Page 1

M SERIES

M-15/45/90 Ice Dispensers

INSTALLATION & SERVICE GUIDE

Part Number 5011634

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

March 23, 2005 REV1

Page 2

FOREWORD

Manitowoc Beverage Equipment (MBE) developed this manual as a reference guide for the owner/

operator , service agent, and installer of this equipment. Please read this manual before installation

or operation of the machine. A qualified service technician should perform installation and startup of this equipment, consult the Troubleshooting Guide within this manual for service assistance.

If you cannot correct the service problem, call your MBE Service Agent or Distributor . Always have your model and

serial number available when you call.

Your Service Agent___________________________________________________________________

Service Agent Telephone Number ______________________________________________________

Your Local MBE Distributor ___________________________________________________________

Distributor Telephone Number _________________________________________________________

Model Number ______________________________________________________________________

Serial Number _______________________________________________________________________

Installation Date _____________________________________________________________________

UNPACKING AND INSPECTION

Note: The unit was thoroughly inspected before leaving the factory. Any damage or irregularities should

be noted at the time of delivery.

WARRANTY INFORMATION

Consult your local MBE Distributor for terms and conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general adjustments, cleaning, accessories and related servicing.

Your warranty card must be returned to Manitowoc Beverage Equipment to activate the warranty on this

equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves

the MBE factory .

No equipment may be returned to Manitowoc Beverage Equipment without a written Return Goods

Authorization (RGA). Equipment returned without an RGA will be refused at MBE’ s dock and returned to

the sender at the sender’s expense.

Please contact your local MBE distributor for return procedures.

Page 3

TABLE OF CONTENTS

FOREWORD ........................................................................................................ 2

UNPACKING AND INSPECTION ........................................................................2

WARRANTY INFORMA TION ............................................................................... 2

SAFETY ...............................................................................................................5

IMPORT ANT SAFETY INSTRUCTIONS ............................................................................. 5

CARBON DIOXIDE WARNING........................................................................................... 5

QUALIFIED SERVICE PERSONNEL .................................................................................. 5

SHIPPING , STORAGE, AND RELOCATION....................................................................... 5

ADDITIONAL WARNINGS ................................................................................................. 5

GROUNDING IN STRUCTIONS ......................................................................................... 6

INSTALLATION.................................................................................................... 7

COUNTER TOP INST ALLA TION........................................................................................ 7

DRAINAGE OPTIONS ....................................................................................................... 7

OPERATION ........................................................................................................ 8

UNIT INSPECTION ............................................................................................................ 8

ICE RECOMENDED FOR DISPENSING ............................................................................. 8

ICE STORAGE AND DISPENSING .................................................................................... 8

PUSH LEVER ICE DISPENSING........................................................................................ 8

PUSH BUTTON ICE DISPENSING..................................................................................... 8

BEVERAGE SYSTEM ........................................................................................................ 8

SPECIFICA TIONS ............................................................................................................. 9

AGIT ATION TIMER ........................................................................................................... 11

DOOR............................................................................................................................... 11

BIN FLOW RESTRICTOR & ICE FLOW............................................................................12

GEAR MOTOR REMOV AL................................................................................................12

Page 4

TABLE OF CONTENTS

USER MAINTENANCE ......................................................................................13

CLEANING AND SANITIZING ...........................................................................................13

EXPLODED VIEWS, PARTS & DIAGRAMS .....................................................14

M-15A/15B/45/90 ST ANDARD ALL VOL T AGES ................................................................14

M-15C ST ANDARD ALL VOL T AGES ................................................................................14

M-15C WITH AGIT A TION TIMER ......................................................................................15

M-90 WITH LIGHTS AND VAL VES ALL VOL TAGES ........................................................15

M-15 EXPLODED VIEW (TOP) .........................................................................................16

M-15 EXPLODED VIEW (BASE) .......................................................................................17

M-15 A EXPLODED VIEW (FRONT)..................................................................................18

M-15 B EXPLODED VIEW (FRONT)..................................................................................19

M-15 C EXPLODED VIEW (FRONT)..................................................................................20

M-45/90 EXPLODED VIEW (BASE)...................................................................................21

M-45/90 EXPLODED VIEW (FRONT) ................................................................................23

M-90 EXPLODED VIEW (FRONT) .....................................................................................25

TROUBLESHOOTING....................................................................................... 27

INDEX ................................................................................................................ 31

Page 5

Installation and Service Manual

SAFETY

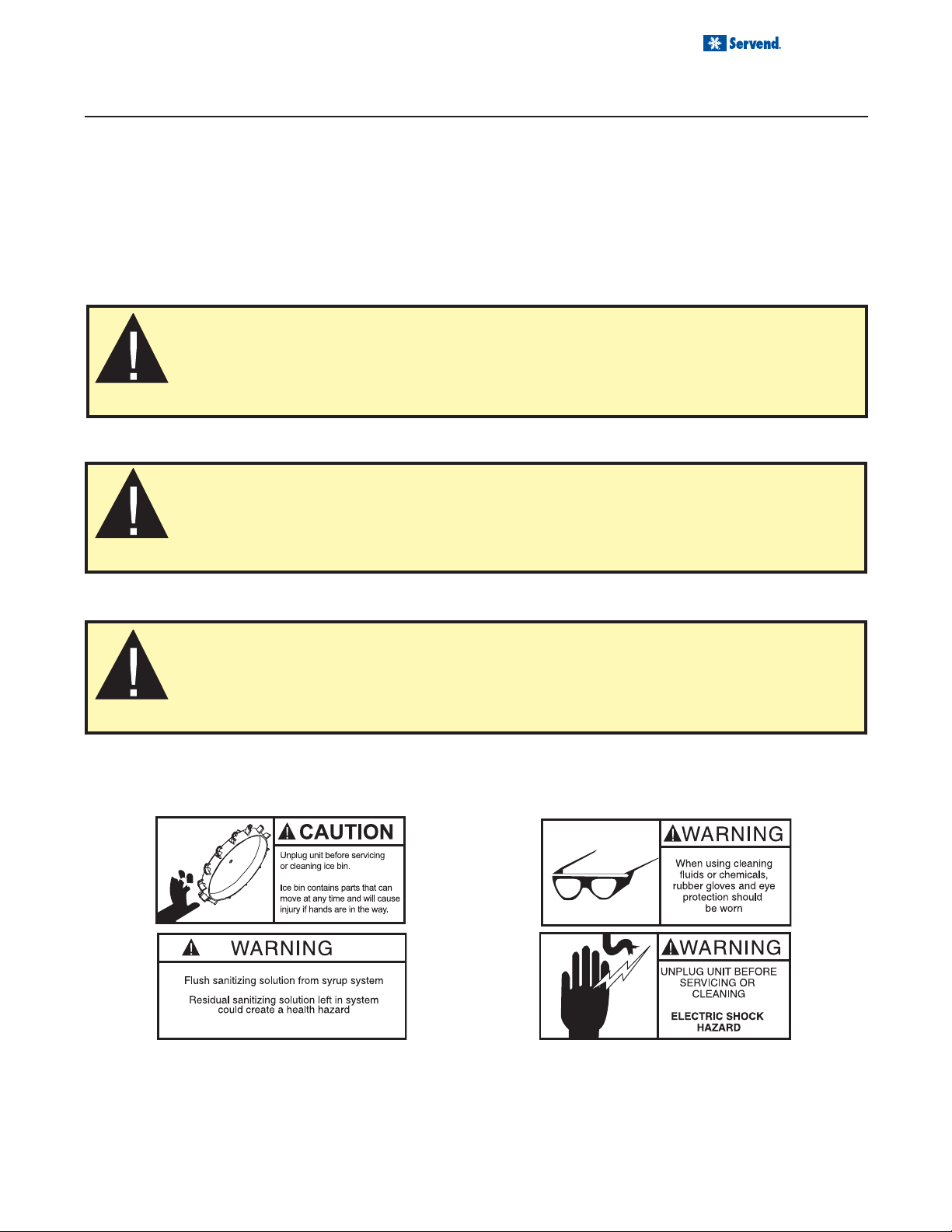

IMPORTANT SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual. Learn how to operate the SV unit properly . Do not

