the charger socket.

The spray width should be subsequently checked - ideally with a piece of cardboard laid out on the ground - and the flow

rate adjusted. If the unit is switched on the battery monitoring LED lights green (fig. page 3/4)

Before using the MANKAR HQ the breather hole of the lid has to be opened.

If the air-vent is closed there won’t be an even chemical flow.

After usage the breather hole has to be closed to prevent leaking.

General remarks about the function and regarding the application of the unit

Pesticides: This applicator was originally designed for the undiluted application of Roundup products (Glyphosate).

Practical experience has shown, however, that other herbicides can also be deployed in conjunction with this technology.

Considering the many products on the market with their differing formulations, it is not possible to provide a complete list

with application rate recommendations. The specifications depicted below for adjusting the applicator relate to the usage of

Roundup UltraMax (Glyphosate 450 gr/ltr). In general, all products with a comparable viscosity are suitable. If you intend to

use a product other than Roundup UltraMax, its application should be initially tested on a trial basis over a small area. In

any case, the usage instructions for the chosen herbicide should be observed along with the local requirements.

Because of the compatibility with the materials used never use aggressive, solvents containing cleaning agents or gasoline.

Applicator function: The rotating atomiser is driven by means of a rechargeable battery. Metering takes place by means of

a metering valve. Droplets are formed by the centrifugal force of the rotating atomiser. The droplets are discharged

downwards by the rotating atomiser through a step-free, adjustable segment. The residual chemical in the tank, not able to

be applied, is approximately 10 ml. This residual fluid can be refilled back into the original herbicide container.

Checking applicator function: Chemicals can flow at differing rates, more quickly or slowly, due to temperature variations.

For this reason, the flow rate depicted in the metering table must be checked and corrected as necessary. This technology

is not suitable for the application of water. Always use herbicides for testing the spray process and for calibrating the flow

rate. Check the rotating atomiser for cleanliness and free turning movement on a daily basis. Check the application volume

from time to time throughout the season.

Deployment of the applicator: Position the spray hood directly above the ground - if the spray hood is held too high, the

danger of spray driftage exists. During operation, chemical fluid will collect in the atomiser reservoir and can continue to drip

for few seconds after pressing the switch- valve unit. Make sure that the valve of the bottle lit is open before use. After

usage close the valve again to provide leakage.

Attention!

If there is any leakage the stop working and repair the unit.

Before lifting or tilting the spray hood, it is essential that the stop valve is closed and the atomiser motor is switched off.

Cleaning: It is common practice that spraying systems need a minimum of service and maintenance same applies for the

MANKAR HQ. Rinse the unit with warm clear water. To accelerate the cleaning procedure a cleaning agent like “tankcleaner” can be used. Regular cleaning reduces sediments and prevents obstructions of the valve and blocking of the

atomizer.

1= open

0= closed

Draft of the bottle lid

Page 3

16.08.2013 3

Scope of delivery and assembly

Dosing

MANKAR HQ 20

at a walking speed of 4 km/h and 20 °C Roudup PowerFlex

applied Pre-position Droplets per ml per

quantity desired metering knob minute minute

1l / ha A 33 1,3

2l / ha A-B 67 2,7

3l / ha B 100 4,0

3,75l / ha B-C 133 5,3

MANKAR HQ 30 MANKAR HQ 45

at a walking speed of 4 km/h and 20 °C Roudup PowerFlex at a walking speed of 4 km/h and 20 °C Roudup PowerFlex

applied Pre-position Droplets per ml per applied Pre-position Droplets per ml per

quantity desired metering knob minute minute quantity desired metering knob minute minute

1l / ha A 50 2,0 1l / ha B 75 3,0

2l / ha B 100 4,0 2l / ha B-C 150 6,0

3l / ha B-C 150 6,0 3l / ha C 225 9,0

3,75 l / ha C 200 8,0 3,75l / ha C-D 300 12,0

Contens: - MANKAR HQ

- Reservoir 0,5L HQ

- Charger 6V

- Shoulder strap

- Stretch covers for spray

hood

- Operating instructions

Insert the resevoir into the guide

rail and fix it with the k n urle d

head screw

MAKE SURE THAT YOU

CHARGE THE MANKAR

HQ

D

B

C

Droplets/min

O.K.