allow anyone to operate the unit without proper training and keep it in proper working condition.

Unauthorized modifications to the SV may impair function and/or safety and affect the life of the unit.

CARBON DIOXIDE WARNING

DANGER: Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas causes

tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO2 gas leak is

suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO2 lines

and pumps should not be installed in an enclosed space. An enclosed space can be a cooler or small

room or closet. This may include convenience stores with glass door self serve coolers. If you suspect CO

may build up in an area, venting of the B-I-B pumps and / or CO2 monitors should be utilized.

QUALIFIED SERVICE PERSONNEL

WARNING: Only trained and certified electrical and plumbing technicians should service this unit. All

wiring and plumbing must conform to national and local codes.

2

SHIPPING, STORAGE, AND RELOCATION

CAUTION: Before shipping, storing, or relocating this unit, syrup systems must be sanitized. After

sanitizing, all liquids (sanitizing solution and water) must be purged from the unit. A freezing environment causes residual sanitizing solution or water remaining inside the unit to freeze, resulting in

damage to internal components.

ADDITIONAL WARNINGS

Installation and start-up of this equipment should be done by a qualified service technician. Operation,

maintenance, and cleaning information in this manual are provided for the user/operator of the equipment.

Save these instructions.

5

Page 6

SAFETY

GROUNDING IN STRUCTIONS

WARNING: Risk of electrical shock. Connect to a properly grounded outlet only .

This appliance must be grounded. In the event of malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of electric shock. This appliance is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor with insulation having an outer surface that is green with or without yellow

stripes is the equipment grounding conductor. If repair or replacement of the cord or plug is necessary , do not connect the equipment-grounding conductor to a live terminal. Check with a qualified

electrician or serviceman if the grounding instructions are not completely understood, or if in doubt

as to whether the appliance is properly grounded. Do not modify the plug provided with the appliance – if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING – When using electric appliances, basic precautions should always be followed, including the following:

a)Read all the instructions before using the appliance.

b)T o reduce he risk of injury , close supervision is necessary when an appliance is used near

children.

c)Do not contact moving parts.

d)Only use attachments recommended or sold by the manufacturer .

e)Do not use outdoors.

f) For a cord-connected appliance, the following shall be included:

• Do not unplug by pulling on cord. T o unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use and before servicing or cleaning.

• Do not operate any appliance with a damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in any manner . Return appliance to the nearest

authorized service facility for examination, repair , or electrical or mechanical adjustment.

g)For a permanently connected appliance – Turn the power switch to the off position when

the appliance is not in use and before servicing or cleaning.

h) For an appliance with a replaceable lamp – always unplug before replacing the lamp.

Replace the bulb with the same type.

i) For a grounded appliance – Connect to a properly grounded outlet only. See Grounding

Instructions.

SAVE THESE INSTRUCTIONS

Page 7

INSTALLATION

COUNTER TOP INSTALLATION

Check the equipment location. Assure the proper drain and

electrical requirements are available before proceeding.

Carefully remove the dispenser from the shipping carton.

If the dispenser is to be set on legs, lay the dispenser on its’

back. Use the shipping cardboard as a protective interface

between the dispenser and the floor. Thread the legs into

the leg gussets on the bottom corners of the dispenser. If

the dispenser is to be set on a counter without the legs,

most local codes require the dispenser to have a silicone

seal between the counter and the dispenser.

Carefully pick up the dispenser, setting it in place. Be sure

the dispenser is stable and level. Place a level on the top of

the bin, side to side and front to back to see if the bin is

level. If the dispenser has legs, level the dispenser bin by

adjusting the dispenser legs. If the dispenser does not have

legs, shim between the counter top and the dispenser.

Remove the splash panel and drain pan from the front of

the dispenser. If your dispenser has beverage valves at-

Installation and Service Manual

tached, these valves will be attached to the splash panel.

Included inside the dispenser from the factory is a length

(1.8m [6ft.]) of vinyl tubing. One half of this tubing is to be

used for the bin drain, with the other half of the tubing used

for the drain pan drain. Att ached to the tubing are two tubing adaptors.

If beverage valves are supplied with your dispenser, connect them to the beverage system at this time according to

the information supplied by the beverage supplier.

Route the electric wires under the dispenser and out to the

electrical receptacle.

Replace the drain pan to the dispenser. Secure the free

ends of the vinyl drain tubing to the drain connections supplied by the owner/operator. Attach the splash panel to the

front of the dispenser.

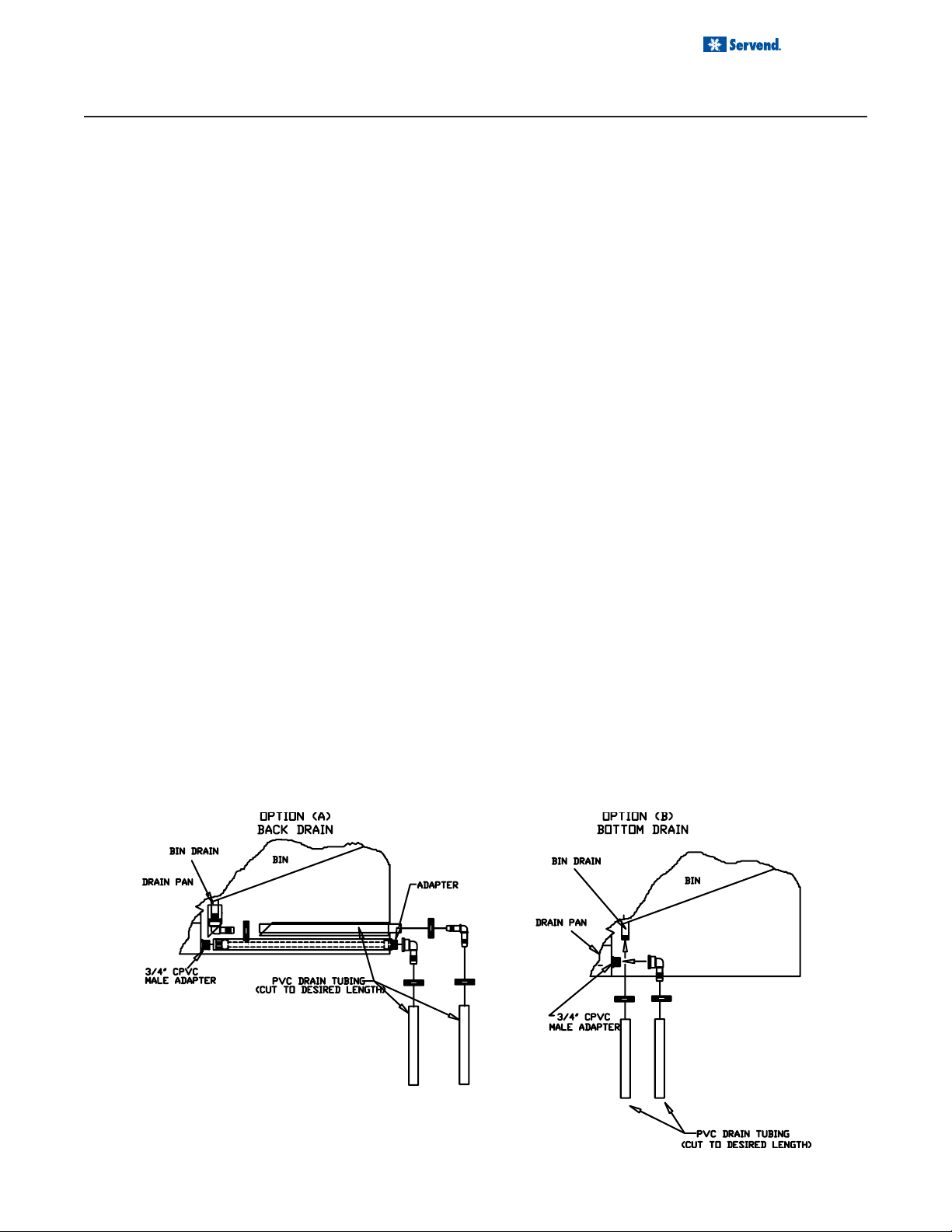

DRAINAGE OPTIONS

OPTION A

One drain tube fitting is with a 90° bend. This fitting attaches to the bin drain fitting. Underneath the dispenser

toward the front of the dispenser is the bin drain. Attach

the 90° fitting to the bin drain outlet. Slip the drain tubing

over the tubing end of the fitting. Secure the tubing with

the hose clamp provided.

The second drain tube fitting is a straight connector. This

fitting attached to the drain pan fitting of the dispenser.

Attach the fitting to the drain pan. Slip the drain tubing

over the tubing end of the fitting. Secure the tubing with

the hose clamp provided. Insulate all drain tubes.

OPTION B

One drain tube fitting is with a straight connector. This fitting attaches to the bin drain fitting. Underneath the dispenser toward the front of the dispenser is the bin drain.

Attach the straight fitting to the bin drain outlet. Slip the

drain tubing over the tubing end of the fitting. Secure the

tubing with the hose clamp provided.

The second drain tube fitting is a 90° bend. This fitting

attached to the drain pan fitting of the dispenser. Attach

the fitting to the drain pan. Slip the drain tubing over the

tubing end of the fitting. Secure the tubing with the hose

clamp provided. Insulate all drain tubes.

7

Page 8

Installation and Service Manual

OPERATION

UNIT INSPECTION

Thoroughly inspect the unit upon delivery . Immediately report any damage that occurred during transportation to the

delivery carrier. Request a written inspection report from a claims inspector to document any necessary claim.

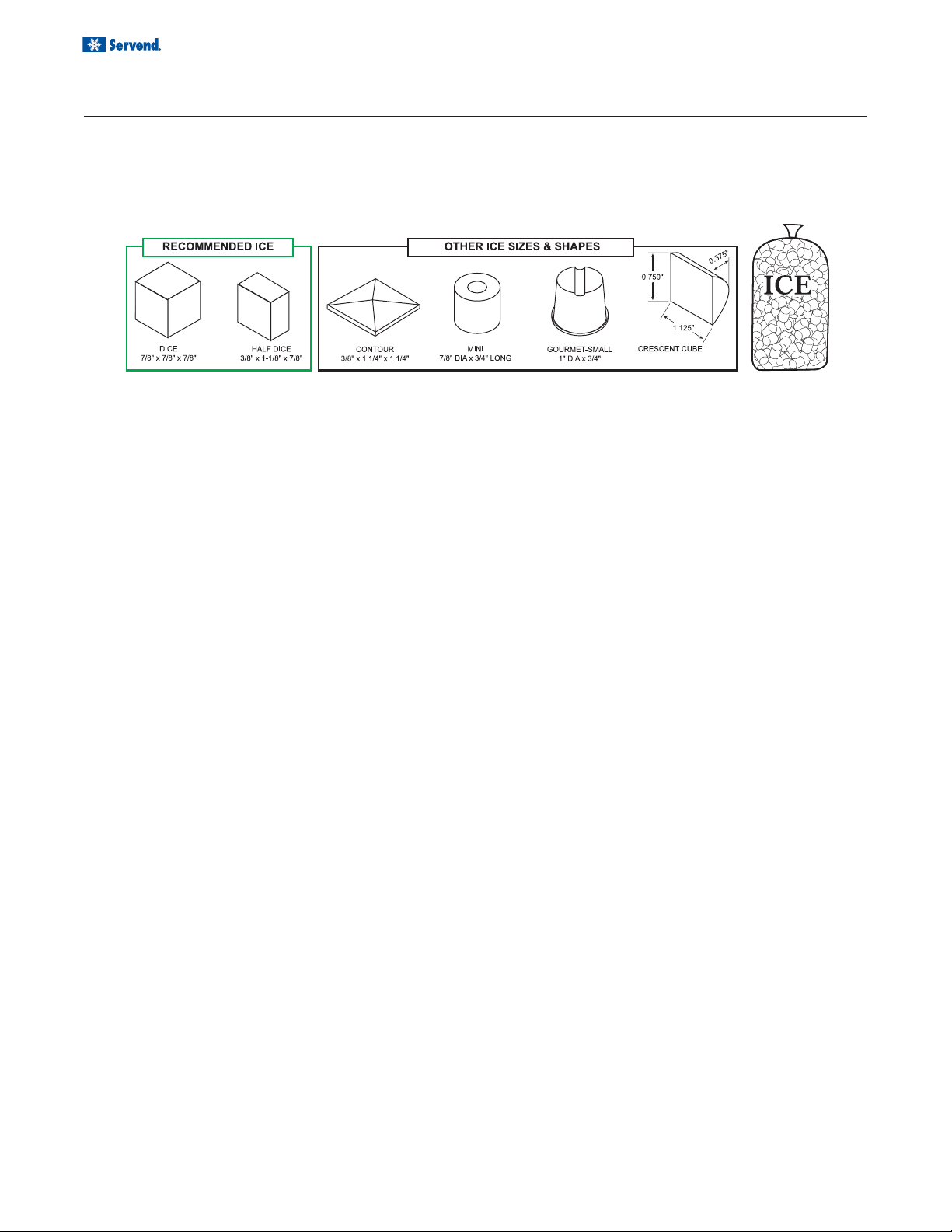

ICE RECOMENDED FOR DISPENSING

Servend dispensers are designed to dispense hard, cube ice up to one-inch square. The ice shapes and sizes

listed above are recommended for dispensing. Warm “Super Cooled” Ice Before Dispensing “Super Cooled”

ice is not recommended for dispensing. “Super cooled” ice is ice that has been stored in freezers below 32

Should it be necessary to temporarily use “super cooled” ice, allow the ice to warm at room temperature for 25

to 30 minutes before placing the ice in the dispenser.