Droplets/min

ml/min

Page 4

17.03.2011 4

Setting and verification

Flow rate

• Place an underlay (e.g. cardboard or paper) on the ground.

• Fill the chemical tank with herbicide (undiluted).

• Set down the applicator as pictured below.

• Remove the hose from the atomizer. (B)

• Place the measuring cylinder beneath the flow rate controller (see drawing on page 3).

• First set metering valve to maximum. (D)

• Actuate switch/valve unit (C) and select continuous operation by pushing the button switch forward.

• When the herbicide reaches the metering valve (identifiable i n the flow rate controller), the desired setting

(see table) is adjusted on the valve. (D)

• Collect the herbicide for 60 sec. in the measuring cylinder.

• If desired quantity is not reached, readjust metering valve and calibrate again.

• Afterwards reattach the hose.

Example for the MANKAR HQ: The setting A is an approximation for Roundup UltraMax; 3 ml/min. Deviation from

the desired volume can be regulated at the metering valve by setting a greater or lesser flow rate.

Spray width

• Hold the applicator in its working position above the overlay (e.g. cardboard or paper). Actuate the button switch

and initially direct the spray hood at the underlay, appraising the spray width at various heights above the section

being sprayed. The spray width must be set in such a manner that the droplets are discharged over the entire

spray hood width. The optimal spray width is set by the manufacturer under standard operating conditions.

• It is possible to compensate for deviations by loosening the screw (F) and sliding the width adjustment on the

atomiser (see drawing) to adjust either side so that the spray jet just misses the edge of the hood.

Working width

• The whole spray hood of the MANKAR HQ can be turned continuously to get a working width from 45 to 15 cm.

When the desired volume is obtained, the spray width verified and the working width adjusted, the application

process can begin.

E. Correct rotation direction for disc

G: Setting of spray hood adjustment

G

Page 5

17.03.2011 5

Cleaning

Do not clean the applicator with a high-pressure spray or with an intense water jet spray.

Cleaning during the season: During short breaks in the work day (a few hours), the herbicide can

remain in the system as long as the metering valve is closed. After completion of work task: before

cleaning, return the chemical into its original container. Set the metering valve to maximum (water

cock symbol). Fill the chemical tank half way with water, actuate the button switch and allow the

atomiser to run for 3 minutes over a collector tank or spread the cleaning fluid over the previously

worked surface. Remove the remaining water from the tank.

Cleaning after the season: Rinse the unit with warm water or cleaning agent like “tankcleaner” as

described above. The spray hood and the atomiser housing can be cleaned with a moist cloth,

except the atomiser disc in order to avoid damage. For heavy contamination, the atomiser housing

should be unscrewed to remove contaminants and plant parts. Connect the unit to the battery

charger (see page 3).

Charging the applicator and care of the accumulator

The applicator is fitted with an automatic charging device. Trickle charging is possible.

In order to charge a completely empty battery back up to full capacity, ca. 16 hours charging time is required. When a battery is

empty, it should be immediately recharged. Never leave a battery discharged for long periods.

Battery charging Minimum charging time Time interval

Fully discharged 8 hrs. immediately

Short-term usage 3 hrs. immediately

Storage without usage ( 2 hrs. 1 x per month) or permanent charge

The applicator can be used for ca. 8 hours with a fully charged battery.

Battery and motor monitoring

If the battery is fully charged the LED lights green. If the battery was

charged for 8 hours and the monitoring LED still lights red, the

atomiser disc might be seized. Reason for that can be insufficient

cleaning. (see fault remedy below)

Another reason might be a defective battery. In this case the battery

has to be replaced.

Fault remedy

Fault Cause Remedy

Atomiser disc not Atomiser contaminated Thoroughly clean atomiser, remove plant parts if needed

turning Battery empty Charge battery

Fuse blown Replace fuse on powerpack

(Replacement fuses are located in the powerpack

housing)

No electrical contact Check cable or connector contact

Battery defective Install new battery

Atomiser motor defective Install new motor module

Atomiser spray Rotation disc turning in the wrong direction Connect cable correctly!

one-sided Selectively plug the brown cable onto the contact pin

on the switch/valve unit

Connect the blue cable via the round pin plug.