ICE STORAGE AND DISPENSING

o

F.

Ice is stored in the dispenser’s bin. Ice is transported from the bottom of the bin to the ice dispense point by the paddle

wheel. The injection molded paddle wheel has paddles which lift the ice to the dispense point.

PUSH LEVER ICE DISPENSING

The customer’s cup presses against the push plate. The

push plate then raises a microswitch actuator arm on the

right side of the dispensing chute. The microswitch actuator arm hits the lever of the microswitch.

The energized microswitch activates the solenoid, which

pulls down the solenoid plunger. The plunger is connected

to a cable, which is then connected to a pulley . This raises

the door of the ice chute.

The energized microswitch also activates the gear motor.

The gear motor turns the agitator and paddle wheel, lifting

the ice from the bottom of the bin to the ice dispenser point.

Ice falls forward through the open door, through the bin

spout, through the ice chute and into the customer’s cup.

PUSH BUTTON ICE DISPENSING

Customer’s finger presses the push button, located in the

merchandiser frame. The button is labeled “ICE”

The push button energized the plunger microswitch. The

energized microswitch activating the solenoid, which pulls

down the solenoid plunger. The plunger is connected to a

cable, which is then connected to a pulley . This raises the

door on the ice chute.

The energized microswitch also activates the gear motor.

The gear motor turns the agitator and paddle wheel, lifting ice from the bottom of the bin to the ice dispense point.

The dispenser paddle wheel turns counter clockwise looking at the wheel from the outside front of the dispenser.

Ice falls forward through the open door, through the bin

spout, into the ice chute and into the customer’s cup.

BEVERAGE SYSTEM

Installation and maintenance of the beverage system is not covered in this manual. The Servend M series dispenser

is an ice only dispenser. In some applications, the dispenser provides a mounting location for optional beverage

valves. Please contact your MBE Service Company for installation and maintenance of your beverage system.

8

Page 9

OPERATION

SPECIFICATIONS

Installation and Service Manual

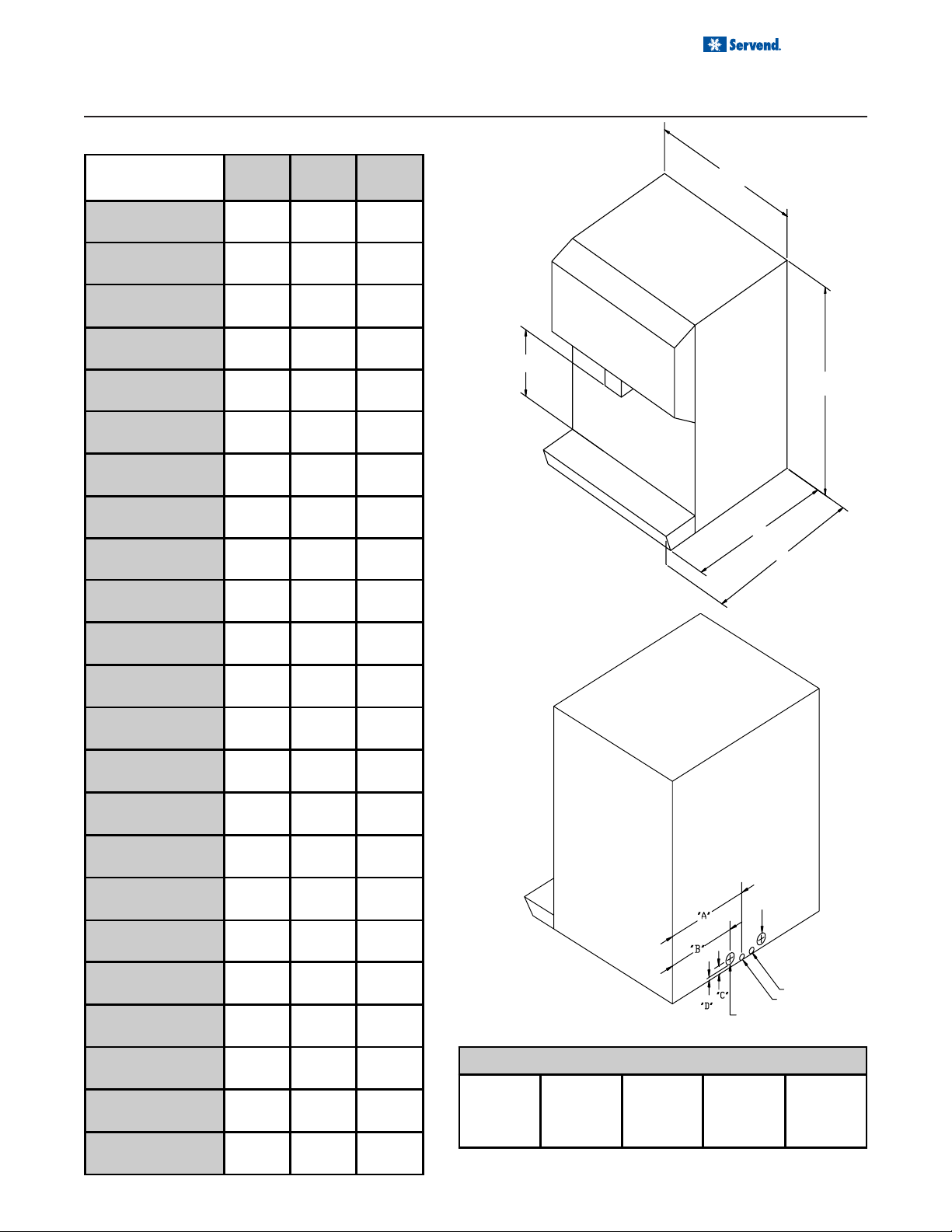

M-15 M-45 M-90

Width 38.1 cm

(15")

Depth - overall 71.1 cm

Depth - cou nter

top

Height 81.3 cm

Dispense Heig ht 24.8 cm

Bin Top S ize -

width

Bin Top S ize depth

Rear "A" 19.1 cm

Rear "B" 19.1 cm

Hole "E" Height

(to p h o le)

(28")

66 cm

(26")

(32")

(9 .75" )

38.1 cm

(15")

52.1 cm

(20.5")

(7 .5")

20.5 cm

(8 .06" )

38.1 cm

(15")

71.1 cm

(28")

66 cm

(26")

61.6 cm

(32")

24.8 cm

(9.7 5" )

38.1 cm

(15")

45.4 cm

(17.88")

29.3 cm

(11.5 ")

(7.5 ")

38.1 cm

(15")

71.1 cm

(28")

66 cm

(26")

81.3 cm

(32")

24.8 cm

(9.75")

38.1 cm

(15")

45.7 cm

(18")

29.2 cm

(11.5")

19.1 cm

(7.5")

WIDTH

DISPENSE HEIGHT

HEIGHT

DEPTH COUNTERTOP

DEPTH OVERALL

Hole "F"

Diameter

Hole "G"

Diameter

Hole "H" H eight

(b o tto m h o le )

Hole "E"

Diameter

Hole "H"

Diameter

Right side to bin

drain

Right side to

drain pan drain

Rear to bin drain 35.9 cm

Rear to drain pan

drain

Bin drain fitting

size

Drain pan fitting

size

Ice storage

capacity

Motor

Horsepower

7.8 cm

(3 .06" )

5 cm

(2")

5 cm

(2")

19.0 cm

(7 .5")

25.4 cm

(10.0")

(14.12")

53.3 cm

(21.0")

3/4"

M.I.P.T.

3/4"

M.I.P.T.

40.8 kg

(90lb)

1/15 1/15 1/15

5 cm

(2" )

5 cm

(2" )

18.8 cm

(7.5 ")

25 cm

(10")

38.7 cm

(15.25")

47.6 cm

(18.75")

3/4"

M.I.P.T.

3/4"

M.I.P.T.

20.4 kg

(45lb)

5 cm

(2")

5 cm

(2")

16.8 cm

(6.62")

25.4 cm

(10.0")

35.9 cm

(14.12")

53.3 cm

(21.0")

3/4"

M.I.P.T.

3/4"

M.I.P.T.

40.8 kg

(90lb)

120 Volts 60 Hz. - 1.2

amp (U.S.

Standard)

HOLE "H"

HOLE "E"

Electric voltage - Cycle - Amperage

100 Volts 50 / 60 Hz.

- N/A

220 Volts 50 Hz. -

0.44 amp

220 Volts

60 Hz. - N/A

HOLE "G"

HOLE "F"

240 Volts

50 Hz. -

0.35 amp

9

Page 10

Installation and Service Manual

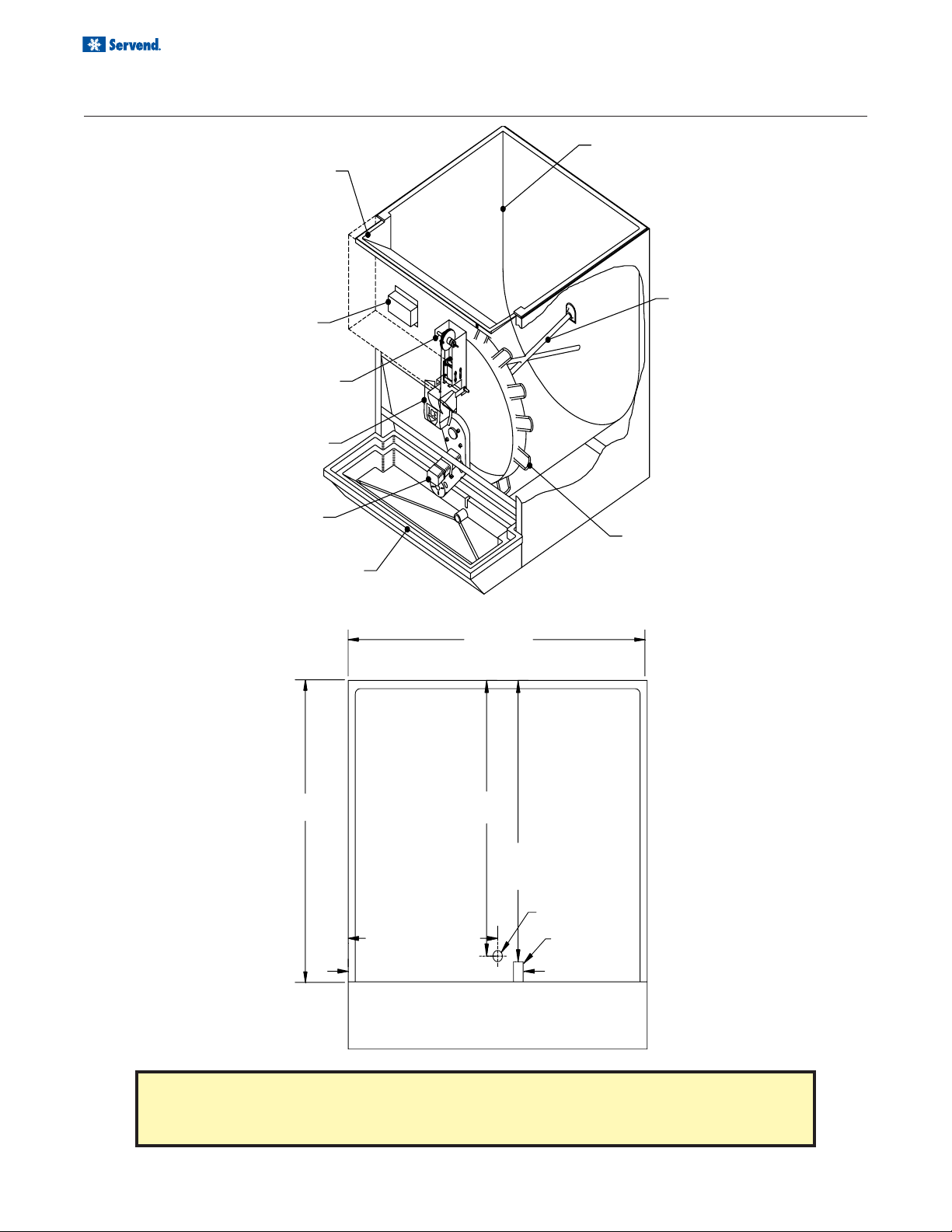

ELECTRICAL BOX

OPERATION

ICE BIN

MANUAL FILL AREA

(M-200 & LARGER)

AGITATOR

DOOR ASSEMBLY

ICE CHUTE

GEAR MOTOR

DRAIN PAN

BIN LEGNTH

RIGHT

SIDE

REAR TO

BIN DRAIN

RIGHT SIDE TO BIN DRAIN

BIN WIDTH

REAR

REAR TO

DRAIN PAN

DRAIN

PADDLE WHEEL

LEFT

SIDE

BIN DRAIN

DRAIN PAN DRAIN

10

RIGHT SIDE TO DRAIN P AN DRAIN

DRAIN PAN

CAUTION: Cutting the countertop may decrease its strength. Counter should

be braced to support the dispenser countertop weight plus ice storage capacity and weight of icemaker, if applicable.

Page 11

OPERATION

AGITATION TIMER

The agitation timer is standard equipment for the dispensers with

90.7 kg. (200 lbs.) and larger bin storage. This timer is available

as an option for all other dispensers. The purpose of the timer is

to periodically agitate the ice in the bin, preventing the ice from

congealing together.

The timer is located in the electrical box of the dispenser. The two

dials on the timer should be set to agitate the ice for two seconds

every four hours of non ice dispenser use.

T o check the agitation timer , turn the off time dial (right dial on the

drawing below) counter clockwise until the dial stops. Do not use

the dispenser for 15 minutes. Within that time period, the agitator

will turn. If the agitator does not turn, replace the timer .