Check to ensure the battery connection to the

powerpack is correctly poled, brown cable to Plus (+).

Atomiser spray too wide Width adj ust men t improperly set Loosen the screw (F, see page 4) and correct the

width setting to the left or to the right, respectively

Atomiser drips Metering valve incorrectly set Check setting, see table

Atomiser disc defective / contaminated Replace / clean disc

Atomiser spray discharge contaminated Clean

Atomiser foams Residual water in system Completely empty container, hose, segmental atomiser.

Chemical not Metering valve clogged Set scale to maximum . flush the unit with warm

flowing evenly water or use cleaning syringe

(accessory art.-no. 100348).

Breather hole of the lid is clogged Clean the lid with warm water

Page 6

16.08.2013 6

Components und spare parts for MANKAR HQ

Item Part No. Description

1 102905 Cover for frame, left, MANK AR HQ

102906 Cover for frame, right, MANKAR HQ

2 102908 Grip front plate, MANKAR HQ

3 103341 Grip-frame, left, MANKAR HQ 2012

103342 Grip-frame, right, MANKAR HQ 2012

4 103343

Spray hood tube with electronics, socket and fuse

holder complete, MANKAR-HQ

5 102901 Shaft-spray hood adjustment, left, HQ

102902 Shaft-spray hood adjustment, right, HQ

6 102907 Spray hood 45 cm MANKAR HQ

7 103441 Mounting-set for spray hood HQ 20 cm

8 100979 Spray hood 20 cm

9 103442 Mounting-set for spray hood HQ 30 cm

10 101662

Spray hood 30 cm width from 2007 without atomiser

and spray hood bracket

102965 Screw kit MANKAR HQ

102445

Charger 100-240, 6V DC / 450mA (NEW)

no pic.

Item Part No.

Description Item Part No. Description

103150

Atomiser for MANKAR HQ 1 102915 Dosing valve for MANKAR HQ

1 103153

Motor-module for atomiser MANK AR-HQ

2 100478

Atomiser disc f or segment atomiser

3 101996

Segment-module for segmental atomiser inc l . width

1 102946

Slide cap for MANKAR HQ

2 102914

Valve unit MANKAR HQ

1 103320

Bottle lid for 0,5 litre reservoir with breather 3 102890 Micro switch for MA NK AR HQ

2 102958

Knurled screw M 4x20 mm 4 103417 Storage battery 6V - 3,8 Ah / 3, 2Ah

3 104951

Reservoir 0,5 L for MANKAR HQ 2015 5 100693 Socket, d=2,1 mm

6 103319

Flow controller cpl. PC, HQ PC-glas s 35.0 mm

7 100365

Fuse holder complete MINI-MANTRA / MANKAR /

FLEXOMANT / …

7

6

10

9

1

2

4

5

6

8

7

Page 7

16.08.2013 7

Storage

1. Empty the tank. The undiluted herbicide can be decanted into the original tank.

2. Fill the tank half with water or cleaning agent for example “Tank-cleaner” and mount it.

3. Set the Dosing valve to the max (water tap symbol)

4. Switch the unit on (switch on hand grip) let it run for app. 3 minutes

5. Charge the MANKAR HQ with the attached charger

6. The unit can be cleaned with a moist cloth

If you follow the instructions for cleaning and maintenance, the MANKAR HQ will give

pleasure to you for a long time.

Page 8

02.06.2016 8

EG-Declaration of conf ormity

Council Directive 2006/42/EG

Mantis ULV-Sprühgeräte GmbH, Vierlander Straße 11 a, 21502 Geesthacht declare under our sole

responsibility that the following products are in conformity with the provisions of the following Council

Directive: 2006/42/EG

Typ MANKAR-HQ with 0,5-l-reservoir, MANKAR-HQ with 1-l-bottle

Hiske Weissmann

Managing Director

Geesthacht January 2016

_______________________ _________________________________

(Place and date of signature) (Name, title and signature)

Loading...

Loading...