If the solenoid is electrically activated when the agitation timer

moves the gear motor, the timer has shorted out internally and

must be replaced.

T o correctly reset the agitation timer, turn both dials counter clockwise until they stop. Y our “point s” on the dials will be set at “0”.

Turn the ON time (left dial) from the “0” to the “2”.

Turn the OFF time (right dial) from the “0” to the “4”.

The drawing shows the position of the dials when the timer is set

correctly .

Installation and Service Manual

DOOR

The door is used to stop the flow of ice to the container when the microswitch is released. The door assembly is not

used to reduce the flow of ice. See the ice flow reducer section.

When operated, the door should open completely. This

would be a minimum of 3.8 cm (1.5 in) as measured

from the bottom of the chute opening to the bottom

of the door when energized.

To adjust the door opening, raise or lower the door solenoid in the opposite direction you wish to effect the door .

EXAMPLE: If you wish to open the door wider, lower the

door solenoid. This will raise the door wider.

To move the solenoid, loosen the four machine screws

on the side of the coil. Slide the solenoid in the direction

you wish to move it. Tighten the screws on the solenoid

to secure the coil in place.

11

Page 12

Installation and Service Manual

OPERATION

GEAR MOTOR REMOVAL

These instructions are provided as a guide for the removal of the gear motor. Depending on the model number of your

dispenser, these instructions may vary slightly.

1. Disconnect power from the electric receptacle.

2. Remove all ice from the ice storage bin of the dispenser.

3. Remove the paddle wheel pin from the paddle wheel

/ agitator assembly inside the dispenser bin.

4. Remove the agitator assembly from the dispenser

bin by pushing the agitator to the back of the bin.

Angle the front of the agitator to the side. Pull the

agitator forward then out of the dispenser.

5. Remove the paddle wheel from the dispenser by

pulling the hub of the paddle wheel to the back of

the bin and off the gear motor shaft.

6. Remove the four bolts from the front wall of the dispenser. These bolts mount into the gear motor case.

7. Remove the front from the dispenser and expose

the gear motor.

8. Disconnect the electric connector from the gear motor wire leads.

9. Remove the strap from around the gear motor.

10. You should be able to remove the gear motor from

the dispenser.

11. To install a replacement gear motor, reverse this

procedure.

ICE BIN

GEAR MOTOR

BIN FLOW RESTRICTOR & ICE FLOW

The delivery of the ice from the dispenser is influenced by

several factors. The primary influence is the type of ice being

dispensed. If you are dispensing a wet, rounded corner ice,

this ice will dispense at a faster rate than an ice with square

corners.

Regardless of the ice you are dispensing, it is possible to

reduce the delivery of the ice. However the reduction will

AGITATOR

PADDLE WHEEL

depend upon the type of ice. DO NOT REDUCE THE DOOR

OPENING TO REDUCE ICE FLOW .

A flow restrictor is available as an option for installation in the

dispensing chute of the dispenser. This restrictor will prevent

a full paddle wheel “cup” of ice from being delivered into the

chute. This will then reduce the delivery of ice to the container.

12

Page 13

OPERATION

BIN FLOW RESTRICTOR & ICE FLOW

To install the ice flow restrictor:

1. Remove the merchandiser.

2. Remove the door assembly.

3. Drill 3/16” hole in top of chute from the bin as shown

in the above drawing.

Installation and Service Manual

4. Place the restrictor in the chute, holding with the bolt

and nut.

5. Tighten nut.

6. Replace door assembly and merchandiser.

USER MAINTENANCE

CLEANING AND SANITIZING

CAUTION: All cleaning must meet your local health department regulations. Use only warm

soapy water to clean the exterior of the tower. Do not use solvent s or other cleaning agents. Do not

pour hot coffee into the drain pan. Pouring hot coffee down the drain pan can eventually crack the

drain pan, especially if the drain pan is cold or still contains ice.

1. Unplug the dispenser from the electric receptacle.

2. Mix a cleaning solution consisting of a mild non abrasive detergent with water according to the package

directions.

3. Using the cleaning solution and a soft bristle brush or

cloth, wash the following dispenser parts: (With a top

mounted ice maker, accessibility is through the front

opening of the ice maker.) Paddle wheel pin (removed

from the dispenser) Agitator (removed from the dispenser) Paddle wheel (removed from the dispenser)

Entire bin area Ice chute Rear agitator bushing Drive

shaft assembly inside bin.

4. Mix a solution of 1.5 cl (1/2 oz.) household bleach to

7.5 L (2 gal) of clean water. To achieve 5.25% Cl Na

O concentration per gallon of water, the mixture should

supply 100 PPM (parts per million) of available

chlorine. Or mix a solution of any NSF approved sanitizer, following the directions for mixing and applying

that sanitizer.

5. Using the sanitizing solution and a soft bristle brush

or cloth, clean each of the dispenser parts listed above.

6. Do not rinse the parts af ter they have been sanitized.

Replace all parts back to the dispenser.

7. Pour in fresh clean ice into the dispenser bin. Or turn

the ice maker back on.

8. Plug the dispenser into the receptacle.

9. Check for proper ice dispensing.

13

Page 14

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-15A/15B/45/90 STANDARD ALL VOLTAGES

TO ELECTRIC

POWER SUPPLY

TO ELECTRIC

POWER

SUPPLY

M-15C STANDARD ALL VOLTAGES

14

Page 15

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-15C WITH AGITATION TIMER

M-90 WITH LIGHTS AND VALVES ALL VOLTAGES

15

Page 16

Installation and Service Manual

KEY # DESCRIPTION PART NUMBER (all models)

1 Lid 4100075

2 Flipper Door 4105503

3 Flipper Door Rod 4100008

4 Flipper Door Frame 4105502

5 Paddlewheel 2602235

6 Agitator 4105706

7 Paddlewheel Pin 5001683

8 Drain Kit Assembly 2602528

9 Mushroom Bushing O101702

11 Bin Insulator Plate 7015901

51 1/4-20 x 1" Stainless Steel Hex Head Cap Screw O900636

52 8 x 3/4 Stainless Steel Tapping Screw O901007

EXPLODED VIEWS, PARTS & DIAGRAMS

M-15 EXPLODED VIEW (TOP)

16

Page 17

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-15 EXPLODED VIEW (BASE)

KEY # DESCRIPTION PART NUMBER (all models)

10 Bin Insulator 2601968

Gearmotor 115 Volt - 60 Hz 1000120

100 Volt - 50/60 Hz 1000120

12

220 Volt - 50 Hz 5000345

220 Volt - 60 Hz 5000345

240 Volt - 50 Hz 5000345

13 Motor Cover 4100024

14 Vinyl Grommet O905702

15 Motor Brace 4570042

16 Large Radiator Clamp O903205

Capacitor for Gearmotor (5 mfd)115 Volt - 60 Hz 1001741

(8 mfd)100 Volt - 50/60 Hz 1001710

17

(3 mfd)220 Volt - 50 Hz 5000344

(3 mfd)220 Volt - 60 Hz 5000344

(2 mfd)240 Volt - 50 Hz 5000343

18 Capacitor Bracket 4100062

19 Electrical Box Assembly 4100051

20 Shield for Transformer & Relay 5002242

21 24 Volt Relay 5000900

KEY # DESCRIPTION PART NUMBER (all models)

Transformer 115 Volt - 60 Hz 1001424

100 Volt - 50/60 Hz 5001087

22

220 Volt - 50 Hz 5000967

220 Volt - 60 Hz 5000967

240 Volt - 50 Hz 5000967

30 Power Cord 115 Volt - 60 Hz ONLY 2600711

39 Electric Box Lid 1000507

40 Bin Insulator Gasket O400231

41 Motor Shaft Sleeve 2602236

42 1/4 x 5/8 Spring Pin O905005

43 Wiring Diagram 5002215

44 Motor Insulator Spacer 2602208

46 Galvanized Extension - Left 4100070

47 Galvanized Extension - Right 4100071

48 Finger Guard 4100063

49 Mylar Foam Hole Cover O301203

50 8 x 1/2 Stainless Steel Tapping Screw O901001

54 10-32 x 1/2" Screw O901301

55 10-32 ESNA Nut O902316

56 Ground Screw O903903

57 1/4-20 x 3/8 Bolt O900635

17

Page 18

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-15 A EXPLODED VIEW (FRONT)

18

KEY # DESCRIPTION PART NUMBER

21 Inner Ice Shield 4100038

22 Push Plate Retaining Bracket 4100007

Door Assembly (LESS SOLENOID COIL) - see page 36 for

23

solenoid door parts

24 Drip Pan Assembly 4105901

25 Drip Pan Rod 4100000

26 Hitch Pin O905209

27 UL Cover 4100022

28 2 1/8" Heyco Plug 1200320

29 UL Cover Top Angle (2 required) 4100069

31 Fake Valve Cover 4105508

32 Vented Heyco Plug 1200321

33 Pushplate 4100054

34 "ICE" Sticker O301299

46 10-32 x 1/2 Thumb Screw O901501

47 8 x 1/2 Stainless Steel Tapping Screw O901001

56 Fake Valve Alignment Brace 4100006

4105908

Page 19

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-15 B EXPLODED VIEW (FRONT)

KEY # DESCRIPTION PART NUMBER

21 Inner Ice Shield 4100038

Door Assembly (LESS SOLENOID COIL) - see page 36 for

23

solenoid door parts

24 Drip Pan Assembly 4105901

25 Drip Pan Rod 4100000

26 Hitch Pin O905209

27 UL Cover 4100022

28 2 1/8" Heyco Plug 1200320

29 UL Cover Top Angle (2 required) 4100069

31 Fake Valve Cover 4105508

32 Vented Heyco Plug 1200321

33 Push Button 5006080

34 "ICE" Sticker O301299

47 8 x 1/2 Stainless Steel Tapping Screw O901001

55 Fake Valve Alignment Brace 4100006

4105908

19

Page 20

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-15 C EXPLODED VIEW (FRONT)

KEY # DESCRIPTION PART NUMBER

Door Assembly (LESS SOLENOID COIL) - see page 36 for

23

solenoid door parts

24 Drip Pan Assembly 4105901

25 Drip Pan Rod 4100000

26 Hitch Pin O905209

27 UL Cover 4100022

28 2 1/8" Heyco Plug 1200320

29 UL Cover Top Angle (2 required) 4100069

31 False Valve Cover 5002229

32 Solenoid Cover 4100076

33 Vented Heyco Plug 1200321

34 Cover Chute 4100072

35 Push Button 5002217

36 "ICE" Sticker O301299

37 "DO NOT LIFT BY SHROUD" Sticker 5002473

38 "ICE" Sticker (Push Button) 5002538

45 6-32 x 3/8 Screw 5002197

50 8 x 1/2 Stainless Steel Tapping Screw O901001

53 8-32 x 1/2 Knurl Screw O904403

58 Fake Valve Alignment Brace 4100006

--- Timed Agitation Kit 5006794

--- Flow Restrictor Kit 5006796

--- Compressed Ice Agitator Kit 5006903

5002533

20

Page 21

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-45/90 EXPLODED VIEW (BASE)

See Electrical

view

21

Page 22

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-45/90 EXPLODED VIEW (BASE)

KEY # DESCRIPTION

1 Agitator 7015702 7015702

2 Paddlewheel Pin 5001683 5001683

3 Paddlewheel 2602235 2602235

4 Mushroom Bushing O101702 O101702

5 Lid 4570035 4570035

6 Bin Insulator 2601968 2601968

19 Screw for Mushroom Bushing O901001 O901001

20 Motor Cover 4630035 4570043

Gearmotor 115 Volt 60 Hz 1000120 1000120

100 Volt 50/60 Hz 1000120 1000120

220 Volt 60 Hz 5000345 5000345

21

240 Volt 60 Hz 5000345 5000345

220 Volt 50 Hz 5000345 5000345

240 Volt 50 Hz 5000345 5000345

PART NUMBER

M 45

PART NUMBER

M 90

22 Bin Insulator Plate 7015901 7015901

23 Bin Insulator Gasket O400231 O400231

24 Cosmetic Motor Cover 7010127 7010127

25 Stand Off Wire Tie 1000430 1000430

26 Wiring Diagram 5000016 5000016

Door Assembly (LESS SOLENOID COIL) - see

27

page 36 for solenoid door parts

28 Motor Brace 4570042 4570042

29 Splash Panel Clip 7000002 7000002

30 Extra Large Radiator Clamp O903205 O903205

42 Electric Cord 2600711 2600711

44 Drain Kit 2602528 2602528

45 Motor Insulator Spacer 2602208 2602208

47 Motor Shaft Sleeve Roll Pin O905005 O905005

48 Motor Shaft Sleeve 2602236 2602236

4635907 4575918

22

Page 23

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-45/90 EXPLODED VIEW (FRONT)

KEY # DESCRIPTION

Medallion - PL ICE 5000167 O300102

- PL with valves ICE N / A 5006865

- PB ICE N / A 5006866

7

- PB with valves ICE N / A 5006867

- PL PEPSI N / A O300170

- PB with valves WHITE N / A 5006730

- PB with valves CLEAR N / A 4572101

8 Merchandiser (includes angles) 4635902 4575803

9 Splash Panel 4570024 4570024

10 Push Plate 7060000 7060000

11 Chute Mounting Bracket 7010003 7010003

12 Push Plate Brace 7010032 7010032

13 Ice Chute 4575506 4575506

14 Fluorescent Tube 1000318 1000318

15 Drain Pan Pin 7010008 7010008

16 Drain Pan 4575914 4575914

17 Drain Pan Grid O100119 O100119

18 Microswitch Actuator Slide 7060002 7060002

Door Assembly (LESS SOLENOID COIL) - see

27

page 36 for solenoid door parts

Ballast 120 Volts 60 Hz 1000315 1000315

100 Volts 50/60 Hz 5000870 5000870

31

220 Volts 50 Hz 5000348 5000348

220 Volts 60 Hz 5000349 5000349

240 Volts 50 Hz 5000350 5000350

32 Light Socket Bracket 7050046 7050046

33 Fluorescent Light Socket 1001001 1001001

34 Microswitch Actuator 4630031 7010017

PART NUMBER

M 45

4635907 4575918

PART NUMBER

M 90

23

Page 24

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-45/90 EXPLODED VIEW (FRONT)

KEY # DESCRIPTION

35 Starter Base 1001006 1001006

36 Fluorescent Starter 1001005 1001005

37 Shoulder Plate 7060016 7060016

38 Electrical Box Cover 1000507 1000507

39 Electric Box 4635906 4575912

Capacitor 120 Volts 60 Hz 1001741 1001741

100 Volts 50/60 Hz 1001710 1001710

40

220 Volts 50 Hz 5000344 5000344

220 Volts 60 Hz 5000344 5000344

240 Volts 50 Hz 5000343 5000343

41 Capacitor Bracket 1001707 1001707

43 Merchandiser UL Angle (Right) 4630025 4570052

46 Merchandiser UL Angle (Left) 4630027 4570064

PART NUMBER

M 45

PART NUMBER

M 90

M-45/90 EXPLODED VIEW (FRONT NOT SHOWN)

KEY # DESCRIPTION

--- Motor Plate Bolts O900636 O900636

Leg 4" Plastic 5000684 5000684

---

Empty light 115 Volt 60 Hz 5006233 5006233

---

Buzzer Alarm 115 Volt 60 Hz 1001501 1001501

---

--- Heavy Duty Lid N / A 5000829

--- Ice Flow Restrictor 7012003 7012003

--- Light Kit 5001579 4572121

--- Push Button Switch Assembly 1001120 1001120

Transformer for Valves 115 Volt 60 Hz 1001424 1001424

---

Extended Splash Panel Standard N / A 4572134

---

--- Grid Lifter 7012155 4572039

--- Nugget Adaptor Kit 5001207 5001207

4" Stainless 5001021 5001021

2 1/2" black 5000920 5000920

220 / 240 Volt 50 / 60 Hz 5000391 5000391

220 / 240 Volt 50 / 60 Hz 5000390 5000390

100 Volt 50/60 Hz 5001087 5001087

220 Volt 50 Hz 5000967 5000967

220 Volt 60 Hz 5000967 5000967

240 Volt 50 Hz 5000967 5000967

Punched for 4 Flomatic Valves N / A 5000403

PART NUMBER

M 45

PART NUMBER

M 90

24

Page 25

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

M-90 EXPLODED VIEW (FRONT)

25

Page 26

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

KEY # DESCRIPTION PART NUMBER

8 Left Merchandiser Angle 4590057

9 Right Merchandiser Angle 4590054

10 Ice Chute 5001991

11 Knurled Screw O904403

12 Splash Panel Punched for 4 Valves 5000403

23 Translight - All You Can Drink 5000635

24 Merchandiser 5001477

31 Clear Medallion 5000611

32 Opaque Medallion 5000406

33 Push For Ice Switch - 2" Square 1001120

34 Medallion Screw O904403

36 Splash Panel Screw 0901001

M-90 EXPLODED VIEW (FRONT)

26

Page 27

Installation and Service Manual

TROUBLESHOOTING

CONDITION INVESTIGATION HOW TO CHECK CORRECTION

Dispenser does not dispense

ice.

Dispenser does not dispense

ice.

There is no power to the

dispenser.

There is power to the

dispenser, however nothing

runs.

The gear motor runs but the

dispensing paddle wheel

doe s not turn.

Gear mo to r runs but the

dispensing paddle wheel

doe s not turn.

Is the dispenser plugged in? Plug the dispenser in.

The dispenser is plugged in

with power to the receptacle.

With a me ter, check to see i f

power is getting to the white

and black cord wires inside

the electric box.

Is power goi ng through the

microswitc h? W ith the

dispenser plugged i n, meter

probes on the “C” and “NC ”

terminals of the mi croswitch,

energize the microswitch. If

the meter starts out

registering voltage, then does

not register voltage when the

switch is pushed, the switch

is good.

If the g ear mo to r a tte mpts to

start but fails to do so, check

the capacitor. To completely

check the ca pa citor, you must

use a capacitor checker

according to the instructions

supplied.

If gear moto r fa ils to attempt

to start, check the gear motor.

To check the gear motor,

disconnect power from the

dispenser. Disconnect the

gear motor wires in the

junction box. Check for

continui ty through the gear

motor.

Remove the paddle wheel pin

in the bin area. Is this pin

broken or missing?

Remove the agitator and

paddle wheel. Are you able

to turn the shaft from the gear

motor wi thout turning the

motor a rmature itse lf?

If no power is present, check

the cord and plug of the

dispenser. Replace if broken

wire or connection is

detected.

If no power is going through

the microswitch, replace the

switch or locate the broken

connection.

If capacitor does not test

correctly, replace the

capacitor.

If gear motor does not test

correctly, replace the gear

motor.

If the paddle wheel pin is

broken or missing, replace

the pin.

Lower i ce bin level.

Dispenser crushes ice as it

dispenses.

Dispenser runs but does not

dispense ice.

Is the ice in the bin of the

proper size and type of ice?

Is there at least one half bin

of ice?

Is the ice in the bin of the

proper size and type of ice?

Is the bin drain clean and

open?

See page 5 for acceptable

ice.

Is the ice being used a full

size pi ece of ice? i.e. cubes

full, not shallow, etc.

Adjust door to minimum or

larger opening.

Microswitch may be sticking.

Check the microswitch and

linkage to the microswitch.

Clean linkage and

micros witch. Re p lace

microswitch if necessary.

27

Page 28

Installation and Service Manual

28

Page 29

Installation and Service Manual

29

Page 30

Installation and Service Manual

30

Page 31

INDEX

B

brixing ....................................... 2

C

Carbon Dioxide ......................... 5

CAUTION .......................... 11, 12

claims ........................................ 8

Cleaning .................................... 2

CO 2........................................... 4

CO2 monitors ............................ 4

cube ice .................................... 8

D

damage ................................ 2, 8

delivery ................................ 2, 8

Diagrams

14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26

Dispensing ................................ 8

distributor.................................. 2

F

FOREWORD .............................. 2

H

health department................... 12

I

Ice ............................................. 8

Ice Storage................................ 8

INSPECTION .............................. 2

inspection ............................ 7, 8

Installation Date ........................ 2

irregularities .............................. 2

M

Maintenance ........................... 13

MBE ........................................... 2

Model Number ........................... 2

modifications............................. 5

O

Operation .................................. 5

Q

Qualified Service Personnel..... 5

R

regulations .............................. 12

Relocation ................................. 5

return procedures .................... 2

S

SAFETY ............................... 5, 6

sanitizing................................... 4

Serial Number ........................... 2

service assistance ................... 2

Service Personnel .................... 5

Shipping .................................... 5

Shipping, Storage, Relocation .. 5

soa py wate r ........................... 12

solvents .................................. 12

start-up ..................................... 5

Storage ..................................... 5

T

TROUBLESHOOTING .............. 27

U

Unit Inspection .......................... 8

UNPACKING .............................. 2

W

Warning .................................... 5

WARRANTY INFORMA TION ..... 2

water-to-syrup ratio. See brixing

Page 32

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

5011634 March 23, 2005 REV1

Loading...

Loading...